Abstract

Esterase enzymes play an important role in biology because they are responsible for the hydrolysis of choline esters. In their absence, the original state of the post synaptic membranes cannot be reestablished. Therefore, the aim of the work is to study the inhibiting action exerted by the group of compounds on these enzymes. Among these class of inhibiting compounds, pesticides are important because of the potential danger as a result of their large scale use in agriculture. Pesticides are generally determined using liquid or gas chromatography methods with various detection techniques. These methods are very sensitive and discriminating, however they require sample pretreatment such as extraction, preconcentration and clean up, which are skilled techniques and high cost treatment and also time consuming. In this study, acetyl cholinesterase and butyrylcholinesterase based biosensors have emerged as a promising tool for the detection and characterization of pesticides which are inhibitors of these enzymes. Although the physiological function of butyrylcholinesterase in comparison with acetyl cholinesterase is ambiguous, it has larger substrate specificity towards choline esters. Therefore, the development of a more selective electrode against choline, can lead to more sensitive determination of the inhibitor being investigated. Hence in the present work, a method based on inhibition of butyrylcholinesterase was attempted for quantification of carbofuran on the basis of cholinesterase inhibition. Butyrylcholinesterase with an activity of 10.2 units/mg was immobilized on a solid surface by cross linking with glutaraldehyde. The immobilized system was calibrated by correlating the inhibition of the butyrylcholinesterase activity with varying concentrations of the butyryl choline chloride and carbofuran. The sensing mechanism was investigated for its response to carbofuran concentrations ranging from 125 to 1,000 ppm. The effects of butyryl choline chloride concentration on the response of the sensing strip were also determined. Through this work, a sensing element made up of a carbon based electrode, containing the immobilized butyrylcholinesterase, has been described. This element has certain practical advantages like smaller size, user friendly, easy portability and disposability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pollution of water and soil by pesticides has become a major area of concern, due to the use of large amount of pesticides in agriculture and related activities. The current detection methods for pesticides residues in food, ground water and soil require pretreatment of samples and are time consuming. In this context, sensing systems based on the inhibition of the cholinesterases are the best alternative choice. These systems have the potential to replace the classical analytical methods by simplifying or eliminating sample preparation protocols and making field testing easier and faster with significant decrease in costs per analysis. Research work explaining the effect of temperature and pH on the kinetics of inhibition of horse serum and human serum cholinesterase by using four organophosphorus compounds and five carbamates has been reported and it was established that the rates of inhibition by a given compound on human serum cholinesterase and horse serum cholinesterase were of the same order of magnitude although their catalytic mechanisms were different [1]. Development of a potentiometric butyryl choline sensor for organophosphate pesticides and investigations on the action of inhibitors on the enzyme also has been reported [2]. Immobilization of enzymes on pre-activated transfer membranes which were physically attached to glass pH electrodes has been attempted and the sensor was successfully used to detect pesticide concentrations ranging from 35 ppb to 21 ppm in soil extracts [3]. Studies on cholinesterase inhibitor analysis involving butyrylcholinesterase, choline oxidase and peroxidase and the dependance of the three enzyme on the electrode response has been reported earlier [4]. A butyrylcholinesterase sensor using polyurethane based ion selective membranes was fabricated and the immobilization technique was investigated for detecting paraoxon [5]. A direct, selective, rapid and simple determination of organophosphate pesticides by integrating organophosphorus hydrolase with electrochemical and optical transducers has been described in detail by researchers [6]. The organophosphorus hydrolase catalysis, involving the hydrolysis of a wide range of organophosphate compounds, releasing an acid and an alcohol that could be detected directly has been discussed in earlier studies. A detailed review of cholinesterase has been carried out for biosensors from basic research to practical applications focusing on the various methods of immobilizing enzymes, including amperometric bi-enzymatic ChE/ChO biosensors, mono-enzymatic potentiometric biosensors and second generation mono-enzymatic choline esterase biosensors, their electrode materials and fabrication techniques [7]. Mohammadi et al. have carried out a detailed review on enzyme inhibition for determination of pollutants and toxic compounds [8]. It is evident from literature although most of the investigations use the principle of cholinesterase inhibition, information on more reliable immobilization protocols which allow such biosensing systems to be competitive for development of small, portable instrumentation for rapid toxicity testing is scarce. Hence in the current work a simple mechanism using immobilized butyrylcholinesterase was investigated and proposed for detecting carbofuran.

Materials and Methods

Butyrylcholinesterase Assay and Immobilization

Butyrylcholinesterase purchased from Sigma-Aldrich was used throughout this work. For the determination of butyrylcholinesterase activity a procedure as described elsewhere [9] with slight modifications was followed. 7.5 ml of butyryl choline chloride (2.5 mM) was mixed with equal volumes of gelatin (0.01 %) and salt solution (0.005 %). The pH of this mixture was adjusted to 7.0 at 25 °C using 0.01 M sodium hydroxide. Butyrylcholinesterase solution (0.1–1 ml) was added for about 5 min and the volume of 0.01 M sodium hydroxide per time needed to maintain a pH 7.0 was recorded. A suspension of 15 mg of carbon black in 0.25 ml of Tween 80 in benzene (10 mg/ml) was mixed and spread on a filter paper so as to obtain a uniform carbon layer. Strips of equal size were then cut from this and soaked for 4 h in 12.5 % solution of glutaraldehyde in 0.1 M sodium phosphate buffer solution of pH 7.4 and containing 0.15 M NaCl at 37 °C in water bath. These strips were then soaked overnight at 4 °C in butyrylcholinesterase solution.

Response of the Sensor

A calibration curve was plotted between different butyrylcholinesterase concentrations and the potential developed using a multimeter (Sanwa JP-12D Multitester, Sanwa Electric Instrument Co., Ltd., Tokyo, Japan). The resistances and voltages of the sensor strips before and after the immobilization were recorded. The voltages obtained were used in the equation of the calibration curve to find out the activity of the immobilized strips. The whole experiment was carried out at room temperature and at a pH of 7.0.

Effect of Butyryl Choline Chloride on the Immobilized Strip

Varying butyryl choline chloride concentrations (0.02, 0.06 and 0.1) were prepared. From each of the three concentrations, 10 μL of butyryl choline chloride was applied on three different sensor strips. The potential was checked using a multimeter for all the three different concentrations. The activity of the butyrylcholinesterase on the sensor was determined in all the three cases before and after immobilization. The temperature was maintained at 33 °C and pH 7.0. A similar experiment was carried out to check the effect of butyryl choline chloride concentration on the free butyrylcholinesterase. Three different concentrations 3.32, 3.984, and 4.48 of butyryl choline chloride were used to check for the maximum difference in the potential.

Effect of Butyrylcholinesterase Concentration

In order to study the effect of butyrylcholinesterase concentration, different concentrations of butyrylcholinesterase were made to react with the same concentration of butyryl choline chloride. A stock solution of the butyrylcholinesterase with concentration 1.48 mg/ml was diluted in phosphate buffer (pH 7.0) buffer to four different concentrations. The butyryl choline chloride concentration was 5 mM and a pH 7.0 was maintained throughout the experiment. The temperature was kept at 33 °C.

The Effect of Varying Butyryl Choline Chloride Volume

This experiment was carried out by varying the volume of butyryl choline chloride used in the experiment. Three different sets of experiments were done with the butyryl choline chloride volumes of 100, 200 and 300 μl and the variation in the potential was observed. Butyrylcholinesterase concentration used in this test was 1.48 mg/ml and the temperature was maintained at 33 °C with the earlier pH.

The Effect of Carbofuran

Under the standard test conditions developed, the experiment for different concentrations of carbofuran was performed to check the response of the sensor. To measure the response of carbofuran, 10 μl of 1,000 ppm of carbofuran was put on the strips. After the addition of the 10 μl of butyryl choline chloride, the difference in potential was observed using a multimeter. Thus the activity of the sensing strip before and after the addition of carbofuran was recorded. Three different concentrations of butyryl choline chloride were used. The temperature was maintained at 33 °C and the buffer pH was 7.0. For determining the effect of varying concentration of carbofuran, three strips were first coated with 10 μl of 0.10 M butyryl choline chloride. Carbofuran solutions of concentration of 125, 250 and 1,000 ppm were added and the potential was measured. From these observations, the decrease in butyrylcholinesterase activity before and after addition of varying concentrations of carbofuran was determined.

Results and Discussion

An enzyme coated strip was developed by immobilizing butyryl choline esterase and its response for varying concentrations of the butyrylcholinesterase and butyryl choline chloride was analyzed. Furthermore, different carbofuran concentrations were tested to determine the range within which the strip could be put to use. The activity of butyrylcholinesterase was established using the earlier described method and found to be 10.2 units/mg.

Response of the Butyrylcholinesterase Strip

Butyryl choline esterase was immobilized on the strip as per the procedure detailed earlier. The resistance of the sensor strip was measured before and after the immobilization step. The resistance of the enzyme coated strip increased by 27.57 % after the immobilization. The response of the sensor was stable only for a short period of time. This probably may be due to the uneven nature of the coating on the strip.

Effect of Varying Butyrylcholinesterase Concentration

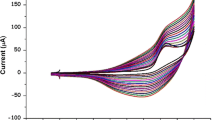

Potential measurements with the sensor strip were made whilst stirring a sample solution magnetically at constant temperature. A calibration curve of the sensor was obtained which along with the time-course of potential measurement was used to calculate the butyrylcholinesterase activity. The activity of the butyrylcholinesterase at each concentration was determined. The potential developed was plotted against the percentage of the initial butyrylcholinesterase activity. Figure 1 shows the dependence of the response with varying concentrations of butyryl choline esterase. It was observed that with the increase in concentration of butyrylcholinesterase the response increased. From the slope of the plot, the activity corresponding to any concentration of butyrylcholinesterase could be determined.

Effect of Butyryl Choline Chloride Concentration

The current work on pesticide detection is based on the principle of inhibition of butyrylcholinesterase. Hence the activity of the developed sensor was tested with varying butyryl choline chloride concentrations in order to determine the butyryl choline chloride concentration which would give the best response. It was observed that the response increased with increase in butyryl choline chloride concentration (Figs. 2, 3, 4). The change in potential with respect to time was observed to be maximum in the experiment with butyryl choline chloride concentration of 4.48 mM. However, there was a deviation of the response of the strip from linearity in experiments with 4.48 mM, which may probably be due to the fluctuations in temperature during the measurements. A second set of experiments was carried out by varying the butyryl choline chloride volumes and in this case too it was found that there was increase in potential with the increase in volume of butyryl choline chloride. This indicates higher amounts of ion generation due to higher product formation due to the catalytic activity. Figures 5, 6 and 7 depict that the potential and activity of the strip with lowest butyryl choline chloride concentration showed minimum change in potential and percentage activity while the strip with higher concentration of butyryl choline chloride showed the maximum change. Thus it can be concluded that with the increase in concentration of butyryl choline chloride on each sensor strip, there is an increase in product formation which leads to an increase in potential and activity for the duration tested.

Effect of Carbofuran at Varying Butyryl Choline Chloride Concentration

Carbofuran was used as the model analyte for the optimization of the inhibitor assay procedure. The dependence of the concentration of butyryl choline chloride used for the measurement on the inhibition effect was evaluated. The results of the effect of carbofuran concentration are depicted in Figs. 8 and 9. From these results it is evident that inhibition was proportional to the concentration of the butyryl choline chloride, since there was significant change in potential with the tests involving carbofuran.

Effect of Butyryl Choline Chloride at Varying Carbofuran Concentration

The sensor strip was tested for its response by carrying out measurements with carbofuran concentrations varying from 125 to 1,000 ppm (Figs. 9 and 10). As the concentration of carbofuran was increased there was a substantial change in the potential measured. Highest levels of carbofuran showed maximum change in the potential. Owing to the tediousness of the tests and maintenance of the measurement temperatures only three levels of carbofuran were tested. Since the rate of decrease of potential increased with the concentration of carbofuran, it can be concluded that this mechanism could be favourably used for detecting the carbofuran levels up to 1,000 ppm. From the tests conducted, the inhibition of butyrylcholinesterase due to the presence of carbofuran as inhibitor was successfully measured using the butyrylcholinesterase coated strip. Responses to any samples with unknown carbofuran concentrations could easily be determined using the standard plot.

Conclusion

Through this work a butyrylcholinesterase based sensor capable of detecting presence of carbofuran in the environment was developed. Butyrylcholinesterase was immobilized and the response of the constructed electrode was measured. The effects of varying butyryl choline chloride concentration, carbofuran concentration on the output of the butyrylcholinesterase sensor strip were investigated. The activity of the butyrylcholinesterase coated strip was best observed at higher butyryl choline chloride concentrations and lower carbofuran concentration. The developed mechanism was able to detect carbofuran concentrations as low as 125 ppm and worked best at a butyryl choline chloride concentration of 4.48 mM. The results of the present study indicate that a butyrylcholinesterase based sensor can be constructed and used for the detection of carbofuran. Further investigations have to be carried out to improve the stability and sensitivity of the sensor strip. Further work in this area may be concentrated on determining the nature of inhibition and kinetics of the inhibition reaction.

References

V. Simeon, C.E. Reiner, A. Vernon, Effect of temperature and pH on carbamoylation and phosphorylation of serum cholinesterases. Biochem. J. 130, 515 (1972)

T. Imato, N. Ishibashi, Potentiometric butyrylcholine sensor for organophosphate pesticides. Biosens. Bioelectron. 10, 435 (1995)

S. Kumaran, M. Morita, Application of a cholinesterase biosensor to screen for organophosphorus pesticides extracted from soil. Talanta 42, 649 (1995)

J.D. Faxon, A.L. Ghindilis, P. Atanasov, E. Wilkins, Direct electron transfer based on tri-enzyme electrode for monitoring of organophosphorus pesticide. Sens. Actuat. B 35–36, 448 (1996)

Y.A. Cho, S.H. Lee, G.S. Cha, Y.T. Lee, Fabrication of butyrylcholinesterase sensor using polyurethane-based ion selective membrane. Biosens. Bioelectron. 14(4), 435 (1999)

P. Mulchandani, A. Mulchandani, I. Kaneva, W. Chen, Biosensor for direct determination of organophosphate nerve agents. 1. Potentiometric enzyme electrode. Biosens. Bioelectron. 14, 77 (1999)

S. Andreescu, J.-L. Marty, Twenty years research in cholinesterase biosensors—from basic research to practical application. Biomol. Eng. 23, 1 (2006)

H. Mohammadi, A. Amine, S. Cosine, C. Mousty, Mercury-enzyme inhibition assays with an amperometric sucrose biosensor based on a trienzymatic-clay matrix. Anal. Chim. Acta 543, 143 (2005)

A. Singh, Enzyme Assays (Regency Publications, New Delhi, 2007), p. 199

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dey, M., Bhuvanagayathri, R. & Daniel, D.K. Biosensor based on Butyrylcholinesterase for Detection of Carbofuran. J. Inst. Eng. India Ser. E 96, 9–14 (2015). https://doi.org/10.1007/s40034-015-0060-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40034-015-0060-6