Abstract

Natural dyes have promising features; however, there are some drawbacks limiting their application in textile dyeing, for example, low dyeing, and fastness properties due to the weak interaction with textiles. Many attempts have been made to improve these shortcomings by using additional chemicals such as metallic mordants which are classified as hazardous chemicals that cause some serious environmental problems. Therefore, we have designed a facile green method for the extraction of natural dye from Henna leaves using Acacia nilotica pods to improve the color intensity and enhance fibers/dye affinity. In this study, wool fabrics were dyed with Henna and Henna/Acacia dye at different dyeing conditions. FTIR and UV–vis spectrums showed peaks corresponding to tannin and its derivatives in the aqueous extract of modified Henna. Modified Henna dyed samples exhibited noticeable improvement in the color strength (K/S value), washing, rubbing, and lightfastness with excellent antibacterial activity against E. coli and S. aureus.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Natural colorants have been used in textile dyeing ages ago. Recently, they are substituted by synthetic dyes because of their lower production cost and a wide range of bright colors, with good durability for different usage conditions (washing, rubbing, and light) (Samanta et al. 2009, 2011; Büyükakinci et al. 2017). Synthetic dyes are produced from intermediate chemicals via toxic processes that harm both the environment and human health. Consequently, the use of environmentally friendly natural dyes for textiles has been becoming a very important subject (Alebeid et al. 2015b; Batran et al. 2015; Ebrahimi et al. 2016). Natural dyes have many advantages, and the most significant feature is that they well matched with the environment and were safe whether in the production or use stages, biodegradable, and do not generate harmful effluents upon the degradation (Samanta et al. 2009). Natural dyes are extracted from different resources including plants (barks, leaves, roots, fruits or seeds, and flowers that contain coloring constituents such as flavonoids, tannin, and quinonoid) (Kasiri et al. 2012, 2013, Haji et al. 2018).

Henna is a small tree grown in many regions such as India, Pakistan, Egypt, Sudan, and Yemen. Henna powder has been used since ancient times as a decoration for women and as a natural cosmetic for staining hair, hands, and feet, and it is known as hennotannic or lawsone and indexed as Natural Orange 6 with CI 75,480. Lawsone is the main component in the leaves of Henna with a chemical name; 2-hydroxy-1,4-naphthoquinone (Badri et al. 1993; Mohd et al. 2012, Alebeid et al. 2015a) (Fig. 1a). Henna has many advantages, such as it does not contain substances harmful to human health and the environment, and it simply matches nature. Many researchers have studied the dyeing of textiles with Henna dye extracted from leaves (Ali et al. 2009; Alebeid et al. 2015a; Batran 2015; Ebrahimi et al. 2016; Rahman et al. 2017).

Acacia nilotica (L.) belongs to the family Fabaceae, and it is a medium-sized tree, cultivated in subtropical and tropical areas of the Americas, Australia, Africa, and South Asia, widely used as timber, source of fodder, tannin, and gum. Acacia nilotica pods (Fig. 2) were used in some African regions for leather tanning and as a source of dyes (Lugman et al.2015; Arife et al. 2017).

Acacia pods are rich in secondary metabolites containing tannins, flavonoids, and gums (Arife et al. 2017). It is a substantial source of polyphenol compounds because it contains condensed tannin, gallic acid, ellagic acid, catechin, and epigallocatechin-7-gallate (Fig. 1b) (Manar et al. 2011). The total tannin content is approximately 23% of the total weight (Singh et al. 2009a). Acacia nilotica pods are revealed to have antibacterial activity against various microorganisms including Staphylococcus aureus and Escherichia coli (Oladosu et al. 2013).

Besides significant environmental advantages of the Henna dye, it is also having some weaknesses restricting their use in textile dyeing such as low wash, rub, and lightfastnesses due to the poor bonding with the textile substrates (Mohd et al. 2012; Alebeid et al. 2015).

Many attempts have been made to improve these shortcomings by using additional chemicals such as metallic mordants, crosslinkers, and cationic agents. Discharging effluents containing these chemicals pose a threat toward both the environment and human health (Mohd et al. 2012; Shahid et al. 2013 Alebeid et al. 2015).

In our previous studies, we used cationic agents (3-chloro-2-hydroxy propyl trimethylammonium chloride, and Chitosan) in pretreating fabrics to enhance the dyeability of Henna as well as to prevent heavy metal pollution (Alebeid et al. 2015, 2019).

The current research aims to design the dyeing method based on the natural dye, without external toxin chemicals, that the prepared extract possessed significant dyeing ability. In this research, Henna dye was extracted using Acacia nilotica pods extract which was used to improve the color intensity and enhance fibers/dye affinity.

To our best knowledge, this is the first ever study to extract a natural dye that can be dyed without any chemical auxiliaries. This extracted dye not only offers an outstanding improvement in dyeing and fastness properties but also provides antibacterial activity against two types of bacteria.

Experimental

Materials and chemicals

Wool fabric was purchased from Wuxi Shuoding Chemical Technology Co., Ltd., and Henna powder Acacia nilotica Pods were imported from Eldamar Co. Ltd., Sudan.

Method

Henna dye extraction using Acacia nilotica pods

Acacia nilotica (L.) pods were extracted by stirring the powdered pods in a mixture of water–ethanol (90:10 v/v) at 70 °C for 2 h; then, the extract was filtered in vacuum filtration. The powdered Henna was then added to the A. nilotica pods extract and stirred at room temperature for 24 h. Thereafter, the obtained extract was filtered to remove the insoluble remains and dried in a freeze dryer.

Dyeing Procedure

Wool fabrics were dyed with modified and unmodified Henna dye solutions without any chemical additions. Chitosan was used in pretreating some samples that will then be dyed with unmodified Henna, to investigate the dyeability of the modified Henna without any auxiliaries. The dyeing process was carried out using YP Color-Tech., Shanghai Chain-LIH Automation equipment co., LTD.

Fabrics were dipped into a dye bath of Henna extract (modified and unmodified) with a dye liquor ratio (1:20) at different temperatures; 40 °C, 60 °C, 80 °C and 90 °C for 60 min (Fig. 2). Thereafter, samples were taken out from the dye bath and washed thoroughly in tap water afterward soaping (2 g/L soap flakes, 10 g/L Na2CO3, liquor ratio 1:30, temp. (95 °C for 10 min). Subsequently, the fabrics were rinsed and dried.

Characterizations

FT-IR spectrometer (FT-IR 4200, JASCO, USA) and, UV spectrophotometer (UV-2600, SHIMADZU, Japan) were used to characterize the dried extract of Acacia nilotica pods, henna dye, and modified Henna. The color strength of the dyed fabrics (K/S) was assessed by a Color Quest XE, Hunter lab Co. USA. Wash fastness test was conducted according to the ISO standard 105-C10:2006 in SW-12A Tester, Wenzhou Darong Textile Instrument Co. Ltd. China. The lightfastness test was evaluated using the Air-Cooled Weather Condition Meter per the standard ISO 105-B02: 1994, MOD. Antibacterial activity of the dyed samples was assessed using the inhibition zone method against two types of bacteria, Staphylococcus aureus, and Escherichia coli, and the test was conducted per the standard AATCC test method 147–2004.

Results and discussion

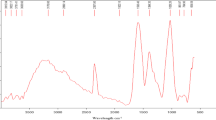

ATR-FTIR study

The FTIR-ATR spectra of the Acacia nilotica L. (Fig. 3a) show the vibrational band corresponding to the -OH stretching (νO-H) for polyphenolic extracts. The C-H, CH2, and CH3 stretching vibrations at ~ 2920 cm−1 are due to the carbohydrates and sugar derivatives (Arshad et al. 1969). The band at ~ 1620 cm−1 is a conjugation of the C = O vibration of the ketone. The peaks at ~ 1523 cm−1 and ~ 1450 cm−1 are assigned to aromatic skeletal vibration and CH de-formation, respectively, which are characteristic peaks of ellagitannins (Lugman et al. 2015). The peak at 1353 cm−1 is a characteristic peak of hydrolyzable tannins, which is assigned to the symmetric stretching of the C-O bond of ester function, and the peaks at ~ 1083 cm−1, ~ 872 cm−1, and ~ 705 cm−1 are the characteristic peaks of Gallo tannins (Arshad et al. 1969; Arife et al. 2017; Alebeid et al. 2019).

Figure 2b and 2c show the typical spectrums of Henna dye; the wide peak found at ~ (3423 cm−1) is ascribed to phenolic O–H stretching frequency (Alebeid et al. 2015). The aromatic C-H stretching group is shown at ~ 2930 cm−1, the aromatic C = O appeared at 1449 cm−1, the C-H bending peak is noted at ~ 1373 cm−1 and ~ 1253 cm−1, and the C-O stretching band is observed at ~ 1160 cm−1. Peaks at ~ 1722 cm−1 and ~ 1620 cm−1 signify the existence of two carbonyl bands integrated with a double bond (α, β-unsaturated carbonyls). Therefore, approving the possibility of possessing a 1,4-naphthoquinone (Chandrakalavathia et al. 2018).

The spectrum of modified Henna (Fig. 3b) showed new peaks, at ~ 1516 cm−1, ~ 1450 cm−1, ~ 1083 cm−1, ~ 872 cm−1 and ~ 705 cm−1. These peaks also appeared in the spectrum of Acacia nilotica pods extract and could be ascribed to the new components embedded into the Henna dye. The peaks at 1523 cm−1 and 1450 cm−1 are assigned to aromatic skeletal vibration and CH deformation, which are characteristic peaks of ellagitannins. The peaks at 1083 cm−1, ~ 872 cm−1 and 705 cm−1 are the characteristic peaks of gallotannins (Arife et al. 2017).

These results confirmed the presence of new functional groups (Chromophores and auxochomes) in the modified Henna. The presence of these components in the modified dye engages in increasing the color intensity and forming chemical bonds with the wool fibers.

UV–vis analysis

Figure 4 presents the optical absorption band from 200 to 700 nm for modified and unmodified Henna dyes. The two dyes exhibited common peaks of lawsone at 270 and 367, the peak at 367 nm might be due to C = O and OH groups (Chandrakalavathia et al. 2018). The long tail of the band at 367 nm that is reaching far into the visible region is responsible for the yellow-orange color of lawsone (Dhaouadi et al. 2015).

As it can be seen from the UV–vis spectrum (Fig. 4a), the intensity of the absorbance peak of modified dye at 270 nm increased due to the active groups that constituted in the modified Henna (tannin, coumarins, gallic acid).

The lower wavelength peak at 225 nm of modified Henna is ascribed to the intermolecular hydrogen bonding leading to coupling (Chandrakalavathia et al. 2018).

Possible chemical interaction between modified henna and wool fabric

As illustrated in the introduction part, Acacia nilotica pods are rich sources of polyphenols, composed mainly of condensed tannin. Generally, plant tannins have a strong affinity for proteins and, therefore, for animal fibers made up of keratin (wool fibers) (Arife et al. 2017).

Introducing these components into the Henna dye leads to improve the affinity and interaction between wool fibers and modified Henna; herein are some suggested interaction mechanisms;

•The abundant hydrogen bonds occur between pseudo vacant hydrogen orbits of phenol groups with free electron pairs of oxygen or nitrogen in the fiber structure.

•The ionic bonding between the deprotonated phenol group and the protonated amino groups of wool fibers.

• The small amount of Acacia gum on the modified Henna could act as a cross-linking agent between the dye and wool fibers.

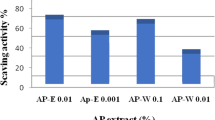

Color strength (K/S value)

Color strength values of the dyed fabrics are demonstrated in Fig. 5 a, b. As it can be seen (Fig. 5b), different color shades obtained on wool fabrics were dyed with modified and unmodified Henna in the absence of chemical auxiliaries. Samples dyed with modified Henna showed higher color strength (darker colors) as compared with untreated and chitosan treated fabrics dyed with unmodified Henna.

This result could be attributed to the new auxochromes (OH, COOH) that have introduced into the modified Henna, and the presence of these groups increases the color intensity and creates strong chemical interaction with the wool fibers. Moreover, the tannin components in Acacia nilotica pods act as biochemical mordants, which may aid in increasing the affinity between wool fibers and the modified dye.

The color strength improved noticeably with increasing the dyeing temperature, and higher temperature has a positive impact on improving the solubility of the dye as well as the swellability of fibers, thus, increasing the extent of dye molecules penetration into the fibers. Moreover, the dye presences in water as single molecules and aggregates which are too big to get into the fibers at a lower temperature. Increasing the temperature leads to cracking of the clusters; therefore, the number of monocular particles present in the dye solution will be increased. Once the fabric took a particle, additional monomers deliberate from the clusters were taken up by the fabric, consequently, leading to complete dyeing (Alebeid et al. 2015).

CIE Lab system was used to evaluate the color parameter and the color difference, and the results are illustrated in Table 1. According to a* and b* values, the color of the dyed fabrics was found in the yellow–red quadrant. Samples dyed with modified Henna showed lower L* values which indicate that these samples have darker colors. L* values decreased with raising the temperature from 40 to 90 °C indicating that the darker color could be obtained at a higher temperature. Moreover, there is a noticeable color difference (ΔE) between samples dyed with modified Henna and unmodified Henna dyed samples.

Color fastness assessments

Textiles are exposed to different usage conditions (washing, rubbing and light). Consequently, durability to those conditions is tremendously important and hence has been assessed and illustrated in Table 2. Washing fastness was assessed in respect of color change and staining on the multifiber fabric.

As illustrated in Table 2, samples dyed with modified Henna showed very good to excellent wash fastness. Color change and staining of adjacent fabrics (wool and cotton) of these samples were very good ratings (4–5), while unmodified Henna dyed fabrics showed good to fair fastness.

Rubbing fastness (dry and wet) of the modified Henna dyed samples was very good to excellent, whereas samples dyed with unmodified Henna exhibited fairly good to good rubbing fastness. Lightfastness of the ample dyed with modified Henna was very good due to the presence of tannin in the Henna acacia dye.

It is revealed from the data in Table 2 that the fastness properties of the fabrics dyed with modified Henna improved noticeably as compared with unmodified Henna dyed samples while the fastness properties of these samples were quite similar to that of chitosan treated samples, and this result indicates that the affinity of the wool fibers toward modified Henna is high, subsequently, strong chemical bonds could be formed between the dye and fabric without the need for chemical treatments.

Modified dyes have abundant hydroxyl groups (OH); thus, numerous hydrogen bonds could be formed between the hydrogen orbits of phenol groups and free electron pairs of oxygen and nitrogen in the fiber structure.

Antibacterial activity analysis

Wool fabric provides a large surface to volume ratio with the facility to hold moisture, which is a suitable condition for microorganism’s growth (Mohd et al. 2012 and Dumitrescu et al.2018). Consequently, there is a pressing need to inhibit bacterial growth for protecting both clothes and wearers. In this study, Henna (modified and unmodified) dyed fabrics were tested against two types of bacteria: S. aureus and E. coli. The antibacterial activity of the dyed samples was assessed by measuring the inhibition zone that developed on agar medium, and the results are illustrated in Table 3 and Fig. 6. It can be observed that all Henna (modified, unmodified) dyed fabrics showed antibacterial activity due to the variety of active groups (alkaloids) in the Henna leaves (Arun et al. 2010). Samples dyed with modified Henna exhibited higher antibacterial activity against S. aureus and E. coli as compared with the chitosan treated and untreated fabrics dyed with unmodified Henna. Extraction of Henna dye using Acacia nilotica pods produces a dye with antibacterial activity as both of the plants have active components (tannin, flavonoids) against various microorganisms. Modified Henna is rich in phenolic compounds such as Gallic and Ellagic acid, and their derivatives, and these components have strong antibacterial activity against various types of bacteria because of the oxidation property which absorbs and neutralizes the free radicals (Sibanda and Okoh 2007; Singh et al. 2008; Min et al. 2008; Sharma et al. 2014; and Muhammad et al. 2015). Antibacterial activity of chitosan treated sample is greater than untreated fabric dyed with unmodified Henna, due to the interaction between the chitosan (positively charged) and the bacterial remains (negatively charged) at the surface of the cell which causes wide changes on the cell leading to cell permeability (Mohd et al. 2012).

Conclusion

A cleaner wool fabric dyeing was investigated using Henna dye modified with Acacia nilotica pods. In this study, acacia pods were used in the extraction of Henna dye to increase the color intensity and improve the affinity between the dye and fibers facilitating dyeing without adding chemicals. FTIR and UV–vis reveal the presence of tannin, coumarins, and gallic acid in the aqueous extract of modified Henna. The presence of these substances in the modified dye engages in increasing the color intensity and forming chemical bonds with the wool fibers. As a result, dyeing and fastness properties of the samples dyed with this dye were improved noticeably as compared with unmodified Henna dyed samples.

Samples dyed with modified Henna showed higher dyeing and fastness properties as compared with chitosan treated samples, and these results confirm the effectiveness of this dye in dyeing without any chemical additives. Moreover, modified Henna dyed fabrics exhibited excellent resistance against E. coli and S. aureus, due to the tannin and flavonoids components in the modified Henna.

It can be concluded that the extraction of Henna dye with Acacia nilotica pods extract is a novel, green method to produce functional dye with dyeing ability without the need of chemicals; therefore, a cleaner dyeing process could be achieved using this dye.

References

Alebeid OK, Liujun P, Wenlong Z, Jiping W (2019) Sustainable wool fibers dyeing using henna extract in non-aqueous medium. Environ Chem Lett. https://doi.org/10.1007/s10311-019-00949-y

Alebeid OK, Tao Z, Seedahmed AI (2015a) New approach for dyeing and UV protection properties of cotton fabric using natural dye extracted from henna leaves. Fibres Text East Eur 23(5):60–65

Alebeid OK, Tao Z, Seedahmed AI (2015b) Dyeing and functional finishing of cotton fabric using henna extract and TiO2 nano-sol. Fiber Polym 16(6):1303–1311

Ali S, Hussain T, Nawaz R (2009) Optimization of alkaline extraction of naturaldye from henna leaves and its dyeing on cotton by exhaust method. J Clean Prod 17(1):61–66

Arife CAZ, Gokhan Z, Cigdem KO, Urana D, Eylem K (2017) Characterization and application of Acacia nilotica L as an alternative vegetable tanning agent for leather processing. Fresenius Environ Bull 26(12):7319–7326

Arshad M, Beg A, Siddiqui ZA (1969) Infrared spectroscopic investigation of tannins. Macromol Mater Eng 7:67–78

Arun P, Purushothamjayarani KGJ, Kumari V (2010) In vitro antibacterial activity and flavonoid contents of Lawsonia inermis (henn). Int J Pharm Tech Res 2:1178–1181

Badri B, Burkinshaw S (1993) Dyeing of wool and nylon 6.6 with henna and lawsone. Dyes Pigm 22(1):15–25

Batran S (2015) Efficient staining of actinomycetoma and eumycetoma grains using henna extract. Biotech Histochem 90(8):568–572

Büyükakinci BY (2017) Investigation of dyeing methods on wool fabrics with hibiscus and its antibacterial efficiency. Ind Textila 68(2):103–107

Chandrakalavathia T, Sudha V, Sindhujab M, Harinipriya S, Jeyalakshmia R (2018) Photosonoelectrochemical analysis of Lawsonia inermis (henna) and artificial dye used in tattoo and dye industry. J Photochem Photobiol 360:44–57

Dhaouadi K, Walid M, Dallali S, Manel B, Saloua O, Sebei H, Fattouch S (2015) Commercial Lawsonia inermis L. dried leaves and processed powder: phytochemical composition, antioxidant, antibacterial, and allelopathic activities. Ind Crops Prod 27:544–552

Dumitrescu I, Mitran E-C, Varzaru E, Constantinescu R, Iordache OG, Stefanescu D, Pislaru M (2018) Multi-functional effects of textiles dyed with madder roots powder (Rubiatinctoria). Ind Textila 69(6):451–457

Ebrahimi I, Gashti PM (2016) Extraction of polyphenolic dyes from henna, pomegranate rind, and Pterocarya fraxinifolia for nylon 6 dyeing. Color Technol 132:162–176

Haji A, Qavamnia SS, Nasiriboroumand M (2018) The use of D-optimal design in optimization of wool dyeing with Juglans regia bark. Ind Textila 69(2):104–110

Kasiri MB, Safapour S (2012) Natural dyes and antimicrobials for green treatment of textiles. Environ Chem Lett 12:1–13

Kasiri MB, Safapour S (2013) 2013 Natural dyes and antimicrobials for textiles. In: Lichtfouse E, Schwarzbauer J, Robert D (eds) Green Materials for Energy, Products and Depollution, 6th Chapter. Springer Science+Business Media, Dordrecht

Lugman JR, Shahid U, Farqeer M (2015) Acacianilotica(L.): a review of its traditional uses, phytochemistry, and pharmacology. Sustain Chem Pharm 2:12–30

Manar MS, Frederick HD, Mohamed HA (2011) In vitro anti-uveal melanoma activity of phenolic compounds from the Egyptian medicinal plant Acacia nilotica. Fitoterapia 82:1279–1284

Min BR, Pinchak WE, Merkel R, Walker S, Tomita G, Anderson RC (2008) Comparative antimicrobial activity of tannin extracts from perennial plants on mastitis pathogens. Sci Res Essays 3:66–73

Mohd Y, Aijaz A, Mohammad S, Mohd I, Shafat A, Nikhat M, Faqeer M (2012) Assessment of colorimetric, antibacterial and antifungal properties of woollen yarn dyed with the extract of the leaves of henna (Lawsonia inermis). J Clean Prod 27:42–50

Muhammad BS, Warunee H, Joel T, Anil KA (2015) Screening of phytochemicals and in vitro evaluation of antibacterial and antioxidant activities of leaves, pods and bark extracts of Acacianilotica (L.) Del. Ind Crops Prod 77:873–882

Oladosu P, Isu NR, Ibrahim K, Okolo P, Oladepo DK (2013) Time kill-kineticsantibacterial study of Acacia nilotica. Afr J Microbiol Res 7(46):5248–5252

Rahman Bhuiyan MA, Islam A, Ali A, Islam MN (2017) Color and chemical constitution of natural dye henna (Lawsonia inermis L) and its application in the coloration of textiles. J Clean Prod 167:14–22

Samanta AK, Agarwal P (2009) Application of natural dyes on textiles. Indian J Fiber Text Res 34:384–399

Samanta AK, Konar A (2011) Dyeing of textiles with natural dyes. In: Kumbasar EPA (ed) natural dyes. InTech, Croatia

Shahid M, Mohammad F (2013) Recent advancements in natural dye applications: a review. J Clean Prod 53:310–331

Sharma C, Aneja KR, Surain P, Dhiman R, Jiloha P, Meashi V, Kaur M (2014) In vitro evaluation of anti-microbial spectrum of Acacia nilotica leaves and barkextracts against pathogens causing otitis infection. J Innov Biol 1:051–056

Sibanda T, Okoh AI (2007) The challenges of overcoming antibiotic resistance:plant extracts as potential sources of antimicrobial and resistance modifyingagents. Afr J Biotechnol 6(25):2886–2896

Singh R, Singh B, Singh S, Kumar N, Kumar S, Arora S (2008) Anti-free radicalactivities of kaempferol isolated from Acacia nilotica L. Willd Ex Del Toxicol In Vitro 22(8):1965–1970

Funding

This work was supported by the National Key Research and Development Program of China (2017YFB0309600), Key Technology Research and Development Project of Zhejiang Province (2017C03016) and Key Research and Development Program of Xinjiang Production and Construction Corps (2019AA001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Alebeid, O.K., Pei, L., Elhassan, A. et al. Cleaner dyeing and antibacterial activity of wool fabric using Henna dye modified with Acacia nilotica pods. Clean Techn Environ Policy 22, 2223–2230 (2020). https://doi.org/10.1007/s10098-020-01951-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-020-01951-7