Abstract

Pullulan is a microbial exopolysaccharide hydrogel biopolymer that is biodegradable, renewable, and environmentally friendly. However, to meet the demands of the utilization, it is still necessary to enhance the yield and molecular characteristics of pullulan formed by different strains. Available in powder form, pullulan enhances the benefits of this natural material when combined with nanoparticles (NPs) and synthesized into pullulan NPs. NPs are gaining attention as a cutting-edge technology in the fields of pharmaceuticals, medicine, food, agriculture processing, and packaging. Pullulan biopolymers provide an environmentally friendly solution that effectively addresses the world's waste disposal issue by removing untreated waste from the agro-food industries and using this waste as a potential substrate for pullulan biosynthesis. Nowadays, pullulan in the form of NPs, nanocomposites, and nanoformulation has become increasingly popular because of their specific application needs with enhanced molecular properties like strength, durability, electrical conductivity, and catalytic activity. This approach offers a valuable product called pullulan-based nanopolymer, which holds promise in various industries. Pullulan with the highest yield capacity to date has the potential to significantly decrease production costs and increase applicability range. This review provides detailed insights into the latest methods for extracting pullulan biopolymers from agricultural and food waste materials in the form of polysaccharides. Moreover, the article covers the synthesis of various types of pullulan-based nanoparticles, nanocomposites, and nanoformulations. Furthermore, it delves into the diverse applications of these pullulan nanopolymers across agriculture, food and medical sectors.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pullulan is a polysaccharide made up of repeating subunits of maltotriose, also called glucan which is synthesized by yeast-like fungus Aureobasidium pullulans by an aerobic synthesis method [1, 2]. It was first observed by Bauer in 1938 as a polysaccharide in A. pullulans after that it was first isolated and characterized by Bernier from A. pullulans broth culture [3, 4]. The industrial market of pullulan is expanding quite quickly. The initial company that commercialized pullulan synthesis was Hayashibara Co. Ltd. in 1976 [5]. Up to the year 2000, the industrialized process of pullulan manufacturing was restricted by patent rights obtained by Hayashibara. However numerous other industries began producing pullulan commercially after Hayashibara's patent expired. The USA's Sigma-Aldrich, Inc. is among the leading manufacturers of pullulan. Pullulan's unique qualities and future uses are driving up its popularity, which is growing daily. According to Singh and coworkers, the market cost of standard pullulan developed by Sigma-Aldrich, Inc. USA was US $ 2000 kg−1 in 2009 [6]. By 2020, that price had risen to US $12,000 kg−1 [1].

It exhibits renewable, odourless, tasteless, non-mutagenic, toxin-free, non-immunogenic, and non-carcinogenic natural polymeric properties [7,8,9]. Therefore, due to its considerable adaptability and flexibility, it plays a wide role in various fields [10,11,12]. Pullulan is typically used as a prebiotic, a filler in beverages and sauces, and as a texturizer in culinary pastes like mayonnaise. In the food sector, pullulan is favoured as a low-calorie food material used to produce low-calorie products including baked pastries, low-calorie noodles, and synthetic rice. Because pullulan has sufficient adhesive properties, it can be used as a binder [13]. In comparison to other polysaccharides, it has a comparatively low viscosity and does not change throughout a broad pH range of 2–11 [14]. It can withstand temperatures as high as 250–280 °C. It begins to break down at temperatures higher than this. It may produce a film with strong oxygen (O2) barrier properties but also is water soluble, non-toxic, biodegradable, and edible. It has been a GRAS product since 2002, and the EU subsequently recognized it for use as a food additive in 2004 [15]. Due to its superb O2 barrier properties, pullulan film is used in most food and agriculture industries as a packaging application. Foods high in unsaturated lipids (such as meat, fish, and nuts) and vitamins (such as fruits and vegetables) are especially well protected by these films [5]. In the 1990s, pullulan coating was used for the first time to protect food, and it quickly gained popularity as an edible thin protective layer [16]. Additionally, because this polymer is non-immunogenic, non-carcinogenic, and non-mutagenic, researchers use it in targeted drug and gene delivery [11, 17]. Pullulan derivatives must possess hydrophobic and cationic moieties to function as an appropriate macromolecule in the nanoparticle production process for drug delivery [18]. Pullulan can easily be chemically modified as it exhibits multiple hydroxyl groups. Pullulan-based NPs also showed remarkable non-immunogenicity so it is useful as a plasma expander [19] and has an inherent affinity for the liver [18, 20]. Despite these advantages, pullulan production is another challenge concerning (i) economical production and its utilization in different industries that completely depend on inexpensive substrates, and (ii) physicochemical similarity with synthetic plastic.

Raw substrates limit the industrial production and commercial application of pullulan. As its production proved to be expensive ($25 kg−1) than other exopolysaccharides [21]. Pullulan production under submerged fermentation containing a medium supplemented with carbon, nitrogen and other essential nutrients makes the upstream process expensive that affects the final cost of pullulan [7]. Since media components are responsible for about 30% of the total production cost, choosing cheaper ones can lower the overall production price [21]. In this regard, many agricultural and agro-derived substrates are utilized as inexpensive substrates for the commercial synthesis of pullulan [7].

Global population growth has raised the need for agro-food production and, consequently, the need for agro-food processing wastes has also been raised. About 1.3 billion tonnes of food are discarded annually, based on the latest assessment from the Food and Agriculture Organisation (FAO) [22]. Food businesses and household wastes are major contributors to agro-food waste, which is harmful to the environment in both prior and after-market sites [23]. Such wastes are frequently dumped in landfills or used to make compost. However, the production of value-added products like pullulan from these agro-food wastes would not only encourage waste recovery but also generate higher benefits [24].

However, the natural physiochemical structure of lignocellulose present in agro-food waste creates a hindrance to the effective valorization of these substrates for pullulan biopolymer production due to their heterogenic and recalcitrance properties. This rigidity of the substrates poses an economic and technical challenge in biomass conversion to biopolymer. To sort out these problems different pretreatment methods are utilized separately and in combination. These treatments alter the physicochemical structure of the agro-food biomass which gives it more accessibility to the substrate for pullulan production [15].

The second drawback related to their physicochemical properties such as poor mechanical property, insolubility in organic solvent, and absence of hydrophobic group, limits the application of pullulan in various fields [11, 25]. These drawbacks can be overcome by the conjunction of pullulan with another nanomaterial. Different studies on pullulan-based nanocomposite showed their possible uses in agro-food, medical, and pharmaceutical industries. The incorporation of some functional ingredients like NPs into pullulan for their application on the agro-foods products surface promotes safety or even nutritional and sensory attributes [26]. Pullulan nanocomposites are an example that is formed by blending a pullulan with NPs that can effectively resolve the problem of biopolymer film/coating. These NPs-incorporated biopolymers exhibit properties such as good antibacterial, antifungal, and antiviral features compared to only pullulan biopolymer film [27]. Whereas, they also have a critical role as a nanoformulation in biomedical and pharmaceutical research and development such as nanogels, nanoparticles (NPs), and microspheres in drug delivery, gene delivery, plasma expander, vaccination and anticoagulants [1, 15, 16]. This review highlights the recent research on the synthesis of pullulan polymer from renewable agro-food waste resources and its transformation into valuable commercial biomaterials as a solution to waste management. Furthermore, it also elaborates on the conjunction of pullulan with other nanoparticle and their relevance in the application of various sectors.

Agro-food waste as a substrate for pullulan production

Pullulans are biological polymers that are produced by microbes using polysaccharide resources like agro-food waste [28]. These wastes are the consequences of the increasing worldwide population and their lifestyle which has increased the requirement for agriculture products and food. These untreated agro-food waste creates severe damage to the environment in the way of pollution [29, 30]. The agro-food waste is tough to manage because it is enriched with many nutrients and its unsafe disposal could create an extensive negative impact on the environment and human health. Traditional waste management such as landfilling, bio-composting, and incineration is previously practiced for agro-food waste management. That proved to be time-consuming and unsafe generating landfill leachate and exposure to toxic gases [31]. Keeping this in consideration, various research on agro-food waste is carried out on merging agro-food management with additional commercial goods like volatile fatty acids (VFA), biohydrogen, bioplastic (PHA), and more [30].

Over the last decades, biopolymers have become more famous among other valuable agro-food wastes-derived products in many different industrial fields including food, agriculture, pharmaceutical, biomedical, and other industrial sectors. This is because of their biodegradability/compostability, biocompatibility, and their sustainable characteristics [23, 24]. Agro-food waste acts as a polysaccharide substrate that can be specifically converted into bio-derived compounds that exhibit various chemical behaviour. These compounds can then be utilized to yield new biopolymers as a substitute for petroleum-derived polymers [32]. Out of agro-food-derived polymers, the extracellular polysaccharides (EPS) derived from fungal polysaccharides like pullulans biopolymers show great interest. Therefore, the transformation of these agro-food waste by-products through different pretreatment methods shows two main benefits: (i) The sustainable degradation of agro-food waste that directly decreases environmental pollution, and (ii) helps a circular bio-economy by the development of value-added biomaterials such as biopolymers that show a broad range of opportunities in different industrial fields.

Furthermore, there remains a need to acquire biomaterials through economically viable methods that can guarantee the complete utilization of agro-food wastes utilizing sustainable practices. Polysaccharides are the least expensive and most readily biodegradable of these biomolecules, making up around 75% of all organic compounds on Earth [33]. These are consequently among the most prevalent polymers that occur naturally, acting as important components of both plants and animals (like cellulose in plants and hyaluronic acid in mammals) or as a method of storing food (like starch or glycogen). All of these biopolymers, composed of algal or microbial polysaccharides like xanthan gum and pullulan as well as exudates from plants like gum arabic, karaya gum, and tragacanthin gum, are the most basic natural carbohydrate molecule building blocks that are made up of repeating units accompanied to one another through glycosidic bonds. They are frequently employed as chemical markers, especially for cell identification [34].

The amount of polysaccharides that can be derived from agro-food waste, which amounts to roughly 300 billion tonnes annually [7], is far greater than the amount of natural raw materials available in nature that are able to produce polysaccharides. Utilization of these wastes will allow for the preservation of natural resources for future generations while also removing some pollutants and lowering greenhouse gas (GHG) pollution [28]. Agro-food waste offers numerous benefits, but it also has drawbacks as it contains a significant amount of lignocellulosic materials, which are difficult to process due to their complex structural makeup. This prevents microorganisms from using them as a source of food. It is regarded as a significant barrier in the way of producing biopolymers by microbial fermentation. Therefore, the pretreatment of the lignocellulosic feedstock turned out to be an extremely significant phase in the fermentation process. The efficiency of these pretreatment procedures controls the availability of free sugars and subsequent conversion towards biopolymers. Enzymatic, physiochemical, chemical and a mix of several processes are some of the pretreatment procedures for breaking lignocellulosic material [30]. According to Kumar and Sharma [35], the choice of pretreatment is based on the characteristics and content of the lignocellulosic material for the hydrolysis process that produces a favourable outcome. This part highlights the pretreatment method selected to synthesize pullulan from food and agricultural waste.

Biosynthesis strategies for pullulan

A general method of pullulan production is illustrated in Fig. 1. Biosynthesis of pullulan was highly influenced by substrate type, environmental conditions, and strain modification at the genetic level that is described in this section.

Role of different agro-food waste on pullulan production

Previously, pullulan was produced from A. pullulans using sugars such as sucrose, glucose, fructose, and maltose. However, it can also be alternatively synthesized with various agro-food wastes such as green gram husk [36], cassava starch, corn steep liquor, and soybean meal hydrolysate [37], Sesame seed oil cake [38], potato starch hydrolysate [39], cassava waste [21], sugarcane bagasse hydrolysate [40] and cassava bagasse and Asian palm kernel [41], etc. The composition of saccharified intermediate affects pullulan production from different agro-food wastes. This part covers the pullulan production from the most common agro-food wastes.

The potatoes in the food industry have been investigated most frequently when it comes to developing ready-to-eat items. The processing units for potatoes produce a lot of trash. According to Huang and coworkers [42], potato trash has a rich starch content (2.0%-2.5%) and a low content of reducing sugars (0.08%-0.12%). Potato waste disposal can lead to serious problems for the environment and human health. Different microbial flora may utilize starch to serve as a carbon source for pullulan fermentation. The two molecules that makeup starch are amylose and amylopectin. Because of their complexity in structure, almost all industrially significant microbes find it difficult to use these compounds in their original state. Despite this, starch that has been hydrolyzed serves as simple sugars, making it an excellent substrate for the growth of microorganisms. Two processes are involved in the enzymatic breakdown of starch: first, α-amylase administration, and then partially hydrolyzed starch is exposed to a mixture of pullulanase and glucoamylase. α-Amylase breaks down the α-1,4 glucose bonds in amylose, resulting in liquefied gelatinized starch. To efficiently hydrolyze starch, pullulanase and glucoamylase are combined [43]. Pullulanase hydrolyzed the α-1,6 glucose links of amylopectin, while glucoamylase hydrolyzed the α-1,4 glucose linkages at the same time for the production of high-glucose syrup. The rate of starch liquefaction is increased by the immobilization of glucoamylase and pullulanase in Ca-alginate beads, and the resultant hydrolysate can function as a potential source for pullulan biosynthesis [44]. The hydrolysate that is produced by β-amylase instead of glucoamylase increases pullulan up to two times [45]. Certain strains of A. pullulans can partially undergo hydrolysis of potato starch due to the presence of amylase a starch-degrading enzyme. Pullulan synthesis can be greatly enhanced by this partially hydrolyzed potato starch [46]. A. pullulans has produced more pullulans in a 10-L bioreactor if potato starch hydrolysate is enriched with sucrose [39]. The stimulating effect on the microbial enzyme skilfully raised the pullulan yield in a potato starch hydrolysate-based medium [39].

Grapes constitute a crucial raw substrate used in the production of juice and wine. The grape skin is peeled off and the juice is drawn from the pulp during the processing step. This grape skin and juice-free pulp during processing constitute a waste called grape pomace, while grape juice is primarily utilized in the production of ready-to-drink beverages. According to Israilides and coworkers [47], the composition of grape pomace is as follows: protein (7.8%), total sugars (85.2%), reducing sugars (3.4%), and glucose (1.28%). While grape pomace in its solid state can be challenging to work with, grape skin and pulp extract are more user-friendly. One method for making grape pomace extract is to add hot water to the pomace, agitate for 30 min, and then filter the mixture [48]. The pullulan made up of grape pomace extract exhibited homogeneity and high molecular weight, resulting in increased yield [46].

Whey is a liquid byproduct produced after the coagulation of protein and fat present in the milk during the process of making cheese. According to Yang and coworkers [49], whey comprises lactic acid (0.1%-0.8%), proteins (0.8%), lactose (4.5%), and salts (1.0%). It is an efficient and affordable medium for pullulan biosynthesis because of these components. Furthermore, the proteins in whey might be eliminated by boiling it to 90 °C for 20 min, which will increase its usefulness for fermentation operations. By filtering out the protein precipitates, deproteinized whey is produced, which has around 80% lactose [50]. It has been claimed that A. pullulans may produce pullulan in shake-flask fermentations using deproteinized whey as a possible carbon feedstock [50].

Rice hull is the outer brown covering of rice obtained during rice processing. The primary components of rice hull are lignocellulose including cellulose (50%) and lignin (25%-30%), as well as silica (15%-20%). Rice hull is a promising substrate for fermentation due to these components [51, 52]. The majority of microbes are unable to use lignocellulosic carbohydrates in their natural state. Thus, rice husk hydrolysate is formed by transforming the complex carbohydrates into fermentable sugars through the process of saccharification of the rice hull. The process used to saccharify rice hull determines the quantity of sugars found in the hydrolysate [53]. Wang and coworkers [54], reported that the hydrolysate of rice hulls contains the following constituents: xylose (25.52% ± 0.83%), glucose (5.89% ± 0.18%), arabinose (3.37% ± 0.18%), galactose (0.22% ± 0.20%), and acetic acid (0.35% ± 0.02%). A. pullulans was successfully utilized to produce pullulan using rice hull hydrolysate in a stirred-tank fermentor. The presence of acetic acid in hydrolysate could hinder fungal growth and negatively impact pullulan synthesis. Therefore, to get over this problem, the original strain of A. pullulans can be evolved adaptively from acetic acid to increase the pullulan yield throughout fermentation.

Molasses is a byproduct of sugarcane or sugar beet juice refining to form tiny sugar particles. It is a viscous liquor with a dark brown colour that contains around 45%-55% of all fermentable sugars, along with non-sugar molecules (2%-4%), fructose and glucose (10%-25%), minerals, and moisture [55, 56]. The sugar factory releases substantial quantities of molasses into the closest water supply, which significantly contaminates the environment. Because of these types of sugars, molasses can be readily metabolized by A. pullulans and used as a carbon source for pullulan synthesis [47]. But molasses additionally includes heavy metals (Cu, Fe, Mn, Zn, Ca, Mg, etc.) that prevent microbial growth, deactivate beneficial enzymes, and reduce the production rate of the end product [57]. Therefore, pretreating the molasses is a crucial step in achieving a satisfactory product yield both qualitatively and quantitatively. The easiest way to remove heavy metals from molasses is by treating it with H2SO4. Molasses were pretreated by adding 1 N of H2SO4, letting the mixture rest for 24 h, and then centrifuging the liquid to extract the supernatant [57]. The pullulan obtained from the pretreated molasses was twice as high in the shake-flask fermentation than untreated molasses. In this manner, pretreated molasses proved to be an economical production medium for pullulan synthesis [58]. Pullulan production is increased by 49.0 g/L when pretreatment molasses is used, according to several studies [59], 23.0 g/L [60] in stirred tank reactors and 18.5 g/L in an airlift reactor [61].

Brewery waste is a good substrate for pullulan production. The brewing plants produce a byproduct called spent grain liquor. This spent grain liquor is obtained as liquid waste after the extraction of wort from spent grains. The brewing sector produces a significant volume of discarded grain liquor, which is an incredible source of waste. Both suspended particles and organic compounds can be found in spent grain liquor. According to Xiros and coworkers [62], it is composed of hemicellulose (40%, w/v), cellulose (12%, w/v), starch (2.7%, w/v), proteins (14.2, w/v), lignin (11.5%, w/v), lipids (13%, w/v), and ash (3.3%, w/v). The organic content of spent grain liquor is expressed as biochemical oxygen demand (BOD) and is the main pollutant of the water ecosystem. A. pullulans uptakes this spent grain liquor and is responsible for the pullulan production [50].

Role of physico-chemical/fermentation condition on pullulan biosynthesis

The microbial-assisted approach for the biosynthesis of pullulan by bio-polymerization of agro-food waste is dependent on fermentation [19]. Fermentation is a versatile approach to synthesize products of added value like microbial biopolymers, since fermentation factors influence the feasibility and the economic side of the method [63]. Process optimization plays a crucial role in cutting the expenses of any industrial production [58]. Therefore, optimizing the fermentation process is crucial to advance the formation of microbial EPS. Growth conditions such as pH, temperature, oxygen concentration, agitation, and culture medium composition are important factors to optimize [64, 65]. Microbial type plays an important role in the chemical structure, monomer composition, physical, chemical, and rheological characteristics of polysaccharides and in this way, the process is strain-specific [66]. Consequently, management of the fermentation conditions, such as selecting suitable substrates and exploiting excellent productive strains, makes the industrial production of polysaccharides efficient with the required characteristics possible [67]. Since carbon- and energy-intensive activities play a major role in EPS synthesis, dietary needs, and environmental factors also have an impact on the strains needed to synthesize EPS. As a result, there is controversy over microbial growth, nutrient availability, and other fermentation factors that affect polysaccharide synthesis. Thus, it seems likely that these circumstances have strain-specific impacts on polysaccharide synthesis [65]. Yeast-like cells are the main producers of pullulan in cultures during the late exponential and early stationary phases [5, 68, 69]. Additionally, on the basis of microbial growth, various fermentation circumstances, like batch, batch-fed, or continuous process, may be used for polysaccharide synthesis [70, 71].

pH has the potential to alter the growth profile, which can significantly raise or lower the pullulan yield. It is frequently noted that the ideal temperature and pH conditions for the highest biomass yield and for the synthesis of polysaccharides are distinct. Therefore, it could be necessary to reach the highest biomass within one set of conditions before changing culture conditions to acquire the highest polysaccharides. pH of the medium progressively lowers from initial pH 6.5 throughout the course of the first 24 h fermentation [72]. Pullulan productivity is impacted by structure of A. pullulans, which is influenced by the pH of the medium [73]. According to Lee et al. [74], mycelia are formed at pH 2.5, and yeast-like colonies are formed at pH 4.5. Pullulan synthesis requires a pH of around 5.5 and 7 [73]. There is an optimum pH for polysaccharide synthesis or biomass growth than this [74, 75]. While pullulan biosynthesis is poor at lower pH values, and biomass growth increases [46, 76]. Published data indicate that pullulan synthesis increased when the medium pH was permitted to naturally decline instead of being kept constant [74, 77]. As shown by Lee et al. [74], pullulanase function causes a progressive decline in the fraction of high molecular weight pullulan when the pH is not regulated. But if the pH drops below 2.5, pullulan yield may be negatively impacted by extreme acid exposure [76, 78]. The ideal pH and temperature for pullulan synthesis are not always specified same in the literature; they might range between 5.5 to 7.5 and 25 to 30 °C, based on the physical characteristics of the microbe [58, 79].

The medium's temperature needs to be kept at 30 °C for the cell growth which usually peaks at 75 h. The production of pullulan starts if nutrients start dropping low at the final stage of the logarithmic growth cycle. Pullulan biosynthesis reaches its peak during the stationary phase, which lasts from 70 to 90 h. Pullulan biosynthesis is favoured by nitrogen deprivation. Ammonium ion level reduction inhibits biomass formation, which is a key factor in the redirection of carbon sources to polysaccharide synthesis. But towards the end of the growth cycle, A. pullulans also synthesizes pullulanase, an enzyme that breaks down pullulan. Consequently, pullulan-degrading enzymes cause a reduction in pullulan productivity after the stationary phase [80]. Pullulan yields of roughly 70% and higher are typically attainable [72, 76].

No matter the scale of polysaccharide production, the nitrogen content of the nutritional medium is the limiting factor [81]. Therefore, the fermentation medium is designed to have a high carbon-to-nitrogen ratio. Although the substrates to be used should be inexpensive, the nutrient needs for the industrial production of microbial polysaccharides remain the same [63, 82]. Growth conditions such as on substrate composition (breeding factors), fermentation conditions (pH, temperature), and the improvement of A. pullulans strains also play a key role in the production of microbial EPS including pullulan [83]. Both the cell growth and metabolite production enhancement depend on the culture media contents, mainly proper amount of media nutrients with an optimized carbon/nitrogen concentration [84, 85]. Yeast-like fungus Aureobasidium pullulans exhibited quality to use a multiple type carbon substrate and can produce pullulan by the simple and complex sugars, for example glucose, fructose, mannose, maltose, as well as xylose, ribose, arabinose, sucrose, and lactose [86]. Pullulan is made commercially with starch hydrolysate that has 40%–50% dextrose equivalent (DE). A range of 5% to 15% is kept for the sugar content. Pullulan formation is checked by extreme sugar content [44]. According to reports, too much sugar prevents the biosynthesis of pullulan by inhibiting the enzymes that produce pullulans, such as α-phosphoglucose mutase, UDPG-pyrophosphorylase, and glycotransferase. Pullulan synthesis is therefore more suited for fed-batch reactors [76]. Several carbon substrates, such as mono- or disaccharides, may be employed to produce pullulan. The impact of six distinct sugar supplies (glucose, sucrose, dextrin, fructose, maltose, and xylose) on the pullulan biosynthesis through A. pullulans Y68 was investigated by Duan et al. [86]. According to their findings, pullulan production from glucose (8%) was found the highest possible level, while significantly lowering the yields in sucrose, fructose, xylose, dextrin, and maltose [87].

According to Singh and Saini [88], the capacity to uptake several carbon substrates was likely a unique trait of strains for pullulan biosynthesis. Agricultural waste [72], olive oil and sucrose [89], deproteinized whey [60], beet molasses [90], sweet potato [73], and potato starch hydrolysate [73] were all used as inexpensive substrates in order to effective production of pullulan through fermentation method by employing A. pullulans [58]. This is because the fast growth of the biotechnology sector remains linked to the requirement to broaden the raw material base using new, less expensive carbon substrates [84].

According to reports, pullulan is a secondary metabolite that yeast-like cells synthesize when there is an ammonium shortage [5, 91]. Additionally, each strain is nitrogen specific in order to produce pullulan i.e. present in the growth media [85]. The majority of the strains have been favoured ammonium sulfate as a choice of nitrogen for growth [88]. However, additional nitrogen sources such as soybean hydrolyzate, peptone or tryptone, ammonium acetate, and sodium nitrate, may also be utilized for the biosynthesis and secretion of pullulan in the fermentation medium [84]. Additionally, pullulan yields and the physical characteristics of fungal strains are directly influenced by the pH of the growth media [84]. A polymorphic fungus called Aureobasidium pullulans can produce mycelia, colorless chlamydospores segmented by septa, budding blastoconidia (yeast-like cells), and spores that secrete black melanin. Pullulan is currently only known to be produced by chlamydospores and unicellular blastoconidia [2, 92]. The range of 5.5–6.5 pH is the ideal beginning pH for the synthesis of pullulan [69]. Varying strains of A. pullulans have slightly varying optimal temperatures for the production of pullulan, which have been observed to range from 25 to 28 ˚C [93].

It is generally known that microorganisms including bacteria and fungus produce extracellular metabolites, like polysaccharides [94]. Exopolysaccharides (EPS), intracellular polysaccharides, and structural polysaccharides are all examples of polysaccharides that fall under the category of biopolymers [94]. The extracellular biosynthesis of pullulan occurs at the cell wall membrane as a loose and slimy coating on the outermost layer of the cell [95]. According to recent theories, pullulan biosynthesis may occur in the Aureobasidium melanogenum P16's cell wall and periplasm [2, 96]. Pullulan is the primary linear glucosic polysaccharide derived from fungus Dematium pullulans (de Bary) or yeast-like fungus Aureobasidium pullulans (de Bary) Arnaud (earlier known as Pullularia pullulans de Bary) [88]. However, some species of A. pullulans show limitation to high synthesis of exopolysaccharide pullulan [97]. While various species are identified as pullulan producers, including genus of Aureobasidium, namely A. melanogenum, A. leucospermi, A. proteae, A. thailandense, and A. nambiae [2, 98, 99]. Fungal species also contributed in the pullulan production such as saprophytic fungus Tremella mesenterica [100], parasitic fungal strains Teloschistes flavicans [101] and Cryphonectria parasitica [102]. The pullulan production potential was also observed in the other fungal varieties such as edible mushrooms Cyttaria harioti and Cyttaria darwinii [103, 104], yeasts such as Rhodotorula bacarum and Rhodosporidium paludigenum [105, 106], as well as in bacteria like Micrococcus luteus [107]. The formation of pullulan by A. pullulans results in the unwanted black pigment known as melanin. It develops and is discharged throughout the medium near the finish of the exponential cycle, providing it with a black colour [76]. To overcome this problem, the producer strain of A. pullulans shifts to a colour variant that fails to produce melanin [6, 87].

Role of biosynthetic mechanism on pullulan biosynthesis by A. pullulans

A complex metabolic reaction occurs during the biosynthesis of pullulan. Precursors synthesized inside the microbial system accelerate the rate of pullulan production. According to Simon and coworkers [108], pullulan biosynthesis is facilitated by the deposition of carbohydrate residues within the cell at the early phases of fermentation. Pullulan is biosynthesized in the microbial cell's cytoplasm and subsequently excreted to the cell surface by penetrating the β-glucan layer. This creates a lightly adhered slimy coating over the cell surface which is made up of pullulan biopolymer [109]. Metabolic route for pullulan biosynthesis was described by Duan et al. [86] and Sugumaran and Ponnusami [94]. A. pullulans is able to consume various carbon sources such as mannose, sucrose, maltose, fructose, galactose, xylose and even the agro-industrial waste. It took a while to determine which enzymes and encoding genes play a role in the synthetic pathways of this EPS, and the process of pullulan synthesis was not fully understood before the year 2020 [2]. There are two main phases in the biosynthesis of pullulan. Initially, uridine diphosphate glucose (UDPG), the precursor, is produced [109]. UDP-glucose is a widely recognized precursor of pullulan biosynthesis [110]. However, Shingel also hypothesized that lipid intermediates carrying glucose could potentially have a role in this pathway [111]. Second, pullulan is created by polymerizing the precursor molecules [109]. The transformation of glucose into pullulan compounds depends on the existence of important enzymes like α-phosphoglucose mutase, uridine diphosphoglucose (UDPG) pyrophosphorylase, and glucosyltransferase [86, 88]. α-phospho glucomutase enhances the formation of glucose-1 phosphate from glucose-6 phosphate [86]. Pullulan precursor, UDP-glucose is formed from glucose 1 phosphate by UDPG-phyrophosphorylase [1]. Figure 2 illustrates the detail regarding a general fungal metabolic process for the formation of pullulan and the key enzyme involved.

Pullulan production is dependent on biosynthesis regulation. Pullulan's low productivity, low Mw, and impurities notably black-pigmented melanin [112] have restricted its commercialization currently [113]. Because of the significance of pullulan's characteristics, its production price, bioprocessing, and strain alteration are being extensively researched as ways to increase pullulan's Mw and yield. Genetic engineering is used in numerous attempts to control pullulan production by effective genome editing methods which were developed in 2019 [2]. It helps to control the appropriate genes and enzymes involved in the pullulan production pathway in various strains of Aureobasidium spp. [103].

Chen et al. [92] simultaneously deleted duplicated AMY1 genes encoded α-amylase and duplicated PKS1 genes involved in melanin production in A. melanogenum TN3-1. This resulted in a mutant AMY-PKS-11 that converted 140.0 g/L glucose to yield 103.50 g/L pigment-free pullulan with an Mw of 3.2 à 105 Da [114]. When cultivated in a 10-L fermentor, the triple mutant DT15 produced 58.14 g/L of pullulan with the same Mw of 3.02 × 106 Da. However, its wild-strain P16 yielded 65.5 ± 3.5 g/L of pullulan with a Mw of 0.35 × 106 Da [113].

Therefore, further work needs to be done to increase pullulan yield and to enhance the chemical characteristics of pullulan by altering on molecular level of the producer by synthetic biology techniques. Byproducts such as melanin, glucan, and polymalic acid are typically present in pullulan produced through A. pullulans fermentation [19, 115, 116]. However, the existence of these contaminants makes pullulan purification much more challenging. The A. pullulans strains has a potential to suppress the formation of melanin compounds which is a crucial component of the industrial synthesis of pullulan [85]. Melanin was one of the challenges of pullulan production [93], and this substance was eliminated using an appropriate solvent throughout the fermentation and precipitation of EPS.

The biosynthetic pathways of distinct strains vary, leading to variations in the product molecular weight among strains because of variances in metabolic routes and cell structure [12, 94]. In this reference, Chen and coworkers [12] studied the regulation of the biosynthesis of pullulan in A. pullulans BL06. They discovered that by regulating the key synthesis pathway of pullulan impurities such as deletion of the important genes, the Mw of pullulan products can be changed in addition to the yield and purity of extracellular pullulan. A. pullulans BL06 was isolated from the environment and shown to produce large yields of pullulans. Additionally, three strains with knockout genes were created: A. pullulans BL06 ΔPMAs, A. pullulans BL06 Δmel, and A. pullulans BL06 ΔPMAsΔmel. In addition, a fermentation output of 83.4 g/L pullulan in a 5 L bioreactor with a molecular weight of 3.3 × 106 Da was obtained. The strain BL06 has great prospects for industrialization since it offers the benefits of high production and high Mw. Moreover, a different commercial strain of A. pullulans, BL06 ΔPMAs, was developed by deleting the gene encoding for polymalic acid (PMA) synthase. This strain can produce moderately high yields of pullulan with high purity. After being transformed, the strain was able to produce 1.3 × 105 Da pullulan at a yield of 140.2 g/L in a 5 L bioreactor, without the presence of PMA or melanin. It has been observed that pullulan synthesis is increased by overexpressing the pullulan synthase enzyme [2].

In addition to low Mw, low pullulan yield was another barrier for pullulan industrial application. Usually, high pullulan biosynthesis takes place in a high sucrose medium that avoids glucose. The reason behind this is that pullulan is glucose sensitive and the existence of a high glucose concentration in the culture media represses many genes linked to pullulan biosynthesis and declines the pullulan yield [85, 117]. Hence, depression of glucose is required for the enhancement of pullulan biosynthesis [2].

A previous report indicated that the removal of gene coding for CreA from a glucose-derepressed mutant of A. melanogenum showed a higher pullulan yield. CreA or MIG1 genes are global regulators in fungi, including yeasts that encode glucose repression that takes part in glucose repression. The Mig1 and CreA proteins, Cys2His2 (C2H2) zinc-finger proteins, are able to bind the well-characterized 50-SYGGRG-30-rich sites in the promoters of a variety of glucose-repressed genes, including those responsible for pullulan biosynthesis [117, 118]. Another study showed that a higher yield of pullulan (64.93 g/L) from glucose at a concentration of 120.0 g/L was produced by the glucose-derepressed mutant of A. melanogenum P16 in comparison to the corresponding native strain (52.0 g/L) in the similar growth conditions [117]. The other proteins that play a role in glucose repression and derepression include the transcription factor Mig1, the hexose kinase Hxk2, the protein kinases Reg1-Glc7, Med8, Cyc8-Tup1, Snf1, the protein kinase Adr1, and the catalase Cat8 [118]. Additionally, it is hypothesized that Msn2 and the associated signaling pathway control pullulan production in A. melanogenum P16. The Msn2 protein, a C2H2 Zn finger, has a DNA-binding domain that detects the particular promoter sequences (AGGGG and CCCCT) of the regulated genes, containing the majority of the genes involved in pullulan biosynthesis [2]. The UGP1 gene, which codes for UDPG-pyrophosphorylase (Ugp1), catalyzes the production of UDP-glucose, the sole precursor of pullulan biosynthesis, that is responsible for accelerated pullulan biosynthesis when the Msn2 protein is localised in the nucleus of A. melanogenum P16 [2].

However, hexokinase and isomerase are required for the transformation of various carbon substrates to the pullulan precursor, UDPG [85]. A second gene, UGT1, which codes for a protein, i.e., similar to the UDP glucose, glycoprotein glucosyltransferase (Ugt1), has also been identified as being involved in the production of pullulan [110]. Pullulan was overproduced when this gene was overexpressed in A. melanogenum P16 as produced 63.38 g/L in the natural strain as compared to 80.2 g/L in a modified one. Whereas its deletion greatly lowered the amount of pullulan that was biosynthesized. For incompletely glucosylating folder glycoproteins, the Ugt1 protein was proposed to serve as a "folding sensor" [92]. Currently, it was shown that the PUL1 gene encodes for the pullulan synthetase protein may function as an auxiliary protein for a component necessary for the glucan synthetase 2 (AmAgs2) activity, a crucial enzyme for the production of pullulan. In two mutants of A. pullulans, the PUL1 gene deletion prevented the production of pullulan [15, 92].

Recent methods to extract pullulan from agro-food wastes/downstream process

The most important stage in every biotechnology sector is the planning and establishment of an effective bioprocess. Process development is eventually impacted by the growing requirement to lower the rising product costs [119]. Pullulan undergoes a multi-stage downstream processing step to ensure its security during purity recovery. It must be effective, and reliable, and enhance pullulan extraction productivity while requiring the least amount of manufacturing expenses [120]. Downstream becomes more difficult to extract the pullulan because of interference from contaminants, leftovers from fermentation, and substrate and medium additives employed in the formulation of the fermentation medium.

The choice of an inexpensive, complex substrate typically results in reduced upstream processing costs for pullulan when the fermentation medium is formulated at an industrial level. Additionally, these inexpensive, complex substrate components go unused during fermentation, and isolating them raises the additional steps in the downstream procedure and adds to the price of production. However, the employment of pure substrates in the fermentation medium reduces the number of steps involved in pullulan’s downstream processing, but achieving so comes at a cost. To meet the specifications for pullulan's particular usage, different downstream processing techniques are employed to attain the required degree of purity in the material. Generally, the number of downstream processing steps needs to be kept minimum to minimize production costs and handling times while also preventing pullulan loss at various stages of purification [121].

Liquid–liquid separations are processed after solid–liquid separations in the product recovery stage. Pullulan's downstream processing begins with the separation of solids from liquids. These solids are culture supernatants present in the cellular biomass after fermentation. The efficacy of filtration or sedimentation during solid–liquid separation is influenced by various factors. These factors include the kind of microbe employed in fermentation, as well as its shape and flocculation capabilities [121]. In this stage, cell biomass can be separated by filtering or centrifugation.

Pullulan is processed further by a series of procedures called liquid–liquid separation. Pullulan can be purified using both alcoholic and non-alcoholic organic solvents due to its renowned insolubility in organic solvents. Pullulan has also been processed downstream using standard methods such as chromatography, ultrafiltration, gel filtration, and dialysis. Aqueous two-phase systems have also been employed in a few situations to purify pullulan [121]. Pullulan undergoes a sequence of separate unit activities in its downstream processing that are combined to purify the product. The following steps are used for the extraction of microbial pullulan from the fermentation medium: (1) microbe harvesting; (2) removal of unwanted by-products, like cellular proteins and melanin; (3) polysaccharide precipitation; (4) ultracentrifugation/dialysis; and (5) freeze drying (product polishing step) [94].

Centrifugation

The type of association between the polysaccharide to be extracted and the cell determines the separation as well as purification procedures for capsular polysaccharides. Centrifugation is used to accomplish separation whenever the capsular extracellular polymeric substances (EPS) have a poor association with bacteria [82, 122].

Various techniques are used to extract various exopolysaccharide types from bacteria. Centrifugation is typically used to recover EPS that has slime forms. The kind and viscosity of the polysaccharide determine centrifugation speed and duration. Ultracentrifugation can be used to extract microbial biomass or waste products from the growth culture for improved outcomes in the lab [82]. For the separation of pullulan, the solid-state fermented medium was centrifuged at 10,000 r/min for 25 min. Pullulan present in the resultant supernatant was precipitated by adding double volumes of cold acetone for complete pullulan precipitation. Eventually, the precipitated pullulan was separated by centrifugation at 10,000 r/min for 20 min [21]. Centrifugation and cross-flow filtration are two methods for removing cell biomass [85]. While, activated carbon adsorption or the use of a salt and alcohol mixture are two methods for removing the melanin pigment [5]. Pullulan is soluble in water and insoluble in the majority of organic solvents. Thus, it is possible to extract the product from the purified supernatant through the addition of an adequate volume of organic solvents like ethanol, acetone, and isopropyl alcohol. The polysaccharides start to precipitate when the organic solvent is added. For greater purification, the first two stages must be repeated. Ion exchange and/or ultrafiltration are used to pullulan solutions to get a higher purity of the biopolymer [76].

Pullulan is usually purified by removing the cells from the culture, removing the melanin from the culture, removing the melanin pigment from the broth, precipitating the pullulan by adding the appropriate solvents and resuspending the precipitate. Finally, purifying the resultant mixture through ultrafiltration or chromatography [76]. It is possible to precipitate, dry, and mechanically grind purified pullulan into a powder [76, 85].

Physical treatment

Heat treatment has been utilized to enhance the separation of microbial cells from the broth in the case of thermostable EPS. Heat treatment has no impact on the viscosity of these polysaccharides; however, it does cause pasteurization, which destroys the microbes and inactivates the enzymes of the culture broth [82]. Extraction of capsular polysaccharides requires a distinct process because the capsular EPS must first be separated from the cells [123].

Chemical treatment

Centrifugation is preceded by more intensive treatments (e.g., alkaline treatment, treatment with NaCl, EDTA, and C2H5OH precipitation) for the tightly attached capsular EPS with the cells. In addition to chemical treatments, the microbial cell suspensions can be boiled for 15 min, heated at 60 °C in a saline solution, 65 °C in a mixture of phenol and water, or sonicated [82, 124].

Pullulan nanoparticles/nanocomposites/nanoformulation synthesis

The goal of nanotechnology is to know about and take advantage of the nanoscale processes that nature uses to create its constituent parts. According to Coltelli et al. [28], it is the process of creating and characterizing materials and structures at the nanoscale that has improved physicochemical qualities over bulk materials. To obtain a single material with better physicochemical properties, pullulan must be modified to combine the advantages of natural polymers with other substances [11]. Pullulan's function and application scope can be expanded through derivatization. It is possible to increase pullulan's activity by adding different chemical structures to its framework. It is possible to substitute other chemical groups for the nine hydroxyl groups that are found on Pullulan's repeating units (C6H10O5)n. Chemical processes such as amidification, copolymerization, sulfation, esterification, oxidation, etherification, and others are used in derivatization. Every derivative has distinct physicochemical features as a result of chemical change [125]. All the three types of pullulan derivatives preparation under the specific preparation condition are described in this section. There are various ways to prepare pullulan derivatives with their specific preparation condition.

Pullulan nanoparticles

The primary goal of nanotechnology is to create nanoparticles with predictable shape and size, polymeric film and even distribution. It is commonly known that different metal NPs have a wide range of beneficial uses in many fields, such as biomedicine and health care. As a result of their extensive use, metals like gold, silver, zinc, copper, and so forth are mainly in the spotlight. Nanoparticles can be prepared using a variety of techniques, such as chemical and physical approaches. This can effectively generate pure, well-defined nanoparticles, however, are costly, unstable, lengthy, and possibly hazardous to human welfare and the environment [126]. Green chemistry-based eco-friendly approaches to nanoparticle production could be a substitute for chemical synthesis [127].

Recently, a new "green" idea called the biosynthesis of biopolymers-mediated metal NPs has been developed in light due to their excellent water dispersity, abundance, non-toxicity, stability, biocompatibility, biodegradability, and eco-friendly qualities. So far, biopolymers such as pullulan have been widely employed for the synthesis of NPs [128]. But lately, research has mostly focused on the use of pullulan as a stabilising and reducing agent [129]. Pullulan was utilized for developing compression mouldings, fibres, drug delivery carrier materials, and edible films because of its promising adhesive and film-forming capabilities [13, 130].

Ghaffarlou and coworkers [131] synthesized a simple and green method for pullulan-stabilized silver and gold nanoparticles for the inhibition of quorum sensing. Using this approach, 15 mL of deionized water was stirred at 40 °C until pullulan was fully dissolved. Subsequently, 1 mL of either 0.01 mL of silver nitrate (AgNO3) or 0.01 mL of HAuCl4·3H2O was added to this mixture. The mixture was continuously stirred for 5 h while it was at room temperature. Ag(I) or Au(III) were reduced into zerovalent metallic states present in the metal ion-absorbed pullulan solution by heating it to 70 °C and shaking it for 5 h at 150 rpm. It resulted in the formation of AgNPs/Pull and AuNPs/Pull. Pull-Ag and Pull-Au solutions changed colour after heating to pink and light brown, respectively, signifying the production of metallic Ag and Au NPs. AgNPs/Pull and AuNPs/Pull solutions were employed unfiltered.

Additionally, pullulan-capped Ag NP was effectively created with the use of radiation-induced techniques including gamma irradiation. A reducing agent was not used in the preparation of stable Ag-NP/PL nanocomposites, which had an average size of 3.98 nm. Ag NP production was verified by UV–visible spectroscopy, which found a plasmonic band at 410–420 nm. The XRD pattern demonstrated that the Ag-NPs’ crystalline structure was fcc for every sample. TEM imaging confirmed that the Ag-NPs were evenly distributed throughout the pullulan matrix. Further, the fragmentation was induced by γ in the Ag-NPs. This resulted in a gradual decrease in the particle diameter of silver nanoparticles at higher doses of 50 kGy. Ag-NP/PL was discovered to have a negatively charged zeta potential and to be a stable, well-dispersed particle in a colloidal suspension. This Ag-NP/PL biofilm exhibited potential antibacterial properties against S. aureus. As a result, pullulan-capped Ag NPs are suitable for a wide range of applications such as antimicrobial biofilm packaging [132].

Hong and coworkers [133], synthesized phthalyl pullulan NP. They dissolved 1 g of pullulan in 10 mL of dimethyl formamide (DMF) and introduced 0.1% (by mole) of dimethylaminopyridine per pullulan sugar residue to the mixture as a catalyst. To the aforementioned solution, more phthalic anhydride was added at various molar ratios per pullulan: 6:1 (phthalic anhydride: pullulan; PPN1), 9:1 (phthalic anhydride: pullulan; PPN2), and 12:1 (phthalic anhydride: pullulan) (PPN3). This resulted in PPNs with varying levels of phthalic group substituted. The reaction was run in nitrogen for 48 h at 54 °C. To create self-assembled phthalyl pullulan nanoparticles, the resulting PPNs were dialyzed twice: once in DMF to eliminate any unreacted phthalic anhydride, and again in distilled water (D.W) for 1 day at 4 °C. Following ultra-centrifugation of the produced PPNs, the unreacted pullulan was extracted [133].

In support of this, Jayeoye and coworkers [134] demonstrated that pullulan (PUL) not only acted as a stabilizing agent but also took part in the production of the NP by adjusting the reaction environment's surface energy. They used tannic acid (TA) to synthesize pullulan-stabilized Au NP and then explored hazardous Ag+ detection based on Au/Ag core–shell nanostructure creation. Initially, 8 g of pullulan was dissolved in 100 mL of water and agitated at room temperature to create an 8% pullulan solution. The solution was held for an hour after being heated to 60 °C. The solution was kept swirling while the heat supply was cut off. After that, it was kept for an entire night at 4 °C to guarantee the polymer's total dissolution. The fabrication of TA/PUL-AuNPs was done as follows. 40 mL of 2.5% PUL (optimal amount of biopolymer) was poured into an aluminium foil-shielded beaker while shaking. Next, 0.8 mL of tannic acid (18 mM) was introduced, followed by 1.2 mL of 0.1 M NaOH, and lastly, 1 mL of Au (III) chloride trihydrate (78 mM) was quickly introduced. Before being utilized, the combination was kept at room temperature for an hour while being vigorously stirred. Finally, it was then kept in an amber bottle at 4 °C [134].

In another study, a polymeric NP carrying valsartan was produced [135]. Valsartan is a cardiovascular drug function as an angiotensin II receptor blocker. Pullulan acetate served as a degradable polymeric structure, while Pluronic F127 was used as a stabilizer to create pullulan NP by the nanoprecipitation process. In short, 5 mL of acetone was used for dissolving pullulan acetate. A pullulan/acetone solution was used to precisely weigh and dissolve valsartan. 15 mL of D.W was used to dissolve 10 mg of pluronic-F127. The aqueous phase solution was mixed with the organic phase dropwise until the organic solvent completely evaporated. This was done while the mixture was magnetically agitated at 1000 rpm and room temperature (25 °C). To extract the unbound drug from the created NP, the final nanosuspension was centrifuged for 30 min at 30 °C and 10,000 rpm. According to Pavaliou and coworkers [135], the precipitate-carrying NP was resuspended in D.W and screened through a 0.22 μm Millex filter membrane after the supernatant was thoroughly drained. The NP-carrying valsartan exhibited a limited dispersity (polydispersity index < 0.2), nanometric diameters (below 200 nm), and high trapping capacity of valsartan. According to this study, pullulan and its derivatives have a lot of possibilities for creating NPs that could be used to carry drugs for the cardiovascular diseases.

According to reports, pullulan-based NPs are effective against a range of microbes with their antibacterial properties. Pullulan was utilized as the reducing and stabilizing agent which shows the fast technique for the biosynthesis of silver nanoparticles (AgNPs) stabilized by pullulan [128]. The resulting NPs have been discovered to be in spherical shape and range in size from 10 to 55 nm on average. Additionally, the antimicrobial activity of these pullulan stabilized AgNPs was assessed by employing the agar well diffusion technique against two Gram-positive (Bacillus subtilis and Staphylococcus aureus) and two Gram-negative (Escherichia coli and Serratia marcescens) bacteria. According to the results obtained by this experiment, it was clearly indicated that all pathogenic bacteria were suppressed in a dosage-dependent way. Nevertheless, the examined strains of B. subtilis, S. aureus, S. marescenes, and E. coli showed a reduction in the inhibitory impact of pullulan-stabilized NPs [128].

Pullulan-mediated NPs showed notable effectiveness against foodborne and multidrug-resistant bacteria along with common infectious microorganism. Pullulan biopolymer was used with AgNPs, which then tested for antibacterial, antifungal, and antibiofilm properties in vitro [136]. These NPs, which ranged in size from 2 to 40 nm, possessed a rod-like shape and a hexagonal shape. Their antibacterial activity was tested against infectious agents, i.e., responsible for foodborne illnesses and are drug-resistant, including E. coli, Klebsiella pneumoniae, Pseudomonas aeruginosa, and L. monocytogenes. They were also tested for their antifungal and antibiofilm properties against pathogenic organisms that form biofilms, including E. coli, Bacillus cereus, L. monocytogenes, and P. aeruginosa.

According to the findings, P. aeruginosa, K. pneumoniae, and E. coli are the three pathogenic bacteria that are most sensitive to AgNPs. Contrarily, L. monocytogenes, a pathogen found in food has been shown to be less sensitive to biogenic AgNPs. Both fungal pathogens were discovered to be sensitive to AgNPs in a way, i.e., dose-dependent with regard to antifungal action. Additionally, beneficial behaviors against all biofilm microorganisms have been observed [136]. The formation of AgNPs has also been explored with pullulan produced from the fungus Aureobasidium mangrovei, which was isolated from Oman. Additionally, the antibacterial and antifungal properties of the resulting pullulan-AgNPs were also assessed towards bacteria including E. coli, S. aureus, B. cereus, and P. aeruginosa as well as fungi including Curvularia lunata and Fusarium incarnatum.

All investigated bacteria and fungi responded well to the ability of pullulan-mediated silver nanoparticles to limit their growth [137]. The previous findings of many authors revealed that Gram-negative bacteria are more susceptible to pullulan-capped AgNPs than Gram-positive bacteria, i.e., generally described in terms of distinctions between the cell wall compositions of both bacteria [136, 138]. As Gram-positive bacteria are made up of a thicker three-dimensional peptidoglycan layer than Gram-negative bacteria. In this way, the peptidoglycan layer prevents AgNPs from penetrating Gram-positive bacteria [139].

The previous studies regarding the antibacterial activity of pullulan-stabilized NPs are in conflict [128, 136]. The physical and chemical characteristics of NPs, such as size, shape, and surface charge, may represent the primary cause of the variation in AgNPs' action on the two types of bacteria [140, 141]. When comparing three different shapes of AgNPs such as spherical, rod-shaped, and truncated triangular, it was found that the latter truncated triangular had the strongest antibacterial properties [142]. But most recently, it was revealed that spherical AgNPs had the highest antibacterial activity in the inhibitory zone, followed by disk AgNPs and triangular plate AgNPs [143]. The pullulan-stabilized AgNPs produced in the two investigations mentioned above have also multiple forms [144].

AgNPs' antibacterial properties result in the release of Ag ions [Ag +] from the NPs [Ag°]. Because of this, the surface area of NPs which is determined by their shape depends on the number of Ag ions they discharge [143]. Pullulan is regarded as a biopolymer substance for the production of Ag NPs to enhance the reduction mechanism excluding the use of accelerating, reducing, or complexing agents. Pullulans polysaccharide structure is also thought to increase its antibacterial properties by surrounding Ag-NPs, resulting in more stable, uniform, and monodisperse NPs. Furthermore, the particle size can be adjusted to the appropriate size by adding capping agents like polymers, which include pullulan [132].

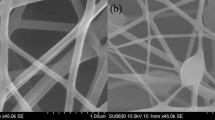

It has been noted that the pullulan polymer works as a capping and stabilising agent, causing the synthesis of stabilized pullulan-capped AgNPs after gamma irradiation, which first decreased the Ag ions [132]. AgNPs are stabilized and protected from agglomeration by the capping process. Additionally, after capping, surface-capped AgNPs exhibit improved antibacterial properties [15, 145]. These pullulan-stabilized AgNPs have a surface charge of -72 mV, making them extremely stable with little tendency to aggregate. The significant antibacterial action of these NPs for S. aureus was also mentioned in the reports [132]. Similar to this, a nanocomposite thin film synthesized from transparent pullulan and AgNPs was assessed for its effectiveness against A. niger [146]. On observation, disruptive effects on conidia following this interaction were clearly seen in the scanning electron microscopic analysis of A. niger conidia after treatment with this pullulan nanocomposite film. These results imply that conidial damages may be linked to cell wall breakdown and eventual cytoplasmic leakage, which results in cell death [146].

Additionally, it has been noticed that the cell disruption process is dependent on the AgNP concentration in the film; the greater the concentration, the greater the cell disruption observed.

The aforementioned research demonstrates that pullulan-based NPs have significant antibacterial capability against a variety of microbial diseases, among which multidrug-resistant and biofilm-forming organisms [15].

Pullulan nanocomposites

Pullulan showed a potential application in food packaging and biomedical applications. However, pure pullulan films have significant disadvantages regarding their low physical and chemical properties such as brittleness and antimicrobial properties. In the food sector, designing pullulan-derived blends and composite films is the best way to get beyond these inherent restrictions. Thus, it acquires multipurpose packaging solutions that enhance the safety of food, preservation time, and quality. Moreover, combining nanoparticles with biopolymer has drawn interest as a way to modify biopolymers [147, 148]. When compared to traditional micro composites, the high surface area and uniform dispersion of the nanoparticles in the polymeric matrix produce exceptional qualities [148, 149]. However, because of their strong antibacterial and antioxidant properties, natural essential oils are a viable option for creating innovative packaging materials that will extend the period of storage of food items [150]. A derivative of pullulan showed enhanced mechanical properties.

Pullulan’s mechanical properties can be improved by carboxymethylation and periodate oxidation, which in turn improve the efficiency of nanocomposite materials. The process of carboxymethylation requires adding carboxylate or carboxymethyl chitosan to the chemical makeup of pullulan. As illustrated in Fig. 3, carboxymethylated pullulan can be made by reacting pullulan with isopropyl alcohol and sodium chloroacetate. As an outcome, pullulan's structure acquires carboxylate groups [11, 151].

The mechanical durability of pullulan is also improved by periodic oxidation. Pullulan's compatibility with blood and biodegradation properties have led to its selection as a carrier. Nevertheless, there is no functional group in the pullulan structure that can transport the macromolecular product. Pullulan's interaction with sodium periodate that adds an aldehyde group is known as "periodate oxidation of pullulan." The polysaccharide directly couples with the drug upon the addition of the aldehyde group, making it an appropriate transporter [25].

Pullulan has been combined with different functional agents like sakacin-A [152], thymol [153, 154], silver nanoparticles [131, 155], essential oils and nanoparticles [150, 155, 156], lysozyme [157], cholinium carboxylate ionic liquids [158], graphene oxide [159], bacterial cellulose [160, 161], nanofibrillated cellulose [162, 163], and gelatine [103]. Due to the interaction of the different individual components, either chemically or physically, it enhances the films' mechanical properties [148] or provides their bioactivity, especially antibacterial properties [158].

Additionally, silicon oxide was used to create nano-SiO2 (NS), an amorphous powder that exhibits a tridimensional structure, using the SiO(2-x) formulation, where x ranges between 0.4 and 0.8 [148]. Because of its remarkable properties such as its small size, high surface energy, wide specific surface area, unsaturated chemical bonds, and hydroxyl group on the surface, NS is easily dispersed across polymer matrices and is increasingly being used as a nanofiller in nanocomposites [148]. SiO2 is the primary component of sand in various world regions [164]. Nearly every NP exhibits a few negative impacts on the human body. However, there is little worry regarding NS's eco-pollution [148, 164].

Pullulan was utilized to create a nanocomposite bone scaffold. Ag-silica Janus particles (Ag-silica JPs) are a nano-platform, exhibiting a ball-stick morphology. Ag-silica JPs and pullulan were combined to create a nanocomposite scaffold that had improved mechanical and biological characteristics. The synergistic capabilities of Ag and silica’s antibacterial and bioactive activities were obtained by synthesizing Ag-silica JPs using a one-step sol–gel technique [165].

Utilizing polysaccharide-based nanofillers is a good way to create bio-nanocomposite films. These films are far better suited to applications such as surface hydrophobicity, mechanical strength, and barrier than pure biopolymer coatings. This study examined the effects of starch nanocrystals derived from waxy rice starch (WSNC) and native starch (NSNC) on the physical–chemical characteristics of pullulan-based nanocomposite films and the successful maintenance of fresh beef [166].

Chitosan-pullulan-silver-nanocomposite (CSPN) films is a novel model drug moxifloxacin (Mox) loaded ternary nanocomposite. This was effectively created employing traditional solvent casting of an aqueous composite solution. Pullulan and chitosan, two polysaccharides, were used as reducing, capping, or stabilizing agents in ternary nanocomposites. Both were shown to be a potential carrier system for Mox and AgNPs. The produced films known as ternary nanocomposite (CSPN) showed antibacterial effectiveness. Thus, it may be used successfully in tissue engineering, drug delivery, scaffolding for skin conditions, wound healing, and other medical uses [167].

Pullulan nanoformulation

Drugs are delivered at a predefined rate through sustained-release drug delivery nanoplatforms. This keeps the delivery of drug dosage steady for a predetermined rate of time while minimizing adverse reactions. Sustained-release drug delivery nanomaterials can be classified into several types. First is the lipid-based nanoplatforms (including nanostructured lipid carriers, solid lipid nanoparticles, cubosomes, microemulsion, and liposomes). Second is the polymer-based nanoplatforms (dendrimers, polymeric nanocarriers micelles, hydrogels); metallic nanocarriers (superparamagnetic nanocarriers, silver, and gold-based nanocarriers); carbon-based nanoplatforms (fullerenes, carbon nanotubes, nanodiamond); nanoplatforms derived from cells or biomimetic ones (exosomes, virus-based nanocarriers). Third is the protein-based nanoplatforms (zein and albumin nanoparticles) [125].

Biodegradable polymeric nanosystems are now becoming one of the most interesting drug/gene delivery systems and anticoagulants. Pullulan is a type of biopolymer known to be both extremely biocompatible and biodegradable. Due to their special ability to self-assemble into core–shell structured NPs, they are, therefore, frequently employed in these nanoformulations [168]. Since NPs can greatly minimize drug adverse reactions and increase the efficiency of drugs, targeted therapy using NPs has gained attention in the treatment of cancers [169]. Its blood compatibility and biodegradation features make it suitable to be utilized as a carrier for macromolecules. However, there is no functional group in the pullulan structure that can transport the macromolecular product. Moreover, it is a hydrophilic polymer that dissolves in water, which makes it challenging to encapsulate charged and hydrophobic proteins [170]. Thus, its low stability, hydrophilic nature, and lack of functional groups are the major challenges limiting the application of the delivery system. These three bottlenecks remarkably affect the in vivo release and bioavailability of the drugs [168].

Pullulan stability and hydrophilicity can be modified by means of succinylation, cholesterol integration, and urethane derivatization and employed as a stabilizing agent. To address this problem, pullulan was modified to carry hydrophobic or charged regions. Through a reaction with negatively charged succinic anhydride (acetic, propionic, and butyric anhydrides), succinylation triggers the integration of the carboxylic group into pullulan. It results in the formation of pullulan acetate (PLAc), pullulan propionate (PLPr), and pullulan butylate (PLBu). This renders pullulan suitable for the transport of positively charged proteins in drugs [11, 171]. As illustrated in Fig. 4, when 4-dimethylaminopyridine (DMSO) is present as a catalyst, succinylation takes place for 24 h at 40 °C.

In pullulan, C-6 acts as the chosen location for succinic anhydride. It is necessary for N, N′-carbonyldiimidazol to activate the COOH group in succinylated pullulan. The amine and the resultant derivative can be linked [170]. SPA (succinylated pullulan acetate) was used to create a microsphere for the transportation of protein. The double emulsion approach was used for loading lysozyme (Lys) as a model protein drug into the microsphere, replacing PLGA [poly (dl-lactic acid-co-glycolic acid)] with SPA. As a result, extended stability of proteins and three times greater protein loading capacity were observed.

Cholesterol content modification is another method to improve the long-term viability of the pullulan nanoformulation. Pullulan integrated cholesterol as a hydrophobic group. Pullulan which had been treated with cholesterol was used to create an epirubicin self-assembled nanoparticle. To do this, a hydrophobic component, like long carbon chains or cholesterol groups, must modify pullulan [172]. An amphiphilic polymer will be produced as a result of this. This can be used to create the NP that self-assembles. Pullulan with a hydrophobic group is made by attaching the cholesterol group to pullulan using alkylenediamine and monochloroacetate as depicted in Fig. 5.

Cholesterol-modified nanoparticles demonstrated improved drug stability with an extended half-life, increased blood plasma concentration, and relatively low toxicological effects for drugs [172]. To load the drug mitoxantrone (MTO), an additional NP was developed utilizing pullulan conjugated with cholesterol. The chosen drug has a lot of negative consequences because it is not specific to cancers. Targeted administration of the drug improved stability, permeability, retention impact, effectiveness, and decreased drug update by normal tissues. These were the outcomes of loading MTO in cholesterol-modified pullulan NP. Human serum albumin (HAS) was added again to the MTO-CHP NP, which stabilized the release of the drug by decreasing the rate of drug distribution in acidic environment [173].

Yuan and coworkers [174] worked on cholesterol content modification of pullulan and synthesized three kinds of pullulan NP polymers by the dialysis method. These three pullulans were called CH-modified animated pullulan (CHAP), CH-modified carboxylated pullulan (CHSP), and cholesteric hydrophobically (CH)-modified pullulan (CHP). This demonstrated the interaction between HSA protein and the various surface elements of NPs. When polymers have the same degree of cholesterol substitution, the number of charge groups changes the size of NPs. The quantity and kind of charge of nanomaterials were strongly correlated with their size, charge, drug loading characteristics, interaction with HSA, and drug release. With greater amino substitutions, CHAP NPs comprised the largest, followed by CHSP NPs in the next place, and CHP NPs in the last place, all having a similar level of hydrophobicity alteration. The properties like the binding constant, the delayed drug release, and the HSA coverage all depended on the size and surface charge of the NPs. CHP NPs exhibited the maximum coverage, while the positively charged CHAP binding constant remained the strongest, indicating the quickest drug release. The drug release of NPs was further delayed by the addition of HSA. The slowest rate of drug release was observed when CHAP NPs adsorbed HSA.

In addition to the first two pullulan derivatives, the pullulan urethane derivative seeks to improve the nanoformulations' thermostability [1, 175]. The synthesis of urethane derivative improves pullulan's solubility in a wide range of organic solvents, water resistance, and thermostability [176]. The preparation involves reacting pullulan with either hexyl or phenyl isocyanate (HIC), which introduces N-phenyl urethane or N-hexyl urethane groups into the pullulan structure. The insertion of PIC and HIC modifies pullulan’s features in different ways. For example, adding more PIC causes pullulan’s tensile strength and glass transition temperature to drop. Pullulan becomes more soluble in ethanol when PI is added, whereas it becomes more soluble in acetone and H2O when HI is added [11, 175].

Opportunities of pullulan nanopolymer

The pullulan production from agro-food processing waste has been one of the exciting approaches to managing piles of an organic-rich substrate with the production of value-added products such as nanoparticles/composites/hydrogels [177]. Pullulan nanopolymer films are superior to conventional food packaging with increased antimicrobial activity, physico-chemical properties that increase their durability.

Furthermore, integration of other NPs with pullulan polymer would be a ground-breaking technique by shrinking the edible film particles' size to the nanometre (nm) range [178]. It enhanced the film's physicochemical strength, food bioavailability, taste, texture, and consistency, achieved through modification of particle size, possible cluster formation, and surface charge of food materials [179]. This section summarizes the application of pullulan nanopolymer in the form of nanoparticle/nanocomposites/nanoformulation in different sector.

Pullulan nanocomposite in agriculture and food

As a packaging agent

Packaging is described as a vital tool for storing food products for a prolonged duration of time without spoiling while maintaining their original, chemical, and sensory attributes [180]. Agricultural products (seeds and crops) and food products (vegetables and foods) are protected by the packaging to avoid impurities, dirt, microbes, and chemicals. The application of non-biodegradable petroleum-derived packaging for post-harvested horticulture products is extremely hazardous to the health of humans and the environment. Thus, the use of natural biodegradable packaging materials for agro-food packaging has received particular attention. Due to its water-soluble, non-toxic, and non-mutagenic edible properties, experts think pullulan may prove a viable polymer for their application in this scenario. Primarily because of its superior film-forming and adhesion qualities, this biopolymer can create edible films or coatings for a variety of foodstuffs [181].

A lot of emphasis has recently been focused on the production of edible films carrying antimicrobial chemicals as a successful method to increase the period of storage of fruits and vegetables and limit the possibility of spoilage by pathogens. Approximately one-third of conventionally grown crops suffer destruction, mostly as a result of infestations of insects, harm from microbes, extreme weather, poor soil performance, and a lack of available nutrients. To solve these problems, we urgently need more advanced technology. In this way, the agro-technological revolution, i.e., about to change the current agricultural system while ensuring food security has been made possible in part by nanotechnology. As a result, NPs are evolving into cutting-edge materials, so they will change the way of contemporary agriculture. The United States Department of Agriculture-USDA first placed up a "roadmap" for the use of nanotechnology utilization in the areas of agriculture and food in December 2002 [182].

Considering the potential for the creation of biodegradable polymers, nanocomposites are opening up new avenues for investigation. Polymer-silicate nanocomposites were found to have better properties, including high thermal stability, durability, and enhanced gas barrier capabilities [183]. AgNPs were combined with petroleum-derived polymers like PVC (polyvinyl chloride), PE (polyethylene), and PET (polyethylene terephthalate) to provide a more opulent material for packaging. AgNPs are extremely effective against a variety of microorganisms, such as bacteria, viruses, and fungi, along with enhancing packaging protection [184,185,186].