Abstract

Transition metal oxides (TMOs), such as tin dioxide (SnO2)-based materials, are claimed to be one of the most interesting classes of solids, exhibiting varieties of properties, structures and applications. TMOs have been attracting growing research attention due to their characteristic properties such as plentiful active sites, the high theoretical capacity and diverse reaction mechanisms. Herein, the optimal condition for fabricating SnO2-carbon nanotube (SnO2/CNTs) nanohybrids using the atmospheric pressure chemical vapor deposition and thermal growth process has been described. As well as, the SnO2 thin film was exposed to the functionalized multiwalled carbon nanotubes (F-MWCNTs) via solution mixing for thermal growth process. The effect of essential parameters on optical and morphological properties of thin films was optimized. According to the results, the conditions in which the nanohybrid films had the best quality are as follows: 300 °C re-heating temperature, DMSO solvent, and 6 mg amount of FMWCNTs. Absorption and reflection modes of UV/Vis spectroscopy detected the peak changes of the fabricated films in each stage and confirmed their crystal structure. Furthermore, the crystal structure and atomic composition of the SnO2-carbon nanotubes films were analyzed to assess surface properties of the thin films by scanning electron microscopy and by X-ray diffraction (EDX), respectively. This new synthetic method suggested a facile means to produce SnO2/MWCNT thin films with the aim of using it to fabricate the gas sensors.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hybrid materials made of semiconducting metal oxides such as SnO2 and carbon nanotubes, as the most widely used gas-sensitive material, have attracted the attention of researchers in recent years due to their various applications [1, 2]. One of the reasons for increasing the sensing properties of hybrid materials based on SnO2/CNTs nanocomposite is attributed to their very large specific surface area and the formation of additional nanochannels by hollow carbon nanotubes for gas diffusion. In other ways, as is well known the n–p heterojunction is formed at the interface between SnO2 and carbon nanotubes because SnO2 is an n-type semiconductor while carbon nanotubes form p-type semiconductors [3].

In hybrid material, SnO2 and CNTs can be connected with each other by different ways, CNTs coated by metal oxide as well as metal oxide doped with CNTs. The high contact surface area with a narrow pore size distribution and good stability of carbon nanotubes makes them suitable candidates for hybridization with tin oxide [2]. On the other hand, CNTs walls are inert with chemical reactions, so it is very hard to use in chemical applications. To use CNTs in the chemical applications, the compatible agents are required to attach or cover on CNTs wall. These hybrid materials have both the large surface area, high conductivity of CNTs and the selectivity [4, 5].

Among semiconductors, SnO2 has attracted the most attention due to its high sensitivity, chemical stability, and fast recovery. As mentioned, SnO2 is a n-type semiconductor whose resistance decreases in the presence of certain gases. Weak selectivity and high temperature performance are the most important limitations of SnO2-based sensor. To overcome these limitations, various impurities such as carbon nanotubes are usually added to SnO2 [6,7,8,9].

The active van der Waals, coulombic and interatomic coupling, in addition to the large number of atoms on the surface of nano-metal oxides, meaningfully improve the chemical and physical properties of the oxide materials versus its bulk structure. The objects of this work are finding a simple method to obtain SnO2/CNTs hybrid materials having appropriate morphology proposed for using as the basic material for gas sensors manufacturing. The selection of SnO2 as a component of SnO2/MWCNTs nanocomposite structure depends on its application.

Recently, some reports based on coating of multiwalled carbon nanotubes (MWCNTs) on SnO2 thin films and using this hybrid layer as new and chemical gas-sensitive sensor appears to be encouraging [4, 10,11,12,13]. According to some articles, the presence of CNTs in their combined films with SnO2 can affect the increase in nanocomposite surface, better charge transfer and chemical absorption. Furthermore, the combination of functionalized groups to the surface of CNTs would be an enhanced technique raising the much better surface area and films conductivity [4, 10, 14, 15].

Several different methods have been used to synthesize SnO2, including electro-deposition, sol–gel, as well as physical deposition, diffusion, sputtering and thermal decomposition. However, the problem of these techniques incorporates high-cost and time-consuming procedures. Most of these disadvantages could be resolved using the atmospheric pressure chemical vapor deposition (APCVD). It is a synthesis method where the substrate is exposed to one or more volatile precursors, at atmospheric pressure, which react or decompose on the surface to produce a deposit. In APCVD, a solid material is deposited from a vapor by a chemical reaction occurring on or in the vicinity of a normally heated substrate surface. The subsequent solid material is commonly in the form of a thin film. This method is almost simple, economic, time saving and can be achieved with no pressure [16].

As a result, in the present work, facile and new strategy to fabricate functionalized SnO2/MWCNTs nanocomposite hybrid material was reported which can used in sensor application. We have used low-cost and simple techniques, one of which is the APCVD process and the other is the thermal growth method. SnO2 thin films were grown by chemical vapor deposition (CVD) on glass substrates at atmospheric pressure. Then, SnO2/CNTs nanocomposite was produced with an easy and novel thermal growth method. Thermal growth method is also a simple and novel way for the fabrication of MWCNTs on the SnO2 films. Effect of some parameters on the hybrid film as well as morphology properties was also investigated using SEM and EDX techniques. Furthermore, the effect of UV radiation of the synthesized nanocomposites was also reported. This new, low-cost and high-efficiency method was used for the first time to prepare the hybrid nanocomposite.

Experimental

Chemicals and reagents

SnCl45H2O (Riedel-deHean 99.9%), dimethyl sulfoxide (DMSO), ammonium hydroxide, and acetone (99.5%) from Merck (Darmstadt, Germany) were used of analytical grade without further purification.

MWCNTs (outer diameter ≤ 20 nm, lengths of 5–15 µm, and purity ≥ 95%) were purchased from the Research Institute of the Petroleum Industry (Tehran, Iran). Ultra-high oxygen as precursors and N2 as carrier gas were used. Nitric and sulfuric acids for the functionalization of multiwalled carbon nanotubes were purchased from Merck too.

Apparatus

The ultraviolet-visible spectrophotometer (UV–Vis) (UV-2550/Shimadzu) was used to investigate the changes in crystallographic structures of the sensing films in each stage. The APCVD reactor (3Z. MTDI.900 °C Modern Technology Development Institute) was used for the deposition of the SnO2. The surface morphological features of the SnO2 films and SnO2/MWCNTs nanocomposite were studied using SEM and EDX (TESCAN-XMU, Czech Republic).

Chemical vapor deposition of SnO2

In brief, the synthesis process includes (i) the preparation of a glass substrate, (ii) the glass bed was coated with SnO2 nanoparticles by CVD which was achieved through a combinatorial chemistry approach at 400 °C, using tin tetrachloride as the source of SnO2, water, and oxygen as precursors with nitrogen (N2) as the carrier gas, and (iii) after deposition of SnO2 on the glass bed, the coated glass film is aged at 300 °C, for two hours.

The substrates were cleaned using acetone and de-ionized water to remove the impurity of the glass and the substrates were placed within the tube of fused quartz of inside diameter 40 mm. The substrate was established perpendicularly in the reaction tube and the temperature was controlled by an electric furnace. SnCl4.5H2O and de-ionized water were placed in the Pyrex containers heated at temperatures around 65 °C and 95 °C, respectively, and then were bubbled into the reaction tube using nitrogen as the carrier gas. The substrates were regular glass wafer Si/SiO2 with 1.5 mm thick. A simple pictorial arrangement of the precursors and deposition setup is shown in Fig. 1.

In several runs, different temperature of preheating and zone reactor had been examined. As a result, suitable preheating and reaction zones temperature was selected. The activator gas (H2O vapor) was carried with N2 and the other activator gas (SnCl4.5H2O vapor) was carried with O2. The flow rates for N2 and O2 were 800–1000 cm3/min. The temperature of the glass surface (substrate) during deposition was 400 °C, while the deposition time was 3 h. Several runs of the experiment were carried out and the optimum run was chosen for the best deposition process. Finally, the films were characterized for their optical properties. The optical transmission spectra were obtained using UV–Vis spectroscopy. Some of the best-characterized films were selected and used for the growth of substrate structure of functionalization of multiwalled carbon nanotube (F-MWCNTs) thin films.

Functionalization of multiwall carbon nanotube

From the literature, several chemical processes have been mentioned to evaluate the dispersion of CNTs in aqueous solution [17,18,19]. CNTs have a robust tendency to agglomerate depending on their high surface area. The different methods of dispersion of CNTs in aqueous media are used to qualify and compare the effectiveness of functionalization processes.

Firstly, 1.0 g CNTs were immersed in a mixture of H2SO4/HNO3 (3:1) (temperature: 25 °C). Next, CNTs were placed in an ultrasound bath for 5 h (temperature: 0 °C). Afterward, this media became neutral with NH3 until pH: 6.5–7 and centrifuged (time: 10 min, and 1700 recycle/min). The resulting solution was cleaned and washed several times with double distilled water until the pH was reached around neutral. The washed solution was centrifuged and CNTs powder was dried at 60 °C using an oven and carboxylic acid-functionalized nanotubes (MWCNT–COOH) were obtained. The carboxyl groups (–COOH) inserted onto the surface of the MWCNT improve its quality of dispersion and interaction.

Growth of carbon nanotubes

The F-MWCNTs was dispersed into DMSO with ratio of 2/10 mg/mL (20 mL of DMSO + 0.004 g of CNTs) with using an ultrasonic bath for 10 min.

Fabrication of SnO2-coated multiwalled carbon nanotubes

To synthesize F-MWCNT-based hybrid materials, there are two key methods. The first method is to mix the component with CNT in solution and, then, deposit the solution on the substrate [20,21,22,23]. In the second method, CNT scaffold is grown on substrate; then, functional component is deposited directly on as-grown CNT framework [24, 25].

Due to the simplicity and efficiency of the first method, we used this one to cover the substrate.

The SnO2-coated film was exposed to the functionalized carbon nanotubes (F-MWCNTs) that was dispersed in DMSO using the ultrasonic waves. The film was aged for thermal growth of F-MWCNTs on the SnO2 film under optimal conditions (time: 20 h, temp: 50 °C).

Results and discussion

Fourier transformed infrared spectroscopy

Figure 2 illustrates the FTIR spectra of initial and functionalized CNTs to analyze the efficiency of functionalization on nanotubes. As can be observed in the spectrum (a), the MWCNTs are devoid of very weak infrared signals of functional groups lead to the weak difference of charge state between carbon atoms and providing a silent spectrum. In spectrum (b), the broad peaks between around 3200 and 3800 cm−1 are the characteristic stretching vibrations of C–H and O–H bonds. The peak of FMWCNT at 3500 cm−1 regions observed attributed to the stretching OH from carboxylic groups. The peak related to C=O bonding at approximately 1600 cm−1 is seen due to surface oxidation of CNTs. The peaks at approximately 1000–600 cm−1 could be assigned to the fingerprint region of FMWCNT.

UV–vis/spectroscopy study

The atomic composition of SnO2 and SnO2 /MWCNTs films was investigated by UV/Visible Spectroscopy (absorption and reflection modes) to investigate the changes in crystallographic structures of the fabricated films in each stage. The UV/Vis spectra are shown in Fig. 3.

We investigated the optical absorbance and reflection structures of SnO2 films prepared at various substrate surfaces. It is also found that the average strong absorption band of the SnO2 films exceeded ~ 310 nm in the UV/Visible region (λ = 200–800 nm). This indicates that the SnO2 films were prepared by the CVD method successfully. In essence, SnCl4 and H2O as initial precursors were straightforward interacted to produce SnO2 thin film on the glass substrate, as following reaction:

As can be seen, SnO2-CNTs spectrum extended the absorption edge blue shifted from 350 to 400 nm compared to SnO2 film. This shift could be related to interaction of MWCNTs with the SnO2 as well as rearrangement of polar density within the band gap of the SnO2 [16].

Deck et al. [26] and De Jong et al. [27] shown the experimental correlation between the essential properties of the metal nanoparticle with synthesized CNTs. The literature suggested that the capability of Fe, Co and Ni to grow CNTs due to their high carbon solubility, large electronegativity variances and diffusion of carbon through the core of the composite [26]. According to the mentioned articles, a growth mechanism has been assumed that the electronegativity of the tin as well as solubility and diffusion of the carbon nanotube through that thin film affects the properties of the prepared composite.

Characterization of synthesized nano-composites

The morphology of samples was observed using SEM analyses. Figure 4 shows the SEM image of SnO2 and SnO2/MWCNTs nanocomposite, respectively. Figure 4a is confirmed that SnO2 particles are present on the surface of glass substrate. The morphology of the SnO2 adopts a nearly uniform size in the substrate. Furthermore, it shows the SnO2 particles are agglomerated. For SnO2/MWCNT films, it clearly observed that the MWCNTs are dispersed in the matrix of SnO2. Carboxylic groups of MWCNTs could be related to tangled orientation in the nanocomposite. Meanwhile, Fig. 5 shows EDX spectra of the SnO2-CNTs nanocomposite. The EDX spectrum of the C-doped SnO2 shows and peaks are detectable from other materials such as Na, Mg, Al, and Ca.

Optimization

Several parameters that effect of deposition on the thin film including effects of reheating temperature on thin films, effects of solution that use for dispersing CNT and amount of MWCNTs were examined.

Re-heating temperature effects on thin films

The CNT thin-film layer is strongly adhered to the first coat or the previously transferred thin-film by re-heating. The re-heating temperature is preferably in the range of the transfer temperature. In the fixing process, the effects of re-heating temperature are investigated. Results are shown in Table 1. According to the results, the re-heating temperature is vital parameter in fabrication of thin films that should be control. Consequently, 300°c was chosen for deposition SnO2/CNTs temperature.

Effect of the disperser solvent

We used two solvent solutions for dispersing the CNTs: water and DMSO. According to the results, DMSO was chosen as the optimal disperser solvent. UV–VIS spectral analyses are in agreement with the experimental results (Fig. 6). As can be seen, DMSO is an amphiphilic/aprotic solvent that can provide strong hydrogen-bonding groups for facilitating growth MWCNTs on the SnO2 film in thermal method.

Effect of FMWCNTs amount

2–8 mg of FMWCNTs was examined in 20 mL of DMSO. The deposition efficiency for 6 mg CNTs was suitable (because of SEM and UV/VIS spectra results) but not suitable for 2 mg CNTs. The 6 mg CNTs were the optimal deposition nanocomposite (Fig. 7).

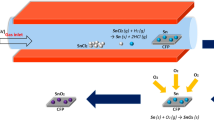

The whole synthesis process of SnO2/MWCNTs thin film using a facile and easy method is presented in Fig. 8. The results propose that the thin films can be prepared at low temperature which can be used for the large-scale production of sensors with low cost.

Conclusions

Overall, in this work, the combination of CVD and thermal growth methods provide an inexpensive and novel way to produce tunable SnO2/MWCNT composites. This technique was be simple and easy to carry out to produce thin films that can be used in large scale. It was observed that the structure of the thin film changes dramatically with the deposition time, temperature and, heating time in both phases of the experiment. UV/Visible patterns confirmed the structure of both SnO2 and the SnO2/MWCNTs composites. Additionally, SEM and EDX analysis displayed that MWCNTs nanoparticles were successfully coated on the surface of SnO2 films via thermal growth. Results showed that between two examined dispersing solvents, DMSO offered better solution compared to water for film synthesized. The thermal growth and deposition techniques were utilized to form transparent, hybrid metal oxide-CNT coatings that would be used in a number of applications, including gas sensing and photocatalysis.

References

N. Van Hieu, N.A.P. Duc, T. Trung, M.A. Tuan, N.D. Chien, Sens. Actuators B Chem. 144, 450 (2010)

N. Rani, K. Khurana, N. Jaggi, Appl. Nanosci. 11, 2291 (2021)

S. Das, V. Jayaraman, Prog. Mater. Sci. 66, 112 (2014)

Y.-L. Liu, H.-F. Yang, Y. Yang, Z.-M. Liu, G.-L. Shen, R.-Q. Yu, Thin Solid Films 497, 355 (2006)

P. Jayanthi, G. Saranya, J. Duraimurugan, P. Sengodan, S. Ravichandran, R. Usha, N. Bhuvaneshwari, J. Sol-Gel Sci. Technol. 108, 112 (2023)

S. M. Ingole, S. T. Navale, Y. H. Navale, D. K. Bandgar, F. J. Stadler, R. S. Mane, N. S. Ramgir, S. K. Gupta, D. K. Aswal, and V. B. Patil, J. Colloid Interface Sci. (2017).

G.D. Khuspe, R.D. Sakhare, S.T. Navale, M.A. Chougule, Y.D. Kolekar, R.N. Mulik, R.C. Pawar, C.S. Lee, V.B. Patil, Ceram. Int. 39, 8673 (2013)

S.B. Naghadeh, S. Vahdatifar, Y. Mortazavi, A.A. Khodadadi, A. Abbasi, Sens. Actuators B Chem. 223, 252 (2016)

M. Narjinary, P. Rana, A. Sen, M. Pal, Mater. Des. 115, 158 (2017)

Y. Zhao, J. Zhang, Y. Wang, Z. Chen, Nanoscale Res. Lett. 15, 40 (2020)

Y. Jia, L. He, Z. Guo, X. Chen, F. Meng, T. Luo, M. Li, J. Liu, J. Phys. Chem. C 113, 9581 (2009)

S.J. Young, Z.D. Lin, Microsyst. Technol. 24, 55 (2018)

Y.X. Liang, Y.J. Chen, T.H. Wang, Appl. Phys. Lett. 85, 666 (2004)

S. Majumdar, P. Nag, P.S. Devi, Mater. Chem. Phys. 147, 79 (2014)

S. Navazani, M. Hassanisadi, M.M. Eskandari, Z. Talaei, Synth. Met. 260, 116267 (2020)

M.D. Badry, M.A. Wahba, R.K. Khaled, S.K. El-Mahy, J. Electron. Mater. 49, 3191 (2020)

N. Sezer, M. Koç, Surfaces and Interfaces 14, 1 (2019)

A.G. Osorio, I.C.L. Silveira, V.L. Bueno, C.P. Bergmann, Appl. Surf. Sci. 255, 2485 (2008)

R. Sharma, A.K. Sharma, V. Sharma, Cogent Eng. 2, 1094017 (2015)

Y. Fu, N. Nabiollahi, T. Wang, S. Wang, Z. Hu, B. Carlberg, Y. Zhang, X. Wang, J. Liu, Nanotechnology 23, 45304 (2012)

M. Baro, P. Nayak, T.T. Baby, S. Ramaprabhu, J. Mater. Chem. A 1, 482 (2013)

S. Claramunt, O. Monereo, M. Boix, R. Leghrib, J.D. Prades, A. Cornet, P. Merino, C. Merino, A. Cirera, Sens. Actuators B Chem. 187, 401 (2013)

S.-K. Lee, D. Chang, S.W. Kim, J. Hazard. Mater. 268, 110 (2014)

D. Jung, M. Han, G.S. Lee, Carbon N. Y. 78, 156 (2014)

H.E. Unalan, P. Hiralal, D. Kuo, B. Parekh, G. Amaratunga, M. Chhowalla, J. Mater. Chem. 18, 5909 (2008)

C.P. Deck, K. Vecchio, Carbon N. Y. 44, 267 (2006)

K.P. De-Jong, J.W. Geus, Catal. Rev. 42, 481 (2000)

Acknowledgements

This work was done in the Payame Noor University, Mashhad, Iran.

Author information

Authors and Affiliations

Contributions

Somayyeh Ziaei carried out the experiments, involved in data collection, performed the analytic calculations, involved in sample analysis, involved in writing—original draft, and involved in data interpretation. Zarrin Es’haghi involved in conceptualization, supervised the project, verified the analytical methods, contributed to the final version of the manuscript, and edited the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ziaei, S., Es’haghi, Z. Combination of chemical vapor deposition and thermal growth methods for facile synthesis of tin oxide-doped multiwalled carbon nanotubes. J IRAN CHEM SOC 21, 1403–1411 (2024). https://doi.org/10.1007/s13738-024-03007-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-024-03007-9