Abstract

The Korea Research Institute of Standards and Science (KRISS) established the standard of absorbed dose to water of high-energy x-rays based on the graphite calorimetry. Some of the ionization chambers were directly calibrated under high-energy x-rays. Uncertainty of the chamber calibration was 0.43% (k = 1). kQ,Q0, the beam quality correction factor, of the chambers were determined for the chamber models of the NE2571 and PTW30013, too. Determined kQ,Q0 showed good agreement with the literal data within the stated uncertainty. International equivalence of this KRISS standard was also confirmed, in separate studies, by participating in international comparison studies with the National Metrology Institute of Japan and also with the Bureau international des poids et mesures (BIPM.RI(I)-K6). Now, the KRISS is providing a direct calibration service for user’s ionization chambers under high-energy x-rays. This service could contribute improving the quality assurance of x-ray therapy at hospitals by reducing the uncertainty of dose measurement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Korea Research Institute of Standards and Science (KRISS) established the standard of the absorbed dose to water for therapeutic high-energy x-rays and developed the direct calibration procedure for the ionization chambers under the high-energy x-rays. So far, the absorbed dose to water of high-energy x-rays used in domestic hospitals has been traceable to the absorbed dose to water of 60Co gamma-rays standard of the Korea Research Institute of Standards and Science. The effect of the difference in quality between the high-energy x-rays and 60Co gamma-rays is considered by using a quality correction factor, kQ,Q0 (or kQ) provided by IAEA Technical Report TRS-398 [1], an international protocol for external beam radiotherapy, or by TG-51 [2, 3] of the American Association of Medical Physicists. However, the kQ,Q0 given in the protocol are provided only for each model of the chamber, so the characteristic difference between the chambers cannot be considered. This difference contributes to an increase in the uncertainty of the absorbed dose to water, which affects the quality control of the radiation therapy. For this reason, direct calibration under high-energy x-rays has been carried out in the UK since 1989 [4, 5] (direct calibration of the air kerma until the 1990s). Recently, direct calibration of water absorbed dose for high-energy x-rays has been mandatory in Australia since 2014 [6]. In Korea, all technical preparations for direct calibration has already been completed at KRISS.

Measurement traceability is a characteristic that connects the measurement results to measurement standards through an unbroken chain of the calibration [7]. Measurement traceability enables the comparison of results measured by different equipment or people at different times, places or hospitals. In other words, the measurement results are equivalent within a range of the combined uncertainty. This is the core of the quality assurance of treatment, which allows treatment policies to be maintained consistent and makes it possible to accumulate case experiences in each hospital, and to compare and share the treatment results among the radiation oncologists working in different hospitals [8].

One of the most important elements in the measurement traceability is the uncertainty. It is because the uncertainty allows the measurement results to be compared with each other. For this reason, until the early 2000s, countries around the world accepted the revised protocol which was shifted from the air kerma based [4, 9, 10] to the absorbed dose to water based [1,2,3, 5].

ICRU 24 requires the uncertainty of the absorbed dose to the target volume should be within 5% (k = 1) [11]. And there is a need for lower uncertainty for radiation-sensitive tissues. However, it is not easy to maintain the uncertainty of the absorbed dose to the patient below 5% [12]. Of course, the major reason is that the dose in the patient’s body is entirely dependent on calculation. However, the uncertainty involved in the calibration of high-energy x-rays cannot be ignored, yet. Following the standard protocols based on the current 60Co gamma-rays absorbed dose standard, the expected uncertainty of the measured absorbed dose to water under the high-energy x-rays is typically about 1.5% (k = 1) [1], where the uncertainty of 1% (k = 1) is caused by kQ,Q0 [1]. With the direct calibration in the high-energy x-rays, the uncertainty in the dose measurement can be reduced down to less than 1%. For this reason, TRS-398 recommends the direct calibration as the top priority if it is available.

Direct calibration under the high-energy x-rays has not yet become common, for several reasons. The first reason is the technical difficulty. The most preferred primary method of the measurement of absorbed dose to water under high-energy x-rays is calorimetry using water or graphite as a medium. The calorimetry was first developed in the 1970s by the National Bureau of Standards (NBS) [13]. However, due to the difficulty of implementing the technology, it did not spread until the 2000s. Currently, about ten countries have established their own standards for absorbed dose to water under the high-energy x-rays and maintaining their international equivalence of measurements through the CIPM Mutual Recognition Arrangement (CIPM MRA), where CIPM stands for International Committee for Weights and Measures (Comité international des poids et mesures). KRISS developed a graphite calorimeter in 2015 and conducted international comparison studies with National Metrology Institute of Japan (NMIJ) in 2016 [14] and with the International Bureau of Weights and Measures (Bureau international des poids et mesures, BIPM) in 2017 (BIPM.RI(I)-K6) to demonstrate the international equivalence of the new measurement standard. The degree of equivalence of the KRISS standard is maintained in the BIPM's key comparison database (KCDB) [15] at http://kcdb.bipm.org.

The second reason is the argument that the direct calibration is not necessary because the standard for absorbed dose to water under 60Co gamma-rays is more consistent among countries than in the case of the high-energy x-rays [6]. This contributes solely to the superior stability of 60Co gamma-rays. The 60Co gamma-ray field simply decays with the half-life but the x-rays of an electron accelerator cannot be so constant. In fact, the international comparison results under 60Co gamma-rays are relatively better; however, this is meaningless since the calibration under 60Co gamma-rays eventually increases the uncertainty of the hospital users.

The third reason is the economic burden of the secondary standard dosimetry laboratory (SSDL). In order to fully implement direct calibration, the SSDLs have electronic linear accelerators incurring a lot of cost burden. This is an important issue because it may threaten current calibration system, and is also the main reason for not accepting direct calibration in North America. For this reason, TRS-398 suggests that it is not necessary to undergo direct calibration under high-energy x-rays every year and proposes to perform a direct calibration every third calibration cycle or when damage to the ionization chamber is suspected. However, recently, with the widespread use of the electron linear accelerators, some studies on the feasibility of direct calibration in the SSDL have been conducted [16, 17].

Direct calibration under high-energy x-rays can also be used for quality assurance purpose. As mentioned above, the kQ,Q0 values provided by the protocol cannot cover the differences between the individual ion chambers. Even within the same model of chambers, the characteristics may differ due to the structural differences in production or metamorphosis during storage. In fact, in 2010, a study conducted in Korea reported a variation in response up to 2.4% within a same chamber model [18]. This is a much larger difference than the uncertainty (1%, k = 1) of kQ,Q0 suggested in the protocol and may degrade the treatment quality. This kind of problem can be found and be acted upon via an external audit as claimed by S.H. Kim et al. [18].

In this manuscript, the procedure of direct calibration established by the KRISS and the resulting kQ,Q0 values obtained through measurement of some ion chambers are presented.

2 Materials and methods

2.1 Graphite calorimeter

Graphite calorimeter model C1505-4 was used [19]. The schematic structure of the model C1505-4 is as shown in Fig. 1, which was installed and operated as shown in Fig. 2.

Model C1505-4 is a Domen type calorimeter. The core has a diameter and thickness of 16 mm and 3 mm, respectively, equipped with three thermistor thermometers and one thermistor heater, and is covered with two layers of jackets. The temperature change in the core was measured by a DC-type Wheatstone bridge. The signal noise of the Wheatstone bridge is about 0.3 μVpp, which corresponds to a temperature of 0.08 mK. More details on the model C1505-4 are reported in Ref. [19].

From the signals of the graphite calorimeter core, the water absorbed dose was determined through two steps. First, the graphite absorbed dose was determined, and second, multiplied by the graphite-to-water absorbed dose conversion factor to finally determine the water absorbed dose.

In order to determine the graphite absorbed dose, it was necessary to know the energy of the radiation absorbed in the core and the mass of the core. The mass of the core was determined to be (1.103 47 ± 0.000 11) g through precise measurements when the graphite calorimeter was built. The radiation energy absorbed by the core was determined through an electric power calibration procedure, that is, a process of comparing the temperature rise of the core raised by radiation with the temperature rise of the core due to electric heating up by the thermistor heater. The power Px supplied from the thermistor heater was determined as Px = VxVs/Rs, where Vx, Vs were the voltage drops across the thermistor heater and a constant standard resistance (resistance value Rs) connected in series to the thermistor heater, respectively. Therefore, the graphite absorbed dose was traceable to the unit of absorbed dose (Gy) through the calibrations with the mass standard (kg), voltage standard (V), and resistance standard (Ω).

The graphite-to-water absorbed dose conversion factor, kG,W, was determined using a Monte Carlo simulation technique [20]. This method was validated by previous research groups [21,22,23]. EGSnrc code [24] was used in this study. kG,W was determined as kG,W = DW/DG, where DW, DG were the absorbed dose calculated at the calibration point (10 g/cm2 water depth at the central axis of the beam) in a water phantom (30 × 30 × 30 cm3) and at the core center of the computational model of the graphite calorimeter, respectively. kG,W, includes the gap effect correction [25] and the depth correction, as well. kG,W of the model C1505-4 thus determined was as shown in Fig. 3. Figure 3 shows the pattern of kG,W against the beam quality index of high-energy x-rays, i.e., tissue phantom ratio 20, 10 (TPR20,10). Details of kG,W evaluation were reported in Ref. [20].

2.2 High-energy x-ray standard field

High-energy x-ray standard fields are generated using a medical linear electron accelerator model Elekta Synergy® Platform. Three types of x-ray energy sets (6, 10, 18) MV, (6, 10, 15) MV, (4, 8, 25) MV can be configured through combination of filters of the accelerator. (6, 10, 18) MV set has been the default since 2015. The reference irradiation direction of the x-rays was horizontal. All the irradiations in this study were performed in horizontal setting but the characterization of the x-rays. Characteristics of the x-rays were evaluated using a large water phantom (50 × 50 × 40 cm3) in vertical setting to evaluate such as x-ray beam quality index (TPR20,10), lateral profile, and percentage depth dose.

Accelerator x-rays are not such stable as the 60Co gamma-rays. Thus, for the sake of calibrating ionization chambers against the water absorbed dose standard, precise monitoring of the x-rays was needed. To this end, an external monitor chamber was prepared with two thimble-shaped chambers (0.53 cc in volume) connected in parallel and placed after the x-ray emission window. A high-purity, high-density graphite cylinder (12.8 mm inner diameter and 25 mm outer diameter) was overlaid on the monitor chamber to obtain a sufficiently built-up signal. The two ionization chambers were 62.5 mm apart from the center of the beam along the cross-line direction. The ionization current was measured with a precision electrometer, and the temperature and pressure were also measured to correct the effect of air density. The installed external monitor chambers were as shown in Fig. 4. In the case of the medical accelerator of the KRISS, the stability of the inherent monitor chamber installed inside the accelerator was within 0.3% for a day or two, and the stability of the additionally mounted external monitor chambers was within 0.15%.

2.3 Absolute measurement of water absorbed dose

Using the graphite calorimeter, the water absorption dose (rate) (DW/Qm,g) (Gy/nC) of the high-energy x-ray was determined as follows:

where Qm,g was the amount of charge (C) measured by the external monitor chamber, \({\Delta T}_{irr}\) was the temperature rise (K) of the core by irradiation, and Ceff was the effective heat capacity of the core (J/K) [19, 26, 27], meff was the effective mass of the core [19, 23, 27, 28], and ki,g were various correction factors including the graphite-to-water absorption dose conversion factor. Ceff (J/K) was decided as follows.

where EE_cal (J) was the electric energy (J) supplied to thermistor heater for electric power calibration, ΔTE_cal (K) was the temperature rise (K) of the core by electric heating, and kheater was a correction factor for the geometric difference between electric and radiation heating [29].

The calorimeter was positioned so that the center of the graphite calorimeter core was located at a source-to-chamber distance (SCD) of 100 cm. For electric power calibration, electric heating was performed before and after irradiations. Electric heat was supplied approximately at the same rate as the energy absorption expected under the irradiation.

2.4 Calibration of standard ionization chamber

In the high-energy x-ray standard field where the quality was Q, the calibration factors ND,W,Q of the standard ionization chamber was determined as follows.

where MQ was the amount of charge (C) measured by the standard ionization chamber and Qm,ch was the amount of charge (C) measured by the external monitor ionization chamber. MQ was given as follows:

where Mraw was the reading of the standard ionization chamber after the correction for the temperature and pressure was applied, ks was the recombination correction factor, kpol was the polarity effect correction factor, knr,ch was the radial non-uniformity correction factor for the x-ray standard field, and kdepth was the water depth correction factor, ksleeve, was the sleeve effect correction factor, and kSCD was the SCD correction factor. The reference temperature and pressure were 20 ℃ and 101.325 kPa, respectively, when correcting the environmental factors of temperature and pressure.

Five farmer type chambers were calibrated against the graphite calorimeter. Table 1 shows the basic information of the chambers used for the measurement.

The chambers were irradiated in a waterproof sleeve in a water phantom (30 × 30 × 30 cm3). The reference point of the chamber was the geometric center of the chamber, and the reference point was placed at a water depth of 10 g/cm2 on the beam central axis. Since the irradiation direction was horizontal, the phantom window thickness (4.36 mm water equivalent) was included in the water depth. The sleeve was not necessary in the case of a waterproof chamber but had the advantage of improving the positioning reproducibility of the chamber during calibration. When measuring the ionization chamber, the laboratory temperature and humidity were maintained at in the range 20–24 ℃ and 30–70% of relative humidity, respectively, according to the KRISS calibration procedure.

The beam quality correction factors kQ,Q0 of the chambers also were determined as follows from ND,W,Q:

where ND,W,Q0 was the calibration factor for the water absorbed dose of the corresponding ionization chamber in the standard 60Co gamma-ray field.

2.5 Calibration of user ionization chambers

In this study, user ionization chamber calibration was not carried out. However, when a user chamber is submitted for calibration, then it is calibrated against the standard chambers in the same quality of x-rays in the same water phantom, in the same sleeve at the same location and at the same depth. And calibration factor of the user chamber \({N}_{\mathrm{D},\mathrm{W},\mathrm{Q}}^{\mathrm{user}}\) is determined as follows:

Here, ND,W,Q is the calibration factors of the standard chamber, and MQ, Qm,ch and \({M}_{\mathrm{Q}}^{\mathrm{user}}, {Q}_{\mathrm{m},\mathrm{ch}}^{\mathrm{user}}\) are the amount of the charges measured with the user chamber and the external monitor chamber, respectively, under the calibration.

3 Results and discussion

The typical temperature curve obtained with the graphite calorimeter was as shown in Fig. 5. It was obtained under the irradiation of 6 MV x-rays. Here, \({\Delta T}_{irr},\) ΔTE_cal was obtained by extrapolating the pre- and post-drift of the temperature to the midpoint of the heating [30, 31] as shown in Fig. 5b.

Using Eq. (1), the water absorbed dose (rate) of the x-rays was determined as shown in Table 2, which is given as an example of the absolute measurement results of water absorbed dose (rate) at 10 MV x-rays. The relative standard uncertainty of the determined water absorbed dose (rate) was about 0.26%, and the uncertainty due to statistical nature was small, 0.07%. Most of the type B uncertainty originated from the measurement of the effective heat capacity and the determination of the graphite-to-water conversion factor.

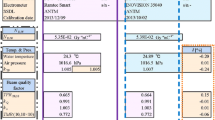

Using Eqs. (3) and (4), the calibration coefficient for the water absorbed dose of the standard ionization chamber were determined as shown in Table 3 where the calibration results of the PTW TN30013 (SN9304) ionization chamber at 10 MV are given.

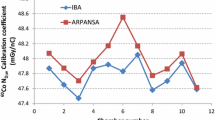

Tables 4 shows kQ,Q0 for each model of the PTW TN30013 and NE2571 chambers determined from the measurements. In Fig. 6, the quality factor is shown as a function of TPR20,10 and %dd(10)x. %dd(10)x was converted from the measured TPR20,10 according to the empirical formula of N. I. Kalach and D. W. O. Rogers [32]. It can be seen that the tendency for the quality of kQ,Q0 is close to linear when the quality factor is plotted along %dd(10)x [33].

kQ,Q0 determined in this study agreed well with the values obtained by other groups. It is expected that the chambers being used in domestic hospitals could be confirmed their kQ,Q0 values.

4 Conclusion

The KRISS established the standard for absorbed dose to water of high-energy x-rays with the standard uncertainty of 0.35% (k = 1) using the graphite calorimetry. The degree of equivalence of the KRISS standard was also confirmed, although it was conducted in a separate study, it is still accessible via the BIPM’s key comparison database (KCDB) [15] at http://kcdb.bipm.org. Now, the KRISS is providing a calibration service for user's ionization chambers.

The KRISS also has established direct calibration procedure of ionization chambers against the new standard. In this study, some ionization chambers have been calibrated and their calibration coefficients were determined with a small standard uncertainty at 0.43% (k = 1). kQ,Q0, the beam quality correction factor, of the ionization chambers were also obtained, and they were in good agreement with the values reported in the existing literature within the stated uncertainty.

Now, the KRISS is ready to disseminate their high-energy x-ray water absorbed dose standard to users and providing direct calibration services. The calibration uncertainty of user’s chamber would be 0.5% (k = 1). This uncertainty is small enough to reduce the uncertainty of the absolute dose measurement of user x-rays down to 1% or less (k = 1). These services would contribute to improving the quality of x-ray treatment in hospitals by reducing the uncertainty in dosimetry.

References

IAEA, Absorbed dose determination in external beam radiotherapy: an international code of practice for dosimetry based on standards of absorbed dose to water, TRS 398, Vienna, 2000.

P.R. Almond, P.J. Biggs, B.M. Coursey, W.F. Hanson, M.S. Huq, R. Nath, D.W.O. Rogers, AAPM’s TG-51 protocol for clinical reference dosimetry of high-energy photon and electron beams. Med. Phys. 26, 1847–1870 (1999)

M. McEwen, L. DeWerd, G. Ibbott, D. Followill, D.W.O. Rogers, S. Seltzer, J. Seuntjens, Addendum to the AAPM’s TG-51 protocol for clinical reference dosimetry of high-energy photon beams. Med. Phys. 41, 04150-1–04150-20 (2014)

S.C. Lillicrap, J.E. Burns, D. Greene, P.C. Williams, Revised code of practice for the dosimetry of 2 to 35 V x-rays and of caesium-137 and cobalt-60 γ-ray beams. Phys. Med. Biol. 28, 1097–104 (1983)

S.C. Lillicrap, B. Owen, J.R. Williams, P.C. Williams, Code of practice for high-energy photon therapy dosimetry based on the NPL absorbed dose calibration service. Phys. Med. Biol. 35, 1355–1360 (1990)

D.J. Butler, G. Ramanathan, C. Oliver, A. Cole, J. Lye, P.D. Harty, T. Wright, D.V. Webb, D.S. Followill, Direct megavoltage photon calibration service in Australia. Australas Phys. Eng. Sci. Med. 37, 753–761 (2014)

International Vocabulary of Metrology – Basic and General Concepts and Associated Terms (VIM 3rd edition), JCGM 200:2012 (JCGM 200:2008 with minor corrections)

ICRU, Prescribing, Recording, and Reporting Photon Beam Therapy, ICRU Report No. 50, MD, 1993

IAEA, Absorbed dose determination in Photon and Electron Beams, An International code of Practice, TRS 277, Vienna, 1987.

Task Group 21, A protocol for the determination of absorbed dose from high-energy photon and electron beams. Med. Phys. 10, 741–771 (1983)

ICRU, Determination of absorbed dose in a patient irradiated by beams of X or gamma rays in radiotherapy procedures, ICRU Report No. 24, MD, 1976.

ICRP, Prevention of Accidents to Patients Undergoing Radiation Therapy, ICRP Publication 86. Ann. ICRP 30 (3), 2000.

S.R. Domen, A heat-loss-compensated calorimeter and related theorems. J. Res. Natl. Bur. Stand. 73C, 17–20 (1969)

I.J. Kim, B.C. Kim, C.Y. Yi, M. Shimizu, Y. Morishita, N. Saitoa, Bilateral comparison of the absorbed dose to water in high energy x-ray beams between the KRISS and the NMIJ. Nucl. Eng. Technol. 52, 1511 (2020)

C. Thomas, The BIPM key comparison database (KCDB): linkage of key comparison results, Rapport BIPM-05/06, Bureau International des Poids et Mesures, Sèvres, France, 2005.

A.E. Walter and L.A. DeWerd, Evaluation of a Megavoltage Calibration Service at the Secondary Standard Level, 26th Annual Council of Ionization Radiation Measurements and Standards, April 16-18, 2018, National Institute of Standards and Technology, Gaithersburg, USA.

C.E. Andersen, G.V. Santurio, L. de Prez, On the potential of direct MV calibration of ionization chambers by secondary standard laboratories. Physica Media. 52(Supplement 1), 11–12 (2018)

S.H. Kim, H. Huh, S.H. Choi, H.J. Kim, C. Lim, D.O. Shin, J. Choi, Chamber-to-chamber variation in the same type of a cylindrical chamber for the measurements of absorbed doses. Korean J. Med. Phys. 21, 120–125 (2010)

I.J. Kim, B.C. Kim, J.H. Kim, J.P. Chung, H.M. Kim, C.-Y. Yi, Building a graphite calorimetry system for the dosimetry of therapeutic X-ray beams. Nucl. Eng. Technol. 49, 810–816 (2017)

Y.H. Kim, C.Y. Yi, I.J. Kim, B.C. Kim, J.H. Kim, Y.M. Seong, H.M. Kim, Monte Carlo studies on dose conversion factors from graphite to water for high energy X-ray beams. Radiat. Phys. Chem. 171, 108760 (2020)

G. Ramanathan, P. Harty, T. Wright, J. Lye, D. Butler, D. Webb., and R. Huntley, The Australian Primary Standard for Absorbed Dose to Water (Graphite Calorimeter), Technical Report No. 166, Australian Radiation Protection and Nuclear Safety Agency, 2014.

R.F. Nutbrown, S. Duane, D.R. Shipley, R.A.S. Thomas, Evaluation of factors to convert absorbed dose calibrations from graphite to water for the NPL high-energy photon calibration service. Phys. Med. Biol. 47, 441–454 (2002)

Y. Morishita, M. Kato, N. Takata, T. Kurosawa, T. Tanaka, N. Saito, A standard for absorbed dose rate to water in a 60Co field using a graphite calorimeter at the national metrology institute of Japan. Radiat. Prot. Dosim. 154, 331–339 (2012)

I. Kawrakow, E. Mainegra-Hing, D.W.O. Rogers, F. Tessier, and B.R.B. Walters, 2015, The EGSnrc Code System: Monte Carlo simulation of electron and photon transport. Technical Report PIRS-701 (CNRC Canada).

B. Owen, A.R. DuSautoy, Correction for the effect of the gaps around the core of an absorbed dose graphite calorimeter in high energy photon radiation. Phys. Med. Biol. 36, 1699–1704 (1991)

M.R. McEwen, A.R. DuSautoy, Primary standards of absorbed dose for electron beams. Metrologia 46, S59–S79 (2009)

J. Renaud, A. Sarfehnia, J. Bancheri, J. Seuntjens, Aerrow: a probe-format graphite calorimeter for absolute dosimetry of high-energy photon beams in the clinical environment. Med. Phys. 45, 414–428 (2018)

J. Witzani, K.E. Duftschmid, Ch. Strachotinsky, A. Leitner, A graphite absorbed-dose calorimeter in the quasi-isothermal mode of operation. Metrologia 20, 73–79 (1984)

I.J. Kim et al., Thermal analysis of a graphite calorimeter for the measurement of megavoltage photon beam absorbed dose, 2014 APMP TCRI Workshop, Daejeon (2014).

J. Seuntjens, S. Duane, Photon absorbed dose standards. Metrologia 46, S39–S58 (2009)

M.R. McEwen, A.R. DuSautoy, Primary standards of absorbed dose for electron beams. Metrologia 46, S59–S79 (2009)

N.I. Kalach, D.W.O. Rogers, Which accelerator photon beams are “clinic-like” for reference dosimetry purposes? Med. Phys. 30, 1546–1555 (2003)

Code of Practice for the Absorbed Dose Determination in High Energy Photon and Electron Beams, Report 18 of the Netherlands Commission on Radiation Dosimetry Revised edition, August 2012.

K.R. Shortt, C.K. Ross, M. Schneider, K. Hohlfeld, M. Roos, A.M. Perroche, A comparison of absorbed dose standards for high energy X-rays. Phys. Med. Biol. 38, 1937–1955 (1993)

C.K. Ross, K.R. Shortt, D.W.O. Rogers, and F. Delaunay, A test of TPR20,10 as a beam quality specifier for high energy photon beams, Measurement Assurance in Dosimetry (Proc. Symp. Vienna, 1993) IAEA, 309–321,1994.

A.S. Guerra, R.F. Laitano, M. Pimpinella, Experimental determination of the beam quality dependence factors, kQ, for ionisation chambers used in photon and electron dosimetry. Phys. Med. Biol. 40, 1177–1190 (1995)

H. Palmans, W. Mondelaers, H. Thierens, Absorbed dose beam quality correction factors kQ for the NE2571 chamber in a 5 MV and a 10 MV photon beam. Phys. Med. Biol. 44, 647–663 (1999)

J.P. Seuntjens, C.K. Ross, K.R. Shortt, D.W.O. Rogers, Absorbed-dose beam quality conversion factors for cylindrical chambers in high energy photon beams. Med. Phys. 27, 2763–2779 (2000)

S. Duane, and M.H. Simon, Experimental determination of the quality-dependent correction factor kQ for ionisation chambers of type NE2561, NE2611 and NE2571, Proceedings of the World Congress on Medical Physics and Biomedical Engineering, Aug 24–29, 2003, Sydney, Australia

J. Medin, C.K. Ross, N.V. Klassen, H. Palmans, E. Grusell, J.-E. Grindborg, Experimental determination of beam quality factors, kQ, for two types of Farmer chamber in a 10 MV photon and a 175 MeV proton beam. Phys. Med. Biol. 51, 1503–2152 (2006)

A. Krauss, R.-P. Kapsch, Calorimetric determination of kQ factors for NE 2561 and NE 2571 ionization chambers in 5 cm×5 cm and 10 cm×10 cm radiotherapy beams of 8 MV and 16 MV photons. Phys. Med. Biol. 52, 6243–6259 (2007)

M.R. McEwen, Measurement of ionization chamber absorbed dose kQ factors in megavoltage photon beams. Med. Phys. 37, 2179–2193 (2010)

L. de Prez, J. de Pooter, B. Jansen, T. Perik, F. Wittkämper, Comparison of kQ factors measured with a water calorimeter in flattening filter free (FFF) and conventional flattening filter (cFF) photon beams phys. Med. Bio. 63, 045023 (2018)

E. Mainegra-Hing, B.R. Muir, On the impact of ICRU report 90 recommendations on kQ factors for high-energy photon beams. Med. Phys. 45, 3904–3908 (2018)

J. Tikkanen, K. Zink, M. Pimpinella, P. Teles, J. Borbinha, J. Ojala, T. Siiskonen, C. Gomà, M. Pinto, Calculated beam quality correction factors for ionization chambers in MV photon beams. Phys. Med. Biol. 65, 075003 (2020)

D.M. González-Castaño, G.H. Hartmann, F. Sánchez-Doblado, F. Gómez, R.-P. Kapsch, J. Pena, R. Capote, The determination of beam quality correction factors: Monte Carlo simulations and measurements. Phys. Med. Biol. 54, 4723–4741 (2009)

Acknowledgements

This work was supported by the Korea Research Institute of Standards and Science, Rep. of Korea under the project ‘Development of measurement standards for ionizing radiation’ with the grant number 19011053.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kim, I.J., Kim, Y.H. & Yi, CY. Absorbed dose to water standard of high-energy x-rays at the KRISS. J. Korean Phys. Soc. 81, 1004–1012 (2022). https://doi.org/10.1007/s40042-022-00619-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40042-022-00619-3