Abstract

This experimental study focuses on the effect of pebbles as an energy storage medium on the performance of a solar distillation system. Two single basin solar stills are fabricated with an effective area of 0.5 m2, the glass cover was tilted at 10° with respect to the horizontal. The experiments on the still were carried out under the same climatic conditions for two different modes of operations, (1) conventional still and (2) modified still (pebbles as storage medium). From the study, it could be concluded that (1) the productivity of solar still is increases 9.5 % when pebbles are used as storage medium (2) the maximum amount of heat losses occurs in the solar still is the combined effect of radiation and convection heat transfer from glass to ambient (3) pebbles have the potentiality to store the heat during high solar intensity period and to release the stored energy to water when the solar intensity is low.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

From 16th century, uses of solar stills are a cheap and easy method for procuring clean water. A resurgence of interest has occurred recently with work focused on methods for increasing the still efficiency and production rate. The root cause focus for achieving high efficiency would be the temperature difference between the water in the basin and the glass cover and reduction of heat lost to the surroundings. Productivity enhancement of this process was one of the main goals of researchers [1–4]. Since the productivity of the solar still increases with increasing the saturation pressure of the water, it is determined by the temperature at the brine surface using layer of black cloth or thin plate to have the uppermost film of water as hot as possible is the best option. A floating porous plate was employed on the brine surface of a deep basin solar still by Doperevsky and Geohieva [5], The results of Doperevsky indicated that a degree of evaporation improvement was obtained, amounting to 30 % at a brine depth of 18 cm. But, at the long run of the experiments, the porous wick material would be clogged by accumulated salt. Bilal et al. [6] studied the effect of using different absorbing materials like black rubber mat, black dye and black ink to enhance the still productivity by 30–40 %. Shukla et al. [7] had used jute cloths for increasing the evaporation rate. One end of the jute cloth was dipped into a water reservoir while the surface of the jute cloth was spread over the basin, exposed to sun rays. They had developed a mathematical model to find the heat transfer coefficients and validate with the experimental values. The effect of muddiness of water in a deep basin type solar still on distillate output was studied by S.O.Onyegegbu [8]. From his study it was found that, the muddy water and clear water samples yielded the same distillate output on a daily (24 h) basis, and the day time the muddy water sample has higher surface temperature, produced more distilled water. Arjunan et al. [9, 10] studied the effect of sponge liner thickness and colors on the performance of the solar still and their result shows that the sponge liners thickness and colors are influences the performance of the solar still considerably. Alaian et al. [11], presented their findings on the performance of solar still amalgamated with pin-finned wick evaporation surface. The experimental measurements indicate that increase in distillate varies with ambient conditions. Enhancing the still productivity is also proved when pin-finned wick is applied in the still. A study on effect of fin configuration parameters on single basin solar still performance was done by EI-Sebaii et al. [12]. From the study, it was found that productivity of the finned plate solar still (FBLS) decreases when increasing the fin thickness and number. The main objective of this study is to improve the performance of the solar still by incorporating pebble as an energy storage material.

Modifications in Solar Still

In the present study, the conventional still is modified to reduce the heat accumulation in the air–vapour space and to store the excess solar energy during sunshine hours for the continuation of the evaporation process at night. For any method of storing heat in solar desalination process to be efficient, the following points should be considered,

-

The temperature of the water in the evaporating zone should not be greatly reduced, and thereby decrease the evaporation rate during the day.

-

Minimum external power should be used in the storing and reclaiming process.

-

The storing technique must be simple, easily available and cheap in order to keep the capital cost of the system as low as possible.

-

Storage medium should have low thermal conductivity to reduce heat loss through the bottom of the still.

For this experimental study a cheap, simple and easily available material, pebble is used as energy storage medium to enhance the productivity of the still. As pebble has lower heat capacity than water and air, its temperature will increase at a faster rate. Heat is then transferred from the pebbles to water by convection. Solar energy during the noon hours is very high. That excess energy will be stored in the pebbles, which will be used to continue the evaporation of saline water during evening and night. As the thermal conductivity of the pebbles is low, it will act as an insulator to reduce the heat loss through sides and bottom of the still.

Experimental Setup

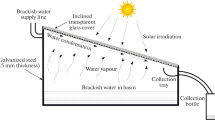

Two simple basin-type solar stills are fabricated with same design parameters, and tested under field conditions at the testing field of the Mechanical Engineering Department, Adhiyamaan College of Engineering, Hosur, Tamilnadu, India. The pictorial view of the single slope single basin solar distillation units are given in Fig. 1. The basin liner is made of galvanized iron sheet of 0.5 × 1 m2 with maximum height of 288 mm, and 1.4 mm thickness. The basin surfaces are painted with black to absorb the maximum amount of solar radiation incident on them. The condenser surface of the still is made of glass with 4 mm thickness and angle of inclination is 10° with horizontal. Glass covers have been framed with wood and sealed with silicon rubber. This has a major role in promoting efficient operation as it can accommodate the expansion and contraction between dissimilar materials. A collecting trough made by G.I. sheet is used in the still to collect the distillate condensing on the inner surfaces of the glass covers and to pass the condensate to a collecting flask. Steel rule is fixed along the inside wall to measure the water level in the basin. The bottom and sides are insulated with 25 mm thick thermocol and 12.5 mm thick wood with thermal conductivity 0.015 and 0.055 W/mK respectively.

The performance of the still is examined during Nov 2008 to Jan 2009 under the same climatic conditions for two different modes of operations: (1) conventional still (2) modified still with pebble as energy storage medium. The pebbles (Fig. 2) are added to the basin water with uniform distribution over the basin liner. As pebbles have lower specific heat capacity than water and air, its temperature would increase at a faster rate and stored as heat at noon time. Later, the stored heat is used to continue the evaporation of saline water when solar energy is low (evening and night time). The thermal conductivity of the pebbles are also low, which will act as an insulator to reduce the heat loss through sides and bottom of the still. The quantity of the pebbles used in the experiments is 5 kg, and the specific heat is 840 kJ/kgK. Based on the recommendation by Arjunan et al. [13], 20 mm water depth was maintained in the basin of the still. During experiments, the temperatures for various locations like water, basin liner, inner and outer wall, ambient and bottom side and solar intensity were recorded every 60 min. The hourly productivity of fresh water is collected through a graduated flask. The daily productivity is obtained as a summation of day and night productivity. The night productivity is the total collection from the end of test to start of test in the next day.

Mathematical Model

The operation of the still is determined any time by using energy balances based on heat and mass transfer relationships. The model attempts to describe the transient behavior of the basin type still. This is given by the energy balance on the glass cover, water in the basin and basin liner. Heat quantities are based on the unit area of the water basin. Figure 3 depicts the energy transfer involved in the still, which have a direct effect on the output.

In order to write the energy balance equations, the following assumptions are made [14]:

-

The level of water in the basin is maintained at constant level.

-

The condensation that occurs at the glass trough is a film type.

-

The heat capacity of the glass cover, the absorbing material, and the insulation material are negligible.

-

No vapor leakage in the still.

-

No temperature gradient along the glass cover thickness and in water depth.

-

The system is in a quasi steady-state condition.

-

The heat capacity of the insulator (bottom and side of the still) is negligible.

Referring Fig. 3, the heat balance equation on basin water, glass cover and basin liner can be written as

Rearranging by substituting basic heat transfer relations, the Eq. (1) becomes,

It is similar to the differential equation format of \(\frac{{dT_{w} }}{dt} + a_{1} T_{w} = f_{1}\); then, the solution of Eq. (4) is

where

where, h tw = h rw + h cw + h rw .

The following assumptions have been made for the solution of Eq. (5);

-

(i)

initial condition for water Tw at t = 0 = Twi;

-

(ii)

f1 is considered as average values of f1 for shorter time intervals.

-

(iii)

The heat transfer coefficient is constant for the time intervals, i.e. a1 is constant.

Similarly Eq. (2) becomes,

where h tg = h cg + h rg .

Rearranging Eq. (3) by using basic equations, the equation becomes,

A computer program has been developed using ‘C’ language for solving the above said nonlinear Eqs. (5), (8) and (9) to predict water temperature, glass temperature and basin liner temperature. The input parameters of the program include climatic, design, operational parameters and relevant thermo-physical parameters are taken from Table 1.

Numerical calculations are initiated assuming the temperatures of different elements of the still to be equal to the ambient temperature at t = 0. Using known initial values for different temperatures, different internal and external heat transfer coefficients are calculated. Employing these values along with climatic parameters, Tw, Tg and Tb are calculated from Eqs. (5), (8) and (9), respectively, for 60 s is used in the simulation. Observing the hourly variation of Tg, Tw and Tb, the procedure is repeated with the new values of Tg, Tw and Tb for a additional time intervals. After knowing Tw and Tg the theoretical hourly yield can be evaluated from equation.

Results and Discussions

The results and discussions for the behaviour and performance of the solar desalination system presented here in the form of graphs. Experiments have been conducted from 9:00 to 17:00 o’clock under the same climatic conditions. In order to do the analysis and comparison fairly the same climatic conditions, the experiment were conducted for a number of days in particular condition to get concurrent results.

The productivity rate varies as time passes from early morning till late afternoon. Figure 4 shows that, the productivity is increases until it reaches the maximum in the afternoon, and decreases in the late afternoon. Due to the absence of energy storage materials, the basin and water temperatures are high in the conventional still during 9:00–12:00 o’clock. This may be reason for higher productivity in conventional still during this period. From 13:00 o’clock onwards the productivity of modified still is high than the conventional still due to the release of extracted heat into water by the pebbles in the morning. It is also noted that, the production at night time (17:00–9:00 o’clock) is high in the pebble still due to its high heat capacity. The total productivity of modified still was 1.25 kg/day which is 9.5 % higher than conventional solar still. It is observed that the theoretical values of the productivity are reasonably matched with the experimental results. The result vividly reveals that, the productivity of the solar stills also depends on the temperature difference between water and glass.

The various energy transfers from the solar still are clearly given in Fig. 5. It is understood that, the energy utilized for converting fresh water (Qd) is high in the modified still than the conventional still due to its higher productivity. Furthermore, the maximum energy loss from the still is at the glass surface by the combination of convection and radiation effect. It was also noted that, unaccountable losses like vapour leakage, reflection losses from sides, absorptivity of glass and water, etc. are more in the conventional still than the modified still.

Conclusion

Based on the experimental results and discussions, it could be concluded that the system has the advantage of using low cost energy storage materials to enhance the still yield and its efficiency. The highest temperature of 81.5 °C is obtained at the inner wall surface, whereas the lowest temperature is recorded at the atmosphere side equal to 28 °C. Energy storage materials in the still store considerable amount of heat during noon hours and release the stored heat to the basin water in the late afternoon hours when radiation is low. Added to it energy storage materials influence the temperature of the solar still components considerably. The basin temperature gets closer to the water temperature, because of the continuous contact between them and leads to heat equilibrium. Furthermore, productivity of the conventional still is higher in the morning whereas the productivity of the modified still is high in the evening hours. The productivity of the solar still is increasing 9.5 % when using pebbles as a storage medium. It was also comprehended that maximum amount of energy losses in the solar still is at glass surfaces by the combination of radiation and convection heat transfer.The theoretical values of the productivity are reasonably matched with the experimental results.

Future Investigations

The following aspects may be considered for the development of this system in future.

-

Optimum size of the pebbles based on its performance.

-

Economic analysis solar still with pebble as an energy storage medium.

Abbreviations

- A:

-

Area of the basin liner (m2)

- Aw :

-

Area of the water surface (m2)

- Cpw :

-

Specific heat of water (kJ/KgK)

- Cw :

-

Heat capacity of basin water (mass × specific heat) (kJ/K)

- hb :

-

Convective heat transfer coefficient from basin liner to water (W/m2K)

- hcg :

-

Convective heat transfer coefficient from glass to ambient (W/m2K)

- hfg :

-

Latent heat of evaporation (kJ/kg)

- hrg :

-

Radiative heat transfer coefficient from glass to ambient (W/m2K)

- htg :

-

Total heat transfer coefficient from glass to ambient (W/m2K)

- htw :

-

Total heat transfer coefficient from water to glass (W/m2K)

- I:

-

Solar radiation falling on the still (W)

- I1 :

-

The radiation falling on to the water surface after transmitting through glass (W)

- I2 :

-

The solar intensity falling on the basin liner after passing through the water mass (W)

- mw :

-

Mass of distilled water (kg)

- Qb :

-

Convection heat transfer from basin liner to water (W)

- Qbot :

-

Conductive heat transfer from basin liner to atmosphere through bottom side (W)

- Qbw :

-

Conduction heat transfer from inside to atmosphere through back wall (W)

- Qcg :

-

Convection heat transfer from glass to ambient (W)

- Qcob :

-

Conduction heat transfer from basin liner to insulation (W)

- Qcw :

-

Convection heat transfer from water to glass (W)

- Qd :

-

Rate of heat energy of distilled output (W)

- Qew :

-

Evaporative heat transfer from water to glass (W)

- Qrg :

-

Radiation heat transfer from glass to ambient (W)

- Qrw :

-

Radiation heat transfer from water to glass (W)

- Qsw :

-

Conduction heat transfer from inside to atmosphere through side wall (W)

- Qsww :

-

Conductive heat transfer from the inside still to outside through water contact vertical sides (W)

- Qu :

-

Unaccountable heat losses (W)

- Ta :

-

Atmospheric temperature (°C)

- Tb :

-

Basin liner temperature (°C)

- Tg :

-

Glass temperature (°C)

- Tw :

-

Basin water temperature (°C)

- Twi :

-

Initial water temperature (°C)

- Ubot :

-

Convective heat transfer coefficient from glass to ambient (W/m2K)

- αb :

-

Absorptivity of basin liner

- αg :

-

Absorptivity of glass

- αw :

-

Absorptivity of water

References

A. Safwat Nafey, M. Abdelkader, A. Abdelmotalip, A.A. Mabrouk, Enhancement of solar still productivity using floating perforated black plate. Energy Convers. Manag. 43, 937–946 (2002)

A.S. Nafey, M. Abdekader, A. Abdelmotalip, A.A. Mabrouk, Solar still productivity enhancement. Energy Convers. Manag. 42, 1401–1408 (2001)

A.S. Nafey, M. Abdekader, A. Abdelmotalip, A.A. Mabrouk, Parameters affecting solar still productivity. Energy Convers. Manag. 41, 1797–1809 (2000)

D.P. Kothari, Rakesh Ranjan, K.C. Singhal, Renewable Energy Sources and Emerging Technologies, 2nd edn. (Prentice-Hall of India, New Delhi, 2011)

I. Doperevsky, M. Geohieva, Some possibilities for solar evaporation intensification. Desalination 45, 93–99 (1983)

A.A. Bilal, S.M. Mousa, O. Omar, E. Yaser, Experimental evaluation of a single-Basin solar still using different absorbing materials. J. Renew. Energy 14, 307–310 (1998)

S.K. Shukla, V.P.S. Sorayan, Thermal modeling of solar stills: an experimental validation. J. Renew. Energy 30, 683–699 (2005)

S.O. Onyegegbu, Solar distillation of pond (muddy) water. Energy Convers. Manag. 24, 1–4 (1984)

T.V. Arjunan, H.S. Aybar, N. Nedunchezhian, The effect of sponge liner thickness on the performance of simple solar still. Int. J. Renew. Energy Technol. 2(2), 169–192 (2011)

T.V. Arjunan, S. Neelakrishnan, K. Sampath Kumar, Shaik Amjad, R. Subramanian, N. Nedunchezhian, Effect of sponge liner colors on the performance of simple solar stills. Energy Sour. Part A Recovery Util. Environ. Eff. 34, 1984–1994 (2012)

W.M. Alaian, E.A. Elnegiry, M.H. Ahemed, Experimental investigation on the performance of solar still augmented with pin-finned wick. Desalination 379, 10–15 (2016)

A.A. EI- Sebaii, M.R.I. Ramadan, S. Aboul Enein, M. EI Naggar, Effect of fin configuration parameters on single basin solar still performance. Desalination 365, 15–24 (2015)

T.V. Arjunan, H.S. Aybar, N. Nedunchezhian, A study on effects of water capacity on the performance of a simple solar still. Int. J. Appl. Eng. Res. 4(11), 2223–2234 (2009)

T.V. Arjunan, H.S. Aybar, N. Nedunchezhian, Effect of sponge liner on the internal heat transfer coefficients in a simple solar still. Desalin. Water Treat. 29(2), 271–284 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arjunan, T.V., Aybar, H.Ş. & Nedunchezhian, N. Experimental Study on Enhancing the Productivity of Solar Still Using Locally Available Material as a Storage Medium. J. Inst. Eng. India Ser. C 98, 191–196 (2017). https://doi.org/10.1007/s40032-016-0280-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-016-0280-7