Abstract

This study focused on determining the effect of powdered activated carbon on treatment performance and membrane fouling for pharmaceutical wastewater treatment by using an anaerobic membrane bioreactor system. The anaerobic membrane bioreactor system was operated without powdered activated carbon addition for 131 days and with powdered activated carbon addition for 169 days. The anaerobic membrane bioreactor performance was evaluated considering the chemical oxygen demand concentration, flux value, biomass concentration, extracellular polymeric substances and soluble microbial product concentrations. In the period operated without the powdered activated carbon addition, the chemical oxygen demand removal efficiencies were in the range of 67–70%, whereas the removal efficiency of chemical oxygen demand increased up to 96% after the powdered activated carbon addition. At the beginning, the system was operated with the flux of 3.2 L/m2 h and the flux decreased to 0.4 L/m2 h on the 131st day. Although the chemical oxygen demand removal performance increased, the addition of powdered activated carbon was not effective in improving the flux. In the study, scanning electron microscope, energy-dispersive X-ray spectroscopy, confocal laser scanning microscopy, optical profilometer measurements and fouling modeling studies were conducted to identify the mechanism of fouling on the membrane. According to these analyzed results, the predominant fouling mechanism was cake layer formation for the fouled membrane used in the period of operation without the powdered activated carbon addition. It was observed that the thickness of the cake layer accumulated on the membrane surface slightly decreased and the cake layer became smoother with powdered activated carbon addition. When the membrane fouling model was evaluated, it was clearly revealed that the cake layer adsorption was dominant before the powdered activated carbon addition. Although the dominant fouling mechanism shifted to the intermediate adsorption with the powdered activated carbon addition, the cake filtration and intermediate adsorption mechanisms were predominant simultaneously.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Anaerobic membrane bioreactor (AnMBR) systems are a combination of anaerobic treatment and membrane process that contributes high organic matter removal (Chen et al. 2020). The AnMBR system has many advantages such as long solid retention time (SRT), low sludge production and low energy requirement which are beneficial in wastewater treatment with high efficiency and ease of operation (Lin et al. 2013; Sohn et al. 2021a). This process has also the advantage of producing energy with the end product of methane and hydrogen due to having the anaerobic degradation process including hydrolysis, acidogenesis, acetogenesis and methanogenesis (Khan et al. 2016; Sohn et al. 2021a). After the digestion of pollutants, the sludge and treated wastewater are separated by the membrane (Ji et al. 2020). AnMBR technology has been applied successfully in the treatment of various wastewater such as slaughterhouse (Saddoud and Sayadi 2007; Jensen et al. 2015), municipal (Martinez-Sosa et al 2011; Dong et al. 2016; Chen et al. 2017a, 2017b), landfill leachate (Xie et al. 2014), domestic (Yue et al. 2015; Jeong et al. 2017; Ji et al. 2020), liquid dairy manure (Wallace and Safferman 2014), food industry such as coffee grounds (Qiao et al. 2013), sugarcane vinasse (Mota et al. 2013), snacks (Ramos et al. 2014) and confectionery (Balcıoğlu et al. 2021). Also, the numerous pilot and full-scale AnMBR studies have been carried out for treating of field crop processing, dairy processing and the beverage industry (Song et al. 2020). In addition, AnMBR has been used commonly for the treatment of pharmaceutical wastewater (Dutta et al. 2014; Xiao et al. 2017; Huang et al. 2018; Mai et al. 2018; Kaya et al. 2019; Chen et al. 2020; Cheng et al. 2021).

Although successful results have been obtained for wastewater treatment in AnMBR systems, membrane fouling has been still one of the biggest obstacles for this process (Chen et al. 2020). One of the most important reasons for the membrane fouling is the production of extracellular polymeric substances (EPS) and soluble microbial products (SMP) by microorganisms that accumulate on the membrane surface and hinder the wastewater filtration (Kaya et al. 2019). Various approaches have been tried to reduce the membrane fouling in the literature. The main approach is the optimization of key parameters such as operating conditions, membrane type and biomass characteristics (Maaz et al. 2019). Besides, there are novel methods such as application of biogas sparging (Vyrides et al. 2009), addition of powdered activated carbon (PAC) (Gao et al. 2016), addition of granular activated carbon (GAC) (Hu and Stuckey 2007) and glass beads (Düppenbecker et al. 2017) to mitigate membrane fouling. In addition, some enhancers such as biochar, zeolite, polyaluminum chloride and iron have been added into the reactor to mitigate the membrane fouling (Sohn et al. 2021a).

The addition of PAC into the reactor provides many benefits in reducing membrane fouling and increasing removal efficiencies of pollutants. PAC could adsorb the pollutants, increase the biodegradability of pollutants and scour the pollutants from the membrane surface (Lei et al. 2019). The dosages of PAC in the AnMBR studies have been applied in the range of 1–4.5 g/L treating synthetic wastewater, such as sucrose-meat extract, saline, textile, pharmaceutical and domestic (Hu and Stuckey 2007; Akram and Stuckey 2008; Vyrides et al. 2009; Baêta et al. 2012; Xiao et al. 2017; Lei et al. 2019; Yang et al. 2019). There are limited studies on the AnMBR operation with PAC addition for treating pharmaceutical wastewater. In these studies, AnMBR systems were operated with the addition of 1 g/L PAC dosage (Xiao et al. 2017; Mai et al. 2018). In these studies, decrease in cake resistance, increase in flux and decrease in transmembrane pressure (TMP) were obtained with the PAC addition. The fouling mechanism has been evaluated with the analyses such as scanning electron microscopy-energy dispersive X-ray analysis (SEM–EDX), molecular weight distribution and membrane resistance (Lei et al. 2019), particle size distribution, TMP and flux (Hu and Stuckey 2007; Akram and Stuckey 2008). To the best of our knowledge, the membrane fouling mechanisms have not been investigated in detail using both membrane autopsy analyses and fouling models in the AnMBR treatment of real pharmaceutical wastewater with the PAC addition.

In the present study, the effect of PAC addition was investigated to enhance the treatment performance and mitigate the membrane fouling of the AnMBR system treating pharmaceutical wastewater. The performance of the AnMBR system was assessed in terms of chemical oxygen demand (COD) removal efficiency, concentration change of total suspended solid (TSS), volatile suspended solid (TVSS), EPS and SMP and the flux change. To understand the fouling mechanism of membrane, the membrane autopsy studies were carried out by using zeta potential, SEM–EDX, optic profilometer and confocal laser scanning microscopy (CLSM) analyses. Furthermore, the flux decline was modeled to determine the membrane fouling mechanism with the combined adsorption fouling models. This work was carried out at the Department of Environmental Engineering, Istanbul University-Cerrahpaşa, Istanbul, Turkey, during 2017–2019.

Materials and methods

Wastewater characteristics

The pharmaceutical wastewater used in the study was obtained from the production tank of a penicillin derivative antibiotic containing two pharmaceutical active compounds (PhACs), namely ampicillin and sultamicillin tosylate, in a pharmaceutical factory located in Istanbul. The pharmaceutical wastewater was stored at +4 °C during the study. The wastewater contains COD of 5600 mg/L, UV254 of 0.053 cm–1, NH4+-N of 14 mg/L, SO42− of 1310 mg/L, SO32− of 110 mg/L, Cl− of 900 mg/L and TSS of 4800 mg/L. Ampicillin and sultamicillin concentrations of wastewater were determined using direct injection HPLC–MS/MS method a laboratory (Food GmbH Jena Analytic and Consulting, Germany) as < 1 μg/L and < 5 μg/L, respectively.

AnMBR setup and operation conditions

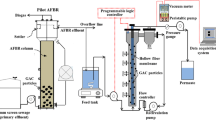

In the present study, an AnMBR reactor with an active volume of 4 L was used (Fig. 1). The AnMBR reactor consists of fermenter control unit, three internal peristaltic pumps (feeding, acid–base dosing and foam), mechanical mixer, pH probe, temperature and level sensor and heating jacket. Also, external peristaltic pump was used to vacuum the permeate. Polyether sulfone (PES) membrane (nominal pore size of 0.005 µm) with an effective area of 66 cm2 was used in the experiments. The AnMBR system was operated under the constant pressure (200 mbar), and a balance that connected to the computer recorded the flux instantaneously.

The permeate flux was calculated the equation given elsewhere (Kaya et al. 2016) using Darcy’s law. The AnMBR system was inoculated with the seed sludge obtained from a full-scale anaerobic treatment plant treating brewery industry wastewater located in Istanbul. Characterization of the seed sludge is given in Table S1.

The AnMBR was fed with the pharmaceutical wastewater with the initial COD concentration of 2500 mg/L during the acclimation period (Stage I). Then, the AnMBR was fed with the wastewater with the initial COD concentration of 5600 mg/L (Stage II). After the 131th day of operation, the membrane was removed and replaced with new membrane. The AnMBR system was operated with the addition of PAC for 169 days with the initial COD concentration of 5600 mg/L (Stage III).

Adsorption studies

In the adsorption studies, a wood-based PAC (WAC I600 M200: particle size of 0.075 mm, bulk density of 550 kg/m3) was used (Eurocarb, UK). Before the experiments, PAC was washed with distilled water and then boiled for 3 h. Subsequently, it was dried at 120 °C and stored in a desiccator before the experiments. The adsorption experiments were carried out with wastewater at 35 °C, pH 7 and 200 rpm using orbital shaker (ZHWY − 211B, Zhicheng, P.R.C.). The adsorption studies were performed under both abiotic and biotic conditions. The total volume was 100 mL of wastewater in the abiotic adsorption studies, and 25 mL of seed sludge and 75 mL of wastewater in the biotic adsorption studies. Samples were filtered (0.45 µm) in the adsorption studies, and COD and UV254 analyses were performed in order to determine the removal efficiencies.

Analytical methods

The physicochemical parameters such as COD, NH4+-N, SO42−, SO32−, Cl−, UV254, TSS and TVSS analyses were conducted according to the Standard Methods (APHA/AWWA/WEF 2005a). UV absorption at 254 nm is used for the characterization of water/wastewater and evaluation of the effectiveness of various treatment processes including advanced treatment methods using PAC that remove organic pollutants (APHA/AWWA/WEF 2005b; Altmann et al. 2016; Vergili and Gencdal 2017). In contrast to other organic analysis parameters (e.g., COD, TOC), UV254 represents only aromatic organic compounds which has double-bonded ring structures (APHA/AWWA/WEF 2005b). T60 UV–Vis spectrophotometer (PG Instruments (Lutterworth, UK)) was used for spectrophotometric measurements including UV254. EPS was extracted by using the method proposed by Frølund et al. (1996). The bound EPS was extracted using cation exchange resin (DOWEX, Marathon-C, Sigma-Aldrich). The extracted samples were kept at +4 °C to analyze for protein and polysaccharide fractions of EPS. Protein and carbohydrate concentrations of SMP and EPS were determined using the methods developed by Lowry et al. (1951) and Dubois et al. (1956), respectively. EPS and SMP on the cake layer were conducted using the method given by Imer-Koseoglu et al. (2011).

Membrane fouling characterization

SEM–EDX analyses of the clean and fouled membranes were conducted to evaluate the morphology of the cake layer and to investigate the elements accumulated in the cake layer of the membrane. To evaluate the biofilm layer and determine the biofilm layer thickness, CLSM analyses (Nikon C2, Japan) were conducted for fouled membranes using Live/Dead Baclight™ method. Membrane surface roughness of the fouled and clean membranes was determined by optical profilometer (Zygo Brand, USA). The roughness of mean square (Rrms) was determined as µm for optical profilometer measurements.

Modeling

Flux modeling, Hermia fouling model and combined adsorption fouling models were used according to Turano et al. (2002); Jafarzadeh and Yegani (2015); Bolton et al. (2006), respectively, and also detailed in supporting information (Tables S2 and S3).

Results and discussion

In this study, the PAC addition to the AnMBR system was applied in order to assess the effect of PAC addition on the membrane fouling and treatment performance. Abiotic and biotic adsorption studies were performed to determine the optimum PAC dosage to be added into the AnMBR system and also to understand the adsorption mechanism.

Abiotic adsorption results

Abiotic adsorption experiments were carried out to determine the equilibrium time for 15 min–144 h with a dosage of 2 g/L PAC. Most of the adsorption took place in the first 15 min, and it took 48 h to reach the equilibrium. Removal efficiencies of COD and UV254 were determined as 64 and 53%, respectively, for equilibrium time of 48 h (Fig. S1a). The COD removal sharply increased to 44% in 15 min and then gradually increased to 64% in 48 h. Although the equilibrium was reached at the same time, lower UV254 removal (53%) was obtained (Fig. S1a). This could be due to the non-aromatic organic compounds that could not be determined with UV254 (APHA/AWWA/WEF 2005b). To determine the optimum PAC dosage, the adsorption experiments were performed at the equilibrium time (48 h) with varying PAC dosages (0.5–16 g/L). As shown in Fig. S1a, the removal efficiencies increased with increasing PAC dosage. The optimum PAC dosage and the adsorption capacity of PAC were found to be 8 g/L and 666 mg/g for COD at the equilibrium, respectively. As a result, high removal efficiencies were obtained for COD and UV254 (95% and 90%) with the optimum PAC dosage of 8 g/L (Fig. S1b).

Adsorption mechanism was determined using Freundlich and Langmuir isotherms. The equations for both isotherms were given elsewhere (Vergili and Gencdal 2017). The Freundlich model fit the experimental data better than the Langmuir model with higher regression coefficient (R2) (0.9832 > 0.8866) for the adsorption of organic matter in terms of COD (Fig. S2). The fit of Freundlich model indicates the heterogeneity of PAC surface with multilayer adsorption. The calculated Freundlich model constant, n, was found to be lower than 1 (n = 0.6648), indicating irreversible adsorption process. This result is in consistence with the studies of Amosa et al. (2015) and Çeçen and Aktaş (2011). Irreversible adsorption could be due to specific functional groups on the active sites of the PAC surface that results in their high-energy covalent bonding with the adsorbates, likewise the oxidative polymerization of organics onto PAC (Çeçen and Aktaş (2011).

Biotic adsorption results

As in this study, it has been reported in the literature that activated carbon adsorption is an effective technology in the removal of organic compounds from wastewater with removal efficiencies exceeding 50% (Real et al. 2017). The addition of activated carbon to bioreactors prevents the membrane fouling as well as increases the removal of organic compounds. In these systems, integrated adsorption (onto PAC and sludge) and biological removal take place together (Çeçen and Aktaş 2011; Kaya et al. 2016). Biotic adsorption studies were carried out in order to determine the removal of organic matter (COD) in the integrated system. The experiment was carried out with a total volume of 100 mL (25 mL activated sludge +75 mL wastewater) using 2, 6, 8 and 10 g/L of PAC dosages for 48 h. As seen in Fig. S3, the removal of organic matter in the biotic adsorption increased by 15% (from 61 to 76%) with the PAC dosage of 2 g/L compared to the abiotic adsorption. The removal efficiency difference between the abiotic and biotic adsorption decreased to 6% (from 95 to 89%) with the PAC dosage of 6 g/L. The presence of seed sludge in the system did not cause a significant change (1%) with 8 g/L of PAC dosage. As further increase in the PAC addition did not cause a change in the removal efficiency, 8 g/L of PAC dosage was determined as the optimum that was similar to abiotic adsorption study. In the study of Cimbritz et al. (2019) adsorption onto PAC was not inhibited by the presence of biomass. They reported similar removal profiles with and without sludge with increasing PAC dosage (5–30 mg/L). Streicher et al. (2016) reported also slightly lower removal rates with low PAC dosages of 20–100 mg/L in the presence of sludge. However, Aghili et al. (2016) reported higher removal rates for PAC+ sludge system likewise our study. They reported an approximately 12% increase in PAC+ sludge system with a higher PAC dosage of 4 g/L. As a result, it is thought that increase in the removal efficiency in the biotic system is due to the high PAC dosage. The reason for no further increase in the removal efficiency after a certain dosage (8 g/L) was the equilibrium conditions.

AnMBR performance results

In this study, the AnMBR system was operated for 131 days without the PAC addition and for 169 days with the PAC addition. The optimum PAC dosage determined by the abiotic/biotic adsorption studies was used as 8 g/L in the AnMBR system. The performance of AnMBR system was evaluated according to COD effluent concentration and TSS concentration change during the 300 days of operation at three stages. COD concentrations of effluent and COD removal efficiencies are given in Fig. 2.

The AnMBR system was fed with initial COD concentration of 2500 mg/L for acclimation until 32nd day (Stage I). During this period, the effluent COD concentration decreased up to 650 mg/L and COD removal efficiencies were in the range of 40–68%. At Stage II, the AnMBR system was fed with initial COD concentration of 5600 mg/L and the effluent COD concentration gradually increased (from 700 to 1900 mg/L) until Day 81 due to feeding with higher initial COD concentration of the wastewater (5600 mg/L of COD). Then, the effluent COD concentrations stayed stable in the range of 1700–1850 mg/L. Between 82nd and 131st days, the COD removal efficiencies were in the range of 67–70%. In the study conducted by Huang et al. (2018) pharmaceutical wastewater treatment with an initial COD concentration of 2700–6000 mg/L using an AnMBR system was investigated and removal efficiencies of 94.0% to 87.1% were obtained. For influent COD values of 2500 and 5000 mg/L, similar removal efficiencies (85–90%) were obtained in the study of Kaya et al. (2017) investigating removal of chemical synthesis wastewater of a pharmaceutical industry using AnMBR. The low efficiency of COD removal may be due to the presence of penicillin beta-lactam antibiotics (ampicillin-sultamicillin) in the wastewater which might inhibit biological activity in the AnMBR (Cheng et al. 2018).

PAC was gradually added to the AnMBR system. At the start of Stage III (132nd day) a new membrane was installed in the AnMBR system and 8 g PAC (2 g/L) was added. The PAC addition into the system was repeated at the 173rd, 215th and 250th days as 8 g. With the first 8 g PAC addition (2 g/L), the effluent COD concentration decreased to 1200 mg/L from 1750 mg/L, and in this period, the COD removal efficiency of up to 79% was obtained. The subsequent PAC addition at the 173rd, 215th (total dosage of 6 g/L) and 250th days (total dosage of 8 g/L) was applied. The effluent COD concentrations were in the range of 480–600 mg/L, 390–500 mg/L and 290–450 mg/L during these periods, and the COD removal efficiencies were up to 91, 93% and 96%, respectively. As more PAC was added, higher removal efficiencies achieved because of the increase in the PAC surface area with increasing PAC dosage. Hu and Stuckey (2007) reported that PAC addition could improve the COD removal efficiency by over 23%. Mai et al. (2018) obtained the removal efficiencies of 22–82% with a PAC dosage of 1 g/L in their study which was used AnMBR treating pharmaceutical wastewater (initial COD concentration of 485–512 mg/L). Lei et al. (2019) obtained up to 97% COD removal efficiency with PAC (dosage of 4.5 g/L) treating synthetic pharmaceutical wastewater (initial COD of 500 mg/L). In these studies, the COD removal efficiencies in the range of 20–98.7% were obtained. In our study, up to 96% removal efficiency was achieved with the PAC addition which was similar given in the literature. Compared to the COD removal efficiency in the AnMBR system operated without the addition of PAC, it is clear that PAC addition improved the COD removal performance. Xiao et al. (2017) and Lim et al. (2020) pointed out that addition of PAC can improve the removal of PhACs due to the adsorption of these micropollutants to the PAC, as increasing the substrate concentration at the adsorption sites enables their biodegradation. It could be said that the COD removal efficiency increased due to both the adsorption of organic pollutants in wastewater onto PAC and the gradual biodegradation of PhACs causing inhibition as a result of concentration gradient between adsorbed PhACs onto PAC+ sludge and bulk liquid.

The AnMBR system was run with initial TSS concentration of 13.3 g/L and initial TVSS concentration of 2.5 g/L. TSS and TVSS variations of mixed liquor are given in Fig. 3.

During the acclimation period (Stage I) the TSS concentration decreased to 8.3 g/L and TVSS concentrations varied in the range of 2.1–2.4 g/L. In the Stage II, the concentration of TSS and TVSS increased to 8.6 and 3.1 g/L, respectively. In addition, TVSS/TSS ratio increased to 36% from 26%. The TSS and TVSS concentrations steadily increased, and the concentrations of TSS and TVSS were obtained up to 18.05 and 11.08 g/L, respectively, at the end of Stage III. The rate of increase in the TVSS/TSS ratio has also increased and reached to 62% from 36% with the addition of PAC. It was thought that increase in the TSS and TVSS concentrations and the TVSS/TSS ratio was caused not only by the addition of PAC, but also by increase in the biomass concentration. Ng et al. (2010) stated that PAC probably encourages faster growth of microorganisms by causing an attachment surface for the substrate. In addition, Sohn et al. (2021b) reported an increase in the biomass concentration with PAC addition to AnMBR by improvement of biomass settling using PAC since it provides sufficient space for attachment of microorganism. Also, the PAC addition probably reduced the inhibitory effect of penicillin beta-lactam antibiotics in the wastewater on the biomass. Therefore, PAC encouraged the increase in the TVSS/TSS ratio. In the literature, the similar results were found that PAC could lead to increase in biomass concentration (Yang et al. 2019).

The AnMBR system was operated at constant pressure. The flux variation of AnMBR is given in Fig. 4.

At the beginning of the operation, the AnMBR system was operated with 3.2 L/m2·h flux, while the flux decreased sharply in the following days. The flux decreased to 0.47 L/m2·h on Day 131. A new membrane was installed in the AnMBR system, and the system was started to operate with the PAC addition of 8 g (2 g/L) on Day 132. The AnMBR system reached to flux value of 3.3 L/m2·h. However, the flux decreased gradually to 0.46 L/m2·h on Day 243. Gas scouring was applied to the membrane in order to recover the flux, and the flux value reached again to 3.3 L/m2·h which was the same with the beginning of the operation. Until the end of the operation, the flux value remained stable at 0.66 L/m2·h with the PAC addition. In a study conducted by Baêta et al. (2012), it was found that higher flux was obtained by PAC due to adsorption of proteins and colloidal substances in the reactor. In addition, Park et al. (1999) stated that the PAC addition up to dosage of 5 g/L reduced the membrane fouling and cake layer; hence, the flux was improved. In this study, although the addition of PAC did not have a significant effect on improving the flux, it could be said that it was effective in stabilizing the flux.

EPS and SMP concentrations were evaluated in terms of protein and carbohydrate. The results during the whole operation are given in Fig. S4.

During the 300-day operation, the concentrations of EPSc, EPSp, SMPc and SMPp, were measured in the range of 16.9–54.4, 0.1–0.3 mg/gVSS, 28.6–62.6 and 0.1–1 mg/L, respectively. The concentrations of carbohydrate fraction varied during the operation, whereas there were no significant variations in the concentrations of protein fraction. EPSc and SMPc were dominant parameters in the mixed liquor during the whole operation due to wastewater characterization. Banti et al. (2018) stated that the carbohydrates in SMPc have a more tendency to retain by membrane compared to SMPp. Therefore, it was thought that the concentration of SMPc was higher compared to SMPp due to the more tendency of carbohydrate to be retained by the membrane. Due to this tendency of carbohydrate, it was thought that EPSc remained in higher concentration compared to EPSp.

There was no significant change in concentration EPSp and SMPp concentration during the whole process. The concentration of SMPc and EPSc decreased after the first PAC addition from 40.4 to 30 mg/L and from 31.5 to 24 mg/gVSS, respectively. The addition of PAC that has a high surface area could decrease initially the concentration of SMPc due to the efficient adsorption (Sohn et al. 2021b). The concentrations of EPSc and SMPc increased steadily until 230th day and reached to 54.9 mg/g VSS and 62.6 mg/L, respectively. This could be ascribed that PAC became saturated with organic contamination and more release of EPS and SMP as a microbial product with excessive growth of biomass (Sohn et al. 2021b). In general, increase in the biomass concentration in the reactor contributed to the increase in the EPSc and SMPc concentration. It is stated that there is a positive correlation between the biomass concentration and the EPS and SMP concentration (Ng et al. 2013). In addition, the adsorbents such as PAC in MBR systems could accelerate the increase in biomass because PAC can could create areas which protect microorganisms against environmental conditions and biofilm growth on PAC (Wang et al. 2016; Aslam et al. 2017). So, the production and accumulation of EPS and SMP at Stage III could be attributed to the PAC addition.

After AnMBR operation without/with the PAC addition, the EPS and SMP concentrations on the membrane cake layer were determined. According to the EPS and SMP analyses for cake layer without PAC, the concentrations of 62.8, 1.2, 1.0 and 2.8 mg/g VSS were found for EPSc, EPSp, SMPc and SMPp, respectively. In addition, the concentrations of 56.4, 1.0, 1.5 and 1.8 mg/g VSS were found for EPSc, EPSp, SMPc and SMPp, respectively, on the cake layer with the PAC addition. In some studies, it was reported that EPS and SMP are one of the main membrane foulants for membrane bioreactors (Ng et al. 2013; Kaya et al. 2019; Yang et al. 2019; Yurtsever et al. 2020) and the addition of PAC could decrease EPS/SMP concentration by adsorption and scouring (Lei et al. 2019; Yang et al. 2019). In this study, the addition of PAC was effective slightly in reducing the EPSc and EPSp concentrations.

Membrane fouling analyses results

Membrane autopsy analyses including SEM–EDX, optic profilometer and confocal microscopy were conducted to evaluate the fouling mechanism of membrane. SEM–EDX, optic profilometer and confocal microscopy analyses were conducted on stripped membranes which were operated without/with the PAC addition (Fig. 5a–d, respectively).

As can be seen in the SEM images (1000X) of stripped membrane surfaces (Fig. 5a), the cake layers attached to the membrane surface and could not be removed completely from the membrane surfaces for both membranes. However, when the two stripped membranes were compared, the surface of the stripped membrane with the PAC addition was smoother. The surface of stripped membrane without the PAC addition had a more heterogeneous surface, and the greater foulants were on the surface compared to the stripped membrane with the PAC addition. Zhang et al. (2017) reported that PAC addition resulted in an external fouling layer. It was thought that the external layer could be stripped more effectively with PAC addition leading a smoother membrane surface in this study.

N and O peaks on the membrane surfaces with the PAC addition showed that the membrane surfaces were covered with the foulant which was mainly caused by microbial product (Yurtsever et al. 2017). Inorganic compounds such as Ca, Fe, Mg which can contribute the gel/or cake layer formation (Pendashteh et al. 2011; Yurtsever et al. 2017) were detected on both membranes. Another notable changes in the EDX analysis were the increase in the weight percentage of C on the membrane surface with the PAC addition. This is thought to be caused by the adhesion of PAC onto the membrane surface. In the optic profilometer analysis (Fig. 5c), Rrms values of 0.369, 1.579 and 2.239 µm were determined for the clean, and the stripped membranes with/without the PAC addition, respectively. As can be seen in Fig. 5c, the surface of stripped membrane with the PAC addition was smoother than that of stripped membrane without the PAC addition. In addition, comparing the biofilm thickness determined by confocal microscopy (Fig. 5d), the biofilm layer thicknesses of the stripped membrane with/without the PAC addition were 220 µm and 547 µm, respectively. It was stated that the scouring effect of PAC (Lei et al. 2019) was effective in the reduction of biomass/cake layer thickness on the membrane. Therefore, the cake layer on the membrane surface with the PAC addition was thinner and smoother. In the present study, it was observed that the cake layer formation was observed in both membranes, but the cake layer on the membrane surface with the addition of PAC was thinner. The addition of PAC reduced the cake layer thickness and contributed to a smoother cake surface. This indicates PAC was effective on the adsorbing pollutants such as colloids and dissolved organics causing cake layer formation (Akram and Stuckey 2008).

Fouling modeling

In order to determine the formation of membrane fouling mechanisms in more detail, the fouling modeling was applied using the flux values obtained during the whole operation. The membrane fouling mechanism was evaluated in three stages (1–131 days, 132–242 days and 243–300 days). 1–131 days include the period until the addition of PAC; 132–242 days include the period between the new membrane and the gas scouring application; 243–300 days include the period from gas stripping to the end of the operating period. The flux, Hermia and combined adsorption fouling model results for membranes (with/without the PAC addition) are given in Tables 1, 2 and 3, respectively.

The k values obtained with Hermia model (1982) were used to describe the best fouling model for the membranes. In addition, MFI values obtained from flux modeling (Table 1) were used to support the membrane fouling mechanism results calculated by Hermia (Table 2) and adsorption fouling model (Table 3). As can be seen in Table 1, the MFI value was determined as 301.71 between the 1st and 131st days. MFI values increased from 301.71 to 463.50 in the operation with PAC addition. This result indicated that the foulants accumulated on the membrane surface. Lin et al. (2013) stated that the accumulation of pollutants in the reactor increases in infinite sludge retention time. It was thought that the infinite sludge retention time led to increase the accumulation of pollutants in the reactor. Thus, it caused to increase in MFI values. In addition, it was thought that the addition of PAC may also contribute to the increase of the MFI value with the foulants. On the contrary, the MFI value decreased to 431.21 from 463.50 between 243rd and 300th days. Considering autopsy analyses and the MFI value (431.21), the PAC addition was effective on the mitigation of the cake layer thickness during this period. According to k values obtained from Hermia models (Table 2) and the normalized mass transfer coefficients (Table 3), predominant fouling mechanism was cake adsorption for between 1 and 131st days. Based on the normalized mass transfer coefficients (Table 3), the predominant fouling mechanism started to shift to the intermediate adsorption occurred membrane pores from the cake adsorption with the PAC addition. But, cake adsorption still remained predominant mechanism compared with intermediate adsorption mechanism at the stages with PAC addition. Huang et al. (2021) pointed out that PAC addition was effective on the reducing irreversible fouling. As stated in Sect. 3.3, the addition of PAC did not have considerable effect on the flux improvement and the flux remained stable with PAC addition. Although cake adsorption with the addition of PAC shifted to intermediate adsorption, which is known as irreversible fouling, it can be concluded intermediate adsorption was not significantly occurred because addition of PAC was effective on adsorbing of pollutants.

Conclusion

In this study, the effect of PAC addition on the treatment performance and membrane fouling of AnMBR system was evaluated using removal efficiency, membrane autopsy and fouling model results. The optimum PAC dosage and also adsorption mechanism onto PAC were also determined. The optimum PAC dosage into the AnMBR system was defined as 8 g (2 g/L) irreversible adsorption mechanism was observed with the selected PAC and real pharmaceutical wastewater containing PhACs, namely ampicillin and sultamicillin tosylate. The PAC addition into the AnMBR system increased the COD removal efficiency up to 29% and the TVSS/TSS ratio up to 26% due to probably reducing the inhibitory effect of penicillin beta-lactam antibiotics in the wastewater. In addition to the improvement in the treatment performance, the PAC addition into the system contributed to the reduction of the cake layer on the membrane surface that was also supported by the autopsy results. Dominant fouling mechanism was the cake filtration without the PAC addition, whereas gradually shifted to the intermediate adsorption with the PAC addition. As a result, this study proved that the operation of AnMBR system with the addition of PAC presented successful results in the treatment of pharmaceutical wastewater.

References

Aghili F, Ghoreyshi AA, Rahimpour A, Rahimnejad M (2016) Dynamic behavior of the adsorption, activated sludge and combined activated sludge-adsorption process for treatment of cheese whey wastewater. Desalin Water Treat 57(35):16404–16414. https://doi.org/10.1080/19443994.2015.1087884

Akram A, Stuckey DC (2008) Flux and performance improvement in a submerged anaerobic membrane bioreactor (SAMBR) using powdered activated carbon (PAC). Process Biochem 43(1):93–102. https://doi.org/10.1016/j.procbio.2007.10.020

Altmann J, Massa L, Sperlich A, Gnirss R, Jekel M (2016) UV254 absorbance as real-time monitoring and control parameter for micropollutant removal in advanced wastewater treatment with powdered activated carbon. Water Res 94:240–245. https://doi.org/10.1016/j.watres.2016.03.001

Amosa MK, Jami MS, Alkhatib MFR, Jimat DN, Muyibi SA (2015) A two-step optimization and statistical analysis of COD reduction from biotreated POME using empty fruit bunch based activated carbon produced from pyrolysis. Water Qual Expo Health 7:603–616. https://doi.org/10.1007/s12403-015-0176-4

APHA (2005b) 5910 UV-absorbing organic constituents In: Standard methods for the examination of water and waste water, 21th ed, American Public Health Association/American Water Works Association/Water Environment Federation, Washington DC, USA

APHA (2005a) Standard methods for the examination of water and waste water, 21th ed, American Public Health Association/American Water Works Association/Water Environment Federation, Washington DC, USA

Aslam M, Charfi A, Lesage G, Heran M, Kim J (2017) Membrane bioreactors for wastewater treatment: a review of mechanical cleaning by scouring agents to control membrane fouling. Chem Eng J 307:897–913. https://doi.org/10.1016/j.cej.2016.08.144

Baêta BEL, Ramos RL, Lima DRS, Aquino SF (2012) Use of submerged anaerobic membrane bioreactor (SAMBR) containing powdered activated carbon (PAC) for the treatment of textile effluents. Water Sci Technol 65(9):1540–1547. https://doi.org/10.2166/wst.2012.043

Balcıoğlu G, Yilmaz G, Gönder ZB (2021) Evaluation of anaerobic membrane bioreactor (AnMBR) treating confectionery wastewater at long-term operation under different organic loading rates: performance and membrane fouling. Chem Eng J 404:126261. https://doi.org/10.1016/j.cej.2020.126261

Banti DC, Samaras P, Tsioptsias C, Zouboulis A, Mitrakas M (2018) Mechanism of SMP aggregation within the pores of hydrophilic and hydrophobic MBR membranes and aggregates detachment. Sep Purif Technol 202:119–129. https://doi.org/10.1016/j.seppur.2018.03.045

Bolton G, LaCasse D, Kuriyel R (2006) Combined models of membrane fouling: development and application to microfiltration and ultrafiltration of biological fluids. J Membr Sci 277:75–84. https://doi.org/10.1016/j.memsci.2004.12.053

Çeçen F, Aktaş Ö (2011) Activated carbon for water and wastewater treatment: integration of adsorption and biological treatment. Wiley, Weinheim

Chen C, Guo W, Ngo HH, Chang SW, Duc Nguyen D, Dan Nguyen P, Bui XT, Wu Y (2017a) Impact of reactor configurations on the performance of a granular anaerobic membrane bioreactor for municipal wastewater treatment. Int Biodeterior Biodegrad 121:131–138. https://doi.org/10.1016/j.ibiod.2017.03.021

Chen C, Guo WS, Ngo HH, Liu Y, Du B, Wei Q, Wei D, Nguyen DD, Chang SW (2017b) Evaluation of a sponge assisted-granular anaerobic membrane bioreactor (SG-AnMBR) for municipal wastewater treatment. Renew Energ 111:620–627. https://doi.org/10.1016/j.renene.2017.04.055

Chen L, Cheng P, Ye L, Chen H, Xu X, Zhu L (2020) Biological performance and fouling mitigation in the biochar-amended anaerobic membrane bioreactor (AnMBR) treating pharmaceutical wastewater. Bioresour Technol 302:122805. https://doi.org/10.1016/j.biortech.2020.122805

Cheng D, Ngo HH, Guo W, Liu Y, Chang SW, Nguyen DD, Nghiem LD, Zhou J, Ni B (2018) Anaerobic membrane bioreactors for antibiotic wastewater treatment: performance and membrane fouling issues. Bioresour Technol 267:714–724. https://doi.org/10.1016/j.biortech.2018.07.133

Cheng D, Ngo HH, Guo W, Chang SW, Nguyen DD, Nguyen QA, Zhang J, Liang S (2021) Improving sulfonamide antibiotics removal from swine wastewater by supplying a new pomelo peel derived biochar in an anaerobic membrane bioreactor. Bioresour Technol 319:124160. https://doi.org/10.1016/j.biortech.2020.124160

Cimbritz M, Edefell E, Thörnqvist E, El-Taliawy H, Ekenberg M, Burzio C, Modin O, Persson F, Wilén B, Bester K, Falås P (2019) PAC dosing to an MBBR–effects on adsorption of micropollutants, nitrification and microbial community. Sci Total Environ 677:571–579. https://doi.org/10.1016/j.scitotenv.2019.04.261

Dong Q, Parker W, Dagnew M (2016) Long term performance of membranes in an anaerobic membrane bioreactor treating municipal wastewater. Chemosphere 144:249–256

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugar and related substances. Anal Chem 28(3):350–356. https://doi.org/10.1021/ac60111a017

Düppenbecker B, Kale S, Engelhart M, Cornel P (2017) Fluidized glass beads reduce fouling in a novel anaerobic membrane bioreactor. Water Sci Technol 76(4):953–962. https://doi.org/10.2166/wst.2017.274

Dutta K, Lee MY, Lai WWP, Lee CH, Lin AYC, Lin CF, Lin JG (2014) Removal of pharmaceuticals and organic matter from municipal wastewater using two-stage anaerobic fluidized membrane bioreactor. Bioresour Technol 165:42–49. https://doi.org/10.1016/j.biortech.2014.03.054

Frølund B, Palmgren R, Keiding K, Nielsen PH (1996) Extraction of extracellular polymers from activated sludge using a cation exchange resin. Water Res 30(8):1749–1758. https://doi.org/10.1016/0043-1354(95)00323-1

Gao Y, Ma D, Yue Q, Gao B, Huang X (2016) Effect of powdered activated carbon (PAC) on MBR performance and effluent trihalomethane formation: at the initial stage of PAC addition. Bioresour Technol 216:838–844

Hermia J (1982) Constant pressure blocking filtration laws-application to power law non-newtonian fluids. Trans Inst Chem Eng 60:183–187

Hu AY, Stuckey DC (2007) Activated carbon addition to a submerged anaerobic membrane bioreactor: effect on performance, transmembrane pressure, and flux. J Environ Eng 133(1):73–80. https://doi.org/10.1061/(ASCE)0733-9372

Huang B, Wang HC, Cui D, Zhang B, Chen ZB, Wang AJ (2018) Treatment of pharmaceutical wastewater containing β-lactams antibiotics by a pilot-scale anaerobic membrane bioreactor (AnMBR). Chem Eng J 341:238–247. https://doi.org/10.1016/j.cej.2018.01.149

Huang W, Zhu Y, Wang L, Lv W, Dong B, Zhou W (2021) Reversible and irreversible membrane fouling in hollow-fiber UF membranes filtering surface water: effects of ozone/powdered activated carbon treatment. RSC Adv 11:10323–10335. https://doi.org/10.1039/D0RA09820E

Imer-Koseoglu DY, Karagunduz A, Keskinler B (2011) Fouling characteristics of microfiltration membranes during the filtration of jet loop membrane bioreactor (JLMBR) activated sludge. Desalin Water Treat 26:124–130. https://doi.org/10.5004/dwt.2011.2121

Jafarzadeh Y, Yegani R (2015) Analysis of fouling mechanisms in TiO2 embedded high density polyethylene membranes for collagen separation. Chem Eng Res Des 93:684–695. https://doi.org/10.1016/j.cherd.2014.06.001

Jensen PD, Yap SD, Boyle-Gotla A, Janoschka J, Carney C, Pidou BDJ (2015) Anaerobic membrane bioreactors enable high rate treatment of slaughterhouse wastewater. Biochem Eng J 97:132–141. https://doi.org/10.1016/j.bej.2015.02.009

Jeong Y, Hermanowicz SW, Park C (2017) Treatment of food waste recycling wastewater using anaerobic ceramic membrane bioreactor for biogas production in mainstream treatment process of domestic wastewater. Water Res 123:86–95. https://doi.org/10.1016/j.watres.2017.06.049

Ji J, Kakade A, Yu Z, Khan A, Liu P, Li X (2020) Anaerobic membrane bioreactors for treatment of emerging contaminants: a review. J Environ Manage 270:110913. https://doi.org/10.1016/j.jenvman.2020.110913

Kaya Y, Bacaksiz AM, Golebatmaz U, Vergili I, Gönder ZB, Yilmaz G (2016) Improving the performance of an aerobic membrane bioreactor (MBR) treating pharmaceutical wastewater with powdered activated carbon (PAC) addition. Bioproc Biosyst Eng 39(4):661–676. https://doi.org/10.1007/s00449-016-1547-3

Kaya Y, Bacaksiz AM, Bayrak H, Gönder ZB, Vergili I, Hasar H, Yilmaz G (2017) Treatment of chemical synthesis-based pharmaceutical wastewater in an ozonation-anaerobic membrane bioreactor (AnMBR) system. Chem Eng J 322:293–301. https://doi.org/10.1016/j.cej.2017.03.154

Kaya Y, Bacaksiz AM, Bayrak H, Vergili I, Gönder ZB, Hasar H, Yilmaz G (2019) Investigation of membrane fouling in an anaerobic membrane bioreactor (AnMBR) treating pharmaceutical wastewater. J Water Process 31:100822. https://doi.org/10.1016/j.jwpe.2019.100822

Khan MA, Ngo HH, Guo WS, Liu YW, Zhou JL, Zhang J, Liang S, Ni BJ, Zhang XB, Wang J (2016) Comparing the value of bioproducts from different stages of anaerobic membrane bioreactors. Bioresour Technol 214:816–825. https://doi.org/10.1016/j.biortech.2016.05.013

Lei Z, Yang S, Li X, Wen W, Huang X, Yang Y, Wang X, Li YY, Sano D, Chen R (2019) Revisiting the effects of powdered activated carbon on membrane fouling mitigation in an anaerobic membrane bioreactor by evaluating long-term impacts on the surface layer. Water Res 167:115137. https://doi.org/10.1016/j.watres.2019.115137

Lim M, Patureau D, Heran M, Lesage G, Kim J (2020) Removal of organic micropollutants in anaerobic membrane bioreactors in wastewater treatment: critical review. Environ Sci: Water Res Technol 6:1230–1243. https://doi.org/10.1039/C9EW01058K

Lin H, Peng W, Zhang M, Chen J, Hong H, Zhang Y (2013) A review on anaerobic membrane bioreactors: applications, membrane fouling and future perspectives. Desalination 314:169–188. https://doi.org/10.1016/j.desal.2013.01.019

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the folin phenol reagent. J Biol Chem 193:265–275. https://doi.org/10.1016/S0021-9258(19)52451-6

Maaz M, Yasin M, Aslam M, Kumar G, Atabani AE, Idrees M, Anjume F, Jamila F, Ahmada R, Kha AL, Lesagee G, Herane M, Kim J (2019) Anaerobic membrane bioreactors for wastewater treatment: novel configurations, fouling control and energy considerations. Bioresour Technol 283:358–372. https://doi.org/10.1016/j.biortech.2019.03.061

Mai DT, Kunacheva C, Stuckey DC (2018) Post-treatment of anaerobic membrane bioreactor (AnMBR) effluent using activated carbon. Bioresour Technol 266:75–81. https://doi.org/10.1016/j.biortech.2018.06.063

Martinez-Sosa D, Helmreich B, Netter T, Paris S, Bischof F, Horn H (2011) Anaerobic submerged membrane bioreactor (AnSMBR) for municipal wastewater treatment under mesophilic and psychrophilic temperature conditions. Bioresour Technol 102(22):10377–10385. https://doi.org/10.1016/j.biortech.2011.09.012

Mota VT, Santos FS, Amaral MCS (2013) Two-stage anaerobic membrane bioreactor for the treatment of sugarcane vinasse: Assessment on biological activity and filtration performance. Bioresour Technol 146:494–503. https://doi.org/10.1016/j.biortech.2013.07.110

Ng CA, Sun D, Zhang J, Wu B, Fane AG (2010) Mechanisms of fouling control in membrane bioreactors by the addition of powdered activated carbon. Sep Sci Technol 45(7):873–889. https://doi.org/10.1080/01496391003667138

Ng CA, Sun DD, Bashir MJ, Wai SH, Wong LY, Wu B, Fane AG (2013) Optimization of membrane bioreactors by the addition of powdered activated carbon. Bioresour Technol 138:38–47. https://doi.org/10.1016/j.biortech.2013.03.129

Park H, Choo KH, Lee CH (1999) Flux enhancement with powdered activated carbon addition in the membrane anaerobic bioreactor. Sep Purif Technol 34:2781–2792. https://doi.org/10.1081/SS-100100804

Pendashteh AR, Fakhrul-Razi A, Madaeni SS, Abdullah LC, Abidin Z, Biak DRA (2011) Membrane foulants characterization in a membrane bioreactor (MBR) treating hypersaline oily wastewater. Chem Eng J 168:140–150. https://doi.org/10.1016/j.cej.2010.12.053

Qiao W, Takayanagi K, Shofie M, Niu Q, Yu HQ, Li YY (2013) Thermophilic anaerobic digestion of coffee grounds with and without waste activated sludge as co-substrate using a submerged AnMBR: system amendments and membrane performance. Bioresour Technol 150:249–258. https://doi.org/10.1016/j.biortech.2013.10.002

Ramos C, Zecchino F, Ezquerra D, Diez V (2014) Chemical cleaning of membranes from an anaerobic membrane bioreactor treating food industry wastewater. J Membr Sci 458:179–188. https://doi.org/10.1016/j.memsci.2014.01.067

Real FC, Benitez FJ, Acero JL, Casas F (2017) Adsorption of selected emerging contaminants onto PAC and GAC: equilibrium isotherms, kinetics, and effect of the water matrix. J Environ Sci Health A Tox Hazard Subst Environ Eng 52(8):727–734. https://doi.org/10.1080/10934529.2017.1301751

Saddoud A, Sayad S (2007) Application of acidogenic fixed-bed reactor prior to anaerobic membrane bioreactor for sustainable slaughterhouse wastewater treatment. J Hazard Mater 149(3):700–706. https://doi.org/10.1016/j.jhazmat.2007.04.031

Sohn W, Guo W, Ngo HH, Deng L, Cheng D, Zhang X (2021a) A review on membrane fouling control in anaerobic membrane bioreactors by adding performance enhancers. J Water Process Eng 40:101867. https://doi.org/10.1016/j.jwpe.2020.101867

Sohn W, Guo W, Ngo HH, Deng L, Cheng D, Cheng D (2021b) Powdered activated carbon addition for fouling control in anaerobic membrane bioreactor. Bioresour Technol Rep 15:100721. https://doi.org/10.1016/j.biteb.2021.100721

Song X, Luo W, Hai FI, Price WE, Guo W, Ngo HH, Nghiem LD (2018) Resource recovery from wastewater by anaerobic membrane bioreactors: opportunities and challenges. Bioresour Technol 270:669–677. https://doi.org/10.1016/j.biortech.2018.09.001

Streicher J, Ruhl AS, Gnirß R, Jekel M (2016) Where to dose powdered activated carbon in a wastewater treatment plant for organic micro-pollutant removal. Chemosphere 156:88–94. https://doi.org/10.1016/j.chemosphere.2016.04.123

Turano E, Curcio S, De Paola MG, Calabrò V, Iorio G (2002) An integrated centrifugation-ultrafiltration system in the treatment of olive mill wastewater. J Membr Sci 209:519–531. https://doi.org/10.1016/S0376-7388(02)00369-1

Vergili I, Gencdal S (2017) Removal of organic matter and etodolac from pharmaceutical industry wastewater by PAC adsorption. Water Environ Res 89(7):641–651. https://doi.org/10.2175/106143017X14902968254520

Vyrides I, Stuckey DC (2009) Saline sewage treatment using a submerged anaerobic membrane reactor (SAMBR): effects of activated carbon addition and biogas-sparging time. Water Res 43(4):933–942. https://doi.org/10.1016/j.watres.2008.11.054

Wallace JM, Safferman SI (2014) Anaerobic membrane bioreactors and the influence of space velocity and biomass concentration on methane production for liquid dairy manure. Biomass Bioenerg 66:143–150. https://doi.org/10.1016/j.biombioe.2014.02.021

Wang H, Qu F, Ding A, Liang H, Jia R, Li K, Bai L, Chang H, Li G (2016) Combined effects of PAC adsorption and in situ chlorination on membrane fouling in a pilot-scale coagulation and ultrafiltration process. Chem Eng J 283:1374–1383. https://doi.org/10.1016/j.cej.2015.08.093

Xiao Y, Yaohari H, De Araujo C, Sze CC, Stuckey DC (2017) Removal of selected pharmaceuticals in an anaerobic membrane bioreactor (AnMBR) with/without powdered activated carbon (PAC). Chem Eng J 321:335–345. https://doi.org/10.1016/j.cej.2017.03.118

Xie Z, Wang Z, Wang Q, Zhu C, Wu Z (2014) An anaerobic dynamic membrane bioreactor (AnDMBR) for landfill leachate treatment: performance and microbial community identification. Bioresour Technol 161:29–39. https://doi.org/10.1016/j.biortech.2014.03.014

Yang S, Zhang Q, Lei Z, Wen W, Huang X, Chen R (2019) Comparing powdered and granular activated carbon addition on membrane fouling control through evaluating the impacts on mixed liquor and cake layer properties in anaerobic membrane bioreactors. Bioresour Technol 294:122137. https://doi.org/10.1016/j.biortech.2019.122137

Yue X, Koh YKK, Ng HY (2015) Effects of dissolved organic matters (DOMs) on membrane fouling in anaerobic ceramic membrane bioreactors (AnCMBRs) treating domestic wastewater. Water Res 86:96–107. https://doi.org/10.1016/j.watres.2015.07.038

Yurtsever A, Calimlioglu B, Sahinkaya E (2017) Impact of SRT on the efficiency and microbial community of sequential anaerobic and aerobic membrane bioreactors for the treatment of textile industry wastewater. Chem Eng J 314:378–387. https://doi.org/10.1016/j.cej.2016.11.156

Yurtsever A, Sahinkaya E, Çınar Ö (2020) Performance and foulant characteristics of an anaerobic membrane bioreactor treating real textile wastewater. J Water Process Eng 33:101088. https://doi.org/10.1016/j.jwpe.2019.101088

Zhang Q, Singh S, Stuckey DC (2017) Fouling reduction adsorbents/flocculants in a submerged anaerobic membrane bioreactor. Bioresour Technol 239:226–235. https://doi.org/10.1016/j.biortech.2017.05.022

Acknowledgements

This work was supported by Scientific Research Project Coordination Unit of Istanbul University-Cerrahpasa (Project No.: 21301).

Author information

Authors and Affiliations

Contributions

GB helped in methodology, investigation, formal analysis, writing–original draft, visualization, project; IV, ZBG and GY performed conceptualization, methodology, resources, data curation, formal analysis, writing–review & editing, visualization; MB contributed to methodology, investigation, formal analysis, visualization, project assistant; YK was involved in conceptualization, methodology, resources, data curation, formal analysis, writing original draft, writing–review & editing, visualization, supervision, project administration, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Editorial responsibility: Lifeng Yin.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Balcıoğlu, G., Vergili, I., Gönder, Z.B. et al. Effect of powdered activated carbon addition on membrane performance and fouling in anaerobic membrane bioreactor. Int. J. Environ. Sci. Technol. 20, 3191–3204 (2023). https://doi.org/10.1007/s13762-022-04203-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-022-04203-x