Abstract

Geotechnical classification of the roof of an underground coal mine is of utmost importance for the assessment of the roof support requirement. Forty-five published cases of the Indian coalfield have been taken for analysis. It has been observed from the cases that stand-up time with CMRI–RMR is not properly correlated, particularly, for short-term stable cases. After re-looking the data set, it has been perceived that the influence of a single weak parameter is sufficient enough to reduce the strength of the roof rock mass. Therefore, the summation of the ratings for estimation of the overall rating of the rock mass is not appropriate. Keeping this in mind, a new geotechnical classification of the coal roof index (CRI) has been proposed similar to the Barton ‘Q’ system of rock mass classification. A multiple regression analysis has been done by considering five independent parameters and one dependent parameter and using the developed new equation to assess the rating range. This study reveals that the newly developed classification system has shown a good correlation with recorded stand-up time compared to CMRI–RMR classification. The range of the proposed CRI classification is varying from 0.001 to 3000. It has been divided into five classes. An exponential correlation between the proposed CRI and CMRI–RMR has also been observed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

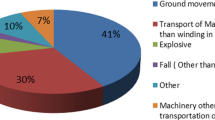

The underground coal mines face a major challenge of the occurrence of roof falls. The risky nature of roof failure is demonstrated by the statistics of mining accidents reported in Indian coal mines [1,2,3,4]. According to reported data from Indian coal mines, the total number of fatal accidents that happened due to roof falls is a very high percentage, 41% between 1973–2014 [5, 6]. So, the overall stability of underground openings helps to increase the productivity and safety of the mine. The stability of the underground coal mine must be evaluated, and the requirement of a suitable support system must be assessed at the time of feasibility study and the stage of excavation [7].

Quick and reliable estimation of underground openings’ stability and appropriate support requirements have been done by rock mass classification systems. The rock mass classification method is used for more than 100 years [6, 8]. The classification systems have been giving quantitative descriptions of geological conditions. The rock tunnelling quality index, Q-system, and the rock mass rating system, RMR [9], are the two most common classifications. Both classifications are widely accepted in the civil and mining industries [10, 11]. The rock geology of coal mines has a layered form, and both classifications do not consider layer thickness of the coal roof. Therefore, both systems of rock classification are not appropriately applicable [12].

Venkateswarlu et al., 1989 proposed a CMRI–RMR geo-mechanical classification of the coal roof. It is extensively being used for assessment of the roof support system in Indian underground coal mines. Basis of field observations, A. Paul et al. [8] pointed out that some of the cases, particularly, for low CMRI–RMR show the instability of the junction roof support suggested by rock load formulation [13] based on CMRI–RMR. Author also observed similar issues for some of the mines having low CMRI–RMR values. Further, after re-looking the base data of geo-mechanical classification [14], it has been observed that some of the short-term stable (< 30 days) cases show a wide range of the CMRI–RMR value. Thus, a new system of geo-mechanical classification of the coal roof has been proposed based on the statistical analysis of the coal mine cases.

Engineering Rock Mass Classification Systems for Underground Coal Mines

Classifications of rock masses are widely used to estimate the amount of rock support needed during pre-construction and to quantitatively describe the quality of the rock mass. As given in Table 1, there are numerous rock mass classification systems that have been developed for both general and specialized uses. The different engineering geological and geotechnical parameters are given varying degrees of emphasis by these classification systems.

The rock geology of coal mines has a layered form. The above-mentioned classifications do not consider layer thickness of the stratum in the roof. Therefore, the application of these classification systems on coal mines are not appropriate. But, there are two classifications such as CMRI–RMR [17] and CMRR [18] which are the most accepted rock mass classifications for the roof of the underground coal mines. CMRI–RMR rock mass classification, developed by Venkateswarlu et al., is being using used in the Indian coal mines for assessment of the roof support system since last 3 decades. CMRR (coal mine roof rating system) is most popular in the USA, Australia, South Africa, etc. The development approach of both the classification is like to Bieniawski’s RMR system. The final rating value in both systems ranges from 0 to 100 [19]. The better quality of roof rock is indicated by higher RMR value. These are briefly explained in subsequent section.

CMRI–RMR

The CMRI–RMR classification is a practical and straightforward method of estimating roof conditions of an underground coal mine. It had been developed by statistical analysis of the various geotechnical data obtained from the Indian underground coal mines. Detail of the geotechnical and geo-mining data has been given in scientific report [20]. Five most important influencing parameters had been identified, i.e. layer thickness, structural characteristics, weatherability, rock’s uniaxial compressive strength (UCS), and groundwater flow rate. Through the use of factor analysis and principal component analysis (PCA), relationships between various parameters were discovered. Layer thickness plays a substantial role in delamination, and it is a cause of the roof deterioration. The layer thickness can be measured by measuring the layers thickness within the bed [8]. Structural features are the cause of roof degradation, which include cracks, major faults, joints, slips, etc. In Indian coal mines, groundwater flow is a significant issue. Because many coal measure rocks deteriorate or disintegrate as a result of weathering, particularly when water is present, weatherability is crucial. It is determined by the slake durability apparatus, and first cycle slake durability index (SDI) was considered for analysis. The rock’s uniaxial compressive strength has been calculated in the laboratory as per standards of the Indian Bureau. Point load index obtained from an irregular piece of rock is converted to estimate the uniaxial compressive strength Co using the empirical relation: Co = 14 Ip. Groundwater seepage rate is measured by drilling a long hole in the roof (1.5–1.8 m) and the percolated water collected through the hole. This water flow is expressed in mL/min. All the geological features are recorded through geotechnical mapping [21].

The CMRI–RMR classification system is derived from the sum of the ratings of five distinct parameters. The CMRI–RMR value is calculated as follows:

where R CMRI_1, R CMRI_2, R CMRI_3, R CMRI_4, and R CMRI_5 are the ratings for layer thickness, structural characteristics, weatherability, UCS of roof strata and flow rate of groundwater, respectively. Weighted average value of CMRI–RMR shall be determined for a case of multiple layers. The maximum rating of the parameters is provided in Table 2.

CMRI–RMR system has some adjustment factors for gallery span, depth, method of extraction, induced stresses, and lateral stress. These adjustments are made accounting for their neutral, negative, and positive contributions to CMRI–RMR values. The following equations are used to calculate the rock load in junctions and galleries using adjusted CMRI–RMR after adjustment, respectively. [13, 17]

where D is density (t/m3) of the roof rock, and B is the width of the gallery (m).

Coal Mine Roof Rating System (CMRR)

Molinda and mark developed the coal mine roof rating (CMRR) over 25 years ago. This classification system’s basic idea has a similarity to Bieniawski’s RMR. The ultimate rating value (CMRR value) ranges from 0 to 100 scale. The ultimate rating is determined by adding up all of the individual ratings for the following five parameters: (a) the intact rock’s uniaxial compressive strength (UCS); (b) the rock’s shear strength (cohesion and roughness); (c) the intensity (spacing and persistence) of the bedding and other discontinuities; (d) the existence of a strong bed in the bolted interval; and (e) the rock’s moisture sensitivity [22].

The procedure of CMRR calculation is split into a two-step. Unit ratings are first established for each layer after the mine roof is divided into structural units. Although a structural unit typically consists of a single lithologic layer, it is possible to combine multiple rock layers if they share similar engineering properties. The second step involves applying the proper adjustment factors and averaging all of the unit ratings within the bolted zone, with the contribution of each unit weighted by its thickness, to determine the CMRR. Figure 1 illustrates the process for estimation of the CMRR value [1, 23, 24].

CMRR flowchart [24]

Proposed Coal Roof Index (CRI) Classification System

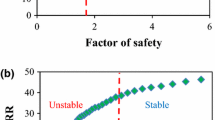

It is worth mentioning that the stand-up time (of unsupported roof) depends on the quality of the roof (i.e. rock classification) and width of the gallery. However, the range of the width of the majority of the cases is 3.0 to 4.5 m. In this study, 45 published cases of Indian coal field have been taken from the scientific report. (CMRI report, 1987). It has been observed, particularly, for short-term stable cases that high RMR value cases are having less gallery width, whereas low RMR value cases have high width of gallery in general. Even than these cases have failed within 30 days. Thus, the reported data have been re-analysed. A correlation graph between the stand-up time and CMRI–RMR has been plotted (Fig. 2).

It has been observed, particular, for the short-term stable cases (i.e. lesser than 30 days) that CMRI–RMR value has a wide range from 27 to 62 which shows a poor correlation between stand-up time and RMR values. After re-look of these cases, it has been observed that rating of the single parameters is low compared to other parameters for most of the cases. This indicates that the influence of a single weak parameters is sufficient enough to reduce the strength of the roof-mass. Therefore, summation of the ratings for estimation of the overall rating of the rock mass is not appropriate.

Keeping above fundamental issue, particularly related to poor rock quality, a new coal roof index (CRI) classification system has been proposed. The proposed classification system is based on the multiplication of individual dependent parameter’s rating similar to Q-system of rock mass classification as given below:

where RCRI_1, RCRI_2, RCRI_3, RCRI_4 and RCRI_5 are the CRI ratings for layer thickness, structural features, weatherability, groundwater flow and UCS of roof strata, respectively. Weighted average value of CRI can be determined for a case of multiple layers with the bolted zone or about 2.5 m.

The appropriate rating system of the influencing parameters has been evaluated by multiple regression analysis (MRA) of the field cases of underground coal mines. Same data set has been chosen for re-analysis of the statistical model of CRI (Eq. 4) w.r.t. to stand-up time. The statistical data of the influencing parameters of all 45 cases are given in Table 3.

Multiple Regression Analysis

Projecting the nature of the relationships between the different input and output variables is the aim of regression analysis. Additionally, it offers the best equation illustrating the relationship between the independent and dependent variables. The result is also predicted using the equation for specific values of the input variables. This study uses MRA with St (stand-up duration) as the output variable and Lt (layer thickness), Sf (structural feature), Sld (slake durability), UCS (uniaxial compressive strength), and Wg (groundwater) as independent variables.

The stand-up time is by and large proportional to the CRI (Eq. 4) where rating of each parameter is correlated with its exponential function. Thus, the multiple regression equation has been framed as follows:

where Lta, Sfb, Sldc, Wgd and UCSe represent the rating of the respective parameters i.e. RCRI_1, RCRI_2, RCRI_3, RCRI_4 and RCRI_5.

The main issue is that R2 magnitude can be significantly impacted by variance in the studied population. Therefore, a high coefficient of determination does not always imply “goodness of fit”. Similarly, as the statistic is mostly impacted by changes in the independent variable, there is no assurance that a small R2 denotes a weak link. Multiple regression analysis (MRA) summary is given in Table 4.

While b is employed as a coefficient of independent variables for the computation of the output value, the b* represents the contribution or effect of the independent variables (Lt, Sf, Sld, Wg, and UCS) on the dependent variable (St) [25, 26]. The MRA is carried out using the simulation data of 45 coal mine cases in India. The relationship below is demonstrated by the MRA models:

Rating Allocation

The rating range of each parameter has been evaluated by breakage of multiple regression equation into five sub-equations (exponential function) which have been derived with their coefficients. The values of raw regression coefficients from MRA for the respective parameters are as follows:

These constants represent the nature and influence of the parameters on the classification. Figures 3, 4, 5, 6 and 7 show the exponential curve of the parameters. The broad range of the parameters, as mentioned in Table 3, has also been shown in the curve.

The ratings of the individual parameters have been distributed by subdividing the equation curve into 6–7 equal division within the broad range.

Broadly, layer thickness value ranges from 0 to 16 cm, respectively, and rating values are subdivided into seven division from 1 to 25. Structural feature value ranges from 0 to 18, which is subdivided into six division for rating ranges from 1 to 30. Slake durability index ranges nearly 40 to 99, therefore the equation curve has been subdivided in six division and rating allocation done from 0.2 to 4.5. The uniaxial compressive strength value ranges from 3 to 70 MPa; therefore, the rating value ranges from 4 to 25 in six equal division. The ground water flow ranges from 0 to more than 2000 ml/min.

The rating system of the all parameters is shown in Table 5. These have been arrived at after several modifications to keep them in conformity with actual observations. To facilitate calculations, those parameters which have a negative influence on stability (viz., groundwater and structural features, increase in whose values deteriorate the roof condition) as shown in Eq. 6 and those parameters which have a positive influence on stability (viz., layer thickness, slake durability and uniaxial compressive strength) were assigned rating value as more than one that were directly related to their value. In above rating allocation, two parameters viz. structural features and ground water flow, have negative impact on stability of underground structure.

Results and Analysis

The results of the MRA have been analysed for ensuring the effectiveness of the proposed coal roof classification system. CRI of all the cases has been calculated using the proposed rating system as mentioned in Table 5 and Eq. 4. The wide numerical range of CRI varies from 0.001 to 3000 and reflects differences in rock mass properties.

Correlation

The graph of scattered data between stand-up time and CRI for the 44 cases has been plotted in logarithmic scale which is shown in Fig. 8. The bet-fit linear trend has also been plotted. The prediction of stand-up time for an underground coal mine is very helpful for assessment of support requirements. A linear, logarithmic equation has been developed as follows:

The coefficient of determination (R2) has been obtained as 0.75. As shown in Fig. 2, R2 between the CMRI–RMR values and stand-up time is 0.46, whereas R2 between the CRI values and stand-up time is 0.75, as shown in Fig. 8. Therefore, the developed CRI classification has around 29 per cent higher coefficient of determination as compared to CMRI–RMR classification.

As discussed earlier, CMRI–RMR showed the poor correlation for the short-term stable cases (≤ 30 days). Therefore, correlation graph has also been plotted for short-term stable cases for both the CMRI–RMR and proposed CRI classification system vis-à-vis stand-up time in Figs. 9 and 10, respectively. Figure 9 shows the scattered data plot for CMRI–RMR classification. It has observed a very low R2 value with respect to stand-up time, which is about 0.09. The CRI value ranges from 0.7 to 30 for short-term stable cases. It has a reasonable R2 value, which is 0.45, and the graph plot has also shown conformity about the best fit line in Fig. 10.

Class System for Proposed CRI

The range of the proposed CRI classification has been divided into five classes viz. very poor (< 1 month), poor [1–3 months), fair [3–7 months), good [7–20 months or ~ 1.5 years) and very good [> 20 months or ~ 1.5 years) based on the stand-up time. Figure 11 shows the class system along with the range of the stand-up time. The upper bound and lower bound of scattered data of all the 45 cases has also shown by black dotted line and average value shown by dark blue line.

The statistical analysis of the data set, in different classes, has been done w.r.t. CRI value and stand-up time and summarized in Table 6.

Statistical relation between CRI and RMR classification system

A statistical relationship between CRI and CMRI–RMR has been established using regression method. Figure 12 shows the exponential best fit curve for the scattered data. Based on the results, the coefficient of determination is 0.75, which may be considered as a good correlation between CRI and CMRI–RMR data set. The developed exponential relationship between CRI and CMRI–RMR is as follows:

Validation

Four Indian coal mine cases have been considered for the validation of the study. Details of CRI classification parameters and their rating values are given in Table 7. The CRI value and stand-up time for all cases have been determined by suggested formulation (Eqs. 4, and 7, respectively). As per the study of Paul et al. [27] and Paul et al. [28], Pandavpara Mine is a stable case and Piparia Mine and Monnet Ispat Mine, Seam II are un-stable case. This study also showing that the CRI value of Pandavpara Mine is 218.75 which comes under strong category rock and projected stand-up time is more than 1.5 year that indicate the stable roof rock. The calculated CRI values for Piparia Mine and Monnet Ispat Mine, Seam II are 7, and 6.25 which comes under poor category of roof rock. The projected stand-up time for both cases also showing un-stable behaviour of roof rock even with roof support as per suggested Eq. 7. The Shyampur Colliery has CRI value of 562.5 which comes under very strong category rock and projected stand-up time for this case is more than five years which indicates the stable nature of roof rock. It has been also observed in the field that galleries of incline 5 and 6 of Shyampur Colliery were stable without any support for more than five years.

Nowadays, underground galleries have been supported just after the excavation stage. Therefore, it is difficult to measure actual stand-up time of un-stable cases in condition of no support. As per author knowledge, similar literature has not been available. However, two un-stable cases have been picked from Paul et al. [27] which are failed even after the support of as per the RMR guideline. It is expected to that these two cases have very short stand-up time in condition of no support which is also evident from this study. So, this study is showing good agreement of classification of roof rock and an average predication of the stand-up time of a coal mines.

Conclusions

Rock mass characterization for the roof is most important for assessment of the roof support requirement. Coal roof index (CRI) rock mass classification of the coal roof has been proposed and developed using the statistical analysis of the field cases. The proposed classification system is based on multiplication of the rating of the five influencing parameters viz. layer thickness, structural features, weatherability, UCS of roof strata and groundwater flow. The range of CRI is 0.01–3000. The CRI has been classified into five class viz. Very weak (CRI: 0.001–5), Weak (CRI: 5.1–20), Fair (CRI: 20.1–100), Strong (CRI: 101–400) and very strong (CRI: > 400). Structural features and groundwater flow shows the negative correlation whereas, layer thickness, weatherability and UCS of roof strata shows the positive correlation. The groundwater flow is to be considered for cases of having weatherability lesser then 95%. Statistical analysis of the wide spectrum of the roof quality revealed the reasonable correlation among the stand-up time vis-à-vis proposed CRI value. This study has been proposed a linear logarithmic relationship between stand-up time of unsupported roof and CRI, which is as follows:

The analysis of all the cases shows slightly better coefficients of determination (R2) of the proposed CRI roof classification compared with the CMRI–RMR. Particularly, for short-term stable cases (< 30 days). An exponentials correlation between proposed CRI and CMRI–RMR has also determined. The developed exponential relationship between CRI and CMRI–RMR is as follows:

This study has been validated from four Indian coal mine cases.

Abbreviations

- B :

-

The width of roadway (m)

- D :

-

Dry density (t/m3)

- CRI:

-

Coal roof index

- Lt:

-

Layer thickness (cm)

- St:

-

Stand-up time in days

- UCS:

-

Uniaxial compressive strength (Kg/cm2)

- Wg:

-

Groundwater flow rate (mL/min)

- Sf:

-

Structural features

- Sld:

-

First cycle slake durability index

- MRA:

-

Multiple regression analysis

- RMR:

-

CMRI–Rock mass rating

References

C. Mark, G. M. Molinda, L. M. Burke, Preventing falls of ground in coal mines with exceptionally low-strength roof: two case studies, 23rd Int. Conf. Gr. Control Min. (2004)

S.K. Palei, S.K. Das, Sensitivity analysis of support safety factor for predicting the effects of contributing parameters on roof falls in underground coal mines. Int. J. Coal Geol. 75(4), 241–247 (2008). https://doi.org/10.1016/j.coal.2008.05.004

M. Young, G. Walton, E. Holley, “Factors predictive of roof instability in addition to the existing CMRR criteria at two case study coal mines. Int. J. Coal Geol. 213(March), 103255 (2019). https://doi.org/10.1016/j.coal.2019.103255

M. Young, G. Walton, E. Holley, Investigation of factors influencing roof stability at a Western U.S. longwall coal mine. Int. J. Min. Sci. Technol. 29(1), 139–143 (2019). https://doi.org/10.1016/j.ijmst.2018.11.019

A.K. Dash, R.M. Bhattcharjee, A. Ahmad, Case study of accidents related to fall from height in Indian coal mining industry: an analysis. Int. J. Sci. Eng. Res. 7(9), 387–392 (2016)

A. Paul, V.M.S.R. Murthy, A. Prakash, A.K. Singh, Estimation of rock load for junctions based on roof failure cases for safe mining operation. Arab. J. Geosci.Geosci. (2020). https://doi.org/10.1007/s12517-020-06045-8

A. Paul, A.K. Singh, N. Kumar, D.G. Rao, Empirical approach for estimation of rock load in development workings of room and pillar mining. J. Sci. Ind. Res. (India) 68(3), 214–216 (2009)

A. Paul, N. Kumar, P. Kumar, A.K. Singh, Application of CMRI-ISM RMR for stability analysis of development workings for ballarpur underground coal mine—an empirical and numerical approach. J. Geol. Soc. India 96(2), 163–170 (2020). https://doi.org/10.1007/s12594-020-1524-y

Z. T. Bieniawski, The geomechanics classification in rock engineering applications (1979)

N. Barton, R. Lien, J. Lunde, L. Barton, R. Lunde, Engineering classification of rock massesfor. Rock Mech. 6(106), 189–236 (1974)

M. Mohammadi, Development of an optimal experimental model for predicting rock mass rating based on tunneling quality index. Int. J. Rock Mech. Min. Sci. 140(February), 104602 (2021). https://doi.org/10.1016/j.ijrmms.2020.104602

A. Taheri, Y. Lee, M.A.G. Medina, A modified coal mine roof rating classification system to design support requirements in coal mines. J. Inst. Eng. Ser. D 98(2), 157–166 (2017). https://doi.org/10.1007/s40033-016-0131-y

C.N. Ghosh, A.K. Ghose, Estimation of critical convergence and rock load in coal mine roadways: an approach based on rock mass rating. Geotech. Geol. Eng.. Geol. Eng. 10(3), 185–202 (1992). https://doi.org/10.1007/BF00881171

M.A. Van Dyke, T.M. Klemetti, C. Compton, Coal mine entry rating system: a case study. Int. J. Min. Sci. Technol. 31(1), 145–151 (2021). https://doi.org/10.1016/j.ijmst.2020.12.010

C. Edelbro, Evaluation of rock mass strength criteria, Licentiate Thesis, Lulea University of Technology, Lulea (2004)

Palmstrom, A., RMi – a rock mass characterization system for rock engineering purposes, Ph.D. Thesis, University of Oslo (1995)

V. Venkateswarlu, A.K. Ghose, N.M. Raju, Rock-mass classification for design of roof supports: a statistical evaluation of parameters. Min. Sci. Technol. 8(2), 97–107 (1989). https://doi.org/10.1016/S0167-9031(89)90507-0

B. G. M. Molinda, C. Mark, BUREAU OF MINES IC 9387 INFORMATION CIRCULAR / 1994 Coal Mine Roof Rating ( CMRR ): A Practical Rock Mass Classification for CoalMines

M. Brook, B. Hebblewhite, R. Mitra, Coal mine roof rating (CMRR), rock mass rating (RMR) and strata control: Carborough Downs Mine, Bowen Basin, Australia. Int. J. Min. Sci. Technol. 30(2), 225–234 (2020). https://doi.org/10.1016/j.ijmst.2020.01.003

B. Singh, CMRI report geomechanical classification of roof rocks vis-`a-vis roof supports, S&T Project Report. (1987)

A. Paul, A.P. Singh, L.P. John, A.K. Singh, M. Khandelwal, Validation of RMR-based support design using roof bolts by numerical modeling for underground coal mine of Monnet Ispat, Raigarh, India- a case study. Arab. J. Geosci.Geosci. 5(6), 1435–1448 (2012). https://doi.org/10.1007/s12517-011-0313-8

D. Hill, Practical experiences with application of the coal mine roof rating (CMRR) in Australian coal mines, Proc. Int. Work. Rock Mass Classif. Undergr. Min., pp. 65–72 (2007)

G. M. Mark, C, Molinda, The coal mine roof rating in mining engineering practice, Undergr. Coal Oper. Conf., no. February, pp. 50–62 (2003)

C. Mark, G.M. Molinda, The Coal Mine Roof Rating (CMRR) - A decade of experience. Int. J. Coal Geol. 64(1–2), 85–103 (2005). https://doi.org/10.1016/j.coal.2005.03.007

G.K. Uyanık, N. Güler, A Study on Multiple Linear Regression Analysis. Procedia - Soc. Behav. Sci. 106, 234–240 (2013). https://doi.org/10.1016/j.sbspro.2013.12.027

A. K. Bharati, A. Ray, M. Khandelwal, R. Rai, and A. Jaiswal, “Stability evaluation of dump slope using artificial neural network and multiple regression, Eng. Comput. (2021). https://doi.org/10.1007/s00366-021-01358-y.

A. Paul, V.M.S.R. Murthy, A. Prakash et al., Modelling of Fragile coal mine roof and estimation of rock loads—some empirical and numerical methods. Min. Metall. Explor. 40, 1879–1897 (2023). https://doi.org/10.1007/s42461-023-00841-y

A. Paul, A.P. Singh, P. Loui, J. et al., Validation of RMR-based support design using roof bolts by numerical modeling for underground coal mine of Monnet Ispat, Raigarh, India—a case study. Arab. J. Geosci.Geosci. 5, 1435–1448 (2012). https://doi.org/10.1007/s12517-011-0313-8

Acknowledgements

The authors would like to express their gratitude to Prof. Nil Ratan Bandyopadhyay and the anonymous reviewer for their valuable comments that helps to improve the article.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors wish to confirm that there are no known conflicts of interest associated with this study, and there has been no significant financial support for this work that could have influenced its outcome.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sonu, Jaiswal, A. Time-Dependent Stability Assessment of Coal Mine’s Gallery Using New Geotechnical Classification. J. Inst. Eng. India Ser. D 105, 1209–1221 (2024). https://doi.org/10.1007/s40033-024-00665-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-024-00665-0