Abstract

In the present study, an attempt has been made to investigate the possibility of protein fabric ecological dyeing with Carica papaya L. leaf dry powder extract as a natural dye. The effect of various metal salts (ferrous sulfate, alum and copper chloride) and natural tannin extracts (harda powder, pomegranate peel, orange peel and amla powder) as mordants on color and fastness properties of dyed protein fabric samples was comparatively observed. Dyeing experiments were performed with and without mordants, using all mordanting techniques, i.e., pre-mordanting, meta-mordanting and post-mordanting. The results of using bio-mordants for wool dyeing were comparable with that of the metallic mordants in terms of color strength and fastness characteristics. Bio-mordants produced quite different colors as expected from a mordant and thus offer full potential to replace metal salts in wool dyeing for ecological dyeing of textiles. UV spectra, FTIR, anti-microbial and UPF values were also evaluated. It was found that dye extract and dyed samples have very good anti-microbial behavior. The bacterial colony counting reduction (%) for both S. aureus and E. coli bacteria was found to be more than 90% for all the dyed fabrics. Dyed fabrics, especially wool, exhibited very large enhancement in UV protection. For wool, the UPF value increased from 79 for undyed wool to 704 after dyeing. In other fabrics, the UPF improvement was not very high owing to the low thickness and cover factor. Thus, dyeing with Carica papaya L. leaf dry powder extract can be a good alternative for medical textiles.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

An increased interest in the use of natural dyes in textile and food coloration industries has been growing since the last few decades. Introduction of natural dyes into modern dye industries is a very promising concept which should be encouraged more and more to reduce the dependency of protein fabric dyeing on some toxic, expensive, more polluted and non-biodegradable synthetic dyes like Azo and Benzedrine dyes. Therefore, the demand and need for the availability of natural dye yielding plants for fulfilling the purpose of ecological coloration has increased at a fast rate. Recently discovered properties of natural color extracts such as insect repellents [1], deodorizing [2],flame retardants [3], UV protection property [4], fluorescence [5,6,7,8], besides being biocompatible, biodegradable, renewable, and non-toxic, have revolutionized all coloring sectors, especially textile industries for producing more aesthetic and highly functional value-added textiles [9]. This is a result of ecological concerns with the use of 118 of the Azo and Benzedrine synthetic dyes with 24 carcinogenic aromatic amines as their primary photolytic degradation products resulting in motivation of researchers toward exploring new eco-friendly substitutes for minimizing their negative environmental impacts [10]. In the application of natural dyes, different dyeing techniques in combination with different mordanting techniques are used to improve color fastness properties. As a result, optimization of the dyeing conditions for dyeing with regard to the type of natural dye is quite common and a broad set of variations in the dyeing recipes is given in the literature available for natural dyeing of textiles [11]. Fashion industry changes every day, therefore the rapid changes in trends and the demand for good fastness properties on different substrates requires a basic database describing possible applications of natural dyes for reduction in parallel optimization work to be done by each dye house. But lower light fastness, poor shade reproducibility, non-standardization of raw material and complexity of extraction processes involved in natural dyeing restrict their use in textile dyeing and finishing applications, besides many advancements have been taken into consideration for modifying color characteristics of dyed textile materials [12]. Mordants play a vital role in natural dyeing processes in terms of achieving broad spectrum of colors of various shades and special performance characteristics on a wide range of natural as well as synthetic textile materials [13]. Chemical nature of mordants and fiber–mordant–dye interactions highly modifies the color characteristics of dyed textiles. The most common mordants in natural dyeing are used to alter the colorimetric parameters and fastness properties of dyed textile materials. These are aluminum, potassium dichromate, copper sulfate, ferrous sulfate and stannous chloride [14]. Use of some earth metals has been successfully employed in textile dyeing as mordants for increasing dyeing behavior of ramie fabrics [15]. Significant amounts of metal ions remain unexhausted in residual mordant baths during dyeing which then are discharged into wastewater, which possess ecological concerns and negative impact on public health [16]. The amount of metal ion discharged from textile industries has been limited strictly beyond a certain limit [17].The rise of new advancements in mordanting processes and selecting new, safe and eco-friendly mordants to replace traditional heavy metal ions have been an important part in the development of natural dyeing processes [18]. The textile industry consumes the biggest amount of water, so extensive data about the effluent production have been collected and are available from the literature [19]. Hence, the use of natural mordants (bio-mordants) in place of metallic salt mordants has been advised by researchers as an effective and safe alternative of textile natural dyeing by considering environmental aspects of pollution and their biodegradable nature [20, 21]. Recently, a lot of research work has been done for the use of bio-mordants as an alternative and safe substitute to metal mordants, and encouraging results have been achieved [22]. Some plants and plant parts with high tannin or metal content may impart mordanting effect to various extents depending on their chemical structure and amount of metal ions present in them [23]. Mordants from natural origins like myrobalan (Terminalia chebula), pomegranate rinds (Punica granatum), tannin, tannic acid, tartaric acid, guava and banana leaves ash have been used for mordanting purposes [5]. Carica papaya (papaya) is a tree-like herbaceous plant and a member of the small family Caricaceae which is widely cultivated for its edible fruits. It originates in the low lands of all tropical countries and many subtropical regions of the world. The present study was undertaken in order to explore dyeing properties of Carica papaya L. leaf powder extract dye alone (control dyeing) and in conjunction with small amounts of metal mordants and alternative bio-mordants. Additionally, comparison between metal mordanted and bio-mordanted protein fabrics samples was also made with the aim of making this research a viable alternative for non-biodegradable metal mordants with eco-friendly, biodegradable and non-toxic bio-mordants.

Materials and Methods

Four protein fabrics, i.e., wool, silk, soya and milk, were used for the present study. Soya and milk fabrics were sourced from Champs Agro unit, Thane, India, and wool and silk fabrics were purchased from Khadi Gram Udyog, Bhiwani, India. Carica papaya leaves were plucked from a garden in Bhiwani. They were further dried in shadow and converted to dry powder using a grinder. Natural mordants used in study, such as orange peel, pomegranate peel, amla powder and harda powder, were procured from the local market. Other laboratory-grade chemicals used in study such as alum, sodium hydroxide, acetic acid, ferrous sulfate, copper and sulfate were of Hi-Media (Table 1).

Fabric Pre-treatment

All fabrics were ready for dyeing when purchased, but still they were washed thoroughly with 0.5 g/l wetting agent for 1 h MLR as 1:20 at 70 °C for removal of any dust and dirt particles present in the sourced fabrics to insure even dyeing of fabrics.

Preparation of Dye Solution and Dyeing

Using optimized conditions of extraction, i.e., MLR 1:30, pH 3, time 60 min at 100 °C, the dye was extracted from Carica papaya. All fabrics were cut into 20 × 20 cm size samples and dyed for optimizing different dyeing parameters, i.e., MLR, pH, and temperature of the dye bath and time of dyeing for obtaining maximum K/S value. As shown in Table 2, Box and Behnken experimental design was used for considering all variables. Further, the dyed fabrics by optimized dyeing recipe were mordanted with four natural mordants such as amla powder, harda powder, orange peel powder and pomegranate powder to improve dyeing fastness properties. Dyed fabrics with optimized dye recipe were also mordanted with three chemical mordants, i.e., alum, copper sulfate and ferrous sulfate, to compare their fastness behavior with natural mordants.

Further, the dyed fabrics were mordanted with four natural mordants such as pomegranate powder, orange peel powder, harda powder and amla powder by optimized dyeing recipe to improve dyeing fastness properties. Further, all dyed fabrics were also mordanted with three chemical mordants, i.e., ferrous sulfate, alum and copper sulfate to compare their fastness behavior with natural mordants.

Characterization of Dye Extract

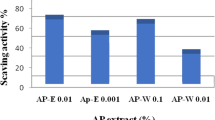

Anti-oxidant Property

Anti-Diphenyl-2-picryl-hydrazyl (DPPH) assay was used to measure anti-oxidant testing of dye extract was carried out by to calculate the free radical scavenging activity (RSA). Anti-oxidant property is a measure of capacity of its extracts to scavenge the stable free radicals of DPPH, and to measure that property, samples of 0.20 ml volumes were added to 3.8 ml of 0.1 mM DPPH solution in ethanol as reported [24]. Samples were put in dark for 30 min afterward to complete the reaction at room temperature for decolorizing the solution. Further, de-colorization was checked on spectrophotometer at 517 nm wavelength and RSA percentage was calculated using formula (1):

where Absorbance(sample) refers to the absorbance of the solution having dye extract and Absorbance(control) refers to the absorbance of the solution having the de-ionized water.

Tannin Content

The Carica papaya extract was assessed for qualitative analysis by treating 0.5% solution of extract with various reagents such as aqueous ferric chloride, gelatine, lead acetate and copper sulfate solution. After the addition of reagent, the color change was observed to measure total tannin content of the Carica papaya extract [25, 26].

Flavonoid Content

Carica total flavonoid content was calculated by measuring the absorbance and taking quercetin as a standard sample. Totally, 25 mg of aqueous water extract was dissolved in 25 ml of methanol, diluted till 300 ppm concentration, and 2 ml of this solution was added with 0.1 ml of AlCl3 following the addition of 0.1 ml of sodium acetate and 2.8 ml of distilled water. Total flavonoid content of the solution was measured using formula (2) after assessing absorbance at 750 nm wavelength using UV spectrophotometer (make: Systronics).

where x = concentration (ppm) of extract, V = volume of sample solution (extract) (ml); DF = dilution factor of sample solution, w = sample weight (g) [27].

Phenolic Content

Carica papaya extract’s total phenolic content (TPC) was measured by Folin–Ciocalteu method [28]. Totally, 0.1 ml of Carica papaya leaf extract 200 µg/ml was kept in a test tube after the addition of 0.1 ml solutions of 50% Folin–Ciocalteu reagent further followed by vortexing for 1 min. After the addition of 2 ml of 2% sodium carbonate (Na2CO3), this mixture was kept for the chemical reaction in a dark room for 30 min. Afterward, the absorbance of the extract solution was read at 750 nm wavelengths with the UV–Vis spectrophotometer, and using formula (3) total phenolic content was calculated.

where x = concentration (ppm) of extract, V = volume of sample solution (extract) (ml), DF = dilution factor of sample solution, w = sample weight (g).

Analysis of Color Co-ordinates of Dyed Fabrics

All the dyed samples were assessed for measuring color co-ordinates (L, a, b and K/S) using Premier Colorscan computer color matching system at D65 illuminant/100 observer.

Evaluation of Fastness Properties of Dyed Fabrics

The light fastness, rubbing fastness (wet and dry) and washing fastness of the dyed fabric samples were evaluated as per ISO 105-BO2:2002, ISO-105-X12 and IS: 3361:79 methods, respectively.

FTIR and UV–visible Spectrophotometer Analysis of Dye and Dyed Fabric Samples

Carica papaya dye extract and dyed fabrics were assessed for FTIR analysis using a double-beam FTIR spectrophotometer in attenuated total reflectance (ATR) mode attachment (Bruker, model: Alpha) using OPUS software at M.D. U, Rohtak. Extract was also analyzed through UV–visible spectrophotometer by scanning from 200 to 800 nm wavelength using UV-2450 spectrophotometer (Shimadzu) at IIT, Delhi.

Ultraviolet Protection Factor (UPF) Evaluation of Dyed Fabrics

All the dyed fabric samples were tested for their UPF values with UV-2600 series in the range of 280–400 nm, Model UV-2600 (A11665101436), from the total spectral transmittance based on AS/NZS 4399:2017 method [29]. As per Eq. (4), UPF is defined as the ratio of average effective UVR irradiance of unprotected skin to the average effective UVR irradiance of dyed fabric protected skin.

where Eλ: erythemal spectral effectiveness, Sλ: solar spectral irradiance in Wm−2 nm−1, Tλ: spectral transmittance of fabric (%), ∆λ: the bandwidth in nm (5 nm), λ: the wavelength in nm (290–400 nm). As per standard, textile fabrics having UPF of 25–39 are categorized as “Very Good” with 96–97.4% of UVR blocked, UPF of 40 or above as “Excellent” with ≥ 97.5% of UVR blocked and UPF rating of 15–24 are categorized as “Good” with 93.3–95.9% of UVR blocked [30, 31].

Anti-microbial Behavior Evaluation of Dye and Dyed Fabrics

Extracted dye and dyed fabrics were evaluated for anti-microbial behavior using AATCC-100 method using gram-positive (S. aureus) and gram-negative (E. coli) bacteria at IIT, Delhi.

Quantitative Assessment of Anti-microbial Behavior

The stock solution of Carica papaya Leaf extract was tested to check the degree of antibacterial activity using AATCC 100 method. Testing was followed by taking 20 g/1000 ml of Luria broth for preparing the liquid culture media, and the test specimens of different concentrations (1% and 2%) ranging from 5 ppm to 200 ppm were further dispersed in 10 ml of Luria broth. Afterward, test organism having volume 106 cfu/ml count of 20 μl was incubated at 200 rpm at 37 °C for 24 h. As control, water similar to that of test specimens was used after incubation with Luria broth. In a test tube containing 9 ml distilled water, 1000 μl solution was transferred and shaker was used to shake it. Again, the same amount taken in micropipette was further diluted with 9.9 ml distilled water in the other test tube. Repetition of process was done as per bacterial growth in each flask. From the last diluted test tube, 20 μl of inoculums was taken and spread on agar plates. Agar plates were incubated for 24 h at 37 °C, and grown visible bacterial colonies were counted.

Anti-microbial activity of dyed fabrics was assessed by cutting samples into 2 in. × 1 in. swatches and further exposed to 20 μl of bacterial inoculums containing 108 cfu/ml of bacteria. Undyed fabric swatches were used as control. All dyed and undyed swatches were placed for 24-h incubation in a 50-ml sterilized flask containing 10 ml sterilized distilled water. All the incubated flasks were shaken for 1 h at 200 rpm to remove bacteria from fabric swatches. Afterward, sterilized water serial dilutions up to 106 were prepared. Agar plates were prepared by using the diluted liquor (20 μl) followed by incubation for 24 h at 37 °C. Equation (5) is used to calculate bacterial reduction percentage.

where A represents bacterial colonies for the control after 24-h incubation time; B represents bacterial colonies for sample after 24-h incubation time.

Results and Discussion

K/S was taken as the optimized criteria for different variables for dyeing with required dye volume and optimized dyeing, as shown in Table 3.

It is quite clear from Table 3 that all Carica papaya extract-dyed protein fabrics have maximum K/S values in acidic medium, while other variables like time and temperature vary as per fabric that may be due to maximum saturation achieved at those conditions.

Anti-oxidant Activity of the Carica papaya Extract

All natural species of plants have rich phenolics, carotenoids, flavonoids and secondary metabolites in their chemical structure which are contributing factors for the anti-oxidant behavior of these species. Carica papaya leaf extract was tested for anti-oxidant activity against the free radicals by DPPH because its chemical reaction is very easy to perform [32, 33]. The findings of the study are as follows:

Ascorbic acid calibration curve equation:

where y is absorbance value and x is amount of ascorbic acid, absorbance of Carica papaya leaf extract = 0.523

It can be seen that the Carica papaya leaf extract has good anti-oxidant potential so can be used in cosmetics and finishing of facial wipes, etc. for textile application as reported by Thakare et al. [34].

Tannin Content of the Carica papaya Extract

Tannins are the natural polyphenol with molecular weight of 500–3000 g/mol with very good water solubility and found in plants, herbs, fruits, etc. These are widely used in different foods, cosmetic, pharmaceutical industries and functional textiles like facial wipes, etc. Their applications as color stabilizers and balancing fining agents in wines are contributing factors for their increased applications. Therefore, to assess the amount of tannin content in natural extracts is very important to specify its anti-oxidative properties [35, 36].

The tannin content of the Carica papaya leaf was calculated to be 85.06 mg/g dry matter which can be utilized in dyeing and finishing of textile with the above-said beneficial properties.

Flavonoid Content of the Carica papaya Extract

Flavonoid is a polyphenolic compound with a number of hydroxyl groups attached to aromatic ring structures which is ubiquitous in nature [37]. Anti-oxidants are also found in the form of flavonoids [38, 39].

Standard calibration curve of Rutin was used to measure the flavonoid content of Carica papaya leaf extract [40], and findings are as follows:

Absorbance of Papaya leave extract = 0.594,

So its flavonoid content = 12.77 mg equivalent to Rutin.

Thus, Carica papaya leaf extract flavonoids contents justify the significant anti-oxidant properties and its potential as a dyeing agent for textiles.

Phenolic Content of the Carica papaya Extract

The presence of abundant phenolic (–OH) groups in the natural dyes and mordants is responsible for its coloring behavior [41]. Gallic acid is used to estimate the amount of phenol content of any natural substrate [42]. After calibrating the values, the obtained phenolic content of Carica papaya leaf extract was 62.36 mg GAE/g dry (supplementary information). As reported toward hindering the influence of free radicals and ROS, phenolics have been reported as strong anti-oxidants which are the basis of several chronic human infections [37].

Crude Dye Extraction from Carica papaya Leaf Powder and Dyeing of Protein Fabrics

In the present study, water-soluble Carica papaya extract was applied to protein fabrics to check its coloring behavior and the colorant obtained as yield was 37.5% which is better than the reported amount in natural extracts [43]. After extraction, the leaves become slightly brown in color showing maximum removal of auxochromes and chromophore from the skin [44]. After color extraction, four protein fabrics, i.e., wool, silk, soya and milk, were dyed and showed very good affinity toward the extract. Tannin present in Carica papaya leaf is in very good amount in extract bonds with fabrics either a covalent bond or ionic bond which are also enriched with amino and carboxylic groups. Dyeing of textile substrate without any mordant with Carica papaya extract is totally an ecological approach. Mordanting was carried out using natural as well as chemical mordants to produce a broad spectrum of shades obtained followed by all three mordanting processes, i.e., pre-mordanting, meta-mordanting and post-mordanting.

Color Measurement Using Computer Color Matching System

As shown in Table 4, all dyed samples with different mordants exhibit different shades as per mordant color. As alum does not have much effect on color, ferrous sulfate again gives tones of gray, and copper sulfate changes shades into a greenish tone. Pomegranate peel has a large amount of tannins, hence highlights its own shades in combination with Carica papaya extract. Harda powder along with Carica papaya modifies the shades of dyed fabrics up to a little extent, while orange peel and amla powder do not affect the actual shade obtained with true extract. Wool being coarse absorbs large quantity of dye resulting in brilliant shades obtained followed by milk, soya and silk fabrics being low in GSM or fabric density [45].

Table 4 shows color spectrum and K/S values for dyed fabrics, and it is clear from Table 4 that a particular trend was not followed by all mordants in different mordanting techniques.

Color Fastness Analysis

Tables 5, 6, 7 and 8 show results of color fastness of the dyed fabric with Carica papaya leaf extract, and values of the tables clearly indicate that all fabrics possess very-good-to-excellent wash and rubbing fastness. Chemical mordants form H-bond or coordinate bonds with dye and fabric resulting in very-good-to-excellent fastness properties. Natural mordants also perform very well and possess very good rubbing and wash fastness which may be the result of tannin present in them. Light fastness shows different trends in all four dyed fabrics, somewhere no change in shade or little change in shade, somewhere it is darker, which may be the reason for different oxidation behaviors of fabrics with different mordants [46]. Hence, the overall findings of all color fastness of Carica papaya extract-dyed fabric exhibit very good potential of application as a colorant for dyeing of textiles in an eco-friendly way.

FTIR and UV–visible Analysis

The FTIR spectrum was performed for Carica papaya leaf extract to identify the functional groups of the active components present in the extract based on the peak values in the region of IR radiation. As shown in Fig. 1, the broad peaks at different wavenumbers showed the presence of different functional groups like 654.59 cm−1 for C=C, 784.96 cm−1 for C=C, 861.97 cm−1 for C–H, 1028.26 cm−1 for C–F, 1394.35 cm−1 for O–H, 1593.40 cm−1 for N–H, 1922.16 cm−1 for C=C=C, 2357.95 cm−1 for O=C=O, 2899.14 cm−1 for N–H, 3170.60 cm−1 for C–H, 3633.60 cm−1 for –OH, 3731.41 cm−1 for –OH, 3822.17 cm−1 for –OH and 3915.94 cm−1 for –OH [47]. This can be clearly seen from the obtained peaks that papaya leaf extract has maximum –OH, N–H, C=C, C–H and other functional groups present in the extract which may be responsible for their functionality toward textile substrates [48].

As shown in Fig. 2, the UV–visible spectrum of Carica papaya leaf extract in water, 20% w/v has maximum absorbance of 1.58 at 206 nm wavelength which is dependent on specific acylation configuration and sugar conjugation [49].

Ultraviolet Protection Factor (UPF) Analysis

Ultraviolet protection factor is defined as the extent of the ability of the textile to protect UV radiation, and it is strongly dependent on the concentration of dye in fabric as well as dye–fiber interactions fiber properties, yarn and fabric construction. Hence, different UPF values can be obtained from the same extract depending upon fabric construction such as PPI, EPI, type of weave thickness, porosity and moisture content [50].The UPF values of wool, silk, soya and milk fabrics dyed with Carica papaya water extract, as shown in Table 9, were determined from the total spectral transmittance based on AS/NZS 4399:1996.

It can be clearly observed from Table 9 that among the four undyed fabrics, wool has the highest UPF due to its compact and dense structure, while milk, soya and silk fabrics possess low UPF due to their light and shear fabric structure. After dyeing, the same trend was followed and wool showed significantly improved UPF than the other three protein fabrics. Improved UPF values may be due to absorption of significant amount of Carica papaya leaf-extracted particles by wool fabric. However, improvement was observed in the other three fabrics also, but very less UPF values were obtained again due to less absorption of natural extracted particles inside the fabric because of the structure of these fabrics being lighter [45].

Anti-microbial Property

The Carica papaya leaf extract and the extract-dyed protein fabrics showed very good anti-microbial property against E. coli (gram −) and S. aureus (gram +) bacteria. As mentioned in Table 10, Carica papaya leaf extract has very good bacterial reduction percentage. Therefore, the extract and dyed fabrics have wide potential in medical textile applications.

Conclusion

In the present study of dyeing of protein fabrics with Carica papaya leaf extract, the findings are as follows. Carica papaya leaf extract has a very good amount of tannin, phenolic content and flavonoids that make it effective for finishing and coloring of textiles. The plant is available in abundance in nature and has a number of medicinal applications. Dyeing behavior showed very good affinity toward all four protein fabrics with a brilliant and wide color spectrum obtained after mordanting. All natural mordants showed very-good-to-excellent color fastness properties along with chemical mordants providing an eco-friendly alternative to chemical mordants. FTIR spectra showed a number of functional groups present in extract showing its application in finishing and coloration of textiles. UPF values are very good, and all dyed fabrics possess very high bacterial reduction percentage; and these can be the leading factors for application in medical and functional textiles.

In summary, natural mordanting followed by treatment with Carica papaya leaf-extracted dye using environmentally friendly solvents can significantly enhance UPF, anti-microbial property, color strength and fastness of dyed substrates offering directions for manufacturing textiles with good appearance and health benefits but without environmental hazards.

References

M.M.M. Specos, J.J. Garcia, J. Tornesello, P. Marinoa, M.D. Vecchia, M.V.D. Tesoriero, L.G. Hermida, Microencapsulated citronella oil for mosquito repellent finishing of cotton textiles. Trans. R. Soc. Trop. Med. Hyg. 104, 653–658 (2010)

L. Huang, M. Gerber, J. Lu, A.E. Tonelli, Formation of a flame retardant cyclodextrin inclusion compound and its application as a flame retardant for poly (ethylene terephthalate). Polym. Degard. Stab. 71, 279–284 (2001)

W. Sricharussin, C. Sopajaree, T. Maneerung, N. Sangsuriya, Modification of cotton fabrics with β-cyclodextrin derivative for aroma finishing. J. Text. Inst. 100, 682–887 (2009)

S. Islam, M. Shahid, F. Mohammad, Perspectives of natural product based agents derived from industrial plants in textile applications—a review. J. Clean. Prod. 57, 2–18 (2013)

A. Guesmi, N. Ladhari, N.B. Hamadi, M. Msaddek, F. Sakli, First application of chlorophyll-a as biomordant: sonicator dyeing of wool with betanin dye. J. Clean. Prod. 39, 97–104 (2013)

A. Guesmi, N.B. Hamadi, N. Ladhari, F. Saidi, H. Maaref, F. Sakli, Spectral characterization of wool fabric dyed with indicaxanthin natural dye: study of the fluorescence property. Ind. Crops Prod. 46, 264–267 (2013)

G.W. Taylor, Natural dyes in textile applications. Rev. Prog. Color. 16, 53–61 (1986)

M. Yusuf, A. Ahmad, M. Shahid, M.I. Khan, S.A. Khan, N. Manzoor, F. Mohammad, Assessment of colorimetric, antibacterial and antifungal properties of woolen yarn dyed with the extract of leaves of henna (Lawsonia inermis). J. Clean. Prod. 27, 42–50 (2014)

H.T. Deo, B.K. Desai, Dyeing cotton and jute with tea as a natural dye. J. Soc. Dyers Color. 115, 224–227 (1999)

L. Ahlstrom, C.S. Eskilsson, E. Bjorklund, Determination of banned azo dyes in consumer goods. Trend Anal. Chem. 24, 49–56 (2005)

T. Bechtold, A. Turcanu, E. Ganglberger, S. Geissler, Natural dyes in modern textile dye houses—how to combine experiences of two centuries to meet the demands of the future? J. Clean. Prod. 11, 499–509 (2003)

S. Islam, L.J. Rather, M. Shahid, M.A. Khan, F. Mohammad, Study the effect of ammonia post-treatment on color characteristics of annatto-dyed textile substrate using reflectance spectroscopy. Ind. Crops Prod. 59, 337–342 (2014)

A. Manhita, V. Ferreira, H. Vargas, I. Ribeiro, A. Candeias, D. Teixeira, T. Ferreira, C.B. Dias, Enlightening the influence of mordant, dyeing technique and photodegradation on the colour hue of textiles dyed with madder—a chromatographic and spectrometric approach. Microchem. J. 98, 82–90 (2011)

D. Cristea, G. Vilarem, Improving light fastness of natural dyes on cotton yarn. Dyes Pigments 70, 238–245 (2006)

S. Islam, F. Mohammad, Natural colorants in the presence of anchors so-called mordants as promising coloring and antimicrobial agents for textile materials. ACS Sustain. Chem. Eng. 3, 2361–2375 (2015)

A.K. Samanta, P. Agarwal, Application of natural dyes on textiles. Indian J. Fibre Text. Res. 34, 384–399 (2009)

M. Shahid, S. Islam, F. Mohammad, Recent advancements in natural dye applications: a review. J. Clean. Prod. 53, 310–331 (2013)

S.N. Chattopadhyay, N.C. Pan, A.K. Roy, S. Saxena, A. Khan, Development of natural dyed jute fabric with improved colour yield and UV protection characteristics. J. Text. Inst. 104, 808–818 (2013)

G.H. Zheng, H.B. Fu, G.P. Liu, Application of rare earth as mordant for the dyeing of ramie fabrics with natural dye. Korean J. Chem. Eng. 28, 2148–2155 (2011)

M. Yusuf, M. Shahid, M.I. Khan, S.A. Khan, M.A. Khan, F. Mohammad, Dyeing studies with henna and madder: a research on effect of tin (II) chloride mordant. J. Saudi Chem. Soc. 19, 64–72 (2012)

S.M. Burkinshaw, N. Kumar, The mordant dyeing of wool using tannic acid and FeSO4, Part 1: initial findings. Dyes Pigments 80, 53–60 (2009)

P.S. Vankar, R. Shanker, D. Mahanta, S.C. Tiwari, Ecofriendly sonicator dyeing of cotton with Rubia cordifolia Linn. using biomordant. Dyes Pigments 76, 207–212 (2008)

H. Aminoddin, Functional dyeing of wool with natural dye extracted from Berberis vulgaris wood and Rumex hymenosepolus root as biomordant. Iran. J. Chem. Chem. Eng. 29, 55–60 (2010)

D. Villano, M.S. Fernandez-Pachon, M.L. Moya, A.M. Troncoso, M.C.G. Parrilla, Radical scavenging ability of polyphenolic compounds towards DPPH free radical. Talanta 71, 230 (2007)

A.E. Hagerman, Y. Zhao, S. Johnson (1997), Methods for determination of condensed and hydrolyzable tannins, in Antinutrients and Phytochemicals in Food, pp. 209–222 (1997)

M.L. Sanz, I.M. Castro, M.M. Arribas, Identification of the origin of commercial enological tannins by the analysis of monosaccharides and polyalcohols. Food Chem. 111, 778–783 (2008)

S. Adeel, T. Gulzar, A. Muhammad, F. Rehman, S. Muhammad, H. Iram, N. Iqb, Appraisal of marigold flower based lutein as natural colorant for textile dyeing under the influence of gamma radiations. Radiat. Phys. Chem. 130, 35–39 (2017)

L. Yu, J. Perret, M. Harris, J. Wilson, S. Haley, Free radical scavenging properties of wheat extracts. J. Agric. Food Chem. 50, 1619–1624 (2002)

K.L. Hatch, Making a claim that a garment is UV protective. AATCC Rev. 3, 23 (2003)

G. Hustvedt, P.C. Crews, The ultraviolet protection factor of naturally-pigmented cotton. J. Cotton Sci. 9, 47–55 (2005)

M.M. Alam, M.T. Islam, A review on ultraviolet protection of textiles. Int. J. Eng. Technol. Sci. Res. 4, 404–412 (2017)

S. Lalas, J. Tsaknis, Extraction and identification of natural antioxidant from the seeds of the Moringa oleifera tree variety of Malawi. J. Am. Oil Chem. Soc. 79, 677–683 (2002)

S. Pulipati, P.S. Babu, U. Naveena, S.K.R. Parveen, S.K.S. Nausheen, M.T.N. Sai, Determination of total phenolic, tannin, flavonoid contents and evaluation of antioxidant property of Amaranthus tricolor (L). Int. J. Pharm. Phytochem. Res. 9, 814–819 (2017)

V.N. Thakare, A.A. Suralkar, A.D. Deshpande, S.R. Naik, Stem bark extraction of Ficus bengalensis Linn for anti-inflammatory and analgesic activity in animal models. Ind. J. Exper. Biol. 48, 39–45 (2010)

C.A. Rice-Evans, N.J. Miller, G. Paganga, Structure-antioxidant activity relationships of flavonoids and phenolic acids. Free Radic. Biol. Med. 20, 933–956 (1996)

Y. Zou, Y. Lu, D. Wei, Antioxidant activity of a flavonoid-rich extract of Hypericum perforatum L. in vitro. J. Agric. Food Chem. 52, 5032–5039 (2004)

Sumaiyah, Masfria, A. Dalimunthe, Determination of total phenolic content, total flavonoid content, and antimutagenic activity of ethanol extract nanoparticles of Rhaphidophora pinnata (L.F) schott leaves. Rasayan J. Chem. 11(2), 505–510 (2018)

M.P. Kähkönen, A.I. Hopia, J.H. Vuorela, J.P. Rauha, K. Pihlaja, T.S. Kujala, M. Heinonen, Antioxidant activity of plant extracts containing phenolic compounds. J. Agric. Food Chem. 47, 3954–3962 (1999)

V.L. Singleton, R. Orthofer, R.M. Lamuela-Raventós, Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteau reagent. Methods Enzymol. 22, 152–178 (1999)

P. Shetgiri, P. D’Mello, Antioxidant activity of flavonoids—a comparative study. Indian Drugs 40, 567–569 (2003)

K.H. Prabhu, M.D. Teli, N.G. Waghmare, Natural dye extraction from waste barks of Turkish red pine (Pinus brutia Ten.) timber and eco-friendly natural dyeing of various textile fibers. Fibers Polym. 12, 753 (2011)

A. Waterhouse, Wine phenolics. Ann. N. Y. Acad. Sci. 957, 21–36 (2002)

J.S. Ledakowicz, J. Olczyk, J. Polak, M. Grąz, A.J. Wilkołazka, Dyeing of Textile Fabrics with Bio-dyes. Fibers Text. East. Eur. 23, 120–126 (2015)

A. Kechi, R.B. Chavan, R. Moecke, Dye yield, color strength and dyeing properties of natural dyes extracted from ethiopian dye plants. Text. Light Ind. Sci. Technol. 2, 137–145 (2013)

M.F. Hasan, Study on the changes of GSM (Gm/m2) of grey knitted fabric from pretreatment to finishing. Int. J. Text. Sci. 4, 119–136 (2015)

A.A. Nabawia, M.T.H. Moselhey, O.W. Guirguis, Study the effect of different dyeing conditions of extracted natural dye from leaves of neem on silk fabrics. J. Chem. Metrol. 12, 34–58 (2018)

J. Lee, M.H. Kang, K.B. Lee, Y. Lee, Characterization of natural dyes and traditional korean silk fabric by surface analytical techniques. Materials 6, 2007–2025 (2013)

S.M. Dhivya, K. Kalaichelvi, UV–Vis spectroscopic and FTIR analysis of Sarcostemma brevistigma, wight. andarn. Int. J. Curr. Pharm. Res. 9(3), 44–49 (2017)

C. Septhum, V. Rattanaphani, S. Rattanaphani, UV–vis spectroscopic study of natural dyes with alum as a mordant. Suranaree J. Sci. Technol. 14, 91–97 (2006)

H.P. Gies, C.R. Roy, G. Elliot, Z. Wang, Ultraviolet radiation protection factors for clothing. Health Phys. 67, 131 (1994)

Acknowledgements

The authors are grateful to the Department of Fashion Technology, BPSMV, Khanpur Kalan and Indian Institute of Technology, Delhi, for providing technical assistance for the study.

Author information

Authors and Affiliations

Contributions

The design of the study, experiments, interpretation of the data, writing of the paper, and all correspondences and revisions were performed by Neetu Rani. The experiments were performed by Neetu Rani under the guidance and supervision of Dr. Lalit Jajpura and Dr. B.S. Butola.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Rani, N., Jajpura, L. & Butola, B.S. Ecological Dyeing of Protein Fabrics with Carica papaya L. Leaf Natural Extract in the Presence of Bio-mordants as an Alternative Copartner to Metal Mordants. J. Inst. Eng. India Ser. E 101, 19–31 (2020). https://doi.org/10.1007/s40034-020-00158-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40034-020-00158-1