Abstract

Anaerobic digestion is a promising technology for biogas recovery from lipid-based wastes. Although other types of such wastes have been investigated, sewage scum (SS) produced from primary and secondary settling tanks of wastewater treatment plants is yet to be fully explored as an alternative source of biogas. To this end, anaerobic co-digestion and blending were adopted as strategies to enhance biogas production from SS using biochemical methane potential (BMP) assay while three kinetic models were used for interpretation. This work examines the synergistic effect of percentage sewage scum loading: 10%, 20%, and 40% (volatile solids basis) during mesophilic co-digestion with various organic substrates, viz., organic fraction of municipal solid waste (OFMSW), old landfill leachate (OL), new landfill leachate (NL), and a leachate blend (LB) prepared from 67% old leachate and 33% new leachate. After 27 days, results showed that the highest level of improvement in the net cumulative methane yield (CMY) was observed in SS:OL ratio of 40:60 where the yield increased by 67% (105.2 ± 33.1 mL gVS−1) when compared with OL alone (35 ± 0.3 mL gVS−1). This increase was linked to positive synergism and improved anaerobic biodegradability of the mixtures. In addition, reactors containing leachate blends showed a higher methane recovery (338.1 ± 30.6 mL gVS−1) by 5.38-fold over other sets due to the associated effect of leachate blending. Furthermore, the modified Gompertz model achieved a better fit with up to an R2 value of 0.999 while co-digestion substantially reduced the lag time by 2.5-fold (2.1 day) compared with mono-digestion.

Results from this study suggests that existing facilities can incorporate either SS addition or leachate blending as environmentally friendly strategies to improve biogas production during waste treatment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The demand for renewable and sustainable energy production has recently become a global concern, resulting in a fast-growing rate of 16.4% per year over the period of 2007–2017 [1, 2]. To meet this demand, biogas from anaerobic digestion (AD) has been evaluated as one of the promising pathways for renewable bioenergy production [3, 4]. Strict regulations prohibiting landfilling of organics in Europe and North American territories make AD a viable option for simultaneous waste treatment, energy, and nutrient recovery [3, 5]. A variety of wastes including agricultural residues, manure, slaughterhouse waste, organic fraction of municipal solid waste (OFMSW), and sewage sludge are amenable to AD, and as a result of this, AD now contributes to more than 35% of bioenergy generated from waste biomass [6,7,8,9,10]. However, this process is very complex because biogas production depends on the physical and chemical properties of the waste. Moreover, the outcome of AD can be affected by environmental factors such as temperature, pH, toxicants, nutrient imbalance, acidification, and ammonia issues [7, 11,12,13,14].

While some of organic waste source streams, especially OFMSW, have been investigated more often than others, there is interest to widen the range of alternative substrates and co-substrates used for bioenergy production. The digestion of OFMSW has been reported to have several limitations such as high solids content, low carbon-to-nitrogen ratio (C/N), heterogeneity, inhibition, and instability issues due to ammonia and volatile fatty acid (VFA) accumulation [8, 13,14,15,16]. On the other hand, fat, oil, and grease (FOG) and lipid-rich wastes (e.g., oil mill effluents, greasy sludge, dairy, slaughterhouse waste, and waste cooking oil) are attractive and highly investigated sources of biogas production [5, 9, 17,18,19,20]. The huge biogas generation potential has been attributed to the highly reduced organic matter content, high COD content (up to 2.90 gCOD g−1 FOG), and the high number of carbon and hydrogen atoms in their molecule [21, 22]. FOG wastes are also reported to contain VFA or short-chain fatty acids (SCFA) which can be readily biodegraded by methanogens for biogas production [17]. But compared to other types of investigated FOG-rich wastes, sewage scum (SS) has not received much attention from researchers, hence the need for the current study. SS, also known as clarifier skimming, is the sewage solid which is often buoyed up by entrained FOG, gas, plastic material, soaps, waxes, or other impurities floating on the surface of primary settling tanks, secondary treatment, and secondary settling tanks in wastewater treatment plants (WWTPs) [4, 17]. In WWTPs, FOG in SS is suggested to represent between 25 and 40% of total chemical oxygen demand (COD) of wastewater [4].

The digestion of lipid-rich wastes has been widely conducted in batch reactors [9, 23, 24], anaerobic membrane bioreactors [25, 26], and high-rate anaerobic reactors, such as expanded granular sludge bed (EGSB) reactor [27], upflow anaerobic sludge blanket (UASB) reactor [28, 29], and hybrid UASB reactor [30]. However, there are concerns about mono-digestion or sole degradation of FOG-laden wastes because some FOG wastes show poor biodegradability due to overloading when treated as sole substrates [17, 19, 31, 32]. Additionally, operational issues such as digester foaming, clogging, scum build-up, sludge-bed washout, or complete digester failure persist during treatment in most anaerobic reactors [5, 28, 32]. For instance, Jeganathan et al. [28] treated a complex oily wastewater from the food industry in three different UASB configurations. Although a COD removal efficiency of over 80% was achieved at an organic loading rate (OLR) of 3 kg COD m−3d−1, process failure occurred at higher OLRs due to sludge floatation and biomass washout caused by high concentration of FOG.

Furthermore, methanogenic inhibition attributed to accumulation of long-chain fatty acids (LCFA), which are intermediates during anaerobic degradation of FOG wastes persists to date [9, 21]. Specifically, LCFA adsorption onto cell surfaces disrupts mass transfer efficiency, hampering biomethane production in the process. In Pagés-Díaz et al. [19], LCFA accumulation terminated methane production and further decrease methane concentration from 76 to 45% when OLR of 0.9 gVS L−1 d−1 was applied during the treatment of slaughterhouse waste. The authors concluded that the high lipid content of the waste (175 g kg−1 fresh matter) also caused foam formation and hydrogen accumulation in the biogas. Szabo-Corbacho et al. [26] reported the cessation of methanogenesis at up to 50% at LCFA concentrations above 100 mg/g TS even though methane yield remained stable. Shakourifar et al. [21] observed digester failure due to LCFA accumulation when the reactor’s grease trap waste mixture content was over 40% during treatment (OLR of 3.7gVS L−1 day−1). The authors also observed that LCFA accumulation caused VFA accumulation due to the inhibition of the methanogenic archaea which utilizes VFAs as substrate [21]. Cirne et al. [33] concluded that even though the digestion of lipid-rich substrates increases methane yield, it could also result in a pH reduction especially if the slower growing methanogens cannot utilize the VFAs present in the digester at the same rate of the acetogenic bacteria.

Moreover, the C/N ratio of fatty wastes varies widely, and some have been reported to be outside the widely recommended optimum value of 20:1–30:1, thus giving room for possible nutrient imbalance during digestion [34,35,36]. For instance, Hachicha et al. [36] reported a C/N ratio of 56.7 for olive mill wastewater sludge, Silvestre et al. [34] also reported a C/N ratio of 39 for grease trap sludge (GTS), while Kurade et al. [37] observed a ratio of 68.3 for FOG waste. On the other hand, C/N ratio values between 9 [31] and 23 [34] have also been reported for restaurant waste oil and trapped grease waste respectively. The type of the FOG waste and concentration will likely determine the final C/N ratio [38]. However, an optimal balance between C and N is highly required for the proper growth and metabolism of the microbial community during AD [11]. Consequently, unbalanced C/N ratios during FOG digestion can lead to process failure due to higher ammonification and/or VFAs production in the reactor [17, 35].

To overcome the various drawbacks regarding FOG digestion, pre-treatment [15, 24, 30, 39, 40] and anaerobic co-digestion (ACo-D) of FOG wastes with other organics [3, 11, 13, 14, 39, 41] are some of the strategies that have been widely recommended. While pre-treatment may require additional expenses for implementation, ACo-D can make use of existing facilities without raising current costs. ACo-D refers to the simultaneous digestion of complimentary solid or liquid organic wastes combined in the proper percentages [3, 17]. ACo-D can cause an improvement of kinetic performance of the resulting substrate mixture and synergism as a result of nutrient balancing, dilution of inhibitory intermediates and increase in buffering capacity of the resulting mixture [3, 39, 42,43,44]. The high specific methane generation potential of FOG wastes and high C/N ratio makes an ideal substrate for co-digestion with a variety of complimentary organics to boost biogas yield [5, 17]. However, excessive substrate concentration or high loading rate of FOG waste in the influent-co-digestion mixture could still cause a process failure resulting from LCFA accumulation and overloading [21, 31, 38]. Hence, successful ACo-D involving FOG rich wastes will depend on the source and type of FOG waste, temperature, and reactor configuration [21, 31].

Results from several studies suggest improved biogas yield can be achieved during ACo-D of other organic substrates with FOG wastes [18, 21, 31, 45]. For instance, Wan et al. [31] reported up to 137% increase in methane yield during mesophilic co-digestion of TWAS and FOG(64%VS). Alqaralleh et al. [18] investigated the co-digestion of thickened waste activated sludge (TWAS) and grease trap FOG using a ratio of 40:60(VS). The results showed that methane yield was improved by 112.7% when compared to the digestion of TWAS alone. During a co-digestion study, Martín-González et al. [45] reported a 36% increase in methane production as a result of adding WWTP sourced FOG waste to OFMSW during digestion. Also, Shakourifar et al. [21] recorded up to 68% increase in methane production when a mixture of fermented primary sludge and TWAS was codigested with 40% (VS) restaurant grease trap waste mixture.

Similar to ACo-D is the concept of leachate blending which exploits the combination of markedly different properties of landfill leachate types to improve biogas yield. In a BMP study, Nair et al. [46] showed that blending of new and old landfill leachate (OL) could improve biogas yield by 19–41%. Leachate blending was suggested to act as a form of treatment and stabilization for the high organic load in new leachate (NL) by addition of acclimatized microorganisms (methanogens) and alleviating inhibitory effects of ammonia and VFAs. This concept was recently tested and proven in bioreactor landfills recirculating leachate blends where biogas production improved by 77.2–193.2% [47]. Therefore, the application of this concept to SS could help improve biogas recovery in the long run.

ACo-D experiments involving SS are still few and limited studies have examined the effect of adding SS to OFMSW or leachate blend (blend of fresh and old leachate). Based on studies conducted so far [18, 21, 31, 45], it is reasonable to hypothesize that the addition of SS can bring about a positive effect on biogas production during co-digestion. However, further research on mesophilic ACo-D of SS and other organic substrates is urgently required, especially to determine if SS addition in an ACo-D mixture can bring about improved biogas production or not. One of the best ways to estimate the biogas potential of organic substrates and co-substrates is by conducting a biochemical methane potential (BMP) test. BMP tests are inexpensive, repeatable and the information gathered from the tests are useful for substrate characterization, evaluation of optimal design and performance of ACo-D processes [41, 48]. Through the application of different kinetic models to the BMP test results from ACo-D, variables such as lag phase, hydrolysis constant, maximum methane production, and methane production rate can be estimated in order to evaluate the efficiency of the process [49]. The differences in operating conditions used during AD experiments such as pH, temperature, various substrate concentrations, and inoculum sources are some of the reasons for the complexities of the process [11, 49]. As a result, drawing reliable conclusions on model application to these variables has remained a challenge because existing literature on the application of models has also been suggested to be inconsistent. Some of the widely applied models have been reported to be inadequate in explaining the mechanisms of the AD process especially under critical conditions [49]. It is in this regard that the application of linear and non-linear regression kinetic modelling was suggested for application to co-digestion studies [48,49,50]. A comparison of kinetic models applied to ACo-D processes can assist researchers to effectively evaluate, optimize process efficiency, and monitor variables involved in the process [49, 51, 52].

Consequently, the three central objectives of this study were to (i) investigate and assess the effect of percentage SS loading (VS basis) on biogas production during the mesophilic ACo-D with OFMSW, (ii) and assess the effect of percentage SS loading (VS basis) on biogas production during the mesophilic ACo-D with landfill leachate, and (iii) investigate the overall co-digestion biodegradation kinetics of the study by comparing the first-order model, modified Gompertz model, and the logistic function model. This study is of major relevance as previous studies have indicated that full biogas potential of individual substrates may not be realized during mono-digestion. Therefore, the results from this study will provide more information on the addition of SS as well as how SS loading affects biogas production during co-digestion with OFMSW and leachate.

2 Materials and methods

2.1 Materials

The SS used in this study was collected from the surface of a primary sedimentation tank of the wastewater treatment plant in Gatineau, QC, Canada. The inoculum used was also obtained from the mesophilic digester of the plant. The OFMSW and NL were sourced from a compost facility in Moose Creek, ON, Canada. The OFMSW contained mostly food waste, paper, cardboard, and yard waste. The OFMSW was macerated to an average size of 1–2 mm using a food processor. The OL was collected from a closed engineered landfill located in Carp, ON, Canada. While in operation, the landfill accepted municipal waste and the landfill leachate was estimated to be between 15 and 25 years old. All samples were collected in hermetically sealed plastic buckets and transported to the University of Ottawa where they were stored at 2 °C until they were used.

2.2 Experimental setup

Table 1 shows the experimental design. The experiments were conducted in 2 phases. In phase 1, single substrate AD tests were conducted to determine the BMP of all substrates; SS, OFMSW, NL, OL, and LB (33% NL and 67% OL). The LB composition was selected based on results from Aromolaran and Sartaj [47] which showed that 33% NL and 67% OL were the best performing combination in terms of biogas production. In the second phase, co-digestion experiments were conducted to investigate the effect of %SS addition on biogas production from ACo-D of OFMSW and SS. Also, the effect of %SS addition to leachate during ACo-D of SS and leachate was investigated. The second phase was done by varying the %SS (VS) in the bottles containing the co-substrates. The bottle composition and mixing ratio considered were 10%VS SS:90%VS substrate, 20% VS SS:80%VS substrate, and 40%VS SS:60%VS substrate, where substrate was OFWSW, NL, OL, or LB. Except for the OL reactor which was conducted in a 1-L reactor with 750-mL working volume, all other batch anaerobic experiments were conducted in 250-mL glass serum bottled with a working volume of 150 mL. All BMP bottles were prepared in duplicates. In addition to the substrates, 70 mL of anaerobic inoculum and distilled water was added to all the bottles. The pH of some of the bottles was maintained within the range of 6.5 and 8.2 as prescribed by Speece [53]. The bottles were purged with nitrogen gas for about 1 min to maintain anaerobic conditions. No supplemental nutrients were added to the bottles since the inoculum is a viable source of micronutrients, trace elements, and vitamins for the biodegradation of substrates [11]. C:N ratio of new leachate is usually around 10, while C:N ratio of old leachate could be anywhere below 2 [54]. For OFMSW, the C:N ratio can be between 11.4 and 27 depending on the source [8, 16, 55]. On the other hand, FOG-rich wastes such as sewage scum generally have very high carbon and hydrogen atoms are therefore recommended as co-substrates with other substrates with improper C:N ratio [5, 34]. The bottles were sealed using self-healing caps and silicon. The BMP bottles were then agitated on a New Brunswick Scientific Controlled Environment Incubator Shaker Model G-25 rotating at 100 rounds per minute (rpm) at 30 ± 1 °C.

2.3 Analytical procedure

To prevent pressure build-up in headspace, biogas production from the BMP bottles were vented and measured daily using a BD 21G1/2 needle connected to a laboratory constructed U-tube manometer. The measured biogas volumes were converted to standard temperature and pressure (STP), (0 °C and 1 atm) using Eq. 1 [56].

where VSTP is the volume of gas (L) at standard temperature (0 °C) and pressure (1 atm); V is the volume of gas (L) measured at temperature T; T is the temperature of gas (°C) or the ambient space; and Pw is the vapor pressure (mmHg) of water as a function of temperature.

Biogas measurement was terminated when the measurable biogas production was less than 1% change in the volume of biogas recorded in the previous 3 days. The net biogas volume for the samples was computed by deducting the biogas contribution of the inoculum (blank). Biogas composition was analyzed weekly according to standard method 2720C, APHA [57] using a GOW-MAC gas chromatograph (Series 400, Gow-Mac Instrument Co., USA) equipped with a thermal conductivity detector and fitted with a packed column (HayeSep® T 80/100). Helium gas was used as the carrier gas with an inflow rate of the helium was at 30 mL/min. The temperatures of the column, detector, and injector were constantly maintained at 35 °C, 185 °C, and 50 °C, respectively.

All samples were analyzed for total solids (TS), volatile solids (VS), pH, total alkalinity, chemical oxygen demand (COD), VFA, and total ammonia nitrogen (TAN) in triplicates. TS and VS were determined according to standard method 2540G, APHA [57]. pH was determined using a HQ40d portable multi-parameter meter fitted with an Intellical PHC201gel filled pH electrode (HACH, USA). Total alkalinity test was based on TNTplus™870 reagent vials (Method 10239, HACH USA). COD was determined based on TNTplus™ 823 (Method 10212, HACH, USA) with DR6000 ultraviolet–visible spectrophotometer (HACH, USA) and a digital reactor block 200 (HACH, USA). TAN was determined based on TNT plus™ 832 reagent vials (Method 10205, HACH, USA), while VFA was determined based on TNT plus™ 872 reagent vials (Method 10240, HACH, USA).

2.4 Data analysis

Many models have been applied in order to simulate the anaerobic digestion process and predict methane production. Due to the complexity of the AD process, kinetic model comparison has been suggested as a strategy to obtain reliable and true parameter estimation [48, 49]. Consequently, three common kinetic AD models were applied and assessed in this study; first-order equation (FO), modified Gompertz model (GM), and logistic function (LF) shown in Eqs. 2, 3 and 4, respectively [18, 47].

where \(\beta (t)\) is the biogas accumulation (mL gVS−1) at specific time, t is the time (hour). \(\beta o\) is the ultimate production potential (mL gVS−1). Rm is the methane production rate (mL gVS−1hr −1), λ is the lag phase (hour), and e = 2.7183. k is the hydrolysis rate constant (hr−1) [18]. \(\lambda , \beta o,\) Rm, and k were fitted using the generalized reduced gradient non-linear regression algorithm of solver on Microsoft Excel with minimum residual sum of squared errors between experimental data and the model curve [58]. Maximum number of iterations was set at 100 in all cases.

2.5 Synergistic effects

Synergistic effects are produced due to the inner reactions of the various components in a co-digestion study. The calculated yield (CYcalculated) in each co-digestion ratio was estimated based on the net experimental cumulative biogas yield (CBY) of mono-digestion of each substrate using Eq. 5 [[3, 15, 48].

where t is the digestion time (hours); CYcalculated (t) (mL gVS−1) is the estimated biogas yield at time t; Net CBYsubstrate1(t) (mL gVS−1) is the measured biogas yield of substrate1 only at the time (t); P1 is the percentage(%) of substrate1 in the mixture; Net CBYsubstate2 (t) (mL gVS−1) is the measured biogas yield of substrate2 alone at the time t; and P2 is the percentage (%) of substrate2 in the co-digestion mixture. Synergistic effect exists if the CYcalculated is more than the net CBY from the BMP co-digestion experiment. Furthermore, the ratio of the net experimental CBY is compared with the CYcalculated according to Eq. 6 [51].

-

if α > 1; the co-digestion mixture has a synergistic effect in the net experimental CBY.

-

if α = 1; the substrates work independently from the co-digestion mixture.

-

if α < 1; the co-digestion mixture has a competitive or antagonistic effect in the final mixture.

3 Results and discussion

3.1 Substrate characteristics

The characteristics of the samples and inoculum used in this study are shown in Table 2. The values in the table represent the mean ± standard deviation for triplicates.

3.2 Single substrate digestion

The net average CBY evolved from the substrates after 27 days (648 hours) of operation are presented in Fig. 1. When the net CBY (per mass of VS) is considered, the results show the LB sample had the highest biogas of 351.6 ± 3.1 mL gVS−1 followed by OFMSW (322 ± 7.9 mL gVS−1), NL (301.8 ± 3.1 mL gVS−1), OL (66.8 ± 2 mL gVS−1), and the least measured in the SS with 31.6 ± 0.3 mL gVS−1. The average methane yields, and percentages were 14.2 ± 0.5 mL gVS−1 (44.9%CH4), 205.2 ± 1.3 mL gVS−1 (67% CH4), 34.7 ± 0.4 (51.9% CH4), 242.6 ± 0.3 mL gVS−1 (69% CH4), and 219.0 ± 9.3 mL gVS−1 (68% CH4) for SS, NL, OL, LB, and OFMSW, respectively. Higher biogas production in the LB sample can be ascribed to the synergistic effect of leachate blending where the old leachate content is considered to have a greater buffering capacity as well as a more acclimated methanogenic consortia which leads to a rapid methanogenesis of the organic load from the new leachate content [46, 47]. However, the OL by itself contains negligible concentration of easily biodegradable organics hence the low biogas production observed [59]. The reported biogas yield value of 351.6 ± 3.1 mL gVS−1 from LB in this study is consistent with the 321 mL reported by Nair et al. [29] where a similar blend of leachate was digested. In addition, biogas yield from the OFMSW sample in this study (322 ± 7.9 mL gVS−1) agrees with past research works. Ara et al. [3], Bala et al. [60], Pavi et al. [61], and Abudi et al. [15] reported biogas yields of 225 mL gVS−1, 228 mL gVS−1, 215 mL gVS−1, and 214.5 mL gVS−1, respectively, during OFMSW digestion.

There is an obvious process imbalance in the SS reactor, and this could probably be related to the LCFA accumulation and possible imbalance in certain FOG wastes as single substrates [17, 19, 31, 32]. It is important to note that although lipid wastes are known to be highly biodegradable, the biodegradability is often affected by LCFA accumulation leading to methanogenic inhibition. Therefore, poor degradability expressed here is not in the context of substrate recalcitrance but as a result of the inhibition caused by LCFA accumulation.

Furthermore, the concentration of VFA present for conversion into biogas by the methanogenic archaea could have been another factor why low biogas yield was obtained from the SS reactor. The VFA (as acetic acid) concentration during the first week shows that the LB was 4237.4 mg L−1, the NL was 3527.4 mg L−1, while the OFMSW, OL, and SS were 2237.4 mg L−1, 174.4 mg L−1, and 74.1 mg L−1, respectively. Percentage VFA reductions at the end of the study were 78% (811 mg L−1), 36.3% (111 mg L−1), 81% (818 mg L−1), and 58.9% (918 mg L−1) in NL, OL, LB, and OFMSW, respectively, except for SS where the VFA concentration had increased to 1550 mg L−1. VFAs are regarded as the main metabolic intermediate during AD [3, 31]. Wan et al. [31] had reported a digester failure when adding 75% or more of FOG in the influent, which caused severe acidification of the digester. Therefore, rapid acidification or VFA accumulation is regarded as one of the major issues affecting mono-substrate digestion as they result in imbalance in acidogenesis and methanogenesis rates. Moreover, LCFA accumulation can also lead to VFA accumulation due to methanogenic inhibition of the archaea utilizing VFAs as substrate [21, 35]. The results from this study indicate that VFA conversion efficiency might have been affected thereby inhibiting optimal biogas production in the SS reactor. As a result, maximum biogas potential of SS was not achieved due to possible inhibition [21]. Shakourifar et al. [21] reported digester failure citing VFA accumulation when the concentration reached 3.2 g L−1 (as acetic acid) during treatment of grease trap waste mixture and sludge. When it comes to SS treatment in anaerobic reactors, a carefully selected OLR can be applied to avoid overloading. Alternatively, a pre-treatment can be applied prior to digestion [30]. These options will greatly improve the biodegradability as well as the biogas yield. However, there may be additional cost implications for pre-treatment.

3.3 Co-digestion of SS and OFMSW

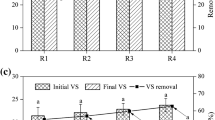

One of the objectives of this study was to investigate the effect of co-digestion of SS and OFMSW. Figure 2 shows the average net CBY evolved from OFMSW with 10%, 20%, and 40%SS (VS basis) addition as well as CY in each case. The details of the CY are later presented in Table 3.

It can be deduced from Fig. 2 that 10% SS + OFMSW, 20% SS + OFMSW, and 40% SS + OFMSW produced a net CBY of 292.1 ± 0.6 mL gVS−1 (54.9%CH4), 324.8 ± 3.1 mL gVS−1 (65%CH4), and 450.1 ± 1.6 mL gVS−1 (68%CH4), respectively. This indicates a positive synergism in net CBY with increasing %SS. The digestion of OFMSW has been suggested to be potentially cumbersome and subject to potential biogas inhibition partly due to rapid acidification, scarce bio-available nutrients (especially nitrogen), and presence of improper materials, among other factors [8, 13, 14, 16]. Therefore, there is a need for co-digestion with complimentary substrates [8, 15, 40]. The improvement observed in net CBY can be ascribed to synergism as well as a balanced acidogenic and methanogenic consortia produced due to ACo-D [3]. The highest increase when comparing net CBY and CY in the three co-digestion scenarios involving OFMSW was 118.7% observed in the case of 40%SS + OFMSW with a net CBY of 450.1 ± 1.6 mL gVS−1 and a CY of 205.8 mL gVS−1. With a net CBY of 292.1 ± 0.6 mL gVS−1 from 10% SS + OFMSW, there was an antagonistic effect (− 0.3%) with regard to the CBY from OFMSW alone which produced 322 ± 7.9 mL gVS−1. This indicates that this ratio is not compatible.

In the case of the 20% SS + OFMSW which produced a net CBY of 324.8 ± 3.1 mL gVS−1, this co-digestion mixture did not significantly improve net CBY when compared to the net CBY of OFMSW alone. This might be because of the presence of inhibitory compounds. However, with a CY of 263.9 mL gVS−1 from 20% SS + OFMSW, there was a 23.1% increase when comparing the net CBY and CY, thus indicating that the co-digestion mixture indeed produced more biogas than the expected amount. This increase translates to an α of 1.2 and indicates evidence of synergistic effect in the final biogas production. The 40% SS + OFMSW produced 39.8% more net biogas than OFMSW alone. Within the co-digestion group, 40%SS + OFMSW produced the highest net CBY involving OFMSW and SS.

The net CBY from this mixture also produced 54.1% and 38.6% more net biogas than 10% SS + OFMSW and 20% SS + OFMSW, respectively. This indicates an increase in net CBY with increase in %SS. Instead of digesting SS alone, overall results show the net CBYs were improved by 9.2-, 10.2-, and 14.2-fold increases when 10% SS, 20% SS, and 40% SS were, respectively, added to SS. The huge improvement here is partly linked to methanogenic inhibition in the SS reactor. As shown in Fig. 2, a 118.1% increase was observed when comparing the CBY and CY of 40% SS + OFMSW. This translates to an α of 2.2 which indicates there is some evidence of synergism and nutrient balancing in the final biogas production of the reactor. Additionally, the results demonstrate that a 39% more biogas can be produced from OFMSW when up to 40% SS is added.

The shape of the graphs in Fig. 2 however indicates diauxic characteristics where multiphasic biogas production is obvious. This pattern of biogas production has been previously reported during microalga mono-digestion [62], ACo-D digestion of low carbohydrate with high-fat agricultural wastes [63], as well as cow manure with food waste or leaves or straw [64], industrial paper wastes [65], and treatment of fat-rich diary wastewater [23]. Diauxic pattern during AD has been suggested to occur when microorganisms consume two or more substrates at differing rates, thus causing a two-phased reaction outline [62]. It could also be signs of methanogenic inhibition. Diauxic pattern in this study can also be attributed to metabolic adjustments during the biodegradation of the various components of the ACo-D mixture including the presence of FOG-rich content [63]. This is because measured methane production yield (Fig. 5) in all reactors is well within the range of the various \(\beta o\) (mL gVS−1) values estimated by the applied kinetic models.

3.4 Co-digestion of SS and leachate

This study also aims to evaluate the effect of SS co-digestion with leachate samples (OL, NL, and LB). As shown in Table 3, the 10% SS + NL reactor produced a net CBY (303.2 ± 3.1 mL gVS−1), which is quite negligible when compared to the gas production from digesting only NL (301.8 ± 3.1 mL gVS−1). On the other hand, 14.6% and 63.6% improvement were observed in the case of 20% SS + NL (345.9 ± 0.6 mL gVS−1) and 40% SS + NL (493.6 ± 2.8 mL gVS−1) in relation to digestion of NL alone. These results indicate that biogas production can be increased through the addition of lipid-based wastes to NL. Moreover, the α values calculated are greater than 1, thus indicative of the fact that the mixture (co-digesting NL with SS) had some synergetic effect in the final biogas production. In Table 3, the α value of 1.1, 1.4, and 2.3 obtained from 10% SS + NL, 20% SS + NL, and 40% SS + NL corresponds to 10.3%, 39.6%, and 133.4% improvement in biogas production respectively.

This can be further observed in Fig. 3 where the CY is compared with the net CBY from the 20% SS. The CY was also compared with 40% SS additions in Fig. 4. The net CBY was observed to improve by 9.6-, 10.9-, and 15.6-folds in 10% SS + NL, 20% SS + NL, and 40% SS + NL, respectively, when considered along with the net CBY from SS alone.

Average methane yield and percentages were observed to be 206.2 ± 10.7 mL gVS−1 (65.1% CH4), 235.2 ± 5.2 mL gVS−1 (68% CH4), and 296.1 ± 28.3 mL gVS−1 (59.8% CH4) in 10% SS + NL, 20% SS + NL, and 40% SS + NL, respectively. The above results prove the benefit of ACo-D over mono-digestion.

Assuming complete conversion of the net COD to methane at STP, i.e., 350 mL gCOD−1 [66, 67], Table 4 shows that the biodegradability of NL increased from 38.4% during mono-digestion to a maximum of 80.6% when 40% SS was added. This result shows that the addition of SS to NL can help improve overall biodegradability of the mixture due to synergism as well and increased presence of biodegradable organics.

Among the substrates used in this study, the OL had the most depleted biodegradability. As mentioned earlier, the OL had a net CBY of 66.8 ± 2.0 mL gVS−1. Compared to OL alone, the 10% SS + OL (87.3 ± 1.4 mL gVS−1), 20% SS + OL (131.6 ± 0.6 mL gVS−1), and 40% SS + OL (154.7 ± 1.4 mL gVS−1) improved net CBY by 30.7%, 97%, and 131.6%, respectively. Average methane percentages were 55.6% CH4, 64.5% CH4, and 67.3% CH4 in 10% SS + OL, 20% SS + OL, and 40% SS + OL, respectively. In addition, net CBY from SS alone indicates biogas was improved by 2.8-, 4.2-, and 4.9-folds with the addition of 90% OL, 80% OL, and 60% OL to SS, respectively. Compared to the digestion of OL alone which has negligible amount of easily biodegradable organics, the results show that the co-digestion of OL and SS enhanced net CBY mainly due the synergistic effect of co-digestion and possible nutrient balancing. When comparing the net CBY and CY, 40% SS + OL translated to the highest value of 193.3% increase (shown in Table 3 and Fig. 4) further proving the positive effect of ACo-D. In addition, α values from all the three different %SS additions to OL are greater than 1, emphasizing the presence of positive synergism in the mixture. As seen in Table 4, the addition of SS to OL improved the anaerobic biodegradability of the substrate from 30.9% during mono-digestion to 70.33% in 40% SS + OL. The improvement indicates that the biodegradability of OL can be enhanced through the addition of SS.

Similar to NL and OL, in the case of LB, the improvement in net CBY was proportionate with increasing %SS and reducing LB content. While the net CBY from LB alone was 351.6 ± 3.1 mL gVS−1, the study shows a biogas improvement of 8.1%, 24.9%, and 41.4% was obtained with 10%, 20%, and 40% SS additions, respectively. The increase in biogas with increase in %SS can as well be ascribed to the effect of co-digestion and leachate blending [46, 47]. Observed CH4 yield and percentages from 10% SS + LB, 20% SS + LB, and 40% SS + LB reactors are 64.2%, 65.7%, and 68%, respectively. As opposed to SS digestion alone, the net CBY improved by 12.0-, 13.9-, and 15.7-fold in 10% SS + LB, 20% SS + LB, and 40% SS + LB, respectively. Table 3 also shows the differences in net CBY and CY in all these cases discussed above. A more interesting observation in the case of the LB is the improved performance of the sample over other leachate samples used as co-substrates on a case-by-case basis (i.e., 10%, 20%, and 40% SS addition). From the results, the samples containing LB produced the highest net CBY of 380.1 ± 3.1 mL gVS−1, 439.1 ± 3.2 mL gVS−1, and 497 ± 3.1 mL gVS−1 in 10%, 20%, and 40% SS addition, respectively. Although the net CBY from 40% SS + NL and 40% SS + LB were 493.6 ± 2.8 mL gVS−1 and 497.2 ± 3.1 mL gVS−1, respectively. Nonetheless, the net cumulative CH4 production was higher in 40% SS + LB with 338.1 ± 30.6 mL gVS−1 (68% CH4) and 296.1 ± 28.3 mL gVS−1 (59.8%CH4) in 40% SS + NL which reinforces the benefit of leachate blending in a co-digestion mixture. The greater number of methanogens in old leachate coupled with the presence of new leachate has been suggested to help improve overall biogas production [46, 47]. Figure 3 compares the net CBY and CY from the 20% SS addition to each leachate substrate. The net CBY from 20% SS + LB represents a 233.6% improvement over the 20% SS + OL sample and 26.9% improvements over 20% SS + NL sample [46, 47].

Figure 4 also shows the same trend for the case of 40% SS addition to different leachate types. The benefit of leachate blending over other co-digestion leachate mixtures in this study is therefore obvious. The shape of the two graphs of Fig. 3 and Fig. 4 also suggests diauxic characteristics as earlier observed in ACo-D of SS and OFMSW. The experimental CH4 yields observed in all reactors are well within the ranges of \(\beta o\) (mL gVS−1) values estimated by the applied kinetic models except for 20SS + OL where a significant difference was observed in estimations by FO and MG models.

The practicality of the selected optimal ratios in this study also needs consideration and hence the reason a higher SS addition percentage higher than 40%VS content was not investigated in this study. Moreover, overloading of the reactor with SS could potentially result to methanogenic inhibition by LCFA accumulation [31]. Overall, the addition of SS to the substrates enhanced the net cumulative methane yield methane (CMY) from each of the single substrates used in this study. Figure 5 highlights the summary of the CMY in both mono-digestion and co-digestion modes. The results of this study have therefore shown that the 40% SS addition has best improved biogas production in all co-digestion mixtures using the various co-substrates.

4 Kinetic model comparison and results

The application of kinetic models to ACo-D experiments is useful for the evaluation of the process efficiency as well as the interpretation of the methane data [48,49,50]. In this study, FO (Eq. 2) was applied to estimate the hydrolysis rate constant k (hr−1), while GM (Eq. 3) and LF (Eq. 4) were applied to estimate the lag phase λ(hr), methane production rate Rm (mL gVS−1 hr−1), and the ultimate methane production βo (mL gVS−1). As an example, Fig. 6 compares the net CMY with the βo (mL gVS−1 estimated from the models for the 40%SS scenario only). Table 5 also shows the comparison of the parameters estimated from FO, MG, and LF models when applied to the experimental results of this study. The ability of the models to interpret the experimental data is determined by the coefficient of correlation (R2) value. It can be seen from Table 5 that the models are a good fit because the R2 value for the FO ranged between 0.935 and 0.992, while the MG and LF ranged between 0.937 and 0.999 and 0.925 and 0.998, respectively.

When ultimate methane production, βo (mL gVS−1), is considered in the 3 models in the co-digestion experiment, it is obvious that it aligns well with the net CMY as it increases with the increase in %SS addition, further proving the fact that the addition or co-digestion with SS will enhance net CMY over mono-substrate digestion alone. The 40% SS produced the highest βo (mL gVS−1) over the 10% and 20% SS additions to OFMSW and leachate samples. However, similar to the experimental results, βo estimated from FO models was observed to reduce to 185 mL gVS−1 at 10% SS + OFMSW from 264 mL gVS−1 estimated from OFMSW alone. βo (mL gVS−1) estimated from the MG and LF were also reduced under the same condition as well and remained consistent with the experimental results. In the above scenario, βo (mL gVS−1) estimated also reduced when the values from the NL alone is compared to the 10%SS + NL. It is however possible there was insufficient bioavailable nutrients within the co-digestion mixture to handle the added organic load in both scenarios.

When the methane production rate Rm (mL gVS−1hr−1) estimated by the MG and LF is considered within the single substrate digestion experiment, higher values of 1.27 and 1.28 mL gVS−1hr-1 were estimated by the MG and LF models, respectively, for NL. Considering the fact that the LB samples were 0.64 and 0.68 mL gVS−1hr−1 from the respective MG and LF models, it is possible that the rate of methane production was delayed due to microbial acclimation and VFA conversion time in the leachate mixture. This is despite the fact that the LB had produced the highest methane quantity amongst the substrates digested individually. OFMSW had estimated Rm (mL gVS−1 hr−1) values of 0.77 mL gVS−1hr−1 and 0.81 mL gVS−1hr−1 from MG and LF, respectively. This may suggest the presence of high soluble organics within the reactor for improved methane production rate. In general, the LF estimated higher values than the MG in this case. When it comes to the co-digestion involving leachate samples, the LB containing reactors could be observed to have higher rates estimated by LF and MG in the 3 instances of SS addition. However, the model estimated Rm (mL gVS−1 hr−1) values in the NL and LB appears to increase with 20% SS and reduced when 40% SS were added. The decreased rate could mean the methane production rate was slightly inhibited by the high lipid content as it approached 40% SS as observed in 40% SS + LB and 40% SS + NL. This suggests a higher organic load was a factor. In contrast, the Rm (mL gVS−1 hr−1) in the OL co-digestion mixtures increased with increasing %VS of SS at a very low rate. This could be connected to the fact that introduction of SS increased the organic VS load in the presence of adapted methanogens in the OL facilitated a positive synergism for improved methane production.

Kinetic phases of a bacteria are lag phase, exponential growth phase, and stationary phase [68]. The lag phase λ(hr) refers to an adjustment period where the bacteria cells are expected to modify and take advantage of the new environment to begin methane production [56, 69]. However, the lag phase is often influenced by environmental conditions as well as preincubation conditions [47].

λ(hr) values estimated by MG and LF are closely related and follow a similar pattern in both single substrates and ACo-D experiments. The LF appears to overestimate the lag time in contrast to the MG value. The estimated λ(hr) values from the MG and LF models from the single substrate digestion appears to emphasize the fact that a longer lag time was required for an improved methane production. High TAN concentration could have been a factor as it affects methane production [10, 12]. While the OFMSW had estimated values of 43.7 hr (MG) and 57.9 hr (LF), the TAN was only 248 ± 32 mg L−1. On the other hand, NL experienced a higher lag time with estimated values of 122.4 hr (MG) and 128.1 hr (LF), suggested to be as a result of a higher TAN value of 2,260 ± 53 mg L−1 in the reactor. In the co-digestion experiment, the λ(hr) appears to reduce consistently with increase in percentage SS. Compared to the single substrate experiment, all λ(hr) values estimated from the co-digestion experiment were shorter. In this study, for instance, while OFMSW alone had an estimated value of 43.7 hr and 57.9 hr from MG and LF, respectively, these durations reduced to 25.1 hr (MG) and 41.2 hr (LF) upon adding 10% SS despite the reduction in βo (mL gVS−1). The λ(hr) values in the co-digestion of SS and OFMSW in this work is lesser to values reported by Ponsá et al. [50] where 8.9 days (213.6 hr) was reported for OFMSW + vegetable oil and 9.1 days (218 hr) was reported for OFMSW + animal fat. Difference in FOG type as well as inoculum source might have been a reason for the difference [17, 38]. Similar reduction in λ(hr) was observed in 10% SS + NL where the lag phase was reduced by almost 50%. βo (mL gVS−1) however improved in the 10% SS + LB sample, but there was a reduction in the lag phase value from 94.1 hr (MG) and 112.1 hr (LF) to 88 hr (MG) and 100.8 hr (LF), thus signifying the positive effect of SS addition through lag time reduction and improvement of methanogenic activities.

5 Conclusion

This work investigated the effect of SS loading (VS basis) on biogas production during the mesophilic co-digestion with OFMSW as well as landfill leachate in batch BMP reactors. The sole digestion of SS was observed to be inhibited by LCFA and VFA accumulation. However, biogas production from the four different substrates (OFMSW, NL, OL, and LB) was enhanced by increasing the percentages of the added sewage scum during co-digestion. Overall, there was an improvement in biodegradability of the co-digestion mixtures over the mono-substrates as a result of increased organic matter presence. Also, the Net CBY exceeded the calculated yield in all instances in further acknowledgement of the benefit of synergism and nutrient balancing during co-digestion. The addition of 40% SS (VS basis) was observed to have promoted the highest biogas production during ACo-D with OFMSW or leachate. In the co-digestion involving addition of SS to leachate samples, leachate blending was observed to have played a major role in improving the net CBY of LB samples due to increased synergism and high methanogenic population present in old leachate. Furthermore, kinetic model application to the methane data showed that the LF and MG provided a better estimation of the parameters than the FO. Methane production was achieved quickly through lag phase reduction due to synergistic effect of co-digestion.

Nevertheless, it is worth investigating the pre-treatment of SS prior to treatment in anaerobic reactors. It is also recommended that the effect of inoculum macronutrient, micro-nutrients, and activity on a standard substrate should be investigated. Additionally, the effect of inoculum adaptation during primary and secondary substrate addition as a function of time should be investigated. Finally, further studies can also investigate the effect of the various co-digestion scenarios on the microbial community diversity and relative abundance of the micro-organisms.

Abbreviations

- ACo-D:

-

Anaerobic co-digestion

- AD:

-

Anaerobic digestion

- BMP:

-

Biomethane potential

- C/N:

-

Carbon-to-nitrogen

- CBY:

-

Cumulative biogas yield

- CMY:

-

Cumulative methane yield

- COD:

-

Chemical oxygen demand

- CY:

-

Calculated yield

- FO:

-

First order

- EGSB:

-

Expanded granular sludge bed

- FOG:

-

Fat, oil, and grease

- GTS:

-

Grease trap sludge

- LB:

-

Leachate blend

- LCFA:

-

Long chain fatty acid

- LF:

-

Logistic function

- MG:

-

Modified Gompertz

- NL:

-

New leachate

- OFMSW:

-

Organic fraction of municipal solid waste

- OL:

-

Old leachate

- PS:

-

Primary sludge

- SCFA:

-

Short-chain fatty acid

- SS:

-

Sewage sludge

- STP:

-

Standard temperature and pressure

- TAN:

-

Total ammonia nitrogen

- TS:

-

Total solids

- TWAS:

-

Thickened waste activated sludge

- UASB:

-

Upflow anaerobic sludge blanket

- VFA:

-

Volatile fatty acid

- VS:

-

Volatile solids

- WWTP:

-

Wastewater treatment plant

References

Rezaeitavabe F, Saadat S, Talebbeydokhti N, Sartaj M, Tabatabaei M (2020) Enhancing bio-hydrogen production from food waste in single-stage hybrid dark-photo fermentation by addition of two waste materials (exhausted resin and biochar). Biomass Bioenerg. https://doi.org/10.1016/j.biombioe.2020.105846

Baghbanzadeh M, Savage J, Balde H, Sartaj M, VanderZaag AC, Abdehagh N, Strehler B (2021) Enhancing hydrolysis and bio-methane generation of extruded lignocellulosic wood waste using microbial pre-treatment. Renew Energy 170:438–448

Ara E, Sartaj M, Kennedy K (2015) Enhanced biogas production by anaerobic co-digestion from a trinary mix substrate over a binary mix substrate. Waste Manage Res 33:578–587

Young B (2012) Enhancement of the mesophilic anaerobic co-digestion of municipal sewage and scum. Master's thesis. University of Ottawa, Canada

Long JH, Aziz TN, Reyes FLDL, Ducoste JJ (2012) Anaerobic co-digestion of fat, oil, and grease (FOG): A review of gas production and process limitations. Process Saf Environ Prot 90:231–245

Fardin JF, de Barros O, Dias APF (2018) Biomass: Some Basics and Biogas. In: Advances in Renewable Energies and Power Technologies. Elsevier, pp 1–37

Rasapoor M, Young B, Brar R, Sarmah A, Zhuang WQ, Baroutian S (2020) Recognizing the challenges of anaerobic digestion: Critical steps toward improving biogas generation. Fuel. https://doi.org/10.1016/j.fuel.2019.116497

Semeraro B, Summa D, Costa S, Zappaterra F, Tamburini E (2021) Bio-delignification of green waste (Gw) in co-digestion with the organic fraction of municipal solid waste (ofmsw) to enhance biogas production. Applied Sciences (Switzerland). https://doi.org/10.3390/app11136061

Ning Z, Zhang H, Li W, Zhang R, Liu G, Chen C (2018) Anaerobic digestion of lipid-rich swine slaughterhouse waste: Methane production performance, long-chain fatty acids profile and predominant microorganisms. Biores Technol 269:426–433

Adghim M, Sartaj M, Abdehagh N (2021) Enhancing Mono- and Co-digestion of Poultry Manure by a Novel Post-hydrolysis Ammonia Stripping Approach in a Two-Stage Anaerobic Digestion Process. Waste Biomass Valorization 12:6045–6056

Odejobi OJ, Ajala OO, Osuolale FN (2021) Anaerobic co-digestion of kitchen waste and animal manure: a review of operating parameters, inhibiting factors, and pretreatment with their impact on process performance. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-01626-3

Akindele AA, Sartaj M (2018) The toxicity effects of ammonia on anaerobic digestion of organic fraction of municipal solid waste. Waste Manage 71:757–766

Mehariya S, Patel AK, Obulisamy PK, Punniyakotti E, Wong JWC (2018) Co-digestion of food waste and sewage sludge for methane production: Current status and perspective. Biores Technol 265:519–531

Ziaee F, Mokhtarani N, Pourrostami Niavol K (2021) Solid-state anaerobic co-digestion of organic fraction of municipal waste and sawdust: impact of co-digestion ratio, inoculum-to-substrate ratio, and total solids. Biodegradation 32:299–312

Abudi ZN, Hu Z, Sun N, Xiao B, Rajaa N, Liu C, Guo D (2016) Batch anaerobic co-digestion of OFMSW (organic fraction of municipal solid waste), TWAS (thickened waste activated sludge) and RS (rice straw): Influence of TWAS and RS pretreatment and mixing ratio. Energy 107:131–140

Panigrahi S, Dubey BK (2019) A critical review on operating parameters and strategies to improve the biogas yield from anaerobic digestion of organic fraction of municipal solid waste. Renew Energy 143:779–797

Salama ES, Saha S, Kurade MB, Dev S, Chang SW, Jeon BH (2019) Recent trends in anaerobic co-digestion: Fat, oil, and grease (FOG) for enhanced biomethanation. Prog Energy Combust Sci 70:22–42

Alqaralleh RM, Kennedy K, Delatolla R, Sartaj M (2016) Thermophilic and hyper-thermophilic co-digestion of waste activated sludge and fat, oil and grease: Evaluating and modeling methane production. J Environ Manage 183:551–561

Pagés-Díaz J, Westman J, Taherzadeh MJ, Pereda-Reyes I, Sárvári Horváth I (2015) Semi-continuous co-digestion of solid cattle slaughterhouse wastes with other waste streams: Interactions within the mixtures and methanogenic community structure. Chem Eng J 273:28–36

Wu LJ, Kobayashi T, Li YY, Xu KQ (2015) Comparison of single-stage and temperature-phased two-stage anaerobic digestion of oily food waste. Energy Convers Manage 106:1174–1182

Shakourifar N, Krisa D, Eskicioglu C (2020) Anaerobic co-digestion of municipal waste sludge with grease trap waste mixture: Point of process failure determination. Renew Energy 154:117–127

Diamantis V, Eftaxias A, Stamatelatou K, Noutsopoulos C, Vlachokostas C, Aivasidis A (2021) Bioenergy in the era of circular economy: Anaerobic digestion technological solutions to produce biogas from lipid-rich wastes. Renew Energy 168:438–447

Cavaleiro AJ, Pereira MA, Alves M (2008) Enhancement of methane production from long chain fatty acid based effluents. Biores Technol 99:4086–4095

Bai X, Folk S, Chen YC (2021) Co-digestion of sewage sludge and fat, oil, and grease with BioAmp pretreatment under mesophilic conditions. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-01418-9

Lutze R, Engelhart M (2020) Comparison of CSTR and AnMBR for anaerobic digestion of WAS and lipid-rich flotation sludge from the dairy industry. Water Resour Ind. https://doi.org/10.1016/j.wri.2019.100122

Szabo-Corbacho MA, Pacheco-Ruiz S, Míguez D, Hooijmans CM, García HA, Brdjanovic D, van Lier JB (2021) Impact of solids retention time on the biological performance of an AnMBR treating lipid-rich synthetic dairy wastewater. Environ Technol (United Kingdom) 42:597–608

Pereira MA, Roest K, Stams AJM, Mota M, Alves M, Akkermans ADL (2006) Molecular monitoring of microbial diversity in expanded granular sludge bed (EGSB) reactors treating oleic acid. FEMS Microbiol Ecol 41:95–103

Jeganathan J, Nakhla G, Bassi A (2006) Long-term performance of high-rate anaerobic reactors for the treatment of oily wastewater. Environ Sci Technol 40:6466–6472

Kim SH, Han SK, Shin HS (2004) Two-phase anaerobic treatment system for fat-containing wastewater. J Chem Technol Biotechnol 79:63–71

Gomes DRS, Papa LG, Cichello GCV, Belançon D, Pozzi EG, Balieiro JCC, Monterrey-Quintero ES, Tommaso G (2011) Effect of enzymatic pretreatment and increasing the organic loading rate of lipid-rich wastewater treated in a hybrid UASB reactor. Desalination 279:96–103

Caixia W, Quancheng Z, Guiming F, Yebo L (2011) Semi-continuous anaerobic co-digestion of thickened waste activated sludge and fat, oil and grease. Waste Manage 31:1752–1758

Eftaxias A, Diamantis V, Michailidis C, Stamatelatou K, Aivasidis A (2020) Comparison of anaerobic digesters performance treating palmitic, stearic and oleic acid: determination of the LCFA kinetic constants using ADM1. Bioprocess Biosyst Eng 43:1329–1338

Cirne DG, Paloumet X, Björnsson L, Alves MM, Mattiasson B (2007) Anaerobic digestion of lipid-rich waste-Effects of lipid concentration. Renew Energy 32:965–975

Silvestre G, Rodríguez-Abalde A, Fernández B, Flotats X, Bonmatí A (2011) Biomass adaptation over anaerobic co-digestion of sewage sludge and trapped grease waste. Biores Technol 102:6830–6836

Usman M, Salama ES, Arif M, Jeon BH, Li X (2020) Determination of the inhibitory concentration level of fat, oil, and grease (FOG) towards bacterial and archaeal communities in anaerobic digestion. Renew Sustain Energy Rev. https://doi.org/10.1016/j.rser.2020.110032

Hachicha R, Hachicha S, Trabelsi I, Woodward S, Mechichi T (2009) Evolution of the fatty fraction during co-composting of olive oil industry wastes with animal manure: Maturity assessment of the end product. Chemosphere 75:1382–1386

Kurade MB, Saha S, Salama ES, Patil SM, Govindwar SP, Jeon BH (2019) Acetoclastic methanogenesis led by Methanosarcina in anaerobic co-digestion of fats, oil and grease for enhanced production of methane. Biores Technol 272:351–359

Chow WL, Chong S, Lim JW, Chan YJ, Chong MF, Tiong TJ, Chin JK, Pan GT (2020) Anaerobic co-digestion of wastewater sludge: A review of potential co-substrates and operating factors for improved methane yield. Processes. https://doi.org/10.3390/pr8010039

Li C, Champagne P, Anderson BC (2015) Enhanced biogas production from anaerobic co-digestion of municipal wastewater treatment sludge and fat, oil and grease (FOG) by a modified two-stage thermophilic digester system with selected thermo-chemical pre-treatment. Renew Energy 83:474–482

Grosser A, Neczaj E, Jasinska A, Celary P (2020) The influence of grease trap sludge sterilization on the performance of anaerobic co-digestion of sewage sludge. Renew Energy 161:988–997

Siddique MNI, Wahid ZA (2018) Achievements and perspectives of anaerobic co-digestion: A review. J Clean Prod 194:359–371

Kashi S, Satari B, Lundin M, Horváth IS, Othman M (2017) Application of a mixture design to identify the effects of substrates ratios and interactions on anaerobic co-digestion of municipal sludge, grease trap waste, and meat processing waste. J Environ Chem Eng 5:6156–6164

Achinas S, Euverink GJW (2019) Elevated biogas production from the anaerobic co-digestion of farmhouse waste: Insight into the process performance and kinetics. Waste Manage Res 37:1240–1249

Crolla A, Kinsley C (2008) Optimzing Energy producton fram anaerobically digested manure and co-substrates for medim sized dairy farms, final report to OMAFRA. University of Guelph, Alfred Campus

Martín-González L, Castro R, Pereira MA, Alves MM, Font X, Vicent T (2011) Thermophilic co-digestion of organic fraction of municipal solid wastes with FOG wastes from a sewage treatment plant: Reactor performance and microbial community monitoring. Biores Technol 102:4734–4741

Nair A, Sartaj M, Kennedy K, Coelho NMG (2014) Enhancing biogas production from anaerobic biodegradation of the organic fraction of municipal solid waste through leachate blending and recirculation. Waste Manage Res 32:939–946

Aromolaran A, Sartaj M (2021) Enhancing biogas production from municipal solid waste through recirculation of blended leachate in simulated bioreactor landfills. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-01260-5

Pan Y, Zhi Z, Zhen G, Lu X, Bakonyi P, Li YY, Zhao Y, Rajesh Banu J (2019) Synergistic effect and biodegradation kinetics of sewage sludge and food waste mesophilic anaerobic co-digestion and the underlying stimulation mechanisms. Fuel 253:40–49

Martín MA, Fernández R, Gutiérrez MC, Siles JA (2018) Thermophilic anaerobic digestion of pre-treated orange peel: Modelling of methane production. Process Saf Environ Prot 117:245–253

Ponsá S, Gea T, Sánchez A (2011) Anaerobic co-digestion of the organic fraction of municipal solid waste with several pure organic co-substrates. Biosys Eng 108:352–360

Nielfa A, Cano R, Vinot M, Fernández E, Fdz-Polanco M (2015) Anaerobic digestion modeling of the main components of organic fraction of municipal solid waste. Process Saf Environ Prot 94:180–187

Nguyen DD, Jeon BH, Jeung JH, Rene ER, Banu JR, Ravindran B, Vu CM, Ngo HH, Guo W, Chang SW (2019) Thermophilic anaerobic digestion of model organic wastes: Evaluation of biomethane production and multiple kinetic models analysis. Biores Technol 280:269–276

Speece RE (1983) Anaerobic biotechnology for industrial wastewater treatment. Environ Sci Technol 17:416A-427A

Trabelsi I, Horibe H, Tanaka N, Matsuto T (2000) Origin of low carbon/nitrogen ratios in leachate from old municipal solid waste landfills. Waste Manage Res 18:224–234

Prabhu MS, Mutnuri S (2016) Anaerobic co-digestion of sewage sludge and food waste. Waste Manage Res 34:307–315

Kafle GK, Kim S-H (2012) Kinetic Study of the Anaerobic Digestion of Swine Manure at Mesophilic Temperature: A Lab Scale Batch Operation. J Biosyst Eng 37:233–244

American Public Health Association, Baird R, Eaton AD, Rice EW, Bridgewater L (2017) Standard methods for the examination of water and wastewater

Angus MB (2001) A step-by-step guide to non-linear regression analysis of experimental data using a Microsoft Excel spreadsheet. Comput Methods Programs Biomed 65:191–200

Pastor L, Ruiz L, Pascual A, Ruiz B (2013) Co-digestion of used oils and urban landfill leachates with sewage sludge and the effect on the biogas production. Appl Energy 107:438–445

Bala R, Gautam V, Mondal MK (2019) Improved biogas yield from organic fraction of municipal solid waste as preliminary step for fuel cell technology and hydrogen generation. Int J Hydrogen Energy 44(1):164–173. https://doi.org/10.1016/j.ijhydene.2018.02.072

Pavi S, Kramer LE, Gomes LP, Miranda LAS (2017) Biogas production from co-digestion of organic fraction of municipal solid waste and fruit and vegetable waste. Biores Technol 228:362–367

Markou G, Ilkiv B, Brulé M, Antonopoulos D, Chakalis L, Arapoglou D, Chatzipavlidis I (2020) Methane production through anaerobic digestion of residual microalgal biomass after the extraction of valuable compounds. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-00703-3

Kim MJ, Kim SH (2017) Minimization of diauxic growth lag-phase for high-efficiency biogas production. J Environ Manage 187:456–463

Ashekuzzaman SM, Poulsen TG (2011) Optimizing feed composition for improved methane yield during anaerobic digestion of cow manure based waste mixtures. Biores Technol 102:2213–2218

Walter A, Silberberger S, Juárez MFD, Insam H, Franke-Whittle IH (2016) Biomethane potential of industrial paper wastes and investigation of the methanogenic communities involved. Biotechnol Biofuels. https://doi.org/10.1186/s13068-016-0435-z

Xie S, Wickham R, Nghiem LD (2017) Synergistic effect from anaerobic co-digestion of sewage sludge and organic wastes. Int Biodeterior Biodegradation 116:191–197

Filer J, Ding HH, Chang S (2019) Biochemical methane potential (BMP) assay method for anaerobic digestion research. Water (Switzerland). https://doi.org/10.3390/w11050921

Morales G, Llorente I, Montesinos E, Moragrega C (2017) A model for predicting Xanthomonas arboricola pv. pruni growth as a function of temperature. PLoS ONE. https://doi.org/10.1371/journal.pone.0177583

Swinnen IAM, Bernaerts K, Dens EJJ, Geeraerd AH, van Impe JF (2004) Predictive modelling of the microbial lag phase: A review. Int J Food Microbiol 94:137–159

Acknowledgements

The funding provided by NSERC (211162) is acknowledged and appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aromolaran, A., Sartaj, M. & Alqaralleh, R.M.Z. Biogas production from sewage scum through anaerobic co-digestion: the effect of organic fraction of municipal solid waste and landfill leachate blend addition. Biomass Conv. Bioref. 13, 16049–16065 (2023). https://doi.org/10.1007/s13399-021-02152-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02152-y