Abstract

Pasta was prepared from brown rice (var. PR 118) flour incorporated with sodium alginate (0.5–2.5%), xanthan gum (0.5–2.5%), vital gluten (2–10%) and pre-gelatinized flour (10–50%) as binders. Effect of these binders on the quality characteristics of brown rice pasta was evaluated. Incorporation of xanthan gum (1.5%), vital gluten (8%), pre-gelatinized flour (40%) individually and their combination as xanthan gum (1.5%) + vital gluten (4%) + pre-gelatinized flour (20%) were found optimum to improve the cooking quality and overall acceptability of brown rice pasta. Xanthan gum (1.5%) + pre-gelatinized flour (20%) in combination can also be incorporated into brown rice in order to prepare gluten-free pasta. In addition to being a diversified convenience food, non-wheat pasta would be suitable for people suffering from wheat intolerance. Shelf life of selected pasta samples was evaluated during storage at ambient conditions for 3 months. Type of binder and storage period did not influence the cooking quality and sensory attributes of pasta significantly (p ≤ 0.05). Least significant variation was found in moisture, water activity and free fatty acid content of pasta over 3 months of storage period.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pasta is a stable food product, mostly produced by mixing durum wheat semolina and water. It can be consumed as fresh or can be dried for future use [7]. Rice can also be used as a raw material for production of pasta but during production, some technological problems may arise due to lack of gluten [4]. Rice pasta prepared without any binder had poor strength, low firmness and more cooking losses [25]. Gluten-free pasta produced with the addition of higher levels of modified starch, xanthan gum (XG) and locust bean gum to rice flour found to have similar quality characteristics as wheat-based pasta [30]. Pre-gelatinization of starch improves functional properties and gives texture to the product [25]. Hydrocolloids mimics the visco-elastic properties of gluten and results in improved structure, mouthfeel, acceptability and shelf life. Gums can be used singly or in combination with starch to create certain effects [25].

Rice has become an attractive raw material for the production of new cereal-based foods like bread and pasta [6]. However, thiamine deficiency is very common, where polished rice is consumed as staple food [27]. Brown rice provides 15 essential nutrients, including B vitamins, niacin, potassium, antioxidants, phyto-nutrients and fibres. Consumption of brown rice can overcome the morbidity rate caused by thiamine deficiency. Promoting brown rice is a formidable challenge as most of the Asians have acquired taste for polished rice [28]. In brown rice pasta, the role of fibre and interaction of fibre and starch seems to warrant investigation in view of the ever increasing popularity of high-fibre pasta and the associated technological problems in its production [18]. Non-wheat pasta would be suitable for people suffering from wheat intolerance [29].

Keeping in view the above facts, the present work was planned with the objective to optimize the levels of different binders (sodium alginate, xanthan gum, vital gluten and pre-gelatinized flour) alone and in combination to produce good quality brown rice pasta with respect to cooking and sensory quality.

Materials and Methods

Material

Paddy (var. PR 118) was procured from Department of Plant Breeding and Genetics, PAU, Ludhiana. Xanthan gum and sodium alginate were purchased from Thames Chemicals (S D Fine Chemicals Limited), Ludhiana, Punjab. Vital gluten (VG) was purchased from local market, Ludhiana, Punjab, India. All the chemicals used in the analysis were of AR grade.

Preparation of Brown Rice Flour

Brown rice was obtained by dehulling of paddy (13% moisture) using Satake dehuller (SB10D—MILLTOP, Leland Street, NSW, Australia). Grinding of brown rice was done using Cemotac mill to obtain brown rice flour of particle size <200 µ. Brown rice flour had 6.68% crude protein, 1.76% ash, 2.56% fat, 0.28% crude fibre and 76.88% carbohydrate on dry weight basis as determined by the standard AACC methods [1].

Preparation of Pre-gelatinized Flour (PGF)

Rice flour was tempered to a moisture content of 40% with water in a mixer. The tempered rice flour was spread (1-cm-thick layer) on a cheese cloth. Steaming was done at 85 °C for 45 min in order to achieve 70–80% degree of gelatinization [2] followed by drying at 50 °C in a hot air oven. The pre-gelatinized flour was ground to uniform particle size [25].

Preparation of Pasta

Different binding agents (sodium alginate, xanthan gum, vital gluten and pre-gelatinized flour) at various levels (Table 1) were mixed with brown rice flour. Weighed amount of brown rice flour-binding agents was put into pasta-mixer-extruder (Model: Dolly, La Monferina, Asti, Italy), and 35 ml water was slowly added. The mixture was mixed for 10 min to distribute water uniformly throughout the flour particles. The moist flour aggregates were placed in a metal extruder attachment of the pasta machine fitted with adjustable die. The dough was extruded through the die into rotini (spiral) shape and cut to about 5 cm length using a cutter attached to the pasta extruder. The extruded pasta was dried in a tray drier with air circulation at 50 ± 2 °C for 60 min, cooled, packed in high-density polythene bags and stored at refrigeration temperature (7 °C) until analysis. These samples were evaluated for cooking quality and sensory properties by standard procedures.

Cooking Quality of Brown Rice Pasta

Cooking time (the time required for complete cooking of pasta), water absorption, volume expansion and gruel solid losses were determined by AACC methods [1].

Sensory Properties

The cooked pasta samples were served in dishes for sensory evaluation. Cooked pasta was evaluated for sensory attributes (appearance, texture and flavour) through a panel of semi-trained judges (n = 10) [11]. Final judgement as overall acceptability score was obtained by averaging the scores given by all the panellists.

Storage Stability

Based on the cooking and sensory properties, selected pasta samples were stored at ambient storage conditions (20–30 °C, 50–70% relative humidity) for 3 months after packing in high-density polyethylene (75 µ) pouches and analysed for cooking quality and sensory properties at monthly interval. The stored pasta was also evaluated for moisture content, water activity and free fatty acid content by standard procedure of AACC [1].

Total Phenolic Content and Radical Scavenging Activity

Phenolic compounds were extracted by refluxing 1 g powdered pasta sample with 80% aqueous methanol for 2 h. Total phenolic content of methanolic extracts was determined with Folin–Ciocalteu colorimetric method [26]. The DPPH assay of methanolic extract (as obtained for estimation of total phenolic content) of pasta samples was performed according to the method described by Yamaguchi et al. [31].

Statistical Analysis

The experimental data were subjected to analysis of variance for a complete random design using Statistical Package for Social Sciences (SPSS Inc., Chicago) software (version 18.0). Tukey’s tests were used to determine the difference among means at the level of 0.05 [5]. The results are presented as mean ± SD (n = 3).

Results and Discussion

Effect of Sodium Alginate and Xanthan Gum

Cooking time of the pasta prepared with addition of sodium alginate and xanthan gum varied from 330 to 435 s (Table 2). Lowest cooking time was noticed for the pasta prepared with 2.5% sodium alginate, while highest cooking time was observed with pasta prepared with 0.5% sodium alginate and 1.5% xanthan gum. Significant (p ≤ 0.05) variation in cooking time of pasta prepared at different levels of sodium alginate and xanthan gum was observed. The data reported in Table 2 depicted that incremental addition of gums reduced the cooking time of pasta. This may be due to the adherence of starch granules to one another and more homogeneous distribution of water through the dough system due to the polymeric structures of gums [24].

Non-significant (>0.05) variation was reflected with respect to water absorption of brown rice pasta prepared with addition of different levels of sodium alginate and xanthan gum, though per cent water absorption increased slightly with increase in the level of gums. Compared to pasta prepared with addition of sodium alginate, xanthan gum incorporated pasta had higher water absorption and significantly differed. Brown rice pasta containing 1.5% xanthan gum absorbed 234.5% water, which non-significantly (p > 0.05) increased to 239.7% at 2.5% level. Water absorption increased due to hydrophilic nature of gums [13]. Yalcin and Basman [30] also observed higher water absorption and swelling volume in noodle samples supplemented with xanthan gum.

Increase in water absorption of the pasta also coincided in increased volume or volume expansion of pasta. Volume expansion for pasta at 1.5% level of sodium alginate and xanthan gum was 1.36 ml/g and 1.38 ml/g, which increased to 1.40 ml/g and 1.52 ml/g at 2.5% level, respectively. However, the volume expansion of pasta showed non-significant (p > 0.05) changes as affected by both, the type of gum added and the varied level of gums. The highest volume expansion was observed for the pasta prepared by addition of 2.5% xanthan gum. Alginate is polymer build-up of β-d mannuronic and α-l guluronic acids. The carboxyl and hydroxyl groups in the structure allow alginate to readily bind water. Hence, the increased hydration properties might be due to the high affinity of alginate to water. Addition of alginate enhances the swelling ability of starch granules [14].

Leaching of solids in cooked water was decreased significantly (p ≤ 0.05) as the level of sodium alginate and xanthan gum in pasta increased. Gruel solid loss (GSL) for pasta sample with 1.5% xanthan gum was 1.29% which significantly decreased to 1.04 and 0.98% at 2.0 and 2.5% level, respectively. These results are in agreement with the study of Yalcin and Basman [30] who observed that supplementation of rice noodles with xanthan gum results in significant decrease in cooking loss indicating improved noodle quality. Yadav et al. [29] also found decrease in gruel loss on incorporation of hydrocolloids (carboxyl methyl cellulose) in pearl millet- and barley-based non-wheat pasta. Addition of sodium alginate improved the cooking quality of pasta as inferred from percent solid loss. GSL decreased as the level of sodium alginate increased. Pasta having 0.5% sodium alginate lost 1.62% solids which further decreased to 1.10% when level of sodium alginate increased to 2.5%. Use of alginate reduces the cooking loss of wheat noodles due to strong binding of starch on the surface of alginates [14].

Overall acceptability of pasta quietly influenced by the type and level of binders added in pasta making. Pasta prepared with 1.5% xanthan gum fetched the highest overall acceptability score (8.3), whereas pasta prepared with 0.5% sodium alginate was rated as least acceptable among all the samples. Other samples showed non-significant (p > 0.05) variation in the overall acceptability score. In general, increasing the level of sodium alginate up to 1.5% increased the overall acceptability of pasta, whereas addition of xanthan gum beyond 1.5% resulted lower overall acceptability score.

Effect of Vital Gluten

Table 3 gives the effect of vital gluten on the cooking quality of brown rice pasta. Significant (p ≤ 0.05) variation was found in time required to cook the pasta prepared with varying level of vital gluten. Incremental addition of vital gluten up to 8% level significantly lowered the cooking time of brown rice pasta; however, non-significant (p > 0.05) changes in cooking time were observed with further addition (10%) of vital gluten. Least cooking time (330 s) was observed at 10% level of vital gluten. The water absorption of dry gluten is less than that of native gluten. It is typically 1.3–1.5 parts of water to 1 part of dry gluten as compared to about 2.5–3 times for native gluten. During drying of vital gluten, most of the changes, especially in water absorption and rheological properties, are caused by the drying process. Drying results in denaturation of protein. However, Raina et al. [21] reported that with increasing the protein source in mix, cooking time of pasta increased. This may be because they used pre-gelatinized flour for pasta making.

Table 3 also depicts a view of water absorption (%) and volume expansion (ml/g) of vital gluten-added brown rice pasta on cooking. With increase in level of vital gluten in flour, there was a significant (p ≤ 0.05) decrease in water absorption and subsequently the expansion in volume also reduced. Sharp fall in water absorption of pasta prepared with 4 and 6% vital gluten was noticed after which it declined steadily to 168.7 and 159.9% at 6 and 8% level of vital gluten, respectively. However, Sharma et al. [22] reported increased water absorption and volume expansion of pasta on addition of native plant protein sources. Our results are in contrast with Sharma et al. [22], because we used dried gluten flour; however, they used different botanical sources in native form.

Similar trend as that of water absorption was seen in volume expansion of brown rice pasta. Volume expansion was 2.24 ml/g (4% vital gluten) which reduced to 1.75 ml/g (6% vital gluten), with increase in level of vital gluten from 4 to 10%. More than 36% reduction in initial volume of pasta was recorded by increasing the level of vital gluten from 4 to 10%. Masur et al. [19] observed that incorporation of protein positively affected the size and slope of bread crumb. Increase in loaf volume, weight and slice volume was evident with the addition of gluten. However, Majzoobi et al. [15] reported that the addition of gluten reduces cooking loss and increases water absorption. This may be again due to use of native or less extensively heated gluten by Majzoobi et al. [15].

Gruel solid loss of brown rice pasta prepared with addition of vital gluten at varying level did not altered radically. Significant changes in GSL of pasta only with 4 and 8% and those of 4 and 10% were recorded, while at other levels, the GSL varied non-significantly (p > 0.05). The per cent solid loss for pasta at 4% vital gluten was 2.22, which decreased to 1.59 at 6% gluten. Gruel solid loss of 1.51 and 1.44% was noted at 8 and 10% level of vital gluten incorporated in pasta, respectively. Kaur et al. [9] also found nonlinear decrease in gruel solid loss of pasta enriched with different plant protein sources. However, Yadav et al. [29] found that addition of whey protein concentrate increases gruel loss in non-wheat pasta based on pearl millet and barley. This was might be due to higher solubility of whey protein concentrate as compared to gluten.

Overall acceptability of pasta prepared with addition of 4–10% vital gluten ranged in between 7.4 and 8.1. Significant (p ≤ 0.05) difference in the overall acceptability of pasta prepared at 6 and 10% level of vital gluten was noticed, and other levels of vital gluten did not influenced the overall acceptability of pasta, significantly. These results are in agreement with the studies of Kaur et al. [9] which indicated an increase in overall acceptability of protein-enriched pasta.

Effect of Pre-gelatinized Flour

Data presented in Table 4 depict the effect of pre-gelatinized flour on cooking quality and overall acceptability of pasta. Cooking time did not show significant variation as the level of pre-gelatinized flour increased. Cooking time for pasta having pre-gelatinized flour as binder varied non-significantly (p > 0.05) from 328 to 333 s. The increasing level of pre-gelatinized flour reduced the cooking time of pasta. Reduction in cooking time of pasta prepared using pre-gelatinized rice flour was also observed by Raina et al. [21].

Similar to cooking time, pre-gelatinized flour at varying level did not show significant changes in the water absorption of cooked pasta. The water absorption of pasta varied narrowly from 106.3 to 119.5%. Furthermore, it was observed that water absorption portrayed nonlinear trend. It ranged from 108.2 to 119.5% by varying the level of pre-gelatinized flour in pasta between 20 to 30%. Further increase in the level of pre-gelatinized flour between 30 and 40% decreased the water absorption in the range of 110.6–106.3%. The use of pre-gelatinized flour or parboiled flour promotes the formation of less hydrophilic starchy structure, resulting in lower water uptake [16]. Similar to water absorption, volume expansion of cooked pasta also exhibited the same pattern. Volume expansion, however, showed significant (p ≤ 0.05) variation at 30 and 50% level of pre-gelatinized flour. Gelatinization of starch enhances the cooking quality of rice noodles, and the noodle samples with a gelatinization level of 25% exhibit lower cooking loss [30]. Increase in cooking loss was observed in noodle samples as gelatinization level increased to 30%. However, higher degree of starch gelatinization increases the tendency of macromolecule to re-associate and thus results in newly organized structure that retard further starch swelling and solubilization during cooking [17].

It is evident from Table 4 that gruel solid loss decreased on addition of pre-gelatinized flour up to 40% level at which maximum reduction in GSL was observed. GSL of cooked pasta dropped significantly (p ≤ 0.05) from 2.35 to 1.61% by increasing the level of pre-gelatinized flour from 20 to 30%. Yalcin and Basman [30] also observed that the increase in gelatinization level from 15 to 25% results in decrease in cooking loss from 15.4 to 11.1% in rice noodles. Incorporation of pre-gelatinized flour beyond 30% level further increased the gruel solid loss from 1.68 (40%) to 1.72 (50%), but the increase was non-significant. Fernandes et al. [3] explained that during cooking solid loss is due to the solubilization of loosely bound gelatinized starch from surface of product and increases with increase in pre-gelatinized flour level. Addition of pre-gelatinized flour up to 40% in pasta resulted in increasing the overall acceptability of the product. However, non-significant (p > 0.05) difference in the pasta prepared with different levels of pre-gelatinized flour was observed.

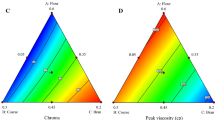

Effect of Additives in Combination

The effect of various binders, viz. xanthan gum, vital gluten and pre-gelatinized flour in combination was assessed for the preparation of brown rice pasta, and results are presented in Table 5. Significant (p ≤ 0.05) changes in the cooking quality and overall acceptability of brown rice pasta prepared with addition of various binders in combination were observed. Lowest cooking time was observed with the pasta prepared with 1.5% xanthan gum and 4% vital gluten. Maximum water absorption was observed in the cooked pasta prepared with 1.5% xanthan gum and 20% pre-gelatinized flour, whereas volume expansion was highest in the pasta prepared with 4% gluten and 20% pre-gelatinized flour. Other pasta samples showed non-significant (p > 0.05) changes in the volume expansion (Table 5). Gruel solid loss was less in the pasta containing 1.5% xanthan gum, 4% vital gluten and 20% pre-gelatinized flour; however, other pasta samples showed non-significant variation in GSL. The hydrocolloid–amylose complex formed during cooking reduces starch molecules solubilization upon heating in excess water and thus results in decrease in cooking loss and increase in weight gain of cooked rice [10]. The data on cooking quality with respect to cooking time, water absorption and volume expansion and gruel solid loss elaborated that the cooking quality of brown rice pasta was better when binders were used in combination. Among combinations, XG (1.5%) + VG (4%) + PGF (20%) level proved best in terms of cooking quality of brown rice pasta. Structure building and water binding properties of starch, gums and hydrocolloids mimic gluten in the manufacture of gluten-free bakery products [14]. The overall acceptability of the pasta prepared with 4% vital gluten and 20% pre-gelatinized flour was low (6.1) and significantly (p ≤ 0.05) differed from pasta prepared with other combinations of binders which showed non-significant alterations in the overall acceptability score and ranged between 7.9 and 8.1.

Chemical Composition

Brown rice pasta incorporated with different levels of additives differed significantly from each other with respect to crude protein and ash content, whereas fat and fibre content varied non-significantly (p > 0.05) (data not presented). Among all the brown rice pasta, pasta with 8% vital gluten had highest protein (14.0%), fat (2.58%) and ash (1.75%). Not much variation was found in different pasta samples for fibre content which ranged from 0.27 to 0.34%.

Effect of Storage Period on Cooking Quality

The brown rice pasta prepared with incorporation of selected levels of additives which showed most desirable quality characteristics in terms of cooking time, water absorption, volume expansion, gruel solid loss were evaluated for the storage stability after packing in high-density polyethylene pouches at ambient conditions.

The brown rice pasta of better quality was obtained by incorporation of various additives, viz. xanthan gum (1.5%), vital gluten (8%), pre-gelatinized flour (40%), xanthan gum (1.5%) + pre-gelatinized flour (20%) and xanthan gum (1.5%) + vital gluten (4%) + pre-gelatinized flour (20%). The stored pasta was studied for changes in cooking quality at monthly interval. The data pertaining to effect of storage period on these characteristics are presented in Table 6.

The time required for cooking of the pasta was influenced by the type of additive incorporated as well as storage period. Higher cooking time was observed for the brown rice pasta prepared with addition of xanthan gum (1.5%), while lower values of cooking time were observed for the brown rice pasta prepared with the addition of xanthan gum (1.5%) + pre-gelatinized flour (20%). Further, it was noticed that as the storage period increased successively, there was decrease in cooking time. This trend was observed in all the pasta samples irrespective of the type and level of additive added. Kaur et al. [8] reported that the bran physically disrupt gluten matrix and provides path for water absorption into the whole wheat spaghetti strand and thus reduces cooking time. The decrease in cooking time over the storage period may be attributed to the slight degradation of polymeric starch in brown rice pasta and decreased capacity of additives to act as binder.

The amount of water absorbed by the pasta during cooking is affected by type of additive used and storage period. Similar to cooking time, the highest value of water absorption was observed for xanthan gum (1.5%) incorporated pasta and lowest value for the brown rice pasta prepared with pre-gelatinized flour (40%). Gums can increase the water absorption of pasta during cooking or soaking [12]. It was observed that pre-gelatinized flour when used alone contributed lower to water absorption and retention than when used in combination with gluten and xanthan gum. Moreover, the water absorption of freshly prepared pasta was highest and continuously decreased with the storage period. The same drift in water absorption of brown rice pasta was observed excluding the type of additive used for preparation of pasta. The reason for such performance of pasta with respect to water absorption may be same as quoted for the changes in cooking time.

During cooking, the polymers (starch, protein, fibres, gums) absorb water, get swelled and result in increase in the volume which is considered as the desirable characteristic of pasta. Thus, cooking time, water absorption and volume expansion are directly related to each other and this trend is well reflected in our study as evident from Table 6. Same results for volume expansion were observed as has been reported for cooking time and water absorption taking into consideration the effect of additive type used and storage period. Further, the change in volume expansion was also significant as recorded for cooking time and water absorption. Gums form a network of starch granule and encapsulate it during cooking and prevent excessive swelling and diffusion of amylase [20].

Cooking of pasta is associated with cooking temperature and time-dependent degradation and solubilization of the polymers and other constituents of pasta. As consequence, the solids from pasta are lost in the cooked water. Higher is the cooking temperature and time, more is the loss of gruel solids. Higher gruel solid loss was observed for the pasta which was cooked for more time. Further, type of additives also influenced the gruel solid loss. The highest value of gruel solid loss was observed for the pasta prepared with 40% pre-gelatinized flour and lowest value for the pasta prepared with xanthan gum (1.5%) + vital gluten (4%) + pre-gelatinized flour (20%). Higher level of pre-gelatinized flour resulted in more gruel solid loss, whereas the high-strength intact polymers (xanthan gum and gluten) resulted in less gruel solid loss. Besides this, the storage period which affected the cooking time, water absorption and volume expansion also has its impact on the gruel solid loss. As the storage period of pasta progressed, the gruel solid loss also increased.

Changes in Moisture Content, Water Activity and Free Fatty Acids Content during Storage

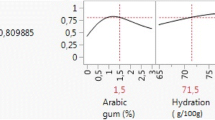

Moisture content of any product is the predominant parameter defining the stability and thus shelf life. Higher moisture content usually is associated with the detrimental changes in physico-chemical properties of the food product. Moisture content of freshly prepared pasta varied from 6.5 to 7.7% which increased to 8.5% at the end of 3 months of storage. Figure 1 shows that the increase in moisture content in pasta was not directly associated with the type and level of additive incorporated but was solemnly noticed as the function of storage conditions. The trend of changes in moisture content of pasta over the entire storage period was almost same for all the samples. However, it was elucidated that the rate of increase in moisture content of all the pasta samples was more during first month of storage. As the storage period advanced over the first month, the rate of uptake of moisture by pasta decreased. Non-significant (p > 0.05) changes were observed in the moisture content of pasta stored for 2 and 3 months. Hence, further storage period do not likely to influence the changes in moisture content of pasta, noticeably.

Water activity represents the true or free water available for the growth of micro-organisms and other biochemical reaction which are deteriorative in nature. Hence, water activity determination of the product is of utmost importance in shelf life and storage stability assessment. Often, water activity is considered as the function of moisture content of the product. The value for water activity of brown rice pasta showed not much variation after 3 months of storage. The increase in water activity value of pasta products was correlated with increased moisture content; however, no direct linear relationship between water activity and moisture content was observed. This behaviour explicates the fact that the increased moisture during storage in pasta may be held differently by various additives used. Further, increase in water activity of pasta containing additives in combination was more profound compared to other additive-added pasta. Similarly, the gluten incorporated pasta showed very subtle increase in the water activity value over other pasta samples. This may be attributed to the variation in water holding capacity of different additives. Storage stability point of view, the pasta prepared with inclusion of vital gluten performed better as it restricted to augment the water activity and thus possible biochemical changes.

Development of free fatty acids during storage is detrimental to the quality of food products as it not only produces the offensive flavour in the product but also enhances the rate of oxidative degradation through formation of free radicals. Free fatty acids are formed by hydrolysis of fat in the product, and the rate of formation of free radical is the function of moisture and temperature. Free fatty acid content of the brown rice pasta samples was highly affected during first month of storage period. The free fatty acid content of pasta increased from initial value of 0.564–1.128%. Increase in free fatty acid content of pasta at the end of 1 month of storage period was more reflective than the remaining storage period. From second month onwards, non-significant (p > 0.05) increase in free fatty acid content was observed. The presence of lipase enzyme increases free fatty acid content of bran under favourable conditions during storage [23]. This may be due to fact that the moisture uptake of pasta also slowed down after 1 month of storage. Further, no convincing effect of additive type on free fatty acid content and overall acceptability (Fig. 2) of pasta was noticed.

Antioxidant Activity

The total phenolic content (TPC) of pasta varied from 49.90 to 65.17 mg/100 g, highest TPC being found in pasta prepared with addition of xanthan gum, while lowest value of TPC was observed in the pasta prepared with 40% pre-gelatinized flour as binder. Further, significant (p ≤ 0.05) difference in the total phenolic content of all the pasta samples was observed. The radical scavenging activity (RSA) of pasta sample varied in a very narrow range (61.74–68.26). Highest RSA was observed for the pasta prepared with 8 per cent gluten which differed significantly (p ≤ 0.05) from all other pasta sample for RSA, while the total antioxidant activity of other pasta samples was non-significantly varied.

Conclusions

Vital gluten and other binders improved the quality of pasta by reducing the cooking loss and can be used as additives as these increase the binding properties of brown rice flour. Lower cooking time was noticed with increase in the level of the binders. The two combinations of binders and vital gluten, i.e., xanthan gum (1.5%) + pre-gelatinized brown rice flour (20%) and xanthan gum (1.5%) + vital gluten (4%) pre-gelatinized brown rice flour (20%), were found optimum additives for preparation of acceptable quality of brown rice pasta. Pasta samples stored for 3 months period did not show significant quality changes. Brown rice along with above binders possessed impetus potential for the preparation of pasta.

References

AACC (2000) Approved Methods of American Association of Cereal Chemists, 10th edn. American Association Cereal Chemists Inc, St. Paul

Cai W, Diosady LL (1993) Model for gelatinization of wheat starch in a twin-screw extruder. J Food Sci 58:872–875

Fernandes MDS, Shen GAR, Leoro MGV, Chang YK, Steel CJ (2013) Effect of adding unconventional raw material on the technological properties of rice fresh pasta. J Food Sci Technol 33:257–264

Gallagher E, Gormley TR, Arendt EK (2004) Recent advances in the formulation of gluten-free cereal-based products. Trends Food Sci Technol 15:143–152

Gomez AK, Gomez AA (2010) Statistical procedures for agricultural research, 2nd edn. Wiley, New York

Hagenimana A, Ding X, Fang T (2006) Evaluation of rice flour modified by extrusion cooking. J Cereal Sci 43:38–46

Hager AS, Zannini E, Arendt EK (2012) Gluten free pasta—advances in research and commercialization. Cereal Food World 57:225–229

Kaur G, Sharma S, Nagi HPS, Dar BN (2012) Functional properties of pasta enriched with variable cereal brans. J Food Sci Technol 49:467–474

Kaur G, Sharma S, Nagi HPS, Ranote PS (2013) Enrichment of pasta with different plant proteins. J Food Sci Technol 50:1000–1005

Lai HM (2012) Effect of rice properties and emulsifiers on the quality of rice pasta. J Sci Food Agric 82:203–216

Larmond E (1970) Methods for sensory evaluation of food. Canada Department of Agric Publications, Ottawa

Larrosa V, Lorenzo G, Zaritzky N, Califano A (2013) Optimization of rheological properties of gluten-free pasta dough using mixture design. J Cereal Sci 57:520–526

Lazaridou A, Duta D, Papageorgiou M, Belc N, Billiaderis CG (2007) Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J Food Eng 79:1033–1047

Lee S, Bae IY, Jung JH, Jang KI, Kin YW, Lee HG (2008) Physiochemical, textural and noodle-making properties of wheat dough containing alginate. J Texture Stud 39:393–404

Majzoobi M, Ostovan R, Farahnaky A (2011) Effects of gluten powder on the quality of wheat flour spaghetti cooked in distilled or salted water. J Texture Stud 42:468–477

Marti A, Caramanico R, Bottega G, Pagani MA (2013) Cooking behaviour of rice pasta: effect of thermal treatments and extrusion conditions. J Food Sci Technol 54:229–233

Marti A, Pagani MA (2013) What can play role of gluten in gluten free pasta? Trends Food Sci Technol 31:63–71

Marti A, Seetharaman K, Pagani MA (2010) Rice based pasta: a comparison between conventional pasta making and extrusion cooking. J Cereal Sci 52:404–409

Masur SB, Taracchand KC, Kulkarni UN (2010) Effect of incorporation of gluten and wheat bran on quality characteristics of bread flour. Karnataka J Agric Sci 23:473–475

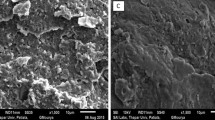

Purnima C, Ramasarma PR, Prabhasankar P (2012) Studies on effect of additives on protein profile, microstructure and quality characteristics of pasta. J Food Sci Technol 49:50–57

Raina CS, Singh S, Bawa AS, Saxena DC (2005) Textural characteristics of pasta made from rice flour supplemented with proteins and hydrocolloids. J Texture Stud 36:402–420

Sharma S, Kaur A, Kaur G, Nanda V (2013) Influence of different protein sources on cooking and sensory quality of pasta. Int J Eng Res Appl 3:1757–1763

Sharma S, Kaur S, Dar BN, Singh B (2014) Storage stability and quality assessment of processed cereal brans. J Food Sci Technol 51:583–588

Sivaramakrishnan HP, Senge B, Chattopadhyay PK (2004) Rheological properties of rice dough for making rice bread. J Food Eng 62:37–45

Sozer N (2009) Rheological properties of rice pasta dough supplemented with protein and gums. Food Hydrocoll 23:849–855

Velioglu YS, Mazza G, Gho L, Onmah BD (1998) Antioxidant activity and total phenolics in selected fruits and vegetables and grain products. J Agric Food Chem 46:4113–4117

Vetha-Varshini PA, Azhagusundaram K (2010) Brown rice—hidden nutrients. Process Food Ind 5:27–32

Vetha-Varshini PA, Azhagusundaram K, Vijay Parveen P (2013) Brown rice—hidden nutrients. J Biosci Technol 4:503–507

Yadav DN, Balasubramanian S, Kaur J, Anand T, Singh AK (2012) Non-wheat pasta based on pearl millet flour containing barley and whey protein concentrate. J Food Sci Technol. doi:10.1007/s13197-012-0772-2

Yalcin S, Basman A (2008) Effect of gelatinization level, gum and transglutaminase on the quality characteristics of rice noodles. Int J Food Sci Technol 43:1637–1644

Yamaguchi T, Takamura H, Matoba T, Terao J (1998) HPLC method for evaluation of the free radical scavenging activity of foods by using 1,1-diphenyl-picrylhydrazyl. Biosci Biotechnol Biochem 62:1201–1220

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaur, N., Sharma, S., Yadav, D.N. et al. Quality Characterization of Brown Rice Pasta Supplemented with Vital Gluten and Hydrocolloides. Agric Res 6, 185–194 (2017). https://doi.org/10.1007/s40003-017-0250-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40003-017-0250-1