Abstract

In this work, a hydrophilic task-specific ionic liquid (TSIL) of 1-chloroethyl-3-methylimidazolium chloride functionalized with 8-hydroxyquinoline was used in a dispersive liquid–liquid microextraction method followed by flame atomic absorption spectrometry for the enrichment and determination of trace amounts of cadmium (Cd2+) ions. The simultaneous chelation and extraction of Cd2+ ions was carried out by the TSIL. Fine droplets of the water-immiscible TSIL containing target analyte were generated in situ by addition of an anion exchanger potassium hexafluorophosphate (KPF6) salt to the sample tube. After phase separation by centrifugation for 4 min, the sedimented TSIL was diluted with acidified ethanol for measurement of Cd2+ content. Some significant parameters influence the preconcentration of Cd2+ ions such as sample pH, TSIL volume, amount of KPF6, non-ionic surfactant and salt concentration were investigated. Under the optimal conditions, calibration curve was linear in the range of 5–250 µg L−1 Cd2+ with correlation coefficient of 0.9975 and a detection limit of 0.55 µg L−1. The relative standard deviation for six replicate measurements of 50 µg L−1 Cd2+ was 1.5%. The method was successfully applied for the extraction and determination of Cd2+ ions in water and food samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metals such as Cd2+ ions are considered as environmental pollutants and their effects on human health have been studied. Among these metals, Cd2+ is considered as one of the most hazardous elements and found naturally in the earth’s crust [1]. It enters into the environment due to improper disposal of wastes or contaminants [2]. Also, this metal can be accumulated in the body through foods and drinking waters for a long time and cause destructive effects on several organs such as kidneys, liver and lungs even at low concentrations [3,4,5,6].

According to the World Health Organization (WHO) and the United States Environmental Protection Agency (EPA), the maximum permissible concentration of Cd2+ in drinking water is 3.0 and 5.0 µg L−1, respectively [3]. Therefore, the development of new enrichment methodologies to determine the trace amounts of Cd2+ in environmental and food samples has attracted significant attention. In this regard, several detection techniques such as inductively coupled plasma-mass spectrometry (ICP-MS) [4], inductively coupled plasma-atomic emission spectrometry (ICP-AES) [5], flame atomic absorption spectrometry (FAAS) [6], electrothermal atomic absorption spectrometry (ET-AAS) [7] and UV–Vis spectrophotometry [8] have been used for determination of trace levels of Cd2+. The FAAS is one the most commonly used techniques for determination of metals in various samples, because of easy operation, low costs analysis, and high sample throughput. Since, the FAAS technique does not have enough sensitivity to measure trace metal ions in complex matrices, it is necessary to use a preconcentration step before analytical measurement [9]. Several sample preparation methods have been developed for separation/preconcentration of Cd2+ from environmental matrices including liquid–liquid extraction (LLE) [10], solid-phase extraction (SPE) [11, 12], co-precipitation [13] and cloud point extraction (CPE) [14]. However, the development of these traditional extraction methods are limited to some weaknesses such as time consuming, and the use of a large amount of toxic and harmful organic solvents [15]. Therefore, current trends in analytical chemistry are focused on simplification and miniaturization of sample preparation procedures with the use of less reagents and toxic solvents. New development in microextraction methods such as solid-phase microextraction (SPME), liquid phase microextraction (LPME), single drop microextraction (SDME), hollow fiber-based LPME (HF-LPME), and dispersive liquid–liquid microextraction (DLLME) offer unique benefits such as simplicity, rapidity, high enrichment factor, and environment benignity [16,17,18,19].

The DLLME is considered as one of the most rapid, low cost, and simple microextraction methods with a high extraction efficiency and enrichment factor [20]. Currently, this method is mostly applied to aqueous samples, whereas initial extraction and/or further cleanup may be needed for samples with complex matrices [21, 22]. In this method, the analyte can be extracted from an aqueous sample solution into an extraction phase in the presence of a disperser solvent. Addition of small amount of disperser solvent to the sample solution disrupts the extraction phase into microdroplets which enables efficient mass transfer of the analyte into the extraction phase and reduces the extraction time. However, the most commonly used disperser solvents such as methanol, acetonitrile, tetrahydrofuran and acetone are toxic. Moreover, the use of relatively high amount of disperser solvent leads to higher solubility of the target analyte in the aqueous phase and reduces partition coefficient of the analyte into the extraction phase [23]. In addition, the common use of halogenated hydrocarbons as extraction solvent is hazardous to the environment.

Room temperature ionic liquids (RTILs) are green solvents which are considered as alternative extractants for traditional organic solvents because of their unique physicochemical properties such as non-volatility, good thermal stability, tunable viscosity and miscibility with water and polar organic solvents [24]. They have been used widely in various analytical separation/preconcentration methods. Recently, ionic liquids based microextraction has attracted particular attention of analytical chemists [25]. As a consequence, new ionic liquid-based DLLME methods (IL-DLLME) including temperature-controlled [26, 27], ultrasound, vortex, and microwave-assisted IL-DLLMEs [28,29,30], and in situ solvent formation IL-DLLME (in situ IL-DLLME) [31] have been developed to eliminate the disperser solvents. Among them, in situ IL-DLLME is a simple and fast microextraction method in which a metathesis reaction takes places with extraction process in one step. In this method, a hydrophilic IL is dissolved in an aqueous solution. Then, by adding an ion exchange reagent, a cloudy solution of the hydrophobic IL containing the preconcentrated target analyte is obtained [32]. In the mentioned DLLMEs, the presence of an appropriate chelating agent for extraction of metal ions is necessary. The use of task specific ionic liquids (TSIL) is an alternative strategy to enhance the metal affinity for the IL phase in DLLME. TSILs are designed by incorporation of a bidentate or a polydentate ligand as a functional group covalently bound to the cationic or anionic part of IL [33]. This type of ILs increases the affinity of the target species to the IL phase and enhances its distribution ratio for a task specific extraction. TSILs can be used in the sample pre-treatment to reduce the used volatile organic solvents, and to develop eco-friendly separation [34,35,36].

Herein, we report a simple and fast in situ DLLME method for the preconcentration of trace amounts of Cd2+ in water and food samples followed by FAAS detection. The introduction of 8-hydroxyquinoline (8-HQ) to the 1-chloroethyl-3-methyl imidazolium cation showed effectiveness for the chelation and extraction of Cd2+ ion into the IL phase and provided high extraction efficiency. The association of the prepared TSIL with potassium hexafluorophosphate (KPF6) salt by in situ anionic metathesis reaction generated hydrophobic TILs. After addition of KPF6 salt, very fine droplets of the IL were dispersed in the aqueous phase. The developed method has simplicity, ease of operation, without use of an organic/disperser solvent or additional chemical reagent that distinguishes it from conventional DLLME. Effects of different parameters on the extraction recovery of Cd2+ ions using TSIL were investigated.

Experimental

Instrumentation

The determination of Cd2+ ions was carried out on a Shimadzu Model AA-6300G flame atomic absorption spectrometer (Kyoto, Japan) equipped with a deuterium lamp for background correction. An appropriate cadmium hollow cathode lamp at a wavelength of 228.8 nm was used as the radiation source, operated at 8.0 mA with a spectral slit width of 0.7 nm. All measurements were made in an air/acetylene flame. All solutions were prepared in ultrapure water (18 MΩ) which obtained from an Aqua Max system (Young-Lin, Korea). A centrifuge (Hettich Model EBA 20, Germany) was used to phase separation. Measurement of the pH values were performed with a Bench top pH meter Model 3001 using a combination glass electrode (Trans Instrument, Singapore).

Regents and materials

All chemicals used in this work were of analytical reagent grade. 1,2-Dichloroethane, N-methylimidazole, potassium hexafluorophosphate (KPF6), and 8-hydroxyquinoline (8-HQ) were purchased from Merck (Darmstadt, Germany). The non-ionic surfactant Triton X-114 was obtained from Sigma (St. Louis, MO, USA) and used without further purification. Stock solution of Cd2+ at a concentration of 1000 mg L−1 was prepared by dissolving appropriate amounts of Cd(NO3)2·4H2O salt in ultrapure water. Working standard solutions also were prepared by diluting the stock solution of Cd2+ with ultrapure water. Phosphate buffer (0.1 M) was used in preparation of the sample solutions with pH adjustment using 1.0 mol L−1 NaOH or 1.0 mol L−1 HCl solutions.

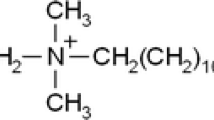

Synthesis of TSIL

Synthesize of the TSIL was carried out as previously reported with a minor modification [37]. Briefly, a mixture of 1,2-dichloroethane (1.77 g, 17.9 mmol) and N-methylimidazole (1.34 g, 16.3 mmol) was stirred at 45 °C for 12 h to obtain an oily IL 1-chloroethyl-3-methylimidazolium chloride ([Cl-C2C1Im][Cl]). 8-HQ (1.45 g, 10 mmol) and KOH (0.56 g, 10 mmol) were dissolved in dry ethanol, and the reactants were added to the ethanolic solution of [Cl-C2C1Im][Cl]. The mixture was refluxed under stirring for 12 h. The resulting solid product, [8-HQ-C2C1Im][Cl] ionic liquid, was recrystallized with anhydrous ethanol and dried in an oven under vacuum.

Extraction procedure

An aliquot of 10.0 mL of aqueous sample solution containing 50 µg L−1 of Cd2+ in a phosphate buffer (0.1 mol L−1, pH 7) was transferred to a 15.0-mL conical-bottom centrifuge tube. The appropriate quantities of NaNO3 and Triton X-114 solutions were added to the sample solution to obtain concentration at 0.1% (w/v) and 0.075% (w/v), respectively. Then, 600 µL [8-HQC2C1Im][Cl] in water (2.5%, w/v) was added to the tube and shaken until a homogeneous phase was obtained. In order to form the hydrophobic microdroplets of TSIL, [8-HQC2C1Im][PF6], KPF6 solution (0.1%; w/v) was added to the mixture. Fine droplets of the extractant solvent were formed and the resulted cloudy solution was centrifuged at 3500 rpm for 4 min to accelerate separation of the two phases. The trace amount of analyte could be extracted into the IL phase. After removing the supernatant, the sedimented IL phase was diluted to 1.0 mL acidic ethanol (HNO3, 0.1 mol L−1) as the diluting solvent for direct analysis by FAAS. The extraction recovery of Cd2+ ions (R%) was defined as the percentage of the amount of analyte (C0) which was extracted into the sedimented IL phase (CIL):

where VIL, V0, C0, and CIL, are the volume of sedimented IL phase, volume of sample solution, initial concentration of Cd2+ ions in the aqueous sample and sedimented IL phase, respectively. The CIL was calculated by the calibration curve obtained from standard solutions of Cd2+ ions and the sedimented IL phase volume.

Preparation of real samples

In this study, some food samples including potato, lettuce and rice (from local market) and three water samples including tap water (Our Laboratory, University of Birjand, Iran), underground water (Shokatabad, 3 km of west of Birjand, Iran) and bottled mineral water (Damavand, Iran) were used to investigate the applicability of the developed method under the optimized conditions. The water samples were diluted with four portions of phosphate buffer and adjusted to the desired pH value with 1.0 mol L−1 NaOH or 1.0 mol L−1 HCl.

To prepare food samples, 5 g of each sample were weighted and washed with ultrapure water. To each sample, 10 mL of concentrated HNO3 was added to decompose organic matrices and heated on a hot plate to dryness. Then, 5 mL of hydrogen peroxide, 30% (w/v), was added and heated for 2 h to complete the digestion. It was then cooled, filtered, and diluted with phosphate buffer to 100 mL in a volumetric flask and the pH was adjusted to the desired value with 1.0 mol L−1 NaOH.

Results and discussion

To achieve optimal conditions for the extraction recovery of Cd2+ ions, the influences of several experimental parameters, such as sample pH, IL volume, ion exchange reagent volume, amount of non-ionic surfactant and salt concentration on the recovery of Cd2+ by the developed microextraction procedure were assessed.

Effect of pH

The sample pH is a key factor in the extraction of metal ions because it affects the metal–chelate complex formation. In the TSIL, O and N donor atoms of 8-HQ could form a strong bond with Cd2+ ion and led to form a neutral complex. Thus, the influence of sample pH on the extraction of Cd2+ ions was investigated in the range of 2.0–8.0 using phosphate buffer (Fig. 1). The results in Fig. 1 showed that the maximum extraction recovery was achieved at pH 7.0. At low pH values, the extraction recovery of Cd2+ ions was decreased by taking protonation of the donor atoms in 8-HQ into account which prevented the complex formation of 8-HQ with Cd2+ ions. The enrichment of Cd2+ ions enhanced with the increasing pH value from 5.5 to 7.0 and decreased gradually when pH value increased probably owing to the formation of Cd(OH)2. Thus, a pH value of 7.0 was selected as the optimum pH for the further experiments.

Effect of TSIL volume

The extraction recovery of Cd2+ ions is affected by the amount of TSIL. To obtain maximum extraction recovery, the effect of TSIL amount on the extraction recovery of Cd2+ was assayed within the volume range of 100–600 µL TSIL (2.5%, w/v) (Fig. 2). It was found that the extraction recovery increased with increase of TSIL volume probably due to the improvement of mass transfer of the analyte to TSIL phase and remained relatively constant when the volume was more than 500 µL. Therefore, 600 µL of 2.5% (w/v) TSIL was chosen in the next studies.

Effect of ion exchange reagent

To achieve complete separation of TSIL phase from aqueous solution, the introduction of an anion exchange reagent to the hydrophilic TSIL was beneficial for in situ changing it to a hydrophobic TSIL through a metathesis reaction. Several experiments were carried out with variation of KPF6 concentration in the range of 0.02–0.12% (w/v) when TSIL was fixed at 2.5% (w/v). It is obvious from Fig. 3 that the extraction recovery was increased up to 0.07% (w/v) KPF6 and then remained constant. Thus, 0.1% (w/v) of KPF6 was selected as the optimum concentration for the subsequent studies.

Effect of non-ionic surfactant

Often some IL droplets remain on the wall of the centrifuge tube and lead to decrease the extraction recovery. It is expected that a non-ionic surfactant Triton X-114 as anti-sticking agent can overcome this drawback. In addition, diluted non-ionic surfactant can be used as a dispersion medium. In this work, the effect of Triton X-114 on the extraction recovery of Cd2+ was investigated. Maximum recovery was obtained in the range of 0.05–0.1% (w/v) Triton X-100 (Fig. 4). At higher concentrations, the extraction of Cd2+ ions diminished probably due to more incorporation the chelated TSIL into the coacervate phase.

Effect of salt concentration

It seems the increasing of ionic strength could assist to separate phases and improves the extraction recovery due to salting out effect. To evaluate the effect of salt concentration on the extraction recovery of Cd2+, additional experiments were devoted at different concentrations of NaNO3 from 0 to 4% (w/v). The results showed that increasing the NaNO3 concentration up to 2.0% (w/v) resulted in the increase of Cd2+ extraction recovery (Fig. 5). Upon increasing the salt concentration, viscosity of the sample solution increased that decreased the mass transfer of the analyte from the aqueous phase to the IL phase, which in turn decreased the extraction recovery. Moreover, at high ionic strength, IL could not well disperse in the sample solution and the extraction recovery reduced.

Interferences study

To investigate the influence of common coexisting ions on the selectivity of the method and extraction of Cd2+ from food and water samples, various amounts of cations and anions were added to the binary sample solutions containing 50 µg L−1 Cd2+. In these experiments, the concentration of coexisting ions which caused in ± 5% variation in absorbance of the extracted Cd2+ were considered as the tolerance limit. As can be seen in Table 1, some common alkaline and earth alkaline ions in food or water samples such as K+, Li+, Mg2+, Ca2+, Ba2+ and the selected anions exhibited the tolerance limits of more than 100. Furthermore, no considerable interferences were observed for the investigated transition metals up to 100-fold excess except for Co2+, Cu2+ and Ni2+ which interfered at 25-, 40-, and 40-fold excess, respectively.

Analytical figures of merit

Under the optimum experimental conditions, the analytical features of the method were examined. The calibration curve showed a linear concentration range between 5 and 250 µg L−1 Cd2+ with a correlation coefficient of 0.9996. The limit of detection (LOD) and limit of quantification (LOQ) were calculated based on 3Sb/m and 10Sb/m, respectively, where Sb is the standard deviation of the blank signal and m is slope of the calibration curve, were found to be 0.55 and 1.83 µg L−1, respectively. The relative standard deviation (RSD %) for six replicate analysis of the 50 µg L−1 Cd2+ solutions was 1.5%. The enrichment factor, defined as the ratio of Cd2+ concentration in the settled IL phase to the initial aqueous sample, of 500 was achieved.

The analysis of real samples

The applicability of the developed method was assessed by preconcentration and determination of Cd2+ in the food samples such as potato, lettuce, rice and in the water samples like tap water, underground water and mineral water by the addition/recovery experiments. The results are summarized in Table 2. Satisfactory recoveries were obtained in the range of 84–113% for different samples. The reproducibility was determined by triplicate extractions of the spiked studied samples. Results shown in Table 3 indicate that for all the studied samples, the RSD% was within the range of 2–5%. These results indicate that the method has potential for the determination of Cd2+ in food and water samples.

Comparison with the other methods

The figures of merit of the in situ-TSIL-DLLME developed method were compared with the other reported liquid–liquid microextraction methods for separation/preconcentration of Cd2+ followed by the determination with FAAS [16, 17, 23, 38,39,40,41,42,43,44,45] (Table 3). The features of the present method using the TSIL include wide linear range, good precision, high enrichment factor and suitable LOD. The developed method is simple, easy to use, does not use an organic solvent, disperser solvent, heat, ultrasonic or additional chemical reagents that distinguish it from the conventional DLLM method.

Conclusions

Appending 8-HQ coordinating group to an imidazolium cation generated the task-specific ionic liquid [8-HQ-C2C1Im][Cl]. The anion exchange of [8-HQ-C2C1Im][Cl] with KPF6 afforded a hydrophobic TSIL [8-HQ-C2C1Im][PF6]. In this work, we investigated the potential of the cation functionalized ionic liquid as a chelating agent and extracting solvent for Cd2+. Our results showed that it efficiently extracted Cd2+ from aqueous solution. Such TSIL-based DLLME requires low amount of extraction solvent without any need for chelating reagent or dispersing solvent resulting in a fast and low cost of operation for the microextraction. The modified DLLME is also environmental friendly, reproducible and simple method that can be used for trace analysis of Cd2+ ions in food and water samples by FAAS.

References

N. Goudarzi, J. Agr. Food Chem. 57, 1099 (2009)

E.M. Martinis, R.A. Olsina, J.C. Altamirano, R.G. Wuilloud, Anal. Chim. Acta 628, 41 (2008)

E. Marguí, I. Queralt, M. Hidalgo, J. Anal. At. Spectrom. 28, 266 (2013)

L. Li, B. Hu, L. Xia, Z. Jiang, Talanta 70, 468 (2006)

F. Cubadda, A. Raggi, Microchem. J. 79, 91 (2005)

T.R. Daher, Anal. Chem. 67, 405 (1995)

A.N. Anthemidis, K.-I.G. Ioannou, Anal. Chim. Acta 668, 35 (2010)

X. Wen, Q. Yang, Z. Yan, Q. Deng, Microchem. J. 97, 249 (2011)

M. Behbahani, A. Bagheri, M.M. Amini, O. Sadeghi, M. Salarian, F. Najafi, M. Taghizadeh, Food Chem. 141, 48 (2013)

A.N. Anthemidis, G.A. Zachariadis, C.G. Farastelis, J.A. Stratis, Talanta 62, 437 (2004)

S. Cerutti, M. Silva, J. Gasquez, R. Olsina, L. Martinez, Spectrochim. Acta Part B 58, 43 (2003)

G. Khayatian, M. Jodan, S. Hassanpoor, S. Mohebbi, J. Iran. Chem. Soc. 13, 831 (2016)

T. Oymak, S. Tokalıoğlu, V. Yılmaz, S. Kartal, D. Aydın, Food Chem. 113, 1314 (2009)

R. Galbeiro, S. Garcia, I. Gaubeur, J. Trace Elem. Med. Biol. 28, 160 (2014)

S. Dadfarnia, A.M.H. Shabani, E. Kamranzadeh, Talanta 79, 1061 (2009)

F. Bamdad, M. Ardalani, M.R. Sangi, J. Braz. Chem. Soc. 25, 246 (2014)

F. Sanchez Rojas, C. Bosch Ojeda, J.M. Cano Pavon, Anal. Methods 3, 1652 (2011)

F. Shah, M. Soylak, T.G. Kazi, H.I. Afridi, J. Anal. At. Spectrom. 27, 1960 (2012)

M. Naeemullah, T.G. Tuzen, Kazi, RSC Adv. 6, 2876 (2016)

M. Rezaee, Y. Assadi, M.R. Hosseini, E. Aghaee, F. Ahmadi, S. Berijani, J. Chromatogr. A 1116, 1 (2006)

M.-M. Mousavi, M. Nemati, A.A. Alizadeh Nabili, M. Mahmoudpour, S. Arefhosseini, J. Iran. Chem. Soc. 13, 2211 (2016)

T. Asadollahi, S. Dadfarnia, A.M.H. Shabani, M. Amirkavei, J. Food Sci. Technol. 52, 1103 (2015)

M. Chamsaz, A. Atarodi, M. Eftekhari, S. Asadpour, M. Adibi, J. Adv. Res. 4, 35 (2013)

P. Zhang, L. Hu, R. Lu, W. Zhoua, H. Gao, Anal. Methods 5, 5376 (2013)

E.M. Martinis, P. Berton, R.G. Wuilloud, TrAC Trends Anal. Chem. 60, 54 (2014)

H. Bai, Q. Zhou, G. Xie, J. Xiao, Talanta 80, 1638 (2010)

I.V. Azevedo, O.L. Araujo, Food Control 50, 901 (2015)

S. Li, S. Cai, W. Hu, H. Chen, H. Liu, Spectrochim. Acta Part B At. Spectrom. 64, 666 (2009)

G. Leng, G. Lui, Y. Chen, H. Yin, D. Dan, J. Sep. Sci. 35, 2796 (2012)

A.T. Jouibari, N. Fattahi, Food Addit. Contam. Part A 32, 1140 (2015)

C. Yao, J.L. Anderson, Anal. Bioanal. Chem. 395, 1491 (2009)

Y. Yan, X. Chen, S. Hu, X. Bai, J. Chromatogr. A 1368, 1 (2014)

E. Stanisz, J. Werner, H. Matusiewicz, Microchem. J. 110, 28 (2013)

M. Gharehbaghi, F. Shemirani, Anal. Methods 4, 2879 (2012)

P. Liang, L. Peng, Talanta 81, 673 (2010)

S. Sadeghi, A.Z. Moghaddam, Anal. Methods 6, 4867 (2014)

S. Sadeghi, A.Z. Moghaddam, RSC Adv. 5, 60621 (2015)

S. Khan, E. Yilmaz, T.G. Kazi, M. Soylak, Clean Soil Air Water 42, 1083 (2014)

S. Mahpishanian, F. Shemirani, Talanta 82, 471 (2010)

G.A. Kandhro, M. Soylaka, T.G. Kazi, E. Yilmaza, H.I. Afridi, At. Spectrosc. 33, 166 (2012)

M. Chamsaz, M. Eftekhari, A. Atarodi, S. Asadpour, M. Ariani, J. Braz. Chem. Soc. 23, 1630 (2012)

S.S. Arain, T.G. Kazi, H.I. Afridi, K.D. Brahman, S. Naeemullah, A.H. Khan, M.A. Panhwar, J.R. Kamboh, Memon, Environ. Monit. Assess. 187, 309 (2015)

E. Yilmaz, M. Soylak, Anal. Chim. Acta 886, 75 (2015)

N. Khan, T.G. Kazi, H.I. Afridi, M.B. Arian, Anal. Lett. 51, 673 (2018)

J.J. Ma, X. Du, J.W. Zhang, J.C. Li, L.Z. Wang, Talanta 80, 980 (2009)

Acknowledgements

The authors are grateful to the Research Council of the University of Birjand for funding this work (Grant no. 35.662).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sadeghi, S., Sarrafi, N. A dispersive liquid–liquid microextraction based on a task-specific ionic liquid for enrichment of trace quantity of cadmium in water and food samples. J IRAN CHEM SOC 15, 1913–1920 (2018). https://doi.org/10.1007/s13738-018-1388-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-018-1388-x