Abstract

In this study, enzyme-induced calcite precipitation (EICP)-based treatment for tropical soils contaminated with divalent heavy metals such as cadmium (Cd), nickel (Ni), and lead (Pb) were evaluated for their sorption and desorption capabilities. Heavy metals were taken in three different combinations: a single metal and a combination of two and three metals. They were mixed with locally available kaolinite and montmorillonite soils. EICP-treated soil retained the maximum quantity of Cd among all the heavy metals studied. The Cd retention exceeded Ni and Pb retention. The same was confirmed with desorption studies, relying on aggressive chelants such as ethylene diamine tetra acetic acid (EDTA) and citric acid. Before subjecting the kaolinitic soil to EICP treatment, it was found that the sorption capacity for Cd and Ni was 2.124 and 1.974 mg/g for Cd and Ni, respectively. The sorptive values increased to 3.457 and 4.418 mg/g for Cd and Ni, respectively, after EICP treatment. The retention is attributed to the formation of CdCO3 and NiCO3 in the soil matrix, which exhibits very low values of solubility product even in the presence of aggressive chelants. The study establishes that EICP treatment is a prospective method for remediation of soils laced with heavy metal ions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Soil is considered one of the most worthful natural resources, which is continually being destroyed by human activity. Soil is also a medium that accommodates living organisms in its mass and thereby imparts a suitable environment for the food chain to exist. It is reported that each gram of soil can accommodate a billion microorganisms [1]. Other than microbes, soils are also adaptable for fungi, mites, earthworms, arthropods, rodents, and nematodes [1, 2]. These organisms in soil are closely related to the biodiversity above the ground and contribute to nature's biomass [3, 4]. Furthermore, soil for a civil engineer happens to be a material of great importance, as it is a naturally existing medium that transfers the load of the superstructures constructed over them to the lower harder strata. It is also valuable for storing water in the void spaces, thus maintaining aquifers; this contributes to improving the soil fertility and increases the yield of crops. Soils also possess contaminant retention capacity and act like filters sorbing heavy metals and preventing them from draining into the groundwater table [5].

Industrialization, vast construction activity, and substantial mining are a consequence of the population growth and attempt to meet the population's ever-increasing demands. Industrial effluents contaminate land and, as a result, endanger the ecology. Site remediation is expensive since traditional cleanup procedures are outmoded, such as excavation and dumping on vacant land. Physical removal of pollutants is challenging. Engineered landfills have been established as the most cost-effective method of disposing of municipal solid waste and hazardous wastes. Most heavy metals are classified as hazardous wastes. They are highly detrimental to human health, such as Pb, Cd, As, Zn, Cu, Hg, Cr, and Ni. Some of the effects on human health due to these heavy metals are that Hg causes mutations and genetic harm, while Cu and Pb affect the brain and bones.

Precipitation–dissolution, oxidation–reduction, and adsorption–desorption processes are used to remove heavy metals from the soil, with adsorption–desorption being the most successful geochemical technique for remediation of contaminated soil. The retainment of contaminants is achievable in soil via encapsulation, which is a strategy used to reduce the toxic effects of heavy metals. One of the most promising techniques for soil contaminant retention is utilizing the calcium carbonate precipitation process.

EICP (enzyme-induced calcite precipitation) and microbial-induced calcium carbonate precipitation (MICP) are the two ways of precipitating CaCO3. These techniques can replace conventional materials such as lime, cement, etc., which leave a more significant CO2 footprint in our atmosphere. It should be emphasized that EICP is a biologically inspired soil improvement approach that uses urease enzyme derived from jack beans [6,7,8,9,10] or watermelon seeds to commence urea hydrolysis in an aqueous solution and create calcium carbonate by merging carbonate ions with calcium ions. [11]. A detailed review of the available literature summarizes that the development of bio-stabilization methods has proved to be sustainable, ecofriendly, and effective in soil treatment leading to improvement in the geotechnical performance of soil-like permeability reduction, reducing the porosity of soil mass, improving bearing capacity, control of soil erosion/dust, mitigating liquefaction of soils, seepage control, stabilizing slopes, and even contaminant remediation. The possibility of intrusion of bacteria in soils for calcite precipitation is limited due to their size. Soil pores with sizes less than 0.5 µ cannot accommodate the microbes for the process of calcite precipitation since the size of microbes ranges from 0.5 µm to 3 µm [12]. In contrast, enzyme particulate has a size of about 12 nm [13], which can make the process of precipitation of calcite more convenient even in fine clays.

Soil treatment with MICP/EICP may lead to issues like groundwater contamination with chloride and precipitates of CaCO3. The applicability of these techniques poses challenges such as treatment cost and the type of soil to be treated. Further studies on bio-treatment can address these concerns to develop better application methods of bio-treatment. Bio-stabilization is a potential environment-friendly and sustainable method of improving soils. However, excess calcite formation may lead to groundwater contamination by chloride, and the ammonia ions formed during hydrolysis may pose a threat to the surrounding air and water and may increase the potential of corrosion in the area due to the increase in pH. EICP is preferred over MICP since it is advanced and requires less monitoring among the two methods. Literature suggests that precipitates developed by MICP are vulnerable to moisture and may dissolve, and also, a controlled environment has to be maintained for proper growth and culturing of bacteria and production of urease enzyme. MICP is also affected because the bacteria growth conditions are specific to the species type and are governed by factors such as pH, temperature, and availability of oxygen. In contrast, the use of free urease in EICP is more promising in calcite precipitation in voids of soil grains. EICP method provides a convenient approach to soil treatment because of its ease of application and less maintenance in comparison with the MICP method of soil treatment. The above discussion brings out the advantages of EICP over MICP and highlights the disadvantages of MICP over EICP. Therefore, bio-stabilization of soils has the potential to meet the ever-growing demands of building new infrastructure as well as remediating contaminants in the soils.

Further, the challenge of reducing the pollution of the environment and developing sustainable techniques can be well achieved by the implementation of these techniques. Bio-stabilization of the soil is an emerging trend with relatively simple onsite applications; the stabilizer of a particular type onsite is carried out by injecting the stabilizer in the work area to achieve the purpose. The development of precipitate in the voids of the soil helps reduce the hydraulic conductivity. The application of MICP/EICP has stretched to an extent that ponds can be created in the regions with soils having high permeability by reducing the permeability of soil CaCO3. Nevertheless, the nature of stabilizers and their application in the site is also a concern. Many studies have focussed on the geotechnical aspects of the issue, the biological processes involved, the behaviour of improved soils, improvements in modelling the behaviour of treated soil, and the challenges related are reviewed by [14]. Many researchers have dealt only with the strength aspects, and the geoenvironmental aspects are not given their due. As per a recent report, current bio-inspired geotechnics research focuses on soil excavation and penetration, soil–structure interface shearing, load transfer between foundation and anchorage elements and soils, and mass and thermal transport with organisms like worms, clams, ants, termites, fish, snakes, and plant roots serving as inspiration. As a result, cross-disciplinary contacts and partnerships will benefit both geotechnical engineering and biology in terms of new or enhanced solutions and mechanisms [15]. Therefore, this study emphasizes the use of enzyme-based amendments for geoenvironmental aspects. Studies have indicated that this novel sustainable material performs better in terms of its life cycle assessment and long-term economic benefit, but initial costs involved are in a higher range compared to conventional materials but the benefits derived in terms of strength, longevity, sustainability, carbon emissions, outsmarts the present economic analysis. It has been identified that the application of this biogeochemical method is vastly found in cohesionless soils or sand and not in cohesive soils or clays, and the use of this technique for heavy metal remediation is carried out often on individual heavy metals and remediation of two or more heavy metals in soils were not usually studied. The present study was carried out on cohesive soils from India, emphasizing contaminant remediation for both individuals and combinations of two or more heavy metals to ascertain the efficacy of EICP treatment.

Materials and Methods

Soils

Soils used in this study were collected from two different parts of the state of Karnataka, India. Soil A is a red soil which is Kaolinitic obtained from Bengaluru district (13° 2′ 14.1396'' N, 77° 37′ 11.928'' E) and Soil B is a black cotton soil which is Montmorillonitic obtained from Yadgir District (16° 45′ 20.556'' N, 77° 9′ 4.5072'' E). Soils were procured from a depth of 3 m beneath the ground surface to avoid intruded degradable matter, peat and any other impurities in the soil samples. Soil samples procured were sealed in clean polyethylene covers and were stored in the lab for conducting basic tests. All the samples were tested in triplicates to have better repeatability and reproducibility. Basic test results conducted on these soils are tabulated in Table 1. According to the Unified Soil Classification System, Soil A was identified as clay with low plasticity (CL) and Soil B was identified as clay with high plasticity (CH).

Urease Enzyme and Other Ingredients

Enzyme can be extracted from plants as well as microbes [27, 28] and are even found in algae, fungi and invertebrates, and also occurs in soils as soil enzymes [29]. Enzyme used for this study was extracted from a draught resistant bean called as Jack Bean commonly known as Chickasaw Lima bean [27]. Urease enzyme derived from this bean is a pure form of protein and jack bean is one of the common sources of enzyme [30]. Canavalia ensiformis (jack bean) Type III, powder, 15,000–50,000 units/g solid (Urease Enzyme) was procured from Sigma-Aldrich, St. Louis, MO, USA. Additional ingredients used for preparation of enzyme solutions along with urease enzyme were Urea (NH2-CO-NH2), Calcium Chloride dihydrate (CaCl2.2H2O) because CaCl2 is perhaps the most preferred and competent source utilized for elicitation of calcite precipitates [31], and non-fat milk powder brought from Winlab Chemical, Market Harborough, United Kingdom.

Enzyme Solutions

Treatment of soil was carried out with three enzyme solutions, firstly a basic solution of urease enzyme was prepared by putting together urea, calcium chloride dihydrate and urease enzyme in deionized water [32]. Further modified enzyme solution was prepared by adding non-fat milk powder in the basic enzyme solution. Modified enzyme solutions were of two forms with variations in the concentrations of the ingredients; therefore, three enzyme solutions were prepared for treating the soils. These enzyme solutions are referred as M1, M2, and M3 in this work henceforth. Details of the concentrations of ingredients used to prepare these enzyme solutions are given in Table 2.

Heavy Metal Contaminants

Soils were spiked with cadmium (Cd), nickel (Ni), and lead (Pb) individually as well as in combination in this study. Initially, a stock solution of these contaminants was prepared with a concentration of 1000 mg/l and later required concentrations were obtained with this stock solutions as discussed by Mohammed and Moghal [33].

Stock solutions were prepared using analytical grade nitrates of cadmium (Cd(NO3)2), lead (Pb(NO3)2), and nickel (Ni(NO3)2). Solutions of heavy metal salts were set up in beakers of borosilicate glass to keep an adequately wet consistency so that soils can be spiked with contaminants. Oven-dried samples of soil were washed with distilled and deionized water and were spiked with specific concentration of stock solution to attain required load ratios of contaminants [34].

According to the literature, Pb and Cd are susceptible to periodic and extended saturation in soils. Mine soils contain Pb and Cd in abundance. The sorption and precipitation of metals with Fe and Mn oxides are among the most important chemical processes of contaminant (Pb, Zn, Cd, and Cu) binding in stream sediments and alluvial soils, according to several research on mining-affected river systems. It has been stated that smelter activities are the primary cause of severe contamination of local soils, with Pb moving downward at a rate of 0.3 to 0.36 cm/yr. On conducting caged TCLP (toxicity characteristics leaching procedure) on Cd, Ni, and Pb, it was found that at an initial concentration of 3000 mg/kg, leaching rates were 3.1812 and 0.3445 cm/yr, 1.145 and 0.072 cm/yr, 1.14063 and 0.100 cm/yr for raw and amended soils, respectively, which is in confirmation with the work conducted by Wang et al., [32]. Hence, it can be deduced that for extreme concentrations of heavy metals, it is imperative to monitor their behaviour [35].

In this study, sorption experiments were conducted on both soils spiked with heavy metals (Cd, Ni, and Pb) individually in different samples, and heavy metal combination like Cd + Ni, Pb + Cd, Ni + Pb, and Ni + Cd + Pb were spiked in soil samples separately to understand competitive sorption. Dosage of heavy metal contaminants for conducting sorption experiments for treated as well as untreated soils were maintained as, i) 10, 20, 50, and 100 mg/l initial concentration, and ii) 1:5, 1:10, 1:20, 1:50 and 1:100 solid-to-liquid (S/L) ratios.

Extractants

For desorption studies, citric acid and EDTA extractants were used with molar concentrations equal to 0.5, 0.25, and 0.1 for removing heavy metals from soil by method of acid digestion, and 1:20 solid-to-liquid ratio was fixed for all the trials.

Both citric acid [36] and EDTA [37] were demonstrated to be viable in separating heavy metals from surface of soil grains. It was noted by Gu and Yeung [36] that Cd desorption from soils was effective with industrial wastes having high concentrations of citric acid with pH range between 4 and 8.

Sorption Tests

Samples of soil were initially blended with distilled water and shaken for 24 h, and required dose of heavy metal solution was spiked after which the soil was again shaken for 24 h. After shaking, soil sample is separated from the fluid using Whatman 42 debris less filter paper and the measure of heavy metal sorbed is distinguished by testing the filtrate in atomic absorption spectrophotometer (AAS) (PerkinElmer Model A-Analyst 400).

To ensure accuracy in the outcomes, each test was performed on three samples and normal of the equivalent was taken. The measure of heavy metal sorbed on the soil surface was obtained by ascertaining the distinction between the underlying and last mass of heavy metal in the filtrate arrangement. To accomplish the ideal convergence of heavy metals arrangements that is 10, 20, 50, and 100 mg/l, 50 ml of deionised twofold distilled water is spiked with 0.5, 1, 2.5, and 5 ml of stock solution (1000 mg/l) individually. All solutions with contaminants were kept up to a solid to fluid (s/l) proportion of 1:20, addition of 1000 mg/l contaminant stock solutions fluctuates the s/l proportion to 1:20.5, 1:21, 1:22.5, and 1:25 separately, and this difference in s/l proportion is defended by ASTM D3987 [38]. Hydrochloric acid (HCL) of 1 M was used to maintain the pH of samples at 5. Soil particles get scattered and hydrated when shaken for 24 h in deionised twofold distilled water, and reaches equilibrium. At this stage, contaminants are added for assuring each conceivable soil grain to sorption. To guarantee steady dilution ratio, the stock solution of exceptionally high concentration was spiked in relatively smaller volume of fluid to keep up ideal concentration of contaminant, i.e., 100 mg/l. It is very well understood that the s/l proportion increments marginally with a distinction of 0.1, and this is an acceptable technique for keeping up the ideal concentration of contaminant [39].

Diverse dilution ratios were kept up to conduct the sorption tests. Dilution ratio is the proportion of measure of fluid in ml taken for a particular mass of soil in grams to be combined as one to accomplish the ideal proportion. The proportions kept up in the investigation were 1:5, 1:10, 1:20, 1:50, and 1:100 by blending soil 5 g oven dried soil in deionized double distilled water of volumes 25, 50, 100, 250, and 500 ml separately. Further concentration of contaminants was kept up to 100 mg/l, by adding 2.5, 5, 10, 25, and 50 ml of 1000 mg/l stock solution. Stock solutions of contaminants prepared were used to spike contaminants in solutions using micropipette supplied by Thermo Fisher Co. Before and after spiking contaminants, the test solutions were shaken for a duration of 24 h at 30 rpm. The aqueous solutions had a pH of five before spiking contaminant to avoid crystallization of heavy metals after spiking and once the solutions were tested in AAS, pH was again determined. Similar procedure was adopted while spiking two contaminants together, that is Pb + Cd, Ni + Pb, Cd + Ni, and Ni + Cd + Pb. Concentration of each heavy metal among the two spiked together was maintained equal to 100 mg/l [40].

Measure of contaminant sorption on soil was represented as sorption coefficient (qe) in mg/g, calculated using Eq. 1.

where: \({\mathrm{C}}_{0}\) = heavy metal concentration at initial stage (mg/L), \({\mathrm{C}}_{\mathrm{e}}\) = heavy metal sorbed on soil (mg/L), m = dry soil mass (mg), and V = solution volume in litres.

Desorption Tests

Soil samples with contaminants were tested for amount of desorption after 40 days of curing, so that contaminants can firmly get acquainted in the soil. Heavy metal dosages of 100 mg/kg and 50 mg/kg were maintained for conducting desorption experiments. Oven-dried 50 g soil was cleaned using distilled water before spiking contaminants in it. Preferred dosage of contaminants (100 mg/kg and 50 mg/kg) is spiked in soil by using 1000 mg/l contaminant stock solutions and mixed to make it homogenous and later the container with this mixture was protected from cross-contamination by covering it with foil of aluminium. The aluminium foils are pricked to facilitate escaping of water by evaporation. These containers are placed on an elevated horizontal platform in a humidity-controlled chamber for a span of 40 days to ensure proper bonding takes place between heavy metal ions and soil. Temperature in room was maintained around 27 °C and the humidity was maintained around 40 to 45%. Same procedure was employed for spiking the combination of heavy metals in the soils treated with Enzyme solutions. After 40 days, five grams of soil sample was immersed in 20 ml extractant solutions of molarity equal to 0.5, 0.25 and 0.1 in polytetrafluoroethylene bottle of volume equal to 50 ml and shaken in mechanical shaker for 24 h at 30 rpm according to ASTM D3987 [38] so that heavy metal entrapped in soil is released due to the extractants.

Further, this slurry with contaminants obtained after shaking is passed through a filter paper to separate soil grains and contaminant fluid is tested in AAS to identify the amount of contaminants removed from soil. These tests were performed on three samples and average of the three results were taken finally for determining the removal efficiency using the expression given in Eq. 2 [41]. Before discarding the solutions tested in the AAS, their pH is determined.

Results and Discussion

Industrialisation has paved the way to pollution of water and soil and continuous activities of pollution lead to deposition of high concentration of heavy metals in soil. These heavy metals intrude in the cell cycle of organisms paving the way to development of cancer [42], methods of reducing toxic effects of heavy metals in soil are urgently needed. Since contamination due to heavy metals has been a serious concern to be dealt with today, methods like chemical precipitation, soil washing, ion exchange, oxidation, electrochemical treatment and reverse osmosis are implemented to minimize the untoward impact of heavy metals in contaminated environments [6, 7, 43, 44], heavy metal remediation in fly ash deposits has also become a serious issue to be discussed [8]. Use of EICP method for contaminant remediation through sorption studies is one among the emerging trends in the field of soil stabilization, this study will probably open new horizons in contaminant remediation methods for researchers to explore further for more effective and stable techniques for remediating the contaminants.

Coefficient of sorption (qe) in mg/g (Refer Eq. 1) was found for treated soils and untreated soils, and plots for qe against initial concentrations were drawn to understand the behaviour of sorption of heavy metal.

Sorption Studies

Effect of Initial Concentration on Sorption Potential of Soils with Individual Heavy Metals

In this section, sorption coefficients obtained for different initial concentrations for Soil A and Soil B are discussed.

Cd sorption increased from 2.4523 mg/g (pH 6.11) and 1.352 mg/g (pH 6.44) to 5.8519 mg/g (pH 7.09) and 5.4235 mg/g (pH 6.44) for soil B and soil A, respectively, when treated with M2 at 100 mg/l initial concentration. Treatment with M1 and M3 exhibited better sorption coefficients for Cd in comparison to treatment with M2, by more than 2.4523 mg/g and 1.352 mg/g for Soil B and Soil A, respectively, at 100 mg/l concentration.

For a contaminant load of 100 mg/l, sorption coefficients of Ni for Soil A with different initial concentration before and after treatment with M2 were 1.513 mg/g (pH 6.32) and 7.0838 mg/g (pH 7.63) whereas sorption coefficients of Ni for Soil B before and after treatment with M2 were 1.8754 mg/g (pH 6.35) and 7.6873 mg/g of Ni (pH 7.88). Soil treatment carried out with M1 and M3 also portrayed better results in sorbing Ni in comparison with sorption of Ni on raw soil whereas M2 was the most effective enzyme solution in providing more sorption sites for Ni.

Pb sorption coefficients showed that M2 displayed the best performance compared to M3 in sorbing Pb than untreated soils. This can be probably due to the low concentration of ingredients of enzyme solution. Sorption coefficient of Pb at initial concentration of 100 mg/l was 5.6925 mg/g (pH 7.01) for M2-treated Soil A and 6.6741 mg/g (pH 8.24) for M2-treated Soil B and sorption coefficients of Pb at initial concentration of 100 mg/l were 1.5476 mg/g (pH 6.87) and 1.8139 mg/g (pH 7.01) for raw Soil A and raw Soil B, respectively. Further sorption of Pb and Cd was less than that of Ni, and M2 proved to be the most effective enzyme solution in sorption of heavy metals. Overall observations indicated that treatment with M1 and M3 exhibited better sorption of heavy metals in soils than sorption on untreated soils except for Pb, where it may very well be seen that sorption for raw soils was poor when compared with treated soils. This emphasizes on the adequacy of enzyme treatment of soils in providing appropriate environment for the sorption of heavy metals in soil.

Increase in sorption of heavy metals can be attributed to CaCO3 precipitates formed on soil grains which offer sites for adsorption of heavy metals ions [9]. CaCO3 plays an important role in improving heavy metals sorption [10]. Calcium carbonate is known to biomineralize heavy metals like Ni, Zn, Cu, Co, Cd and Zn and transforming them to precipitates [11]. In the present work, main source of sorption are precipitates of CaCO3 in soil. Heavy metal adsorption relies on parameters such as size of cations, adsorbent affinity, solubility, etc. It was reported by Dixit et al. [42] that adsorption of heavy metals takes place by means of a mechanism described as heavy metals precipitation at micro-level and protons exchange. The adsorption trend for heavy metals in the present work for Soil A and Soil B was Ni > Pb > Cd.

pH has a great impact on the mechanism of adsorption, surface of CaCO3 gets positively charged when value of pH is greater than 8. Negative charges also exist in the environment but they are ineffective, therefore anionic heavy metals in the solution get attracted paving the way for adsorption [45]. Pb sorption on CaCO3 surfaces is recorded to be exceptionally high according to Godelitsas et al. [46]. They also revealed that the Pb sorption on calcite surface additionally showed the development of PbCO3 (cerussite), and arrangement of cerussite is useful in reducing perilous impacts of Pb. Sorption mechanism of heavy metals on calcite probably takes place because of ion exchange process, formation of hydroxycarbonates and carbonates of heavy metals, complexation and adsorption [47]. From the available literature on usage of CaCO3 to act as sorbent, different forms of CaCO3 like precipitates formed by earthworms [48], eggshells [49], natural limestone [50], lime [51] and calcite precipitates by microbial activity [9] are also found to be effective in promoting sorption. Makuchowska-Fryc [49] reported that behaviour of heavy metal sorption on CaCO3 does not rely on its source but on concentration of heavy metal present initially in solution. Therefore, the mechanism involved in sorption process due to CaCO3 precipitates developed by enzyme solutions in the present study can be presumed to be same as that in which CaCO3 precipitates are developed by other means. Adsorption of Ni was more than Pb and Cd in the present work and one probable cause is the existence of Ni in enzyme (urease) used in which Ni content is around 17% in urease extracted from jack bean [30]. Therefore, the Ni present in calcite precipitated by urease activity probably get clubbed with ions of Ni already existing in contaminant solution. Table 3 shows statistical analysis of sorption coefficients obtained for soil A and soil B for heavy metal contaminants, and it was observed that sorption range of soils with M2 treatment shows better results than that of untreated soils.

Effect of Initial Concentration on Sorption Potential with Two Metal Ions

Contaminant solution spiked with heavy metals simultaneously was tested to understand their adsorption behaviour. Contaminants which intrude from the source into soils may not be always alone, and they can be in combinations of two or more contaminants getting intruded in the soil. Understanding their behaviour together in the soil and treating them to reduce their adverse effects can address many environmental concerns. Present work attempted to conduct sorption tests on soil sample spiked with combinations of Cd + Ni, Pb + Cd, Ni + Pb, and Ni + Cd + Pb with initial concentrations of 10, 20, 50, and 100 mg/l and dilution ratios of 1:5, 1:10, 1:20, 1:50, and 1:100 for each heavy metal.

Cd and Ni Case

Two metal ions spiked together in test solution were tested twice in AAS by replacing the corresponding metal ion lamp (in AAS). It can be observed that simultaneous heavy metal sorption in raw soils is comparatively less than the sorption on treated soils and was also observed that maximum sorption was observed for soils treated with enzyme M2. The trend depicted that Cd sorption was more than Ni in raw soil.

At an initial concentration of 100 mg/l, 2.0968 mg/g and 1.8862 mg/g of Cd and Ni sorbed on untreated Soil A with solution pH equal to 6.21, whereas Cd sorption was 4.8215 mg/g and Ni sorption was 4.3166 mg/g for M2-treated Soil A with solution pH of 7.11. For raw soil B, sorption coefficient of Cd was 2.4861 mg/g and that for Ni was 2.4689 mg/g (pH 5.91) and sorption improved to 6.8419 mg/g for Cd and 5.4178 mg/g for Ni (pH 6.14) after M2 treatment.

Ni and Pb Case

Sorption of Ni and Pb simultaneously on treated soils exhibited encouraging outcomes. At an initial concentration of 100 mg/l, sorption coefficients of Ni and Pb were 1.632 mg/g and 1.208 mg/g (pH 5.86) for raw Soil A whereas for raw soil B, sorption coefficients of Ni and Pb were 2.8631 mg/g and 2.5611 mg/g (pH 5.37), respectively.

Sorption coefficients for M2-treated soils were 3.8288 mg/g for Ni and 4.2109 mg/g for Pb in Soil A at pH of 6.33 and for Soil B, sorption coefficients of 6.8241 mg/g for Ni and 5.8057 mg/g for Pb at pH of 6.21 were observed at 100 mg/l initial concentration.

Cd and Pb Case

Sorption coefficients show domination of one heavy metal compared to the other when spiked together in the test solution. EICP treatment of soil proved to be effective in sorption of Cd and Pb and it was observed that competitive sorption between Cd and Pb for treated soils was better in comparison with the untreated one.

At 100 mg/l initial concentration, treatment with M2 gave sorption coefficients of 5.861 mg/l for Pb and 5.412 mg/l (pH 6.82) for Cd in Soil A and sorption coefficients of Pb and Cd for raw Soil A were 2.8722 mg/l and 2.8618 mg/l (pH 6.33), respectively. For soil B, treatment with M2 portrayed that the sorption coefficients of Pb and Cd were 5.632 mg/l and 4.632 mg/l (pH 6.49), respectively, and sorption coefficients of Pb and Cd for untreated soil were 2.8563 mg/l and 3.1056 mg/l (6.55), respectively, with 100 mg/l initial concentration.

Effect of Initial Concentration on Sorption Potential with Three Metal Ions

As depicted in Fig. 1, sorption coefficients of Cd, Ni, and Pb were spiked together in test solutions in treated and untreated soils. It can be understood from Fig. 1 that sorption is effective for a combination of Cd, Ni, and Pb. These heavy metal ions were successful in finding sites on the treated soil samples to settle down and among the three heavy metals, Pb sorbed better compared to Cd and Ni on treated soil samples. Sorption coefficients (mg/l) of Ni, Cd and Pb were 2.7401, 2.851, and 2.637, respectively, for untreated Soil A with solution pH of 6.18, whereas sorption coefficients (mg/l) of Ni, Cd, and Pb for Soil A treated with M2 were 4.6781, 5.511, and 6.9261, respectively, with solution pH of 6.27 at an initial concentration of 100 mg/l.

Sorption coefficients (mg/l) of Ni, Cd, and Pb were 1.388, 1.9182, and 2.5391, respectively, for untreated Soil B with solution pH of 6.23, whereas sorption coefficients (mg/l) of Ni, Cd and Pb for Soil B treated with M2 were 6.3317, 5.1057, and 6.8793, respectively, with solution pH of 6.41 at 100 mg/l initial concentration. Sorption studies were conducted for treated as well as untreated soils with variation of dilution ratios of heavy metals in concentration. The results for sorption tests with different dilution ratios showed that sorption coefficient reduced with the decrease of dilution ratios, and maximum values of sorption coefficients were obtained for 1:100 dilution ratio since availability of heavy metal ions for sorption will be more. On the other hand, availability of greater surface areas for heavy metal ions also leads to greater sorption [10].

Variation of sorption of Cd against dilution ratios is plotted in Fig. 1. It can be observed that when dilution ratio is 1:100, coefficient of sorption is also maximum. Values of sorption coefficients for Cd with dilution ratio of 1:100 and with 100 mg/l concentration for untreated raw Soil B and Soil A were 4.711 mg/l and 3.3564 mg/l with pH values 5.84 and 5.69, respectively. After treatment with M2, sorption increased to 6.6487 mg/l for Soil B and 6.583 mg/l for Soil A with solution pH of 7.32 and 6.29, respectively.

For Ni, it was observed that all enzyme solutions were effective in sorbing Ni in both soils. Ni sorption on Soil A treated with M2 was observed to be 10.081 mg/l (pH 6.38) and for Soil B treated with M2, Ni sorption was 15.039 mg/l (pH 6.11) for 1:100 dilution ratio. For raw Soil A and Soil B, sorption coefficients were 3.529 mg/l (pH 5.88) and 6.737 mg/l (pH 6.33), respectively, with dilution ratio of 1:100.

Sorption of Pb happened to be the most effective when soil was treated with M2. Soil A treated with M2 exhibited a Pb sorption coefficient of 8.771 mg/l at a pH of 6.32 whereas the sorption of Pb for raw soil A was 3.690 mg/l at a pH of 6.44 for a dilution ratio of 1:100. While soil B treated with M2 gave sorption coefficient of 9.40151 mg/l at a pH of 5.85 for 1:100 dilution ratio, sorption coefficient of untreated Soil B was 5.50383 mg/l for 1:100 dilution ratio at pH of 6.11. It is evident that soil treatment with enzyme solutions boosts the capacity of soil grain surfaces to create sites for heavy metal ions to occupy.

Cd and Ni Case

The outcomes showed that sorption coefficients of Cd and Ni were 3.7145 mg/g and 3.5014 mg/g for untreated Soil A (pH 6.64) whereas for untreated Soil B, Cd and Ni sorption values were 5.2036 mg/g and 5.2910 mg/g (pH 6.83) for dilution ratio of 1:100. Enzyme treatment improved sorption of Cd and Ni in both soils, and M2 was most effective in sorption of Cd and Ni together. After treatment with M2, sorption values of Ni and Cd were 10.6642 mg/g and 7.1624 mg/g for Soil A (pH 7.08) and sorption values of Cd and Ni for Soil B were 9.8116 mg/g and 12.6730 mg/g (pH 6.97) at 1:100 dilution ratio.

Ni and Pb Case

Sorption of heavy metals with different dilution ratios was observed to be better after treatment with M2 and sorption was comparatively higher for Pb than Ni. It can be observed for untreated Soil A that sorption coefficients of Ni and Pb were 3.5671 mg/l and 3.32514 mg/l (pH 6.33), respectively, whereas sorption coefficients of Ni and Pb happened to be 7.1001 mg/l and 11.0668 mg/l, respectively, for treated Soil A at 1:100 dilution ratio. For raw Soil B, sorption coefficients were 5.0658 mg/l and 5.1681 mg/l for Ni and Pb, respectively, with test solution pH of 6.71 and for soils treated with M2, sorption coefficients of Ni and Pb happened to be 9.6251 mg/l and 12.2501 mg/l, respectively, at pH of 6.27 and 1:100 dilution ratio.

Cd and Pb Case

It was observed that the sorption coefficient was better for treated soils than untreated ones. Sorption coefficients for Pb and Cd for raw soil A were 4.0056 mg/l and 4.622 mg/l (pH 6.38), respectively, and for soil A treated with M2, sorption coefficients for Pb and Cd were 6.7124 mg/l and 6.9928 mg/l (pH 5.69), respectively. For untreated soil B, sorption coefficients of Pb and Cd were 4.2681 mg/l and 4.7152 mg/l (pH 6.87), respectively, while improvement in sorption coefficient was observed when treated with M2 and the values were 7.4419 mg/l for Pb and 7.2584 mg/l for Cd (pH 6.61) with test solutions having a 1:100 dilution ratio.

Sorption Potential with Three Metal Ions

Sorption of both heavy metals were observed to be better in treated soils than untreated soils. It was observed that M2-treated soils exhibited better sorption of heavy metal ions than M1- and M3-treated soils. Sorption coefficients for Ni, Cd and Pb were 5.2146 mg/l, 5.1107 mg/l, and 4.3622 mg/l (pH 6.81), respectively, for untreated soil A. After treatment with M2, sorption coefficients were 8.3517 mg/l, 7.7186 mg/l, and 6.5149 mg/l (pH 6.01), respectively. And for raw soil B, values of sorption coefficients for Cd, Ni and Pb were 5.5539 mg/l, 5.7419 mg/l, and 5.7739 mg/l (pH 5.90), respectively, whereas treatment with M2 yielded sorption coefficients of 9.3255 mg/l, 8.2019 mg/l, and 7.1568 mg/l (pH 6.13), respectively, for dilution ratio of 1:100 as depicted in Fig. 2. It was observed that soil treatment with M2 exhibited best outcomes in heavy metal sorption whereas M3 treatment portrayed lesser sorption in comparison with sorption on soils treated with M1 and M2. Although, it was observed that sorption after treatment with M3 was higher than sorption in untreated soil.

CaCO3 precipitated in soil has good capability to attract heavy metal ions to encircle its surface [52,53,54]. Calcite is presumed to have enormous specific surface and hollow structure with consistent chemical characteristics, due to which it has lot of applications especially in heavy metal adsorption [55, 56]. These reasons have encouraged to take up sorption studies for the present work. Greater adsorption was observed on M2-treated soils than those soils treated by M1 and M3 because, M2 treatment leads to higher CaCO3 precipitation since non-fat milk powder is used in it [32]. Electronegativity in the soil mass due to ions of heavy metals play a significant role in adsorption process, and heavy metal ions having higher electronegativity get easily sorbed compared to those with lesser electronegativity [57, 58]. The order of electronegativities of heavy metals tested in this work was Cd < Ni < Pb, and were 1.69, 1.91 and 2.33, respectively. pH is also one among the controlling factors of sorption and contaminant solubility in soil [59, 60].

Impact of electronegativity on sorption phenomenon was justified in this study for dilution ratios opted, but experiments conducted on sorption for varying initial concentrations was not justified by electronegativity. Ionic radii of heavy metals impact the process of adsorption because, heavy metal ions compete for empty sites on adsorbent, and heavy metal ions having greater ionic radius succeed in occupying sites on adsorbent. Thus heavy metal ions get adsorbed by find their place in CaCO3 crystal lattice [61]. Since Pb has an ionic radius equal to 202 pm which is more than ionic radius of Ni and Cd of 163 pm and 158 pm, Pb sorption is more than Ni and Cd. Achal et al. [62] researched on bioremediation of soils contaminated by Pb using biologically precipitated CaCO3, and found that Pb did not exist in the same form in which it was spiked and Pb got transformed to nontoxic and insoluble carbonate (PbCO3) from toxic and soluble type due to presence of CaCO3 in in the soils. Hence, they concluded bio precipitated CaCO3 is futile in Pb immobilization.

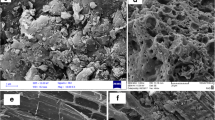

Cd sorption on the surface of calcite is appreciable mostly because of its similarity of ionic radii of ions of Ca in calcite precipitates [63, 64]. Makino et al. [65] utilized CaCl2 to cleanse soils polluted with Cd and they observed that around 55% of Cd removal from soil was done. They also found that Cd had potential to form anion complexes like SO4, CO3, Cl and PO4 and this behaviour of Cd supported the precipitated calcite in immobilizing it [66]. O'Connor et al. [67] checked the sorption of Cd in calcareous soil and found CaCO3 is efficient in the removal of Cd. Results observed from simultaneous sorption portrayed that the sorption of heavy metals is lesser in comparison with individual sorption tests which may be due to scarcity of sites for metal ions to settle on sorbent. This outcome is generally observed in sorption processes [68]. Adsorption process represented in Fig. 3 shows the accumulation of heavy metal ions on the surfaces of calcite precipitates in soil. As per Zhang and Achal [69], a detailed microstructural analysis on EICP interactions with Cd has been undertaken and concluded that Cd ions were stably immobilized as carbonate precipitates identified as pure otavite (CdCO3) and calcite co- precipitate (CaCO3-Cd), vaterite/aragonite subjected to chemisorption (CaMg(CO3)2) and are in confirmation to our work.

Desorption Studies

Generally heavy metals are removed from soil by oxidation–reduction, adsorption–desorption and precipitation-dissolution processes, the most effective among these geochemical methods is adsorption–desorption technique for remediation of contaminant [70]. Removal of heavy metals is also achieved by bio-precipitation, chemical precipitation, ion exchange, biosorption, adsorption, physical separation, solvent extraction, electrochemical separation, cementation and flotation [71, 72]. Another approach adopted to reduce the toxicity of heavy metals include contaminant retaining by encapsulation in soil as encapsulation reduces mobility of metal ions in soil. Use of nano-material like nano-calcium silicate for retaining Pb, Ni, and Cd was also found to be effective [39, 73] in remediation of contaminants. However, costs consociated with production of nano-compound in large quantities is economically not feasible. Among the methods to encapsulate metals ions in soils, the use of microbes is also tested by researchers. This technique, called as bioremediation, includes processes like microbial induced calcite precipitation (MICP) used for encapsulating heavy metals in precipitated calcite. MICP technique encourages metabolic action in certain types of bacteria like Sporosarcina Pasteurii, which works for formation of inorganic precipitates like CaCO3 outside the cellular structure of bacterium and these precipitates have capability to bond soil grains together.

Furthermore, heavy metal encapsulation is also possible in soil within CaCO3 crystals. Another method of bioremediation is the EICP technique, which is also effective in immobilizing contaminants. Enzymes are preferred since they are ecofriendly and nontoxic [74] and EICP method can be a promising technique to be adopted for in-situ applications. Desorption tests (elaborated in clause 2.7) were conducted on treated and untreated soils spiked with heavy metals individually and simultaneously. The results obtained from desorption experiments are plotted with molar concentrations of extractants on abscissa and removal efficiencies (%) of heavy metal on ordinate. The lesser values of removal efficiency indicate the immobilization of heavy metals in soil and therefore cannot be removed from it.

Desorption of Individual Heavy Metals from Soils

This section aims to understand the capability of EICP method in retaining heavy metals in soil and also to identify suitable dosage of enzyme solution which leads to retention of heavy metals to the maximum, and to find percentage of retention of contaminants in soil after EICP treatment. Remediation of contaminants in soil by precipitates of CaCO3 is easy in implementation and economic. According to a scoring suggested by Dejong et al. [75], this method is readily accepted by the society. Before conducting the desorption tests, actual load ratios of heavy metals (Cd, Ni, and Pb) in the samples were found by acid digestion tests for 50 mg/kg and 100 mg/ kg load ratios. Table 4 shows the actual load ratios of heavy metal ions spiked in soil samples.

Desorption of Cd, Ni, and Pb

The maximum Cd removal efficiencies were observed as 50.39% and 46.37% for raw Soil B and raw Soil A. The minimum Cd removal efficiency of 3.97% and 5.39% were observed when it was extracted with citric acid (0.5 M) for M2-treated Soil B and Soil A, respectively. If the percentage of silt and clay particles is more in soil, then the release of Cd decreases because heavy metal deposits become strong in finer clay fractions [76]. Therefore, it was witnessed that higher clay or silt content leads to the improvement of the capacity of soil to retain heavy metals [77, 78]. These observations are in congruence with the outcomes obtained in this work.

Removal efficiency of Cd was low because of precipitation of comparatively greater amount of calcite in soil with M2 treatment. Wang et al. [79] discovered that existence of CaCO3 precipitated in soil played a vital role in immobilization of heavy metals after treatment of soils. EICP technique used in the present study for heavy metal retention is more effective in retaining Cd in comparison to the retention of Ni and Pb.

pH also plays an important role in Cd retention in soil. With decrease in pH of test solution, Cd desorption increases. Further, an increase in soil pH results in retaining Cd ions [80]. Citric acid extractant is found to desorb lesser amount of Cd ions with lower molar concentrations and Cd desorption is more with higher molar concentrations. This is attributed to the formation of complexes of Cd and citric acid in aqueous state, detaching from surfaces of soil. EDTA is found to retain more amounts of Cd in spite of pH being equal to 5.05 [81]. The pH range was around 5–8 in citric acid chelant (0.1 M) which was used to extract Cd. While pH range was between 3 and 6 and molarity of citric acid solution was 0.5, it leads to a comparatively higher Cd removal.

The maximum desorption of Ni was 72.36% for raw Soil B and 57.2% for raw Soil A and minimum desorption values of Ni were 20.26% and 34.48% for M2-treated Soil A and M2-treated Soil B, respectively, after extraction by EDTA (0.5 M). Ni is most common contaminant found in brownfields, and nickel pollution begins from the release of ventures including metal plating, nickel refinement, and mining locales. Nickel hastens into a steady compound as nickel hydroxide [Ni(OH)2], in slightly neutral and alkaline solutions. Ni can be adequately eliminated by EDTA as well as citric acid extractants [37], and retention of nickel can be perceived from the connection between the sorptive surface and particle fixation that diminishes metal ion evacuation. Urease utilized in the investigation is allegedly dynamic and stable especially when EDTA extractant solution shows neutral pH. The enzymatic action assumes a significant part in already existing nickel in urease. It is established that ions of nickel take actively part in strengthening the enzyme activity, and therefore attempts made to separate nickel from the urease were not fruitful [30]. Thus, pre-existing nickel in the urease enzyme and nickel added as contaminant mostly get clustered to behave in such a way that Ni retention in soil increases.

In case of Pb, Soil A without treatment and contaminated by Pb exhibited higher removal efficiency, which ranged from 97.52% to 99.96% for soil washed with EDTA (0.5 M) extractant and for load ratios of 100 mg/kg and 50 mg/kg, respectively. When citric acid was used to wash M2-treated Soil A contaminated with Pb, removal efficiencies decreased to 26.26% and 11.2% for load ratios of 100 mg/kg and 50 mg/kg, respectively. Kumpiene et al. [82] conducted study on immobilization of Pb by chemicals containing phosphorus, like hydroxyapatites and apatites, in natural and synthetic forms. This was because of the ionic exchange and precipitation of minerals of pyromorphite-type which reduce the mobility of Pb, and also because of Ca compounds which are usually efficient in ensuring immobilization of Pb with increase in pH of soil. When pH ranges around 8–9, it paves the way for Pb retention. Around 99% of retention of Pb was achieved by Wang et al. [79] by using stabilizers like CaCO3 and Ca(H2PO4)2 in a dumpsite of Taiwan.

Desorption of Combination of Heavy Metals

Since the soils spiked with contaminant solutions were cured for 40 days, the process of settling of contaminants in soil can happen thoroughly, and therefore behaviour of simultaneously spiked heavy metals in treated as well as untreated soils give a better understanding of their behaviour.

Desorption of Cd and Ni Spiked Together

It was observed that the removal efficiencies in aqueous solutions reduced after treating soils with enzyme solutions. It was observed that Ni and Cd removal efficiencies spiked together with a load ratio of 50 mg/kg in both soils extracted by different molar concentrations of EDTA solution. It was observed that Cd removal efficiency reduced to 11.2% for M2-treated Soil A whereas the removal efficiency was 21.28% for raw Soil A. The removal efficiency of Ni for M2-treated Soil A reduced to 11.64% from 15.24% for raw Soil A. Further, when soil B was tested, Cd removal efficiency was 11.18% after M2 treatment and Ni removal efficiency post M2 treatment was 10.84%. The removal efficiencies for raw Soil B were 18.33% and 15.68% for Ni and Cd, respectively, for 100 mg/kg load ratio of Ni and Cd spiked together and extracted using EDTA. Majority of removal efficiencies obtained from these tests were better for soils treated using M2. Removal efficiencies for Ni and Cd decreased to 6.08% and 10.98% from 10.84% and 12.66%, respectively.

Desorption of Ni, Pb and Pb, Cd Spiked Together

Simultaneous desorption of Ni and Pb with 100 mg/kg and 50 mg/kg load ratios were conducted. It can be understood from the study that removal efficiencies are less with higher load ratios of 100 mg/kg of heavy metal contaminant spiked in the soil when compared to 50 mg/kg. Removal efficiency in Soil A treated with M2 was 6.3% and 27.2% for Ni and Pb, respectively, when extracted by 0.5 M EDTA solution whereas for raw Soil A, the removal efficiency was 5.3% and 26.82% for Ni and Pb, respectively, when extracted by 0.5 M EDTA solution. For M2-treated Soil B, removal efficiencies of Ni were 9.72% and 27.06% for Pb when extracted by 0.5 molarity EDTA solution and the removal efficiencies for Ni and Pb were 4.1% and 26.66%, respectively, when extracted with 0.5 M EDTA for raw Soil B. It can be observed that the desorption of heavy metals Ni and Pb are not above an average value of 60% of all removal efficiencies.

For a molar concentration of 0.5 EDTA, removal efficiencies of Pb and Cd were 22.4% and 18.14%, respectively, for Soil A treated with M2, whereas removal efficiencies of Pb and Cd were 18.62% and 16.04%, respectively, for untreated Soil A. For M2-treated Soil B, the removal efficiencies of Pb and Cd were 25.26% and 17.3%, respectively, whereas for untreated soil, the removal efficiencies of Pb and Cd were 16.56% and 11.72%, respectively.

Desorption of Ni, Cd, and Pb Spiked Together

Figures 4, 5, 6 and 7 give details of removal efficiencies against different molarities of extractants (Citric Acid and EDTA) with load ratios of 50 mg/kg and 100 mg/kg of Ni, Cd and Pb spiked together. Removal efficiency of each heavy metal from the same solution were found by testing in AAS. It was observed that removal efficiencies for treated soils were not appreciable when compared to the untreated soils. The removal efficiencies of treated soils were generally found to be more than the removal efficiencies of untreated samples. Figures 4, 5, 6 and 7 depict that the removal efficiency of Cd for raw soil is minimum when compared to the treated samples. Use of EICP technique was not very much effective for simultaneous desorption of heavy metals, the reason can be attributed to the space of heavy metals ions possible within the calcite lattice which is occupied by multiple metal ions. These metal ions probably does not get encapsulated uniformly because of which the results are not specific when removal efficiencies of Ni, Cd, and Pb are spiked together.

At a point when the concentrations of metal ions are less, the amount of sites to hold the heavy metals are high and this results in immobilization of metals ions [83]. Mechanism involved in the retention of Ni can be visualized as a phenomenon wherein metal ions get bound to a carboxylic group which initiates competition among metals, protons and exchangeable ionic interactions in solution leading to Ni immobility [84]. Heavy metal precipitation takes place when the solution reaches saturation with specific element by heterogeneous or homogeneous process of aggregation. The former process of aggregation takes place because of nucleation in supersaturated phase of soil solution, while the latter process comes into existence due to precipitates formed by nucleation of soil grains and thus the soil grains hold metals on their surface [85].

Cd and Pb are adsorbed on CaCO3 formations in soil, thereby preventing their escape. Retention of Cd and Pb was predominant because of polydopamine CaCO3 than natural CaCO3 [86]. Therefore, it is inferred that reduction in desorption of Pb and Cd observed in this work were because of CaCO3 in soil. Retention of Pb can occur even because of precipitation reaction and diffusion of solid-state, due to which PbCO3 and PbSO4 get precipitated when level of heavy metal contamination crosses the level of solubility of hydroxides and carbonates at a given pH [87, 88]. Hence, it can be understood from the desorption tests of individual heavy metals that enzyme treatment is effective in reducing hazardous effects of heavy metal contaminants.

The main procedure which results in the formation of CaCO3 is urea hydrolysis incited by urease enzyme into NH3 and CO2, and further the NH3 speciation leads to the formation of NH4+ ions, thereby creating a suitable environment for CaCO3 precipitation in CaCl2 solution rich in calcium [89]. It is even proposed that heavy metal ions having their ionic radii close to Ca2+ like Cu2+, Pb2+, Sr2+ and Cd2+ get incorporated in crystal lattice of CaCO3 by substituting Ca2+ ions or even by creating defects on crystals of calcium carbonate or by penetrating interstice of CaCO3. This phenomena indicates the potential of EICP technique in positively remediating heavy metals [90]. Formation of heavy metal carbonates takes place in a microenvironment comprising mineral carbonates, applicable to even radionuclides like strontium forming elements like strontium carbonate (SrCO3) [91]. Metal ions scattered in soil probably cluster around existing carbonates which are already existing in soil, and retention of heavy metal takes place because of precipitation of carbonates of heavy metals [92,93,94]. Mechanism of enzymatic bioremediation is effective in treatment of heavy metal by bioaccumulation established in paper pulp [34, 92].

Desorption experiments conducted on different combinations depicted that immobilization of spiked heavy metals simultaneously in soil was generally not effective after its treatment with enzyme solutions. Han et al. [95] noted that with increase in concentration of heavy metals, average removal efficiencies of 80% can be observed and further it may reach up to 99%, posing grave impact on environment. Heavy metal accumulation takes place continuously through different sources of contamination leading to dreadful effects. Application of immobilization methods on contaminated sites may reduce the impacts by either encapsulating or crystalizing the contaminants. CaCO3 precipitates in soils show different reactions to different contaminants [61].

Carbonate formation like PbCO3, NiCO3 and CdCO3 as bio minerals of all the three contaminants (Cd, Ni and Pb) in soils by biomineralization technique in polluted soils was witnessed by Li et al. [96]. They also found that morphologies of bio minerals differ, varying from rhombohedral shape or needle shape, spherical shape with their dimension varying from a maximum of 50 µm to a minimum of 10 µm. Govarthanan et al. [97] studied on biomineralization of lead using Bacillus sp. KK1 bacterium in mine tailings, wherein they observed that around 26% of exchangeable Pb reduces because of biomineralization, is inspired by precipitated calcite [98]. It can be inferred from the desorption study conducted on simultaneously spiked heavy metals that it did not portray effective results in some cases of enzyme treatment. While the results were appreciable in encapsulating combinations of heavy metals, this improvement did not indicate the effectiveness of any specific enzyme solution common in all cases. In yet another case of sequentially defining the five phases of soil and the physical and chemical speciation of heavy metal interaction, it covers the basic order (from greatest to least): residue fraction > bound to organic matter fraction > bound to Fe–Mn oxides fraction > bound to carbonates fraction > exchangeable fraction. Under rain, snow, or acid rain circumstances, water-soluble, ion-exchanged, and carbonate-bound heavy metals are active and may quickly move to groundwater and soil, but the organically bound state, the iron-manganese oxidation state, and residual heavy metals are rather stable and these are the phases where EICP remains active [99].

Conclusions

Biogeochemical process such as EICP is a sustainable and environment-friendly solution in the field of ground improvement and remediation in which precipitates of CaCO3 are formed in the presence of specific chemicals and catalysed by means of a plant derived urease enzyme. The outcomes of the present study indicate that EICP has proved its efficacy in fixing Cd, Ni, and Pb spikes in Soil A (Kaolinite) and Soil B (Montmorillonite), as well as for the immobilization of heavy metals within the soil. Following are some of the specific findings of this work:

-

Enzyme treatment improved the adsorption of heavy metals on soils wherein M2 facilitated the maximum amount of adsorption of heavy metals. For Soil A and Soil B, the order of sorption for individual metal ions was observed as Ni > Pb > Cd, at an initial concentration of 100 mg/l and dilution ratio of 1:100 of heavy metals.

-

Heavy metals, when spiked simultaneously in soils paved the way for competitive sorption. Heavy metals with higher ionic radius and electronegativity had greater chances of occupying the empty spaces on the adsorbent. Soil B had comparatively greater capability of sorbing heavy metals on its surface compared to soil A.

-

EICP treatment with M2 exhibited better retainment of heavy metals in comparison to the treatment with enzymes, M1 and M3. The order of heavy metal encapsulation in soil occurred in the order of Cd > Ni > Pb when individual desorption studies were conducted.

-

Enzyme treatment of soil successfully retained maximum amount of Cd than Pb and Ni. The same trend was established even during the desorption studies conducted by washing the heavy metal sorbed soils with citric acid and EDTA.

-

The outcomes from the above experimental studies revealed that EICP has adequate capacity to immobilize heavy metals in polluted soils. The studies depicted obvious results for Cd in contrast to Ni and Pb and this strategy can be utilized to immobilize specific pollutants by distinguishing its viability on other heavy metals too.

-

Desorption studies on heavy metals spiked simultaneously portrayed that carbonate of heavy metals such as NiCO3, PbCO3, and CdCO3 (Otavite) are likely to be formed on the surfaces of soil after CaCO3 and heavy metals interact while increasing the pH. These carbonates of heavy metals in the soil mass become insoluble thereby changing the form of heavy metal to a nontoxic state.

The application of bio-inspired solution such as EICP which is inspired from the natural cemented soil deposits provides an innovative and alternative solution for improving the geo-mechanical properties of soils and for addressing the various geoenvironmental issues. It is also imperative that the upscaling potential of these bio-inspired techniques need to be assessed before its actual application. EICP, being sustainable and environment-friendly with reduced greenhouse gas emissions, has proven to be effective for heavy metal immobilization in clayey soils. Existing literatures suggest that the application of EICP is still very limited to organic soils and hence this technique needs to be branched out into various soil types for understanding the effects on these soils. There are still many factors to be considered and improvised such as sourcing of an urease enzyme which is cheaper and non-ammonia releasing, reduced treatment time, etc. With a close collaboration between researchers and practicing engineers, this technique can be exploited for its potential benefits and viability in the actual field and hence would become a highly effective technique in the field of ground improvement in future.

References

Roesch LFW, Fulthorpe RR, Riva A et al (2007) Pyrosequencing enumerates and contrasts soil microbial diversity. ISME J 1:283–290. https://doi.org/10.1038/ismej.2007.53

Bardgett R (2005) The biology of soil: a community and ecosystem approach. Oxford University Press, Oxford, New York

Fierer N, Strickland MS, Liptzin D et al (2009) Global patterns in belowground communities. Ecol Lett 12:1238–1249. https://doi.org/10.1111/j.1461-0248.2009.01360.x

Wardle DA, Bardgett RD, Klironomos JN et al (2004) Ecological linkages between aboveground and belowground biota. Science 304:1629–1633. https://doi.org/10.1126/science.1094875

Moghal AAB, Sivapullaiah PV (2012) Retention characteristics of Cu2+, Pb2+, and Zn2+ from aqueous solutions by two types of low lime fly ashes. Toxicol Environ Chem 94:1941–1953. https://doi.org/10.1080/02772248.2012.732579

Wang J, Chen C (2009) Biosorbents for heavy metals removal and their future. Biotechnol Adv 27:195–226. https://doi.org/10.1016/j.biotechadv.2008.11.002

Vullo DL, Ceretti HM, Daniel MA et al (2008) Cadmium, zinc and copper biosorption mediated by Pseudomonas veronii 2E. Biores Technol 99:5574–5581. https://doi.org/10.1016/j.biortech.2007.10.060

Moghal AAB (2013) Geotechnical and physico-chemical characterization of low lime fly ashes. Adv Mater Sci Eng. https://doi.org/10.1155/2013/674306

Warren LA, Maurice PA, Parmar N, Ferris FG (2001) Microbially mediated calcium carbonate precipitation: implications for interpreting calcite precipitation and for solid-phase capture of inorganic contaminants. Geomicrobiol J 18:93–115. https://doi.org/10.1080/01490450151079833

Cai G-B, Zhao G-X, Wang X-K, Yu S-H (2010) Synthesis of polyacrylic acid stabilized amorphous calcium carbonate nanoparticles and their application for removal of toxic heavy metal ions in water. J Phys Chem C 114:12948–12954. https://doi.org/10.1021/jp103464p

Li M, Cheng X, Guo H, Yang Z (2016) Biomineralization of carbonate by terrabacter tumescens for heavy metal removal and biogrouting applications. J Environ Eng 142:C4015005. https://doi.org/10.1061/(ASCE)EE.1943-7870.0000970

Al Qabany A, Soga K, Santamarina C (2012) Factors affecting efficiency of microbially induced calcite precipitation. J Geotech Geoenviron Eng 138:992–1001. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000666

Martinez BC, DeJong JT, Ginn TR et al (2013) Experimental optimization of microbial-induced carbonate precipitation for soil improvement. J Geotech Geoenviron Eng 139:587–598. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000787

Rahman MM, Hora RN, Ahenkorah I et al (2020) State-of-the-art review of microbial-induced calcite precipitation and its sustainability in engineering applications. Sustainability 12:6281. https://doi.org/10.3390/su12156281

Martinez A, DeJong J, Akin I et al (2021) Bio-inspired geotechnical engineering: principles, current work, opportunities and challenges. Géotechnique. https://doi.org/10.1680/jgeot.20.P.170

D18 committee test methods for specific gravity of soil solids by water pycnometer ASTM International

Bureau of Indian Standards (1980) IS 2720–3–1: methods of test for soils, Part 3: determination of specific gravity, section 1: fine grained soils

D18 Committee Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International

Bureau of Indian Standards (1985) IS 2720–5: methods of test for soils, Part 5: determination of liquid and plastic limit

Bureau of Indian Standards (1972) IS 2720–6: Methods of test for soils, Part 6: Determination of shrinkage factors

D18 committee test method for pH of soils ASTM International

D18 committee test methods for moisture, ash, and organic matter of peat and other organic soils ASTM International

ASTM D1557 - 12e1 Standard test methods for laboratory compaction characteristics of soil using modified effort (56,000 FT-LBF - FT - Sup - 3 - Sup - (2,700 KN-M - M - Sup - 3 - Sup - ) ) | PDF | Soil | Materials. In: Scribd. https://www.scribd.com/document/367652171/ASTM-D1557-12e1-Standard-Test-Methods-for-Laboratory-Compaction-Characteristics-of-Soil-Using-Modified-Effort-56-000-Ft-lbf-ft-sup-3-sup-2-700-K. Accessed 13 Sep 2021

Bureau of Indian Standards (1992) IS 2720–9: methods of test for soils, Part 9: Determination of dry density- moisture content relation by constant mass of soil method

D18 Committee test method for unconfined compressive strength of cohesive soil ASTM International

Bureau of Indian Standards (1991) IS 2720–10: methods of test for soils, Part 10: determination of unconfined compressive strength

Knorr B (2014) Enzyme-induced carbonate precipitation for the mitigation of fugitive dust. Dissertation, Arizona State University

Yasuhara H, Neupane D, Hayashi K, Okamura M (2012) Experiments and predictions of physical properties of sand cemented by enzymatically-induced carbonate precipitation. Soils Found 52:539–549. https://doi.org/10.1016/j.sandf.2012.05.011

Krajewska B (2018) Urease-aided calcium carbonate mineralization for engineering applications: a review. J Adv Res 13:59–67. https://doi.org/10.1016/j.jare.2017.10.009

Blakeley RL, Zerner B (1984) Jack bean urease: the first nickel enzyme. J Mol Catal 23:263–292. https://doi.org/10.1016/0304-5102(84)80014-0

Achal V, Pan X (2014) Influence of calcium sources on microbially induced calcium carbonate precipitation by Bacillus sp. CR2. Appl Biochem Biotechnol 173:307–317. https://doi.org/10.1007/s12010-014-0842-1

Almajed A, Tirkolaei HK, Kavazanjian E, Hamdan N (2019) Enzyme induced biocementated sand with high strength at low carbonate content. Sci Rep 9:1135. https://doi.org/10.1038/s41598-018-38361-1

Mohammed SAS, Moghal AAB (2014) Soils amended with admixtures as stabilizing agent to retain heavy metals 2216–2225 https://doi.org/10.1061/9780784413272.216

Mohammed SAS, Moghal AAB, Sanaulla PF, et al (2017) Cadmium fixation studies on contaminated soils using nano calcium silicate—treatment strategy 434–442 https://doi.org/10.1061/9780784480434.047

Moghal AAB, Lateef MA, Mohammed SAS et al (2020) Efficacy of enzymatically induced calcium carbonate precipitation in the retention of heavy metal ions. Sustainability 12:7019. https://doi.org/10.3390/su12177019

Gu Y-Y, Yeung AT (2011) Desorption of cadmium from a natural Shanghai clay using citric acid industrial wastewater. J Hazard Mater 191:144–149. https://doi.org/10.1016/j.jhazmat.2011.04.054

Khodadoust AP, Reddy KR, Maturi K (2004) Removal of nickel and phenanthrene from kaolin soil using different extractants. Environ Eng Sci 21:691–704. https://doi.org/10.1089/ees.2004.21.691

ASTM D3987 - 12 Standard practice for shake extraction of solid waste with water ASTM International, West Conshohocken, PA, USA

Moghal AAB, Reddy KR, Mohammed SAS et al (2017) Sorptive Response of chromium (Cr+6) and mercury (Hg+2) from aqueous solutions using chemically modified soils. JTE 45:105–119. https://doi.org/10.1520/JTE20160066

ASTM D4646 - 16 (2016) Test method for 24-h batch-type measurement of contaminant sorption by soils and sediments ASTM International: West Conshohocken, PA, USA

Moghal AAB, Ashfaq M, Al-Shamrani MA, Al-Mahbashi A (2020) Effect of heavy metal contamination on the compressibility and strength characteristics of chemically modified semiarid soils. J Hazard Toxic Radioact Waste 24:04020029. https://doi.org/10.1061/(ASCE)HZ.2153-5515.0000527

Dixit R, Wasiullah MD et al (2015) Bioremediation of heavy metals from soil and aquatic environment: an overview of principles and criteria of fundamental processes. Sustainability 7:2189–2212. https://doi.org/10.3390/su7022189

Kapoor A, Viraraghavan T (1995) Fungal biosorption — an alternative treatment option for heavy metal bearing wastewaters: a review. Biores Technol 53:195–206. https://doi.org/10.1016/0960-8524(95)00072-M

Volesky B (2001) Detoxification of metal-bearing effluents: biosorption for the next century. Hydrometallurgy 59:203–216. https://doi.org/10.1016/S0304-386X(00)00160-2

Karageorgiou K, Paschalis M, Anastassakis GN (2007) Removal of phosphate species from solution by adsorption onto calcite used as natural adsorbent. J Hazard Mater 139:447–452. https://doi.org/10.1016/j.jhazmat.2006.02.038

Godelitsas A, Astilleros JM, Hallam K et al (2003) Interaction of calcium carbonates with lead in aqueous solutions. Environ Sci Technol 37:3351–3360. https://doi.org/10.1021/es020238i

Habte L, Shiferaw N, Khan MD et al (2020) Sorption of Cd2+ and Pb2+ on aragonite synthesized from eggshell. Sustainability 12:1174. https://doi.org/10.3390/su12031174

Fraser A, Lambkin DC, Lee MR et al (2011) Incorporation of lead into calcium carbonate granules secreted by earthworms living in lead contaminated soils. Geochim Cosmochim Acta 75:2544–2556. https://doi.org/10.1016/j.gca.2011.02.015

Makuchowska-Fryc J (2019) Use of the eggshells in removing heavy metals from waste water - the process kinetics and efficiency. Ecol Chem Eng S 26:165–174. https://doi.org/10.1515/eces-2019-0012

Sdiri A, Higashi T (2013) Simultaneous removal of heavy metals from aqueous solution by natural limestones. Appl Water Sci 3:29–39. https://doi.org/10.1007/s13201-012-0054-1

Moghal AAB, Mohammed SAS, Al-Shamrani MA, Zahid WM (2014) Performance of soils and soil lime mixtures as liners to retain heavy metal ions in aqueous solutions 160–169 https://doi.org/10.1061/9780784413432.017

Zhu X, Kumari D, Huang M, Achal V (2016) Biosynthesis of CdS nanoparticles through microbial induced calcite precipitation. Mater Des 98:209–214. https://doi.org/10.1016/j.matdes.2016.03.008

Nancharaiah YV, Lens PNL (2015) Selenium biomineralization for biotechnological applications. Trends Biotechnol 33:323–330. https://doi.org/10.1016/j.tibtech.2015.03.004

Zachara JM, Cowan CE, Resch CT (1991) Sorption of divalent metals on calcite. Geochim Cosmochim Acta 55:1549–1562. https://doi.org/10.1016/0016-7037(91)90127-Q

Tang Y, Elzinga EJ, Jae Lee Y, Reeder RJ (2007) Coprecipitation of chromate with calcite: batch experiments and X-ray absorption spectroscopy. Geochim Cosmochim Acta 71:1480–1493. https://doi.org/10.1016/j.gca.2006.12.010

Elzinga EJ, Rouff AA, Reeder RJ (2006) The long-term fate of Cu2+, Zn2+, and Pb2+ adsorption complexes at the calcite surface: an X-ray absorption spectroscopy study. Geochim Cosmochim Acta 70:2715–2725. https://doi.org/10.1016/j.gca.2006.02.026

Merdy P, Gharbi LT, Lucas Y (2009) Pb, Cu and Cr interactions with soil: sorption experiments and modelling. Colloids Surf, A 347:192–199. https://doi.org/10.1016/j.colsurfa.2009.04.004

Seco A, Marzal P, Gabaldón C, Ferrer J (1997) Adsorption of heavy metals from aqueous solutions onto activated carbon in single Cu and Ni systems and in binary Cu–Ni, Cu–Cd and Cu–Zn systems. J Chem Technol Biotechnol 68:23–30. https://doi.org/10.1002/(SICI)1097-4660(199701)68:1%3c23::AID-JCTB595%3e3.0.CO;2-N

Soares MAR, Quina MJ, Quinta-Ferreira RM (2015) Immobilisation of lead and zinc in contaminated soil using compost derived from industrial eggshell. J Environ Manag 164:137–145. https://doi.org/10.1016/j.jenvman.2015.08.042

Fleming M, Tai Y, Zhuang P, McBride MB (2013) Extractability and bioavailability of Pb and As in historically contaminated orchard soil: effects of compost amendments. Environ Pollut 177:90–97. https://doi.org/10.1016/j.envpol.2013.02.013

Kang C-H, Kwon Y-J, So J-S (2016) Bioremediation of heavy metals by using bacterial mixtures. Ecol Eng 89:64–69. https://doi.org/10.1016/j.ecoleng.2016.01.023

Achal V, Pan X, Zhang D, Fu Q (2012) Bioremediation of Pb-contaminated soil based on microbially induced calcite precipitation. J Microbiol Biotechnol 22(2):244-247. https://doi.org/10.4014/jmb.1108.08033

GarcÍa-Sánchez A, Álvarez-Ayuso E (2002) Sorption of Zn, Cd and Cr on calcite. Application to purification of industrial wastewaters. Minerals Eng 15:539–547. https://doi.org/10.1016/S0892-6875(02)00072-9

Al-Degs YS, El-Barghouthi MI, Issa AA et al (2006) Sorption of Zn(II), Pb(II), and Co(II) using natural sorbents: equilibrium and kinetic studies. Water Res 40:2645–2658. https://doi.org/10.1016/j.watres.2006.05.018

Makino T, Sugahara K, Sakurai Y et al (2006) Remediation of cadmium contamination in paddy soils by washing with chemicals: Selection of washing chemicals. Environ Pollut 144:2–10. https://doi.org/10.1016/j.envpol.2006.01.017

Kumari D, Qian XY, Pan X, Achal V, Li Q, Gadd GM (2016) Microbially-induced carbonate precipitation for immobilization of toxic metals. Adv Appl Microbiol 94:79–108. https://doi.org/10.1016/bs.aambs.2015.12.002

O’Connor GA, O’Connor C, Cline GR (1984) Sorption of cadmium by calcareous soils: influence of solution composition. Soil Sci Soc Am J 48:1244–1247. https://doi.org/10.2136/sssaj1984.03615995004800060008x

Campillo-Cora C, Conde-Cid M, Arias-Estévez M et al (2020) Specific adsorption of heavy metals in soils: individual and competitive experiments. Agronomy 10:1113. https://doi.org/10.3390/agronomy10081113

Li W, Zhang Y, Achal V (2022) Mechanisms of cadmium retention on enzyme-induced carbonate precipitation (EICP) of Ca/Mg: Nucleation, chemisorption, and co-precipitation. J Environ Chem Eng 10:107507. https://doi.org/10.1016/j.jece.2022.107507

Goldberg S, Criscenti LJ, Turner DR, et al. (2007) Adsorption-desorption processes in subsurface reactive transport modeling https://doi.org/10.2136/vzj2006.0085

Blais JF, Djedidi Z, Cheikh RB et al (2008) Metals precipitation from effluents: review. Pract Periodical Hazard Toxic Radioact Waste Manag 12:135–149. https://doi.org/10.1061/(ASCE)1090-025X(2008)12:3(135)

Moghal AAB, Reddy KR, Mohammed SAS et al (2016) Lime-amended semi-arid soils in retaining copper, lead, and zinc from aqueous solutions. Water Air Soil Pollut 227:372. https://doi.org/10.1007/s11270-016-3054-1

Mohammed SAS, Moghal AAB (2016) Efficacy of nano calcium silicate (NCS) treatment on tropical soils in encapsulating heavy metal ions: leaching studies validation. Innov Infrastruct Solut 1:21. https://doi.org/10.1007/s41062-016-0024-9

Madhu A, Chakraborty JN (2017) Developments in application of enzymes for textile processing. J Clean Prod 145:114–133. https://doi.org/10.1016/j.jclepro.2017.01.013

Dejong JT, Soga K, Kavazanjian E et al (2013) Biogeochemical processes and geotechnical applications: progress, opportunities and challenges. Géotechnique 63:287–301. https://doi.org/10.1680/geot.SIP13.P.017

Vega FA, Covelo EF, Andrade ML (2008) A versatile parameter for comparing the capacities of soils for sorption and retention of heavy metals dumped individually or together: results for cadmium, copper and lead in twenty soil horizons. J Colloid Interface Sci 327:275–286. https://doi.org/10.1016/j.jcis.2008.08.027

Acosta JA, Jansen B, Kalbitz K et al (2011) Salinity increases mobility of heavy metals in soils. Chemosphere 85:1318–1324. https://doi.org/10.1016/j.chemosphere.2011.07.046

González Costa JJ, Reigosa MJ, Matías JM, Covelo EF (2017) Soil Cd, Cr, Cu, Ni, Pb and Zn sorption and retention models using SVM: variable selection and competitive model. Sci Total Environ 593–594:508–522. https://doi.org/10.1016/j.scitotenv.2017.03.195

Wang YM, Chen TC, Yeh KJ, Shue MF (2001) Stabilization of an elevated heavy metal contaminated site. J Hazard Mater 88:63–74. https://doi.org/10.1016/S0304-3894(01)00289-8

Mohammed SAS, Sanaulla PF, Moghal AAB (2016) Sustainable use of locally available red earth and black cotton soils in retaining Cd2+ and Ni2+ from aqueous solutions. Int J Civ Eng 14:491–505. https://doi.org/10.1007/s40999-016-0052-z

Zhou DM, Wang SQ, Chen HM (2001) Interaction of Cd and citric acid, EDTA in red soil. J Environ Sci 13(2):153–156

Kumpiene J, Lagerkvist A, Maurice C (2008) Stabilization of As, Cr, Cu, Pb and Zn in soil using amendments – a review. Waste Manag 28:215–225. https://doi.org/10.1016/j.wasman.2006.12.012

Manjeet B, Diwan S, Garg VK, Pawan R (2009) Use of agricultural waste for the removal of nickel ions from aqueous solutions: equilibrium and kinetics studies. Int J Environ Sci Eng 1(2):108–114. https://doi.org/10.5281/zenodo.1075328

Attar K, Demey H, Bouazza D, Sastre AM (2019) Sorption and desorption studies of Pb(II) and Ni(II) from aqueous solutions by a new composite based on alginate and magadiite materials. Polymers 11:340. https://doi.org/10.3390/polym11020340

Karna RR, Luxton T, Bronstein KE et al (2017) State of the science review: Potential for beneficial use of waste by-products for in situ remediation of metal-contaminated soil and sediment. Crit Rev Environ Sci Technol 47:65–129. https://doi.org/10.1080/10643389.2016.1275417

Li C, Qian Z, Zhou C et al (2014) Mussel-inspired synthesis of polydopamine-functionalized calcium carbonate as reusable adsorbents for heavy metal ions. RSC Adv 4:47848–47852. https://doi.org/10.1039/C4RA08193E

Peters RW (1999) Chelant extraction of heavy metals from contaminated soils. J Hazard Mater 66:151–210. https://doi.org/10.1016/S0304-3894(99)00010-2

Cline SR, Reed BE (1995) Lead removal from soils via bench-scale soil washing techniques. J Environ Eng 121:700–705. https://doi.org/10.1061/(ASCE)0733-9372(1995)121:10(700)

Kavazanjian E, Almajed A, Hamdan N (2017) Bio-inspired soil improvement using EICP soil columns and soil nails https://doi.org/10.1061/9780784480793.002

Ran D, Kawasaki S (2016) Effective use of plant-derived urease in the field of geoenvironmental/ geotechnical engineering. J Civil Environ Eng 6:1–13. https://doi.org/10.4172/2165-784X.1000207

Dhami NK, Reddy MS, Mukherjee A (2013) Biomineralization of calcium carbonates and their engineered applications: a review. Front Microbiol. https://doi.org/10.3389/fmicb.2013.00314

Madrid L, Diaz-Barrientos E (1992) Influence of carbonate on the reaction of heavy metals in soils. J Soil Sci 43:709–721. https://doi.org/10.1111/j.1365-2389.1992.tb00170.x

Torres-Aravena ÁE, Duarte-Nass C, Azócar L et al (2018) Can microbially induced calcite precipitation (MICP) through a ureolytic pathway be successfully applied for removing heavy metals from wastewaters? Crystals 8:438. https://doi.org/10.3390/cryst8110438