Abstract

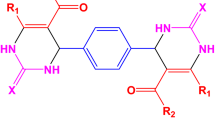

The triazine-based functionalized HY zeolite nanoparticles have been employed for synthesis of the pharmaceutically valuable 1, 4-dihydropyrano [2, 3-c] pyrazole and tetrahydrobenzo[b]pyran derivatives as a novel, versatile and effectual heterogeneous catalyst and characterized by FT-IR, XRD, BET, FE-SEM, TGA, EDX and MAP. The reactions were carried out under mild and green condition and short reaction times with high yield and easy workup process. The heterogeneous nanocatalyst can be simply recovered and reused for at least five times without considerable loss of activity.

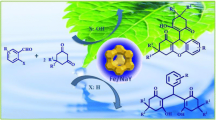

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Multicomponent reactions have become an efficient method for generation of biologically active heterocyclic compounds that are valuable in organic chemistry and also widely used in chemical industries and medicine. Also, these reactions have greater benefits including environmentally friendly processes, high yields, simple handling without needing for separating the intermediates with low expense, fast reaction times and no side by-products [1,2,3,4,5].

Pyrans and pyrano [2, 3-c] pyrazoles are important categories of natural compounds and have obtained a great consideration due to their biological and pharmacological properties [6, 7]. These heterocycles derivatives widely have been used as the pigments, cosmetic [8, 9], UV absorbers, antibacterial [10, 11], anticancer [12], anti-inflammatory [13, 14], analgesic, molluscicidal [12, 14] and antimicrobial [15,16,17] (Scheme 1). So, due to their essential utilities, synthesis of pyran and pyranopyrazole derivatives is an attractive challenge to chemists yet.

Although, in recent years, many methods have been developed for the synthesis of these heterocyclic derivatives, but most of these reported procedures possess some serious limitations such as long reaction times, harsh reaction conditions, high amount of catalyst loading, insufficient yields, catalyst separation tedious process and long work-up, use of a perilous and toxic catalyst or solvent and costly operation [18,19,20,21,22,23,24], so, because of these disadvantages, design and development of methods based on green chemistry principles, which are convenient and efficient, is a substantial matter (Scheme 1).

Lately, as using the catalysts in chemical reactions become one of the most critical factors in green chemistry [25,26,27], synthesis of new or modified catalysts has been more attentions. In fact, efficient catalyst enhances the selectivity and efficiency of a reaction, so by-products are eliminated or decreased. The utility of heterogeneous catalysts has encouraged chemists, because this type of catalyst has been simply removed from the reaction medium and causes the reaction process to be eco-friendly and easy [28, 29]. Zeolites are aluminosilicate that is widely applied as an efficient type of heterogeneous catalysts [30]. Zeolite NaY as a well-known category of zeolites, because of outstanding properties including significant thermal stability, having pores in the size of molecular dimension or nanosize, high porous particular surface area, intrinsic acid/base catalytic nature, facile separation from a reaction mixture and decreasing of environmental pollutions concerns has obtained a great deal of fondness [31,32,33]. The surface of zeolite can be easily modified by organic molecules to change the surface properties and improve the selectivity and activity of the catalysts [34,35,36,37,38].

Here, we wish to report synthesis-modified HY zeolite (Scheme 2) and estimate its activity as a new and efficient catalyst in the synthesis of various heterocyclic compounds with high yields in green and eco-friendly conditions. This efficient and novel catalyst can be easily separated and reused several times without remarkable loss of activity (Scheme 3).

General methods

All chemicals were purchased from Merck or Aldrich companies and utilize without further purification. The FT-IR spectra were recorded by Bruker Alpha spectrometer. The 1H, 13C NMR spectra were reported on Bruker on 300 MHz Bruker spectrometer. The X-ray powder diffraction (XRD) was investigated on the PHILIPS PW1730 instrument (Cu-Kα radiation and λ = 0.15406). The BET was obtained with BELSORP MINI II (adsorption/desorption of nitrogen at 77 °K). Energy-dispersive X-ray (EDX) and scanning electron microscopy (SEM) were prepared on a MIRA III instrument. The thermogravimetric analysis (TGA) was performed using a matter TGA TA4000 system. Melting points were measured by electrothermal digital apparatus.

General procedure for the synthesis of 1, 4-dihydropyrano [2, 3-c] pyrazole derivatives

The mixture of phenylhydrazine (1 mmol), ethyl acetoacetate (1 mmol) and catalyst (0.05 g) in H2O (5 mL) was magnetically stirred and heat at 80 °C. After completion of the reaction as monitored by TLC, benzaldehyde (1 mmol) and malononitrile (1 mmol) were added to the mixture. After completion of the reaction, and the progress of the reaction that monitored by TLC, the catalyst was separated from by filtration, washed with hot ethanol and dried. Finally, the solvent was evaporated and the pure product was obtained by recrystallizing in 96% ethanol.

General procedure for the synthesis of tetrahydrobenzo[b]pyran

A mixture of benzaldehyde (1 mmol), malononitrile (1.2 mmol), dimedone (1 mmol) and catalyst (0.2 mol %) and H2O (5 mL) was prepared and refluxed at 100 °C. After completion of the reaction as demonstrated by TLC, the catalyst was separated by filtration, washed with hot ethanol and dried in oven. The solvent was evaporated, and the obtained solid was gained and purified by recrystallization from ethanol.

The synthesis of HYZ@SiO2-Pr-NH-tris-py-triazine

Preparation of HY zeolite

NaY zeolite was mixed with 200 ml of NH4Cl aqueous solution and stirred at room temperature to 24 h to exchange Na+ ion with NH4+. The solid was filtered and washed with water. Then, the obtained HY zeolite was generated by calcination at 300 °C for 5 h to remove NH3.

Preparation of HYZ@SiO2-Pr-Cl

3-Chloropropyltrimethoxycyclic (CPTs) (5.45 mmol, 0.3 mL) was reacted with HY zeolite (0.5 g) in 20 ml toluene at reflux condition for 24 h under nitrogen atmosphere, (Chloropropyl-functionalized HY zeolite was prepared by adding 3-chloropropyltrimethoxycyclic (CPTs) (5.45 mmol, 0.3 mL) to HY zeolite (0.5 g) in 20 ml toluene and the mixture was refluxed for 24 h under a nitrogen atmosphere), then the solid powder was filtered and washed with dry toluene, and then dried at 80 °C in an oven for 8 h.

Preparation of HYZ@SiO2-Pr-NH-C (CH2OH)3

Z-HY@SiO2-Cl (1 g) was suspended in dry toluene (15 mL) by using ultrasonic for 30 min, then, tris (hydroxymethyl)aminomethane (20 mmol) and 2,4,6-Trimethylpyridine (20 mmol) were added to this suspension. The reaction mixture was dispersed using ultrasonic again for 1 h, then was refluxed at 110 °C for 48 h under nitrogen atmosphere. The product was separated by filtering and washed with toluene, chloroform and hot ethanol, and was dried at 60 °C under vacuum oven.

Synthesis of triazine dichloride-functionalized (grafted) HY zeolite (HYZ@SiO2-Pr-NH-tris-(TCl2))

Z-HY@SiO2-THAM (1 g) was added to dry THF (10 mL) and triethylamine (2.5 mmol, 0.37 mL), and then, cyanuric chloride (2.5 mmol, 1 g) was added. The reaction mixture was magnetically stirred for 24 h at room temperature. The resulting solid was filtered, washed with hot dry THF, ethanol, and dried at 60 °C under vacuum in the oven.

Synthesis of ethanol pyridyl-grafted HYZ@SiO2-Pr-NH-tris-(TCl2) (HYZ@SiO2-Pr-NH-tris-py-triazine)

Z-HY@SiO2-THAM-TDCl (0.5 g) was ultrasonically dispersed in dry DMF (15 mL) for 30 min; then, 2-pyridineethanol (2.37 mmol) and triethylamine (2.37 mmol) were added to and refluxed at 110 °C for 48 h under nitrogen atmosphere. The catalyst was separated by filtering, washed with hot DMF and hot ethanol, and dried at 60 °C.

Results and discussion

Synthesis and structural characterization of HYZ@SiO2-Pr-NH-tris-py-triazine

The synthesized functionalized zeolite has been characterized by Fourier transform infrared (FT-IR) spectroscopy, X-ray diffraction (XRD), scanning electron microscopy (SEM), WDS map scan, energy-dispersive X-ray spectroscopy (EDS), thermogravimetric analysis (TGA) and nitrogen absorption–desorption study (BET).

The FT-IR spectra of NaY, HY zeolite, HYZ@SiO2-Pr-Cl, HYZ@SiO2-Pr-NH-C(CH2OH)3, Z-HYZ@SiO2-Pr-NH-tris-(TCl2) and HYZ@SiO2-Pr-NH-tris-py-triazine are shown in Fig. 1. The two bands that appeared at 787 cm−1 and 1022 cm−1 were ascribed to asymmetric and symmetric stretching frequently band of Al–O–Si, respectively. The bending frequently band of Al–O–Si was revealed at 459 [39, 40]. The stretching and bending vibrations of the hydroxyl group in the zeolite network emerged at 1635 cm−1 and 3447 cm−1 [41]. The FT-IR spectrum of HY is similar to NaY zeolite, but the region in 3443 cm−1 of HY is wider than NaY due to increasing surface hydroxyl groups. Tow bonds were observed at 2944 cm−1 and 2896 cm−1 in the FT-IR spectrum of Z-HY@SiO2-Cl, corresponding to C–H stretching groups and confirm the alkyl group's presence on the surface of the zeolite. The stretching and frequently bending adsorptions of N–H bonds appeared at around 3500 cm−1 and 1648 cm−1. The peaks at 1400–1600 cm−1 were assigned to C=N and C=C bands in heterocyclic rings [42]. So, according to the results from the spectra, graft of the functional groups onto the surface of the NaY zeolite was confirmed.

The powder X-ray diffraction (XRD) technique was used for evaluation of crystalline and phase composition of HY and functionalized HY zeolite (Fig. 2). The diffraction peaks which revealed at 6.2, 10.1, 11.9, 15.65, 18.65, 20.35, 23.75, 26.9, 30.7, 31.35 and 33.9 were devoted to the (111), (2 2 0), (3 1 1–511), (3 3 1), (333), (4 4 0), (5 3 3), (6 4 2), (5 5 5), (824) and (6 6 4) planes. These results are in good agreement with the reported literature for NaY zeolite (JCPDS: 75-1860). The XRD patterns of catalyst indicated no change in structure and morphology of NaY zeolite, so, the functionalized and synthesized zeolite has a cubic structure with high purity and crystallinity. The average size of the crystallites is estimated by using Scherrerʼs formula (D = 0.9 λ/βCos (θ)) and it has been obtained to be 18.78 nm for nanoparticles [43,44,45].

The nitrogen adsorption/desorption isotherm of the catalyst is described in Fig. 3 and the data were obtained from BET analysis are illustrated in Table 1. The type-IV isotherm which was acquired of the hysteresis loop at pressure p/p0 between 0.5 and 1, shows the existence of mesoporous phase and the pore size distribution (BJH) in Fig. 3 also represents that the particle size is between 1 and 12 nm which is corresponding to mesoporous phase. Decrease of pores area surface and pores volume was observed after functionalization of NaY zeolite with organic groups which confirms the incorporation organic groups into the zeolite pores [46,47,48].

The thermal stability of HYZ@SiO2-Pr-NH-tris-py-triazine zeolite was evaluated by TGA-DTA analysis under N2 current (Fig. 4). Its thermogravimetry demonstrated 4 step weight loss. In the primary step, 4.8% weight losing to 180 °C temperature was observed which is related to losing adsorbed water and residue of solvent in zeolite structure. The 14% weight losing at 180–400 °C in the secondary stage corresponded to organic groups grafted to the zeolite. The weight losing at 400–600 °C in third step corresponds to the removing silicon atoms bonded to the zeolite surface. Finally, the last step is related to the decomposition of zeolite structure [49]. The result represents that the functionalization of zeolite has occurred successfully and the prepared zeolite has high thermal stability.

The surface morphology and histogram of catalyst were evaluated by scanning electron microscopy (Fig. 5). The results demonstrate that catalyst has a cubic morphology and it is according to referenced NaY zeolite. This indicates that the morphology of NaY zeolite is not changed after functionalization process and the average diameter of particles is around 27 nm which this tiny particle size causes high surface area and high catalytic activity.

The elemental composition of the prepared catalyst was obtained by EDX which elucidates element distribution through a point analysis map (Fig. 6). The outcomes represent the homogenous distribution of all the elements. Also, the uniform dispersion of C and N elements in zeolite confirmed that the grafting of organic materials on the zeolite structure has been successfully done.

The elemental content of functionalized zeolite was characterized by EDX analysis (Fig. 7). The spectrum displays the presence of Si, Al, O, C, N, Na elements in the structure. The higher Si/Al ratio in the catalyst (2.8) compared with NaY zeolite [45] and the existence of C and N peaks revealed that the zeolite was functionalized with organic materials.

Catalyst efficiency study

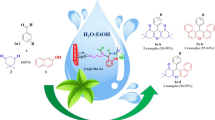

Utilization of HYZ@SiO2-Pr-NH-tris-py-triazine as the catalyst in the synthesis of imino-2H-chromenes derivatives

After identification and characterization of the synthesized catalyst, its catalytic activity in synthesis of pyrano chromenes was studied. The reaction parameters including temperature, solvent and amount of catalyst loading were optimized by selecting the reaction of 4-chlorobenzaldehyde, malononitrile and dimedone as the model reaction (Table 2). The results exhibit that in the absence of the catalyst, the insignificant yield was obtained (Table 2, entry 1). When the NaY zeolite was used, the yield obtained was about 30% (Table 2, entry 2), this result demonstrates that the NaY zeolite has catalytic properties, the reasons include: zeolites, because of their cage-like porous structure, have a very high surface area and adsorption capacity. Also, the sizes of channels and cavities are in the range typical for many molecules of interest (5–12 Å) and suggest at the same time, shape selectivity, which can be used to direct a given catalytic reaction toward the desired product, avoiding undesired side reactions. The comparison between (by comparing) NaY, HY, HYZ@SiO2-Pr-Cl, HYZ@SiO2-Pr-NH-C (CH2OH)3, HYZ@SiO2-Pr-NH-tris-(TCl2) and HYZ@SiO2-Pr-NH-tris-py-triazine confirmed that HYZ@SiO2-Pr-NH-tris-py-triazine is an efficient catalyst that can provide an excellent yields of imino-2H-chromenes derivatives (Table 2, entries 2–6 and 10). By increasing the catalyst amount loading, the yields of products were developed because of growth in catalyst’s basic sites, but the best yields of products were acquired by 0.03 g of catalyst loading (Table 2, entries 7–10). When the amount of catalyst was more than 0.03 g, the changes in yields of the reaction were not significant. Several solvents were investigated and the results show that the water is more efficient than other solvent (Table 2, entries 10–14). On the other hand, it is in good agreement with the principles of green chemistry. Finally, the temperature effects as an important factor were evaluated, so the room temperature was chosen as the best temperature for this reaction (Table 2, entries 15–17). After optimizing the reaction condition, various aldehydes were reacted under optimized conditions to investigate the generality, applicability and efficacy of this procedure and imino-2H-chromenes derivatives were generated in superb yields. So, we understood that the prepared catalyst is an extremely efficient catalyst in generation of imino-2H-chromenes derivatives. (Table 3).

According to the literate [55], the probable mechanism for synthesis of dihydropyrano[c] chromenes is demonstrated (Scheme 4). At first, the HYZ@SiO2-Pr-NH-tris-py-triazine activates the malononitrile, then the intermediate 2 is formed by Knoevenagel condensation between aldehyde and malononitrile anion. Subsequently the desired product is obtained by the Michael addition of dimedone to the intermediate 2 followed by cyclization and tautomerization.

Utilization of HYZ@SiO2-Pr-NH-tris-py-triazine as the catalyst in the synthesis of dihydropyrano [2, 3-c] pyrazole derivatives

Next, the catalyst activity of HYZ@SiO2-Pr-NH-tris-py-triazine in the synthesis of dihydropyrano [2, 3-c] pyrazoles was investigated. For optimization of reaction conditions, different parameters effects were studied on the reaction between phenylhydrazine, ethyl acetoacetate, 4-Clbenzaldehyde and malononitrile as the model reaction. The reaction was performed in different solvents (Table 4, entries 10–14) and water as the solvent was lead to higher yields. For evaluating the effect of temperature, the reaction was carried out at 25, 60, 80 and 100 °C and the best result was acquired at 25 °C (Table 4, entries 10 and 15–17).

Possible mechanism for one-pot synthesis of dihydropyrano [2, 3-c] pyrazole using HYZ@ SiO2-Pr-NH-tris-py-triazine as a catalyst (Scheme 5)

The reaction was also performed at 25 °C in water with a different amount of catalyst loading and according to the results, the best efficiency was founded when the reaction was performed by 0.03 g of catalyst loading (Table 4, entries 7–10).

To confirm efficiency and applicability of this new procedure, the reactions were performed by utilizing several aldehydes. As can be seen in Table 5, although all reaction was accomplished with appropriate yields, but aldehydes including electron-withdrawing groups were more reactive than aldehydes has electron-releasing groups and their reactions performed in shorter reaction times.

The suggested probable mechanism for preparation of dihydropyrano[2,3-c] pyrazole derivatives which is similar to other reported admissible mechanism [60] is illustrated in Schem5. First, the Knoevenagel condensation occurred between aldehyde and activated malononitrile in the presence of HYZ@SiO2-Pr-NH-tris-py-triazine as the catalyst to produce intermediate 2. Then, the reaction between phenyl hydrazine and ethyl acetoacetate leads to formation of pyrazolone 7. Eventually, Pyranopyrazol was constructed through Michael's addition of compound 6 with compound 7 that is followed by cyclization.

Recycling ability of the catalyst

According to commercial applications ability and also to adaptation with the principles of green chemistry, the substantial section of importance and efficiency of a chemical methodology is evaluated by recoverability and reusability of the used catalyst. So, we investigated the recovery and reusability of HYZ@SiO2-Pr-NH-tris-py-triazine as the catalyst in the reaction of 4-chlorobenzaldehyde (1 mmol), malononitrile (1 mmol) and dimedone (1 mmol) in optimized condition. After completion of the reaction, the catalyst was easily separated by filtration, washed with hot ethanol and dried under vacuum and reused for five cycles. The results indicate that the catalyst can be reused for 5 times without considerable reduction in catalyst activity. Comparing the FT-IR of recycled catalyst with the refresh catalyst confirms that no changes in the catalyst demonstrated (Figs. 8, 9).

The efficiency of this procedures was compared with some reported methods (Table 6). The results display that this new catalyst and methodology is surely more efficient, because of high yields, mild condition and the recyclability of the catalyst.

Physical and spectroscopic data for new products are given:

6-amino-4-(4-hydroxy-3-nitrophenyl)-3-methyl-1-phenyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (11 m)

A light yellow solid, mp 176–179 °C, IR (KBr) νCm-1: 3427, 3317, 3111, 2958,2860, 2192, 1676, 1628, 1592, 1534, 1486, 1429, 1374, 1268, 1241, 1213, 1174, 1120, 1065 cm−1. 1H NMR (300 MHz, DMSO-d6) δH:11.37 (s,1 H, OH), 8–8.11 (m, 5 H, HAr), 7.90 (m, 1 H, HAr), 7.79 (s, 2 H, HAr), 7.63 (s, 2 H, NH2), 5.05 (s, 1 H, CH), 2.16 (s, 3 H, CH3), and 13C NMR (75 MHz, DMSO-d6) δ: 162.7, 157.1, 154.2, 151.4, 147.8, 146.2, 135.1, 134.3, 134.2, 129.4, 128.8, 128.5, 128.3, 127.7, 124.2, 116.2, 98.8, 60.8, 26.0, 13.4 ppm.

6-amino-4-(4-hydroxy-3,5-dinitrophenyl)-3-methyl-1-phenyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (11n)

A yellow solid, mp 180–183 °C, IR (KBr) νCm-1: 3355, 3188, 3063, 2931,2807, 2191, 1680, 1623, 1541, 1480, 1341, 1268, 1297, 1239, 1104, 1066, 910, 784, 760, 715 cm−1. 1H NMR (300 MHz, DMSO-d6) δH: 10.71 (s,1 H, OH), 8.90 (s, 2 H, HAr), 7.87 (d, 1 H, HAr), 7.71 (s, 2 H, HAr), 7.58 (d, 2 H, HAr), 7.18 (s, 2 H, NH2), 5.14 (s, 1 H, CH), 1.91 (s, 3H, CH3) and 13C NMR (75 MHz, DMSO-d6) δ: 157.1, 154.2, 151.3, 144.4, 144.3, 135.1, 134.3, 133.0, 129.4, 128.8, 128.1, 127.7, 127.1, 119.0, 116.3, 111.4, 99.8, 60.9, 22.8, 13.3 ppm.

2-amino-4-(4-hydroxy-3-nitrophenyl)-7,7-dimethyl-5-oxo-5,6,7,8-tetrahydro-4H-chromene-3-carbonitrile (6 m)

A white solid, mp 185–190 °C. IR (KBr) νCm-1: 3397, 3329, 3195, 3063, 2939,2817, 2198, 1683, 1663, 1628, 1531, 1475, 1370, 1331, 1246, 1211, 1164, 1138, 1035, 678 cm−1. 1H NMR (300 MHz, DMSO-d6) δH: 10.92 (s,1 H, OH), 7.61–7.06 (m, 5 H, HAr and NH2), 4.22 (s, 1 H, CH), 2.24 (d, 2 H, J = 16.2 Hz, CH2), 2.15 (d, 2H, J = 16 Hz, CH2), 1.02 (s, 3 H, CH3), 0.94 (s, 3 H, CH3) and 13C NMR (75 MHz, DMSO-d6) δ: 196.1, 164.6, 160.6, 159.6, 137.4, 136.0, 134.1, 124.9, 119.4, 115.0, 111.6, 53.9, 50.1, 32.4, 30.2, 28.9, 26.7, 26.5 ppm.

2-amino-4-(4-hydroxy-3,5-dinitrophenyl)-7,7-dimethyl-5-oxo-5,6,7,8-tetrahydro-4H-chromene-3-carbonitrile (6n)

A light yellow solid, mp 196–201 °C, IR (KBr) νCm-1: 3450, 3329, 3216, 3184, 2961,2861, 2191, 1687, 1661, 1633, 1599, 1539, 1473, 1431, 1370, 1328, 1254, 1216, 1144, 1110, 1039, 921 cm−1. 1H NMR (300 MHz, DMSO-d6) δH: 10.88 (s, 1 H, OH), 7.63 (s, 1 H, HAr), 7.36 (m, 1 H, HAr), 7.10 (s, 2 H, NH2), 4.23 (s, 1 H, CH), 2.24 (d, 2 H, J = 15.9 Hz, CH2), 2.10 (d, 2 H, J = 15.6 Hz, CH2), 1.021 (s, 3 H, CH3), 0.94 (s, 3 H, CH3) and 13C NMR (75 MHz, DMSO-d6) δ: 196.2, 163.1, 159.0, 151.4, 136.6, 136.5, 134.7, 123.7, 120.0, 119.7, 112.5, 74.7, 57.9, 50.3, 34.9, 32.2, 28.7, 27.1 ppm.

Conclusion

In conclusion, the triazine-based functionalized HY zeolite nanoparticles were recognized as a novel, efficient and reusable heterogeneous catalyst for synthesis of 1, 4-dihydropyrano [2, 3-c] pyrazole and tetrahydrobenzo[b]pyran derivatives under mild and green conditions. The structure and morphology of the catalyst were characterized by FT-IR, XRD, BET, EDX-MAP, SEM and TGA analysis methods. The result shows that the functionalization on the surface of the NaY zeolite was attended without compromising the zeolite structure. The high yield, short reaction times, easy workup, green and environmentally friendly procedure recognized the advantageous of this work.

Data availability

“Data available in article supplementary material” is acceptable.

References

F. Chen, J. Zheng, M. Huang, Y. Li, Res. Chem. Intermed. 41, 5545 (2015)

A.V. Ivachtchenko, Y.A. Ivanenkov, V.M. Kysil, M.Y. Krasavin, A.P. Ilyin, Russ. Chem. Rev. 79, 787 (2010)

M. Shiri, Chem. Rev. 112, 3508 (2012)

S. Santra, ChemistrySelect 4, 12630 (2019)

F. Afsharnadery, K. Khosravi, M.A. Zolfigol, Appl. Organometal. Chem. 35, e6297 (2021)

S. Mozaffarnia, R. Teimuri-Mofrad, M.-R. Rashidi, J. Iran. Chem. Soc. 18, 1455 (2021)

M. Salimi, M.A. Nasseri, B.N. Jazi, J. Iran. Chem. Soc. 16, 2221 (2019)

D.S. AlMarzouq, N.M.H. Elnagdi, Molecules 24, 1806 (2019)

E. Jahangard, L. Khazdooz, A. Zarei, Iran. J. Catal. 10, 57 (2020)

A. Sapkal, S. Kamble, ChemistrySelect 5, 12971 (2020)

A. Yaghoubi, M.G. Dekamin, ChemistrySelect 2, 9236 (2017)

J.-L. Wang, D. Liu, Z.-J. Zhang, S. Shan, X. Han, S.M. Srinivasula, C.M. Croce, E.S. Alnemri, Z. Huang, PNAS 97, 7124 (2000)

S.C. Kuo, L.J. Huang, H. Nakamura, J. Med. Chem. 27, 539 (1984)

M.E. Zaki, H.A. Soliman, O.A. Hiekal, A.E. Rashad, Z. Naturforsch. C 61, 1 (2006)

R. Kumar, N. Yadav, R. Lavilla, D. Blasi, J. Quintana, J.M. Brea, M.I. Loza, J. Mestres, M. Bhandari, R. Arora, Mol. Divers. 21, 533 (2017)

A. Moshtaghi Zonouz, D. Moghani, Synth. Commun. 46, 220 (2016)

S.A. Hamrahian, S. Salehzadeh, J. Rakhtshah, F. Haji Babaei, N. Karami, Appl. Organomet. Chem. 33, e4723 (2019)

R.-Y. Guo, Z.-M. An, L.-P. Mo, S.-T. Yang, H.-X. Liu, S.-X. Wang, Z.-H. Zhang, Tetrahedron 69, 9931 (2013)

A. Keyume, Z. Esmayil, L. Wang, F. Jun, Tetrahedron 70, 3976 (2014)

M.A. Nasseri, S.M. Sadeghzadeh, Monatsh. Chem. 144, 1551 (2013)

A. Saha, S. Payra, S. Banerjee, Green Chem. 17, 2859 (2015)

Y.A. Tayade, S.A. Padvi, Y.B. Wagh, D.S. Dalal, Tetrahedron Lett. 56, 2441 (2015)

M. Wu, Q. Feng, D. Wan, J. Ma, Synth. Commun. 43, 1721 (2013)

M.A. Zolfigol, A. Khazaei, A.R. Moosavi-Zare, J. Afsar, V. Khakyzadeh, O. Khaledian, J. Chin. Chem. Soc. 62, 398 (2015)

A. Michrowska, Ł Gułajski, Z. Kaczmarska, K. Mennecke, A. Kirschning, K. Grela, Green Chem. 8, 685 (2006)

R. Sips, J. Chem. Phys. 16, 490 (1948)

V.H. Grassian, CRC press (2005)

R.K. Grasselli, A. Sleight, Elsevier, (1991)

H. Knözinger, K. Kochloefl, UEIC (2000)

M. Zendehdel, S. Khaghaninejad, F. Tavakoli, S. Ganji, JICS 17, 2555 (2020)

A. Corma, J. Catal. 216, 298 (2003)

J. Weitkamp, Solid State Ion. 131, 175 (2000)

J. Weitkamp, L. Puppe, Springer Science & Business Media, (2013)

A. Çıtak, B. Erdem, S. Erdem, R.M. Öksüzoğlu, J. Colloid Interface Sci. 369, 160 (2012)

J.A. Melero, R. van Grieken, G. Morales, Chem. Rev. 106, 3790 (2006)

F. Su, C. Lu, S.-C. Kuo, W. Zeng, Energy Fuels 24, 1441 (2010)

T. Yokoi, Y. Kubota, T. Tatsumi, Appl. Catal. A: Gen 421, 14 (2012)

R. Razavian Mofrad, H. Kabirifard, M. Tajbakhsh, G. Firouzzadeh Pasha, Appl. Organometal. Chem. 35, e6383 (2021)

I.I. Ivanova, E.E. Knyazeva, Chem. Soc. Rev 42, 3671 (2013)

H.M. Lankapati, D.R. Lathiya, L. Choudhary, A.K. Dalai, K.C. Maheria, ChemistrySelect 5, 1193 (2020)

F.R. Ribeiro, Springer Science & Business Media (2012)

K. Sarkar, K. Dhara, M. Nandi, P. Roy, A. Bhaumik, P. Banerjee, Adv. Funct. Mater. 19, 223 (2009)

A. Jentys, J. Lercher, Studies in Surface Science and Catalysis, Elsevier, pp. 345 (2001)

N. Bu, X. Liu, S. Song, J. Liu, Q. Yang, R. Li, F. Zheng, L. Yan, Q. Zhen, J. Zhang, Adv Powder Technol. 31, 2699 (2020)

F. Zhang, L. Xu, N. Hu, N. Bu, R. Zhou, X. Chen, Sep. Purif. Technol. 129, 9 (2014)

A. Corma, Chem. Rev. 97, 2373 (1997)

M.J. Hudson, J.A. Knowles, J. Mater. Chem. 6, 89 (1996)

M. Kruk, M. Jaroniec, Y. Sakamoto, O. Terasaki, R. Ryoo, C.H. Ko, J. Phys. Chem. B. 104, 292 (2000)

C. Jin, W. Fan, Y. Jia, B. Fan, J. Ma, R. Li, J Mol Catal A Chem 249, 23 (2006)

L. Fotouhi, M.M. Heravi, A. Fatehi, K. Bakhtiari, Tetrahedron Lett. 48, 5379 (2007)

T.-S. Jin, A.-Q. Wang, X. Wang, J.-S. Zhang, T.-S. Li, Synlett 2004, 0871 (2004)

M.S. Nejad, H. Sheibani, Catal. Lett. 148, 125 (2018)

D. Azarifar, S.-M. Khatami, M.A. Zolfigol, R. Nejat-Yami, JICS 11, 1223 (2014)

Y. Sarrafi, E. Mehrasbi, A. Vahid, M. Tajbakhsh, Chin. J. Catal. 33, 1486 (2012)

E. Mosaddegh, A. Hassankhani, Chin. J. Catal. 35, 351 (2014)

T.-S. Jin, R.-Q. Zhao, T.-S. Li, ARKIVOC 11, 176 (2006)

A.A. Hamid, M. Abd-Elmonem, A.M. Hayallah, F. Elsoud, K.U. Sadek, Chem. Select 2, 10689 (2017)

N.S. Kaminwar, S.U. Tekale, A.B. Chidrawar, L. Kótai, R.P. Pawar, Lett. Appl. NanoBioSci 9, 1521 (2020)

M.A. Zolfigol, M. Tavasoli, A.R. Moosavi-Zare, P. Moosavi, H.G. Kruger, M. Shiri, V. Khakyzadeh, RSC Adv. 3, 25681 (2013)

M.A. Zolfigol, R. Ayazi-Nasrabadi, S. Baghery, V. Khakyzadeh, S. Azizian, J. Mol. Catal. A Chem. 418, 54 (2016)

K.G. Patel, N.M. Misra, R.H. Vekariya, R.R. Shettigar, Res. Chem. Intermed. 44, 289 (2018)

R.A. Rather, Z.N. Siddiqui, J. Organomet. Chem. 868, 164 (2018)

K. Niknam, A. Piran, Green and Sustainable Chemistry 03, (2013)

Acknowledgements

This work was supported partially by research council the Arak University.

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alimohammadi, E., Kaveh, K. & Ali, Z.M. Preparation of triazine-based functionalized HY zeolite and its application in the green synthesis of tetrahydrobenzo[b]pyran and 1, 4-dihydropyrano [2, 3-c] pyrazole derivatives as a novel mesoporous recyclable nanocatalyst. J IRAN CHEM SOC 19, 4721–4734 (2022). https://doi.org/10.1007/s13738-022-02635-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-022-02635-3