Abstract

In oil recovery processes, fluids injected to increase oil production may find preferential paths or fractured rocks that offer less resistance to passage through the reservoir, leaving many areas of the reservoir without being swept and consequently reducing the oil recovery efficiency, increasing water production compared to oil production. Conformance control technique can be applied to avoid these problems and then redirect the injected fluids to the segments that were previously not being reached. The preformed particle gels (PPG) have been evaluated for this application, which were obtained from precursor hydrogels and injected into oil reservoirs in the form of brine suspensions. In this study, an evaluation was conducted on the thermal, rheological, morphological, stability, and swelling properties of partially hydrolyzed polyacrylamide (PHPA) crosslinked with polyethyleneimine (PEI) PPG. Another study of this work was the evaluation of gel-breaker systems based on ammonium persulfate and sodium hypochlorite, which can be used to solve eventual operational problems arising from obstructions in the PPG application. The results indicated that the optimal chemical composition of the precursors consisted of 1.0% partially hydrolyzed polyacrylamide (PHPA) crosslinked with 3.0% polyethyleneimine (PEI). This combination exhibited higher material strength and swelling capacity, exceeding 20 times its initial mass. The ammonium persulphate proved to be a powerful gel-breaker, causing reductions in elastic modulus by as much as 97%, alongside causing structural damage that was confirmed by scanning electron microscopy (SEM).

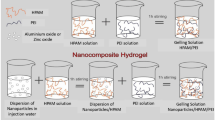

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Oil production can be carried out through various operational processes applied to on-shore and offshore fields. The aim of oil recovery techniques is always to increase oil production and extend the lifespan of producing fields. There are three types of oil recovery processes: primary recovery, secondary recovery, and enhanced recovery. These techniques, especially secondary and enhanced recovery, operate by injecting fluids according to the specific needs of the production line, using saline water, gases such as CO2, chemical and biological additives [1,2,3].

Nonetheless, despite the application of the cited techniques, oil production may decline owing to severe production conditions. One issue may arise from the interaction between the injection fluid and the rock, leading to irregularly distributed damage in the formation zones, consequently impacting properties such as permeability, which can vary significantly [4, 5]. Reservoirs containing fractures or highly permeable zones typically offer preferential pathways through which injected fluids flow, leaving significant portions of the reservoir not swept. Consequently, this results in the failure to sweep the oil present in these areas of the reservoir [6]. As a result, there is an excessive increase in water production, characterizing this as a conformance problem [7, 8]. Within this context, solutions can be applied to correct these rock irregularities and optimize the injected fluid sweeping, referred to as conformance control techniques [9].

Conformance control techniques comprise the permanent or temporary modification of rock profiles. This involves the utilization of mechanical devices or chemical methods capable of restricting fluid flow within the designated region of interest [10, 11]. Mechanical devices include the use of plugs, sealers, coiled tubes, among others. The drawbacks associated with mechanical devices include their high cost, the necessity for a high pumping rate, and their limited applicability in regions close to the injection well [12].

On the other hand, chemical methods involve the use of materials with good penetrability and good blocking capacity. These properties are available in several chemical products, including resins, foams, emulsions, polymers, and gels [13]. Among the chemical methods used, polymeric cross-linked gels stand out as the most promising due to their cost-effectiveness and efficacy in controlling the permeability profile of the rock [14]. After treatment, the subsequent injected fluids go to the lower permeability sections of the reservoir, increasing oil sweep efficiency [15,16,17].

The polymeric systems used are generally composed of a hydrophilic polymer and an inorganic or organic crosslinking agent. They can be classified as in-situ gels and preformed particle gels [18, 19]. Although their function is the same, the difference is related to the application process: in situ gel components are injected and later cross-linked inside the reservoir, while PPGs are injected already in the form of a microparticulate gel and later swell in the reservoir to form the blockage [20,21,22]. The hydrogel forms crosslinked bonds of 3D networks and can absorb a large water volume due to hydrophilicity without dissolving [23, 24].

Despite the benefits of using blocking gels, it is not prudent to overlook any operational problems, such as the obstruction of lines and the blockage formation in unwanted areas. In these situations, gel breakers can be used as a solution to break down polymer gels into materials with lower viscosity and clear unwanted blockages [25]. The most common gel-breakers are composed of enzymes [26], hypochlorites, peroxides [27], persulfates [28] and inorganic acids [29]. Oxidants can chemically fragment the polymer structure and thus make the system less viscous and easier to drain by breaking down the carbon structure, leading to chain scission [30]. The polymer chain's remaining fragments are likely to contain ketone, aldehyde, carboxylate, and carbonyl groups [31].

Gilbert et al. [32] related that the degradation of polyacrylamide by peroxides was proportional to the content applied, reporting a viscosity reduction of about 65% for peroxide concentrations of 96.9 mM. Imqam et al. [29] showed that HCl removed the polyacrylamide gel effectively. Carman [33] suggested that the persulfate oxidizers perform better than organic peroxides as polyacrylamide gel-breakers.

In this work, a polymeric system was developed with potential application in conformance control. Hydrophilic polymers derived from polyacrylamide cross-linked with polyethyleneimine were used to form the hydrogel. This product was tested in pre-formed particle form under salinity and reservoir temperature conditions. Finally, the innovative solutions composed of ammonium persulphate ((NH4)2S2O8) or sodium hypochlorite (NaClO) were tested as chemical substances with gel-breaking potential and then tested against the breakability of the polyacrylamide-formed gels.

Experimental

Materials

Partially hydrolyzed polyacrylamide with molar mass 4.8 × 106 g/mol (FP 3130S) and hydrolysis degree between 25 and 30% was provided by SNF Floerger (São Paulo, Brazil). Branched polyethyleneimine with weight average molar mass (Mw) of 25.000 g/mol, purchased from Sigma-Aldrich (São Paulo, Brazil), was used as an organic crosslinker. The brine solution used in the swelling test had the following salt composition: NaCl (27.870 mg/L), KCl (717 mg/L), CaCl2 (429 mg/L) and MgCl26H2O (924 mg/L), purchased from Sigma-Aldrich. The oxidizing substances tested were ammonium persulfate and sodium hypochlorite 10% w/v, obtained from Sigma-Aldrich. All chemicals were used as received. De-ionized water was used to prepare solutions.

Determination of hydrogel composition

A “design of experiments” (DOE) was used to identify the best PHPA and PEI concentrations to form a hydrogel with suitable properties for application. A central composite rotational design (CCRD) was performed to evaluate the influence of PHPA concentration and PEI crosslinker concentration over Sydansk gel strength code of the hydrogel, the hydrogels storage modulus (G') (obtained by rheological analyses) and the dry mass of hydrogel after the freeze-drying step. In total, 11 experiments were performed, and the statistical data was analyzed with the aid of Minitab Statistical Software. DOE allowed the study and evaluation of complex relationships between the input variables over response variables, and the 11 experiments were composed of four factorial points, four axial points, and three central points [6].

Table 1 demonstrates the polymer concentrations proposed in this statistical study. These concentrations and crosslinking reaction time were based on a previous work, where a preliminary study of the influence of concentration and preparation of polymer composites had been carried out [7]. To conduct the tests, stock solutions of the PHPA polymer were prepared with a concentration of 1.5% w/v, while the PEI crosslinker stock solution was prepared with a concentration of 20% w/v. The solutions were prepared at room temperature with magnetic stirring for 72 h to facilitate the solubilization of the polymers. The hydrogels were formed by dispersing the PEI solution into the PHPA solution, followed by continuous magnetic stirring for 1 h. Subsequently, the mixture was heated in an oven at 70 °C for 48 h to induce crosslinking reactions.

Sydansk gel strength code

The Sydansk gel strength code evaluation is a semi-quantitative method used to monitor the performance of the formed gel. It is a practical and widely utilized approach for the development of hydrogels applied in conformance control [34]. The procedure consisted of preparing 20 mL of hydrogels with the concentrations specified in Table 1. The bottles were sealed and then placed in an oven set at 70 °C for 48 h. The testing procedure consisted of rotating the vials containing the gel formulations by 180° and assigning a gel strength code (ranging from A to I) based on the way the sample flowed inside the vial [7].

Rheological analysis

The rheological behavior of the hydrogels was assessed after 48 h of aging at 70 °C using an oscillatory shear test, with shear stress ranging from 0.01 to 100 Pa at a constant frequency of 0.1 Hz, to determine the region of linear viscoelasticity. In this region, the storage modulus (G') and loss modulus (G") remain independent of the stress variation because the material’s structure is also preserved. Subsequently, an oscillation frequency sweep was conducted from 0.01 to 100 Hz (with a fixed strain) to gather information about the microstructure of the hydrogels and to monitor the values of G' and G''. The tests were conducted using the TA Instruments Discovery Hybrid Rheometer (DHR3), equipped with a 40-mm titanium cone-plate accessory.

Obtaining and testing preformed particle gels

The smaller particles of the polymeric gels were obtained by dehydration and grinding. The systems were submitted to a freezing process followed by 72 h of freeze-drying. Subsequently, they were grounded in an analytical mill until the achievement of micrometric particles. The methodologies employed to assess the preformed particle gels will be detailed in the following sections.

PPG swellability test

The measurements of maximum PPG swelling capacity were performed to determine the ability to swell and obstruct high permeability pathways. The test was performed at reservoir temperature and salinity conditions and determined by immersing the dried particles in an aqueous phase, which could be de-ionized water or brine (whose composition is described in Table 2). The brine composition is equivalent to “desulfurized seawater”, usually used in oil fields as injection water for secondary recovery or as fluid for additives injection in enhanced oil recovery.

Subsequently, 0.1 g of dried PPG was added into a flask containing 10 mL of de-ionized water or brine, and the mixture was stirred for 1 h. After stirring, the dispersion was allowed to settle for 24 h at a temperature of 70 °C. The remaining water was separated from the swollen particles through vacuum filtration using a 70 mm paper filter. Finally, the swelling ratio (Sr) was determined by applying Eq. 1:

where,

Sr: swelling ratio (g/g).

Ms: dry PPG mass (g).

Mi: swollen PPG mass (g).

PPG rheological analysis

Rheological tests were performed with the 1% w/v suspensions of preformed particles in brine after 24 h of aging at 70 °C. Initially, shear stress variation from 0.01 to 100 Pa at a constant frequency of 0.1 Hz was used to determine the linear viscoelasticity region. Then, oscillation frequency sweeps were made from 0.01 to 1 Hz (fixing the strain) to monitor the G' and G'' values.

Scanning electron microscopy (SEM)

The sample was fixed with conductive adhesives on the sample holder and coated with gold in a BAL-TEC sputter coater, model SCD 005, making them conductive and suitable for this type of microscopy. The analyses were performed with a 10 keV electron acceleration voltage, primary and secondary electron detector, and with magnification to max. 5000 times in a TESCAN electron microscope.

Development and evaluation of polymeric gel breakers

The selection of chemicals suitable for breaking and degrading polymer gels was based on the literature and the availability of reagents. Oxidizing agents, particularly persulfates and hypochlorites, were found to be extensively utilized for this purpose [28,29,30]. Thus, sodium hypochlorite and ammonium persulfate were chosen for the study of gel-breakers. The gel-breaker solution was obtained in 10% w/v aqueous solution form for hypochlorite and in pure powder form for ammonium persulfate. The influence of sodium hypochlorite and ammonium persulfate concentration on the degradation of suspensions with PPG was studied. The gel-breaker solution concentrations are presented in Table 3. For solution preparation, commercial sodium hypochlorite was diluted to lower concentrations. Ammonium persulfate was prepared by weighing the material with subsequent magnetic stirring until the salt was completely solubilized in distilled water.

Suspensions of 20 mL of PPG at 10% w/v concentration were prepared in synthetic brine. Gel-breakers solutions were added to the flasks containing these suspensions in 0.5 mL volume and followed by constant stirring for 20 min. Later, the systems were placed in an oven at 70 °C for a period of 24 h. The degradation was evaluated by rheological analysis in oscillatory shear, as described previously, comparing the gel strength before and after degradation.

Results and discussion

Experimental design of hydrogel precursor concentrations

In this step, the characterizations of the PPG precursor hydrogels were produced. Through DOE, the aim was to evaluate the variation of polymer and crosslinker concentrations (input variables) in desired responses, which were: (i) Sydansk gel strength code; (ii) modulus of elasticity (G’)—measured by rheological analysis and (iii) dry gel mass. Table 4 shows the results applied in DOE for each composition. To evaluate the gel strength using the Sydansk code, each code was represented by a numerical value, called an input code. Values between 1 and 9 were assigned, with 1 being the first code (A) and 9 being the last code (I).

Central composite rotational designs have enough degrees of freedom to make it possible to use quadratic models to try to fit the experimental responses. Thus, a generic quadratic model can be described by Eq. 2:

Y = β0 + β1X1 + β11X12 + β2X2 + β22X22 + β12X1X2 + ε .(2)

where,

Y: output variable (Sydansk code (input), elastic modulus value or dry gel mass).

β0: constant of the model.

X1: linear term of polymer concentration (% w/v).

β1: coefficient associated with variable X1 (polymer concentration).

X2: linear term of crosslinker concentration (% w/v).

β2: coefficient of the model associated with variable X2 (crosslinker concentration).

X1X2: polymer and crosslinker interaction term.

β12: coefficient associated with interaction term.

X12: quadratic term of polymer concentration (% w/v).

β11: coefficient associated with quadratic term X12 (polymer concentration).

X22: quadratic term of crosslinker concentration (% w/v).

β22: coefficient associated with quadratic term X22 (crosslinker concentration).

ε: experimental error.

The significance level α considered for this work was 5%. Therefore, terms that present p-values < 0.05 show significance and will be considered in the final model, while terms with p-values above 0.05 could show no significance and will be removed from the final model.

Sydansk code

Figure 1 shows the appearance of the gels obtained after a gelation period of 48 h at 70 °C. Table 5 presents the statistical results of the influence of polymer and crosslinker concentration on the strength of the gels.

A p-value of 0.425 was observed for the term X1X2, above the significance level (α = 0.05). The interaction term X1X2 was removed, and a new analysis of responses was carried out, obtaining values within the significance level range (final p-value). Those results that present p > 0.05 are highlighted in red in the table. The determination coefficient R2 values show that the proposed model explains 98.03% of the variability of response experimental data obtained.

The most significant and positive effects were observed for the linear term of polymer (X1) and linear term of crosslinker (X2) concentrations. This implies that an increase in the concentrations of these components led to a favorable enhancement of the response (Sydansk code), with X1 showing greater relevance. Another noteworthy observation is the negative effects associated with quadratic variables. This phenomenon can be attributed to the gel crosslinking process.

According to Adewunmi [35], the crosslinking mechanism between polymers containing the acrylamide group in the structure occurs through the nucleophilic attack of nitrogen electrons present in PEI on the polyacrylamide carbonyl group, characterizing a transamidation reaction.

The positive effects can be explained by considering that increasing the concentrations of precursors provides more active sites for the formation of crosslinks [36]. On the other hand, interactions between PHPA molecules and between PEI molecules are not favorable for increasing gel strength when compared to interactions between PHPA and PEI, which explains the negative effects.

As a way of testing the obtained model, a system named “prediction” (Fig. 2) was used, consisting of FP 3130S with polymer and crosslinker contents of 1.0% w/v and 1.5% w/v, respectively. Equation 3 governing this experimental setup is provided below:

Sydansk code = – 7.20 + 14.94X1 + 5.936X2 – 6.64X12 – 1.063X22 .(3)

where,

X1: PHPA concentration (% w/v).

X2: crosslinker concentration (% w/v).

By applying the concentrations from the “prediction” sample to the predictive model obtained, a value of 8.036 was achieved. This response can be correlated with the H and I codes, as these codes were assigned numbers, with H being 8 and I being 9. Therefore, the use of the model for prediction was successful with the tested sample.

Rheology

To evaluate the systems of the DOE by rheology in oscillatory shear, it was necessary to determine the strain rate to be used for the frequency sweep tests. Therefore, the linear viscoelastic region was determined, which corresponds to the strain range where the viscoelastic properties (G' and G'') are independent of the strain variation and the structure of the material is preserved. A system with intermediate composition was chosen among the concentrations that were used in the study, corresponding to the conditions of the central point, with 0.6% w/v of PHPA and 2.0% w/v of PEI. It is important to note that for this test, the polymer was used after being aged for 3 days at 70 °C. The frequency of 0.1 Hz was used to determine linear viscoelastic strain in the rheological test. Figure 3 shows the elastic and viscous modulus values of the material plotted against strain (%), with the strain varying within a range from 0.5% to 5000%.

The results indicated that the modulus remained linear up to a strain close to 100%. Therefore, we considered the region of linear viscoelasticity within the strain range between 0.5% and 100%, which is highlighted in Fig. 3. Values higher than 100% showed that the applied deformation could damage the three-dimensional structure of the gel, causing it to become unstable. Therefore, a strain of 1% was selected to conduct the frequency sweep analyses of the DOE study, ensuring that the destruction of gel structures did not occur for each composition studied.

Figure 4 provides a summary of the elastic modulus values for each composition, obtained from the oscillatory shear curves utilizing a 1% strain and frequency sweep ranging from 0.01 to 100 Hz. To demonstrate the results more clearly, a frequency of 1 Hz was used to plot the bar graph. The legends of the samples were created with intuitive nomenclatures to the polymer (P) and crosslinker (C) concentrations.

A straight line was drawn at 20 Pa storage modulus to more easily identify the systems that presented the highest G' values, which were: (4) 1P–3R; (6) 1.17P–2C and (8) 0.6P–3.41C. Based on the DOE input variables and the experimental responses obtained from G', the main effects and the interaction between these two factors, the respective standard errors, the p-value associated with each term and the coefficient of determination R2 were calculated. A significance level (α = 0.05) was considered for statistical analysis. These results are shown in Table 6.

The initial effect analysis evaluated the model considering all terms (variables). However, the p-value values for quadratic terms X12 (0.803) and X22 (0.380) were above the significance level, showing no statistical significance for the overall model. Therefore, the quadratic terms were removed, and a new effect analysis was performed, maintaining the terms with p-values within the range of the significance level. The results showing p > 0.05 (no statistical significance) are highlighted in red in the table. The coefficient of determination R2 values showed that the proposed model explains 98.48% of the variability of experimental responses obtained.

The most significant and positive effects are polymer concentration (X1) and crosslinker concentration (X2). Increasing the concentrations of these components favored the improvement of the storage modulus response, being more remarkable for polymer concentration (X1). With the increasing in concentration of the precursors, the active sites to form the crosslinker were increased and, consequently, more crosslinks were formed in the systems. These bonds were able to withstand the shear stress imposed in the rheological analyses, accentuating the storage modulus observed.

Through the triplicates performed in the central points, the lack of fit (F-value) was determined. As the F-value was not significant (greater than significance level α = 0.05), the model presented no lack of fit and was considered adjusted. Thus, predictive equations of the storage modulus responses as a function of the input variables were obtained. The sample designated as “prediction” consisted of polymer and crosslinker contents of 1.0% w/v and 1.5% w/v, respectively. It was subjected to testing in the fitted model, as depicted in Eq. 4 below:

G' (Pa) = 2.60 + 0.11 X1–1.11 X2 + 11.87 X1X2 . (4)

where,

X1: PHPA concentration (% w/v).

X2: crosslinker concentration (% w/v).

By inputting the concentrations of the "prediction" sample into Eq. 4, the predicted storage modulus output value was 18.85 Pa. This result closely matched the actual response obtained from the analysis, which was 19.13 Pa, as illustrated in Fig. 4. Therefore, the model demonstrated efficiency in predicting the response for the tested sample, as depicted in Fig. 5.

Gel mass

The dry gel mass was considered a relevant response for the DOE due to the necessity of obtaining enough material for the preparation of PPGs. The mass of dry gel obtained after the freeze-drying step is presented in Table 4. Table 7 shows the information obtained from the DOE with the dry gel mass as the response.

The initial analysis evaluated the effects of the model considering all terms of the generic quadratic model. However, the p-values for the interaction term between the precursors were above the significance level (α = 0.05). As performed in the previous DOE, the terms with no statistical significance were removed from the model and a new effect analysis was performed, obtaining terms with p-values within the range of the significance level. The results above p > 0.05 (no statistical significance) are highlighted in red in Table 7. The coefficient of determination R2 shows that the proposed model explains 96.13% of the variability of the experimental data collected.

Table 7 suggests that the linear variables positively influenced the increase of dry gel mass. This fact may be associated with the crosslinking reaction, which is associated with the formation of a three-dimensional polymeric network and, consequently, showing higher gel formation. Another potential explanation lies in the masses of the polymers introduced into the flask for the crosslinking reaction. Even if these precursors do not actively engage in the reaction, they may contribute for the final mass response.

The model showed no lack of fit, as F-value is above the significance level, and the model was considered fitted. Therefore, the predictive equation for the dry gel mass response was tested. As before, the system composed of 1.0P–1.5C was tested. Equation 5 shows the predictive model obtained from the DOE for dry gel mass:

Dry gel mass (g) = – 0.5089 + 0.88 X1 + 0.493 X2 − 0.57 X12 – 0.086 X22 . (5)

where,

X1: PHPA concentration (% w/v).

X2: crosslinker concentration (% w/v).

When the sample concentrations are applied to the predictive equation of dry gel mass model, a predicted response of 0.347 g is obtained. The experimental value obtained was 0.293 g. The divergence of the values can be explained by the experimental conditions during the weighing process.

Preformed particle gels

The responses evaluated in the “Design of Experiments (DOE)” were optimized by increasing the concentrations of polymer and crosslinker, reaching the maximum values of 1.0% w/v for polymer concentration and 3.0% w/v for crosslinker concentration, under conditions suitable for advancing to the subsequent stages of the study.

Particle swelling capacity test

The swelling ratio of the dried PPGs was assessed upon contact with either brine (Table 3) or distilled water, at a concentration of 1% w/v (dry PPG). Figure 6 presents a photograph depicting the dried PPG 1.0P–3.0C sample alongside the same sample swollen in distilled water following a 24-h aging period at room temperature.

Initially, the influence of the crosslinker concentration on the swelling ratio of these particles was evaluated. Therefore, dry PPGs obtained with contents of 1%, 2%, and 3% w/v of PEI and 1% w/v of PHPA were tested. The swelling study was conducted in both distilled water and brine. The results of this test are shown in Table 8.

Some observations were obtained from this initial study:

-

i.

The increase in crosslinker concentration provided a reduction in the swelling ratio values of PPGs, both in distilled water and in brine. This may have occurred because the increase of crosslinker concentration promotes the formation of crosslink bonds, thereby forming a denser three-dimensional polymeric network. Consequently, this restricts the entrapment of water molecules within the gel structure, as illustrated in Fig. 7.

-

ii.

When in the presence of brine, the swelling ratio values of the PPGs were higher than those obtained in distilled water, especially for 2% and 3% w/v of crosslinker. As illustrated in Fig. 8, it is expected that the cations present in the brine could be leading to repulsions inside the polymeric network, due to the aversion between the positive charges present in these ions, when dissociated in solution.

Scanning electron microscopy and energy dispersive spectroscopy

Scanning electron microscopy (SEM) analysis enabled the assessment of the surface morphology of the PPG samples. The micrograph evaluation for this step is presented in Fig. 9, while the detected elements are listed in Table 9.

The micrographs showed a homogeneous three-dimensional appearance characteristic of polymeric gels, displaying a harmonious surface. The presence of the majority of elements (C, N, and O) is explained due to the molecular composition of the polymeric gels since they are formed by amide and imine groups. Moreover, a potential explanation for the presence of elements such as sodium (Na), calcium (Ca), potassium (K), and chlorine (Cl) could be contamination, as de-ionized water was utilized in the formulation of the gels.

Gel breakers

One of the main questions about the blocking gel application to treat a heterogeneous oil reservoir is what to do if the gel blocks different areas than those of interest. If this happens, a major economic problem is created for the producing company in question, as the production coming from that reservoir will be reduced. Therefore, in parallel to the development of a blocking agent for conformance control, it is of fundamental importance to develop or evaluate a gel-breaker specifically for the gel that will be applied. Even in laboratory tests involving porous media testing, having practical solutions readily available in the event of pipe blockages through which the gel flows is highly advantageous.

In this study, the efficiencies of the chemicals sodium hypochlorite (NaClO) and ammonium persulfate ((NH4)2S2O8) in breaking the developed PPGs were evaluated. The efficiency of oxidant products as polymer gel breakers has already been proven in the literature and by field tests [27, 37, 38]. The concentrations of sodium hypochlorite used were 0% (control), 1%, 3%, 5%, and 10% w/v, while that of ammonium persulfate was 0% (control), 1%, 5%, 10%, 20% and 30% w/v. The evaluated hydrogel was obtained from the dry PPG at the concentration of 1% w/v polymer and 3% w/v crosslinker. PPG was used at a concentration of 5% w/v in brine with the aim of obtaining a stronger gel (strength code I according to Sydansk evaluation). Figure 10 shows images of the samples after the 24-h aging test period at 70 °C with the two breakers.

With the use of NaClO, different aspects were observed regarding the fluidity of the gel. Even though it presented certain fluidity for all concentrations of the breaker, a larger fraction of the gel remained intact at the bottom of the bottle, or at the top of the poured bottle. On the other hand, it was observed in tests with the ammonium persulfate breaker—(NH4)2S2O8—those concentrations above 5% were sufficient to change the gel-force code and make them more fluid, with detachment from the bottom of the bottles.

Concentrations of 20% and 30% w/v drastically reduced the fluidity of the system, moving the code from I to C. To validate what was observed in the visual tests, rheological analyses were carried out to evaluate the viscoelastic behavior. Table 10 shows the elastic modulus at different concentrations of the gel-breakers at a frequency of 1 Hz.

In general, the increase in the concentration of gel-breaker products provides a reduction in the elastic modulus of gels for both gel-breakers tested. When comparing the G' in the frequency of 1 Hz the following events were noted:

-

(i)

1% and 3% w/v of NaClO: not enough to significantly reduce the elastic modulus (G') of the gels.

-

(ii)

With the NaClO breaker: the maximum G' reduction observed was around 27%.

-

(iii)

1% of (NH4)2S2O8: the lowest concentration of the breaker, efficiency in the reduction of G' was observed to be higher than that obtained with NaClO (34%).

-

(iv)

From 5% of (NH4)2S2O8 onwards: greater G' reductions were obtained at concentrations higher than 10%, reaching a G' reduction of 97% with 20% of (NH4)2S2O8.

The gel-breaking agents are chemical species that act as oxidizing agents, taking electrons from other molecules. In this way, the partial breaking of the polymeric network bonds occurs, causing the sample to lose the gel properties and increase the flowability. This result can be justified by the reduction potential (E°red) of these oxidizing products, where hypochlorite presents E°red = 0.81 V, while persulfate has E°red = 2.01 V, presenting a higher potential to reduce while oxidizes the polymeric structure of PPG.

Scanning electron microscopy

Figure 11 shows micrographs of the PPGs after 24 h in contact with the most effective gel-breaking conditions tested to reduce the elastic modulus, being (1) control, (2) PPG with 20% (NH4)2S2O8 and (3) PPG with 10% NaClO. The micrographs on the left correspond to images generated by the back-scattered electron detector, which provides a distinction of the elemental composition, while the images on the right are from the secondary electron detector, which correlates with the topography of the sample. According to the observed topography, image 1 presents an integral and harmonic surface with no structural damage, as previously reported. It is worth noting that the cracks observed in this image are from gold plating and cannot be related to structural damage. Images 2 and 3 show irregularities and damages on the surface, compared to image 1.

The SEM images do not clearly show the three-dimensionality of the structure damaged, but the rheological results of Table 10 confirm that indeed damage to the gel structures happened, which suggests polymeric network breaks down with the presence of oxidizing species.

Conclusion

The purpose of this work was to develop polymeric agents with potential applicability as sealants through preformed particle gels for application in oil reservoir conformance control. Another objective was to suggest gel-breaker agents to address any operational issues. The “Design of Experiments (DOE)” revealed promising concentrations of the hydrogels exhibiting enhanced resistance and elasticity for producing PPGs. Additionally, it indicated improved conditions for increasing the mass of the product, which is crucial for PPG production. With F-values for lack of fit greater than 5%, above significance level, the statistical models obtained from the DOE were considered adjusted. The models showed good predictability, as validated by subsequent experiments. In the swelling tests, the PPGs swelled more than 20 times in relation to their initial mass. Another relevant point was that the particles swelled more in brine, a result that is relevant and in accordance with the material application. At last, gel-breaking agents achieved reductions in elastic modulus up to 37% for sodium hypochlorite and up to 97% for ammonium persulphate at concentrations of 10% and 20% w/v, respectively. The effectiveness of breaking down PPG was confirmed by microscopic analysis, which showed damage to the morphological and chemical structure of these gels.

Data availability

No data was used for the research described in the article.

References

Lakatos I, Lakatos-Szabó J (2008) Global oil demand and role of chemical EOR methods in the 21st century. Int J Oil Gas Coal Technol 1:46–64. https://doi.org/10.1504/IJOGCT.2008.016731

Bai B, Zhou J, Yin M (2015) A comprehensive review of polyacrylamide polymer gels for conformance control. Pet Explor Dev 42:525–532. https://doi.org/10.1016/S1876-3804(15)30045-8

Aguiar KLNP, Oliveira PF, Mansur CRE (2020) A comprehensive review of in situ polymer hydrogels for conformance control of oil reservoirs. Oil Gas Sci Technol 75:1–14. https://doi.org/10.2516/ogst/2019067

Pereira ABP, Baracho CL, Oliveira PF, Mansur CRE (2023) Influence of coal fly ash on the PPG properties and plugging ability in carbonate rocks for conformance control of oil reservoirs. Geo Sci Technol 231:1–9. https://doi.org/10.1016/j.geoen.2023.212297

Chung T, Bae W, Nguyen NTB, Dang CTQ, Lee W, Jung B (2012) A review of polymer conformance treatment: a successful guideline for water control in mature fields. Energy Sources 34:122–133. https://doi.org/10.1080/15567030903567683

Wolf M, Paulino AT (2019) Full-factorial central composite rotational design for the immobilization of lactase in natural polysaccharide-based hydrogels and hydrolysis of lactose. Int J Biol Macromol 135:986–997. https://doi.org/10.1016/j.ijbiomac.2019.06.032

Pereira KAB, Pereira KAB, Oliveira PF, Mansur CRE (2020) Behavior of partially hydrolyzed polyacrylamide/polyethyleneimine reinforced with coal fly ash for preformed particle hydrogels. J Appl Polym Sci 137:1–13. https://doi.org/10.1002/app.49423

Mehrabianfar P, Malmir P, Soulgani BS, Hashemi A (2020) Study on the optimization of the performance of preformed particle gel (PPG) on the isolation of high permeable zone. J Pet Sci Eng 195:107530. https://doi.org/10.1016/j.petrol.2020.107530

Pereira KAB (2019) Desenvolvimento de hidrogéis nanocompósitos poliméricos à base de poliacrilamida e óxidos de alumínio e de zinco com potencial aplicação na melhoria de conformidade em reservatórios de petróleo [dissertation]. Federal University of Rio de Janeiro, Macromolecule Institute

Tessaroli FGC, Gomes AS, Mansur CRE (2018) Hydrogels applied for conformance-improvement treatment of oil reservoirs. Hydrogels 1:69–87. https://doi.org/10.5772/intechopen.73204

Amaral CNR, Oliveira PF, Roman IO, Mansur CRE (2020) Preformed particle gels with potential applicability for conformance control of oil reservoirs. J Appl Polym Sci 137:48554. https://doi.org/10.1002/app.48554

Alhadi AAA (2017) Evaluation of new generation of viscoelastic surfactants as diverting agents for high-temperature formations [dissertation]. Office of Graduate and Professional Studies: Texas A&M University; https://oaktrust.library.tamu.edu/handle/1969.1/165884

Aali H, Kazemi S, Larijani RS, Zarghami R, Mostouf N (2022) CFD-DEM modeling of breakage of non-spherical particles in fluidized beds. Chem Eng Res Des 189:593–605. https://doi.org/10.1016/j.cherd.2022.11.047

El-Karsani KSM, Al-Muntasheri GA, Hussein IA (2020) Polymer systems for water shutoff and profile modification: are view over the last decade. SPE J19:135–149. https://doi.org/10.2118/163100-PA

Al-Muntasheri GA (2012) Conformance control with polymer gels: what it takes to be successful. Arab J Sci Eng 37:1131–1141. https://doi.org/10.1007/s13369-012-0234-1

Bai B, Wei M, Liu Y (2013) Field and lab experience with a successful preformed particle gel conformance control technology. Soc Pet Eng 1:1–17. https://doi.org/10.2118/164511-MS

Singh R, Mahto V, Vuthaluru H (2018) Development of a novel fly ash-polyacrylamide nanocomposite gel system for improved recovery of oil from heterogeneous reservoir. J Pet Sci Eng 165:325–331. https://doi.org/10.1016/j.petrol.2018.02.038

Lenji MA, Haghshenasfard M, Sefti MV, Salehi MB, Heidari A (2018) Experimental study of swelling and rheological behavior of preformed particle gel used in water shutoff treatment. J Pet Sci Eng 169:739–747. https://doi.org/10.1016/j.petrol.2018.06.029

Aguiar KLNP, Pereira KAB, Mendes MSL, Pedroni LG, Oliveira PF, Mansur CRE (2020) Study of the modification of bentonite for the formation of nanocomposite hydrogels with potential applicability in conformance control. J Appl Polym Sci 195:107600. https://doi.org/10.1016/j.petrol.2020.107600

Imqam A, Bai B (2015) Optimizing the strength and size of preformed particle gels for better conformance control treatment. Fuel 148:178–185. https://doi.org/10.1016/j.fuel.2015.01.022

Tongwa P, Baojun B (2015) A more superior preformed particle gel with potential application for conformance control in mature oilfields. J Pet Explor Prod Technol 5:201–210. https://doi.org/10.1007/s13202-014-0136-8

Bai YR, Xiong CM, Wei FL, Li JJ, Shu Y, Liu DX (2015) Gelation study on a hydrophobically associating polymer/polyethylenimine gel system for water shut-off treatment. Energy Fuels 29:447–458. https://doi.org/10.1021/ef502505k

Zhang Z, Abidi N, Lucia L (2023) Smart superabsorbent alginate/carboxymethyl chitosan composite hydrogel beads as efficient biosorbents for methylene blue dye removal. J Mater Sci Technol 159:81–90. https://doi.org/10.1016/j.jmst.2023.02.045

Zhang Z, Abidi N, Lucia L, Chabi S, Denny CT, Parajuli P, Rumi SS (2023) Cellulose/nanocellulose superabsorbent hydrogels as a sustainable platform for materials applications: a mini-review and perspective. Carbohydr Polym 2023:120140. https://doi.org/10.1016/j.carbpol.2022.120140

Wang Z, Bai B, Zhou E, Pu J, Schuman T (2019) Experimental evaluation of oxidizing breakers for a polyacrylamide-based re-crosslinkable preformed particle gel. Energy Fuels 33:5001–5010. https://doi.org/10.1021/acs.energyfuels.9b00709

Meng Y, Zhao F, Jin X, Feng Y, Sun G, Lin J, Jia B, Li P (2021) Performance evaluation of enzyme breaker for fracturing applications under simulated reservoir conditions. Molecules 26:3133. https://doi.org/10.3390/molecules26113133

Lionel TF, Muhammad SK, Abdullah SS (2020) Viscosity-reducing agents (breakers) for viscoelastic surfactant gels for well stimulation. Energy Fuels 34:15686–15700. https://doi.org/10.1021/acs.energyfuels.0c03410

Okromelidze GV, Garshina OV, Nekrasova IL, Iljyasov SE (2014) Method of well-killing operation by using visco-elastic gels with controllable destruction terms. SPE Russian Petrol Tech Conf. https://doi.org/10.2118/171302-MS

Imqam A, Bai B, Wei M, Elue H, Muhammed FA (2016) Use of hydrochloric acid to remove filter-cake damage from preformed particle gel during conformance-control treatments. SPE Prod Operat 31:247–257. https://doi.org/10.2118/172352-PA

Sarwar UM, Cawiezel KE, Nasr-El-Din HÁ (2011) Gel degradation studies of oxidative and enzyme breakers to optimize breaker type and concentration for effective break profiles at low and medium temperature ranges. Fractur. Techn. Conf. Exhib, SPE Hydra. https://doi.org/10.2118/140520-MS

Xiong B, Loss RD, Shields D, Pawlik T, Hochreiter R, Zydney AL, Kumar M (2018) Polyacrylamide degradation and its implications in environmental systems. NPJ Clean Water. https://doi.org/10.1038/s41545-018-0016-8

Gilbert WJR, Johnson SJ, Tsau JS, Liang JT, Scurto AM (2016) Enzymatic degradation of polyacrylamide in aqueous solution with peroxidase and H2O2. J Appl Polym Sci. https://doi.org/10.1002/APP.44560

Carman PS, Cawiezel KE (2007) Successful breaker optimization for polyacrylamide friction reducers used in slick water fracturing. Fractur. Techn. Conf. Exhib, SPE Hydra. https://doi.org/10.2118/106162-MS

Vargas-Vasquez SM, Romero-Zeron LB (2008) A review of the partly hydrolyzed polyacrylamide Cr(III) acetate polymer gels. J Pet Sci Technol 26:481–498. https://doi.org/10.1080/10916460701204594

Adewunmi AA, Ismail S, Sultan AS (2018) Crosslinked polyacrylamide composite hydrogels impregnated with fly ash: Synthesis, characterization and their application as fractures sealant for high water producing zones in oil and gas wells. J Polym Environ 12:1–13. https://doi.org/10.1007/s10924-018-1204-9

He H, Fu J, Zhao H, Yuan F, Guo L, Li Z, Wang X, Peng H (2018) Synergistic mechanism of hydrolyzed polyacrylamide enhanced branched-preformed particle gel for enhanced oil recovery in mature oilfields. Energy Fuels 32:11093–11104. https://doi.org/10.1021/acs.energyfuels.8b01661

Montgomery C (2013) Fracturing fluids. ISRM International Conference for Effective and Sustainable Hydraulic Fracturing. https://doi.org/10.5772/56422

Zhou E (2019) Breaker evaluation and formation damage remediation of re-crosslinkable preformed particle gel (RPPG) [Thesis]. Master of Science in Petroleum Engineering: Faculty of the Graduate School of the Missouri University of Science and Technology

Acknowledgements

We thank the Brazilian National Council for Scientific and Technological Development (CNPq), the National Council for the Improvement of Higher Education (CAPES), Carlos Chagas Filho Foundation for Research Support of Rio de Janeiro State (FAPERJ), and Petrobras for their support.

Funding

Kaio Alves Brayner Pereira reports financial support was provided by the Brazilian National Council for Scientific and Technological Development (CNPq). Beatriz Teixeira Batista reports financial support was provided by National Council for the Improvement of Higher Education (CAPES). Claudia Regina Elias Mansur reports financial support and equipment, drugs, or supplies were provided by Carlos Chagas Filho Foundation for Research Support of Rio de Janeiro State.

Author information

Authors and Affiliations

Contributions

Kaio A. B. Pereira: conceptualization, methodology, validation, formal analysis, investigation, writing—original draft, visualization and supervision. Priscila F. Oliveira: project administration, conceptualization, methodology, validation, writing—review and editing, visualization, supervision. Beatriz T. Batista: Validation and Investigation. Claudia R. E. Mansur: project administration, conceptualization, resources, data curation, writing—review and editing, supervision and funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaio, A.B.P., Priscila, F.O., Beatriz, T.B. et al. Synthesis of a preformed hydrogel based on polyacrylamide and related gel-breakers with potential application for conformance control. Iran Polym J (2024). https://doi.org/10.1007/s13726-024-01336-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13726-024-01336-3