Abstract

In anaerobic digestion, less attention has been focused on the digestion of grease trap waste as a single substrate may be due to high lipid content that may cause inhibition effects resulted from long-chain fatty acids accumulation during the degradation of lipid. The inhibition results in the low and slow production of methane. This study investigates the influence of glycerine supplementation on the continuous stir tank reactor anaerobic treatment of grease trap waste. The operating procedures began with a start-up process and continued with a semicontinuous feeding process in an increasing organic loading rate of 1.3–3.6 gCOD/L day. The results showed that the resistance toward grease trap waste inhibition in a glycerine-supplemented reactor (RGS), measured as lag phase, can be shortened to 4 days during the start-up as compared to the control reactor (Rcontrol). With the reduction in lag-phase occurrence, the performance of RGS reactor affected the overall methane production. At standard temperature and pressure, RGS reactor performance of methane composition was 67%, with methane production rate of 0.376 LCH4/L day and methane yield of 0.19 LCH4/gCODremoved. These results were observed at an organic loading rate of 2.2 gCOD/L day. The overall methane production enhancement from the glycerine-supplemented reactor was 25%. Palmitate accumulation indicated the possible main inhibitor during the lag-phase experience. Furthermore, the system was able to recover methane production performance during semicontinuous feeding stage. The use of glycerine supplementation is a reliable strategy to induce the start-up of anaerobic digestion process of high-lipid substrate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Anaerobic digestion is one of the potential processes of waste lipid recovery for beneficial use to produce biogas. However, despite its likelihood in increasing biogas yield, lipid hydrolysis may be inhibited by the formation of long-chain fatty acids (LCFA) and the destabilization that occur during the methanogenesis phase, hence reducing its biodegradability potential (Angelidaki and Ahring 1992; Pereira et al. 2005).

During the hydrolysis stage, the lipid is essentially degraded by hydrolytic bacteria which degrade the triglycerides in lipid to produce fatty acids (long-chain fatty acids, LCFA) and volatile fatty acids (Alves et al. 2009). Due to the degradation, the accumulation of LCFA became a rate-limiting factor in the anaerobic system. This is because the transport limitation for cell wall absorption will reduce its solubility thus causing several operational problems during the methanogenesis stage. Oleate and palmitate are the culprits since their accumulation is identified as the main cause of inhibition. It was reported that their accumulation in low level over 100 mg/L included the inhibited anaerobic digestion of sewage sludge (Martínez et al. 2012) and cattle manure (Angelidaki and Ahring 1992; Palatsi et al. 2009). The destabilization is detected when there is a presence of lag phase during methane formation and the formation of biomass floatation (Hwu et al. 1998; Long et al. 2011; Palatsi et al. 2010). As a result, the methane production is low and slow, which leads to potential failure of the digester; the risk that the plant operator would not be willing to take. This process of inhibition occurred when treating substrates with a high lipid content (Gonçalves et al. 2012; Kabouris et al. 2009; Rinzema et al. 1994). Thus, the utilization of organic matters that have high lipid content in the anaerobic digestion treatment is a less favorable option to be used as a mono-substrate.

The inhibition scenario occurred when dealing with substrate with high lipid content was reported by several researchers. Hidalgo and Martín-Marroquín (2014) experienced a 13-day lag phase and low methane yield (0.04 LCH4/gVS day) when vegetable oil wastes were treated in a batch of anaerobic process. Pereira et al. (2001) treated skim milk in their study and reported that oleate concentration of 100 mg/L inhibited the batch process resulting in a 5-day lag phase and methane composition of 69%. Shock load of fat-rich dairy wastewater at 900 mg/L of oleate and palmitate does not exhibit any methane production. The methane production affected the start-up of the process by having a lag phase and affected the overall process performance. These finding suggested that methane production is low and slow due to the lipid inhibition during hydrolysis process and thus substrate with high lipid content is a less favorable substrate to be used in anaerobic digestion. Therefore, it is important to investigate a method to deal with lipid inhibition in order to reduce the inhibition and enhance methane production using high-lipid substrate.

Different strategies have been implemented to overcome the inhibitory effects of LCFA. One of the strategies is supplementing glycerine as an extra carbon source to the anaerobic digester system. Glycerine is a by-product produced in a large quantity from biodiesel production industry (López et al. 2009). It is estimated that approximately 10 kilograms of impure glycerine will be produced from 100 kg of biodiesel production (Chi et al. 2007). Because of its mass production in the industry, the market value for glycerine is low. Despite its numerous applications such as soaps and pharmaceutical products, crude glycerine conversion to beneficial products is still being actively researched. Therefore, this study is motivated by glycerine’s low price, high availability, and beneficial values. Not exceeding 6% (v/v), glycerine supplementation was found to increase methane production from anaerobic digestion of pig manure and maize silage (Amon et al. 2006). Razaviarani et al. (2013) conducted a study on the same application but with municipal wastewater as a substrate, while Fountoulakis et al. (2010) used sewage sludge. Both studies reported positive findings on methane production enhancement. However, there is less research on the application of crude glycerine to enhance methane production from grease trap waste (GTW) anaerobic digestion. Furthermore, the information regarding the individual patterns of LCFA degradation during inhibition in treating GTW is scarce. Thus, the purpose of this work is to determine the potential of anaerobic digestion of GTW in enhancing methane production by studying the effects of glycerine supplementation in continuous stir tank reactor process. This research was carried out in Environmental Laboratory, Faculty of Engineering, Universiti Putra Malaysia, from September 2015 until December 2016.

Materials and methods

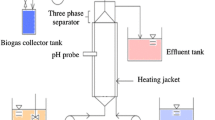

Setup of continuous stir tank reactor (CSTR)

To test the effects of glycerine supplementation, two reactors were used. The first reactor, known as RGS, was supplied with glycerine for the entire experiment. The second reactor, known as Rcontrol, was used as a control, where no glycerine was supplied. According to Fountoulakis et al. (2010) and Ma et al. (2008), the glycerine supplementation of less than 3% (v/v) was adequate to reduce the effects in increase the organic loading imposed by the addition of glycerine. By maintaining this concentration, the tendency of overloading organic loading caused by glycerine can be minimized and is considered not to affect the overall process. Thus, in this study, only 1% (v/v) glycerine was supplemented in RGS in order to minimize the abovementioned risk. Glass reactors with working volume of 1 L were used, and both reactors were equipped with the water-jacketed to sustain required temperature for the entire process. The reactor was fitted with a top stainless steel plate with an attached stirrer, feeding and sampling port, gas sampling port, pH probe, thermocouple, and acid and alkaline port. A control unit was used to monitor the pH and temperature. The produced biogas was collected in a 5-L Tedlar gas sampling bag.

Substrate and inocula

Anaerobic-digested sludge collected from palm oil mill anaerobic sludge (POMS) was used as an inoculum in this study. The anaerobic sludge was obtained from Felda Sertings Hilir Palm Oil Mill Plant and was collected from a settling tank. GTW was sampled from the centralized grease trap of a food service establishment in Putrajaya, Malaysia. Typically, the content of the GTW consists of three layers; top layer consists of floatable grease, middle layer consists of organic-rich wastewater and bottom layer consists of food particle and sediments. The entire content of GTW was ground to get homogenized substrate.

Table 1 shows the characterization of GTW used in the study. After the grounding process, homogenous mixture content was achieved and showed slightly slurry content in orange as depicted in Fig. 1. The physical appearance of GTW showed a typical waste generated from kitchen activities, mostly from cooking (Nitayapat and Chitprasert 2014). Other physical characteristics such as the fraction of VS/TS were high. This may be due to the presence of high-lipid (O&G) fraction that corresponded to the high energy content in GTW (Girault et al. 2012). The chemical characteristic showed that COD was also high in organic content, a good indicator of biomass degradation in anaerobic digestion. High O&G content, COD, and C/N ratio observed in GTW indicated the difficulty in the degradation process (Gerardi 2003; Long et al. 2011). Therefore, high-lipid wastes are often avoided to be used as the main substrate for anaerobic digestion due to its inhibitory effects on the methane production process. Nonetheless, the fraction of VS/TS content showed that GTW had high energy content (92%), and this characteristic indicated that GTW can be considered as a potential substrate to produce higher methane yield (Kabouris et al. 2009; Neczaj et al. 2012). Other than that, a low value of ammonia did not contribute to the inhibition in the anaerobic system.

The molecular formula of GTW derived from an elemental analysis result obtained in this study was C1.61H4.87O. Theoretically, according to Buswell (Buswell and Neave 1930), the gas composition of GTW anaerobic digestion should be 75% methane. This value was slightly higher when compared to the fats sample as demonstrated by Buswell and Neave (1930). At a standard temperature and pressure, the theoretical biogas and methane yield obtained in this study were 870 mL biogas/gVS and 650 mL CH4/gVS, respectively. Based on the individual methyl ester, the long-chain fatty acids (LCFA) showed a wide variation in its composition. The three most abundant LCFA found in the GTW sampled in this study were palmitate, stearate, and oleate. This finding is parallel with common abundant LCFA found in GTW (Neczaj et al. 2012).

To impose low organic loading rate in continuous stir tank reactor experiments, GTW samples were diluted to the required concentration. Crude glycerine supplementation was collected from KLK Bioenergy Sdn. Bhd, a biodiesel plant with a plant capacity of 100,000 mt/annum. The characterization of glycerine used in this study is shown in Table 2.

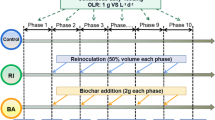

Operating procedure

The operating procedures for all reactors started with start-up operation and continued with semicontinuous feeding operation. During the start-up, the adaptation of biomass was allowed to acclimatize with GTW in batch mode before semicontinuous feeding started. For RGS, 10 mL/L glycerine was added prior to the adaptation of glycerine degradation to the reactor. At this phase, the monitoring of pH, alkalinity, COD, VFA, and LCFA were measured daily. The reactants volume was kept constant and monitored until COD removal measurement was consistent for three consecutive days before continuing with semicontinuous feeding mode.

After the start-up process, the operation of all reactors was switched to a semicontinuous feeding mode with an increasing organic loading rate (OLR). The operating condition is shown in Table 3. The increment of organic loading rate was achieved by increasing the influent flow rate. All reactors were fed once per day according to the required influent flow rate. For RGS, a supplementary 1% (v/v) glycerine was added each day. The reactor performance was monitored and analyzed by methane production, COD, VFA, LCFA, and TS. The stability of the reactors was assessed in terms of pH, total alkalinity, and VFA. The stability and performance of each stage of the reactors were monitored until a steady-state condition was achieved before the new OLR was increased. Steady-state condition is specified by a consistent value of COD, TS, VS, and pH concentrations for three consecutive days.

Analysis and calculations

Monitoring parameters such as pH, TS, VS, COD, O&G, and AN were analyzed for liquid samples according to APHA (1999). The content of the biogas samples was analyzed using gas chromatography (6890 N, Agilent Technologies) equipped with an HP-Molsive 30.0 m × 530 μm × 50.0 μm nominal with a thermal conductivity detector (TCD). Argon was used as a carrier gas at a flow rate of 45 mL/min. The temperature of the injector and detector were 100 and 150 °C, respectively. The column was maintained at 35 °C for 7.5 min, then ramped to 230 °C at 24 °C/min, and held at this temperature for 5 min. Volatile fatty acids (VFA) were analyzed using Thermo Scientific Trace 1300 Gas Chromatography equipped with DB-Wax column and nitrogen as a gas carrier. Sample preparation prior to GC injection was made according to Ibrahim et al. (2014), and a volume of 1 µL sample was injected under splitless mode. The injector and flame ionization detector (FID) temperature were 250 °C, and the column oven was 80 °C. Then, the oven temperature was increased to 180 °C at a rate of 9 °C/min, where it was held for 12 min. Long-chain fatty acids (LCFA) were analyzed using the same GC as VFA equipped with HP-Innowax (30m × 0.25 mm). The carrier gas was Helium (500 kPa) with a split ratio of 13 (column flow: 5 mL/min). An initial oven temperature of 60 °C was maintained for 2 min, then increased to 200 °C at 10 °C/min and maintained at this temperature for another 2 min. Finally, the oven temperature was increased to 240 °C at 5 °C/min and was held for 7 min. Injector and detector temperatures were 250 and 260 °C, respectively.

Results and discussion

Start-up operation

In this study, the first 14 days of reactors operation were treated as a start-up phase. The duration of the start-up phase was determined when the changes of COD removal efficiencies were less than 15% in three consecutive days. This condition was reflected by the stability of volatile acid to alkalinity ratio, and increment of the methane production before any increment of organic loading rate can be introduced into the reactor (Chan et al. 2012; Gerardi 2003). Figure 2 shows the profiles for methane composition, methane production rate, and methane yield during the start-up operation.

From Fig. 2, it can be seen that for RGS, methane production started slowly with a lag phase of 5 days and started to increase from day 6 onward. In Rcontrol, methane production started slowly with a lag phase of 9 days and methane production started to increase rapidly on day 10. On day 14, methane composition (Fig. 2a) for RGS reached a value of 48%, slightly higher than that of 41% in Rcontrol. A similar trend of methane composition was shown by methane production rate (Fig. 2b) and methane yield (Fig. 2c) for both reactors. RGS recorded a higher volumetric methane production rate of 0.072 LCH4/L while Rcontrol produced 0.061 LCH4/L. These trends corresponded with the methane yield of 0.16 and 0.10 LCH4/gCOD for RGS and Rcontrol, respectively.

A lag phase observed in both RGS and Rcontrol indicated that inhibition occurred due to acclimatization taking place at the beginning of the process (Chan et al. 2012; Kabouris et al. 2009; Lansing et al. 2010). During this batch process, microorganisms are being acclimatized with a new environment. In RGS, the supplementation of glycerine during start-up had reduced the lag time to 4 days as compared to Rcontrol’s 9 days. It has been reported that the supplementation of glycerine could provide more organic content and the growth factor (supplementation) that showed positive impacts toward inhibition in the process (Razaviarani et al. 2013). With the reduction in lag-phase duration, the addition of glycerine could enhance the degradation of GTW and may reduce the toxicity of inhibitor so as to become readily acclimatized for further process (Palatsi et al. 2010).

The stability of the reactors was observed according to pH, alkalinity VFA, and LCFA as shown in Fig. 3

As shown in Fig. 3a, no significant changes in pH were observed in Rcontrol and during day 1–8 when the pH ranged from 7.20 to 7.35. This situation may be attributed to the adaptation period of biomass toward GTW, and thus the degradation progress remained low. After the adaptation period, a substantial pH change was observed on day 9 onward indicating that active biodegradation started to increase and became stable until day 14. The same trend was observed in RGS except that rapid pH reduction started on day 6 and became stable at the end of the start-up process. The trend was in appropriate circumstances with the trends showed by methane production performances.

Alkalinity provides buffering capacity to the reactor to reduce major drop-off of the pH. As shown in Fig. 3b, alkalinity values in both reactors showed an increasing trend ranging from 1100 to 2500 mg/L. The increase of total VFA is concurrent with the pH drop-off in the reactor for the first 6 days in RGS and 10 days in Rcontrol after digestion started. It can be seen that concurrent with VFA concentrations, a high VFA/TA ratio was recorded in RGS and Rcontrol with the values ranging from 0.43 to 0.55 and 0.42 to 0.53, respectively. The increase in total VFA and instability of VFA/TA ratio can be associated with a predominance of acid fermentation that occurred during the initial stage of reactor start-up (Mata-Alvarez et al. 2000). This is in accordance with the adaptation of biomass to a new environment as it gets acclimatized into the system (Neves et al. 2010).

The adaptation of biomass can be observed in RGS when the value of VFA concentration decreased on day 6 and became stable in the subsequent days with VFA/TA ratio of less than 0.3. Maintaining pH value within sufficient methanogen ranges (6.8–7.2) and VFA/TA ratio of less than 0.3 by pH adjustment and alkalinity supplementation is important in order to retain the stability of the digestion system and signify the balancing reaction between the acidogenesis and methanogenesis phases (Chan et al. 2012; Gerardi 2003; Neves et al. 2010). However, the biomass in Rcontrol had a longer acid fermentation phase of 10 days than that of RGS. This situation can be attributed to a low tolerance level to the inhibitor in Rcontrol that led to the occurrence of a longer lag phase. It is shown that the production of methane was inhibited during the start-up process of Rcontrol with a 9-day lag phase recorded.

The monitoring of LCFA concentration as depicted in Fig. 3c showed the highest LCFA accumulation in RGS was recorded on day 5 with the maximum value of 247.29 mg/L. It gradually decreased until stability was achieved toward the end of the start-up process. A similar trend was observed in RControl except that the maximum value was recorded on day 10 (361.54 mg/L). Thus, the result implied that the initial lag phase observed during the start-up process in RGS and Rcontrol could be attributed to the rapid LCFA build-up as proposed by Cavaleiro et al. (2008) and Pereira et al. (2002). In a batch assay treating suspended sludge and dairy wastewater, a lag phase of 42 days was observed when the concentration of LCFA accumulated was recorded to be up to 900 mg/L and no methane production was observed when exceeding this value (Cavaleiro et al. 2008). In a batch assay treating granular sludge with oleic acid, the addition of 100 mg/L oleic acid had reduced approximately 80% of methane yield observed with a 13-days lag phase caused by the accumulation of intermediate (palmitate and stearate) in LCFA degradation (Pereira et al. 2002).

The individual profile of LCFA in both reactors is shown in Fig. 4. Oleate accumulation was observed in the first 3 days with the maximum values of 148.01 and 109.12 mg/L in Rcontrol and RGS, respectively. Then, the oleate concentrations decreased with the increasing concentration of palmitate. Palmitate concentration started to increase at a higher concentration than oleate and reached its maximum concentration on day 9 in Rcontrol with the value of 249.78 mg/L. Meanwhile, RGS achieved its maximum concentration on day 5 (134.67 mg/L). It can be seen that the primary inhibitor in both reactors is palmitate considering the long duration of its accumulation. The concentration only started to decrease after day 10 in Rcontrol and day 6 in RGS. In RGS, shorter inhibition was observed when glycerine supplementation reduced the LCFA toxicity most possibly caused by a palmitate toxicant. After the lag time, it is suggested that the palmitate accumulation was relatively low than the inhibited concentration detected in both reactors. For all reactors, stearate concentration showed an increasing value until day 4 with the maximum value of 16.09 and 16.77 mg/L for Rcontrol and RGS, respectively. After day 4, the stearate concentration decreased and was stabilized in lower concentration for all reactors. Following the same trend as stearate, myristate showed a maximum value of 32.41 and 26.76 mg/L in Rcontrol and R12H, respectively. However, there are no significant differences between the concentration of myristate and stearate for all reactors. The concentrations of both acids increased for a few days, maintaining a lower concentration and almost similar values throughout the start-up process. Thus, it is assumed that the occurrence and accumulation of stearate and myristate did not inhibit the process. This finding is in accordance with a study done by Lalman and Bagley (2000) who reported that although very low levels of stearate and myristate were detected, these did not accumulate as significantly as palmitate.

Semicontinuous feeding operation

The overall profiles of methane composition, production rate, and yield during the steady state of semicontinuous feeding operation at different OLR are shown in Fig. 5.

It was observed that the methane composition, methane production rate, and methane yield increased with the increasing OLR from 1.3 gCOD/L day until 2.2 gCOD/L day for all reactors. Each incremental shift in OLR will correspond to the slight decrease in methane composition, production rate, and yield related to the low COD removal for a short period after new loading. This can be attributed to the acclimatized period of biomass toward the increment of organic loading concentration (Chan et al. 2012). The scenario occurred on a temporary basis, and it does not take a long-time methane production to increase. Later, a downward trend of methane production was observed for OLR from 2.5 to 3.6 gCOD/L day for all reactors thus indicating a decreased performance of all reactors.

The overall performance of steady-state condition in all reactors depicted that the effectiveness of methanogen activities reached its maximum efficiency at OLR 2.2 gCOD/L day. At this stable condition, the average maximum methane composition was recorded highest in RGS (67%) as compared to Rcontrol (60%). While for methane production rate, average maximum values recorded for RGS and Rcontrol were 0.376 and 0.287 LCH4/L day, respectively. Furthermore, in line with methane composition and production rate performance, methane yield for all reactors recorded an average maximum value at OLR of 2.2 gCOD/L day. The value of methane yield evaluated for RGS is 0.19 LCH4/gCODremoved and for Rcontrol is 0.14 LCH4/gCODremoved with methane recovery from COD removal of RGS and Rcontrol were 90 and 88%, respectively. The incomplete biomethanation values achieved were mainly due to non-biodegradable matter accumulated in the form of sludge flotation thus hindering a complete biodegradation of organic matter (Long et al. 2011).

An increase in OLR of 2.5 gCOD/L day onward decreased the values of methane composition, production rate, and methane yield. In all reactors, methane composition decreased significantly to less than 50% when the experiments were run until OLR of 3.6 gCOD/L day. As well as methane composition, production rate also recorded a significant decrease for all reactors. The reduction in these values may be caused by organic wash out due to the semicontinuous feeding and the absence of sludge recycle that may reduce tolerance toward the substrate (Alves et al. 2009; Lin et al. 2011; Long et al. 2011). Low levels of VS were recorded during this phase in all reactors with the value of less than 10 g/L.

The stability of the reactors was determined according to pH, alkalinity VFA, and LCFA as shown in Fig. 6. Figure 6a depicted the overall pH trend in all reactors during a steady-state performance. After the acclimatization period during the start-up process, the pH values for RGS and Rcontrol were increasing and maintained within 6.84–7.16 throughout the OLR of 1.3 gCOD/L day until 2.2 gCOD/L day. This suggested a stable operating condition in those reactors for the stated OLR. Subsequently, a decrease in pH was recorded in further OLR for all reactors. This situation indicated the instability of the reactor concurrence with the rapid build-up of VFA toward the end of the experiments as shown in Fig. 6b. The minimum values of pH recorded in all reactors were less than 6.7 at the end of the experiments, indicating an unfavorable condition for methanogenesis. This could be related to the upset in the reactors’ performance. During the stable condition of OLR of 1.3 gCOD/L day until 2.2 gCOD/L day in all reactors, the alkalinity and VFA values were recorded to be in an appropriate condition for active metabolism of methanogens, as the value of alkalinity were within the ranges of 3000 mg/L until 4000 mg/L and VFA concentrations were less than 285 mg/L. This implied that an adequate buffering capacity provides sufficient methanogen pH ranges thus maintaining the stability of the processes.

The VFA values in all reactors started to increase during OLR of 2.5 gCOD/L day onwards. The corresponding alkalinity was also reduced to less than 1000 mg/L in all reactors at the end of the experiments. The VFA/alkalinity ratio also showed unstable condition when the values were greater than 0.3, leading to the upset of the reactors. During the instability period, the pH adjustment and alkalinity supplementation did not improve the condition in all reactors hence signifying that the acid-forming bacteria had overcome the methanogens activities.

Figure 6c shows LCFA degradation trends for both reactors. After having an acclimatized period shown through the lag-phase occurrence during start-up process caused by LCFA inhibition in Rcontrol and RGS, the acclimatized biomass in both reactors are capable to degrade LCFA. The concentration value was consistent between these two reactors until the OLR of 2.2 gCOD/L day recorded a value of less than 170 mg/L. This indicated an increasing and stable tolerance shown by methanogenic activities in an acclimated environment. The biomass is considered as being tolerated and acclimated to LCFA after having a lag phase during start-up. Developed acclimated biomass has a better conversion of LCFA and recovery afterward (Neves et al. 2010; Pereira et al. 2001, 2005; Rinzema et al. 1994). However, the LCFA started to accumulate again when the OLR was increased to 2.5 gCOD/L day until 3.6 gCOD/L day. This is similar to the observation of VFA concentration that leads to digester upset. During the upset of all the reactors, physical observation revealed the occurrence of sludge floatation. This condition repeats what has been observed by Jeganathan et al. (2006). By using oily wastewater from the food industry, at higher OLR of 5.2 gCOD/L day, a maximum of 75% of COD was degraded with a methane yield of 0.24 LCH4/gCODremoved. The appearance of sludge floatation significantly reduced the overall degradation to 40% (Jeganathan et al. 2006). Since no significant difference of LCFA concentrations was observed between RGS and Rcontrol during the semicontinuous feeding operation, individual LCFA profiles were not discussed.

Table 4 summarizes the performance of methane production in glycerine supplementation reactor, RGS and Rcontrol, experimented in previous studies. Glycerine supplementation reactor (RGS) showed higher methane production than in the Rcontrol. The methane production rate was 1.3 times higher in RGS than in the Rcontrol. Although experiencing a lag phase of 5 days during the start-up process, the reactor was able to enhance the capacity of methane production as compared to Rcontrol. This means that glycerine supplementation could reduce the lag-phase occurrence and enhance methane production even though non-acclimated inoculum was used. According to Buswell (Eq. 3.1), in theory, the theoretical methane production produced per gram glycerine added can be calculated based on the ideal gas law. The molecular formula of glycerine is C3H8O3 can produce 58% methane (426 mL) from per gram of theoretical glycerine. Taking into consideration that the density of glycerine used in this study is 1.24 kg/L, therefore, in theory, methane production rate should be 0.34 LCH4/L day. In a stable condition, RGS showed methane production enhancement by approximately 0.1 LCH4/L day when compared to Rcontrol. This indicated that the addition of glycerine provided positive effect since an extra carbon source added might induce the active biomass growth rate and reduce the toxicity by the inhibitor. In this study, it is assumed that by maintaining the glycerine addition of 1% (v/v), the addition of organic loading rate to the reactor did not have an adverse impact to the reactor performance. This finding is comparable to previous studies examining the effects of glycerine supplementation with the same types of reactor and glycerine dosage. The trend observed in this reactor was similar to a previous study by Razaviarani et al. (2013). It is reported that the addition of 1% (v/v) glycerine had increased methane production by approximately 1.8 times as compared to the reactor with no glycerine addition. The difference is mainly due to the types of substrate used; municipal wastewater (Razaviarani et al. 2013) and sewage sludge (Fountoulakis et al. 2010) might have low biodegradability than the substrate used in this study. Increasing the glycerine supplementation dosage to 3% (v/v) did not enhance methane production or improve reactor performance due to the higher organic loading rate and VFA build-up in the reactor (Fountoulakis et al. 2010). On the other hand, lower glycerine supplementation dose applied to the potato processing wastewater by Ma et al. (2008) yielded higher methane production rate as compared to this study. This could be due to the different types of reactor used. The reactor used in their study had a high organic reduction rate than the one used in this study.

Conclusion

The existing results demonstrate that the strategy of glycerine supplementation is reliable to enhance methane production. This strategy demonstrated a reduction of 5 days lag phase when compared to control reactor during the start-up, an enhancement of 7% methane composition, 0.09 LCH4/L day of methane production rate, and 0.05 LCH4/gCODremoved of methane yield during OLR of 2.2 gCOD/L day. The overall methane enhancement for glycerine supplementation strategy is 25°%. Controlling and maintaining the addition of glycerine in small quantities (less than 1% v/v) did not affect the existing organic loading rate hence, an additional source of carbon is provided by the supplementation. The palmitate accumulation was the possible main inhibitor during the occurrence of lag phase in the start-up process. Despite the reported inhibition, the system was able to recover methane production performance during the semicontinuous feeding stage.

References

Alves MM, Pereira MA, Sousa DZ, Cavaleiro AJ, Picavet M, Smidt H, Stams AJM (2009) Waste lipids to energy: how to optimize methane production from long-chain fatty acids (LCFA). Microb Biotechnol 2(5):538–550

Amon T, Amon B, Kryvoruchko V, Bodiroza V, Pötsch E, Zollitsch W (2006) Optimising methane yield from anaerobic digestion of manure: effects of dairy systems and of glycerine supplementation. Int Congr Ser 1293:217–220

Angelidaki I, Ahring BK (1992) Effects of free long-chain fatty acids on thermophilic anaerobicdigestion. Appl Microbiol Biotech 37:808–812

APHA (1999) Standard Methods for the Examination of Water and Wastewater, 17th edn. American Public Health Association, Washington

Buswell AM, Neave SL (1930) Laboratory studies of sludge digestion. Illinois Division of State Water Survey, Bulletin No. 30

Cavaleiro AJ, Pereira MA, Alves M (2008) Enhancement of methane production from long chain fatty acid based effluents. Biores Technol 99(10):4086–4095

Chan YJ, Chong MF, Law CL (2012) Start-up, steady state performance and kinetic evaluation of a thermophilic integrated anaerobic-aerobic bioreactor (IAAB). Bioresour Technol 125:145–157

Chi Z, Pyle D, Wen Z, Frear C, Chen S (2007) A laboratory study of producing docosahexaenoic acid from biodiesel-waste glycerol by microalgal fermentation. Process Biochem 42:1537–1545

Fountoulakis MS, Petousi I, Manios T (2010) Co-digestion of sewage sludge with glycerol to boost biogas production. Waste Manag 30(10):1849–1853

Gerardi M (2003) The microbiology of anaerobic digesters. Wiley, New York

Girault R, Bridoux G, Nauleau F, Poullain C, Buffet J, Peu P, Beline F (2012) Anaerobic co-digestion of waste activated sludge and greasy sludge from flotation process: batch versus CSTR experiments to investigate optimal design. Bioresour Technol 105:1–8

Gonçalves MR, Costa JC, Marques IP, Alves MM (2012) Strategies for lipids and phenolics degradation in the anaerobic treatment of olive mill wastewater. Water Res 46(6):1684–1692

Hidalgo D, Martín-Marroquín JM (2014) Effects of inoculum source and co-digestion strategies on anaerobic digestion of residues generated in the treatment of waste vegetable oils. J Environ Manage 142:17–22

Hwu CS, Tseng SK, Yuan CY, Kulik Z, Lettinga G (1998) Biosorption of long-chain fatty acids inUASB treatment process. Water Res 32(5):1571–1579

Ibrahim V, Hey T, Jönsson K (2014) Determining short chain fatty acids in sewage sludge hydrolysate: a comparison of three analytical methods and investigation of sample storage effects. J Environ Sci 26(4):926–933

Jeganathan J, Nakhla G, Bassi A (2006) Long-term performance of high-rate anaerobic reactors for the treatment of oily wastewater. Environ Sci Technol 40(20):6466–6472

Kabouris JC, Tezel U, Pavlostathis SG, Engelmann M, Dulaney J, Gillette RA, Todd AC (2009) Methane recovery from the anaerobic co-digestion of municipal sludge and FOG. Bioresour Technol 100(15):3701–3705

Lalman JA, Bagley DM (2000) Anaerobic degradation and inhibitory effects of linoleic acid. Water Res 34(17):4220–4228

Lansing S, Martin JF, Botero RB, Nogueira da Silva T, Dias da Silva E (2010) Methane production in low-cost, unheated, plug-flow digesters treating swine manure. Bioresour Technol 101:4362–4370

Lin Y, Wang D, Li Q, Huang L (2011) Kinetic study of mesophilic anaerobic digestion of pulp & paper sludge. Biomass Bioenergy 35(12):4862–4867

Long JH, Aziz TN, De Los Reyes FL III, Ducoste JJ (2011) Anaerobic co-digestion of fat, oil and grease (FOG): a review of gas production and process limitations. Process Saf Environ Prot 90(3):231–245

López JÁS, Martín Santos MDLÁM, Pérez AFC, Martín AM (2009) Anaerobic digestion of glycerol derived from biodiesel manufacturing. Bioresour Technol 100(23):5609–5615

Ma J, Van Wambeke M, Carballa M, Verstraete W (2008) Improvement of the anaerobic treatment of potato processing wastewater in a UASB reactor by co-digestion with glycerol. Biotech Lett 30(5):861–867

Martínez EJ, Fierro J, Sánchez ME, Gómez X (2012) Anaerobic co-digestion of FOG and sewagesludge: study of the process by fourier transform infrared spectroscopy. Int Biodeterioration Biodegradation 75:1–6

Mata-Alvarez J, Mace S, Llabres P (2000) Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour Technol 74:3–16

Neczaj E, Bien J, Grosser A, Worwag M, Kacprzak M (2012) Anaerobic treatment of sewage sludge and grease trap sludge in continuous co-digestion. Global NEST J 14(2):141–148

Neves L, Ferreira R, Oliveira R (2010) Influence of innoculum acclimation in the biodegradation rate and estimated biodegradbility of cow manure, food waste and oil. Environ Eng Manag J 9(3):327–334

Nitayapat N, Chitprasert P (2014) Characterisation of FOGs in grease trap waste from the processing of chickens in Thailand. Waste Manag 34(6):1012–1017

Palatsi J, Laureni M, Andrés MV, Flotats X, Nielsen HB, Angelidaki I (2009) Strategies for recovering inhibition caused by long chain fatty acids on anaerobic thermophilic biogas reactors. Bioresour Technol 100(20):4588–4596

Palatsi J, Illa J, Prenafeta-Boldú FX, Laureni M, Fernandez B, Angelidaki I, Flotats X (2010) Long-chain fatty acids inhibition and adaptation process in anaerobic thermophilic digestion: batch tests, microbial community structure and mathematical modelling. Bioresour Technol 101(7):2243–2251

Pereira MA, Mota M, Alves MM (2001) Degradation of oleic acid in anaerobic filters: the effect of inoculum acclimatization and biomass recirculation. Water Environ Res 73(5):1–11

Pereira MA, Pires OC, Mota M, Alves MM (2002) Anaerobic degradation of oleic acid by suspended and granular sludge: identification of palmitic acid as a key intermediate. Water Sci Technol 45(10):139–144

Pereira M, Pires OC, Mota M, Alves MM (2005) Anaerobic biodegradation of oleic and palmitic acids: evidence of mass transfer limitations caused by long chain fatty acid accumulation onto the anaerobic sludge. Biotechnol Bioeng 92(1):15–23

Razaviarani V, Buchanan ID, Malik S, Katalambula H (2013) Pilot scale anaerobic co-digestion of municipal wastewater sludge with biodiesel waste glycerin. Bioresour Technol 133:206–212

Rinzema A, Boone M, van Knippenberg K, Lettinga G (1994) Bactericidal effect of long chain fatty acids in anaerobic digestion. Water Environ Res 66(1):40–49

Acknowledgement

The authors would like to thank Universiti Putra Malaysia, Universiti Malaysia Terengganu and Fundamental Research Grant Scheme (Vot. No: 9199673) for the financial and technical support of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Gobinath Ravibdran.

Rights and permissions

About this article

Cite this article

Rasit, N., Idris, A., Wan Ab. Karim Ghani, W.A. et al. Glycerine supplementation as a recovery strategy of long-chain fatty acids inhibition on anaerobic digestion. Int. J. Environ. Sci. Technol. 16, 3325–3336 (2019). https://doi.org/10.1007/s13762-018-1928-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-018-1928-z