Abstract

In this study, soy protein isolate and modified starch were evaluated as coat material for developing spray-dried flaxseed oil microcapsules. The emulsions were prepared by varying total solids (TS) and oil load (OL) using high shear mixer and then atomized in spray dryer for encapsulation of flaxseed oil. Emulsion with 30% TS and 30% OL had maximum zeta (ζ) potential value of − 36.83 mV, and emulsion having 25% OL and 30% TS had lowest mean droplet diameter of 701.80 nm. Emulsions exhibited shear thinning behaviour. Microencapsulation efficiency (ME), bulk density, tapped density and flowing properties of microcapsules were studied. ME of microcapsules varied from 63.79 to 95.84%. The microcapsule prepared with 30% OL and 30% TS owing to more oil load and zeta potential was selected for evaluation of certain characteristics. Microcapsules were spherical in shape with average particle size of 37.917 µm. Alpha-linolenic acid (18:3) content was 61.67% in the oil extracted from microcapsule. Fourier transform infrared spectra also confirmed the encapsulation of flaxseed oil by selected coat materials. 38.24% oil was released in simulated gastrointestinal conditions from the flaxseed oil microcapsules, and it increased to 60.86% when accompanied with heating prior to digestion.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Alpha-linolenic acid (ALA) and omega-3 fatty acid are considered to be essential fatty acids which have several physiological health benefits and are associated with their consumption. Owing to this, there is growing demand for omega-3 fatty acids with the market size being valued at USD 2.04 billon in 2016 and a great potential to further grow at 6.6% CAGR from 2012 to 2022. Also, it is quite interesting to note that Asia Pacific is likely to grow at 7.5% from 2015 to 2022 [20].

Flaxseed/linseed (Linum usitatissimum) is a rich source of α-linolenic acid with its oil containing nearly 57–60% level [34]. In spite of having functional importance, the use of flaxseed oil is limited in food products owing to high susceptibility to oxidation. However, stabilizing the flaxseed oil through encapsulation can overcome this problem, where a protective coat is formed on susceptible oil droplets [4].

Microencapsulation offers several advantages other than protecting the bioactives from external environment such as converting liquids to solids, improving material handling properties, controlled release and separating reactive compounds from the environment. There are several ways of encapsulating the core materials, but spray drying is the most extensively employed approach [9]. The different wall materials used so far for encapsulation of flaxseed oil includes whey protein isolate [31], gum Arabic [40], a combination of gum Arabic, whey protein concentrate and Hi-cap 100 [41] and also a combination of maltodextrin, gum Arabic, whey protein concentrate and Hi-cap 100 [6].

Soy protein isolate (SPI) was used as a coating material in microencapsulation by various researchers [4, 7, 36, 43]. Also, modified starches form uniform film around the core material thus form stable emulsion, which makes them highly effective coating agents. Modified starches when used as coating materials offer multiple advantages such as incorporation of greater oil load, more retention of volatiles, high encapsulation efficiency and improved shelf life [24]. Further, when proteins and carbohydrates are used together as coating agents, they result in microcapsules with improved oxidative stability and drying characteristics [4]. Both SPI and modified starches are quite stable, easily available, cheap and effective functional properties with potential application for microencapsulation of essential fatty acids. Also, reports on combination of soy protein isolate and modified starches for flaxseed oil emulsion are very limited in the literature. Thus, the present study was planned to microencapsulate flaxseed oil using modified starch and SPI and evaluate the effect of varying oil load and total solids on certain feed emulsion characteristics and microcapsule properties.

Materials and Methods

Materials

Cold-pressed flaxseed oil was received as gift sample from AAK Kamani Pvt. Ltd., Andheri, Mumbai (Maharashtra, India). Soy protein isolate (SPI) with 90.5% protein was sourced from Shridurga Sales Corporation, Bangalore, India, and modified starch (OSA modified tapioca maltodextrin) from Ingredion India Private Ltd, Thane, Maharashtra, India. All the AR grade chemicals and reagents were used for this study.

Preparation of Emulsion and Microcapsule

Flaxseed oil emulsion was prepared by mixing the calculated amount of flaxseed oil, soy protein isolate and modified starch using hand blender (Phillips, India) for approximately 5 min, and then prepared solution was homogenized with high shear mixer (IKA T-18, Germany) at 18,000 rpm for 5 min and stored at lower temperature (4–7 °C). The quantity of soy protein isolate was fixed at level of 5% w/w of total solids (TS) of emulsion based on preliminary trials. The oil load (OL) of emulsion was 25%, 30% and 35% of TS while, and TS was maintained at 20%, 25% and 30%. The sample preparations for various emulsions (denoted as E1–E9) and microcapsules (denoted as A1–A9) are given in Table 1. The prepared emulsions were preheated in waterbath to 40 °C for microencapsulation in order to decrease the viscosity for proper atomization in drying chamber of spray dryer. For spray drying, inlet and outlet hot air temperatures were maintained at 180 ± 5 °C and 85 ± 5 °C, respectively, while flow rate was maintained from 40 to 60 ml/min. These conditions were selected based on preliminary trials conducted for spray-drying flaxseed oil emulsions. The samples were stored in metalized polyester–LDPE laminate pouches for further analysis.

Physical Properties of Emulsion

Creaming Index

Creaming index for emulsion samples was determined using the method given by Mostafa et al. [29] according to Eq. (1).

where H defines separated phase and H0 represents the initial height of emulsion.

Particle Size Distribution of Emulsion and Zeta (ζ) Potential

The electric charge and size of flaxseed oil emulsion droplets were measured 1 day after their preparation [19] with the help of Zetasizer nano-series ZS90 (Malvern Instruments Ltd., UK). For measuring the particle size, mixing of 1 ml emulsion with 99 ml of distilled water (25 °C) was carried out before taking observations. Emulsion droplet size was denoted as mean diameter in nm, while zeta potential was measured in mV.

Rheological Measurements

The viscosity of emulsions was measured using a dynamic rheometer (Anton Paar Rheometer, MCR-52, Austria, Europe) by slight modification of the method given by Goyal et al. [19] using a CP 75/1° probe at 25 ± 0.1 °C with shear rate varying from 5 to 100/s.

Physico-Chemical Characteristics of Microencapsulated Flaxseed Oil

Moisture Content and Water Activity (aw)

The moisture content of microcapsules was determined gravimetrically as per the method of AOAC [2], and water activity (aw) values of the microcapsules were obtained by water activity meter (Aqua lab, model series 3 TE, M/s Decagon Devices, WA, USA). Charcoal powder was used for calibration of the water activity meter.

Total Oil, Surface/Free Oil and Microencapsulation Efficiency (ME %)

Gravimetric method as given by AOCS was followed for determination of total oil (TO) of microcapsules [3] with minor changes. Oil was extracted by stirring 5 g microcapsule powder and 60 mL of chloroform: methanol (40:60) at 50 °C for 2 h on magnetic stirrer. Solvent was then evaporated, and extracted oil was weighed. Hogan et al. [21] method was followed for calculating free or surface oil and microencapsulation efficiency.

Bulk (ρB), Tapped (ρT) Density and Flowing Properties

The method given by Chinta et al. [8] was followed for estimation of bulk (ρB) and tapped (ρT) density. Calculations for the flowing characteristics, i.e. Carr’s index: a measure of compressibility index and Hausner ratio: indicator of cohesiveness of powder, were done by following the Turchiuli et al. [42] method using the following equations:

Particle Size Analysis

Mastersizer 3000 (Malvern Instruments Ltd., UK) available at Aimil Ltd., Bengaluru, was used for determining the particle size and size distribution of microcapsules. The microcapsule size was analysed by dry method with feed rate range 40 ms−2.

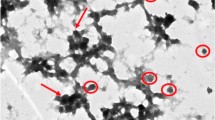

Structural Morphology Using Scanning Electron Microscopy (SEM)

The morphology of flaxseed oil microcapsules was studied by scanning electron microscope (ZEISS, EVO 55 Ultra, UK). The uniform layer of sparsely scattered microcapsule powder (on circular SEM stubs) was coated with gold nanoparticles (25 Å) in a sputter coater (Q150R Rotary-Pumped Sputter Coater). The ion current at 6 mA was maintained along with fine vacuum of 0.07 Torr for 4 min. The observations were taken at 2000, 3000 and 7660× magnification at a working distance of 8 mm with an accelerating potential of 15 kV. The images of selected area were recorded with the help of Smart SEM software.

Fourier Transform Infrared (FTIR) Spectroscopy

In order to investigate the infrared spectra of the functional groups of flaxseed oil microcapsules, an ALPHA FTIR spectrometer (Shimadzu IRAffinity-1S, Japan) with attenuated total reflection (ATR) technique was used. The light beam penetration depth of about 0.5–3 µm in the sample was used. Analysis of sample was repeated twice for ensuring the reliability of peaks obtained in the infrared spectra of microcapsules. The observed spectra recorded the absorbance of the different samples for wavenumber ranging from 4000 to 400 cm−1.

Alpha-Linolenic Acid Content of Microencapsulated Flaxseed Oil Using GC–MS

The method given by Folch et al. [17] was employed with minor variations for extraction of oil from flaxseed oil microcapsules. Twenty-five grams of microcapsules were taken in a separating funnel and mixed with 250 mL solvent mixture of chloroform: methanol (2:1). The mixture was kept undisturbed for 15 min after 3–4 min gentle mixing. This was followed by removal of lower layer of chloroform, and repeated washings were given to the upper layers using 125 mL mixture of chloroform: methanol (2:1) to collect lower chloroform layers. The collected chloroform layers were mixed with 50 mL of distilled water and kept undisturbed for phase separation. After phase separation, lower chloroform layer was collected and evaporated using waterbath at 60 °C.

Extracted fat was derivatized to fatty acid methyl esters (FAME) following the AOAC [2] method and subjected to GC/MS system (Agilent Technologies, Santa Clara, CA) for separation of different fatty acid methyl esters from 150 °C to 230 °C at the rate of 3 °C/min (ramp) with holding time of 10 min at 230 °C. Temperature of injector was maintained at 250 °C, and 3 μL sample injection volume was used for analysis. Comparing the elution times of sample’s fatty acid methyl esters with those of standard FAMEs available in GCMS library, identification of fatty acids was performed and quantification was done by estimating the area per cent. Data were collected and analysed using the GC/MSD program (Agilent Technologies, Inc.). The ALA content was estimated in terms of the % area occupied by the fatty acid methyl ester of alpha-linolenic acid, i.e. butyl 9, 12, 15, octadecatrienoate.

Release of Flaxseed Oil Under Simulated Gastrointestinal Environment

Gastrointestinal conditions were simulated where both gastric conditions (SGC) alone and a combination of SGC and simulated intestinal conditions (SIC) were created to study the release pattern of flaxseed oil from the microcapsules in human digestive tract according to the method given by Burgar et al. [5]. The per cent flaxseed oil release in gastrointestinal condition was measured by sub-sequential exposure of microcapsules to SGC and SIC for 3 and 2 h, respectively. Also, effect of heating for 85 °C for 5 min was also studied as the developed microcapsules are intended for fortification of milk and milk products, which are subjected to heat treatment during processing of milk into different dairy products. The developed microcapsules would be added in milk and later converted into curd. Further, milk is heated at 85 °C for 5 min for facilitating coagulation and developing proper curd texture; thus, this time–temperature combination was selected.

Statistical Data Analysis

All the data were expressed as mean of three replications, and standard deviations were calculated. Differences between the sample means were analysed by Duncan’s multiple range test (DMRT) and least square difference (LSD) at α level of 0.05.

Results and Discussion

The effects of combination of soy protein isolate and modified starch on various emulsion and microcapsule properties are discussed below.

Properties of Emulsion

Creaming Index

The emulsion samples were significantly (p < 0.05) different for creaming index values and the separated oil increased with increasing oil load for the same TS level (Table 2). The creaming index varied from 0.159 ± 0.036 to 7.811 ± 0.328%. The sample having 35% OL and 20% TS was the most unstable sample. The creaming index of the emulsion samples increased with increasing oil load. This might be due to the insufficient coating material (encapsulating agent) for higher oil load samples, leading to sharing of core material (active material) and thereby resulting in irreversible bridging flocculation [11]. Further, if higher amount of coating material is used, surface load increases and, in turn, adversely affects emulsion properties [28]; therefore, the use of very high concentrations of coating material were avoided.

Zeta Potential and Average Droplet Size

The zeta potential of flaxseed oil emulsion samples varied significantly (p < 0.05) with values ranging between − 28.73 and − 38.50 mV (Table 2). The zeta potential value is higher for the sample with higher total solids, except for the emulsion having 30% TS and 30% OL (Table 2) which was most stable in terms of zeta potential (Table 2), due to maximum utilization of soy protein isolate for coverage of oil droplets or uncovered flaxseed oil droplets [10]. Further, the negative values of zeta potential indicate the negative charge on soy proteins isolates used as coating material.

The mean droplet diameter (Z average size) values were significantly (p < 0.05) different for various emulsion samples (Table 2), and the lowest and highest mean droplet diameter of 721.00 ± 48.77 nm and 1360 ± 407.35 nm was observed for sample having 25% OL and 20% TS and emulsion having 25% OL and 25% TS, respectively. Even though the emulsion samples are quite stable in view of zeta potential values, but a particular tend is not visible in the studied range of oil load and total solids, this might be due to protein unfolding, exposure and interaction between hydrophobic groups via the formation of covalent bonds, thereby resulting in a decrease in the emulsifying capacity, promoting droplet coalescence and thereby resulting in larger droplet size [27]. However, droplet size of flaxseed oil emulsions is quite lower as compared to refined vegetable oil emulsions (4170 nm) prepared with soy protein isolate [1].

Rheological Behaviour

The rheological behaviour plays a vital role in defining the processing conditions for various unit operations like pumping, mixing, flowing in pipe and atomizing. The apparent viscosity for studied emulsions decreased with increasing shear rate (5–100/s) (Fig. 1). This confirms the shear thinning behaviour (pseudoplastic nature), a characteristic property of the most food emulsions. The observed shear thinning may be due to spatial distribution of the particles as a result of shear field [22]. The results are in agreement with fish oil and rapeseed oil emulsions studied by Taherian et al. [37] and Dybowska [13], respectively. It is also evident that with the increase in TS level, the viscosity increased but at the same time with the increase in OL for same TS level, there is decrease in viscosity (Fig. 1).

Properties of Microcapsule

All the emulsion samples were subjected to spray drying, and the properties of developed microcapsules are as under.

Water Activity (aw) and Moisture Content

Water activity (aw) of dried food products is lower than 0.30, and for limiting the oxidation of lipid, aw range from 0.2 to 0.3 [32] is ideal. The aw for the microcapsule samples varied from 0.154 to 0.199 (Table 3) which is lower than that observed for flaxseed oil microcapsules prepared using chickpea/lentil protein isolates and maltodextrin (aw 0.25) by Karaca et al. [26]. Also, Polavarapu et al. [32] reported aw value of about 0.3 for fish oil microcapsules. Moisture content of different microcapsules ranged from 2.59 to 4.69% (Table 3). The moisture content of microcapsules varies mainly with the spray-drying conditions like inlet and outlet air temperature and design of dryer, etc. Thus, with the low water activity and moisture content, keeping quality of the prepared microcapsules is expected to be good.

Surface Oil and Microencapsulation Efficiency (ME)

Surface oil of prepared microcapsules varied from 4.16 to 36.21% (Table 3), and it was directly proportional to emulsion droplet size [23] owing to droplet breakdown in larger emulsion droplets during atomization. There was significant (p < 0.05) difference in ME and surface oil values for different microcapsule formulations. The ME ranged from 95.84 to 63.79% (Table 3). The microcapsules containing 25% OL and 30% TS had maximum ME with lesser free oil. Further, the ME varied from 63.79 ± 1.33 to 71.18 ± 0.17% for 35% OL samples. This could be attributed to the fact that with increasing OL, the coating material might be insufficient to cover the core completely close to the drying surface, thereby reducing the diffusion path length towards the air/particle interface which in turn leads to an increase in free oil [40].

Bulk (ρB), Tapped (ρT) Density and Flowing Properties

The storage space requirement and stability of powders (microcapsules) are dependent upon the bulk and tapped density to certain extent. The bulk density and tapped density values for the developed flaxseed oil microcapsules are presented in Table 3. The bulk density for the microcapsules varied significantly (p < 0.05) from 0.32 to 0.36 g/mL. However, Thirundas et al. [39] reported higher bulk density (0.426–0.490 g/mL) for flaxseed oil microcapsules prepared with gum arabic, maltodextrin and tween 80. The tapped density for the microcapsule samples varied significantly (p < 0.05) from 0.47 to 0.52 g/mL. These findings are in agreement to those reported by Fernandes et al. [15] for microencapsulated rosemary oil (0.41–0.52 g/mL) and Finney et al. [16] in case of orange oil microencapsules (0.48–0.65 g/mL).

Carr’s index (% compressibility) and Hausner ratios were used as indicators of powder flowing behaviour. Higher Carr’s index describes higher compressible nature and lesser flowability of powder. Similarly, higher Hausner index indicates more cohesiveness and less flowability of the powder. For the prepared microcapsules from soy protein isolate and modified starch, Carr’s index and Hausner ratio values were 27.61–38.58 and 1.63–1.38, respectively (Table 3). Thus, it can be interpreted that the prepared microcapsules had poor flowability [33]; however, flaxseed oil microcapsule being functional ingredient, the low flowabilty is not a cause of much concern as these microcapsules would be directly mixed with milk or other food ingredients. Kagami et al. [25], Turchiuli et al. [42] and Domian and Wasak [12] also reported poor or very poor flowability for microcapsules of different oils prepared by spray-drying and/or freeze-drying techniques.

Quality Evaluation of Selected Microcapsule

Among all the emulsion samples, the emulsion (E6) with 30% OL and 30% TS was found most stable in terms of highest zeta potential (− 36.83 ± 2.18 mV) and low creaming index (3.12%) (Table 2). Also, the ME of the microcapsule prepared from this sample was 87.12 ± 0.74% (Table 3). Even though maximum microencapsulation efficiency was for A3, but the maximum zeta potential, i.e. stability, was for A6 sample, secondly, as the aim of microencapsulation of flaxseed oil is ultimately for food fortification, so in case of A3 sample, less oil would be incorporated resulting in higher amount of microcapsules to be added in the developed product. Further, its zeta potential is lower than A6 sample. Hence, this sample was selected for evaluation of selected properties, as the intended use of the prepared microcapsule is for fortification with ALA; hence stability forms an important criteria for selection.

Particle Size Analysis

Particle size plays a significant role in its food applications as it determines the texture and mouthfeel of fortified product. The mean particle diameter (d4,3) for the selected A6 microcapsule was 37.917 ± 1.788 µm (Fig. 2). Small size could be due to lower viscosity of emulsion. The predominant size was observed as one representative peak with symmetrical particle size distribution (Fig. 2). However, certain percentage of particles was above 100 µm, which could be attributed to the early agglomeration taking place during spray-drying process, thereby resulting in irreversible linkages between individual particles. Also, the powder was quite homogenous with low span value of 2.067 ± 0.030 µm. The results thus validate that the target of microencapsulation in terms of size is successfully achieved.

Structural Characterization

The external morphology of microcapsules exhibited spherical shape with some rough surface and their edges losing definition (Fig. 3). Significant proportion of flaxseed oil microcapsules also indicated dents on the surface, which is a distinctive feature produced by spray drying [18]. The collapse of emulsion droplets during initial drying period, also due to non-uniform drying and slow film formation, results in dents on microcapsule surface [21, 35]. Furthermore, high total solids could be another possible reason for these surface dents as reported by some researchers [14, 18, 38]. However, agglomeration of powder particles is also quite visible in the electron micrographs. This agglomeration behaviour could possibly result from surface/free oil and moisture absorption by the microcapsules [36] as reported by Onwulata and Holsinger [30] and Hogan et al. [21].

Fourier Transform Infrared Spectra of Microcapsules

The FTIR spectra of microcapsules clearly revealed that the carboxylic acid (C=C∙CO∙OH) (C=C stretch) group interacts with aldehyde group (–RCHO) to form strong bond at 2980 cm−1 indicating the presence of carboxylic group and aldehyde group (Fig. 4). The peaks at 1722.30 cm−1 of flaxseed oil are dissolved by microcapsule peaks. This indicates the integration of flaxseed oil in microcapsules and the presence of alkane group with C=C stretch. It is also evident that major peaks present in the spectra of coating material are also prominent in the flaxseed oil-loaded capsules. However, many peaks were formed probably due to flaxseed oil. In case of microcapsule spectra, peak at 1052 cm−1 is due to the presence of alkyl halide C=C stretch and the peak at 1395 cm−1 is due to carboxylic acid R–CO∙O structure with C=O stretch. The results help in confirming the presence of flaxseed oil in microcapsules having soy protein isolate and modified starch as coating material. It is visible from the FTIR spectra of the coating material and flaxseed oil that the both are closely matching at the characteristic peak of flaxseed oil at 1656 cm−1 (C=C stretch) and down at 1700 cm−1 (C=N Stretch) which has been absorbed by peak of microcapsules at same wavelength. In the FTIR spectra of the microcapsule, no new bonds were formed beside the spectra of coating materials (SPI and modified starch) and core material (flaxseed oil).

ALA Content of Flaxseed Oil Microcapsule Using GC–MS

Two major peaks observed for the oil extracted from flaxseed oil microcapsule were at retention time of 25.120 and 25.308 min (Supplementary Fig. 1) for the fatty acid ester of ALA, i.e. butyl 9,12, 15, octadecatrienoate. The concentration of alpha-linolenic acid (18:3) in the oil extracted from microcapsule was 61.67%, and it can be inferred that prepared flaxseed oil microcapsules had ALA content more than 20%, so just by adding two grams of microcapsules in one serving of any food or dairy product, at least 25% RDA of the ALA can be achieved. Further, the omega-6 fatty acid present in the oil extracted from flaxseed oil microcapsules showed one major peak with retention time of 24.961 min and linoleic acid content was 13.8% in the oil extracted from microcapsule.

Flaxseed oil released from flaxseed oil microcapsules prepared with modified starch and soy protein isolate during simulated gastric and simulated intestinal conditions (SGC 2H − treatment in simulated gastric condition for 2 h, SGC 2H + heating treatment in simulated gastric condition for 2 h and heating for 80 °C for 5 min, SGC 4H − treatment in simulated gastric condition for 4 h, SGC 4H + heating treatment in simulated gastric condition for 4 h and heating for 80 °C for 5 min, SGC + SIC treatment in simulated gastric condition for 2 h followed by treatment in simulated intestinal condition, SGC + SIC + heating treatment in simulated gastric condition for 2 h followed by treatment in simulated intestinal condition and heating for 80 °C for 5 min)

Release of Flaxseed Oil from Microcapsules in Simulated Gastrointestinal Environment

The release of flaxseed oil from developed microcapsules is highly significant parameter as the microcapsules are intended for food or fortification purpose. The per cent oil released under in vitro gastric environment was 15.69% for 6-h incubation (Fig. 5). Additionally, when microcapsules were subjected to heating at 85 °C for 5 min prior to gastric conditions, the per cent release increased from 15.69 to 30.69% for 6-h incubation. This may be due to the fact the heat treatment would have made the protein present in the coating material susceptible to pepsin action, thereby facilitating release of flaxseed oil. There is huge increase in flaxseed oil release when sequentially subjected to imitated gastric and intestinal environment from 38.24% without heating to 60.86% in combination with heating (85 °C for 5 min) prior to digestion. As both carbohydrate and protein hydrolysing enzymes act upon the microcapsules during combined gastric and intestinal digestion condition, so this would have resulted in breakdown of soy protein isolate (protein component) and modified starch (carbohydrate component) coating of microcapsule, facilitating the release of flaxseed oil. Thus, it can be predicted that the SPI and modified starch when used as coating materials would allow the release of flaxseed oil in the human gastrointestinal tract for assimilation of alpha-linolenic acid.

Conclusions

It can be concluded that among all the emulsion samples, the emulsion with 30% oil load and 30% TS was found more stable in terms of low creaming index, highest zeta potential and narrowest particle size distribution. The flaxseed oil emulsions exhibited shear thinning behaviour as commonly observed for food emulsions. Average particle size of the selected microcapsule sample was 38 µm; thus, it can be inferred that the target of microencapsulation in terms of size was achieved. Further, the FTIR spectra also confirmed the entrapment of flaxseed oil in SPI and modified starch matrix. The SEM images illustrated that the spherical shape of microcapsules with the presence of some uneven shape capsules, dents of surface and slight agglomeration. The concentration of alpha linoleic acid (18:3) in the oil extracted from microcapsules was 61.67%. Also, the flaxseed oil gets released to a great extent in the simulated gastrointestinal conditions, thereby making these microcapsules ideal for food fortification. Thus, soy protein isolate and modified starch when used in combination behave as good coating materials for preparing flaxseed oil microcapsules, and the developed microcapsules should be explored for alpha-linolenic acid fortification of food products.

References

Achouri DB, Canovas GVB (2012) Fortification of queso fresco, cheddar and mozzarella cheese using selected sources of omega-3 and some non-thermal approaches. Food Chem 133(3):787–797

AOAC (2005) Official methods of analysis. The association of official analytical chemists, 18th edn. Maryland, AOAC, p 481

AOCS (2000) Determination of oil content in oilseeds. American Oil Chemists Society, Urbana, pp 2–93

Augustin MA, Sanguansri L, Bode O (2006) Maillard reaction products as encapsulants for fish oil powders. J Food Sci 71(2):E25–E32

Burgar MI, Hoobin P, Weerakkody R, Sanguansri L, Augustin MA (2009) NMR of microencapsulated fish oil samples during in vitro digestion. Food Biophys 4(1):32–41

Carneiro HC, Tonon RV, Grosso CR, Hubinger MD (2012) Encapsulation efficiency and oxidative stability of flaxseed oil microencapsulated by spray drying using different combinations of wall materials. J Food Eng 115:443–451

Charve J, Reineccius GA (2009) Encapsulation performance of proteins and traditional materials for spray dried flavors. J Agric Food Chem 57:2486–2492

Chinta DD, Graves RA, Pamujula S, Praetorius N, Bostanian LA, Mandal TK (2009) Spray-dried chitosan as a direct compression tableting excipient. Drug Dev Ind Pharm 35(1):43–48

Desai KGH, Park HJ (2005) Recent developments in microencapsulation of food ingredients. Dry Technol 23:1361–1394

Dickinson E (1992) Hydrocolloids at interfaces and the influence on the properties of dispersed systems. Food Hydrocoll 17(1):25–39

Dickinson E (2001) Milk protein interfacial layers and the relationship to emulsion stability and rheology. Colloids Surf B Biointerfaces 20(3):197–210

Domian E, Wasak I (2008) Microencapsulation of rapeseed oil based on the spray drying method. Pol J Food Nutr Sci 58(4):477–483

Dybowska BE (2011) Whey protein-stabilized emulsion properties in relation to thermal modification of the continuous phase. J Food Eng 104(1):81–88

Faldt P, Bergenstahl B (1996) Spray-dried whey protein/lactose/soybean oil emulsions. 2. Redispersability, wettability and particle structure. Food Hydrocoll 10(4):431–439

Fernandes RVDB, Borges SV, Botrel DA, Silva EK, Costa JMGD, Queiroz F (2013) Microencapsulation of rosemary essential oil: characterization of particles. Dry Technol 31(11):1245–1254

Finney J, Buffo R, Reineccius GA (2002) Effects of type of atomization and processing temperature on the physical properties and stability of spray-dried flavours. J Food Sci 67(3):1108–1114

Folch J, Lees M, Sloane-Stanley GH (1957) A simple method for the isolation and purification of total lipids from animal tissues. J Biol Chem 226:497–509

Gallardo G, Guida L, Martinez V, López MC, Bernhardt D, Blasco R, Hermida LG (2013) Microencapsulation of linseed oil by spray drying for functional food application. Int Food Res J 52(2):473–482

Goyal A, Sharma V, Upadhyay N, Singh AK, Arora S, Lal D, Sabikhi L (2015) Development of stable flaxseed oil emulsions as a potential delivery system of ω-3 fatty acids. J Food Sci Technol 52(7):4256–4265

Grand View Research Report (2018) Omega 3 market size, share and trend analysis report by application (supplements and functional foods, pharmaceuticals, infant formulas, pet and animal feed), By Region, And Segment Forecasts, 2012–2022. Report ID: 978-1-68038-079-8. https://www.grandviewresearch.com/industry-analysis/omega-3-market

Hogan SA, McNamee BF, O’Riordan ED, O’Sullivan M (2001) Microencapsulating properties of whey protein concentrate-75. J Food Sci 66(5):675–680

Hunter RJ (1993) Introduction to modern colloid science. Oxford University Press, Oxford

Jafari SM, Assadpoor E, He Y, Bhandari B (2008) Encapsulation efficiency of food flavours and oils during spray drying. Dry Technol 26(7):816–835

Jin Y, Li JZ, Nik AM (2018) Starch-based microencapsulation. In: Nilsson MSL (ed) Starch in food: structure, function and applications, 2nd edn. Woodhead Publishing, Sawston. https://doi.org/10.1016/b978-0-08-100868-3.00017-2

Kagami Y, Sugimura S, Fujishima S, Matsuda K, Kometani T, Matsumura Y (2003) Oxidative stability, structure, and physical characteristics of microcapsules formed by spray drying of fish oil with protein and dextrin wall materials. J Food Sci 68(7):2248–2255

Karaca AC, Nickerson M, Low NH (2013) Microcapsule production employing chickpea or lentil protein isolates and maltodextrin: physicochemical properties and oxidative protection of encapsulated flaxseed oil. Food Chem 139(1–4):448–457

Kuhn KR, Cunha RL (2012) Flaxseed oil—whey protein isolate emulsions: effect of high pressure homogenization. J Food Eng 111:449–457

McClements DJ (2004) Protein-stabilized emulsions. Curr Opin Colloid Interface Sci 9(5):305–313

Mostafa S, Seham SA, Mohammed H, Nahed M (2011) Development of stable O/W emulsion of three different oils. Int J Pharm Stud Res 2229(4619):45–51

Onwulata CI, Holsinger VH (1995) Thermal properties and moisture sorption isotherms of spray dried encapsulated milk fat. J Food Process Preserv 19(1):33–51

Partanen R, Raula J, Seppaanen R, Buchert J, Kauppinen E, Forssell P (2008) Effect of relative humidity on oxidation of flaxseed oil in spray dried whey protein emulsions. J Agric Food Chem 56(14):5717–5722

Polavarapu S, Oliver CM, Augustin MA (2011) Physicochemical characterization and oxidative stability of fish oil and fish oil–extra virgin olive oil microencapsulated by sugar beet pectin. Food Chem 127(4):1694–1705

Quispe-Condori S, Saldana MDA, Temelli F (2011) Microencapsulation of flax oil with zein using spray and freeze drying. Food Sci Technol 44:1880–1887

Ramcharitar A, Badrie N, Mattfeldt-Beman M, Matsuo H, Ridley C (2005) Consumer acceptability of muffins with flaxseed (Linum usitatissimum). J Food Sci 70(7):504–507

Re MI (1998) Microencapsulation by spray drying. Dry Technol 16(6):1195–1236

Shivakumar KM, Chetana R, Reddy SY (2012) Preparation and properties of encapsulated fat powders containing speciality fat and ω/pufa-rich oils. Int J Food Prop 15(2):412–425

Taherian AR, Britten M, Sabik H, Fustier P (2011) Ability of whey protein isolate and/or fish gelatin to inhibit physical separation and lipid oxidation in fish oil-in-water beverage emulsion. Food Hydrocoll 25(5):868–878

Tang CH, Li XR (2013) Microencapsulation properties of soy protein isolate: influence of preheating and/or blending with lactose. J Food Eng 117(3):281–290

Thirundas R, Gadhe KS, Syed IH (2012) Optimization of wall material concentration in preparation of flaxseed oil powder using response surface methodology. J Food Process Preserv 38(3):889–895

Tonon RV, Grosso CRF, Hubinger MD (2011) Influence of emulsion composition and inlet air temperature on the microencapsulation of flaxseed oil by spray drying. Food Res Int 44:282–289

Tonon RV, Pedro RB, Hubinger MD (2012) Microencapsulation of flaxseed oil by spray drying: effect of oil load and type of wall material. Dry Technol 30(13):1491–1501

Turchiuli C, Fuchs M, Bohin M, Cuvelier ME, Ordonnaud C, Peyrat-Maillard MN, Dumoulin E (2005) Oil encapsulation by spray drying and fluidized bed agglomeration. Innov Food Sci Emerg Technol 6:29–35

Yu Cui J, Taneja A, Zhu X, Singh H (2007) Evaluation of processed cheese fortified with fish oil emulsion. Food Res Int 42:1093–1098

Acknowledgements

The authors would like to gratefully acknowledge Director, ICAR-National Dairy Research Institute, Karnal, India, and head, SRS, ICAR-NDRI, Bengaluru, for financial assistance and AAK Kamani oil industry, Mumbai, India, for gifting flaxseed oil to conduct the present study. Authors also acknowledge IISC, Bangalore, for extending GC–MS and SEM facilities on payment basis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

40003_2020_461_MOESM1_ESM.png

GC-MS chromatogram for flaxseed oil microcapsules containing 30% OL and 30% TS prepared with modified starch and soy protein isolate

Rights and permissions

About this article

Cite this article

Tambade, P.B., Sharma, M., Singh, A.K. et al. Flaxseed Oil Microcapsules Prepared Using Soy Protein Isolate and Modified Starch: Process Optimization, Characterization and In Vitro Release Behaviour. Agric Res 9, 652–662 (2020). https://doi.org/10.1007/s40003-020-00461-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40003-020-00461-8