Abstract

In this study, a novel controller is designed to study low frequency oscillations for load frequency control (LFC) and voltage control of a single area power system. For more accuracy in dynamic and steady state responses, mutual effects between LFC and automatic voltage regulation (AVR) loops are investigated in a combined simulink model of LFC and AVR loops. The effectiveness of the proposed controller is first simulated on model with LFC loop alone. The proposed controller is a hybrid of neural network and fast traversal filters. The proposed hybrid controller requires less number of samples for training of weights, thus making the system fast. To study the coupling effects of AVR and LFC loops, dynamic performance of a complete system model for low frequency oscillation studies comprising of mechanical and electrical loops is done with the proposed controller.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Today, most industries and commercial establishments are affected by power quality (PQ) problems. PQ has attracted considerable attention from both utilities and users, due to the use of many types of sensitive equipments. At the user end, due to non-linear loads, two types of problems occur. One is voltage fluctuation (VF) which is further divided into three categories—sag/swell, flicker and interruptions. Other is load frequency control (LFC). With the growth of inter-connected systems, the voltage and frequency controllers have gained importance. Voltage fluctuation (VF) depends on reactive power flow, whereas, load frequency (LF) depends on real power flow. In an interconnected power system, if a load demand changes randomly, both frequency and tie line power varies. The main aim of LFC is to minimise the transient variations in these variables and also to make sure that their steady state errors is zero. LFC is a very important issue in power system operation and control for supplying sufficient and both good quality and reliable power. To improve the stability of the power system, it is necessary to design LFC systems that control the power generation and active power. The main objective of automatic voltage regulator (AVR) is to maintain terminal voltage magnitude of a synchronous generator to a defined level by controlling its excitation voltage. It plays an essential role to control the reactive power and improve the steady state stability of power system. The voltage and frequency controller has gained importance with the growth of interconnected system and has made the operation of power system more reliable.

Literature survey shows many investigations in the area of LFC and automatic voltage regulation (AVR) of single area power system using schemes such as proportional and integral (PI) [1], neural network (NN) [2], fuzzy logic (FL), genetic algorithm(GA) [3] and particle swarm optimization (PSO) [4]. The conventional PI control method does not work well for different load conditions as they are fixed type controllers. Training of neural network and membership functions of fuzzy logic require a large number of input–output samples, hence increasing the mathematical complexity. Although, PSO is population-based search approach, but it requires large data for training the weights and involves highly complex mathematical operations [5].

To overcome the shortcomings of the above mentioned controllers, a novel approach is proposed, that is, hybrid of neural network (NN) and fast traversal filter (FTF) based controller for LFC and AVR systems. Input to the controller that is the error signal is divided into two parts- linear and non- linear. The linear part of the error signal is minimized by FTF algorithm, whereas the non- linear part is minimized by NN algorithm. This controller requires less memory and less number of samples for training, thus making the system fast. This scheme also corroborates improved performance in shorter time, hence making the system computationally efficient.

Literature survey shows that generally studies are made assuming the fact that there is no interaction between LFC and AVR loops. But the AVR and LFC loops are not in true sense non-interacting. Practically, during dynamic perturbations some interactions between these two control loops exist. Interaction exists in opposite direction of the loops, or in simpler words, control actions in AVR loops, which is a faster loop, affect the magnitude of generator emf. Voltage fluctuations can be controlled by adjusting the excitation winding of the generator [6]. As internal emf determines the magnitude of real power, it is clear that changes in AVR must be felt in LFC loop [6, 7]. Combined model for LFC and AVR were first studied with PI controller in paper [8] for the first time. This work has been extended with the proposed controller Therefore, in this paper, a study is done by incorporating the proposed controller in the combined model (LFC and AVR) for dynamic improvement and its effects on steady state response of turbine output power (Pm). Dynamic behavior of transients is improved by the proposed controller, as shown in the simulation results. Finally, simulation results of the proposed controller are compared with model of combined loops (LFC and AVR) and LFC loop alone. Simulated results also show that there is interaction between LFC and AVR loops.

The Proposed Controller

In the nascent approach, the input signal to the controller is divided into linear and non- linear part. Using FTF algorithm for the linear part and neural network for the non- linear part of the error signal, an efficient controller is developed to achieve faster convergence of weights and the least square of error with a small number of samples. Figure 1 shows the block diagram of the proposed controller, that is NN and FTF based controller. Set point and error signal are inputs to the FTF part of the controller whereas error signal is input to the NN part of the controller. This concept originates from the fact that the non- linear part of the signal tries to adhere to the set point (r) and the linear part (e) tries to maintain the linearity between the two consecutive points. The output of the controller is the sum of the outputs of the non-linear block that is neural network (u1) and the linear block (u2).

The two parts of the controller are explained as follows:

Fast Transversal Filter (FTF)

As clear from the name, transversal FTF makes use of the combination of four separate nth order filters in unison. These filters are denoted by:

-

1.

wn(n), Least squares (LS) prediction filter

-

2.

fn(n), forward prediction error filter

-

3.

bn(n), backward prediction error filter

-

4.

gn(n), gain filter

These filters are the direct consequence of:

-

1.

Requiring the LS prediction filter to be wn(n) transversal in nature.

-

2.

Maintaining the required LS orthogonal conditions at both times n−1 and n.

In predicting LS, the LS error criterion is used to optimally predict the desired signal using the required data. Prediction should be done with a transversal filter structure. The second LS transversal filter used in FTF algorithm is an nth order forward linear prediction filter. This filter computes the Forward Prediction Error (FPE) between the current data vector x(n) and a prediction xf(n) based on the knowledge of past data vectors. The third transversal filter is an nth order backward filter. This computes the Backward Prediction Error (BPE) between the current data vector x(n) and a prediction xb(n) based upon the future data vectors. The last one is the Gain Traversal Filter gn(n). In general, it can be said that these four filters and other scalar parameters are all a natural consequence of minimizing the original LS error. Equations for FTF algorithm are given in Appendix.

The output of the FTF algorithm block, u2(k) is given by

where, wf1 and wf2 are the FTF weights to be updated so as to minimize error.

Neural Network (NN)

A three layered feed-forward neural network is used.

Input to neural network is the error between the set point and the actual output (load frequency). Here, the actual output is the instantaneous value of the system output when simulink model is run.

The output of the NN, u1(k) is given by

where, n is the number of samples taken at a time; wk are the weights of the neural network; b is the bias, u1 is the output of the NN controller.

The weights of the NN are adjusted by well-known back propagation algorithm.

As in Fig. 1, the output of FTF controller (u2) and NN controller (u1) add to give the final output of the proposed controller (u).

Thus, the output of the controller u(k) is:

System Modeling of Single Area Power System

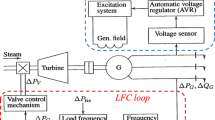

In our study, one machine-infinite bus system with a local load have been considered as shown in Fig. 2, where Z denotes series impedance of transmission line and Y denotes the shunt admittance as a local load. The two main control loops of a generation system are LFC and AVR as seen in Fig. 3.

Linearized Model: Basic Generator Control Loops

The schematic layout of the voltage and frequency control loops is represented in Fig. 3 [4] and Fig. 4. In these loops, LFC and AVR equipments are installed for each generator. Frequency control is slow acting while excitation control is fast acting. Reason for this is that the time constant contributed by the turbine and generator in LFC loop is much larger (mainly due to moment of inertia) than that of the generator field in AVR loop. Thus, load frequency and excitation voltage control are generally analyzed independently assuming that cross coupling between the LFC loop and the AVR loop is negligible. LFC and AVR loops for automatic generation are shown in Fig. 4 when dealt separately.

Load Frequency Control (LFC)

The aim of LFC is to maintain load frequency balance in the system through control of system real power. Even small changes in real power demand lead to changes in frequency. Simulink model of LFC is shown in Fig. 5 [4]. Change in frequency is the input to the controller and its output becomes input to the governor turbine set. Step increase in the load is added to get load frequency variation. R is regulation constant in Fig. 5. This method is referred to as power frequency (P–f) or megawatt frequency control.

Automatic Voltage Regulator (AVR)

Figure 6 is the simulink model for AVR [4]. The controller senses the difference between the reference voltage and the rectified voltage derived from the stator voltage. Controller output is amplified and fed to the excitation circuit. The change of excitation maintains the reactive (VAR) balance in the network. This method is referred to as reactive voltage (QV) or megawatt volt amp reactive (MVAR) control.

First, the system modeling is done for LFC loop alone for change in load of 0.1 p.u. Figure 7 shows the simulink model of controller sub-system. Error in actual and reference frequency is the input to the neural controller subsystem and error and reference frequency are inputs to the FTF controller subsystem. MATLAB function along with a bus system is used in the simulink model of FTF controller which is shown in Fig. 8. Error, change in error, reference frequency and ramp function are the inputs to the MATLAB function block for FTF algorithm and its output are weights of the filter. Output u2 is the product of weights and reference value. Embedded MATLAB function used in the simulink model of Neural Network is shown in Fig. 9. Three layer feed forward neural network is used. Initial weights (w1, w2) and biases (b1, b2) are randomly initialized. These are updated to new weights (w11, w22) and biases(b11, b22) by using back propagation algorithm.

Simulated Results and Conclusion

The simulation was performed using the simulink package available in MATLAB version 7.2. The simulation is done for the model with LFC loop alone for change in load of 0.1 p.u with different controllers—PI, Neural, PSO and the proposed controller. Figure 10 shows the dynamic response of frequency deviation with the proposed controller for LFC alone. The comparison of the dynamic response in terms of peak overshoot, settling time and steady state error with different controllers is tabulated in Table 1. Figure 11 shows the comparative analysis of different controllers. As seen from Fig. 11, steady state error is improved to 0.2 with PSO and to 0.02 with proposed controller as compared to PI and Neural Controller. Peak overshoot and settling time are also reduced considerably using the proposed controller as compared to PSO. Table 1 and Fig. 11 clearly show that the proposed controller makes the dynamic response faster, smoother and minimizes the steady state error.

Combined Model for LFC and AVR Loops with Proposed Controller

After seeing the superiority of the proposed controller with LFC alone, as compared to the classic controllers, now a combined model for LFC and AVR loops with the proposed controller is modeled.

AVR and LFC loops are not in the truest sense non-interacting; cross coupling may at times be troublesome. Interaction in the two loops exists in the opposite direction. Control actions in AVR loop affect the magnitude of generator emf. Internal emf determines the magnitude of real power, therefore changes in AVR loop must be felt in LFC loop [6]. For more accuracy in dynamic and steady state responses, mutual effects between LFC and AVR loops are investigated in a combined simulink model of LFC and AVR loops.

System Modeling [6]

A complete system model for low frequency oscillation studies including mechanical and electrical loops of a single machine-infinite bus model of a power system is considered. One-area power system with local load under study is shown in Fig. 2.

In LFC system, the effect of unbalance between electromagnetic torque and mechanical torque of individual machines is described by the rotational inertia equations. Even small deviation and perturbation in speed can completely change the swing equation to:

where ΔPe is the internal electrical power deviation which is sensitive to the load characteristics; ΔPm is the deviation in power generation; ΔPL is the change in load demand (real power); Kp and Tp are power system equivalent gain and time constant respectively.

The derivation of Eq. (4) can be seen from [8].

The combined model for LFC and AVR loops for power system is based on Eq. (4). The simulink model for the combined loops is shown in Fig. 12 and the nomenclature used is listed below:

- R:

-

Droop characteristic

- Tt :

-

Turbine time constant

- TG :

-

Governor time constant

- Ka :

-

Amplifier gain

- Ta :

-

Amplifier time constant

- Kr:

-

Sensor gain

- Tr :

-

Sensor time constant

- T3 :

-

Generator-field transient time constant

- Δf:

-

Deviation in load frequency

- ΔVt :

-

Deviation of terminal voltage

- ΔPe :

-

Deviation of internal electrical power

- ΔVf :

-

Deviation of field winding voltage

- Δδ:

-

Deviation of torque angle

Simulated Results

The simulation was performed using the simulink package available in MATLAB version 7.2. The simulation was done for the combined model for LFC and AVR loops with the proposed controller assuming that real power 0.9 p.u., reactive power 0.6 p.u., machine terminal voltage deviation 0.091p.u. and change in load 0.1 p.u. The values of K1–K6 parameters shown in Fig. 12 for this condition are tabulated in Table 2. Details about calculation of these parameters are given in [8]. Values for different power system parameters for the simulink model are shown in Table 3.

Figure 13 shows the plots for dynamic responses of combined model for LFC and AVR loops with proposed controller and model with LFC loop alone.

Figure 13a, b show that there is significant effect on the dynamic responses for deviation in load frequency (delf). As clear from Fig. 13a for delf peak undershoot increases to 0.58 p.u. with the combined model from 0.045 p.u. with LFC loop alone. From Fig. 13b, without AVR loop the deviation in mechanical power (pm) is 0.1 p.u., but when both the loops are considered, deviation in pm reduces to 0.08 p.u. Thus, there is reduction of mechanical power when both loops are considered. The electrical power (pe) goes negative as can be seen in Fig. 13c clearly indicating that reduction in mechanical power is supplied by the AVR loop. Figure 13d shows variation in voltage when both loops are considered.

The new proposed controller gives less oscillations than PI controller [8] and combination of PI with power system stabilizer [9] thereby improving the dynamic response considerably.

Conclusion

The characteristics of a reliable power supply are good terminal voltage response and minimum frequency deviation. In the initial part of the paper a novel approach of hybrid NN and FTF based controller is proposed to make the system’s dynamic performance faster and smoother. The conventional controllers like PI, neural and PSO used have large peak overshoot, settling time and steady state error. The proposed controller provides satisfactory stability between frequency overshoot and transient oscillations with zero steady state error. The simulated results show that the proposed controller makes the dynamic response faster, smoother and minimizes the steady state error. In the later part of the paper importance of study of combined model with LFC and AVR loops with the proposed controller are investigated. Simulated results of model with combined LFC and AVR loops are compared with LFC loop alone for one area power system. Results show that there is interaction between LFC and AVR loops.

References

J.C. Basilio, S.R. Matos, Design of PI and PID controllers with transient performance specification. IEEE Trans. Educ. 45(4), 364–370 (2002)

K. Sabahi, M.A. Nekoui, M.A. Teshnehlab, M. Mansouri, K.N. Tossi, Load frequency Control in Interconnected Power System using Modified Dynamic Neural Networks. In 15th Mediterranean Conference on Control and Automation, July 2007

B.V. Prasanth, S.V.J. Kumar, Load frequency control for a two area interconnected power system using robust genetic algorithm controller, J. Theor. Appl. Inf. Technol. 4(12), 1204–1212 (2008)

A. Soundarrajan, S. Sumathi, C. Sundar, Particle swarm optimization based LFC and AVR of autonomous power generating system, Int. J. Comput. Sci. 37(1), 1–8 (2010)

Z.-L. Gaing, A particle swarm optimization approach for optimum design of PID controller in AVR System. IEEE Trans. Energy Convers. 19(2), 384–391 (2004)

O.L. Elgerd, Electrical Energy Systems Theory, 2nd edn. (Tata McGraw Hill, New Delhi, 1983)

H. Bevrani, T. Himyama, Intelligent automatic generation control (CRC Press Taylor and Francis, New York, 2011)

E. Rakhshani, K. Rouzbehi, S. Sadeh, A new combined model for simulation of mutual effects between LFC and AVR loops. In IEEE Conference of Power and Energy Engineering, 1–5 March 2009

E. Rakhshani, J. Sadeh, Application of power system stabilizer in a combined model of LFC and AVR loops to enhance system stability. In IEEE Conference on Power System Technology, October 2010

Author information

Authors and Affiliations

Corresponding author

Appendix: FTF Algorithm

Appendix: FTF Algorithm

It consists of the following steps:

Initialize:

small positive constant.

Iterate:

For n = 1 to n, do:

Extend to the joint process

where, b N (n)is the backward prediction filter, f N (n)is the forward prediction filter, w f (n) is the least square prediction filter, c N (n)is the gain vector, γ N (n) is the angle update parameter, e f(n/n) is the forward prediction error (FPE), e b(n/n) is the backward prediction error (BPE), ɛ f(n) is the forward prediction error (FPE) residual or the energy of the FPE vector e f(n/n) i.e. \( \langle e^{f} (n/n),e^{f} (n/n)\rangle \), \( \varepsilon^{b} (n) \) is the backward prediction error (BPE) residual or the energy of the BPE vector \( e^{b} (n/n) \) i.e. \( \langle e^{b} (n/n),e^{b} (n/n)\rangle \), \( e(n/n) \) is the error, \( x_{N}^{T} (n) \) is the input vector, \( d(n) \) is the desired output vector.

Rights and permissions

About this article

Cite this article

Gupta, M., Srivastava, S. & Gupta, J.R.P. A Novel Controller for Model with Combined LFC and AVR Loops of Single Area Power System. J. Inst. Eng. India Ser. B 97, 21–29 (2016). https://doi.org/10.1007/s40031-014-0159-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40031-014-0159-z