Abstract

In this study, sewage sludge was co-digested with different amounts of mature landfill leachate (0, 5, 10, 20, and 40% v/v) to evaluate the yield capacities of biogas and CH4. The highest biogas yield was obtained from the treatment with 10% leachate dose (T2) and control with 0% leachate dose, while the lowest biogas was produced from the treatment with 40% leachate dose. The highest CH4 production (maximum yield per kg VS consumed) was also obtained from T2, which was about 36% (v/v) higher than the control. This result was confirmed by the first-order kinetic model. It was also observed that the COD, TS, and VS removal efficiencies significantly decreased with increasing the leachate dose. However, the increased dose of leachate did not inhibit TN removal efficiency. This study demonstrates that mature landfill leachate could be treated via anaerobic co-digestion process with sewage sludge to enhance biogas production at low doses (up to 20% v/v).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sewage sludge is a by-product of wastewater treatment plants (WWTPs). Anaerobic digestion of sewage sludge is a commonly used technique in most WWTPs where microorganisms break down biodegradable organic matter in the absence of oxygen to produce biogas (Appels et al. 2008; Chen et al. 2008). The biogas, consisting of 60–70% CH4 (by volume), is a potential energy source to produce heat, electricity, as well as fuel for transportation (Appels et al. 2008).

Sludge is biochemically stabilized in an anaerobic digestion process that results in reduction in sludge volume, removal of most pathogens, and decrease in odor emission (Appels et al. 2008). Addition of substrates to sewage sludge enhances the anaerobic co-digestion process. One of the limitations in anaerobic digestion is nutrient imbalance, which can be overcome by adding nutrient-rich substrates to improve synergistic effects of microorganisms (Xu et al. 2018). Moreover, co-digestion dilutes the toxic elements in the substrates, improves buffer capacity, and increases biogas production (Xu et al. 2018). There has been a wide range of studies on the use of different substrates in co-digestion with sludge. Some of the substrates include municipal solid waste (Sosnowski et al. 2003; Gómez et al. 2006), manure (Murto et al. 2004; Zhang et al. 2014b), food waste (Kim et al. 2004; Prabhu and Mutnuri 2016), grease waste (Davidsson et al. 2008; Silvestre et al. 2014), and landfill leachate (Hombach et al. 2003; Montusiewicz and Lebiocka 2011; Montusiewicz 2014). Anaerobic co-digestion of these organic wastes can enhance biogas production besides treating the waste.

Landfill leachate is a highly contaminated liquid, which is generated when rainwater or melted snow passes through the landfill and interacts with the decomposing organic matter in the waste (Qasim 2017). The leachate typically contains organic matter, inorganic macro-components, heavy metals, and xenobiotic compounds that can adversely affect the environment if inadvertently released in main water bodies (Slack et al. 2005; Huo et al. 2009; Eggen et al. 2010). Chian and Dewalle (1976) classified landfill leachate into three categories based on landfill age and the ratio between biochemical and chemical oxygen demand (BOD5/COD): young leachate (BOD5/COD > 0.5), if landfill age is less than 5 years; intermediate leachate (BOD5/COD 0.1–0.5), if landfill age is between 5 and 10 years; and mature leachate (BOD5/COD < 0.1), if landfill age is more than 10 years. Due to waste stabilization in old landfills, the produced mature leachate is refractory and mostly contains non-biodegradable organic matters such as high humic and fulvic substances (Kulikowska and Klimiuk 2008; Huo et al. 2009). While young landfill leachate can be treated by anaerobic digestion due to the high concentration of organic matter (Pokhrel and Viraraghavan 2004), it is difficult to treat mature leachate alone (Renou et al. 2008). Therefore, co-digestion of landfill leachate and sewage sludge might promote treatment of mature leachate as well as increase anaerobic digestion efficiency of sewage sludge.

Among the use of different substrates, very few studies on co-digestion of sewage sludge and landfill leachate have been conducted. For instance, Hombach et al. (2003) conducted a mesophilic anaerobic co-digestion of sewage sludge with landfill leachate and observed an increase in daily CH4 production and volatile solid (VS) reduction up to 12% v/v of leachate dose. They concluded that as mesophilic anaerobic co-digestion is more economical and produces more biogas, it is a feasible and better alternative method compared to aerobic treatment. In a different study, Montusiewicz and Lebiocka (2011) observed similar results through anaerobic co-digestion of intermediate leachate and sewage sludge. In a study by Guven et al. (2018), organic fraction of municipal solid waste (OFMSW) was co-digested with different wastes including sewage sludge and young leachate. Their results revealed that co-digestion was a promising method to treat and utilize the leachate. Based on the results, compared to the mono-digestion of the leachate, the biogas potential and the removal efficiency of total and volatile solids significantly increased by co-digestion of the leachate + sewage sludge and leachate + sewage sludge + OFMSW.

Most studies on co-digestion of leachate and sludge were conducted with either young or intermediate leachate, and it is worth mentioning that co-digestion of fully mature leachate and sewage sludge has not been thoroughly investigated. In their comprehensive studies, Montusiewicz (2014) and Montusiewicz et al. (2018) performed co-digestion of mature leachate and sewage sludge with bio-augmentional approach and hydrodynamic cavitation pre-treatment of leachate with the variation in leachate characteristics (BOD5/COD 0.05, COD 5600 mg/L). They concluded that bio-augmentation and hydrodynamic cavitation pre-treatment of mature leachate could have primarily improved the efficiency of anaerobic co-digestion system.

Due to the compositional variability among young, intermediate, and mature leachate, the anaerobic co-digestion of fully mature leachate and sewage sludge may lead to variable digestion performance. Therefore, it is important to examine the performance of fully mature leachate (BOD5/COD < 0.1) in the anaerobic co-digestion with sewage sludge. The current anaerobic co-digestion study was conducted to address this knowledge gap utilizing a fully mature leachate having BOD5/COD ratio of 0.08 (< 0.1) and COD values of 1180 mg/L with two different sewage sludges.

The objectives of the study were: (1) to examine the potential of utilizing the mature landfill leachate in co-digestion with sewage sludge and to investigate the amount of biogas and CH4 production capacities as well as biogas composition over the experimental period, and (2) to evaluate the consumption and/or reduction in chemical oxygen demand (COD), volatile solids (VS), total solids (TS), and total nitrogen (TN) after the stabilization of the sludge–leachate mixture.

Materials and methods

Sample collection and preparation

Two different sludges, digested sludge and raw sludge, were collected from the North End Water Pollution Control Centre (NEWPCC), Winnipeg, Manitoba. The point source of digested sludge was the effluent stream of the mesophilic anaerobic sludge digester (operating condition is 37 °C with sludge age ranging from 15 to 20 days), whereas the raw sludge was taken from the effluent stream of the primary/secondary clarifier. The mature landfill leachate was collected from the landfill (well no. 24) in Brady Road Resource Management Facility, which was opened in 1973 and accepts both residential and commercial waste. Digested sludge, raw sludge, and landfill leachate were transported to the Environmental Engineering Laboratory at University of Manitoba and stored at 4 °C until further processing.

Before sample preparation, the substrates were acclimatized to room temperature. Five treatments containing 0, 5, 10, 20, and 40% (v/v) of leachate were prepared, and all treatments were triplicated (Table 1). The ratio of raw sludge and digested sludge was maintained at 60:40 in all treatments (Hombach et al. 2003; Montusiewicz and Lebiocka 2011) to ensure the presence of sufficient organic matter in the treatments.

Anaerobic co-digestion experiment and analytical procedure

Figure 1 depicts the process of anaerobic co-digestion with all underlying steps. Fifteen 600-ml Wheaton laboratory bottles (Sigma-Aldrich, Ontario, Canada) were used for the sewage sludge–leachate co-digestion tests. Rubber-lined phenolic caps were used to vacuum seal the digester bottles. The digester bottles were placed into a water bath with magnetic stirring capability, and temperature was adjusted at mesophilic condition (37 °C) by an automatic water temperature controller. A research respirometer (AER-800, Challenge Technology, Arkansas, USA) coupled with a computer was used to observe daily biogas production from each digester. The anaerobic co-digestion was continued until the biogas production reached a plateau.

Biogas samples were collected from the headspace of each digester on day 2, 5, 7, 10, and 13, and analyzed to determine the proportion of produced CH4 (BMP, bio-methane potential) and CO2 using an Agilent 490 micro gas chromatograph equipped with Molesieve-5A and PoraPlot U columns (GC, Agilent Technologies Canada Inc., Ontario, Canada).

The initial and final pH values were determined using a pH meter. During the experimental period, a long needle syringe was used to retrieve samples from the digesters and determine the pH level using pH strips. The raw sludge, digested sludge, and the landfill leachate were analyzed for the total solids (TS) and volatile solids (VS) according to the Standard Methods for Examination of Water and Wastewater (18th Edition) (APHA 1998). The analysis was performed for raw samples and after the completion of the anaerobic co-digestion process. A Hach kit TNT 827 was used to determine total nitrogen (TN) content. COD was measured following the standard dichromate methods APHA (1998) using HACH DR2800 spectrophotometer procedure. The removal efficiency of COD, TN, TS, and VS was calculated based on their initial contents and the final measurements obtained after stabilization.

The maximum amount of CH4 production in each treatment was also estimated using a first-order kinetic model to compare the results of the analytical tests. CH4 is produced due to organic matter degradation in the anaerobic digestion/co-digestion. To establish a relationship between the amount of organic matter degradation and CH4 production, Chen and Hashimoto (1978) proposed the following equation.

The first-order mass transfer kinetic model for substrate degradation was established by Redzwan and Banks (2004) as follows.

where t is the digestion time, Gmax is the maximum CH4 production, Gt is the CH4 production at time t, St and S0 are the substrate concentration at time t and time 0, respectively, and k is the first-order reaction coefficient.

The combination of Eqs. (1) and (2) results in a first-order kinetic model that demonstrates cumulative CH4 production (Eq. 3), which has been used in a number of studies (Borja and Banks 1994; Redzwan and Banks 2004; Sahito et al. 2013). The model can estimate the maximum CH4 production and reaction coefficient for each treatment.

Statistical analyses

Statistical analyses were carried out using SAS software for Windows (version 9.4, SAS Institute Inc., Cary, NC). Data were examined for possible outliers; Gaussian distribution was conformed with Shapiro–Wilk normality test of residuals, and homogeneity of variances was examined. One-way analysis of variance (ANOVA) (P < 0.05) with Tukey’s multiple means comparison tests was utilized in PROC GLIMMIX to determine the effect of leachate levels on biogas and BMP production, and to examine the effect of treatments on the COD, TS, VS, and TN removal efficiencies. Repeated measures analysis (P < 0.05) with one-way and two-way ANOVA in PROC GLIMMIX was used to examine the effect of leachate levels on cumulative volume of CH4 production, and to determine the effect of time and leachate levels (0, 25, 50, 100, and 200 ml) on pH change and CH4 composition, respectively. Time was considered as the random variable, and covariance structure was chosen from the lowest values of Akaike Information Criterion (AIC) and Bayesian Information Criterion (BIC). PROC NLIN procedure was used for the nonlinear regression analysis to obtain the best-fit parameters, and PROC CORR procedure was used for the correlation study between the estimated and actual methane yield.

Results and discussion

Characteristics of raw materials and their compositions

The leachate and sludge composition were determined after transportation to the laboratory. Table 2 represents the pH, TS, VS, COD, and TN contents in raw sludge, digested sludge, and leachate. The VS to TS ratio in leachate was lower than raw sludge, indicating that there is more inorganic matter in leachate than raw sludge. The characterization data including COD concentration, lower biodegradability fraction (BOD5/COD < 0.1), and higher alkalinity (NH4+–N > 400 mg/l) validated the leachate being investigated as the mature leachate (Kamaruddin et al. 2015; Torretta et al. 2016). Concentrations of TS, VS, COD, and TN in the leachate were much lower than raw and digested sludge (Table 2).

After mixing materials at different volumetric ratios, the characteristics of the resultant treatments were also determined. Table 3 shows that both initial and final pH values gradually increased with the increasing amount of landfill leachate in the treatments (T4 > T3 > T2 > T1 > C). More importantly, the optimal range of 6.8–7.4 was obtained for both influent and effluent pH during anaerobic digestion (Mao et al. 2015). The pH of T2, T3, and T4 was significantly higher than that of control, although the numerical values were very close (Table 3). Generally, the pH range did not fluctuate among treatments. The change in pH was more stable in the treatments having higher leachate concentration than control, indicating a stable operation during the co-digestion process. For instance, the change in pH in control (0% leachate) was 0.25 compared with 0.05 in T4. These observations confirm that the increasing amount of leachate contributed to higher buffering capacity, which was also found by Montusiewicz and Lebiocka (2011). There was no significant interaction between treatment effect and days effect on pH change, indicating that the pH of the treatments was independent of experimental duration. Therefore, no significant change in pH was observed during the experimental period (Table 3).

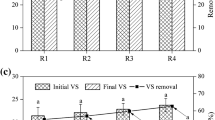

COD, TS, VS, and TN removal efficiency

Figure 2 shows the characteristics of the influents having different compositions that were used in anaerobic co-digestion. Compositional analyses of the influents indicated that by increasing the leachate amount, the average influent COD, TS, and VS significantly decreased due to the higher amount of COD, TS, and VS in the raw and digested sludge than in the leachate. However, the influent TN slightly decreased because of the small difference in TN between the sludge and leachate. The percentage of COD, VS, and TS removal efficiencies decreased with the increasing amount of leachate in the treatments, and the removal efficiency of the control was significantly higher than other treatments.

The maximum VS and TS removal efficiencies of about 34.47 and 24.62%, respectively, were achieved by the control, whereas T1 attained the highest amount of COD removal efficiency of 37.91%. However, there was no significant difference for VS and COD removal efficiencies for T1 and control, which can be due to the low proportion of leachate in T1 (5%).

In general, anaerobic co-digestion is highly efficient if there is high organic matter load and high VS concentration. Low concentration of these parameters can significantly decrease the removal efficiency of COD, TS, and VS (Gómez et al. 2011). Similar results have been found in the current study, and significant differences among treatments were observed with some exceptions for COD, TS, and VS removal efficiencies (Fig. 2a–c). On the contrary, no significant difference among the treatments was observed for TN removal efficiency, indicating that increased amount of leachate did not inhibit TN removal efficiency, where the TN removal ranged from 40.75 to 43.56% (Fig. 2d). In contrast to the current study, Montusiewicz (2014) reported TN removal of 4–15% from the co-digestion of hydrodynamically cavitated mature leachate and sewage sludge.

With the aim of investigating the removal of COD, TS, VS, and TN of leachate separate from that of sludge (together with raw and digested sludge), the expected removal efficiencies attributable to sludge alone was calculated for T1, T2, T3, and T4, assuming that sludge decomposition would be continued at the same rate as it was in control (i.e., 37.91, 24.62, 34.47, and 40.75% for COD, TS, VS, and TN, respectively). As the amount of leachate in the treatments was increased, the TN removal efficiency exceeded due to sludge alone (Table 4), suggesting that some leachate TN was removed during the co-digestion. Opposite trend of COD, TS, and VS indicated no removal of leachate COD, TS, and VS by co-digestion. These observations imply that the nitrogen removal microorganisms such as nitrifying–denitrifying bacteria were more active in the presence of leachate, while the recalcitrant fractions of leachate inhibited the activity of some microorganisms and contributed to lower COD, TS, and VS removal efficiencies than expected. Bio-augmentation, the Fenton’s process, and advanced oxidation processes could be utilized as the pre-treatment options to improve the biodegradability of the mature leachate before co-digestion and could be rendered better results for leachate treatment (DeMorais and Zamora 2005; Bernardo-Bricker et al. 2014; Montusiewicz 2014).

In order to understand the organic fraction removal, the ratio of VS and TS was estimated before and after the co-digestion. As the inorganic fraction mostly remains preserved during the anaerobic co-digestion, the change in VS/TS ratio indicates the degradation of organic fraction with respect to the inorganic accumulation (Zhang et al. 2014a). The VS/TS ratio for control, T1, T2, T3, and T4 was 0.54, 0.54, 0.53, 0.53, and 0.5 before the treatment, which decreased to 0.47, 0.47, 0.47, 0.46, and 0.45, respectively, after co-digestion. These results show that with an increase in leachate dose, VS/TS ratio decreased, although no significance difference was observed among the treatments suggesting quite similar percentages of volatile fraction for all treatments. The reduction in VS/TS ratio after the co-digestion indicates the effective removal of organic fraction in the digesters.

Biogas production

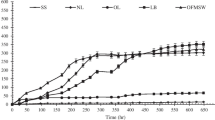

The biogas production and its composition (CH4, CO2) were monitored every 2 days to evaluate the efficiency of the anaerobic co-digestion method. After 14 days, the biogas production attained a plateau.

According to Fig. 3, the highest biogas yield (CH4 production) was related to T2 and control, while the lowest biogas was produced from T4 containing the highest dose of leachate. However, there was no significant difference among the treatments on day 0 and day 1 in terms of CH4 production. On the second day of the experimental period, T4 showed significantly lower cumulative volume of CH4 production than the other treatments. During the initial 13-day period, there was no significant difference between the cumulative volume of CH4 produced in control and T2, while on the 14th day, T2 showed significantly higher amount of CH4 production (2.51 L) than the control (2.39 L). Compared to other treatments, CH4 production in T2 was significantly higher over the experimental period.

With the increasing amount of leachate in the treatments, the CH4 production capacity was drastically reduced due to the reduction in organic content. Hence, T1, T3, and T4 produced less CH4 than the control by approximately 28, 19, and 53%, respectively. There was a significant interaction between the leachate levels (treatments) and experimental time, indicating that significant level of CH4 production depends not only on leachate content of the treatments, but also on the days of operation. Consequently, a consistent reduction in the CH4 production rate was detected during the experimental period (Fig. 3).

Based on two-way ANOVA analysis, the effect of treatments and experimental days on biogas composition (percentage of CH4) was not significant (P > 0.05), although a little fluctuation of CH4 composition was recorded on day 2 and day 7 (Fig. 4). The average biogas composition comprised about 66–68% CH4 and 32–34% CO2. This finding confirms the stable CH4 production over the experimental period (Fig. 4).

The maximum CH4 production and the reaction coefficient for each treatment was also determined by inserting the experimental values of cumulative CH4 production and digestion time in Eq. (3) and performing nonlinear regression analysis. The developed equations for the kinetic model are in Table 5.

Paired t-test and the multiple correlation coefficient (R2) were used to assess the accuracy of the predicted values from the model as compared to the experimental data. For all treatments, probability value in paired t-test was above 0.28 (P > 0.05) and the R2 value between predicted and measured data was above 0.98. These results confirm the accuracy of the model parameters (Gmax and k). The reported k values ranged from 0.03 to 0.07 in the studies (Borja and Banks 1994; Redzwan and Banks 2004; Sahito et al. 2013). However, a much higher range of 0.14–0.2 was observed in the current study, which is due to the use of different substrates and the method of estimating Gmax. Different initial substrate loadings (COD, VS, and TS) caused little variation in k values, suggesting that substrate concentration has little influence on reaction coefficient (k) and similar findings have been reported by Borja et al. (1993). According to Table 5, the highest maximum CH4 production is attributed to T2, which is close to the production rate of control. The decrease in CH4 production in the treatments is also in accordance with the order of CH4 production in the experiments.

Biogas yield

The average biogas yield per kg VS and TS removed in T2 and T3 was significantly higher than other treatments. Biogas and CH4 yield per kg VS and TS removed exceeded the control by approximately 34.4 and 36% in T2, and 15% in T3, respectively (Fig. 5 a, b). According to Montusiewicz and Lebiocka (2011), higher amount of biogas and CH4 yield in T2 and T3 can be ascribed to the higher degree of solubilization with higher dose of leachate and improved buffering conditions. This is also confirmed by the pH measurements, showing that the higher dose of leachate in treatments led to lower pH change and higher buffering capacity. Therefore, increased leachate dose in the treatments made the influent more digestible than the control, resulting in higher biogas yield. However, biogas yield in T3 and T4 was significantly decreased compared to T2 because of the significantly lower concentration of VS, which was about 10% and 30% lower than that of T2. The current study revealed that mature landfill leachate dose up to 20% v/v did not have a substantial influence on digestibility, while different results have been reported elsewhere. For instance, Lebiocka et al. (2010) reported approximately 30% drop in biogas yield with 5% v/v of leachate dose. In a different study, Kawai et al. (2012) reported a 55% drop in methane yield with 33% v/v of leachate dose and Guven et al. (2018) stated a significant drop in biogas and methane production with 50% v/v leachate dose in anaerobic co-digestion compared to sludge alone.

Table 6 compares the CH4 yield per kg of VS removed with other studies having similar experimental conditions. Hombach et al. (2003) reported highest CH4 yield with 20% v/v leachate dose, although the leachate category was unknown, while the current study reported highest CH4 yield with 10% v/v mature landfill leachate dose. The treatments containing 5% and 20% v/v mature landfill leachate achieved similar amount of CH4 yield. Montusiewicz and Lebiocka (2011) conducted study with intermediate leachate containing higher biodegradable fraction and obtained higher CH4 yield with 5% v/v leachate dose. The findings of the current study suggest that the highest CH4 yield can be achieved by utilizing lower percentage of leachate. In addition, more CH4 was produced by control than the previous studies. Higher amount of proteins and fats in the sludge produce higher CH4 production (Montusiewicz and Lebiocka 2011). Moreover, different characteristics of the leachate and sludge, such as TS, VS, COD, TOC, VFA, alkalinity, and toxic substances in the leachate can also affect the CH4 production due to compositional variations.

The mature landfill leachate is known to be highly polluted, toxic, and very refractory in terms of biodegradability and difficult in removing recalcitrant fractions. Previous studies have reported the utilization of considerably young or intermediate leachate via anaerobic co-digestion. While co-digestion of young leachate might not necessarily elicit any significant increase in biogas and methane production (Guven et al. 2018), the current study revealed that fully mature leachate significantly enhanced biogas and methane production.

Conclusion

In this research, different ratios of sewage sludge and mature landfill leachate were co-digested to investigate the biogas and CH4 production and the COD, TN, TS, and VS removal efficiencies. It was observed that VS, TS, and COD in the mature landfill leachate were much lower than the raw and digested sludge. Treatments with higher doses of leachate showed lower removal efficiencies of TS, VS, and COD, while TN removal efficiency in all treatments was almost the same. The utilization of the leachate was favorable to enhance biogas and CH4 yield, which did not affect the biogas composition and the maximum biogas and CH4 production was achieved with 10% v/v mature leachate dose. Treatments with up to 20% v/v leachate dose did not show inhibitory effect for biogas and CH4 yield per kg VS consumed due to the increase in digestibility in the influent. Pre-treatment methods with the purpose of improving biodegradability of mature leachate could be investigated to further enhance the anaerobic co-digestion efficiency.

References

APHA (1998) Standard method for examination of water and wastewater, 18th edn. American Public Health Association, Washington

Appels L, Baeyens J, Degrève J, Dewil R (2008) Principles and potential of the anaerobic digestion of waste-activated sludge. Prog Energy Combust Sci 34:755–781. https://doi.org/10.1016/j.pecs.2008.06.002

Bernardo-Bricker AR, Singh SK, Trovó AG et al (2014) Biodegradability enhancement of mature landfill leachate using Fenton process under different COD loading factors. Environ Process 1:207–219. https://doi.org/10.1007/s40710-014-0016-8

Borja R, Banks C (1994) Kinetics of anaerobic digestion of soft drink wastewater in immobilized cell bioreactors. J Chem Technol Biotechnol 60:327–334. https://doi.org/10.1002/jctb.280600314

Borja R, Martin A, Luque M, Duran M (1993) Kinetic study of anaerobic digestion of wine distillery wastewater. Process Biochem 28:83–90. https://doi.org/10.1016/0032-9592(93)80011-5

Chen Y-R, Hashimoto AG (1978) Kinetics of methane fermentation. Science and Education Administration, Meat Animal Research Center, Clay Center

Chen Y, Cheng JJ, Creamer KS (2008) Inhibition of anaerobic digestion process: a review. Bioresour Technol 99:4044–4064. https://doi.org/10.1016/j.biortech.2007.01.057

Chian ES, Dewalle FB (1976) Sanitary landfill leachates and their leachate treatment. J Environ Eng Div 102:411–431

Davidsson Å, Lӧvstedt C, la Cour Jansen J et al (2008) Co-digestion of grease trap sludge and sewage sludge. Waste Manag 28:986–992. https://doi.org/10.1016/j.wasman.2007.03.024

DeMorais JL, Zamora PP (2005) Use of advanced oxidation processes to improve the biodegradability of mature landfill leachates. J Hazard Mater 123:181–186. https://doi.org/10.1016/j.jhazmat.2005.03.041

Eggen T, Moeder M, Arukwe A (2010) Municipal landfill leachates: a significant source for new and emerging pollutants. Sci Total Environ 408:5147–5157. https://doi.org/10.1016/j.scitotenv.2010.07.049

Gómez X, Cuetos MJ, Cara J et al (2006) Anaerobic co-digestion of primary sludge and the fruit and vegetable fraction of the municipal solid wastes. Renew Energy 31:2017–2024. https://doi.org/10.1016/j.renene.2005.09.029

Gómez E, Martin J, Michel FC (2011) Effects of organic loading rate on reactor performance and archaeal community structure in mesophilic anaerobic digesters treating municipal sewage sludge. Waste Manag Res 29:1117–1123

Guven H, Akca MS, Iren E, Keles F, Ozturk I, Altinbas M (2018) Co-digestion performance of organic fraction of municipal solid waste with leachate: preliminary studies. Waste Manag 71:775–784. https://doi.org/10.1016/j.wasman.2017.04.039

Hombach ST, Oleszkiewicz JA, Lagasse P et al (2003) Impact of landfill leachate on anaerobic digestion of sewage sludge. Environ Technol 24:553–560. https://doi.org/10.1080/09593330309385590

Huo S, Xi B, Yu H, Liu H (2009) Dissolved organic matter in leachate from different treatment processes. Water Environ J 23:15–22. https://doi.org/10.1111/j.1747-6593.2007.00104.x

Kamaruddin MA, Yusoff MS, Aziz HA, Hung Y-T (2015) Sustainable treatment of landfill leachate. Appl Water Sci 5:113–126. https://doi.org/10.1007/s13201-014-0177-7

Kawai M, Kishi M, Hamersley M et al (2012) Biodegradability and methane productivity during anaerobic co-digestion of refractory leachate. Int Biodeterior Biodegrad 72:46–51. https://doi.org/10.1016/j.ibiod.2012.04.003

Kim H, Han S, Shin H (2004) Anaerobic co-digestion of sewage sludge and food waste using temperature-phased anaerobic digestion process. Water Sci Technol 50:107–114. https://doi.org/10.1016/j.biortech.2011.04.088

Kulikowska D, Klimiuk E (2008) The effect of landfill age on municipal leachate composition. Bioresour Technol 99:5981–5985. https://doi.org/10.1016/j.biortech.2007.10.015

Lebiocka M, Montusiewicz A, Zdeb M (2010) Anaerobic co-digestion of sewage sludge and old landfill leachate. Pol J Environ Stud Ser Monogr 2:141–145

Mao C, Feng Y, Wang X, Ren G (2015) Review on research achievements of biogas from anaerobic digestion. Renew Sustain Energy Rev 45:540–555. https://doi.org/10.1016/j.rser.2015.02.032

Montusiewicz A (2014) Co-digestion of sewage sludge and mature landfill leachate in pre-bioaugmented system. J Ecol Eng. https://doi.org/10.12911/22998993.1125463

Montusiewicz A, Lebiocka M (2011) Co-digestion of intermediate landfill leachate and sewage sludge as a method of leachate utilization. Bioresour Technol 102:2563–2571. https://doi.org/10.1016/j.biortech.2010.11.105

Montusiewicz A, Bis M, Pasieczna-Patkowska S, Majerek D (2018) Mature landfill leachate utilization using a cost-effective hybrid method. Waste Manag. https://doi.org/10.1016/j.wasman.2018.03.012

Murto M, Bjӧrnsson L, Mattiasson B (2004) Impact of food industrial waste on anaerobic co-digestion of sewage sludge and pig manure. J Environ Manag 70:101–107. https://doi.org/10.1016/j.jenvman.2003.11.001

Pokhrel D, Viraraghavan T (2004) Leachate generation and treatment—a review. Fresenius Environ Bull 13:223–232

Prabhu MS, Mutnuri S (2016) Anaerobic co-digestion of sewage sludge and food waste. Waste Manag Res 34:307–315. https://doi.org/10.1177/0734242x16628976

Qasim SR (2017) Sanitary landfill leachate: generation, control and treatment. Routledge, Abingdon

Redzwan G, Banks C (2004) The use of a specific function to estimate maximum methane production in a batch-fed anaerobic reactor. J Chem Technol Biotechnol 79:1174–1178. https://doi.org/10.1002/jctb.1107

Renou S, Givaudan J, Poulain S et al (2008) Landfill leachate treatment: review and opportunity. J Hazard Mater 150:468–493. https://doi.org/10.1016/j.jhazmat.2007.09.077

Sahito AR, Mahar R, Brohi KM (2013) Assessment of ex vitro anaerobic digestion kinetics of crop residue through first order exponential models: effect of lag phase period and curve factor. Mehran Univ Res J Eng Technol 32:657–668

Silvestre G, Illa J, Fernández B, Bonmatí A (2014) Thermophilic anaerobic co-digestion of sewage sludge with grease waste: effect of long chain fatty acids in the methane yield and its dewatering properties. Appl Energy 117:87–94. https://doi.org/10.1016/j.apenergy.2013.11.075

Slack R, Gronow J, Voulvoulis N (2005) Household hazardous waste in municipal landfills: contaminants in leachate. Sci Total Environ 337:119–137. https://doi.org/10.1016/j.scitotenv.2004.07.002

Sosnowski P, Wieczorek A, Ledakowicz S (2003) Anaerobic co-digestion of sewage sludge and organic fraction of municipal solid wastes. Adv Environ Res 7:609–616. https://doi.org/10.1016/S1093-0191(02)00049-7

Torretta V, Ferronato N, Katsoyiannis IA et al (2016) Novel and conventional technologies for landfill leachates treatment: a review. Sustainability 9:9. https://doi.org/10.3390/su9010009

Xu R, Zhang K, Liu P et al (2018) A critical review on the interaction of substrate nutrient balance and microbial community structure and function in anaerobic co-digestion. Bioresour Technol 247:1119–1127. https://doi.org/10.1016/j.biortech.2017.09.095

Zhang P, Lin C-J, Liu J et al (2014a) Biogas production from brown grease using a pilot-scale high-rate anaerobic digester. Renew Energy 68:304–313. https://doi.org/10.1016/j.renene.2014.01.046

Zhang W, Wei Q, Wu S et al (2014b) Batch anaerobic co-digestion of pig manure with dewatered sewage sludge under mesophilic conditions. Appl Energy 128:175–183. https://doi.org/10.1016/j.apenergy.2014.04.071

Acknowledgements

The authors gratefully acknowledge the financial support from the Natural Sciences and Engineering Research Council of Canada (NSERC RGPIN-2014-05510).

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: M. Abbaspour.

Rights and permissions

About this article

Cite this article

Berenjkar, P., Islam, M. & Yuan, Q. Co-treatment of sewage sludge and mature landfill leachate by anaerobic digestion. Int. J. Environ. Sci. Technol. 16, 2465–2474 (2019). https://doi.org/10.1007/s13762-018-1889-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-018-1889-2