Abstract

The present study was aimed to optimization of substrate and culture type for lignin-modifying enzymes, decolourization of six synthetic dyes and mycoremediation of artificial textile effluent in bioreactor scale by Lentinus arcularius as a first report. The specific enzyme activity and decolourization capacities of lignin-modifying enzymes were determined using spectrophotometric methods. The highest manganese peroxidase and laccase activities were achieved using solid-state fermentation with tea wastes which was 3.82- and 3.69-fold higher than the control. The representative of azo, anthraquinone and triarylmethane dye groups could be completely decolourized in 1.5–3.0 h by Lentinus arcularius. The lignin-modifying enzymes immobilized in calcium alginate beads with high immobilization yield were used for mycoremediation of artificial textile effluent in flask and reactor scales. It was achieved to almost 90% decolourization for all dyes in each of successive two cycles in flask scale. After four cycles, enzyme activity retained 63% still. Both of manganese peroxidase and laccase enzymes of Lentinus arcularius have a role in decolourization of the textile dyes. In immersion reactor scale, a linear relation was determined between decolourization and detoxification of the tested dyes; 88% decolourization of the effluent was led to 80% decrease in mortality of brine shrimp nauplii.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

More than 100,000 commercially available dyes were reported for their using of industrial dyeing (Zhang et al. 2015) and printing process of which annual worldwide production is almost 800,000 tons (Hassaan and El Nemr 2017). According to Vikrant et al. (2018), “dyes can be classified into different groups according to their mode of applications (vat dyes, dispersive dyes and azoic colours), origin (natural and synthetic) and chemical structures (acridine, anthraquinone, chromophoric, azin and nitroso dyes)”. The chromophore-containing groups of dyes generally consist of functional groups, such as azo, arilmethane, anthraquinone and others. The most dominant dye group is azo dyes that constitute > 50% of the annual worldwide dye production. The production and using of the anthraquinone and triarylmethane-based dyes have increased due to years (Vikrant et al. 2018). Other than food, pharmaceutical, leather and cosmetic, textile industry consumes about 56% of total annual World production as the most avid user of synthetic dyes (Jiang et al. 2013). During manufacturing, total lost dyestuff amount released to the process water is varying from 2 to 50% loss (McMullan et al. 2001). Effluents of the textile industry include a lot of polluting substance such as pigment and dyes, pesticides and heavy metals (Ben Younes et al. 2007) Most of the synthetic dyes are well known with toxic, mutagenic and carcinogenic aspects. Furthermore, they are highly resisted to microbial attack, temperature, light, detergents, chemicals, soap and many chemicals (Rodriguez-Couto 2009; Jiang et al. 2013). This has resulted in escape conventional wastewater treatment processes, the discharge of highly polluted effluents, long-range transportation and persist in the environment. Therefore, in all industrial sectors, textile wastewaters are considered as the most polluting one (Faraco et al. 2009). Because of their hazardous and complex aromatic structures, dye-containing wastewaters of textile industry cause serious environmental problems of which the most important are about gas solubility and water transparency (Faraco et al. 2009). The highly coloured textile effluents cause to reducing the amount of available sunlight for photosynthetic organisms in aquatic ecosystems. Besides, because of the high chemical oxygen demand (COD) the oxygen solubility also reduces. Other than conventional physical wastewater treatment systems (membrane filtration, ion pair extraction, ion exchange, precipitation, adsorption, coagulation/flocculation, ultrasonic mineralization and flotation), chemical methods (oxidation, Fenton reaction, advanced oxidation process photochemical method, electrochemical destruction and ultraviolet irradiation) were also reported for the dye removal from industrial effluents (Katheresan et al. 2018), but all of these methods have their own disadvantages. The disadvantages and limitations of these methods were presented as tables by a lot of paper such as Pang and Abdullah (2013), Yagub et al. (2014), Katheresan et al. (2018). For example, as its limitations, adsorption by activated carbon is not cost-effective and has to be reactivated to disposal of the concentrating problem. Besides, reactivation causes 10 ± 15% loss of the sorbent (Robinson et al. 2001). The other methods have disadvantages of formation of hazardous by-products such as highly toxic aromatic amines (AAs) and application limitation such as intensive energy requirements, handling and disposal problems, high sludge production, high operation cost (Robinson et al. 2001; Pang and Abdullah 2013; Katheresan et al. 2018). Therefore, textile industry is in necessity of applying eco-friendly and applicable treatment technology such as bioremediation applications with fungal enzymes.

Because of ability to degrade lignin, low substrate specificity or non-specific nature of multifunctional lignin-modifying enzymes (LMEs), they possess great potential for bioremediation of broad range of xenobiotics such as dyes and polycyclic aromatic compounds. White rot fungi (WRF) are the most efficient degraders of aromatic compounds and pollutants using those enzymes. For this reason, WRF has application potential for degradation and/or decolourization of dye-containing textile effluent. The main LMEs produced by WRF are laccase, manganese peroxidase (MnP) and lignin peroxidase (LiP). These enzymes have played major role in mycoremediation of synthetic dyes by WRF (McMullan et al. 2001). By far, a lot of WRF species reported to efficiently use degradation/decolourization of different chemical group of synthetic dyes such as azo, anthraquinone and triarylmethane. For instance, laccase enzyme produced by Panus strigellus displayed 60–90% decolourization capacity for azo (reactive blue 220), anthraquinone (Remazol Brilliant Blue R (RBBR)) and triphenylmethane (Malachite Green) dyes in 24–72 h (Cardoso et al. 2018). Similarly, a laccase enzyme from Lenzites elegans was reported for varied mycoremediation ratio from 21.27 to 98.8% for azo (Congo red) and triphenylmethane (Malachite Green, Crystal Violet, Fuchsin Basic, Brilliant Green) dyes (Pandey et al. 2018). On the other hand, MnP enzyme from Cerrena unicolor could effectively decolourize azo (Congo red, methyl orange) anthraquinone (RBBR, bromophenol blue), triphenylmethane (Brilliant Blue R, Crystal Violet) and heterocyclic (azure B) dyes (Zhang et al. 2018). LiP was also reported an efficient enzyme for mycoremediation of azo (Remazol Black, acid red 114, acid black 172, reactive red 120) and anthraquinone (reactive blue 4, acid blue 62) dyes by Bjerkandera adusta (Sodaneath et al. 2017). A lot of other WRF species are also well known for their bioremediation abilities for different types of synthetic dyes with their LMEs such as Funalia trogii (Boran et al. 2019), Irpex lacteus (Sima et al. 2017), Perenniporia tephropora (Ben Younes et al. 2007), Phanerochaete chrysosporium (Faraco et al. 2009), Pleurotus ostreatus (Faraco et al. 2009), P. sajor-caju (Singh et al. 2011), Pycnoporus cinnabarinus (Villegas et al. 2016), different Trametes species (Moilanen et al. 2010; Ryu et al. 2017) and so on.

Lentinus arcularius (Polyporaceae) is WRF species that produces laccase (Okino et al. 2000; Jegatheesan and Eyini 2015), peroxidase (Okino et al. 2000), tyrosinase (Marková et al. 2016) and at least three types of carboxymethyl cellulose (Ishihara et al., 2005). In the presented study, it has been focused on dye decolourization capacity of a L. arcularius isolate (OBCC 3501) which was selected after a screening step. In the screening step, to compare dye decolourization and ligninolytic enzyme production capacity of the 90 Basidiomycetes isolates, three substrates (gallic acid, ABTS and guaiacol) and six synthetic dye (RBBR, Remazol Black, Cibacron Blue 3R, Amaranth, Crystal Violet and Malachite Green) were used in solid media, respectively. The aims of this study were: (1) to induce LME production by the L. arcularius isolate under different culture systems and by different agricultural wastes, (2) to determine its responsible enzyme for dye decolourization and (3) to decolourize artificial dye effluent by alginate-immobilized enzyme in flask and immersion bioreactor scales. All of these studies were performed in Eskisehir Osmangazi University on 2013.

Materials and methods

Dyes and chemicals

The commercial dyes, Cibacron Blue 3R (> 55%) and Remazol Black (> 50%) were kindly donated by Çelikkol Chemical Textile Industry and Trading Co. Ltd. RBBR (50%), Amaranth (85–95%) and Crystal Violet (> 90%) were purchased from Sigma-Aldrich. Malachite Green (> 96%) was from Carlo Erba. 2,2′-Azino-bis(3-ethylbenzothiazoline-6-sulphonic acid) diammonium salt (ABTS), veratryl alcohol (VA) and 2,6-dimethoxyphenol (DMP) were obtained from Sigma-Aldrich. The all used media were purchased from Merck.

Mycoremediation agent

The used fungus for mycoremediation was chosen from among ninety mushroom isolates according to its activity on different dyes and enzyme substrates such as gallic acid and ABTS on solid media (unpublished data). The pure culture was maintained on Potato Dextrose Agar (PDA) slants at 4 °C until used.

The basidiomata specimen from which pure culture isolated was identified by traditional macro- and microscopic examination by using the characteristics described by Ellis and Ellis (1990). The approving of traditional identification of the species was performed with the molecular methods. Internal transcribed spacer (ITS) rDNA region sequence of the species was compared with alignment in the GenBank database. For that purpose, DNA was isolated from the lyophilized mycelia followed by PCR amplification of the ITS rDNA region using ITS1 and ITS4 primers (Murray and Thompson 1980; White et al. 1990). The polymerase chain reaction (PCR) product was checked on agarose gels, purified and then sequenced. The obtained ITS rDNA region sequence was used to perform BLAST search in the GenBank database.

Effect of growth substrate and culture type on lignocellulosic enzyme production

LME production capacity of the fungal isolate was studied under solid-state (SSF), static (SF) and submerged (SmF) fermentation types in presence of different lignocellulosic materials.

Lignocellulosic substrates

Orange peelings (OP), tea wastes (TW) and wheat bran (WB) were used as substrate to compare their effects on LMEs production. All substrates were dried at 30 °C in an incubator and were cut into pieces of 0.5–1 cm. To neutralize organic acids, 10 g of ground OP was soaked to 30 mL of KOH (83.17 mM) for 1 h. Then, the substrate was washed three times with sterile distilled water (SDW) and dried at 30 °C. In SmF and SF cultures, glucose and an inducing compound (2,5-xylidine) were also included to the trials as negative and positive controls, respectively. Sterilized 2,5-xylidine (1 mM final concentration) was added to 3-day-old glucose medium.

Preparation of inoculum

To prepare inoculum, firstly, five mycelial discs (6 mm diam) from the fungal colony grown on PDA for a week were inoculated to 100 mL of potato malt peptone (PMP). After incubation at 28 °C, 100 rpm for 4 days, the mycelium was harvested, washed with 1:10 SDW and total volume was adjusted to 100 mL with SDW. The inoculant was prepared via three times homogenization of the cell suspension for 20 s with 1-min intervals with a Waring laboratory blender (Heidolph Silent Crusher M). The mycelium suspension was used as inocula 4% for all experimental groups.

Culture conditions

SSF cultivation has been carried out in 250-mL flask containing 10 g OP, TW and WB pieces moistened with 30 mL basal medium suggested by Mikiashvili et al. (2006) as a moistening agent (g/L; KH2PO4 0.8; NH4NO3 2; Na2HPO4 0.4; MgSO4 7H2O 0.5; yeast extract 2; ZnSO4 7H2O 0.001; FeSO4 7H2O 0.005; CaCl2 2H2O 0.06; CuSO4 7H2O 0.005; MnSO4 H2O 0.005) to obtain a 1:3 solid waste-to-moistening agent ratio. During 20 days of incubation period at 30 °C, 90% humidity, in complete darkness, the flasks were harvested periodically. Cultures were extracted in 50 mL of cold SDW and shaked an hour at 4 °C, filtrated (Whatman No: 1), and centrifuged (5000 rpm, 10 min., 4 °C) (Tychanowicz et al. 2004). Obtained supernatants were analysed for their reducing sugar and protein contents, pH and LMEs activities.

For LMEs production in the SmF, the culture was grown in mentioned medium which includes OP, TW, WB and glucose (for negative and positive control groups) as carbon source. After inoculation, the cultures were incubated in the conditions of 30 °C, 100 rpm, 100-mL medium/250-mL flask. In harvesting periods, after filtration (Whatman No: 1) and centrifugation (5000 rpm, 10 min., 4 °C) supernatants were used for analytical methods and LMEs activity assay.

The fungus was also grown in SF condition to compare LMEs activities during incubation period. In this culture type, all conditions were the same with SmF other than agitation, as the only difference agitation was not applied in SF cultures.

Enzyme assays and analytical methods

To compare the LMEs activity of L. arcularius OBCC 3501 grown in SmF, SF and SSF conditions, LMEs activities were assayed with spectrophotometric method in triplicates at room temperature. Laccase, MnP and LiP activities were determined at 420, 469 and 310 nm according to Boran et al. (2019), Sodaneath et al. (2017) and Tien and Kirk (1983), respectively. One unit of enzyme activity was defined as the amount of enzyme that oxidized 1 µmol of substrate (ABTS, DMP, VA) per minute and was expressed as units per litre.

In all assays, the reducing sugar amount was determined with the dinitrosalicylic acid method with the use of glucose standard curve (Miller 1959). The protein content in culture fluids was quantified based on the dye-binding Bradford method with bovine serum albumin (BSA) as a standard (Bradford 1976).

Decolourization of synthetic dyes

Six different synthetic dyes (Table 1) were used to determine the decolourization ability of the culture filtrate of L. arcularius. Stock solutions of the dyes (0.1% w/v) were solubilized in water, filtrated through 0.45 µm cellulose nitrate filter and were stored in the dark at 4 °C.

The reaction mixture (3 mL) contained aqueous solution of dye and supernatant in equal volume. Reaction mixtures containing uninoculated medium and distilled water instead of supernatant were used as abiotic controls. The inoculated medium filtrates were boiled and included to the study as biotic control, also. Dye concentrations were selected to obtain 1.3 absorbance at the maximum wavelength (0.12 mM for RBBR, 0.043 mM for Remazol Black, 0.19 mM for Cibacron Blue 3R, 0.038 mM for Amaranth, 0.008 mM for Crystal Violet and 0.013 mM for Malachite Green, final concentration) with or without a mediator 1-hydroxybenzotriazole (HBT) at 1 mM final concentration. All of the experimental and control groups were incubated in static conditions and in complete darkness for 240 min at room temperature.

The decrease in absorbance of the reaction mixtures for each dye was monitored periodically at the peak of the maximum wavelength of the dyes. The decolourization ratio (D) for dyes was calculated according to Eq. 1 and expressed in terms of percentage (Jiang et al. 2013).

where Ai and Af represent the absorbance of the dye at the initial and final time, respectively.

To determine the enzyme responsible for dye decolourization, the enzyme was pre-incubated with selective inhibitors, sodium azide (NaN3) and n-propyl gallate (n-PG) at 30 °C at four hours before addition of the substrate. In order to select suitable inhibitor concentrations for selective inhibition experiments, 1–100 µM NaN3 and 1–5000 µM n-PG were tested. Laccase and MnP enzyme activities were periodically assayed. Thus, specific inhibitor concentrations were determined for each enzyme and dye decolourization assays were repeated in presence and absence of selective inhibitors. The effects of NaN3, n-PG and ethanol on decolourization were also tested.

Dye decolourization by immobilized enzyme

Enzyme immobilization

The enzyme which will be immobilized was firstly partially purified with ammonium sulphate fractionation and dialysis. Crude enzyme solution was saturated by gradual addition of ammonium sulphate to final concentrations 30% and 70%. Then, both of the saturated solutions were centrifuged. The pellets were dissolved in distilled water and were dialysed with 12400 MWCO dialysis tubes (Sigma), and thus, enzyme was concentrated. The ammonium sulphate precipitates, the dialyzates and dialysis liquids were tested their protein amounts and enzyme activities.

The concentrated enzyme solution in dialyzate was mixed with 4% sodium alginate solution in 1:1 ratio. To obtain immobilized enzyme beads, enzyme–alginate mixture was added drop-wise into CaCl2 solution (200 mM) with constant stirring. After transferring to fresh CaCl2 solution, the beads were incubated for 30 min at 4 °C and washed with SDW twice. Immobilization rate (%) was calculated with Eq. 2 of Bilal and Asgher (2015):

Dye decolourization with ca-alginate beads in flask and reactor scale

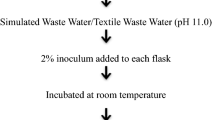

Dye-decolourizing potential of immobilized enzyme was investigated against artificial textile dye effluent which was prepared by mixing of six synthetic dyes and adjusting its absorbance to around 1.3 at the maximum wavelength of it (585 nm).

In flask scale, LMEs immobilized in Ca-alginate beads were added to the 50 mL of artificial textile dye effluent and incubated at 30 °C and 100 rpm. To determine decolourization ratio (%), samples taken from flasks were tested for their absorbance at 585 nm. To test the reusability of the immobilized enzyme, four consecutive decolourization batches were performed. After each cycle, the beads were filtered, washed with SDW and subjected to next batch by replacing with fresh artificial textile dye effluent. The dye amount at the beginning of the each cycle was defined as 100%. Dye decolourization was monitored during all batches.

In reactor scale, an immersion bioreactor designed by Rivela et al. (2000) was used. An image of the used immersion bioreactor is presented in Fig. 1. The enzyme beads were placed into wire mesh baskets and into the bioreactor which was included 3.5 L artificial textile dye effluent. With the use of a pneumatic system, the baskets were held 3 min outside and 1 min inside of the artificial textile dye effluent (immersion frequency 0.25 s−1). Temperature and humidified air were maintained stable with a water jacket and flow metre at 30 °C and 1 vvm, respectively. Two cycles were performed with immersion bioreactor. All of the conditions were same with flask scale studies.

Brine shrimp toxicity test

To evaluate toxicity reduction ability of the immobilized enzyme, much known, simple and inexpensive brine shrimp toxicity test was performed (Rice and Mannes 2004). Non-degraded and degraded artificial textile effluents in different ratios (72, 50, 22 and 12%) taken from immersion reactor were tested for their toxicity level. These effluents were placed into polystyrene plates (12-well flat bottom); then, 10 live Artemia salina nauplii were transferred to each well. During 24 h of incubation at 25 °C, the dead and live nauplii numbers were recorded periodically. Artificial sea salt solution was also included to the study as negative control. The results were expressed as the percentage of mortality (%).

All of the experiments in the paper were carried out at least three replicates. The data were presented as mean values with a standard deviation less than 10%.

Results and discussion

Mycoremediation agent

According to traditional methods, the fruiting body sample was belonging to L. arcularius species. Besides, the similarity index of ITS sequence of the isolate was 97% in the NCBI GenBank. The ITS nucleotide sequence of L. arcularius OBCC 3501 was subsequently deposited in GenBank under accession number KY628652.

Effect of growth substrate and culture type on lignin-modifying enzyme production

L. arcularius was investigated for its ability to produce LMEs with different culture methods in this study for the first time. Three kinds of agricultural wastes, including WB, TW and OP, were tested for their effect on LMEs production as well as glucose and 2,5-xylidine as controls during 20 days of incubation period.

It was found here that LiP activity of L. arcularius is negligible level. Table 2 presents the Lac and MnP activities for SF, SmF and SSF conditions. In accordance with our study, Elisashvili et al. (2008) have reported that LMEs production by basidiomycetes highly depends on the cultivation method of the fungi. MnP activity of the strain varied from 0.7 to 438.1 U/L, while Lac activity was among 0.5–114.5 U/L for all culture types. Among liquid cultures, SmF gave better enzyme activity results except TW and xylidine media. As the best substrate, OP promoted an excellent MnP production in liquid cultures, while Lac production was the same in WB and OP media. On the other hand, no enzyme activity was detected in SSF of OP medium due to the lack of microbial growth. A possible explanation for this situation may be related to the failing of organic acid neutralization in OP medium.

As compared with the other culture types, the SSF favoured to the maximum MnP and Lac activities by the studied fungus species. SSF has important potential for the production of microbial products such as industrial chemicals food and pharmaceutical products for especially with filamentous fungi (Aguilar et al. 2004). Different causes have been proposed to explain higher enzyme production with SSF than SmF such as water activity, minimum catabolic repression, more similar growth conditions to the natural habitat and provoking different physiologicies(Aguilar et al. 2004). The use of TW as substrate for SSF resulted in the highest MnP activity (438. 1 U/L, 11th day) has followed by WB with same cultivation (427.4 U/L, 8th day). The laccase activity showed the same behaviour observed for MnP. The highest Lac activity (114.5 U/L, 11th day) was achieved using SSF with TW followed by SSF with WB (108.0 U/L, 8th day). In the case of TW, the maximum MnP and Lac activities of the strain were 3.82- and 3.69-fold higher than that in the SmF conditions of glucose which was used as control. On the other hand, MnP and Lac activities of WB were 3.73 and 3.48 times higher than control, respectively. Furthermore, the time for maximal MnP and Lac production was 3 days shorter than that of TW medium. Overall, production of both LMEs was favoured by SSF with TW and WB. LMEs production by WRF can be induced by aromatic compounds. Different phenolic compounds, such as vanillic, p-coumaric and ferulic acids, were determined in WB (Onyeneho and Hettiarachchy 1992). Although it has been reported that fresh tea leaves contain upon average 36% polyphenolic compounds, especially catechins (Xuczaj and Skrzydlewska 2005), TW is not common solid substrate for LMEs production studies. Actually, its phenolic ingredients such as theaflavins, thearubigins and gallic acid can be good inducers for the following studies with other WRF species.

In order to better understand the SSF with TW, time-dependent growth and enzyme production curve of L. arcularius was drawn (Fig. 2). The reducing sugar amount of the medium was determined comparatively low level. The protein amount of the medium seems to increase during all incubation period. Concerning to LMEs activities, the MnP and Lac activities of the strain were peaked on the day 11 of incubation, after decreasing of the reducing sugar level to its minimum. In this condition, L. arcularius reached to its maximum enzyme activities in a short time according to the most of the WRF species. It further shows that both of the LMEs were produced from the fourth day of incubation. At the later phase of the incubation, the enzyme activities gradually decreased which might be due to the degradation of the enzyme isozymes by extracellular proteases from the culture broth.

Decolourization of synthetic dyes

Dye decolourization capabilities of L. arcularius have been little studied to date. All the studies have been performed for screening of the basidiomycetes species, and an anthraquinone dye, RBBR, was used as a screening tool to determine enzymatic activity of this species (Okino et al. 2000; Balaes et al. 2013). In the presented study, the culture fluid produced by L. arcularius on TW in SSF conditions was used in decolourization of six synthetic dyes. Enzymatic dye decolourization was confirmed by the lack of activity in control groups, boiled culture fluid and SDW. Dye decolourization capability of the strain in the absence and in presence of a mediator was presented in Fig. 3. All of the dyes including azo, anthraquinone and triarylmethane could be decolourized by L. arcularius. Decolourization ratio of the dyes without mediator varied from 8 to 80%. Decolourization of the anthraquinone dyes, Cibacron Blue 3R and RBBR was much higher than the other dyes without mediator. Furthermore, high decolourization efficiency with over 90% was obtained with the addition of HBT which is a much known laccase mediator. Anthraquinone dyes are known as the second largest water-soluble synthetic dye class (Lu et al. 2007). Therefore, the high decolourization ratio of this group can be accepted as encouraging results in view of the wastewater treatment.

Because of their non-phenolic structure or high redox potential, normally azo dyes are hard to be decolourized by fungal enzymes in absence of a mediator (Jiang et al. 2013). In accordance with this report, in absence of mediator, 8 and 20% decolourization rates were measured for Remazol Black and Amaranth, respectively. But, the presence of mediator substantially enhanced azo dye decolourization efficiency up to 10 times. In this study alone, culture fluid of L. arcularius decolourized 37 and 57% of Malachite Green and Crystal Violet, respectively. On the other hand when decolourization combined with mediator, decolourization efficiencies were achieved to higher values, 87 and 100% for same dyes. An important finding concerning the decolourization of dyes, Amaranth, Cibacron Blue 3R and Malachite Green were completely decolourized in a short time, 1.5–3.0 h, in presence of mediator. Overall, decolourization of dyes with different structure by culture fluids revealed that L. arcularius has efficient decolourization capacity for chemically different dyes (Fig. 3).

To obtain experimental evidence for involvement of LMEs for decolourization of the tested dyes, selective inhibition of the Lac and MnP enzymes was used as a tool. Any of the control groups, NaN3, n-PG and ethanol, has caused decolourization of the tested dyes. When NaN3 was used at 0.1 mM, both of the enzymes were inhibited strongly four hours (Table 3). In this condition, dye decolourization was also completely inhibited which suggested the involvement of the enzymatic decolourization. On the other hand, 5 mM n-PG inhibited to laccase completely, while almost half of the MnP activity was retain after four hours incubation (Table 3). Therefore, we can argue that 5 mM n-PG concentration has distinguishing inhibition capacity for laccase and MnP enzymes of L. arcularius.

To determine responsible enzyme(s) for each dye, decolourization studies were repeated in presence of 5 mM n-PG, as a selective laccase inhibitor, and in absence of HBT, a mediator. For anthraquinone dyes, more than 80% decolourization ratio has recorded which confirmed a major role for laccase. Besides, 62.50 and 64.90% of Remazol Black and Crystal Violet were decolourized by laccase of L. arcularius. On the other hand, decolourization ratio of Amaranth and Malachite Green dyes was recorded as 65.00 and 78.38% of the non-inhibiting condition, respectively. These ratios are evidence for major role for MnP in the decolourization of these two dyes. Overall, these results suggest that both of laccase and MnP produced by L. arcularius have a role in the decolourization of the studied dyes. These results agree with those of Tavčar et al. (2006), who reported that laccase and MnP could participate in the dye remediation by Irpex lacteus. Therefore, it can be argued that the use of different (mixed) purified enzymes or culture fluids of L. arcularius can be an effective alternative for decolourization of textile effluent which includes different groups of dyes.

Dye decolourization by immobilized enzyme in flask and reactor scale

LMEs produced by L. arcularius were purified partially by ammonium sulphate precipitation and dialysis which were used by also other studies (Bilal and Asgher 2015; Bilal et al. 2016). The specific activities and purification fold data are summarized in Table 4. After ammonium sulphate precipitation and dialysis steps, there was not observed protein and LME activity in culture fluids which means that all of the enzymes could be concentrated in dialysate. This concentrated enzyme solution was used to prepare Ca-alginate beads which will be used in dye decolourization studies in flask and reactor scales. In the used immobilization conditions, loading efficiency of laccase and MnP enzymes was calculated as 95.58% and 96.93%, respectively, which can be accepted as a very good result.

The decolourization potential of immobilized LME for artificial textile effluent was investigated in flask and immersion reactor scales. A typical profile of artificial effluent decolourization in flask scale is presented in Fig. 4a. In the first and second cycles, the decolourization proceeded very fast; 77 and 65% of the dyes were decolourized in the first 4 h, respectively. In these cycles, almost 90% of the all dyes were decolourized. Similar findings for reactive and azo dyes decolourization by immobilized MnP of Ganoderma lucidum and Pleurotus spp. were reported by Bilal and Asgher (2015) and Vishwakarma et al. (2012) which decolourization ratios were reported as 80–96 and 99% in 4 and 18 h, respectively. It was also important to note that immobilized LME beads were stayed in their natural colour which means the mechanism of the colour removal was aerobic biodegradation by LME instead of adsorption to beads (Fig. 5). Although decolourization ratio slightly decreased in following two cycles, activity of the enzyme retained 63% of its initial decolourization activity at the end of the fourth day/cycle. It means that the enzyme beads were reusable.

As a last step of the decolourization studies, enzyme immobilized beads were tested for decolourization of artificial textile effluent in immersion bioreactor in two successive cycles of 24 h. In the first cycle, the decolourization rate of 49 and 84% was reached in 12 and 24 h, respectively (Fig. 4b), but these ratios decreased to 35 and 37% in the second cycle. The suggested possible explanations for the diminishing of the decolourization activity in Ca-alginate beads are blocking of some pores of beads that limit the contact between dyes and active site of the entrapped enzyme (Bilal et al. 2016) and/or leaking of enzyme from alginate beads because of washing after the cycles (Iqbal et al. 2014). Because of the enzyme activity in dye solution in both cycle was negligible (87 and 0.8 U/L, respectively), it can be argued that the immobilized enzyme was not lost during the immersion reactor process and the immobilized LME has advantage of not only increase in its stability, but also in its reusability.

Table 5 represents a comparison of textile dye decolourization capacities of various fungi in different bioreactor systems. In some former studies, only one dye or textile effluent was studied for their decolourization in different reactor types such as packed bed (Kapdan et al. 2000; Novotny et al. 2004; Torres-Farradá et al. 2018), trickle bed (Tavčar et al. 2006), rotating disc (Tavčar et al. 2006), stirred tank (Andleeb et al. 2010), air–lift (Ortiz et al. 2016; Sodaneath et al. 2017), expanded—bed (Rodriguez-Couto et al. 2006) and bubble column (Ortiz et al. 2016), but the use of immersion reactor is very rare. The obtained decolourization rate in the present study, 88%, for artificial effluent suggests that L. arcularius can be a promising agent for mycoremediation of textile dyes.

Brine shrimp toxicity test

The toxicity of the non-degraded and degraded artificial textile effluent in different ratios taken from immersion reactor was evaluated using Artemia nauplii. Before enzymatic treatment, the brine shrimp mortality of the non-degraded effluent was reached to 100% at 18 h (Fig. 6), but the mortality reduced to 20% for three concentrations of the degraded effluent in same time. Both of increase and decrease in toxicity of dyes were suggested after enzymatic treatment (Ramsay and Nguyen 2002). Bilal and Asgher (2015) and Bilal et al. (2016) reported that the toxicity of immobilized LME treated dyes was reduced to 75 and 63% according to untreated one. As an important finding, 88% decolourization of the artificial textile effluent was led to 80% reduction in mortality in this study. Therefore, it can be suggested that the dyes were decolourized and detoxified by the immobilized LME of L. arcularius.

Only one dye has been preferred to study in most of the decolourization studies (Tavčar et al. 2006; Lu et al. 2007; Andleeb et al. 2010; Bilal and Asgher 2015). This preference leads to obtain not only higher dye decolourization ratio, but also lower final toxicity level by the studied enzyme(s). The composition and characteristics of real textile industry wastewater change dramatically depending on the country, process, mill, chemicals, produced fabric, equipment in the factory, and season (Yaseen and Scholzi 2019). Therefore, in the case of real or artificial textile wastewater, both of the decolourization and detoxification ratios have been dramatically changed because of its complex structure. Textile industry does not use the dyes alone, and a wastewater from them has a complex structure including a lot of dye together. Therefore, the results presented here can be accepted as very encouraging for these kinds of wastewaters.

Conclusion

In this study, substrate and culture type optimization for LMEs production, decolourization of six synthetic dyes, enzyme characterization, decolourization and detoxification of artificial textile effluent in flask and reactor scales by L. arcularius is firstly reported. In view of the obtained results, it can be argued that the TW in SSF conditions is a very good alternative for the production of high-cost industrial LMEs in terms of process economics. In this way, very cheap wastes can be converted to high-valued industrial enzymes. It was highlighted that both of laccase and MnP have a role in decolourization of the textile dyes by L. arcularius. It has been shown here that Ca-alginate beads of LMEs by L. arcularius can be served as an excellent alternative for dye decolourization, detoxification and mycoremediation applications. Overall, it could be concluded that reusability of the enzyme beads and detoxification ratio of the treated effluent would be the encouraging features for textile effluent treatments.

References

Aguilar CN, Contreras-Esquivel JC, Rodriguez R, Prado LA, Loera O (2004) Differences in fungal enzyme productivity in submerged and solid state cultures. Food Sci Biotechnol 13:109–113

Andleeb S, Atiq N, Ali MI, Razi-Ul-Hussnain R, Shafique M, Ahmad B, Ghumro PB, Hussain M, Hameed A, Ahmad S (2010) Biological treatment of textile effluent in stirred tank bioreactor. Int J Agric Biol 12:256–260

Balaes T, Mangalagiu II, Tanase C (2013) Lignicolous macromycetes: potential candidates for bioremediation of synthetic dyes. Rev Chim 64:790–795

Ben Younes S, Mechichi T, Sayadi S (2007) Purification and characterization of the laccase secreted by the white rot fungus Perenniporia tephropora and its role in the decolourization of synthetic dyes. J Appl Microbiol 102:1033–1042

Bilal M, Asgher M (2015) Dye decolorization and detoxification potential of Ca-alginate beads immobilized manganese peroxidase. BMC Biotechnol 15:111

Bilal M, Iqbal M, Hu H, Zhang X (2016) Mutagenicity and cytotoxicity assessment of biodegraded textile effluent by ca-alginate encapsulated manganese peroxidase. Biochem Eng J 109:153–161

Boran F, Birhanlı E, Yeşilada Ö, Özbey E (2019) Comparison of indigo carmine decolorization by Pseudomonas aeruginosa and crude laccase enzyme from Funalia trogii. Turk J Biol 43:37–46

Bradford M (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein dye binding. Anal Biochem 72:248–254

Cardoso BK, Linde GA, Colauto NB, do Valle JS (2018) Panus strigellus laccase decolorizes anthraquinone, azo, and triphenylmethane dyes. Biocatal Agric Biotechnol 16:558–563

Cheng Z, Hua WX, Ping N (2013) Continuous acid blue 45 decolorization by using a novel open fungal reactor system with ozone as the bactericide. Biochem Eng J 79:246–252

Elisashvili V, Penninckx M, Kachlishvili E, Tsiklauri N, Metreveli E, Kharziani T, Kvesitadze G (2008) Lentinus edodes and Pleurotus species lignocellulolytic enzymes activity in submerged and solid-state fermentation of lignocellulosic wastes of different composition. Bioresour Technol 99:457–462

Ellis MB, Ellis JP (1990) Fungi without gills. Chapman and Hall, London

Faraco V, Pezzella C, Miele A, Giardina P, Sannia G (2009) Bio-remediation of colored industrial wastewaters by the white-rot fungi Phanerochaete chrysosporium and Pleurotus ostreatus and their enzymes. Biodegradation 20:209–220

Hassaan MA, El Nemr A (2017) Health and environmental impacts of dyes: mini review. Am J Environ Sci Eng 1(3):64–67

Iqbal M, Bhatti IA, Zia-ur-rehman M, Bhatti HN, Shahid M (2014) Application of bioassays to evaluate the efficiency of advanced oxidation processes for the detoxification of industrial effluents. Asian J Chem 26:4291–4296

Ishihara H, Imamura K, Kita M, Aimi T, Kitamoto Y (2005) Enhancement of the viscometric endocellulase activity of Polyporus arcularius CMCase IIIa by cellobiose and cellooligosaccharides. Mycoscience 46:148–153

Jegatheesan M, Eyini M (2015) Response surface methodology mediated modulation of laccase production by Polyporus arcularius. Arab J Sci Eng 40:1809–1818

Jiang M, Ten Z, Ding S (2013) Decolorization of synthetic dyes by crude and purified laccases from Coprinus comatus grown under different cultures: the role of major isoenzyme in dyes decolorization. Appl Biochem Biotechnol 169:660–672

Kapdan IK, Kargı F, McMullan G, Marchant R (2000) Biological decolorization of textile dyestuff by Coriolus versicolor in a packet column reactor. Environ Technol 21:231–236

Karimi A, Vahabzadeh F, Bonakdarpour B (2006) Use of Phanerochaete chrysosporium immobilized on kissiris for synthetic dye decolourization: involvement of manganese peroxidase. World J Microbiol Biotechnol 22(12):1251–1257

Katheresan V, Kansedo J, Lau SY (2018) Efficiency of various recent wastewater dye removal methods: a review. J Environ Chem Eng 6:4676–4697

Lu L, Zhao M, Wang Y (2007) Immobilization of laccase by alginate-chitosan microcapsules and its use in dye decolorization. World J Microbiol Biotechnol 23:159–166

Marková E, Kotik M, Křenková A, Man P, Haudecoeur R, Boumendjel A, Hardré R, Mekmouche Y, Courvoisier-Dezord E, Réglier M, Martínková L (2016) Recombinant tyrosinase from Polyporus arcularius: overproduction in Escherichia coli, characterization, and use in a study of aurones as tyrosinase effectors. J Agric Food Chem 64:2925–2931

McMullan G, Meehan C, Conneely A, Kirby N, Robinson T, Nigam P, Banat IM, Marchant R, Smyth WF (2001) Microbial decolorization and degradation of textile dyes. Appl Microbiol Biotechnol 56:81–87

Mikiashvili N, Wasser SP, Nevo E, Elisashvili V (2006) Effects of carbon and nitrogen sources on Pleurotus ostreatus ligninolytic enzyme activity. World J Microbiol Biotechnol 22:999–1002

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Moilanen U, Osma JF, Winquist E, Leisola M, Rodriguez-Couto S (2010) Decolorization of simulated textile dye baths by crude laccases from Trametes hirsuta and Cerrena unicolor. Eng Life Sci 10:242–247

Murray MG, Thompson WF (1980) Rapid isolation of high molecular weight plant DNA. Nucleic Acids Res 8:4321–4325

Novotny C, Svobodova K, Kasinath A, Erbanova P (2004) Biodegradation of synthetic dyes by Irpex lacteus under various growth conditions. Int Biodeterior Biodegrad 54(2):215–223

Okino LK, Machado KMG, Fabris C, Bononi VLR (2000) Ligninolytic activity of tropical rainforest basidiomycetes. World J Microbiol Biotechnol 16:889–893

Onyeneho SN, Hettiarachchy NS (1992) Antioxidant activity of durum wheat bran. J Agric Food Chem 40:1496–1500

Ortiz EJE, Rene ER, Pakshirajan K, Hullebusch DV, Lens PNL (2016) Fungal pelleted reactors in wastewater treatment. Chem Eng J 283:553–571

Pandey RK, Tewari S, Tewari L (2018) Lignolytic mushroom Lenzites elegans WDP2: laccase production, characterization, and bioremediation of synthetic dyes. Ecotoxicol Environ Safety 158:50–58

Pang YL, Abdullah AZ (2013) Current status of textile industry wastewater management and research progress in Malaysia: A Review. Clean Soil Air Water 41(8):751–764

Ramsay JA, Nguyen T (2002) Decolorization of textile dyes by Trametes versicolor and its effect on dye toxicity. Biotechnol Lett 24:1757–1761

Rice SA, Mannes IB (2004) Brine shrimp bioassay: a useful technique in biological investigation. Am Biol Teach 66:208–215

Rivela I, Rodriguez-Couto S, Sanroman A (2000) Extracellular ligninolytic enzyme production by Phanerochaete chrysosporium in a new solid-state bioreactor. Biotechnol Lett 22:1443–1447

Robinson T, McMullan G, Marchant R, Nigam P (2001) Remediation of dyes in textile effluent: a critical review on current treatment technologies with a proposed alternative. Bioresour Technol 77:247–255

Rodriguez-Couto S (2009) Dye removal by immobilised fungi. Biotechnol Adv 27(3):227–235

Rodriguez-Couto S, Rosales E, Sanroman MA (2006) Decolourization of synthetic dyes by Trametes hirsuta in expanded-bed reactors. Chemosphere 62:1558–1563

Ryu H, Ryu HW, Cho KS (2017) Characterization of dye decolorization in cell-free culture broth of Trametes versicolor CBR43. J Microbiol Biotechnol 27(1):155–160

Sima J, Milne R, Novotny C, Hasal P (2017) Immobilization of Irpex lacteus to liquid-core alginate beads and their application to degradation of pollutants. Folia Microbiol 62:335–342

Singh AD, Vikineswary S, Abdullah N, Sekaran M (2011) Enzymes from spent mushroom substrate of Pleurotus sajor-caju for the decolourisation and detoxification of textile dyes. World J Microbiol Biotechnol 27:535–545

Sodaneath H, Lee JI, Yang SO, Jung H, Ryu HW, Cho KS (2017) Decolorization of textile dyes in an air-lift bioreactor inoculated with Bjerkandera adusta OBR105. J Environ Sci Health Part A 52(11):1099–1111

Tavčar M, Svobodová K, Kuplenk J, Novotný C, Pavko A (2006) Biodegradation of azo dye RO16 in different reactors by immobilized Irpex lacteus. Acta Chim Slov 53:338–343

Tien M, Kirk TK (1983) Lignin-degrading enzyme from the hymenomycete Phanerochaete chrysosporium burds. Science 221:661–663

Torres-Farradá G, Manzano AM, Ramos-Leal M, Domínguez O, Sánchez MI, Vangronsveld J, Guerra G (2018) Biodegradation and detoxification of dyes and industrial effluents by Ganoderma weberianum B-18 immobilized in a lab-scale packed-bed bioreactor. Bioremediation J 22:20–27

Tychanowicz GK, Zilly A, de Souza CGM, Peralta RM (2004) Decolourisation of industrial dyes by solid-state cultures of Pleurotus pulmonarius. Process Biochem 39:855–859

Vikrant K, Giri BS, Raza N, Roy K, Kim KH, Rai BN, Singh RS (2018) Recent advancements in bioremediation of dye: current status and challenges. Bioresour Technol 253:355–367

Villegas E, Téllez-Téllez M, Rodríguez A, Carreón-Palacios AE, Acosta-Urdapilleta ML, Kumar-Gupta V, Díaz-Godínez G (2016) Laccase activity of Pycnoporus cinnabarinus grown in different culture systems. Rev Mex Ing Quím 15:703–710

Vishwakarma SK, Singh MP, Srivastava AK, Pandey VK (2012) Azo dye (direct blue 14) decolorization by immobilized extracellular enzymes of Pleurotus species. Cell Mol Biol 58:21–25

White TJ, Bruns T, Lee S, Taylor JW (1990) Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. In: Innis MA, Gelfand DH, Sninsky JJ, White TJ (eds) PCR Protocols: a guide to methods and applications. Academic Press, New York, pp 315–322

Xuczaj W, Skrzydlewska E (2005) Antioxidative properties of black tea. Prev Med 40:910–918

Yagub MT, Sen TK, Afroze S, Ang HM (2014) Dye and its removal from aqueous solution by adsorption: a review. Adv Colloid Interface Sci 209:172–184

Yaseen DA, Scholz M (2019) Textile dye wastewater characteristics and constituents of synthetic effluents: a critical review. Int J Environ Sci Technol 16:1193–1226

Zhang Y, Jing Z, Li Y, Fan J, Kan W (2015) Hydrothermal synthesis of tobermorite from diatomite and its adsorption performance for methylene blue. Mater Res Innov 19(suppl 2):S263–S269

Zhang H, Zhang J, Zhang X, Geng A (2018) Purification and characterization of a novel manganese peroxidase from white-rot fungus Cerrena unicolor BBP6 and its application in dye decolorization and denim bleaching. Process Biochem 66:222–229

Acknowledgements

This work was supported by the Eskişehir Osmangazi University Research Foundation under Grant No. 201019039.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Fatih ŞEN.

Rights and permissions

About this article

Cite this article

Bayburt, C., Karaduman, A.B., Yenice Gürsu, B. et al. Decolourization and detoxification of textile dyes by Lentinus arcularius in immersion bioreactor scale. Int. J. Environ. Sci. Technol. 17, 945–958 (2020). https://doi.org/10.1007/s13762-019-02519-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-019-02519-9

Remazol black,

Remazol black,

Amaranth,

Amaranth,

Cibacron blue 3R,

Cibacron blue 3R,

RBBR,

RBBR,

Crystal violet,

Crystal violet,

Malachite green)

Malachite green)