Abstract

In a highly volatile manufacturing world, the demand of a product changes on everyday basis. Thus, there is a need of flexibility and competitiveness in the part of manufacturing organizations to cope with the situation. It becomes an absolute necessity for any organization to plump for the implementation of advanced manufacturing technology (AMT) for its betterment. The present paper exhibits a decision model based on Taguchi loss function under fuzzy environment in the process of evaluating the AMTs. Triangular fuzzy numbers are used in the analytics to quantify the obscurity immanent in the subjective estimates. An objective estimate is also undertaken in the model to make it more effective and fruitful. The applicability of the algorithm is exhibited by pitting it against a more orthodox fuzzy VIKOR method on a case study of AMT selection. The results gained thereafter could establish the superiority of the proposed approach.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Evolution of revolution in manufacturing has come a long way. It all started from Stone Age to le-agile stage via pyramid age, medieval age, Victorian age, line manufacturing, lean manufacturing and lastly agile manufacturing. Under the volatile market characteristics, manufacturing organizations are constrained to estimate the demand of the products. They are confronted with envisaging the dormant demand of types of products and their quantity as well. The giant outcome of this is a shifting of manufacturing strategies to a more customized product as depicted in Fig. 1 [1]. The manufacturing strategies shifted from make-to-stock (MTS), a mass productive one, to buy-to-order (BTO), a mass customized one, via assembly-to-order (ATO) and make-to-order (MTO) bearing varying proportions of lead time for production (P) and delivery (D) [2] of the product.

The performance of a manufacturing organization in today’s environment is largely dependent on the competitiveness, flexibility and new technological innovations. These can only be achieved through the implementation of advanced manufacturing technology (AMT). This, in today’s volatile market environment, ticks all the boxes, in getting the required attention and occupying the whole industry. Advanced technology is involved in producing in masses as demanded by the customer, using latest innovative technologies while setting a new benchmark as well. As far as customization is concerned, AMT has the upper hand as opposed to conventional technology. It has intensified the applications of advanced intelligence systems to enable rapid manufacturing of new products, dynamic response to product demand and real-time optimization of supply chain networking. The benefits achieved by implementing typical advanced technologies are humungous ones. Quality, flexibility, productivity and eco-friendliness are the ones where AMT is in a whole different league as compared to conventional technologies.

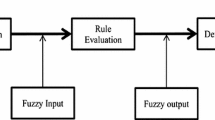

Implementation of AMT involves high level of risk arising from the associated unpredictability. It incorporates phasing out manual labor to a great extent. Instead, it puts money on new equipments, software and, above all, highly customized training of personnel. So, all we need is a decision support system to help manufacturing firms with choosing optimum advanced technology according to their specified requirements. However, in many real-world multi-criteria decision-making (MCDM) problems, human judgment gets subjective. Person concerned, i.e., decision associate (DA) deployed by the manufacturing firm, might be unable to provide crisp estimation in the comparison matrix. Fuzzy MCDM approach handles this kind of situation with a great deal of ease. The linguistic information and triangular fuzzy number (TFN) become the savior in those critical situations. They express a subjective criterion which is otherwise difficult to express in crisp form. In short, TFN and the associated membership function eliminate the uncertainty and fuzziness in an MCDM problem which is otherwise not possible in the crisp data exploration for a subjective criterion. There are some ordinal approaches as well that are not based on TFNs. We have some past researches on sentiment analysis with multi-granular fuzzy linguistic modeling [3], trapezoidal fuzzy numbers [4] and unbalanced fuzzy linguistic information [5] for representation of user information. The present paper converts the linguistic information into fuzzy set [6] comprising of TFNs, by using a suitable conversion scale. It is a prefixed user-defined scale used where incomplete information is prevailing in the system range as well as design range [7, 8]. The common region of these two is depicted by the overlapped portion of the two TFNs [9], in Fig. 2. Subsequently, the weightage factor in decision-making is introduced with the likes of some past researches such as minimum cost strategic weight manipulation with the mixed 0–1 linear programming [10] and heterogeneous preference relation in group decision-making with individual concerns [11].

So, the main contribution of the algorithm is the consideration of uncertainty in Taguchi loss function and a comparison with the fuzzy VIKOR method thereafter. No work has been reported till date regarding the same. In this aspect, the model can be treated as a novel one.

The rest of the paper is arranged as follows: Literature survey for AMT assessment model is presented in Sect. 2. The research background of the proposed model is presented in Sect. 3. The framework is presented in Sect. 4. Section 5 elaborates a case study followed by post-optimality treatment of the parameters. Section 6 analyzes the applicability and validation of the proposed model by comparing the outcome with a well-established VIKOR (Serbian language: VlseKriterijumska Optimizacija I Kompromisno Resenje) method. Last but not the least, Sect. 7 brings the conclusion of the research.

Literature Survey for AMT Assessment Model

This section contains the most recent developments in the world of manufacturing, incorporating the newest ideas and features and some recently proposed algorithms. There have been a handful of researches undertaken in recent times for the performance assessment of AMTs by MCDM approach. Nath and Sarkar [12] exhibited a distance-based fuzzy technique for ordered preference by similarity to the ideal solution (TOPSIS) method for the performance evaluation of AMT. Fernandez and Perez [13] analyzed and brought out a model of emerging occupational risks in the context of advanced technology innovation. Teti [14] proposed a model for manufacturing pertaining to zero defect in machining with a unique solution of signal processing and decision theory. Rohrmus et al. [15] came up with a model of advanced carbon-based manufacturing with environment-friendly green raw materials and green production to contribute to a safer and greener future. Efthymiou et al. [16] introduced a semantic technology approach that could facilitate the knowledge storage and extraction in terms of past production processes configuration for manufacturing systems design and planning. Nath and Sarkar [17] developed a Denovo approach for the performance evaluation of AMTs. They made a comparative study of two MCDM tools, namely preference ranking organization method for enrichment evaluations (PROMETHEE) and Dempster–Shafer theory of evidence (DST) based on the basic ideas of TOPSIS. Chuu [18, 19] proposed models on group decision-making by fuzzy multi-attribute analysis for the evaluation of advanced technology. The mathematical frameworks involved a fusion method of fuzzy information that was performed by maximum entropy-ordered weighted averaging (MEOWA) operators. A scientific approach involving analytic hierarchy process (AHP) and fuzzy AHP as MCDM tools was presented by Al-Ahmari [20] for the selection and evaluation of AMTs. The suggested methodology combined two databases, namely manufacturing organization database and AMTs database for the upliftment of the model. Ahmed et al. [21] addressed a multi-period investment problem for selection, acquisition and allocation of alternative manufacturing technology over a long-range planning horizon by applying linear programming (LP) relaxation solution of a multi-period mixed-integer programming, capacity shifting heuristic and probability analysis. A multi-criteria mathematical model based on data envelopment analysis (DEA) and assurance region (AR) was formed by Liu [22] for the selection of flexible manufacturing systems. A group decision-making model based on consensus was developed by Choudhury et al. [23] for the selection of advanced technology. They used proximity measure, consensus measure and multi-agent system (MAS)-based negotiation to resolve the problem. Yurdakul [24] integrated AHP and goal programming to develop a model for the selection of computer-integrated manufacturing (CIM) in a multi-attribute environment. A distance-based fuzzy MCDM approach was proposed by Karsak [25] for evaluating flexible manufacturing system alternatives. Both the economic figure of merit and the strategic performance variables were integrated in the said approach for making it a robust decision-making procedure. A fuzzy multiple objective programming approach for the selection of flexible manufacturing system was presented by Karsak and Kuzgunkaya [26]. They incorporated fuzzy set theory in the model to cope with the vague nature of future investments and the uncertainty of the production environment. Yusuff et al. [27] tried their hands in developing a preliminary study based on the potential usage of AHP in predicting AMT implementation. The whole implementation process was segregated into four main modules, namely the institutionalization, acceptance, routinization and infusion modules. Kengpol and O’Brien [28] showcased a rapid product development tool by assessing the value of investment in time compression technologies, in a mathematical model that used data structure monitoring with AHP and statistical analysis. Karsak and Tolga [29] developed a fuzzy decision algorithm for the implementation of advanced manufacturing system. Preference ratings of experts for economic, strategic criteria and alternatives were aggregated in measuring fuzzy suitability indices and subsequent ranking of alternatives. Chan et al. [30] suggested an evaluation methodology using fuzzy MCDM, AHP and fuzzy cash flow analysis in going for the selection of optimum technology. They incorporated a factor, namely fuzzy appropriate index in the problem.

There are a few research works carried out on VIKOR as well. A fuzzy model on analytic network process (ANP) in integration with the VIKOR method was proposed by Demirel and Yucenur [31] for the selection of cruise port site. The study also compared the fuzzy ANP and VIKOR method results. Fouladger et al. [32] proposed a project portfolio selection model based on the implementation of an organized framework in fuzzy VIKOR platform. A group MCDM model using fuzzy VIKOR was proposed by Mirahmadi and Teimoury [33] for the selection and evaluation of suppliers. Ramachandran and Alagumurthi [34] proposed fuzzy VIKOR approach for lean manufacturing facilitator selection problem. This method provided the advantage of taking decision which was closer to the ideal solutions. Samantra et al. [35] developed a supplier selection model based on the application of the VIKOR method combined with fuzzy logic.

There are some recently proposed algorithms as well that could contribute in the likes of the current research. Modiri-Delshad et al. [36] presented a backtracking search algorithm (BSA) contemplating valve-point loading effects, prohibited operating zones, multiple fuel options while facing difficulties in economic dispatch (ED). This algorithm can explore search space in an optimization problem to find out the optimal solution in a very short computational time. Kaboli et al. [37, 38] proposed two different algorithms in forecasting long-term electrical energy consumption. One of them used optimized gene expression programming (GEP) and the other one used artificial cooperative search algorithm. A multi-objective metaheuristic particle swarm optimization (PSO) algorithm was proposed by Rafieerad et al. [39] in view of improving mechanical, tribological, anti-corrosion and in vitro bioactivity properties of the nanostructured implants. A nature-influenced algorithm relying on behavior of raindrops, namely rainfall optimization (RFO), in addition to ED algorithm, was proposed by Kaboli et al. [40] in solving constrained optimization problems. Asadi et al. [41] proposed a fuzzy logic control-based algorithm, applied on Li-Ion battery charger, for the performance optimization of charging process. Hlal et al. [42] proposed a mathematical model based on non-dominated sorting genetic algorithm (NSGA-II) and multi-objective particle swarm optimization (MOPSO) for sizing of a hybrid renewable energy storage system as an alternative to fossil fuel-based generators.

Thus, the motto of this survey is to provide an outlook about the different methods and techniques developed for the successful implementation of AMT, thereafter, applications of Taguchi loss function and VIKOR method. The survey successfully establishes the fact that a fair number of research works are being done, to cope with the uncertainty and fuzziness associated with the successful implementation of AMT in a manufacturing establishment.

Background Knowledge

This section presents the background of the current research work undertaken.

The Fuzzy Decision Matrix

A fuzzy preference is represented by decision matrix of the following form:

The five elements of the matrix are as follows:

- (i)

Alternatives, i.e., AMT1, AMT2… AMTm.

- (ii)

\(m\) Numbers of alternatives.

- (iii)

Criteria selected, i.e., CR1, CR2… CRn.

- (iv)

\(n\) Numbers of criteria.

- (v)

Criteria values of alternatives, assigned by the DAs in linguistic values due to the subjectivity, uncertainty and fuzziness present in the problem. In turn, these are converted to TFNs \(\emptyset_{ij} = (a_{ij} ,b_{ij} ,c_{ij} )\) using suitable conversion scales. \(i = 1,2 \ldots m:{\text{no}}.\,{\text{of}}\,{\text{alternatives;}}\,j = 1,2 \ldots n:{\text{no}}.\,{\text{of}}\,{\text{criteria}}\)

The weight matrix consisting of the criteria weights is given by the following:

\(\begin{array}{*{20}c} {\check{\omega} = [\check{\omega}_{1}} & {\begin{array}{*{20}c} {\check{\omega}_{2}} & \ldots \\ \end{array}} & {\check{\omega}_{n }} \\ \end{array}]\emptyset_{ij} = (a_{ij},b_{ij},c_{ij})n\), where \(\check{\omega}_{j } = \left({\omega_{aj}, \omega_{bj}, \omega_{cj} } \right)\) are the TFNs for criteria weights assigned by DAs for n numbers of criteria.

Triangular fuzzy number (TFN)

A TFN eliminates the fuzziness prevailing in a problem. A TFN ‘\(\emptyset_{ij}\)’ is presented by a triplet (Fig. 3) such as \(\emptyset_{ij} = (a_{ij} ,b_{ij} ,c_{ij} )\) where \(a_{ij}\) is the lower limit and \(c_{ij}\) is the upper limit. The membership function \(f_{A} \left( x \right)\) of the TFN follows the conditions noted [43]:

Taguchi Loss Functions

The concept of Taguchi loss function is somewhat different from the traditional loss function popularly known as goal post view (Fig. 4) [44]. Upper specification limit (USL) and lower specification limit (LSL) are the goal posts in the traditional loss function. If the product feature falls within the limit of the designed specifications, it is taken to be of acceptable quality no matter what the deviation is from the center. On the contrary, the same gets rejected if it does not meet the designed specifications. Taguchi suggested a restricted and more focused perspective of characteristic acceptability and indicated that any departure from a preset target value resulted in a loss [45]. According to him, quality can only be defined in terms of the amount of financial loss incurred to the society. It is a graphical representation of how an increase in variation within the specified limits leads to an exponential increase in customer dissatisfaction. A characteristic measurement equal to the target value incurs zero loss. The loss, otherwise, is measured by quadratic functions and measures ought to be taken to minimize the divergence from the targeted zone [46]. The formulation of Taguchi identifies the losses incurred even before a product is shipped [47].

Three types of loss functions [48] could be assimilated depending on the variation in product characteristic. The first one, i.e., nominal is better approach, fixes the target region, either at the center (two-sided equal specification loss function) or allows for nominal shift in both directions from the center (two-sided with specification preference loss function) as shown in Figs. 5 and 6, respectively. The loss is depicted by a quality loss function, and it follows a parabolic curve mathematically given by Eq. 1 as follows:

where \(f_{\text{l}}\) corresponds to the loss incurred, \(l\) is the loss coefficient, \(k\) is the actual size of the product and \(y\) is the nominal value of the specification.

If the difference between actual size and nominal value, i.e., \(k\) − \(y\) is large, loss would be more, irrespective of tolerance specifications. The loss function in Eq. 1 holds good for a single product. But for multiple products, there is slight variation in the loss function and is given by Eq. 2:

where \(V^{2}\) represents the variance of product size and \(\bar{k}\) be the average product size and other variables remain the same as in Eq. 1.

The second one, i.e., smaller is better approach, corresponds to one-sided LSL and the third one, i.e., higher is better approach, corresponds to one-sided USL, as shown in Figs. 7 and 8, respectively. They confront to Eqs. 3 and 4, respectively, as follows:

Taguchi loss function can be used for non-manufacturing applications as well. Liao and Kao [49] developed an MCDM model based on multi-choice goal programming, Taguchi loss function and AHP for selection of supplier. The proposed method allowed decision makers to set multiple aspiration levels for the decision criteria. A robust optimization approach utilizing Taguchi loss function was developed by Ramakrishnan and Rao [50] for solving nonlinear optimization problem. Sharma and Balan [51] developed a supplier selection model with different criteria levels, by integrating TOPSIS, Taguchi loss function and multi-criteria goal programming. They integrated different criteria levels to select the best performing supplier from a number of given options. A mathematical model using Taguchi loss function and principal component analysis (PCA) was developed by Antony [52] for optimizing a multivariate multi-response problem.

The Proposed Methodology

We have discussed various steps of the proposed model in this section. A unified framework for the model is depicted in Fig. 9. The procedural steps are as follows:

Step 1 Formation of decision committee having \(k_{n}\) number of DAs.

Step 2 Ascertainment of the alternatives and the important criteria describing the alternatives.

Step 3 Construction of decision matrix by defining the criteria values as linguistic values and subsequently converting to TFNs. A conversion scale in the range of 0–10 is used here as given in Table 1. Conversion of aggregated criteria weights into TFNs by scale bearing values between 0 and 1 is given in Table 2.

Table 1 Linguistic values for weights of alternatives Table 2 Linguistic values for weights of criteria Step 4 Measure of criteria values of alternatives and the importance weights of criteria by simple arithmetic mean as in Eqs. 5 and 6, respectively:

$$\emptyset_{ij} = [\emptyset_{ij}^{1} + \emptyset_{ij}^{2} + \cdots + \emptyset_{ij}^{{k_{n} }} ]/k_{n} ,$$(5)where \(i = 1,2 \ldots m:{\text{no}}.\,{\text{of}}\,{\text{alternatives}};\,j = 1,2 \ldots n:{\text{no}}.\,{\text{of}}\,{\text{criteria}},k_{n} = {\text{no}}.\,{\text{of}}\,{\text{members}}.\)

$$\check{\omega}_{j} = [\check{\omega}_{j}^{1} + \check{\omega}_{j}^{2} + \cdots + \check{\omega}_{j}^{k}]/k_{n},\check{\omega}_{j} = \left({\check{\omega}_{aj,} \check{\omega}_{bj},\check{\omega}_{cj}} \right) {\text{is}}\,{\text{the}}\,{\text{TFN}}\,{\text{for}}\,{\text{weight}}\,{\text{vector}}$$(6)Step 5 Normalized TFNs for weight vectors are calculated and converted into crisp values as in Eqs. 7 and 8:

$$\omega_{j} = \check{\omega}_{j}/\sum \check{\omega}_{j},\omega_{j} = \left({\omega_{aj},\omega_{bj},\omega_{cj}} \right)\,{\text{is}}\,{\text{the}}\,{\text{normalised}}\,{\text{TFN}}\,{\text{for}}\,{\text{weight }}\,{\text{vector}}$$(7)$$w_{j} = \left( {\omega_{aj} + \omega_{bj} + \omega_{cj} } \right)/3,w_{j} = {\text{crisp}}\,{\text{value}}\,{\text{of}}\,{\text{weight}}\,{\text{vector}}$$(8)Step 6 Normalization of the decision matrix; the normalized TFNs are represented by \(\emptyset_{ij}^{N} = \left( {a_{ij}^{N} , b_{ij}^{N} , c_{ij}^{N} } \right)\). The generating equations for benefit and cost criteria are presented in Eqs. 9 and 10, respectively:

$$\emptyset_{ij}^{N} = \left( {a_{ij}^{N} , b_{ij}^{N} , c_{ij}^{N} } \right) = \left( {{\raise0.7ex\hbox{${a_{ij} }$} \!\mathord{\left/ {\vphantom {{a_{ij} } {c_{j}^{*} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${c_{j}^{*} }$}}, {\raise0.7ex\hbox{${b_{ij} }$} \!\mathord{\left/ {\vphantom {{b_{ij} } {c_{j}^{*} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${c_{j}^{*} }$}}, {\raise0.7ex\hbox{${c_{ij} }$} \!\mathord{\left/ {\vphantom {{c_{ij} } {c_{j}^{*} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${c_{j}^{*} }$}}} \right);\quad c_{j}^{*} = \hbox{max} c_{ij}$$(9)$$\emptyset_{ij}^{N} = \left( {a_{ij}^{N} , b_{ij}^{N} , c_{ij}^{N} } \right) = \left( {{\raise0.7ex\hbox{${a_{j}^{ - } }$} \!\mathord{\left/ {\vphantom {{a_{j}^{ - } } {c_{ij} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${c_{ij} }$}}, {\raise0.7ex\hbox{${a_{j}^{ - } }$} \!\mathord{\left/ {\vphantom {{a_{j}^{ - } } {b_{ij} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${b_{ij} }$}}, {\raise0.7ex\hbox{${a_{j}^{ - } }$} \!\mathord{\left/ {\vphantom {{a_{j}^{ - } } {a_{ij} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${a_{ij} }$}} } \right); \quad a_{j}^{ - } = \hbox{min} a_{ij}$$(10)Step 7 Combining the fuzzy normalized values with the loss function. Calculating Taguchi loss value (\(L_{ij}\)) of the alternatives in fuzzy form, thereby not losing any information that was contained in the problem at the beginning. Specification limits of decision criteria and fuzzy values of alternatives are integrated to achieve the same.

Step 8. Calculating the fuzzy weighted Taguchi loss value (\({\text{WL}}_{i}\)) for each alternative. The generating equation is provided in Eq. 11 as follows:

$${\text{WL}}_{i} = \mathop \sum \limits_{j = 1}^{n} (L_{ij } *w_{j} ),\,{\text{WL}}_{i} = \left( {{\text{WL}}_{ai} ,{\text{WL}}_{bi} ,{\text{WL}}_{ci} } \right)\,{\text{is}}\,{\text{the}}\,{\text{TFN}}\,{\text{for}}\,{\text{weighted}}\,{\text{Taguchi}}\,{\text{loss}}.$$(11)Step 9 Defuzzification [43] of weighted Taguchi loss value as in Eq. 12 and ranking of alternatives based on the same. The lower the value, the higher the ranking.

$${\text{Crisp}}\,{\text{WL}}_{i} = \left( {{\text{WL}}_{ai} + 4* {\text{WL}}_{bi} + {\text{WL}}_{ci} } \right)/6$$(12)Step 10 The assistance of knowledge base and market survey is extracted by the DAs for the installation costs (\(R_{i}\)) of the AMTs. The same is introduced as the objective factor in the mathematics. Calculation of the objective factor measure (\({\text{OFM}}_{i}\)) is carried out by Eq. 13:

$${\text{OFM}}_{i} = \left[ {R_{i} \times \sum \frac{1}{{R_{i} }}} \right]^{ - 1}$$(13)Step 11 Calculating the evaluation index (\({\text{EI}}_{i}\)) for each alternative as in Eq. 14 as proposed by Bhattacharya et al. [53]. Subsequent ranking of the AMTs based on the same. Higher values of \({\text{EI}}_{i}\) produce better ranking of alternatives.

$${\text{EI}}_{i} = \left( {\gamma * {\text{SFM}}_{\text{i}} } \right) + \left( {1 - \gamma } \right)\left( {{\text{OFM}}_{i} } \right);{\text{SFM}}_{i} = {\text{subjective}}\,{\text{factor}}\,{\text{measure}} = {\text{WL}}_{i}^{ - 1}$$(14)where \(\gamma\) = coefficient of cognition; \({\text{SFM}}_{\text{i}} = {\text{Subjective factor measure }}\) for the AMTs.

These above-mentioned steps are utilized by the DAs of three individual decision committees separately to find out three different solutions to the given problem.

A Case Study

The establishment of the proposed model through a real-life case study is presented in this section.

Experimental Setting

The present paper represents a formulation of performance assessment problem of five preselected AMTs. For the purpose of assessment, three decision committees, namely K1, K2 and K3, are formed. They involve a certain number of DAs in the decision committees. All of them are from different virtuosities having considerable experience and expertise to deal with any problem scenario. The overall spectrum of the DAs included in the decision committees is presented in Table 3. The DAs of each decision committee are assigned with the responsibility of the whole assessment process. They go through a number of brainstorming sessions for several hours to get the desired outcome. They initially choose criteria like quality loss, delay in order delivery, operational flexibility and environ safety. At a later stage, they incorporate the installation costs of the AMTs in the form of objective factor measure (OFM) and make ranking as per the values of evaluation indices (EIs). Three different ranking sequences are obtained for the three decision committees. Post-optimality treatment of the parameters is also accomplished for the decision committees by instituting a new factor, i.e., coefficient of cognition, \(\gamma\). The value of the same has to be set between 0 and 1. The cognitive minds of the DAs play a pivotal role in taking comprehensive decision. Explicit knowledge of all the DAs is known and certain. But what’s about their tacit knowledge? Submerged iceberg could represent the tacit knowledge that includes attitude, emotion, commitment and empathy of individual DA. These are the things we cannot judge from outside. That’s why, variation is found in decision-making among the DAs. An optimistic DA sets a high value of \(\gamma\). On the other hand, the value of the same is less for a pessimistic approach. The cognitive mind of the DA is like that iceberg comprising of explicit and tacit knowledge as shown in Fig. 10.

The higher officials of a manufacturing firm would like to implement AMT as it has the leading edge in manufacturing environment worldwide at this day and age. They are forced to efficiently customize their products in a cost-effective manner while keeping the customer satisfaction intact. A successful implementation of AMT offers great productivity, flexibility and profitability. But, on the other hand, implementation of AMT leads to replacing a good amount of manual labor with automated systems requiring large capital investment. It could be a nightmare for the firm if the project goes wrong. So, considering the scenario, the officials formed three decision-making committees. The three decision committees involved four, three and four DAs, respectively, having different profiles and varied fields of expertise. They have given the responsibility to come to a solution individually although the chosen decision criteria and alternatives are same for all of them. There are five alternatives, namely AMT1, AMT2, AMT3, AMT4 and AMT5, among which the optimum selection should be implemented in the firm. They DAs choose four selection criteria which are the most important ones in the given scenario. Two of them are non-beneficial criteria, supposed to be minimized, namely product quality loss (CR1) and delay in order delivery (CR3). The other two are beneficial ones, ought to be maximized, namely operational flexibility (CR2) and environ safety (CR4). The range, target value and specification limits of the decision criteria are given in Table 4 based on the past literature by Pi and Low [45]. From quality perspective, the DAs could set the values according to the convenience and requirement of the firm. They set the percentage target loss at zero, and USL could be set at 2.5%. On time delivery or no delay is one of the most important aspects of AMT implementation. The firm could incur huge loss if there is delay in order delivery. So, the specification limit is set to a maximum of four working days delay, i.e., four working days delay will incur 100% loss. For flexibility, the loss will be zero if flexibility is 100%. The specification limit is set to 65%, i.e., loss will be 100% if the flexibility goes down to 65%. The fourth criteria, environ safety, gets a lot of attention in changing global environment. The outcomes of the AMTs have to be environment-friendly and could save natural environment of surroundings without creating any health hazard to the people. The specification limit, in this case, is set to 80%, at which the loss will be 100%.

Operational Steps

The weights for the decision criteria and values of alternatives are given by DAs of three committees distinctively, as in Tables 5 and 6. The uncertainty and fuzziness associated with the subjective factors can be coped with the introduction of linguistic variables. Thus, the decision matrix is formed with the same. This is, then, converted into TFNs, as in Table 7 and normalized to get unit-free values, as in Table 8. Weights of decision criteria are converted into crisp numerical values corresponding to the DAs of different committees. Taguchi loss function is then put to use according to the nature of individual criterion. The values of loss coefficient are identified as 160,000, 6.25, 42.25, 64 for the decision criteria, following Eqs. 3 or 4, depending on the beneficial or non-beneficial nature. The values are integrated with decision matrix to measure fuzzy loss values of alternatives, exhibited in Table 9. Weights of decision criteria are incorporated with the loss values to find out fuzzy weighted loss of alternatives given in Table 10. The fuzzy attributes values till the later stage of the problem-solving phase helped in keeping the much required information initially contained in the problem. The values are lastly defuzzified to get a comprehensive ranking of the alternatives. The same is presented in Table 11. The lower the weighted loss value, the higher the ranking of the alternative.

Although the basic reasons to implement AMT system is to enhance productivity, quality, flexibility, etc., the ultimate rationale has to be established with economy. The DAs go through market survey and their knowledge base to fix the installation costs of the AMTs as given in Table 12. A mathematical model combining cost-factor components with weighted loss values is established, the basic of which is proposed by Bhattacharya et al. [53] as mentioned earlier. As weighted loss is a minimization function, the inverse of the same is considered as subjective factor measure, to be maximized. In doing so, the cognitive minds of DAs are also analyzed and coefficient of cognition (\(\gamma\)) value is set as 0.67. \(\gamma\) is the measure of positivity in a DA. It makes a balance between the subjective and the objective factor associated with a decision problem. The higher the value, the more optimistic is the DA. So, the value 0.67 is regarded as the mean of the optimism expressed by the DAs across each decision committee. The final deciding factor, i.e., the evaluation indices, is calculated for the AMTs by three decision committees following Eq. 14. The corresponding values and finalized rankings are presented in Table 13. The optimum selection decision is same throughout the committees, and the selection is AMT5.

Post-optimality Treatment

Post-optimality treatment, as the name suggests, is carried out only after the optimum solution to the problem is reached. It is carried out to establish the robustness of the proposed model and also termed as sensitivity or uncertainty analysis. It is used to determine the sensitivity of the model to changes in the input parameters. Any vagueness at the level of input data is managed by TFNs. At the design level, this is carried out by post-optimality analysis. In the presented model, post-optimality treatment is carried out owing to establish a design range for coefficient of cognition (\(\gamma\)), over which we can have optimum selection. This has something to do with the cognitive mind of DAs. This expresses the positivity or the negativity of the DAs. If the group of DAs is optimistic in nature, they see opportunities in challenges. And, the \(\gamma\) value tends to move to the higher side, getting close to 1. On the other hand, a pessimistic group could find out problems even in opportunities and the \(\gamma\) value could move to the lower side close to 0. The value of \(\gamma\) in the present problem is set to 0.67. Post-optimality treatments for three different decision committees are portrayed in Figs. 11, 12 and 13, respectively. The analysis of the same is presented in Table 14.

Application and Result Analysis

The current section presents the applicability of the proposed method in comparison with others and analysis of the result thereafter. It is a bit tedious task to make sure that a new kid on the block is having more competitive advantage than the other big guns, and that, it has got robustness. To prove the same, we have pitted the proposed method with a well-established fuzzy VIKOR method and exhibited the comparison result. We have compared the findings of decision committee K3, of the proposed method, with fuzzy VIKOR, to get an overall understanding about the applicability and practicality of the same.

VIKOR (Serbian language: VlseKriterijumska Optimizacija I Kompromisno Resenje) is a multi-criteria optimization and compromise solution, first showcased by S. Opricovic in his PhD defense in the year 1979. An application of the same was published later in 1980 [54] with a view to solve decision problems with conflicting criteria with acceptable agreement for conflict resolution. VIKOR brings in compromised solution that is the closest to the ideal condition and provide ranking of alternatives. Compromise solution in MCDM was first introduced by Yu [55] and Zeleny [56]. The real applications of VIKOR were presented in 1998 [57], and eventually, it was internationally recognized [58].

The steps of fuzzy VIKOR include the following:

Step 1 Aggregation of fuzzy weights of criteria into TFNs (Table 15) and criteria values of alternatives by following Eqs. 5 and 6.

Table 15 Weights of criteria in TFNs, best fuzzy value and worst fuzzy value (VIKOR) (Committee K3) Step 2 Formation of fuzzy decision matrix as given in Table 7 earlier, same as that of our proposed method.

Step 3 Determination of best fuzzy values \(f_{i}^{*}\) and worst fuzzy values \(f_{i}^{ - }\) for all the selected criteria, where \(f_{j}^{*} = \hbox{max} \emptyset_{ij} ,\) if the \(j{\text{th}}\) criterion is beneficial in nature and \(f_{j}^{ - } = \hbox{min} \emptyset_{ij} ,\) if the \(j{\text{th}}\) criterion is non-beneficial in nature. The same is presented in Table 15.

Step 4 Computation of weighted and normalized Manhattan distance (\(M_{i}\)), weighted and normalized Chebyshev distance (\(C_{i}\)), by following Eqs. 15 and 16:

$$M_{i} = \sum w_{j} \left( {f_{j}^{*} - \emptyset_{ij} } \right)/\left( {f_{j}^{*} - f_{j}^{ - } } \right)$$(15)$$C_{i} = { \hbox{max} }[\sum w_{j} \left( {f_{j}^{*} - \emptyset_{ij} } \right)/\left( {f_{j}^{*} - f_{j}^{ - } } \right)]$$(16)The same is displayed in Table 16.

Table 16 Values of Si and Ri (Committee K3) Step 5 Calculating the index values of AMTs (\(\check{Q}_{i}\)) for the three limits, by following Eq. 17:

$$\check{Q}_{i} = \nabla \left({M_{i} - M^{*}} \right)/\left({M^{-} - M^{*}} \right) + \left({1 - \nabla} \right)\left({C_{i} - C^{*}} \right)/\left({C^{-} - C^{*}} \right)$$(17)where \(M^{*} = \hbox{min} M_{i} ,M^{ - } = \hbox{max} M_{i } ,C^{*} = \hbox{min} C_{i} ,C^{ - } = \hbox{max} C_{i} ;\)

Calculating the average index value, \(Q_{i} = \check{Q}_{i}/3,\) and, inverse of, i.e.,\(Q_{i}^{*}\), \(Q_{i}^{*} = Q_{i}^{ - 1}\). These values are presented in Table 17.

Table 17 Index values (\(Q_{i}\)) (Committee K3) \(\nabla\) is the maximum group utility, i.e., strategic weight for the majority of criteria. The strategies arrive to a compromise solution by taking \(\nabla\) as 0.5.

Step 6 The index value in VIKOR follows the lower the better principle. So, the inverse of the average index values (\(Q_{i}^{*}\)) is taken as the subjective factor measure. On the contrary, the implementation cost of alternative (Table 12) is taken into account to get the measure of objective factor (\({\text{OFM}}_{i}\)) by Eq. 13 presented earlier.

Step 7 Calculating the VIKOR selection Index (\({\text{VSI}}_{i}\)) for each alternative by following Eq. 18:

$${\text{VSI}}_{i} = \left( {\gamma * {\text{SFM}}_{i} } \right) + \left( {1 - \gamma } \right)\left( {{\text{OFM}}_{i} } \right)$$(18)where \({\text{SFM}}_{\text{i}}\) = subjective factor measure = \(Q_{i}^{*}\), \(\gamma\) = coefficient of cognition mentioned earlier in Sect. 4.

Subsequent ranking of the AMTs are determined. Higher value of \({\text{VSI}}_{i}\) betters the ranking of the same. Table 18 shows the values of \({\text{VSI}}_{i}\) and the ranking result as well.

Table 18 VIKOR selection index and final ranking

Experimental Result

The results of the model exhibit that values of evaluation indices for AMT3 and AMT5, measured by committee K1, are pretty close. Although AMT5 retains its winning place carrying forward from the Taguchi weighted loss value, the difference is too marginal. But for the other committees, AMT5 emerges out as a clear and distant winner. The inclusion of cost factor does not change the ranking of the alternatives previously made out of the values of weighted loss. So, the final result is as clear as daylight. The optimum selection is AMT5 although the cost of implementation is a little on the higher side. If an organization is tight on budget, it can choose between AMT3 and AMT4, as they are occupying the second or the third place of priority in the rankings of all the decision committees. Also, the implementation costs of both of them are much lower than that of AMT5. Having said that, it excels highly in all other departments. For this obvious reason, it should be the automatic choice for long run, for any manufacturing organization trying to shift to AMT from traditional ones and get immense benefit out of the same. The post-optimality treatment reveals the desired robustness present in the design of the model. The selection of alternative AMT5 on the values of evaluation index is proving to be the most optimum one in post-optimality treatment too. Almost for the entire range of coefficient of cognition, \(\gamma\), AMT5 remains the only choice. If the value of \(\gamma\) is zero, i.e., the most pessimistic approach, the DAs would make the selection decision based only on cost factor. But, a unit value of \(\gamma\), the most optimistic one, would therefore nullify the cost factor and make the decision only on the basis of Taguchi weighted loss of alternatives for which the lowest value is the most preferable one. The comparison with fuzzy VIKOR clears that the second highest ranked alternative by committee K3 in loss function is the top scorer here in VIKOR, i.e., AMT4. Though the AMT5, the first choice by committee K3 in loss function, is the third choice by the VIKOR method, the difference in overall score is too nominal. So, according to that, AMT5 comes out as the best choice overall in the proposed case study.

Conclusion

Several conclusions have been drawn from the proposed model, and the same has been profoundly discussed in this section. Implementation of AMT by the manufacturing organizations is the need of the hour for achieving sustainable development. Otherwise, gradual decay of the organizations is quite obvious. A framework is proposed in this paper for performance assessment of AMTs using Taguchi loss function to a fuzzy decision model. Some experts in decision-making played a pivotal role in realizing the model. They chose the criteria that could best expound the alternatives from the perspective of the manufacturing firm. Finally, they analyzed the results of the proposed model and rendered their verdict.

The proposed methodology combines Taguchi loss function with the fuzzy decision model, consolidated gain as subjective factor measure of alternatives and the installation cost as objective factor measure of alternatives. It can be implemented successfully in supplier selection, robot selection and many more MCDM problems prevailing in today’s manufacturing scenario. It upped the novelty by drawing in comparison with the traditional VIKOR method.

Also, in Taguchi loss function, fuzziness present in the initial stage is carried forward deep into the problem. We get the Taguchi loss values in terms of TFNs only, during the final legs of the problem solving. Defuzzification is done at a quite later stage. So, the loss of information is significantly less as compared to some traditional decision tools available. The comparison with VIKOR method establishes the same.

The numbers of DAs in decision committees are varying. Expertise of DAs in the committees is not uniform nor their experience. So, there might be slight variation in the end result. But it is in the hand of manufacturing firm, to choose the outcome of a particular committee depending on its own optimized requirements.

Then also, we have the outcome of the post-optimality treatment that could yield a considerable range of \(\gamma\), where the optimum selection for all the committees is same, i.e., AMT5.

On the contrary, it depicts no mathematical comparison between the results obtained from the manuscript and the traditional loss function.

Future scope would include undertaking another form of post-optimality treatment where the weights of criteria would be interchanged and analyzing the final result for the robustness of the problem. This particular research could also be channelized toward investigating group decision-making models in multi-attribute problems under uncertainty and fuzziness. These are considered in cases of fuzziness persistent, be it preliminary stage or be it problem-solving stage.

Lastly, we can say that fuzzy Taguchi loss method with consolidated gain and consolidated loss concept stands right up there and is very much suited for various kinds of critical problems that manufacturing establishments pass through.

Abbreviations

- \(\tilde{D}\) :

-

Decision matrix

- \(\emptyset_{ij = } (a_{ij} ,b_{ij} ,c_{ij} )\) :

-

Triangular fuzzy number

- \(\emptyset_{ij}^{N} = \left( {a_{ij}^{N} , b_{ij}^{N} , c_{ij}^{N} } \right)R_{i}\) :

-

Normalized triangular fuzzy number

- \(\check{\omega}\) :

-

Triangular fuzzy weight matrix

- \(\omega_{j}\) :

-

Normalized triangular fuzzy weight matrix

- \(w_{j}\) :

-

Crisp weight matrix

- \(f_{A} \left( x \right)\) :

-

Fuzzy membership function

- R i :

-

Installation cost for AMT

- \({\text{OFM}}_{i}\) :

-

Objective factor measure of AMTs

- \({\text{SFM}}_{i}\) :

-

Subjective factor measure of AMTs

- \(k_{n}\) :

-

Number of decision associates (DA)

- \(m\) :

-

Number of alternatives

- \(n\) :

-

Number of criteria

- \(\gamma\) :

-

Coefficient of cognition

- \(l\) :

-

Loss coefficient

- \(k\) :

-

Actual product size

- \(y\) :

-

Nominal value of the specification limit

- \(V^{2}\) :

-

Variance of product size

- \(\bar{k}\) :

-

Average product size

- \(L_{ij}\) :

-

Taguchi loss value of AMTs

- \({\text{WL}}_{i} = \left( {{\text{WL}}_{ai} ,{\text{WL}}_{bi} ,{\text{WL}}_{ci} } \right)\) :

-

Fuzzy weighted Taguchi loss value of AMTs

- \({\text{EI}}_{i}\) :

-

Evaluation index

- \(f_{i}^{*}\) :

-

Best fuzzy value

- \(f_{i}^{ - }\) :

-

Worst fuzzy value

- \(M_{i}\) :

-

Weighted and normalized Manhattan distance

- \(C_{i}\) :

-

Weighted and normalized Chebyshev distance

- \({\check{Q}_{i}}\) :

-

Index value of AMT expressed in triangular fuzzy number

- \(\nabla\) :

-

Maximum group utility

- \(Q_{i}\) :

-

Average index value

- \(Q_{i}^{*}\) :

-

Inverse of average index value

- \({\text{VSI}}_{i}\) :

-

VIKOR selection index

References

S. Nath, B. Sarkar, An exploratory analysis for the selection and implementation of advanced manufacturing technology by fuzzy multi-criteria decision making methods: a comparative study. J. Inst. Eng. India Ser. C 98(4), 493–506 (2017)

J. Olhager, The role of decoupling points in value chain management, in Modelling Value. Contributions to Management Science, ed. by H. Jodlbauer, J. Olhager, R. Schonberger (Physica-Verlag HD, Heidelberg, 2012)

J.A. Morente-Molinera, G. Kou, C. Pang, F.J. Cabrerizo, E. Herrera-Viedma, An automatic procedure to create fuzzy ontologies from users’ opinions using sentiment analysis procedures and multi-granular fuzzy linguistic modelling methods. Inf. Sci. 476, 222–238 (2019)

C.-T. Chen, C.-T. Lin, S.-F. Huang, A fuzzy approach for supplier evaluation and selection in supply chain management. Int. J. Prod. Econ. 102, 289–301 (2006)

F.J. Cabrerizo, R. Al-Hmouz, A. Morfeq, A.S. Balamash, M.A. Martínez, E. Herrera-Viedma, Soft consensus measures in group decision making using unbalanced fuzzy linguistic information. Soft. Comput. 21(11), 3037–3050 (2017)

A. Kaufmann, M.M. Gupta, Introduction of Fuzzy Arithmetic: Theory and Applications (Van Nostrand Reinhold, New York, 1985)

M.R. Ureña, F. Chiclana, J.A. Morente-Molinera, E. Herrera-Viedma, Managing incomplete preference relations in decision making: a review and future trends. Inf. Sci. 302, 14–32 (2015)

N. Capuano, F. Chiclana, H. Fujita, E. Herrera-Viedma, V. Loia, Fuzzy group decision making with incomplete information guided by social influence. IEEE Trans. Fuzzy Syst. 26(3), 1704–1718 (2018)

M. Celik, C. Kahraman, S. Cebi, I.D. Er, Fuzzy axiomatic design-based performance evaluation model for docking facilities in shipbuilding industry: the case of Turkish shipyards. Expert Syst. Appl. (2007). https://doi.org/10.1016/j.eswa2007.09.055

Y. Liu, Y. Dong, H. Liang, F. Chiclana, E. Herrera-Viedma, Multiple attribute strategic weight manipulation with minimum cost in a group decision making context with interval attribute weights information. IEEE Trans. Syst. Man Cybern. Syst. (2019). https://doi.org/10.1109/tsmc.2018.2874942

H. Zhang, Y. Dong, E. Herrera-Viedma, Consensus building for the heterogeneous large-scale GDM with the individual concerns and satisfactions. IEEE Trans. Fuzzy Syst. 26, 884–898 (2018)

S. Nath, B. Sarkar, Decision system framework for performance evaluation of advanced manufacturing technology under fuzzy environment. Opsearch (2016). https://doi.org/10.1007/s12597-016-0262-9

F.B. Fernandez, M.A.S. Perez, Analysis and modeling of new and emerging occupational risks in the context of advanced manufacturing processes. Procedia Eng. 100, 1150–1159 (2015)

R. Teti, Advanced IT methods of signal processing and decision making for zero defect manufacturing in machining. Procedia CIRP 28, 3–15 (2015)

D. Rohrmus, V. Döricht, N. Weinert, Green factory supported by advanced carbon-based manufacturing. Procedia CIRP 29, 28–33 (2015)

K. Efthymiou, K. Sipdas, D. Mourtzis, G. Chryssolouris, On knowledge reuse for manufacturing systems design and planning: a semantic technology approach. CIRP J. Manuf. Sci. Technol. 8, 1–11 (2015)

S. Nath, B. Sarkar, Performance evaluation of advanced manufacturing technologies: a denovo approach. Comput. Ind. Eng. 110, 364–378 (2017)

S.-J. Chuu, Selecting the advanced manufacturing technology using fuzzy multiple attributes group decision making with multiple fuzzy information. Comput. Ind. Eng. 57, 1033–1042 (2009)

S.-J. Chuu, Group decision-making model using fuzzy multi-attributes analysis for the evaluation of advanced manufacturing technology. Fuzzy Sets Syst. 160, 586–602 (2009)

A.M.A. Al-Ahmari, A methodology for selection and evaluation of advanced manufacturing technologies. Int. J. Comput. Integr. Manuf. 21(7), 778–789 (2008)

S. Ahmed, N.V. Sahinidis, Selection, acquisition and allocation of manufacturing technology in a multi-period environment. Eur. J. Oper. Res. 189, 807–821 (2008)

S.-T. Liu, A fuzzy DEA/AR approach to the selection of flexible manufacturing systems. Comput. Ind. Eng. 54, 66–76 (2008)

A.K. Choudhury, R. Shankar, M.K. Tiwari, Consensus-based intelligent group decision-making model for the selection of advanced technology. Decis. Support Syst. 42, 1776–1799 (2006)

M. Yurdakul, Selection of computer-integrated manufacturing technologies using a combined analytic hierarchy process and goal programming model. Robot. Comput. Integr. Manuf. 20, 329–340 (2004)

E.E. Karsak, Distance-based fuzzy MCDM approach for evaluating flexible manufacturing system alternatives. Int. J. Prod. Res. 40(13), 3167–3181 (2002)

E.E. Karsak, O. Kuzgunkaya, A fuzzy multiple objective programming approach for the selection of a flexible manufacturing system. Int. J. Prod. Econ. 79, 101–111 (2002)

R.M. Yusuff, K.P. Yee, M.S.J. Hashmi, A preliminary study on the potential use of the analytic hierarchy process (AHP) to predict advanced manufacturing technology (AMT) implementation. Robot. Comput. Integr. Manuf. 17, 421–427 (2001)

A. Kengpol, C. O’Brien, The development of a decision support tool for the selection of advanced technology to achieve rapid product development. Int. J. Prod. Econ. 69, 177–191 (2001)

E.E. Karsak, E. Tolga, Fuzzy multi-criteria decision-making procedure for making advanced manufacturing system investments. Int. J. Prod. Econ. 69, 49–64 (2001)

F.T.S. Chan, M.H. Chan, N.K.H. Tang, Evaluation technologies for technology selection. J. Mater. Process. Technol. 107, 330–337 (2000)

N.C. Demirel, G.N. Yucenur, The cruise port place selection problem with extended VIKOR and ANP methodologies under fuzzy environment, in Proceedings of the World Congress on Engineering, vol II, London, UK (2011)

M.M. Fouladgar, A. Yazdani-Chamzini, S.H. Yakhchali, M.H. Ghasempourabadi, N. Badri, Project portfolio selection using VIKOR technique under fuzzy environment, in 2nd International Conference on Construction and Project Management IPEDR, vol 15 (2011)

N. Mirahmadi, E. Teimoury, A fuzzy VIKOR model for supplier selection and evaluation: case of EMERSUN company. J. Basic Appl. Sci. Res. 2(5), 5272–5287 (2012)

L. Ramachandran, N. Alagumurthi, Lean manufacturing facilitator selection with VIKOR under fuzzy environment. Int. J. Curr. Eng. Technol. 3(2), 356–359 (2013)

C. Samantra, S. Datta, S.S. Mahapatra, Application of fuzzy based VIKOR approach for multi-attribute group decision making (MAGDM): a case study in supplier selection. Decis. Mak. Manuf. Serv. 6(1), 25–39 (2012)

M. Modiri-Delshad, S.H.A. Kaboli, E. Taslimi- Renani, N.A. Rahim, Backtracking search algorithm for solving economic dispatch problems with valve-point effects and multiple fuel options. Energy 116, 637–649 (2016)

S.H.A. Kaboli, J. Selvaraj, N.A. Rahim, Long-term electric energy consumption forecasting via artificial cooperative search algorithm. Energy 115, 857–871 (2016)

S.H.A. Kaboli, A. Fallahpour, J. Selvaraj, N.A. Rahim, Long-term electrical energy consumption formulating and forecasting via optimized gene expression programming. Energy 126, 144–164 (2017)

A.R. Rafieerad, A.R. Bushroa, B. Nasiri- Tabrizi, S.H.A. Kaboli, S. Khanahmadi, A. Amiri, J. Vadivelu, F. Yusof, W.J. Basirun, K. Wasa, Toward improved mechanical, tribological, corrosion and in vitro bioactivity properties of mixed oxide nanotubes on Ti–6Al–7Nb implant using multi-objective PSO. J. Mech. Behav. Biomed. Mater. 69, 1–18 (2017)

S.H.A. Kaboli, J. Selvaraj, N.A. Rahim, Rain-fall optimization algorithm: a population based algorithm for solving constrained optimization problems. J. Comput. Sci. 19, 31–42 (2017)

H. Asadi, S.H.A. Kaboli, A. Mohammadi, M. Oladazimi, Fuzzy-control-based five-step Li-ion battery charger by using AC impedance technique, in Fourth International Conference on Machine Vision (ICMV 2011): Machine Vision, Image Processing, and Pattern Analysis, vol 8349 (International Society for Optics and Photonics, 2012)

M.I. Hlal, V.K. Ramachandaramurthya, S. Padmanaban, H.R. Kaboli, A. Pouryekta, T.A.R.B.T. Abdullah, NSGA-II and MOPSO based optimization for sizing of hybrid PV/wind/battery energy storage system. Int. J. Power Electron. Drive Syst. 10(1), 463–478 (2019)

H.J. Zimmermann, Fuzzy Set Theory and Its Applications (Kluwer, Boston, 1991)

T.L. Albright, H.P. Roth, Managing quality through the quality loss function. J. Cost Manag. (Winter) 7(4), 20–37 (1994)

W.-N. Pi, C. Low, Supplier evaluation and selection using Taguchi loss functions. Int. J. Adv. Manuf. Technol. 26, 155–160 (2005)

R.B. Kethley, B.D. Waller, T.A. Festervand, Improving customer service in the real estate industry: a property selection model using taguchi loss functions. Total Qual. Manag. 13(6), 739–748 (2002)

C. Quigley, C. McNamara, Evaluating product quality: an application of the taguchi quality loss concept. Int. J. Purch. Mater. Manag. 28(3), 19–25 (1992)

P.J. Ross, Taguchi Techniques for Quality Engineering, 2nd edn. (McGraw Hill Professional, New York, 1996)

C.-N. Liao, H.-P. Kao, Supplier selection problem using Taguchi loss function, analytic hierarchy process and multi-choice goal programming. Comput. Ind. Eng. 58(4), 571–577 (2010)

B. Ramakrishnan, S.S. Rao, Robust optimization approach using Taguchi’s loss function for solving nonlinear optimization problems, in American Society of Mechanical Engineers, ed. By Design Engineering Division (Publication) DE, pt 1 ed., vol 32 (ASME, New York, 1991), pp. 241–248

S. Sharma, S. Balan, An integrative supplier selection model using Taguchi loss function, TOPSIS and multi criteria goal programming. J. Intell. Manuf. 24, 1123–1130 (2013)

J. Antony, Multi-response optimization in industrial experiments using Taguchi’s quality loss function and principal component analysis. Qual. Reliab. Eng. Int. 16, 3–8 (2000)

A. Bhattacharya, B. Sarkar, S.K. Mukherjee, Integrating AHP with QFD for robot selection under requirement perspective. Int. J. Prod. Res. 43(17), 3671–3685 (2005)

L. Duckstein, S. Opricovic, Multiobjective optimization in river basin development. Water Resour. Res. 16(1), 14–20 (1980)

P.L. Yu, A class of solutions for group decision problems. Manag. Sci. 19(8), 936–946 (1973)

M. Zeleny, Compromise programming, in Multiple Criteria Decision Making, ed. by J.L. Cochrane, M. Zeleny (University of South Carolina Press, Columbia, 1973)

S. Opricovic, Multicriteria Optimization in Civil Engineering (in Serbian) (Faculty of Civil Engineering, Belgrade, 1998), p. 302, ISBN 86-80049-82-4

S. Opricovic, G.-H. Tzeng, The Compromise solution by MCDM methods: a comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 156(2), 445–455 (2004)

Acknowledgements

The authors acknowledge the support of Jadavpur University, Kolkata, India, and Calcutta Institute of Engineering and Management, Kolkata, India, in carrying out this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nath, S., Sarkar, B. An Integrated Fuzzy Group Decision Support Framework for Performance Assessment of Advanced Manufacturing Technologies: An Eclectic Comparison. J. Inst. Eng. India Ser. C 101, 473–491 (2020). https://doi.org/10.1007/s40032-020-00558-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-020-00558-7