Abstract

Acetylcholinesterase (AChE) biosensor based on conducting poly([2,2̍ʹ;5̍′ 2″]-terthiophene-3̍-carbaldehyde) (PTT) modified glassy carbon electrode (GCE) was constructed. AChE was immobilized on PTT film surface through the covalent bond between aldehyde and amino groups. The properties of PTT modified GCE were studied using cyclic voltammetry (CV), electrochemical impedance spectroscopy (EIS), and scanning electron microscopy (SEM). The biosensor showed an oxidation peak at +0.83 V related to the oxidation of thiocholine, hydrolysis product of acetylthiocholine iodide (ATCI), catalyzed by AChE. The optimum current response of the biosensor was observed at pH 7.5–8.0, 40 °C and 120 U/cm2 of AChE concentration. The biosensor showed a high sensitivity (183.19 μA/mM), a linear range from 0.015 to 1.644 mM, and a good reproducibility with 1.7 % of relative standard deviation (RSD). The biosensor showed a good stability. The interference of glycin, ascorbic acid, histidine, uric acid, dopamine, and arginine on the biosensor response was studied. An important analytical response from these inteferents that overlaps the biosensor response was not observed. The inhibition rate of malathion as a model pesticide was proportional to its concentrations from 9.99 to 99.01 nM. The detection limit was 4.08 nM.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Organophosphate pesticides (OPs) are commonly used to reproduce agricultural productivity. As a result of that, drinking water and food are contaminated by these contaminants. Unfortunately, they are highly toxic compounds and hazardous to human health and the environment. OPs irreversibly inhibit acetylcholinesterase (AChE, E.C 3.1.1.7) (Fukuto 1990). This inhibition causes the increase of acetylcholine and results in more extensive and prolonged activation of the receptor site and causes many side effects such as bradycardia (Proskocil et al. 2010), hypotension, and hypertension (Sullivan and Kieger 2001).

To determine OPs in real samples, a number of analytical procedures such as high-performance liquid chromatography (HPLC) (Morales et al. 2011), flow-injection chemiluminescence (Pulgarín et al. 2006), gas chromatography–mass spectrometry (GC–MS) (Stajnbaher and Zupancic-Kralj 2003), and acetylcholinesterase biosensors (Liu et al. 2011; Wang et al. 2014; Zheng et al. 2015) have been used so far. Among these techniques, biosensors are widely used because of their simpleness, ease of preparation, high sensitivity, especially low cost (Du et al. 2008; Liu and Lin 2005).

Conjugated polymers (CPs) such as polythiophenes (Guler et al. 2015), polyanilines (Shi et al. 2004), and polypirols (Uang and Chou 2003) have been used for fabrication of biosensors because of their unique properties such as transfer of electric charge and catalytical properties. Hence, CPs serve as immobilization matrixes for immobilization of enzymes in construction of biosensors. A conducting polymer film can easily be produced on a solid support via electrochemical oxidation of its monomer using cyclic voltammetry (CV). In this way, the thickness of the polymer film can be controlled. This method enables a suitable way to make a homogenous adhesive film on electrode surface. In addition, conducting polymer film provides a suitable medium for enzyme immobilization. For this reason, CPs have been used extremely for the preparation of biosensors (Homaei et al. 2013).

One of the most significant parts in the construction of a biosensor is the method of enzyme immobilization. Several techniques were successfully used for enzyme immobilization such as adsorption, entrapment, and covalent binding. Covalent immobilization of an enzyme onto a matrix is an important method because the leakage of enzyme can be prevented. The functionalized CPs are promising materials for immobilization of enzymes because they can be immobilized onto CP by covalent binding at the functional sites of CP and biomolecule (Rajesh and Kaneto 2005).

AChE (EC 3.1.1.7) is very important enzyme, which is vital for central nervous system in living organisms. When the active site of AChE interacts with acetylthiocholine (ATCI), thiocholine and acetate occur. Thiocholine is an electroactive substance which produces an irreversible oxidation peak (Du et al. 2007a, b, 2010). The decrease in AChE activity causes the decrease in the oxidation current of thiocholine. OPs decrease AChE activity binding to serin residue of its active site, resulting in the decrease of the oxidation current of thiocholine (Wang et al. 2014).

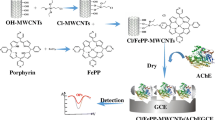

In the study, we report a novel AChE-based voltammetric biosensor for the determination of OPs. For this purpose, [2,2′;5′,2″]-Terthiophene-3′-carbaldehyde (TT) was synthesized as an immobilization matrix. AChE was immobilized on poly(TT) by means of covalent bonding between aldehyde and amino groups (Scheme 1a). The performance of the biosensor was examined using malathion as a model pesticide.

Experimental

Materials

Acetylcholinesterase (500 U/mg protein from electrophorus electricus), glutaraldhyde (25 wt% in water), acetylthiocholine iodide, tetrabutylammonium hexafluorophosphate (TBAPF6), dimethylformamide (DMF), 2-thienylboronic acid, 3-thiophenecarboxaldehyde, and bis(triphenylphosphine) palladium (II) dichloride (PdCI2(PPh3)2) were obtained from Sigma chemical. All other chemicals were purchased from Merck. Autolab PGSTAT 128 N potentiostat was used for all electrochemical measurements carried out in the work. Ag/AgCI reference electrode, platinum (Pt) wire counter electrode, and glassy carbon working electrode (GCE) were acquired from BASi Corporation. The scanning electron microscope (SEM) and nuclear magnetic resonance (NMR) studies were carried out at Selcuk University Advanced Technology Research and Application Center, Turkey.

Synthesis of 2,5-dibromothiophene-3-carbaldehyde

In order to synthesize 2,5-dibromothiophene-3-carbaldehyde, 3-thiophenecarboxaldehyde (0.30 g, 1.12 mmol) was put into a 100-mL round-bottomed flask including 20 mL diethyl ether. The reaction mixture was stirred for 30 min under N2-saturated medium. After that, 4 mL of diethyl ether including Br2 (3.78 mL, 73.82 mmol) and HBr/H2O were put in the mixture and the mixture was stirred in ice water for about 2 h and then heated to 50 °C and stirred until the starting material was finished. After completing the reaction, the mixture was poured into cold water so as to counteract the effect of Br2 and extracted several times using diethyl ether. Lastly, the obtained product was purified (83 % yield) using column chromatography. 1H NMR (400 MHz, CDCI3): δ 9.80 (s, 1H), 7.34 (s, 1H) (Guler et al. 2015).

Synthesis of [2,2′;5′,2″]-terthiophene-3′-carbaldehyde

For the purpose of obtaining [2,2′;5′,2″]-terthiophene-3′-carbaldehyde (TTP), 2,5-dibromothiophene-3-carbaldehyde (250 mg, 0.93 mmol), 2-thienylboronic acid (357 mg, 2.79 mmol), PdCI2(PPh3)2 (70 mg, 0.1 mmol), and KHCO3 (200 mg, 2.0 mmol) were added to a 100-ml round-bottomed flask including 10 ml of DMF/H2O (4:1). The reaction mixture was stirred about 30 min at room temperature and heated to 100 °C under N2-saturated environment until the starting material was finished. The mixture was extracted by means of dichloromethane for several times. The organic phase was then dried with MgSO4 and filtrated. The solvent was removed using rotary evaporator. The oily yellow residue was purified (40 % yield) using column chromatography. 1H NMR (400 MHz, CDCI3): δ 10.1 (s, 1H), 7.56 (s, 1H), 7.49 (dd, j = 5.1 Hz, j = 1.1 Hz, 1H), 7.30 (m, 2H), 7.21 (dd, j = 3.62 Hz, j = 1.1 Hz, 1H), 7.15 (dd, j = 5.2 Hz, j = 3.7 Hz, 1H), 7.04 (dd, j = 5.1 Hz, j = 3.7 Hz, 1H); 13C NMR (400 MHz, CDCI3): δ 185.2, 146.1, 137.8, 136.9, 135.7, 132.2, 129.4, 128.9, 128.5, 128.2, 125.9, 125.1, 122.5 (Çarbaş et al. 2011; Guler et al. 2015).

Preparation of AChE biosensor

GCE working electrode was polished with 0.3 μm of alumina slurry and washed ultrasonically in bi-distilled water for 5 min and then washed with ethanol and bi-distilled water respectively before electropolymerization of TTP monomer on the working electrode. After that, the monomer was electrochemically polymerized on the electrode surface using cyclic voltammetry (CV) method between 0.8 and 1.5 V potentials (Fig. 1). This process was performed in 5 mL of acetonitrile solution containing 22 mM of the monomer and 62 mM of TBAPF6. The working electrode coated with poly(TTP) was washed with acetonitrile so that the unbound species would be on the electrode surface. After TTP being polymerized on GCE, 5 μL of different AChE concentrations prepared in 10 mM of phosphate buffer (pH 7.4) was spread over the poly(TTP)/GCE. Also, after different AChE concentrations was spread over the electrode coated with poly(TTP), 1 % of glutaraldhyde solution was coated on the electrode and allowed to dry in a refrigerator at 4 °C. After drying, poly(TTP)/AChE/GCE was rinsed with 0.1 M of sodium phosphate buffer (pH 7.4) to purge unbound enzyme molecules and stored at 4 °C when not used.

Result and discussion

Surface characterization of the modified electrode

The electron transfer between the polymer and the electrode is one of the most important parameters for biosensor applications. The properties of conducting polymers depend on their morphologies, in addition to the backbone structure. In the study, the surface characterization of different modified electrodes was studied using scanning electron microscopy (SEM). The surface characterization of poly(TTP) coated ITO was investigated before and after AChE immobilization. Figure 2 shows the SEM of ITO (a), poly(TTP)/ITO (b), and poy(TTP)/AChE/ITO (c). Electrodeposited poly(TTP) film via CV showed a granular morphology (b). AChE immobilized on poly(PTT) film using chemical entrapment method resulted compact growth pattern and the glutaraldehyde is seen covering AChE units (c). AChE immobilization was achieved with and without glutaraldehyde and these two working electrode showed the same response to acetylthiocholine iodide, but the working electrode with glutaraldehyde exhibited wider linear response (0.2–6.52 Mm) to acetylthiocholine iodide than that without glutaraldehyde. Limit of detection of the biosensor with and without glutaraldhyde was 0.11 and 0.012 mM/μA (3 × standard deviation of the blank signal/slope), respectively. About 50 % of the decrease in ATCI response was seen after 2 days. For this, we have used the biosensor without glutaraldhyde.

Electrochemical behavior of poly(TTP)

It is well-known that CPs have been used to modify working electrodes because of enhancing the relevant detection sensitivity. Herein, electrochemical impedance spectroscopy (EIS) and CV have been used to study the changes which poly(TTP) and AChE generate on the GCE surface. Figure 3 shows the Nyquist plots of EIS of bare GCE (a), poly(TTP)/GCE and poly(TTP)/AChE/GCE. Rct values of bare GCE, poly(TTP)/GCE and poly(TTP)/AChE/GCE were estimated 158, 58, and 118 kΩ, respectively, which shows that the EIS response of 5 mM of [Fe(CN)6]3−/[Fe(CN)6]4− at poly(TTP)/GCE is much weaker than that at poly(TTP)/AChE/GCE and GCE. This implies that poly(TTP) is a good electron conducting material between the redox probe and the electrode. In addition, EIS studies demonstrated that AChE partially inhibits the electron transfer between the redox probe and the electrode when compared to poly(TTP)/GCE. Figure 4a shows the effect of scan rate on the CV response of poly(TTP)/GCE in 5 mL of acetonitrile containing 62 mM of TBAPF6. The peak current was proportional to scan rate from 0.08 to 0.2 Vs−1. This indicates that a good adhered active polymer film and a non-diffusional redox reaction occurred on the modified electrode surface. As it can be seen in Fig. 4b, a very good linear relationship between peak currents and square root of scan rates occurs at GCE and poly(TTP)/GCE. It is concluded that PTT at GCE surface could efficiently accelerate the electron transfer between electrode and redox probe because the slope of the modified electrode is larger than that of bare electrode.

(a) Cyclic voltammograms of the poly(TTP)/GCE electrode in acetonitrile containing 62 mM of TBAPF6 at different scan rates (0.08, 0.1, 0.12, 0.14, 0.16, 0.18, and 0.2 mV/s). (b) Calibration pilots of [Fe(CN)6]−3 reduction peak current versus square root of scan rate at bare GCE (b) and poly(TTP)/GCE

Electrochemical behavior of poly(TTP)/AChE/GCE

The constructed AChE biosensor immobilized on poly(TTP)/GCE surface was shown in Scheme 1. The electrochemical behavior of the biosensor was investigated using CV method and all electrochemical experiments were performed in 0.1 M phosphate buffer (pH 7.4) and at room temperature. Figure 5 shows the cyclic voltammograms of bare GCE, poly(TTP)/GCE, and poly(TTP)/AChE/GCE in the absence and presence of ATCI. No peak was observed on GCE (a), poly(TTP)/GCE (b), and poly(TTP)/AChE/GCE(c) in the absence of ATCI. When 0.5 mM ATCI was added to the electrochemical cell, an irreversible oxidation peak was observed on poly(TTP)/AChE/GCE (f) at 0.83 V, whereas no detectable peak was observed on GCE (d), poly(TTP)/GCE (e). This is because of the oxidation of thiocholine, the hydrolysis product of ATCI, catalyzed by AChE. These results show that poly(TTP) is a good matrix for AChE immobilization and electron transfer between the electrode and the electroactive compound (thiocholine). The current versus ATCI concentration curve was obtained using CV. As can be seen in Fig. 6b, with the increasing ATCI concentration, voltammetric response increased linearly from 0.015 to 1.644 mM with a correlation coefficient of 0.998 and then leaned toward a plateau value, which shows the Michealis-Menten process (Fig. 6a). The linear range of poly(TTP)/AChE/GCE is wider than 0.72–1.76 mM for AChE-pRGO-CHIT/GCE (Li et al. 2013), 0.3–16.5 μM and 91.5–211.5 μM for AChE/CPBA/AuNPs/RGO-CS/GCE (Liu et al. 2011), and 0.1–0.6 μM for AChE-Fe3O4NP/c-MWCNT/AuE (Chauhan and Pundir 2011). The apparent K m value was determined 1.82 mM according to the Lineweaver-Burk equation. The sensitivity of the biosensor was calculated to be 183.19 μA/mM from the slope of the linear calibration curve. The obtained K m is lower than that attained in literature (Li et al. 1999). The obtained sensitivity is larger than those reported previously for AChE biosensors (Liu et al. 2011; Buiculescu and Chaniotakis 2012).

Cyclic voltammograms, bare GCE (a), poly(TTP)/GCE (b), and poly(TTP)/AChE/GCE (c) in 0.1 M phosphate buffer (pH 7.4) in the absence of ATCI (scan rate: 0.1 Vs−1) and bare GCE (d), poly(TTP)/GCE (e), and poly(TTP)/AChE/GCE (f) in 0.1 M phosphate buffer (pH 7.4) in the presence of 0.5 mM ATCI (scan rate: 0.1 Vs−1)

a CVs of poly(TTP)/AChE/GCE in 0.1 M of phosphate buffer (pH 7.4) after addition of ATCI from 0.0149 to 2.4715 μM (scan rate 0.1 V/s). Inset shows the calibration plot for ATCI sensor. b The linearly increased current of the oxidation peak of thiocholine versus ATCI in 0.1 M of phosphate buffer (pH 7.4) for ATCI determination

Determination of optimum poly(TTP) film thickness

It is demonstrated that the polymer film thickness affects both the response time of the biosensor and conductivity of the polymer. If the film is too thick, the electron transfer between electrode and redox probe will not take place. Thus, the film thickness can be checked by changing its thickness to a desired peak current using CV method (Grennan et al. 2006). In here, four different working electrodes were prepared with different thicknesses (15, 20, 25, and 30 scans) for determination the best film thickness providing the highest peak current in the same 62 mM monomer concentration and 0.1 Vs−1 scan rate. The peak current was determined 2.5 μA for 15 scans, 7.57 μA for 20 scans, 30.41 μA for 25 scans, and 16.26 μA for 30 scans in 0.1 M phosphate buffer (pH 7.4) containing 0.495 mM ATCI. Results show that the peak current of poly(TTP)/AChE/GCE increases with increasing scan rate from 15 to 25 scans then decreases about 50 % for 30 scans. Therefore, the biosensor with 25 scans was used for further study.

Determination of optimal AChE concentration

To investigate the effect of AChE loading on the biosensor response, four different AChE concentrations (90, 120, 135, and 180 U/cm2) were prepared and loaded on poly(TTP)/GCE. The peak current was estimated 21.13 μA for 90 U/cm2, 30.87 μA for 120 U/cm2, 25.42 μA for 135 U/cm2, and 21.13 μA for 180 U/cm2 in 0.1 M phosphate buffer (pH 7.4) containing 0.495 mM ATCI. It can be concluded that the peak current of the biosensor increases with increasing the amount of the immobilized enzyme on the polymer film up to 120 U/cm2 then decreases slowly. This is because enzymes can change the electron transfer rate and they are not conductive molecules and they can inhibit the electron transfer if the concentration is too high. Therefore, the biosensor containing 120 U/cm2 of AChE was used for further study.

Effect of pH and temperature on poly(TTP)/AChE/GCE response

The effect of solution pH on poly(TTP)/AChE/GCE response in 0.1 M of phosphate buffer (pH 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, and 9.5) was investigated. Figure 7a shows that the oxidation current increases with increasing pH from 5.5 to 8.0 and then decreases with increasing pH from 8.0 to 9.5. The maximum current for the biosensor response was observed at pH 7.5–8.0. This optimal pH of poly(TTP)/AChE/GCE is close to that of AChE-based biosensors reported previously (Chauhan and Pundir 2011; Wei and Wang 2015). However, 0.1 M of phosphate buffer with pH of 7.4 was selected for all electrochemical experiments due to the physiological pH.

One of the most important factors affecting the enzyme activity is temperature because above 40–50 °C the rate of enzyme catalysis reactions generally decreases to zero. This decrease is because of the limited stability of the enzyme. To examine the effect of temperature on poly(TTP)/AChE/GCE response, the voltammetric response of the biosensor was studied from 10 to 60 °C. The optimum current response was observed at 40 °C (Fig. 7b). The work was carried out at room temperature (about 25 °C) because its response is not very different from the optimal temperature response. In addition, this optimal temperature was also seen in many biosensors reported previously (Du et al. 2007a, b; Chauhan and Pundir 2011).

Operational and storage stability of poly(TTP)/AChE/GCE electrode

The operational stability of poly(TTP)/AChE/GCE was evaluated by taking into consideration the current response of the same working electrode for the same ATCI concentration (0.5 mM). The average, standard deviation, and relative standard deviation of the sensor were 97.91, 1.73, and 1.7 % after ten sequential measurements (Fig. 8a).

Storage stability is one of the most important properties for enzyme electrode because enzymes do not retain their biological activity for a long time. In the study, the storage stability of poly(TTP)/AChE/GCE electrode was carried out using the same electrode under the same conductions within 30 days. No obvious decrease in ATCI response was observed in the first 10 days. The biosensor retained 64 % of its initial activity for the same ATCI concentration after using over a 30 day period (Fig. 8b). This stability is better than those reported in studies (Gong et al. 2009; Zhai et al. 2013).

Interference study

In the study, the interference effect of ascorbic acid (AA), uric acid (UA) dopamine (DA), glycin, histidine, arginine, and fructose on the biosensor response was investigated because they can disrupt the biosensor response to OPs, resulting in the overlapping of the peak which is proportional to the concentration of the analyte. For this purpose, 0.98 mM of each substance was added into electrochemical cell separately containing 0.98 mM of ATCI. The interference current was determined 2.1 % for dopamine, 3.1 % for glycin, 2.5 % for histidine, 4.3 % for uric acid, 2.8 % for fructose, 3.6 % for ascorbic acid, and 1.9 % for arginine by means of the equation of the interference percentage ((I-Io) × 100/Io). Where I is ATCI response + test compound and Io is ATCI response only obtained by CV. Based on these results, it can be inferred that the biosensor has proved to be of good selectivity to ATCI.

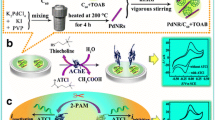

Detection of malathion

After optimization of poly(TTP)/AChE/GCE electrode, malathion was studied as a model pesticide. It is well-known that the oxidation current of thiocholine decreases with the increase of the pesticide concentration because of the inhibition of AChE activity. For this purpose, the voltammetric response of the biosensor to 0.25 mM ATCI was investigated before and after inhibition with different concentrations of malathion in 0.1 M phosphate buffer (pH 7.4). As can be seen in Fig. 9b, the inhibition percentage of malathion is proportional to its concentration from 9.99 to 99.01 nM and the limit of detection is 1.35 ng/mL. The linearization equation was inhibition % = 0.688c + 1.961 with the correlation coefficient of 0.993. Inhibition of AChE by organophosphate and carbamate pesticide arises from phosphorilated and carbamoylated enzyme intermediate products, respectively. These products can be reversed using a simple procedure. AChE can be reactivated using a nucleophilic substance such as pyridine-2-aldoxime methochloride (2-PAM) (Santos et al. 2015). Herein, the inhibited biosensor was reactivated using pyridine-2-aldoxime methochloride as a reactivator. The sensor could recover 97 % of its initial activity after immersing 5 mM of pyridine-2-aldoxime methochloride for 10 min. The fabricated AChE biosensor was comparable with those reported previously (Du et al. 2007a, b; Liu et al. 2011; Kanik et al. 2013).

Detection of malathion in parsley leaves samples

In this section of the study, different parsley leaves extracts containing different amount of malathion were used to evaluate the reliability of poly(TTP)/AChE/GCE biosensor. The standard addition method was employed to detect the amount of the pesticide in the samples. As can be seen from Table 1, the recoveries were estimated to be between 89.3 and 94.7 %. These results show that the constructed poly(TTP)/AChE/GCE biosensor can be used for the analysis of malathion in real samples.

Conclusions

In this study, we have developed a new AChE-based enzyme sensor for quantitative determination of malathion, which used as a model pesticide. The conducting poly(TTP) film has been used, for the first time, for AChE immobilization. This polymer ensures an excellent medium for enzyme immobilization because the imine reaction between aldehyde groups of the polymer and amine groups of the enzyme provides covalent immobilization. Moreover, this biosensor showed an excellent sensitivity (183.19 μA/mM) to ATCI and a good linear range from 0.015 to 1.644 mM. Based on the change of AChE activity when exposing to the pesticide, a novel AChE enzyme sensor with good sensitivity, reproducibility, storage stability, low detection limit, and rapid determination was successfully developed. Therefore, this study enables a simple and new approach for the development the voltammetric AChE sensor for OPs determination.

References

Buiculescu R, Chaniotakis NA (2012) The stabilization of Au NP–AChE nanocomposites by biosilica encapsulation for the development of a thiocholine biosensor. Bioelectrochemistry 86:72–77

Çarbaş BB, Kivrak A, Zora M, Önal AM (2011) Synthesis of a novel fluorescent and ion sensitive monomer bearing quinoxaline moieties and its electropolymeryzation. React Funct Polym 71:579–587

Chauhan N, Pundir CS (2011) An amperometric biosensor based on acetylcholinesterase immobilized onto iron oxide nanoparticles/multi-walled carbon nanotubes modified gold electrode for measurement of organophosphorus insecticides. Anal Chim Acta 701:66–74

Du D, Cai J, Song D, Zhang A (2007a) Rapid determination of triazophos using acetylcholinesterase biosensor based on sol–gel interface assembling multiwall carbon nanotubes. J Appl Electrochem 37:893–898

Du D, Ding J, Cai J, Zhang A (2007b) Determination of carbaryl pesticide using amperometric acetylcholinesterase sensor formed by electrochemically deposited chitosan. Coll Surf B Biointerfaces 58:145–150

Du D, Wang MH, Cai J, Tao Y, Tu HY, Zhang AD (2008) Immobilization of acetylcholinesterase based on the controllable adsorption of carbon nanotubes onto an alkanethiol monolayer for carbaryl sensing. Analyst 133:1790–1795

Du D, Wang M, Cai J, Qin Y, Zhang A (2010) One-step synthesis of multiwalled carbon nanotubes-gold nanocomposites for fabricating amperometric acetylcholinesterase biosensor. Sensors Actuators B 143:524–529

Fukuto TR (1990) Mechanism of action of organophosphorus and carbamate insecticides. Environ Health Perspect 87:245–254

Gong J, Wang L, Zhang L (2009) Electrochemical biosensing of methyl parathion pesticide based on acetylcholinesterase immobilized onto Au–polypyrrole interlaced network-like nanocomposite. Biosens Bioelectron 24:2285–2288

Grennan K, Killard AJ, Hanson CJ, Cafolla AA, Smyt MR (2006) Optimisation and characterisation of biosensors based on polyaniline. Talanta 68:1591–1600

Guler M, Turkoglu V, Kivrak A (2015) A novel glucose oxidase biosensor based on poly([2,2′;5′,2″]-terthiophene-3′-carbaldehyde) modified electrode. Int J Biol Macromol 79:262–268

Homaei AA, Sariri R, Vianello F, Stevanato R (2013) Enzyme immobilization: an update. J Chem Biol 6:185–205

Kanik FE, Kolb M, Timur S, Bahadir M, Toppare L (2013) An amperometric acetylcholine biosensor based on a conducting polymer. Int J Biol Macromol 59:111–118

Li YG, Zhou YX, Jiang JH, Ma LR (1999) Immobilization of enzyme on screen-printed electrode by exposure to glutaraldehyde vapour for the construction of amperometric acetylcholinesterase electrodes. Anal Chim Acta 382:277–282

Li Y, Bai Y, Han G, Li M (2013) Porous-reduced graphene oxide for fabricating an amperometric acetylcholinesterase biosensor. Sensors Actuators B 185:706–712

Liu GD, Lin YH (2005) Electrochemical sensor for organophosphate pesticides and nerve agents using zirconia nanoparticles as selective sorbents. Anal Chem 77:5894–5901

Liu T, Su H, Qu X, Ju P, Cui L, Ai S (2011) Acetylcholinesterase biosensor based on 3-carboxyphenylboronic acid/reduced graphene oxide–gold nanocomposites modified electrode for amperometric detection of organophosphorus and carbamate pesticides. Sensors Actuators B 160:1255–1261

Morales A, Ruiz I, Oliva J, Barba A (2011) Determination of sixteen pesticides in peppers using high-performance liquid chromatography/mass spectrometry. J Environ Sci Health B 46:525–529

Proskocil BJ, Bruun DA, Thompson CM, Fryer AD, Lein PJ (2010) Organophosphorus pesticides decrease M2 muscarinic receptor function in guinea pig airway nerves via indirect mechanisms. PLoS ONE 5:1–11

Pulgarín JAM, Molina AA, López PF (2006) Automatic chemiluminescence-based determination of carbaryl in various types of matrices. Talanta 68:586–593

Rajesh, Kaneto K (2005) A new tyrosinase biosensor based on covalent immobilization of enzyme on N-(3-aminopropyl) pyrrole polymer film. Curr Appl Phys 5:178–183

Santos CSA, Monteiro MS, Soares MVM, Loureiro S (2015) Brain cholinesterase reactivation as a marker of exposure to anticholinesterase pesticides: a case study in a population of yellow-legged gull Larus michahellis (Naumann, 1840) along the northern coast of Portugal. Environ Sci Pollut Res. doi:10.1007/s11356-015-5730-x

Shi L, Xiao Y, Willner I (2004) Electrical contacting of glucose oxidase by DNA-templated polyaniline wires on surfaces. Electrochem Commun 6:1057–1060

Stajnbaher D, Zupancic-Kralj L (2003) Multiresidue method for determination of 90 pesticides in fresh fruits and vegetables using solid-phase extraction and gas chromatography–mass spectrometry. J Chromatogr A 1015:185–198

Sullivan JB, Kieger GR (2001). Clinical environmental health and toxic exposures. Second ed., Philadelphia.

Uang YM, Chou TC (2003) Fabrication of glucose oxidase/polypyrrole biosensor by galvanostatic method in various pH aqueous solutions. Biosens Bioelectron 19:141–147

Wang G, Tan X, Zhou Q, Liu Y, Wang M, Yang L (2014) Synthesis of highly dispersed zinc oxide nanoparticles on carboxylic graphene for development a sensitive acetylcholinesterase biosensor. Sensors Actuators B 190:730–736

Wei M, Wang J (2015) A novel acetylcholinesterase biosensor based on ionic liquids-AuNPs-porous carbon composite matrix for detection of organophosphate pesticides. Sensors Actuators B 211:290–296

Zhai C, Sun X, Zhao W, Gong Z, Wang X (2013) Acetylcholinesterase biosensor based on chitosan/prussian blue/ multiwall carbon nanotubes/hollow gold nanospheres nanocomposite film by one-step electrodeposition. Biosens Bioelectron 42:124–130

Zheng Y, Liu Z, Jing Y, Li J, Zhan H (2015) An acetylcholinesterase biosensor based on ionic liquid functionalized graphene–gelatin-modified electrode for sensitive detection of pesticides. Sensors Actuators B 210:389–397

Acknowledgments

This work was supported by Presidency of Scientific Research Projects (2013-FBE-D003 and 2014-HIZ-FEN 070) of Yuzuncu Yıl University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Roland Kallenborn

Rights and permissions

About this article

Cite this article

Guler, M., Turkoglu, V. & Kivrak, A. Electrochemical detection of malathion pesticide using acetylcholinesterase biosensor based on glassy carbon electrode modified with conducting polymer film. Environ Sci Pollut Res 23, 12343–12351 (2016). https://doi.org/10.1007/s11356-016-6385-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-6385-y