Abstract

This study was based on the comparison for the cultivation of microalgae species Chlorella vulgaris in domestic wastewater and distilled water in order to reduce nutrients and simultaneously generate biomass to produce biodiesel. Microalgae reduces concentration of inorganic pollutants (nutrients), and it was observed that 41% (nitrates) and 37% (orthophosphates) were removed by cultivating microalgae in wastewater, while nitrate and orthophosphate removal efficiency was found to be 36% and 23%, respectively, with its cultivation in distilled water. It is worth mentioning that maximum microalgae biomass productivity was found to be higher at 6.768 mg/L with wastewater cultivation as compared to 3.308 mg/L in distilled water. The lipid extraction from the microalgal biomass produced using wastewater was found to be 25.2% by dry weight. The GC–MS fatty acids analysis of the microalgae lipids demonstrated the presence of myristic (C14:0), palmitic (C16:0), palmitoleic (C16:1), oleic acid (C18:1), linoleic (C18:1) and linolenic acids (C18:3), which are favourable to produce biodiesel with better fuel characteristics. FTIR peaks at 1361 cm−1 and another at 1639 cm−1 revealed the presence of ester linkages in microalgae, and a peak at 1000 cm−1 denotes strong polysaccharide (C–O) bonding. Thus, FTIR analysis revealed well-formed microalgae with all characteristic peaks and distinct finger prints of lipid existence. The energy requirement for microalgae cultivation per litre for a 10 day cultivation period showed higher value with distilled water (1.539 kWh) as compared to its cultivation in wastewater (0.966 kWh). Current investigation suggests that microalgae cultivated using domestic wastewater can produce more biomass as compared to its cultivation in distilled water, with a benefit of freshwater conservation. It also treats wastewater by taking up the nutrients and helps in mitigating eutrophication if untreated wastewater is discharged directly into water bodies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Amidst excessive fossil fuel consumption, as carbon dioxide (CO2) continues to accumulate in the environment, sustainable alternative sources of biofuels are being targeted towards that can suffice the growing need for fuel and also leave the lowest carbon footprint [1]. Microalgae oil production can potentially be carried out more efficiently, leaving smaller carbon footprints and without competition with agricultural land to cultivate edible crops [2]. Microalgae are considered a favourable feedstock to produce third-generation biofuels because they are potentially 10–20 times more oil producing than vegetable oil seed crops [1]. Organic and inorganic pollutants released into the environment as a result of domestic, agricultural and industrial water activities lead to contamination of wastewater [3]. During the wastewater treatments, primary and secondary processes have been introduced in order to eliminate the settleable solids and to decompose organic materials, which results in treated effluent that can be discharged into natural water bodies and has other applications such as for irrigational purposes. Therefore, wastewater loaded with organic and inorganic pollutants such as nitrogen (N) and phosphorus (P) can cause eutrophication in lakes [4]. Microalgae cultures offer an extremely beneficial source of wastewater treatment, providing tertiary biological treatment coupled with the production of potential feedstock for a variety of products such as bio-methane, bio-hydrogen and biodiesel production, composting, as animal feed or aquaculture for fishes. Furthermore, it provides us with a range of other benefits such as reduction of biochemical oxygen demand (BOD5), reducing nitrates/phosphates and removing heavy metals [5].

The microalgae help in CO2 sequestration through carbon absorption from atmosphere for photosynthesis and give us oil for biofuels production. In a previous study, the effect of the removal of CO2 from atmosphere and lipid productivity from microalgae biomass was studied. It was observed that with ambient CO2, the additional 1% by volume CO2 enhanced the microalgae growth. The average growth rate was 60% higher at the logarithmic growth phase with CO2 as driver of algal biomass and lipids production. Therefore, it is an effective method to reduce the carbon emission with producing biofuels and bioenergy from microalgae biomass [6]. Previous research investigation showed microalgae cultivation using an aquaculture wastewater as growth medium with different levels of nutrients, showed that microalgae cell density increased 8.9 times more than the initial level of the microalgae species (Platymonas subcordiformis) while the nutrients removal from wastewater was estimated to be around 87–95% for nitrates and 98–99% phosphates, respectively. Therefore, it was suggested to simultaneously couple the reduction of nitrogen and phosphorus from wastewater by cultivating microalgae and produce biofuels [7]. Research work was conducted on green algae Chlorella sp. cultivated with wastewater and its growth was monitored along with the removal efficiency of nitrogen, phosphorus, chemical oxygen demand (COD) and metal ions. The results showed microalgae can be cultivated with wastewater and it can simultaneously treat wastewater by removing nutrients and other contaminants such as metal ions [8].

Wang et al., 2009 [9] assessed the growth of green algae Chlorella sp. with wastewaters sampled from four different collection points (before and after primary settling tanks, after activated sludge tank and wastewater generated in sludge centrifuge) during the treatment process and growth was monitored with respect to the reduction of nutrients, chemical oxygen demand and metal ions from wastewater. Microalgae species Chlorella sp. showed good adaptation in all of the four wastewater samples and showed significant increase in growth rate in the wastewater generated in sludge centrifuge because of its much higher levels of nitrogen, phosphorus and COD concentrations than those in the other three wastewaters. The ammonia nitrogen removal rates were 82.4%, 74.7%, 0.5% and 78.3% for four wastewater samples, respectively, while the phosphorus removal was found as 83.2%, 90.6%, 4.70% and 85.6%, respectively.

Microalgae appear to be a significant source of biomass to produce biodiesel that has the potential to replace fossil fuels such as mineral diesel. A comparative study was conducted in Pakistan on Cladophora sp., Oedogonium sp., and Spirogyra sp. that showed that Cladophora sp. produced a higher yield of biodiesel than Spirogyra sp. and Oedogonium sp. Moreover, the biomass after lipid extraction can be used as a feedstock for potential industrial applications [10]. Advancement in renewable energy can help Pakistan to tackle energy crises. The indigenous microalgae species, such as Chlorella vulgaris, Chaetoceros sp., Cyclotella sp., Scenedesmus sp., Chlamydomonas sp. and mixed blue microgreen algae were found having favourable growth conditions in an open pond in Pakistan [11]. A previous study showed that mixed microalgae culture was cultivated using secondary treated domestic wastewater for biodiesel production. The total lipid yield was found to be 26.2% by weight of dry biomass and approximately 74% of the lipids were contributed by total glycerides. Fatty Acid Methyl Ester (FAME), i.e. biodiesel composition was mainly composed of palmitic, palmitoleic, stearic, oleic, linoleic and linolenic acid methyl esters. Thus, it was observed that microalgae biomass obtained from its cultivation with domestic wastewater has beneficial properties for its conversion into biodiesel [12].

The present research investigation basically looks into comparing cultivation of microalgae species chlorella vulgaris in distilled and domestic wastewater in photo-bioreactors for sustainable development in the renewable energy sector to produce biodiesel. The biomass productivity yield, concentration of chlorophyll and removal of nutrients (nitrates and orthophosphates) as a function of cultivation time of microalgae were compared and measured. Moreover, the cultivation of microalgae energy consumption analysis based on scale-up factor was also being calculated to look into biomass production feasibility.

Materials and methods

The methodology adopted for this study to microalgae cultivation using wastewater and distilled water is shown in Fig. 1. The experimental work was conducted at a room temperature of 25 ± 1 °C and relative humidity 65% in the Water Testing Laboratory, Department of Environmental Engineering, NED University of Engineering & Technology (NEDUET), Karachi, Pakistan. Domestic wastewater from residential staff colony coming into the NEDUET wastewater treatment plant with a treatment capacity of 56,781 L/day (i.e. 15,000 gal/ day) was collected for experimental analysis.

Tubular photo-bioreactors for microalgae cultivation

The photo-bioreactor tubes were fabricated to cultivate microalgae in a batch scale setup using wastewater for its treatment by reducing the nutrients concentration and simultaneously producing microalgae biomass for 10 days cultivation time. The tubular photo-bioreactors were fabricated from acrylic transparent sheets with an inner diameter 38.1 mm, outer diameter 40.64 mm, and with a wall thickness of 2.54 mm. The length of each tubular photo-bioreactor was 762 mm and had a volume capacity of 750 mL. The five tubular photo-bioreactors were mounted on a metal frame with dimensions with 609.6 mm × 304.8 mm × 304.8 mm inches (length × width × height). The air was provided to each tubular photo-bioreactor through air diffusers (nozzles) at the bottom of each tube connected to the air pump (ACO-308, Hailea, China) having flow rate 60 L/min divided into five tubular photo-bioreactor (i.e. 12 L/min) through a steel nozzle of diameter 5 mm and transparent rubber pipes. The acrylic cylindrical tubes used for photo-bioreactors, were clamped by connectors with a metal frame holder.

Characteristics of domestic wastewater used for microalgae cultivation

The physical and chemical characteristics of domestic wastewater sample such as pH, Biochemical Oxygen Demand (BOD5), Chemical Oxygen Demand (COD), and dissolved oxygen, nitrate and orthophosphate were measured in the laboratory following the Standard Methods for the Examination of Water and Wastewater [13], while heavy metals such as Pb, Zn, Cd and Cu concentrations were measured by Flame Atomic Absorption Spectrophotometry at Centralized Research Laboratory, University of Peshawar, Pakistan.

Ratios of wastewater, culture and media used in experimental work

The microalgae species (Chlorella vulgaris) culture and Standard Guillard’s (F/2) nutrient solution was used as media for microalgae growth procured from the Food and Marine Resources Research Centre (FMRRC), Pakistan Council for Scientific and Industrial Research (PCSIR) Laboratories, Karachi, Pakistan. Wastewater sample (5 L) collected from the wastewater treatment plant was filtered with a filtration assembly having 47 mm microfiber glass filter membrane (Whatman, England) attached with a vacuum pump (DOA-P504-BN, Gast High-Capacity Vacuum Pump, USA). After filtration, the sample was autoclaved (RTA 110, Robus Technologies, UK) to remove undesirable bacteria and germs from the wastewater. This process was carried out at 121 °C at 20 psi pressure for 30 min, sterilizing the wastewater sample and then storing the sample at 4 °C in a closed cap sterilized bottle for experimental work as per the previous study [14]. Different ratios of culture and media were prepared to measure the growth of microalgae with respect to nutrients removal in distilled water (as control samples) and domestic wastewater as shown in Table 1. Each photo-bioreactor was introduced with 500 mL sample as per the ratios prepared.

Measurement of light intensity, pH and electrical conductivity

The intensity of sunlight (Lux) falling on the photo-bioreactor tubes was measured with a light intensity meter (LM-120, Amprobe, Germany), while the pH of the samples was measured using a pH meter (pH Tester, Eutech, USA) and electrical conductivity by (Lovibond, SensoDirect Con 200, Germany).

Nutrients removal determination

For the measurement of nutrient concentrations, the liquid samples were centrifuged using (MPW-2, Wirowka, Germany) at 3000 rpm for 30 min and the supernatant layer was collected. Then the nitrate and orthophosphate concentrations were measured with spectrophotometer at 425 nm and 880 nm, respectively. Nitrate concentration was measured by adding a 10 mL centrifuged liquid sample with powdered Nitrate Aluminium Foil Pillow (Hach, USA) as a reagent to detect the nitrate concentration. The prepared 10 mL solution was introduced into a sample cell holder and the spectrophotometer was operated to measure the concentration of nitrate at 425 nm. Similarly, to measure the amount of orthophosphate removal from the liquid samples, 50 mL centrifuged liquid sample was added and mixed thoroughly by shaking with 8 mL combined reagent solution as per the ratios mentioned in the Standard Methods for the Examination of Water and Wastewater following ascorbic acid method (4500-P.E) [13]. After approximately 10 min, the 10 mL prepared solution was transferred into a sample cell holder of spectrophotometer and its concentration was measured at 880 nm.

Microalgae biomass productivity determination

The microalgae biomass productivity was measured through optical density at 680 nm (OD680) using DR 5000, UV–Vis Spectrophotometer, (Hach, USA) as a microalgae density indicator on alternate days for 10 days cultivation period as per the literature [9]. The standard microalgae biomass concentration (mg/mL) with respect to the absorbance (680 nm) was plotted using the standard Chlorella vulgaris dried biomass obtained from Food and Marine Resources Research Centre, PCSIR Laboratories, Karachi. The dried biomass powder was dissolved in distilled water in the ratios of 1 mg/mL, 2 mg/mL, 3 mg/mL, 4 mg/mL, 5 mg/mL, 6 mg/mL, 7 mg/mL, 8 mg/mL, 9 mg/mL and 10 mg/mL and their respective absorbance were measured.

Chlorophyll measurement

The concentration of chlorophyll (mg/L) was measured on alternate days of microalgae cultivation. The chlorophyll concentration was determined by methanol extraction method followed by using spectrophotometer at 660 nm and 642.5 nm with solvent as a blank as per the protocol mentioned in literature [15].

Lipid extraction and fatty acids methyl ester analysis with GC-FID

The liquid sample with higher biomass productivity (i.e. optical density) and nutrients removal was selected to extract the total lipids from the biomass. For lipid extraction 50 mL microalgae culture sample was centrifuged at 3000 rpm for 30 min and the biomass was separated from the liquid phase. The microalgae biomass was dried in an oven (YCO-NO1, Gemmy Industrial Corporation, Taiwan) at 80 °C for 4 h and then the dried biomass crisps were powdered with mortar and pestle. The total lipids were extracted following the Bligh & Dyer method as mentioned in literature [12] and the lipid yield (by weight) was obtained using an electronic balance (AB 304-S, Mettler Tolendo, Switzerland). The fatty acids methyl ester (FAME) content was measured by GC-FID analyzer (7890B, GC systems, Agilent Technologies Inc., USA) fitted with a flame ionization detector at the International Center for Chemical and Biological Sciences, University of Karachi, Pakistan. The column length 30 m, 0.32 mm, 0.25 µ, and 7 inch cage initial temperature was 150 °C and temperature was ramped up by 8 °C/min to 190 °C and kept at 230 °C for 22 min with ramp of 3 °C/min. The temperature of injector was maintained at 280 °C and the temperature of detector was kept at 300 °C.

FTIR analysis of microalgae biomass

The dried microalgae biomass was analysed using Fourier-transform infrared spectroscopy (FTIR) instrument used from range of 500 to 4000 cm−1 using IRAffinity-1S, Shimadzu Corporation, Japan at the Department of Biomedical Engineering, NED University of Engineering and Technology, Karachi, Pakistan to identify functional bonding presence in microalgae biomass at a resolution of 2 cm−1. The microalgae biomass sample was grounded and placed in sample holder for testing.

Microscopy of microalgae culture

The microscopic analysis of the microalgae cells produced during the cultivation period was carried out using an optical stereo microscope (DMW-143, Motic, China) at 400 × magnification at the Department of Materials Engineering, NED University of Engineering & Technology, Karachi, Pakistan.

Statistical analysis

A paired sample t-test analysis was conducted at a significance level 0.05 with two tailed hypothesis on the biomass productivity as a function of cultivation day (10th day) for both distilled water and wastewater samples.

Cultivation energy analysis

In order to evaluate the economic feasibility of microalgae cultivation, requirement of energy need was determined. The energy requirement for cultivation of microalgae per litre for a duration of 10 days was calculated based on volume fraction ratio [16] to get a more accurate value in order to scale up the production of microalgae biomass. For the cultivation of microalgae in distilled water, energy requirement was calculated incorporating the distillation unit and aeration process, while in wastewater cultivation, the processes of autoclaving and aeration were included for its calculation.

Results and discussion

Properties of raw wastewater

The physical and chemical properties of domestic wastewater used in this research work were measured and are presented in Table 2. The properties showed the pH was within the permissible range of the National Environmental Quality Standards (NEQS) for Municipal and Liquid Industrial Effluents in Pakistan [17]. While the BOD5 was higher than the permissible limit of the effluent into the sea and the dissolved oxygen level was low as per the standard (5 mg/L or more) in the sea for a healthy marine environment, the amount of heavy metals present in the domestic wastewater samples were found to be negligible as compared to the NEQS standard.

Light intensity and pH measurement

The sunlight intensity measured was found to be 1908.6 ± 18.91 lx (35.30 μmol photons m2/s) for a sample size n = 3. The direct sunlight on the photo-bioreactors was avoided to keep the microalgae culture broth healthy because the direct sun rays may cause damage to the microalgae cell walls with temperatures higher than its optimal conditions. All samples with different ratios of culture broth and nutrients with wastewater and distilled water, were having pH values in the range between 7.1 and 7.8.

Microalgae cultivation for nutrients removal

Basically, wastewater contains different types of contaminants and microalgae have an ability to utilize both organic and inorganic nutrients (i.e. nitrogen and phosphorus) from wastewater for its growth. Therefore, in current research work, 10 samples in total were prepared with microalgae culture and media with wastewater and distilled water. The analysis of wastewater sample shows that the concentrations of physical and chemical properties are low as compared to the effluent standard [17]. The initial samples were having concentrations of nitrate and orthophosphate measured as 6.2 mg/L and 2.98 mg/L, respectively.

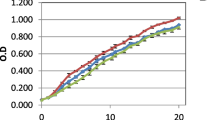

The concentration of nutrients removal from samples with microalgae cultivation was found to be decreasing with respect to the cultivation days, showing that it is being taken up by the microalgae during its photosynthesis, in both wastewater and distilled water. Higher nitrate and orthophosphate removal percentages were around 41.26% and 37.80%, respectively, by cultivating microalgae in wastewater, as shown in Fig. 2a and b. In contrast, nitrate and orthophosphate removal % were roughly 36.54% and 22.48%, respectively, by cultivating microalgae in distilled water as depicted in Fig. 3a and b. It was expected due to the initial higher concentration of nutrients present in growth media in wastewater, resulting in increased microalgae growth rate, biomass yield [18] and also accelerated removal of nutrients for carbon metabolism as compared to cultivation with distilled water [15].

The prepared samples of microalgae culture broth, media (nutrients) and wastewater (samples 1 to 5) were having nitrates concentration on day 1 as 52, 61, 63, 68 and 70 mg/L, respectively. They were reduced to 33, 39, 37, 66.3 and 68.5 mg/L, respectively, on day 10. Similarly, the orthophosphate concentration as 5.65, 7.5, 8.2, 9.0 and 9.8 mg/L at day 1 and it was reduced to 4.38, 6.0, 5.1, 8.26 and 9 mg/L on day 10. The microalgae culture, media (nutrients) and distilled water (samples 6 to 10) were having initial nitrates and orthophosphates concentrations on day 1 same as mentioned earlier, but nitrates concentration was reduced to 33, 39, 57.3, 66.3 and 68.5 mg/L, respectively, on day 10, while the orthophosphates concentration were reduced to 4.38, 6.22, 6.31, 8.26 and 9 mg/L, respectively, on day 10. The results showed that microalgae directly consume inorganic nitrogen compounds and ammonia from samples [19]. The microalgae cultivated using wastewater sample 3 was found better in terms of nutrients removal from wastewater samples, i.e. 41.2% (nitrates) and 37.80% (orthophosphates). These results indicate that a combination of culture broth 15% and 35% media removed maximum nutrients from wastewater. Sample 3, showed slightly higher removal rate of nitrates in comparison with other samples prepared. Therefore, it is pertinent to mention that increasing the dose of chlorella vulgaris affects the removal of nitrates and phosphates from wastewater samples for treatment, but up to certain threshold levels. In present study, it was found 15% microalgae culture in wastewater and higher dosing of microalgae culture will not affect the removal process after its threshold limit because the uptake efficiency of nitrates and orthophosphates from wastewater depends on media composition, environmental factors such as nutrients concentration, light intensity light/dark cycle and microalgae species [20]. It was observed that the change in reduction of nitrates and orthophosphates concentrations occurred mostly after 48 h of contact with chlorella vulgaris culture and according to previous literature, it was observed that chlorella vulgaris speedup the removal process of nitrates and phosphates for the treatment of the wastewater employed [20]. Sample 3 in wastewater had optimum concentration than other ratios for effective nutrients removal by chlorella vulgaris in domestic wastewater, while Sample 6 cultivated in distilled water were found better in nutrients removal; 36.54% (nitrates) and 22.48% (orthophosphates). It is interesting to mention, that microalgae culture used in cultivation of samples 4 and 9 was 5%, while, in samples 5 and 10 it was 10%. Therefore, due to low concentration of microalgae culture used for cultivation, the nitrates and orthophosphates intake by microalgae was observed to be too low. However, the cultivation of microalgae with distilled water showed less uptake efficiency of nutrients as compared to its cultivation using domestic wastewater. This is because microalgae grow in water containing minerals and salts, whereas in distilled water, salts and minerals are negligible, eventually causing reduction in its growth.

Microalgae biomass productivity

The standard microalgae concentration graph was plotted between known concentrations of microalgae biomass and the absorbance noted at 680 nm. The linear regression equation obtained was (y = 0.058x − 0.012) with R-square value 0.995. Tables 3 and 4 show an increasing trend of concentration of microalgae biomass produced in all samples with respect to different cultivation days in wastewater and distilled water. However, it was interesting to note that the biomass productivity with respect to time was higher in cultivating microalgae with wastewater as compared to its cultivation in distilled water. The amount of biomass productivity does not look viable in terms of energy cost but this issue can be resolved in the future by providing more sunlight and carbon dioxide from any exhaust emission source to the microalgae culture. This is also mentioned in the literature that photoautotrophic culture needs substantial amount of carbon to attain high biomass production rate. The amount of carbon dioxide in the ambient air is insufficient to support higher biomass yields that are biologically feasible [21].

The maximum biomass productivity concentrations were found as 6.768 mg/L from wastewater prepared sample 3, while 3.308 mg/L from sample 6, microalgae cultivating in distilled water. The chlorophyll concentration of sample 1 and sample 6 were found higher, i.e. 0.689 mg/L and 0.421 mg/L, respectively, on the 10th day due to higher inoculum concentrations of 25% by volume. Concentration of microalgae biomass produced with respect to different cultivation days using wastewater showed increasing trend in values. While in concentration of microalgae biomass produced in distilled water with respect to different cultivation days showed decreasing trends with sudden fluctuating results in some cases such as in samples 7, 8, 9 and 10. Microalgae biomass production decreases primarily due to the denaturation of essential proteins and enzymes, as well as inhibitory effects on cellular physiology. It was observed that from day 6, microalgae cultivation in distilled water was having nutrients exhausted to a level incapable of its growth and microalgae cell density decreased rapidly with eventually collapsing microalgae culture.

Chlorophyll concentration results

The experimental results observed that chlorophyll concentration of sample 1 and sample 6 was measured to be higher, i.e. 0.689 mg/L and 0.421 mg/L, respectively, on day 10 due to higher inoculum concentrations of 25% and 25% media by volume as presented in Fig. 4. Basically, chlorophyll concentration characterizes the growth pattern of the microalgae. The increasing concentration of pigments in the biomass is attributing to the light harvesting role of these pigments but it does not mean increase in the biomass pigments content was not a linear function of the biomass concentration [22]. It was observed that equal concentrations of microalgae culture and media enhanced the chlorophyll concentration with respect to time.

Lipids extraction yield and fatty acids analysis

The sample 3 with microalgae cultivation in wastewater with highest biomass productivity and nutrients removal was selected for lipid extraction and its fatty acids compositional analysis. Therefore, the extracted lipids yield from biomass harvested from sample 3 was found to be 0.252 g/g of dried microalgae biomass (i.e. 25.2% by dry weight), while the de-oiled cake was found to be 0.733 g/g of dried biomass. Although the lipid yield was not too much from the experiment, for future studies it is suggested to provide sufficient sunlight and carbon dioxide concentration from an external source to improve the microalgae growth rate and lipid yields. The GC–MS fatty acids analysis of the microalgae lipids showed in its composition the presence of myristic (C14:0), palmitic (C16:0), palmitoleic (C16:1), oleic acid (C18:1), linoleic (C18:1) and linolenic acid (C18:3) as shown in Table 5.

The fatty acids profile showed that due to the appearance of saturated and mono saturated fatty acids (C18:2, C18:3) with long chain length, the biodiesel properties such as oxidation stability, cetane number and the iodine value are known to be affected as per the literature [9]. The free fatty acids components having influence on the biodiesel fuel properties, such as palmitic (C16:0) results in having higher cetane number and low iodine value, while oleic acid (C18:1) improves cold flow properties. Linoleic (C18:2) and linolenic acid (C18:3) have an influence on better combustion characteristics in the formation of biodiesel with better fuel quality [23]. The iodine value (IV) determined by fatty acid profile was 15.666 g I2/100 g of oil. The iodine value is a useful parameter in investigating oxidative rancidification and chemical stability of biodiesel derived from different vegetable oils. Higher quantities of fatty acids with double bonds in the sample have greater potential to polymerize and hence reducing its oxidation stability. Therefore, lower IV results in better quality of biodiesel fuel and it was observed in current study the value is too low (15.666 g I2/100 g of oil). Biodiesel produced from vegetable oils with high amounts of saturated fatty acids (i.e. having lower iodine values) will have a higher cetane number (CN). Iodine values more than 50 can result in decreased engine life but gives better lubricity and viscosity characteristics during cold weather months [24]. The calculated value of saponification value (SV) from the fatty acids profile was found 131.17 mg KOH/g of oil. The higher saponification value indicates more proportion of low molecular weight fatty acids in the oil [24] with a possibility of soap formation and difficulty in separation of methyl ester from glycerol molecule during transesterification process. It is suggested that using oils with higher saponification value for biodiesel production would lead to very low yields in the methyl esters. Therefore, two step transesterification is required (i.e. acid-catalysed transesterification process followed by base-catalysed transesterification process) to reduce acid value for microalgae biodiesel production.

FTIR analysis of microalgae biomass

Characteristic peaks at 1000 cm−1 and at 1361 cm−1 denote aliphatic and alcohol groups while Carboxyl groups were observed at 1639 cm−1. FTIR analysis showed a peculiar Hydroxyl group which is seen at 3357 cm−1 to stretching vibration of O–H and N–H [25]. A weak band at 2923 cm−1 is due to asymmetric C–H vibration. The peaks at 1361 cm−1 and another at 1639 cm−1 reveal presence of ester linkage in microalgae. A well pronounced peak at 1000 cm−1 denotes strong polysaccharide (C–O) bonding [26]. The FTIR analysis reveals well-formed microalgae with all characteristic peaks and distinct finger print of lipid existence.

Microscopic analysis results

The microscopic images showed that the number of cells increased from day 1 to day 10, with an increasing trend as shown in Fig. 5. The increased number of cells visible under the microscopic images depicts the marked increase in growth rates of microalgae over time. Because number of cell counting under the microscope provides an estimate of cell growth rate, therefore, under the current experimental work, it was observed that number of cells growth pattern increased with respect to time, showing better growth of microalgae cells.

Statistical analysis results

Statistical analysis was conducted to compare between biomass productivity with respect to cultivation day 10 for both distilled water and wastewater, showing significant results. The results showed that samples 2, 3 and 5 were having statistically significant p values, with higher biomass production yield (mg/L) with wastewater as compared to its cultivation in distilled water with samples 7,8 and 10 with the corresponding confidence level of 95% (Table 6).

Energy requirement for microalgae cultivation

The energy consumption of microalgae cultivation in distilled water and wastewater was calculated and is depicted in Table 7. For microalgae cultivation in distilled water, the energy requirement for distillation unit was calculated by its power consumption (0.580 kW) multiplied by its operating time (1 h) and volume fraction ratio, i.e. 1, because it is a continuous flow system. Then, energy consumed by air pump (kWh) used for aeration was calculated by multiplying the wattage of pump, i.e. 30 W with 10 days (240 h) and volume fraction ratio obtained by dividing volume of sample (500 mL) with total volume of a photo-bioreactor (750 mL). Volume fraction ratio was calculated based on the previous literature [16] and then adding up the power requirement of distillation unit (0.580 kWh) and aeration pump (0.959 kWh) comes to 1.539 kWh.

Now for the microalgae cultivation in wastewater, energy required for autoclaving and aeration was calculated in the same manner as mentioned earlier in this section. The power consumption of autoclave (0.60 kWh) was multiplied by its operating time (0.25 h) and volume fraction ratio, i.e. 5 L sample in 100 L chamber of equipment (5/100 = 0.05). The energy consumed by air pump (kWh) used for aeration was calculated as mentioned above (0.959 kWh). The summation of autoclaving (0.0075 kWh) and aeration process (0.959 kWh) gave total amount of energy required for cultivation of microalgae in wastewater as 0.966 kWh per litre.

Conclusion

Microalgae considered as the third-generation biofuels feedstock that can be cultivated in wastewater to conserve freshwater and also help in mitigating climate change by capturing carbon dioxide from the atmosphere emitted by fossil fuels combustion. Microalgae not only help in CO2 sequestration from the atmosphere alleviating climate change and reduction in greenhouse gases, but also produces biomass for biofuels generation. The microalgae species chlorella vulgaris was cultivated successfully in the laboratory-scale photo-bioreactors (PBR) in wastewater and distilled water. Present study demonstrated that microalgae cultivation simultaneously reduced the nutrients concentration for wastewater remediation and produced biomass for biodiesel production. Nitrates and orthophosphates removal was around 41% and 37%, respectively, by cultivating microalgae in wastewater, while nitrate and orthophosphate removal rates were 36% and 23%, respectively, by cultivating microalgae in distilled water. The maximum biomass productivity concentrations were found to be 6.768 mg/L and 3.308 mg/L from microalgae cultivating in wastewater and distilled water, respectively. The lipids extraction from the microalgal biomass produced using wastewater was found to be 25.2% by dry weight. The lipid yield was low; however, it is suggested to feed microalgae with more sunlight and CO2 to increase the yield. The GC–MS fatty acids analysis of the microalgae lipids showed in its composition the presence of favourable myristic (C14:0), palmitic (C16:0), palmitoleic (C16:1), oleic acid (C18:1), linoleic (C18:1) and linolenic acid (C18:3) having better effect on the quality of biodiesel produced. The FTIR peaks at 1361 cm−1 and another at 1639 cm−1 revealed the presence of ester linkages in the microalgae, and a peak at 1000 cm−1 denoted strong polysaccharide (C–O) bonding. The FTIR analysis revealed well-formed microalgae with all the characteristic peaks and distinct finger prints of lipid existence. As economic analysis is concerned, the microalgae cultivation energy requirement per litre with distilled water (1.539 kWh) was found to be much higher than its cultivation in wastewater (0.966 kWh) for 10-day cultivation period. Therefore, it can be concluded that microalgae cultivation in wastewater produces higher microalgae biomass in a cost-effective manner with respect to its cultivation in distilled water as a feedstock to produce third-generation biofuels. The future work includes the comparison of treatment of domestic wastewater with microalgae cultivation in a raceway pond and its biomass productivity with photo-bioreactors.

References

Narala, R.R., Garg, S., Sharma, K.K., Thomas-Hall, S.R., Deme, M., Yan, L., Peer, M.S.: Comparison of microalgae cultivation in photobioreactor, open raceway pond, and a two-stage hybrid system. Front. Energy Res. 4(29), 1–10 (2016)

Hobuss, C.B., Pauline, F.R., Rosales, P.F., Dalila Venzke, D., Souza, P.O., Gobbi, P.C., Gouvea, L.P., Santos, M.A.Z., Pinto, E., Jacob-Lopes, E., Claudio, M.P., Pereira, C.M.P.: Cultivation of algae in photobioreator and obtention of biodiesel. Braz. J. Pharm. 21(2), 361–364 (2011)

Breida, M., Younssi, S., Ouammou, M., Mohamed, M.B., Hafsi, M.: In: Pollution of Water Sources from Agricultural and Industrial Effluents: Special Attention to NO3ˉ, Cr (VI), and Cu(II). Intechopen, London (2019)

Axinte, O., Bădescu, I., Stroe, C., Neacsu, V., Bulgariu, L., Bulgariu, D.: Evolution of trophic parameters from Amara Lake. Environ. Eng. Manag. J. 14(3), 559–565 (2015)

Abdel-Raouf, N., Al-Homaidan, A.A., Ibraheem, I.B.M.: Microalgae and wastewater treatment. Saudi J. Biol. Sci. 19(3), 257–275 (2012)

Eloka-Eboka, A.C., Inambao, F.L.: Effects of CO2 sequestration on lipid and biomass productivity in microalgal biomass production. Appl. Energy 195, 1100–1111 (2017)

Zhen, G., Yuan, L., Haiyan, G., Song, Y., Mu, J.: Microalgae cultivation using an aquaculture wastewater as growth medium for biomass and biofuel production. J. Environ. Sci. 25, S85–S88 (2013)

Ali, M., Mustafa, A., Saleem, M.: Comparative study between indigenous natural coagulants and alum for microalgae harvesting. Arab. J. Sci. Eng. 44(7), 6453–6463 (2019)

Wang, L., Min, M., Li, Y., Chen, P., Chen, Y., Yuhuan Liu, Y., Ruan, R.: Cultivation of green algae Chlorella Sp. in different wastewaters from municipal wastewater treatment plant. Appl. Biochem. Biotechnol. 1, 1–13 (2009)

Khola, G., Ghazala, B.: Biodiesel production from algae. Pak. J. Bot. 44(1), 379–381 (2012)

Ali, M., Sultana, R., Tahir, S., Watson, I.A., Saleem, M.: Prospects of microalgal biodiesel production in Pakistan—a review. Renew. Sustain. Energy Rev. 80, 1588–1596 (2017)

Soydemir, G., Keris-Sen, U.D., Sen, U., Gurol, M.D.: Biodiesel production potential of mixed microalgal culture grown in domestic wastewater. Bioprocess Biosyst. Eng. 39(1), 45–51 (2016)

APHA: Standard Methods for the Examination of Water and Wastewater. American Public Health Association (APHA), Washington DC (1999)

Hu, X., Zhou, J., Liu, G., Gui, B.: Selection of microalgae for high CO2 fixation efficiency and lipid accumulation from ten Chlorella strains using municipal wastewater. J. Environ. Sci. 46, 83–91 (2016)

Lekshmi, B., Joseph, R.S., Jose, A., Abinandan, S., Shanthakumar, S.: Studies on reduction of inorganic pollutants from wastewater by Chlorella pyrenoidosa and Scenedesmus abundans. Alex. Eng. J. 54(4), 1291–1296 (2015)

Ali, M., Watson, I.A.: Comparison of oil extraction methods, energy analysis and biodiesel production from flax seeds. Int. J. Energy Res. 38(5), 614–625 (2014)

Agency, P.E.P., National Environmental Quality Standards (NEQ’S) for Municipal and Liquid Industrial Effluents in Pakistan. 2016: Islamabad.

Ajala, S.O., Alexander, M.L.: Assessment of Chlorella vulgaris, Scenedesmus obliquus, and Oocystis minuta for removal of sulfate, nitrate, and phosphate in wastewater. Int. J. Energy Environ. Eng. 11(3), 311–326 (2020)

Fernández-Linares, L.C., Guerrero Barajas, C., Durán Páramo, E., Badillo Corona, J.A.: Assessment of Chlorella vulgaris and indigenous microalgae biomass with treated wastewater as growth culture medium. Bioresour. Technol. 244, 400–406 (2017)

Choi, H.-J., Lee, S.-M.: Effects of microalgae on the removal of nutrients from wastewater: various concentrations of Chlorella vulgaris. Environ. Eng. Res. 17(S1), S3–S8 (2012)

Chisti, Y.: Large-scale production of algal biomass: raceway ponds. In: Bux, F., Chisti, Y. (eds.) Algae Biotechnology—Product and Processes. Springer, Basel (2016)

Sánchez Mirón, A., Cerón Garcı́, M.-C., Garcı́a Camacho, F., Molina Grima, E., Chisti, Y.: Growth and biochemical characterization of microalgal biomass produced in bubble column and airlift photobioreactors: studies in fed-batch culture. Enzym. Microb. Technol. 31(7), 1015–1023 (2002)

Knothe, G.: Improving biodiesel fuel properties by modifying fatty ester composition. Energy Environ. Sci. 2, 759–766 (2009)

Ismail, S.A.A., Ali, R.: Physico-chemical properties of biodiesel manufactured from waste frying oil using domestic adsorbents. Sci. Technol. Adv. Mater. 16(3), 1–9 (2015)

Sudhakar, K., Premalatha, M.: Characterization of micro algal biomass through FTIR/TGA/CHN analysis: application to Scenedesmus sp. Energy Source Part A Recov. Util. Environ. Effect 37(21), 2330–2337 (2015)

Forfang, K., Zimmermann, B., Kosa, G., Kohler, A., Shapaval, V.: FTIR spectroscopy for evaluation and monitoring of lipid extraction efficiency for Oleaginous Fungi. PLoS ONE 12(1), 1–17 (2017)

Acknowledgements

The authors would like to offer their gratitude to the NED University of Engineering and Technology, Karachi, Pakistan, for the support and resources to conduct this research study. Moreover, we are thankful to the International Center for Chemical and Biological Sciences, University of Karachi, Pakistan, for the GC–MS analysis of microalgae lipids, Centralized Resource Laboratory, University of Peshawar, Pakistan, for determination of heavy metals and Pakistan Council for Scientific and Industrial Research Laboratories, Karachi, Pakistan, for providing the microalgae culture and media.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ali, M., Masood, A. & Saleem, M. Microalgae cultivation in wastewater for simultaneous nutrients removal and biomass production. Int J Energy Environ Eng 12, 475–485 (2021). https://doi.org/10.1007/s40095-021-00383-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-021-00383-3