Abstract

A novel clean and simple technique for the heterogenization of l-proline organocatalyst has been introduced. This procedure is based on non-covalent immobilization of l-proline on the surface of anion-exchange resin amberlite IRA900OH (AmbIRA900OH) as an efficient, cheap and commercially accessible cationic polymer support. The ion-pair immobilization of l-proline on the surface of amberlite IRA900OH was achieved by the treatment of a MeOH/H2O solution of l-proline with amberlite IRA900OH at 60 °C. l-Proline anion was exchanged with hydroxyl anion and immobilized via ionic interaction between carboxylate group of l-prolinate and quaternary ammonium cation of the cationic amberlite support. The prepared heterogeneous organocatalyst was well characterized using FTIR, TGA, DTG, XRD and elemental analysis techniques. This heterogeneous catalyst was used as an efficient recoverable catalyst for the synthesis of spiroindolone derivatives and good-to-excellent yields were obtained. The efficiency of the catalyst was almost completely maintained after 5 runs and very low leaching amount of organocatalyst into the reaction mixture occurred.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

During the past decade a revolution of organocatalysis in the field of organic chemistry occurred. Organocatalysts are readily available, much easier to handle and free of metal contaminations which are problematic in pharmaceutical processes. Subsequently, organocatalytic reactions are commonly considered to be environmentally benign and sustainable processes. In spite of these attractive features, organocatalysts have been rarely applied in industry [1]. This unpleasant fact can be principally attributed to the unavoidable drawbacks of homogeneous catalytic processes such as unsatisfactory efficiency, low thermal stability and the difficulties in catalyst separation and recycling [2].

One viable approach to address these challenges would be the heterogenization of organocatalysts. For the latter mentioned reason, the immobilization of organocatalysts has been achieved through covalent attachment onto supports such as polymer [3–6], silica [7–9], ionic liquid (IL) [10, 11], β-cyclodextrin [12], Merrifield resin [13] and magnetite [14]. Although the covalent bond gives robustness to the system and allowing a high number of recycling [15–17], this creativity may induce to a partial loss of efficiency due to a lower mobility of the catalyst which reduces the activity and selectivity compared with their small molecular parent catalysts. Consequently, higher catalyst loading (both w/w % and mol%) is required to reach favorable yields [18]. Moreover, laborious synthetic operations are necessary to reach a covalent immobilization and substantial structural perturbations to the parent catalyst skeletons are generally not avoidable in such circumstances.

Noncovalent immobilization strategies recently appeared as creative alternative solutions with their powers being well demonstrated in supported organocatalysis. Several noncovalent immobilization strategies have been used to achieve recoverable organocatalysts. For example, immobilization via hydrophobic interaction [12, 19], biphasic immobilization [20, 21], self-supported gel-types and ion-pair immobilization [22, 23] have been reported. Among these methods, ion-pair immobilization is a conceivable way to immobilize this type of catalysts via ion-exchange with cationic or anionic supports. By this method, anionic organocatalysts can be combined with an organic cation or cationic supports and cationic organocatalysts can also be hybrid with an organic anion or anionic supports leading to non-covalently supported catalysts.

For instance, Itsuno and co-workers reported a novel type of supported chiral quaternary ammonium comprising an ionic bond between the ammonium moieties and the polymer anchored sulfonate anions [24, 25]. In 2008, Kaneda and co-workers prepared the montmorillonite immobilized Macmillan catalyst via cation-exchange strategy [26]. Layered double hydroxide (LDH) appears as inorganic solid cationic support. LDH consists of stacks of positively charged metal hydroxide layers and interlayer anions. Both inorganic and organic anions could be entrapped into the interlayer. Choudary and co-workers reported the synthesis of LDH entrapped proline via anion-exchange method [27]. Imidazolium and its supported forms have been used as cationic supports for prolinate anion and other anionic organocatalysts [28–32].

In continuation of our research devoted to the applications of ion-exchange resins for click synthesis of 1,4-disubstituted-1H-1,2,3-triazoles [33, 34], herein we wish to report ion-exchange resin Amberlite IRA900OH (AmbIRA900OH) as an efficient, cheap and commercially accessible cationic polymer support for the ion-pair immobilization of l-proline anion via ionic interaction between carboxylate group of l-prolinate and quaternary ammonium cation of the cationic Amb support. This heterogeneous catalyst was used as an efficient recoverable catalyst for the synthesis of spirooxindole derivatives.

Experimental

General

1H NMR spectra of samples were recorded at a Bruker Advanced DPX 400-MHz spectrometer. X-ray diffraction (XRD) patterns were recorded on a Philips X’PERT-Pro-MPD diffractometer using Cu Ka radiation (k = 1.542 Å). A continuous scan mode was used to collect 2 h from 5 to 40. Fourier transform infrared (FT-IR) spectra were obtained as potassium bromide pellets in the range 400–4000 cm−1 using an AVATAR 370 Thermo Nicolet spectrophotometer. Elemental analyses (C, H, and N) were performed with a Heraeus CHN-O-Rapid analyzer. The thermogravimetric and differential thermogravimetric (TG-DTG) analyses were performed on Netsch STA449c. The sample weight was ca. 10 mg and was heated from room temperature up to 600 °C with 10 °C/min using alumina sample holders.

Preparation of the [Amb]l-prolinate catalyst

Amberlite IRA-900OH (mesh 16–50, 1 g) was suspended in 10 mL of a 1 M solution of l-proline in MeOH:H2O (1:1). The system was heated at 60 °C for 6 h. The filtration of the reaction mixture followed by washing with MeOH:H2O (1:1) (2 × 10 mL) and H2O (2 × 10 mL) afforded [Amb]l-prolinate catalyst. The prepared catalyst was collected and dried under vacuum.

General procedure for the [Amb]l-prolinate catalyzed multicomponent synthesis of spirooxindoles

A mixture of isatin 1 (1 mmol), dicarbonyl compound 2 (1 mmol), malononitrile or ethyl cyanoacetate 3 (1 mmol) and [Amb]l-Prolinate catalyst (0.08 g, 10 mol %) was added to a 25 mL canonical flask contained water (5 mL) and was stirred at 60 °C for appropriate time. After completion of the reaction as indicated by TLC, the reaction mixture was filtered and washed with acetone (2 × 25 mL) to separate the catalyst. The obtained organic phase was evaporated and the residue was recrystallized from ethanol to obtain the pure products. The recovered catalyst was dried under vacuum and was used in the next consecutive runs.

Selected spectral data

7′-Amino-2,4′-dioxo-2′-thioxo-1′,2′,3′,4′-tetrahydrospiro[indoline-3,5′-pyrano[2,3-d]pyrimidine]-6′-carbonitrile (4d). m.p. 243–245 °C; IR (KBr) cm−1 = 3525, 3430, 3321, 3155, 2200, 1695, 1655, 1620, 1560, 1400, 1345, 1134, 765 cm−1; 1H NMR (400 MHz, DMSO-d6): δ = 6.82 (d, 1H, J = 7.6 Hz, ArH), 6.94 (t, 1H, J = 5 Hz, ArH), 7.14–7.31 (m, 2H, ArH), 7.46 (s, 2H, NH2), 10.58 (s, 1H, NH), 12.55 (s, 1H, NH), 13.7 (br s, 1H, NH). Anal. calcd. for C15H9N5O3S: C, 53.09; H, 2.67; N, 20.64; S, 9.45 %. Found: C, 53.18; H, 2.70; N, 20.50; S, 9.69 %.

7′-Amino-5-bromo-2,4′-dioxo-2′-thioxo-1′,2′,3′,4′-tetrahydrospiro[indoline-3,5-pyrano[2,3-d]pyrimidine]-6′-carbonitrile (4f, C15H8BrN5O3S) White solid; m.p.: 252–254 °C; IR (KBr): cm−1 = 3426, 3311, 3160, 2200, 1693, 1655, 1615, 1570, 1460 cm−1; 1H NMR (400 MHz, DMSO-d6): δ = 6.77 (s, 1H), 7.31–7.75 (m, 4H), 10.69 (s, 1H, NH), 12.54 (s, 1H, NH), 13.81 (brs, 1H, NH) ppm; 13C NMR (100 MHz, DMSO-d6): δ = 46.8, 56.0, 90.9, 111.1, 113.6, 116.8, 127.0, 131.2, 135.4, 141.5, 152.9, 158.1, 159.2, 173.9, 177.0 ppm.

7′-Amino-5-fluoro-2,4′-dioxo-2′-thioxo-1′,2′,3′,4′-tetrahydrospiro[indoline-3,5-pyrano[2,3-d]pyrimidine]-6′-carbonitrile (4g, C15H8FN5O3S) White solid; m.p.: 252–254 °C; IR (KBr): cm−1 = 3420, 3315, 3165, 2200, 1690, 1650, 1610, 1575, 1470 cm−1; 1H NMR (400 MHz, DMSO-d6): δ = 6.77–6.80 (m, 1H), 6.98–7.03 (m, 1H), 7.24 (dd, 1H, J 1 = 8.2 Hz, J 2 = 2.5 Hz), 7.49 (s, 2H, NH2), 10.55 (s, 1H, NH), 12.51 (s, 1H, NH), 13.85 (brs, 1H, NH) ppm; 13C NMR (125 MHz, DMSO-d6): δ = 47.7, 57.5, 91.6, 110.5, 110.5, 112.4, 112.6, 115.3, 115.4, 117.2, 135.2, 135.2, 138.7, 153.5, 159 (J C–F = 128.2 Hz), 174.4, 177.7 ppm.

2-Amino-5′-fluoro-2′,5-dioxo-5,6,7,8-tetrahydrospiro[chromene-4,3′-indoline]-3-carbonitrile (4k) m.p. = 283–284 °C. 1H NMR (DMSO-d6, 500 MHz): δ = 1.91–1.93 (m, 2H), 2.20–2.23 (m, 2H), 2.62–2.68 (m, 2H), 6.75–6.78 (m, 1H), 6.95–6.99 (m, 2H), 7.25 (s, 2H), 10.41 (s, 1H). 13C NMR (DMSO-d6, 125 MHz): δ = 20.6, 27.5, 37.2, 112.1, 112.5, 115.0, 118.1, 137.0, 139.1, 159.4, 167.5, 179.0, 196.0. Anal. Calcd. for C17H12FN3O3: C, 62.77; H, 3.72; N, 12.92; found C, 62.79; H, 3.74; N, 12.93.

Results and discussion

Catalyst preparation

The procedure followed to obtain the ion-pair immobilization of l-prolinate anion on the cationic polymer resin is outlined in Scheme 1. The strategy consists of building up suitable heterogeneous macroporous polymer-supported l-prolinate catalyst on the surface of commercially available amberlite IRA-900OH (mesh 16–50). Preparation of heterogeneous polymer-supported l-prolinate catalyst by this procedure is facile and straightforward. In a typically procedure AmbIRA900OH was treated with a solution of 0.01 M l-proline at 60 °C to achieve [Amb]l-prolinate hybrid.

Characterization of the catalyst

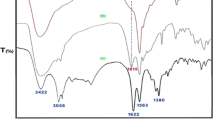

IR spectra

The ion-pair immobilization of l-prolinate anion on the polymer resin can be confirmed by characterizing the pure AmbIRA900OH, pristine l-proline and [Amb]l-prolinate hybrid using FT-IR spectroscopy, as shown in Fig. 1. The FT-IR spectrum of pristine l-proline shows characteristic stretching frequencies include: N–H asymmetric stretching at 3056 cm−1 and carboxylate (COO−) asymmetric and symmetric stretching at 1622 and 1380 cm−1, respectively (Fig. 1a). These bands are observed as new peaks in the FT-IR spectrum of [Amb]l-prolinate hybrid in comparison with the FT-IR spectrum of pure AmbIRA900OH (Fig. 1b vs. a). The carboxylate (COO−) asymmetric and symmetric stretching are presented in [Amb]l-prolinate and found to shift to lower positions at 1615 and 1375 cm−1, respectively (Fig. 1b). In addition, the band at 3056 cm−1 corresponding to the asymmetric stretching vibration of the N–H group in l-proline is also found at 3056 cm−1 in FT-IR spectrum of [Amb]l-prolinate. All the results from the comparison of FT-IR spectra encourage us to anticipate that the l-prolinate anion successfully loaded onto the polymer surface through ionic interaction using ion-pair binding between carboxylate group of l-prolinate and quaternary ammonium cation of the cationic Amb support.

TGA and DTG analysis

Thermogravimetric analysis (TGA) and differential thermal analysis (DTG) associated with the decomposition profiles of the AmbIRA900OH, pristine l-proline and [Amb]l-prolinate hybrid under a nitrogen atmosphere provide further evidence for the immobilization of l-prolinate anion onto the polymer surface (Figs. 2, 3). The 100 % weight loss of pristine l-proline appears at 215–250 °C on the base of its TGA and DTG curves and assigned to the successive cleavage of the l-proline at this interval (Figs. 2c, 3c). The TGA curve of pure AmbIRA900OH shows three weight loss step intervals at 65–100, 150–250 and 370–470 °C. The first weight loss interval at 65–100 °C is most probably due to a loss of adsorbed water (weight loss = ca. 11 wt%). The second weight loss interval at 150–250 °C presumably assigned to the loss of some functional groups (weight loss = ca. 19 wt%) and finally the third weight loss interval at 370–470 °C (weight loss = ca. 34 wt%) could presumably assigned to partial polymer decomposition (Fig. 2b). Figure 3b displays the DTG curve of AmbIRA900OH and is in accordance with the weight loss steps from its TGA curve. The TGA curve of [Amb]l-prolinate hybrid displays four weight loss steps include: 60–100, 150–250, 250–370 and 370–470 °C intervals (Fig. 2a). These four weight loss peaks are well distinguished in the corresponding DTG curve (Fig. 3a). Obviously, in comparison with AmbIRA900OH, a new decomposition interval is observed in TGA and DTG curves of [Amb]l-prolinate hybrid (weight loss = ca. 15 wt%). This weight loss is assigned to the successive cleavage of l-prolinate anion loaded on the surface of the polymer and also referred to the content of l-prolinate moiety on the Amb cationic support. The calculation from TG curve was indicated that 1.3 mmol of l-prolinate organocatalyst is loaded per 1 g of the [Amb]l-prolinate hybrid. It is noticeable that the decomposition temperature of l-prolinate anion in [Amb]l-prolinate hybrid has been increased to 250–370 °C in comparison with the decomposition temperature of pristine l-proline (215–250 °C). These observations mean that the thermal stability of the l-prolinate has increased in comparison with the pristine l-proline and also explain the carboxylate asymmetric and symmetric stretching shifts to lower positions in FT-IR spectrum of [Amb]l-prolinate hybrid (Fig. 1b). The increased decomposition temperature of the l-prolinate suggests that the guest/host interaction was done through the ion-pair exchanges between hydroxyl and l-prolinate anions on the surface of ion-exchange resin and is an indirect proof for the presence of ion-pair interaction between l-prolinate anions and quaternary ammonium cations on the surface of cationic support (Fig. 3a vs. c). The high loading of l-prolinate on the surface of Amb (15 wt%), together with the unique ion-pair binding behaviors between l-prolinate and Amb cation, makes the [Amb]l-prolinate hybrid efficient and stable in the reaction system.

XRD

The crystalline nature of [Amb]l-prolinate hybrid confirms that l-prolinate is non-conveniently supported on cationic polymer support via ion-pair immobilization. The main intense diffraction peaks of pristine l-proline based on the standard spectrum (Fig. 4a) are observed in the XRD pattern of [Amb]l-prolinate hybrid due to the presence of the l-prolinate on the Amb support thanks to a favorable ion-pair binding with quaternary ammonium cations of the ion-exchange resin (Fig. 4b vs. a). This technique gives robustness to the catalytic system and, on the other hand, lets the l-prolinate organocatalyst to be flexible, mobile and free on the surface of the polymer at the same time. Moreover, the thermal stability of organocatalyst has been improved by this way. These mentioned advantages are characteristic properties of homogeneous and heterogeneous catalysts which have been included in [Amb]l-prolinate hybrid.

The one-pot multicomponent synthesis of spiroindonlones using [Amb]l-prolinate catalyst

After preparation and characterization of [Amb]l-prolinate catalyst, its catalytic activity was investigated in a multicomponent reaction of isatin, dicarbonyl compounds and malononitrile (ethyl cyanoacetate) for the synthesis of a category of spirooxindole derivatives under green conditions. To obtain the best conditions for the synthesis of titled compounds, the reaction of isatin (1a), barbituric acid (2a) and malononitrile (3a) was selected as a model reaction. The progress of the reaction was studied in the presence different molar ratios of the prepared catalyst and pristine l-proline in various solvents at different temperatures. The obtained results are summarized in Table 1.

In the absence of catalyst in EtOH, the desired product was obtained in 20 % after 4 h (Table 1, entry 1). With using pristine l-proline as catalyst the product 4a was obtained in 88 % isolated yield after 1.5 h (Table 1, entry 2). The catalytic role of l-proline for the preparation of spiroindolones is confirmed by the comparison of the reaction times and yield of the products from entries 1 and 2. When [Amb]l-prolinate (10 mol%) was used as catalyst in EtOH at room temperature, the product 4a was obtained in 72 % isolated yield after 2 h (Table 1, entry 4). With increasing the temperature to 60 °C, the yield enhanced to 89 % and the reaction time decreased to 1 h. The best results were obtained using [Amb]l-prolinate (10 %) at 60 °C in water as a solvent (Table 1, entry 7). Neither the reaction rate nor the yield of the product was significantly improved in the presence of greater amounts of the catalyst (20 mol%) while reducing the amount of the catalyst (5 mol%) led to the lower yield and longer reaction time (Table 1, entries 8, 9).

After the optimization of reaction conditions and in order to exploit the generality and scope of the reaction in the presence of the introduced [Amb]l-prolinate catalyst, the reaction was extended to various structurally diverse substrates which are shown in Fig. 5.

In all cases, the multicomponent reaction was completed in the course of a desirable and reasonable time and target spiroindolone derivatives (4a–p) were isolated in high yields. These observations clearly indicate the generality and scope of the reaction with respect to the various reagents (Fig. 6).

In order to show the practical reusability of the introduced heterogeneous organocatalyst, the reaction between isatin (1a), barbituric acid (2a) and malononitrile (3a) was selected again as a model under optimized reaction condition. After completion of the reaction, the heterogeneous organocatalyst was separated with a simple filtration, washed with acetone, dried under reduced pressure and the recycled catalyst was used in the next consecutive runs. As seen from Fig. 7, the recycled catalyst could be reused at least up to 5 runs without any loss in its activity.

The nitrogen content of the fresh and reused catalyst was measured using elemental analysis and the comparison of the nitrogen contents indicated that the catalyst lost only 1 % of its nitrogen content after 5 runs. This is a good proof for very low leaching account of l-proline organocatalyst from [Amb]l-prolinate catalyst into the reaction mixture during 5 runs and also confirms that the catalytic ability of [Amb]l-prolinate almost completely has been remained stable after 5 runs in agreement with the recyclability study.

We proposed a plausible mechanism for the formation of spirooxindole derivatives using [Amb]l-prolinate as catalyst. Initially, l-prolinate anion abstracts a proton from malononitrile followed by a typical cascade reaction in which the isatin first condenses with malononitrile to afford isatylidene malononitrile intermediate in water. This step was regarded as a fast Knoevenagel condensation. In the second step, [Amb]l-prolinate catalyst reacts with 1,3-dicarbonyl compound and makes an enamine intermediate. Michael addition of enamine intermediate to Knoevenagel product, followed by ring closing and deprotonation, furnish spirooxindole derivative (Scheme 2).

In order to investigate the selectivity of the chiral heterogeneous [Amb]l-prolinate organocatalyst, the reaction depicted in Scheme 3 was selected as model reaction. The results showed that in the presence of [Amb]l-prolinate, 1,3-cyclohexadione (2c) reacts selectively with isatylidene malononitrile intermediate in competition with barbituric acid (2a) and furnishes its desired spirooxindole.

Several different conditions have been reported in the literature for the synthesis of spirooxindole derivatives, as shown in Table 2. The current methodology offers several advantages, such as a simple procedure, short reaction times, facile synthesis, simple work-up, high yields, and green conditions.

Conclusion

In conclusion, a new heterogeneous organocatalyst based on ion-pair immobilization of l-proline on the surface of amberlite hydroxide has been developed. The novel prepared heterogeneous organocatalyst efficiently catalyzed the one-pot synthesis of spirooxindole derivatives using variety of isatins and dicarbonyl compounds and furnished the corresponding spirooxindoles in good-to-excellent yields under green conditions. The non-covalent immobilization strategy was used for the heterogenization of l-proline via ion-pair immobilization on the surface of amberlite hydroxide. This strategy made the organocatalyst to be mobile and flexible which not only helped the supported catalyst to be as powerful as its non-supported form, but also made it to be easily recoverable with simple filtration.

References

F. Xu, M. Zacuto, N. Yoshikawa, R. Desmond, S. Hoerrner, T. Itoh, M. Journet, G.R. Humphrey, C. Cowden, N. Strotman, P. Devine, J. Org. Chem. 75, 7829 (2010)

H.U. Blaser, B. Pugin, F. Spindler, J. Mol. Catal. A: Chem. 231, 1 (2005)

M. Gruttadauria, F. Giacalone, A.M. Marculescu, R. Notoa, Adv. Synth. Catal. 350, 1397 (2008)

M. Gruttadauria, A.M.P. Salvo, F. Giacalone, P. Agrigento, R. Noto, Eur. J. Org. Chem. 2009, 5437 (2009)

S. Calogero, D. Lanari, M. Orrù, O. Piermatti, F. Pizzo, L. Vaccaro, J. Catal. 282, 112 (2011)

J. Zou, W. Zhao, R. Li, H. Zhang, Y. Cui, J. Appl. Polym. Sci. 118, 1020 (2010)

A. Lu, T.P. Smart, T.H. Epps, D.A. Longbottom, R.K. ÓReilly, Macromolecules 44, 7233 (2011)

A. Zamboulis, N.J. Rahier, M. Gehringer, X. Cattoën, G. Niel, C. Bied, J.J.E. Moreau, M.W.C. Man, Tetrahedron Asymmetry 20, 2880 (2009)

A. Khalafi-Nezhad, E. Shaikhi, Shahidzadeh, S. Sarikhani, F. Panahi. J. Mol. Catal. A: Chem. 379, 1 (2013)

W. Miao, T.H. Chan, Adv. Synth. Catal. 348, 1711 (2006)

S. Luo, X. Mi, L. Zhang, S. Liu, H. Xu, J. Cheng. Angew. Chem. Int. Ed. 45, 3093 (2006)

J. Huang, X. Zhang, D.W. Armstrong, Angew. Chem. Int. Ed. 46, 9073 (2007)

J. Li, G. Yang, Y. Qin, X. Yang, Y. Cui, Tetrahedron Asymmetry 22, 613 (2011)

H. Yang, S. Li, X. Wang, F. Zhang, X. Zhong, Z. Dong, J. Ma, J. Mol. Catal. A: Chem. 404, 363 (2012)

X. Fan, S. Sayalero, M.A. Pericas, Adv. Synth. Catal. 354, 2971 (2012)

P. Kasaplar, P. Riente, C. Hartmann, M.A. Pericas, Adv. Synth. Catal. 354, 2905 (2012)

E. Ozkal, S. Ozcubukcu, C. Jimeno, M.A. Pericas, Catal. Sci. Technol. 2, 195 (2012)

J. Horn, F. Michalek, C.C. Tzschucke, W. Bannwarth, Top. Curr. Chem. 242, 43 (2004)

K. Liu, D. Haeussinger, W.D. Woggon, Synlett. 2298 (2007)

K. Huang, Z.Z. Huang, X.J. Li, J. Org. Chem. 71, 8320 (2006)

H.M. Guo, L.F. Cun, L.Z. Gong, A.Q. Mi, Y.Z. Jiang, Chem. Commun. 1450 (2005)

B. Escuder, F. Rodrı´guez-Llansola, J.F. Miravet, New. J. Chem. 34, 1044 (2010)

F. Rodrı´guez-Llansola, B. Escuder, J.F. Miravet, J. Am. Chem. Soc. 131, 11478 (2009)

Y. Arakawa, A. Chiba, N. Haraguchi, S. Itsuno, Adv. Synth. Catal. 350, 2295 (2008)

Y. Arakawa, N. Haraguchi, S. Itsuno, Angew. Chem. Int. Ed. 47, 8232 (2008)

T. Mitsudome, K. Nose, T. Mizugaki, K. Jitsukawa, K. Kaneda, Tetrahedron Lett. 49, 5464 (2008)

B.M. Choudary, B. Kavita, N.S. Chowdari, B. Sreedhar, M.L. Kantam, Catal. Lett. 78, 373 (2002)

K. Fukumoto, M. Yoshizawa, H. Ohno, J. Am. Chem. Soc. 127, 2398 (2005)

X. Zheng, Y. Qian, Y. Wang, Eur. J. Org. Chem. 515 (2010)

X. Zheng, Y. Qian, Y. Wang, Catal. Commun. 11, 567 (2010)

Y. Qian, X. Zheng and Y. Wang, Eur. J. Org. Chem. 3672 (2010)

W. Chen, Y. Zhang, L. Zhu, J. Lan, R. Xie, J. You, J. Am. Chem. Soc. 129, 13879 (2007)

M. Keshavarz, N. Iravani, A. Ghaedi, A. Zarei Ahmady, M. Vafaei-Nezhad, S. Karimi, SpringerPluss, 2: 64 (2013)

J. Albadi, M. Keshavarz, Synth. Commun. 43, 2019 (2013)

G. Mohammadi Ziarani, S. Faramarzi, N. Lashgari, A. Badiei, J. Iran. Chem. Soc. 11, 701 (2014)

G. Mohammadi Ziarani, A. Badiei, S. Mousavi, N. Lashgari, A. Shahbazi, Chin. J. Catal. 33, 1832 (2012)

B.M. Trost, J.P. Stambuli, S.M. Silverman, U. Schworer, J. Am. Chem. Soc. 128, 13328 (2006)

H.A. Oskooie, M.M. Heravi, N. Karimi, H. Hamidi, Synth. Commun. 41, 3344 (2011)

A. Hasaninejad, N. Golzar, M. Beyrati, A. Zare, M.M. Doroodmand, J. Mol. Catal. A: Chem. 372, 137 (2013)

N. Lashgari, G. Mohammadi Ziarani, A. Badiei, M. Zarezadeh-Mehrizi, J. Heterocyclic. Chem. 51, 1628 (2014)

G. Shanthi, G. Subbulakshmi, P.T. Perumal, Tetrahedron 63, 2057 (2007)

S.-L. Zhu, S.-J. Ji, Y. Zhang, Tetrahedron 63, 9365 (2007)

R. Sridhar, B. Srinivas, B. Madhav, V.P. Reddy, Y.V.D. Nageswar, K.R. Rao, Can. J. Chem. 87, 1704 (2009)

Y. Li, H. Chen, C. Shi, D. Shi, S. Ji, J. Comb. Chem. 12, 231 (2010)

L.-M. Wang, N. Jiao, J. Qiu, J.-J. Yu, J.-Q. Liu, F.-L. Guo, Y. Liu, Tetrahedron 66, 339 (2010)

A. Mobinikhaledi, N. Foroughifar, M.A. Bodaghi Fard, Synth. Commun. 41, 441 (2011)

Y. R. Lee, G. S. Hari, Synthesis, 453 (2010)

Acknowledgments

The authors gratefully acknowledge the Research Council of Yasouj University for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Keshavarz, M. Ion-pair immobilization of l-prolinate anion onto cationic polymer support and a study of its catalytic activity for one-pot synthesis of spiroindolones. J IRAN CHEM SOC 13, 553–561 (2016). https://doi.org/10.1007/s13738-015-0765-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-015-0765-y