Abstract

The impregnation of Amberlite XAD-1180 with Cyphos IL101 (trihexyl(tetradecyl)phosphonium chloride ionic liquid, IL) confers to the resin highly efficient extraction properties for Au(III), Pd(II), and Pt(IV) in highly concentrated HCl solutions. Extraction isotherms (fitted by the Langmuir equation) show maximum extraction capacities proportional to IL loading. Increasing the IL loading has a limiting effect for extraction kinetics, which are controlled by the resistance to intraparticle diffusion: the complete filling of the porous volume of the extractant-impregnated resin (EIR) with the IL considerably hinders mass transfer of target metal ions. The EIRs are selective for precious metals (PGMs) over base metals (BMs), and the selection of appropriate eluents (HCl, HNO3, acidic thiourea) allows recovering almost selectively the three metals in pure or highly enriched proportions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Precious metals (platinum group metals, PGMs) are involved in the manufacturing of many electronic-based materials, automotive and industrial catalysts, jewelry, coins, and so on. Their resources are limited both in terms of extracted amounts from primary sources (mining activities) and in their geographical distribution. All these reasons make their recovery very strategic. In many developed countries, important programs are developed for (a) collecting waste materials (the so-called waste electric and electronic equipment, WEEE; spent catalysts; etc.) and (b) treating these resources (which are part of the so-called Urban Mine) for recovering valuables and decreasing the waste of strategic resources [1]. This combines both environmental purpose, rationale use of limited and non-renewable resources, and economical objective. While the extraction of PGMs (and more specifically gold) from primary mining resources usually proceeds through cyanidation or biohydrometallurgy, the recovery of metals from industrial resources may also involve alternative processes based on pyrometallurgy or advanced hydrometallurgy (thiosulfate, halide leaching, for example) [2–4]. These specific wastes generated in the treatment of WEEEs may involve other types of leachates including HCl solutions containing both base metals (BMs) and PGMs [5]. The challenge, at this stage, consists in developing treatment routes that can first separate PGMs from BMs and, ideally, selectively recover individual metals from the PGM family.

After acidic leaching, the metal-bearing effluents may be treated by different processes depending on the concentration of the metals. While solvent extraction (SX) is a powerful and competitive technique for the recovery of metals from highly concentrated solutions [6–10], the application of SX is not tailored for diluted effluents as the leachates generated in the treatment of printed circuit boards (PCB) or spent catalysts. For such low-concentration solutions, ion-exchange and chelating resins [11–21] or biosorbents may be more competitive [22–24]. Impregnated resins are combining the beneficial effects of high recovery efficiency of solvent extraction and stability (associated to resin support) [25]: the immobilization of the extractant in macroporous resins allows both fast and efficient metal removal and the retention of the extractant. The release of the extractant in the environment may induce hazardous effects and economic loss [26–29]. New generations of extractants have been recently developed: ionic liquids (ILs) are constituted by a large family of compounds associating, as ion pairs, an organic cation (pyridinium, phosphonium, or imidazolium, for example) and an organic or inorganic anion. These ILs are very interesting for solvent extraction processes due to their high thermal stability, non-flammability, ultra-low vapor pressure, great chemical inertness, and tunability. They have been widely investigated over the last decade for metal extraction [30–43] and for the recovery of organic compounds [44–46]. They have been also efficiently used by immobilization in inorganic materials [47–50], resins [51–56], synthetic polymers [44, 57], and activated carbon nanotubes [37], and by encapsulation in biopolymer matrices [58–60].

A previous study on Cd(II) extraction using Cyphos IL101 (trihexyl(tetradecyl)phosphonium chloride) immobilized on Amberlite XAD-7 resin reported the strong influence of the resistance to intraparticle diffusion on the extraction performance of the EIR, especially in terms of uptake kinetics [51]. The IL loading of the porous network of the resin is a key parameter in the control of uptake kinetics: as the IL loading increases the EIR requires longer times for reaching the equilibrium and the apparent intraparticle diffusion coefficient decreases. The progressive saturation of the porous volume of the resin with the IL limits both the diffusion of water and metal ions. More recently, the investigation of the sorption of Bi(III) with the same EIR showed a correlation of the apparent intraparticle diffusion with the variations of the viscosity of the IL when the temperature increases [61]. These conclusions tend to prove the importance of a correct selection of the filling of the porous network of the resin in relation to its textural properties. The influence of the textural properties of the resin on Au(III) sorption was investigated by Lira et al. [62]: eight XAD resins with different textural properties were studied. The extraction kinetics are enhanced while using supports of high pore volume and large pore size. This study concluded that Amberlite XAD-1180 is a good candidate for immobilizing Cyphos IL101.

The present study proposes an extensive study of extraction properties of XAD-1180 resin impregnated with Cyphos IL101 for the recovery of Au(III), Pd(II), and Pt(IV) from HCl solutions. The performances of the EIR are tested varying the IL loading, and HCl concentration. Then the extraction isotherms are determined in 0.01 M HCl solutions varying IL loading (and temperature for Au(III)). The extraction kinetics are compared for different IL loadings (and also particle size for Au(III)). The selectivity of the EIR for PGMs (against BMs) is tested in complex solutions. The metal stripping is also investigated testing various eluents, and the recycling of the EIR is established for at least five cycles using an acidic solution of thiourea. The desorption processes showed specific interactions between the EIR and thiourea, and complementary experiments have been performed using thiourea-treated EIR. SEM-EDX analysis was performed to evaluate the distribution of both the extractant and the metals in the EIR.

Materials and methods

Materials

Cyphos IL101 was kindly supplied by Cytec (Canada). This is a phosphonium salt (trihexyl(tetradecyl)phosphonium chloride, C.A.S. number, 258864-54-9, formula weight, 519.4 g mol−1). It is a slightly viscous room temperature ionic liquid. It is less dense than water (d, 0.8819 g mL−1, at 25 °C) and colorless to pale yellow. It is immiscible with water although it is sparingly soluble in water and can dissolve up to 8% water. The chemical structure is [P R3R′]+ Cl−, where R = hexyl and R′ = tetradecyl. Standard metal solutions were supplied by Perkin Elmer (USA). Stock metal solutions were prepared by dissolving analytic-grade reagents in demineralized water (1 g metal L−1): further solutions were prepared by dilution of the stock solution. Metal reagents were tetrachloroauric acid trihydrate (HAuCl4·3H2O, Sigma-Aldrich, USA), hexachloroplatinic acid (H2PtCl6, Pressure Chemical Co., USA), palladium(II) chloride (PdCl2, Pressure Chemical Co., EUA), zinc(II) nitrate hexahydrate (Zn(NO3)2·6H2O, Baker, USA), iron(III) chloride hexahydrate (FeCl3·6H2O, Baker, USA), nickel(II) nitrate hexahydrate (Ni(NO3)2·6H2O, Monterrey, Mexico), cadmium nitrate tetrahydrate (Cd(NO3)2·4H2O, Monterrey, Mexico), copper(II) chloride dihydrate (CuCl2·2H2O, Karal, Mexico), and cobalt(II) nitrate hexahydrate (Co(NO3)2·6H2O, Monterrey, Mexico). Other reagents (acids, methanol, acetone, thiourea, salts, etc.) were analytical grade and supplied by KEM (Mexico).

Amberlite XAD-1180 resin (styrene-divinylbenzene resin, dipole moment <0.3 Debye) was supplied by Sigma-Aldrich (Saint Louis, USA). Standard average particle size was 680 μm: sieving was performed for investigating the impact of particle size on extraction kinetics. The textural properties of the resin are reported (commercial data):

-

Specific surface area, 600 m2 g−1

-

Pore diameter, 300 Å

-

Pore volume, 1.68 cm3 g−1

Resins are generally conditioned with NaCl and Na2CO3 to prevent bacterial growth (in addition, they may also contain some residual monomers and mineral ions). The resins were therefore conditioned: first the resins were put into contact with acetone for 24 h at 25 °C (for removing residual monomers). After filtration under vacuum to remove the excess of acetone, the resin was rinsed with demineralized water. Then, it was washed with nitric acid (0.1 M) for 24 h (for removing mineral ions). The resin was filtered under vacuum and then rinsed with demineralized water to constant pH. Finally, the resin was put into contact with acetone for 12 h before being filtered under vacuum and dried in a roto-vapor at 80 °C.

Resin impregnation

The IL was immobilized on the resin by the dry impregnation method: 5 g of conditioned Amberlite XAD-1180 resin was mixed with 25 mL of acetone for 24 h. Varying amounts of Cyphos IL101 diluted in acetone (0.5 M) were added to resin slurry for 24 h, under agitation. The solvent was then slowly removed by evaporation in a roto-vapor. Five lots of EIRs were prepared with IL loadings in the range 100–592 mg IL g−1. Previous studies have shown the complete incorporation of the IL in the porous network of the resins under these experimental conditions. The amount of extractant immobilized on the resin (q IL) was quantified by the following “washing” procedure. A known amount of impregnated resin (250 mg) was mixed with methanol (5 mL) for 24 h to dissolve the IL, and the solvent was separated from the resin by decantation. This washing treatment was carried out twice. Finally, the resin was dried at 50 °C for 24 h for complete evaporation of the solvent. The mass difference (M IL) between impregnated (M XAD/IL) and washed resin (M XAD) was used to calculate the amount of extractant immobilized in the EIR (Eq. 1):

Characterization of EIR

For the textural characterization of EIR, nitrogen N2 adsorption isotherms were obtained (at −196 °C) using a BET surface area analyzer (Micromeritics ASAP 2010). The adsorption isotherms were used for the determination of the specific surface area (using the BET method [63, 64]), the pore size distribution, and the pore volume (using the BJH method [65]). The resins were initially conditioned under vacuum at 50 °C (to remove the gas contained in the porous network and measure the dry weight of the sample) before varying the pressure of gas (i.e., N2) in the tank and measuring at equilibrium the volume of gas adsorbed and the saturation pressure.

The morphology and the distribution of elements in the EIRs were determined with scanning electron microscopy coupled with energy-dispersive X-ray analysis (SEM-EDX). These analyses were performed using a scanning electron microscope, Zeiss EVO HD 15 LS (Germany), equipped with a Quantax Bruker energy-dispersive X-ray (EDX) microanalysis system. The resin particles (before and after metal sorption) were frozen in liquid nitrogen prior to mechanical breaking with a thin slice in order to obtain observable cross sections. SEM-EDX facilities were used for obtaining the distribution map of target metal and P element as the tracer of the extractant.

Extraction studies

Metal solutions were prepared in HCl solutions of different concentrations (0.001–8 M) with a metal concentration of 300 mg metal L−1. The extraction experiments were performed by mixing the EIR with metal solutions for 1 week with a solid/liquid ratio (EIR dosage, SD) fixed to m/V = 2 g L−1 (m mass of EIR, g; V volume of solution, L). The contact was operated on a reciprocal shaker (SEV, model INO 650 V-7, Mexico) with an agitation speed of 150 movements per minute at constant temperature. After filtration, the samples were analyzed by atomic absorption spectrometry (AAS Perkin Elmer AAnalyst 200). The amount of metal extracted (q, mg metal g−1 EIR) was calculated by the mass balance equation: q = V(C 0 − C eq)/m, where C 0 and C eq (mg metal L−1) are the initial and equilibrium metal concentrations, respectively. The tests were performed with the different resins loaded with 231 and 391 mg Cyphos IL101 g−1 EIR; a reference test was also systematically performed with non-impregnated resin.

For multi-component metal extraction, the solution was prepared mixing Au(III), Pd(II), and Pt(IV) solutions (at the same concentration, 0.3 mmol metal L−1 in 0.1 M HCl solutions). The same experiment was performed adding to the solution Fe(III), Co(II), Ni(II), Cu(II), Zn(II), and Cd(II) salts (at the same initial metal concentration, 0.3 mmol metal L−1 in 0.1 M HCl solution; q IL, 391 mg IL g−1 EIR). After contact with the EIR for 1 week (SD, 2 g L−1), equilibrium concentrations in the filtrate were analyzed by ICP-AES (Perkin Elmer Optima 8300 DV).

Extraction kinetics were performed by contact under agitation of a fixed amount of EIR (containing between 100 and 592 mg IL g−1 EIR) with a fixed volume of 0.01 M HCl solution containing metal ions (C 0: selected concentrations are systematically reported in the caption of the relevant figures), m/V being set to 0.4 g L−1. Samples were collected at fixed times, and the metal content was determined by visible spectrometry (UV-Vis Varian Cary 50 probe spectrophotometer) at the wavelength λ, 267.5 nm for Au(III), 340.5 nm for Pd(II), and 214.4 nm for Pt(IV), after filtration. After analysis, the solutions were returned to the kinetic reactor.

Stripping studies

Stripping of metal-loaded EIRs (for single-PGM solutions, multi-PGM solutions, and composite PGM and BM solutions) was operated under the same conditions: SD, 2 g L−1; T, 20 °C and contact time, 24 h; q IL, 391 mg IL g−1 EIR; extraction: C(HCl), 0.1 M; C 0, 0.3 mM. Eluents were thiourea (1 M in 0.1 M HCl solution), Na2SO3 (0.1 M), HClO4 (1 M), HCl (8 M), HNO3 (5 M), and water. Filtrated solutions were analyzed by ICP-AES to evaluate the stripping efficiency. The stripping with thiourea was associated to a fast change in the color of the metal-loaded resin; in addition, the extraction kinetics for the next step (following stripping) were apparently faster and the pre-treatment of the EIR with thiourea was tested for the comparison of extraction kinetics.

The recycling of the resin was performed by operating five successive extraction/stripping cycles. For extraction, the experimental conditions were SD, 2 g L−1; T, 20 °C; contact time, 24 h; q IL, 391 mg IL g−1 EIR; C(HCl), 0.01 M; and C 0, 250 mg metal L−1. For stripping, thiourea (1 M in 0.1 M HCl solution) was used (SD, 2 g L−1; contact time, 24 h). Between each cycle extraction and stripping steps, the EIR was rinsed three times (for 8 h, each) with 0.01 M HCl solutions. The amounts of extracted metals and stripped metals were compared at each step.

Results and discussion

Characterization of EIR

The textural analysis of the impregnated XAD 1180 resins at different loadings was performed by nitrogen adsorption. The systems were characterized by a type II sorption isotherm according the classification proposed by Brunauer et al. [63]: this means that the mechanism can be described as a multilayer physical sorption. The isotherms are characterized by poorly marked hysteresis loops that are usually associated to slit-shaped pores or spaces located between parallel plates (hysteresis type B according to de Boer classification) [66].

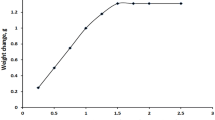

Table 1 reports the main textural characteristics of XAD-1180 resin impregnated with increasing amounts of Cyphos IL101 (see Figure AM1 in Additional Material Section). It is noteworthy that for q IL 592 mg IL g−1, the EIR is saturated with the IL and the textural analysis is not accurate (taking into account analytical conditions and the equipment used for the analysis): for example, the pore volume is below 0.1 cm3 g−1 and the specific surface area below 6 m2 g−1. The pore volume (PV, cm3 g−1) of the EIR linearly decreases with q IL (mg IL g−1 EIR), according

The average pore size (APS, Å) increases with q IL:

The specific surface area (SSA, m2 g−1) varies exponentially with q IL:

The increase of the average pore size with increasing IL loading can be explained by the progressive filling of the thinnest pores with the IL and then a relative increase in the size of residual pores.

The SEM-EDX analysis of the EIR loaded with Au(III), Pd(II), and Pt(IV) metal ions from multi-component solutions is shown in Figure AM2 (see Additional Material Section). The distribution of the P element is homogeneous in the whole mass of the particle: this means that the totality of the porous volume of the resin is accessible to the IL. On the other hand, the concentration of target metals (Au(III), Pd(II), and Pt(IV)) remains constant over the cross section of the particle: all reactive groups are accessible for metal ions.

Influence of HCl concentration and IL loading on metal extraction efficiency

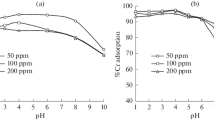

The XAD-1180/Cyphos IL101 EIR shows significant differences in the extraction of Au(III), Pd(II), and Pt(IV) (at C 0 ≈ 1.5 mmol metal L−1) when varying IL loading and HCl concentration (Fig. 1). The EIR has a much stronger affinity for Au(III) than for other metals: with a loading of 391 mg IL g−1 EIR, extraction efficiency exceeds 90% over the whole range of HCl concentrations while for Pt(IV), the extraction efficiency remained between 40 and 50%, regardless of HCl concentration. On the other hand, for Pd(II) extraction, the efficiency progressively decreases from 90% to less than 20%. Pd(II) extraction is more sensitive to HCl concentration than Au(III) and Pt(IV) for extraction by XAD-1180/Cyphos IL101. These trends are confirmed by the experiments performed with lower IL loading (i.e., 231 mg IL g−1 EIR). For Au(III) extraction, the efficiency decreases from 90% at 0.001 M HCl concentration (70% in 0.1 M HCl solutions) to 60% in 2 M HCl solution and tends to stabilize for higher HCl concentrations. For Pd(II) and Pt(IV), the extraction efficiency linearly decreases (from 60 to 10% for Pd(II) and from 28 to 12% for Pt(IV)) with increasing HCl concentration from 0.1 to 8 M.

Influence of HCl concentration and IL loading on Au(III), Pd(II), and Pt(IV) extraction efficiency using XAD-1180/Cyphos IL101 (C 0, 300 mg Au L−1, or C 0, 162 mg Pd L−1, or C 0, 293 mg Pt L−1; EIR dosage, SD, 2 g L−1; agitation time, 7 days for Au(III) and 2 days for Pd(II) and Pt(IV); agitation speed, v, 150 rpm; T 20 °C)

The extraction process is expected to proceed through an ion-exchange mechanism between the counterion (here Cl−) hold by the phosphonium cation (R3R′P+) and the chloro-anionic metal species. The speciation of the metal is thus a critical parameter. However, under selected experimental conditions (i.e., HCl solutions ranging between 0.1 and 8 M), all the metals are present under the form of chloro-anionic species: AuCl4 −, PtCl6 2− (85% or more) and PtCl3 − (15% or less), and PdCl4 2− [67]. These results are consistent with the trends observed for Au(III), Pd(II), and Pt(IV) extraction using XAD-7 impregnated with Cyphos IL101 [53–55]. The relative decrease in metal extraction at high HCl concentration may be associated to the ability of the IL to extract HCl: this effect is more marked at low IL loading. Cieszynska and Wisniewski [33, 68] used both Cyphos IL101 and Cyphos IL104 in toluene for the extraction of Pd(II) from HCl solutions. They report the change in the extraction mechanism with HCl concentration: in 0.1 M HCl solutions, Pd(II) is extracted as (R3R′P+)PdCl3 −, while in 3 M HCl solutions, it is extracted as (R3R′P+)2PdCl4 2−. These results are consistent with the extraction mechanism reported for Pd(II) extraction using XAD-7 impregnated with Cyphos IL101 [54]. At low HCl concentration, the extraction mechanism may include the extraction of PdCl3 − by one ion R3R′P+ (Eq. 5a), while at high HCl concentration, the reaction involves two R3R′P+ and one PdCl4 2− (Eq. 5b):

For Au(III) and Pt(IV) extraction using XAD-7/Cyphos IL101, the reported mechanisms were [53, 55]:

In the case of Pd(II), the change in the binding mechanism with increasing HCl concentration results in the interaction of two IL for binding a single chloro-metal anion (contrary to a 1:1 stoichiometry at low HCl concentration), meaning a higher decrease of extraction efficiency compared with the other metals. For Pt(IV), the expected 2:1 stoichiometric ratio (IL/metal) is not changing with HCl concentration and the decrease at high HCl concentration is mainly due to competitive HCl extraction and higher stoichiometric factor for chloride ion (Eq. 6). Moreover, the level of metal extraction (halved compared with Au(III)) is due to the less favorable stoichiometric ratio (2:1 versus 1:1 for Au(III)).

It is noteworthy that for Au(III), Pd(II), and Pt(IV) extraction using the raw Amberlite XAD-1180 resin the efficiency for metal recovery was negligible. This is completely different to the trends obtained for Au(III) extraction with Amberlite XAD-7. XAD-1180 is a styrene-divinylbenzene resin much less reactive for Au(III) than XAD-7 acrylic ester resin. In the case of XAD-7, in strongly acidic solutions, the resin is suspected to be partially hydrolyzed, forming carboxylic groups that can react with Au(III) chloro-anions to form ion pairs (HAuCl4). In addition, HCl is extracted through interaction with oxygen groups of polyacrylic matrix (=O··H+Cl−), before chloride ions could be exchanged with chloro-anionc metal species (=O··H+AuCl4 −).

Extraction isotherms

Influence of IL loading

The extraction isotherms were established at 0.01 M HCl with the different metal ions with two or three different IL loadings (Fig. 2). As expected, increasing IL loading improves maximum extraction capacity. All the curves show similar trends: (a) steep initial slope and (b) saturation plateau reached at low equilibrium metal concentration. The general form of the extraction isotherm appears to be more consistent with the asymptotic form of the Langmuir equation (saturation plateau) than with the power-like function given by the Freundlich equation. Experimental data were thus modeled using the Langmuir equation (solid lines on Fig. 2):

where q and q m (mg metal g−1 or mmol metal g−1) are the extraction capacities in equilibrium with the residual concentration C eq (mg metal L−1 or mmol metal L−1) and at saturation, respectively, while b (L mg−1 or L mmol−1) is the affinity coefficient.

The Langmuir equation was developed for describing the distribution of a solute (in gas or liquid phase) between a sorbent and the mobile phase. This is a surface phenomenon. As a consequence, the Langmuir model is not strictly designed for describing the extraction of metal species into the aqueous phase immobilized in the porous network of the EIR. However, this equation was frequently used for simulating the solid/liquid distribution of the solute between the two phases in EIRs.

Table 2 reports the parameters of the Langmuir model as well as the metal/IL ratio (at saturation, based on the extraction capacity at saturation, from Langmuir equation, and IL loading). For Pd(II), the stoichiometric ratio (IL/metal) is close to 1; this means that extraction proceeds through the interaction of one IL with one PdCl4 2−, according to Eq. (5a). The 1:1 stoichiometric ratio is consistent with the average value (0.99) of IL/metal molar ratio (Table 2). For Pt(IV), the IL/Pt molar ratio was close to 2 (1.79–1.82); this is consistent with the stoichiometric ratio given by Eq. (6). For Au(III), the IL/metal stoichiometric ratio increases with increasing IL loading (from 0.70 to 0.85): this means close to the expected 1:1 M ratio between target Au(III)-anionic species (i.e., AuCl4 −) and R3R′P+ (Eq. (7).

Comparing the maximum extraction capacities (in molar units) for the three metals, it comes that at low IL loading (i.e., q IL, 231 mg IL g−1 EIR), the metals can be ranked according to the sequence: Au(III) > > Pd(II) > > Pt(IV) while at high IL loading (i.e., q IL, 391 mg IL g−1 EIR), the differences are less marked (at least between Au(III) and Pd(II): Au(III) > Pd(II) > > Pt(IV)). It is noteworthy that the product q m × b (which is analogous to a distribution coefficient, L g−1) remains almost constant (101–104 L g−1) for Au(III) when the IL loading increases while it substantially increases from 3 to 10 L g−1 to 78–79 L g−1 for Pd(II) and Pt(IV). This result can be explained by the reciprocal trends followed by the three metals concerning the affinity coefficient (the so-called b parameter of the Langmuir equation): for Pd(II) and Pt(IV), the affinity coefficient (i.e., b) increases with IL loading, while it decreases in the case of Au(III). While for Pt(IV) extraction using Cyphos IL101 impregnated on XAD-7 resin the trend was consistent with that obtained with XAD-1180 resin [53], a reciprocal trend was observed for Au(III) (increase of affinity coefficient with IL loading) [55]. The affinity coefficient is correlated to the initial slope of the isotherm curve (at low equilibrium metal concentration): the decrease of the affinity coefficient with IL loading means that the IL is progressively losing its reactivity against Au(III) compared with Pd(II) and Pt(IV), consistently with the molar ratio IL/metal at saturation. For Au(III), less loaded EIRs offer a more rational use of reactive groups. Since the affinity coefficients may be impacted by a certain experimental variability, this conclusion should be considered as a trend.

Based on these results, the EIR sounds to have a little preference for Au(III) over Pd(II) and Pt(IV) but probably not sufficient to separate these metals from multi-component solutions; better separation will require playing with the experimental conditions for the stripping step (see below).

Influence of temperature on Au(III) extraction

A focus was made on the effect of temperature on gold extraction using XAD-1180/Cyphos IL101 (Fig. 3 and Table 2). The maximum extraction capacity increases with temperature from 167 to 202 mg Au g−1, while the affinity coefficient does not show a clear trend. However, the poor fit of experimental data at 40 °C (weak fit of the curved zone of the isotherm) makes more complex the comparison of affinity coefficients. Under these conditions, it is rather difficult to calculate the thermodynamic parameters. It is thus impossible to conclude on the spontaneity of the reaction (Gibbs free energy, ΔG°) or the variation of the randomness of the reaction (reaction entropy, ΔS°) [69]. It is just possible concluding that the reaction is endothermic since the sorption slightly increases with temperature.

Extraction kinetics

Extraction kinetics may be controlled by a number of different steps or mechanisms including resistance to film diffusion, resistance to intraparticle diffusion, and the proper extraction kinetic rate combined with interface equilibrium conditions (extraction isotherm parameters) [70]. Previous studies on the extraction of metal ions with phosphonium-based ionic liquids have shown that tetrachloropalladate species, for example, are extracted from HCl solutions in a few minutes [34]. The proper metal extraction can thus be considered instantaneous (at least compared with overall sorption kinetics on resin-supported systems). Previous studies have shown that with XAD-7/Cyphos IL101 EIRs, several hours of contact were required for reaching equilibrium [51, 52, 54, 55]. In an attempt to evaluate the apparent intraparticle diffusion coefficient, without using mathematic concepts that require complex numerical solving, the kinetic data were fitted with the so-called Crank equation (herein called resistance to intraparticle diffusion equation, RIDE), assuming the solid to be initially free of metal and the kinetics to be only controlled by the resistance to intraparticle diffusion [71]:

M(t) and M eq are the amounts of the metal in the resin at time t and equilibrium, respectively; r is the radius of the particle; and q n non-zero roots of the equation:

with

The Mathematica™ software was used for the determination of the apparent intraparticle diffusion coefficient, D e, and for the simulation of experimental data. It is noteworthy that this model was initially developed by Crank for describing mass transfer for homogeneous solid supports. Obviously, the EIR cannot be considered a homogeneous system being constituted of a porous compartment filled with the ionic liquid and by the solid phase (the resin). Anyway, in a first approximation, the equation was tested (concurrently to other models such as the pseudo-first-order rate equation and the pseudo-second-order rate equation) and gave good fit of experimental profiles.

Influence of IL loading

A preliminary study was performed on Au(III) extraction using XAD-1180/Cyphos IL101 EIR loaded with increasing amounts of IL (in the range 100–592 mg IL g−1 EIR). Figure 4 (long-term kinetic profiles) shows that very long contact times are required for achieving complete metal recovery (at high IL loading) or reaching equilibrium. Extraction kinetics are characterized by a very fast initial extraction step that represents between 50 and 90% of total extraction; this step lasts for 3–5 h, followed by a very slow phase that can take up to 30 days. At very low IL loading (i.e., q IL, 100 mg IL g−1 EIR), the extraction is limited to a few percent: the weak removal can be correlated to very slow kinetics and to the possible interaction of the IL with the resin. Indeed, a fraction of the IL is tightly bound to the surface of the support limiting its reactivity for metal extraction [51]. When IL loading increases, the equilibrium concentration progressively decreases, according to the stoichiometric ratio IL/metal (i.e., 1:1). Increasing the amount of IL increases the amount of metal to be bound. However, for the highest IL loading (i.e., q IL, 592 mg IL g−1 EIR), the initial pseudo-equilibrium (end of the initial fast step) occurs at a quite high level: the residual relative concentration tends to stabilize around 0.5–0.4. The extraction continues over several weeks to tend to a complete recovery of the metal consistently with the expected levels of metal recovery (based on the stoichiometric ion exchange capacity and the values reached with q IL, 391 mg IL g−1 EIR). This is a clear and complementary evidence that the saturation of the porous network of the resin (with the IL) strongly impacts the resistance to intraparticle diffusion. The diffusion coefficient of metal ions in phosphonium-based ionic liquids (example of rare earth metal ions [72, 73]) is about one or two orders of magnitude lower than the values of their diffusivity in water [74]. As a consequence, when the entire porous network is filled with the IL, the speed of mass transfer (of metal ions) is considerably reduced. This very long second step can last for several weeks but contributes for limited sorption. This is not really representative of the standard use of the EIRs, and for further investigations, the plots of extraction kinetics have been truncated at 3000 min (i.e., about a little more than 2 days) (Fig. 5).

The Crank equation roughly fits experimental kinetic profiles (solid lines on Fig. 5, short-term kinetic profiles). Table 3 reports the values of the apparent intraparticle diffusion coefficient for Au(III), Pd(II), and Pt(IV) extraction using XAD-1180/Cyphos IL101 EIR. Based on the observations made on long-term kinetic profiles and the pseudo-equilibria reached within the first 2 days of contact, the apparent intraparticle diffusion coefficients (D e) should be taken as indicative values. The overestimated value obtained with q IL 100 mg IL g−1 EIR was explained above in relation to the slow kinetics and the partial inactivation of the IL tightly bound to the resin surface: the amount of reactive IL is low and the saturation of the IL occurs quite fast. In the range q IL 231–391 mg IL g−1, D e progressively decreases. This is consistent with previous studies on Cd(II) uptake using XAD7/Cyphos IL101 [51], or Pd(II) and Pt(IV) uptake using the same EIR [53, 54]: the progressive saturation of the porous network limits the free diffusion of the metal ions in the water phase and the resistance to intraparticle diffusion increases. At higher IL loading, the impact of the complete saturation of the porous network leads to both very slow kinetics and overevaluation of D e. The kinetic profiles for Pd(II) and Pt(IV) follow the same trend: with increasing IL loading from 231 to 391 mg IL g−1 EIR, the D e decreases. The order of magnitude of the intraparticle diffusion coefficient is consistent with previous values obtained with XAD-7 resins impregnated with Cyphos IL101: 1.8 × 10−11–16.6 × 10−11 m2 min−1 for Au(III) [55], 1.6 × 10−11–20 × 10−11 m2 min−1 for Pd(II) [54], or 0.5 × 10−11–4.3 × 10−11 m2 min−1 for Pt(IV) [53]. These values are also consistent with the values obtained in the case of Cyphos IL101 encapsulated in alginate beads: 1 × 10−11–4 × 10−11 m2 min−1 for Au(III) [75], 0.2 × 10−11–2 × 10−11 m2 min−1 for Pt(IV) [59], or around 0.5 × 10−11 m2 min−1 for Pd(II) [60]. This means two or three orders of magnitude higher than the self-diffusivity of these metal ions in water. Indeed, the self-diffusivity of PdCl4 2− and PtCl6 2− is close to 8.4 × 10−8 m2 min−1 [74]. The diffusivity in water and in the ionic liquid phase may be affected by the possible changes in the speciation of metal ions, but the differences between the diffusivity coefficients in water (or IL) and in the EIR are probably too large to be only explained by speciation effect.

Influence of temperature on Au(III) extraction kinetics

The temperature has a limited impact on kinetic profiles (Fig. 6): at 20 and 40 °C, extraction kinetics overlap and the apparent intraparticle diffusion coefficient remains constant (3.4 × 10−11–3.7 × 10−11 m2 min−1). A slight decrease both in kinetics and equilibrium performance (as expected) is obtained when reducing the temperature to 10 °C: D e decreased to 1.1 × 10−11 m2 min−1. A similar increase in the apparent intraparticle diffusion coefficient with the temperature was observed for Bi(III) recovery from HCl solutions using XAD-7/Cyphos IL101 EIR [61]: this was associated to the change in the viscosity of the IL. Indeed, increasing the temperature significantly reduces the viscosity of the solution, especially when the IL contains water. The decrease in the viscosity of the IL improves the mobility of metal species and consequently the intraparticle diffusion coefficient. Marták and Schlosser [76, 77] investigated the impact of water content on the extraction of organic acids in liquid/liquid systems. They show that Cyphos IL101 may extract significant amounts of water (close to 14%, w/w) [76]. This strong water extraction is influenced by the acid concentration [77] through a dual mechanism: (a) co-extraction of butyric acid with water (at high acid concentration) and (b) competitive extraction of the organic acid (at low acid concentration). Obviously, in the present study, the interaction of water and acid (co-extracted) and the effect of hydration on the metal complexes may also affect the mass transfer properties.

Influence of EIR particle size on Au(III) extraction kinetics

Figure 7 shows the impact of the particle size of XAD-1180/Cyphos IL101 on the Au(III) extraction kinetics. Decreasing the size of the particles from 630 to 420 μm allows drastically increasing the extraction kinetics: while several hours (about 10–12 h) are necessary for achieving the complete recovery of the metal for large particles, with the smallest particles, total gold recovery was observed within the first 2 h of contact. This is confirmed by the slight increase in the apparent intraparticle diffusion coefficient (Table 4). This result confirms that resistance to intraparticle diffusion plays a significant role in the control of extraction kinetics. The beneficial effect of decreasing the size of EIR particles may be explained by the decrease in the intraparticle diffusion length in the particle.

It is noteworthy that the size effect on extraction kinetics is important and the wide range of particle sizes in the Amberlite XAD-1180 resin stock [46] may induce significant variations in the impregnation and extraction efficiencies. A thorough size selection (narrower) would contribute to more precise determination of the intraparticle diffusion coefficient.

Metal stripping

The cost of the EIR requires the recycling of the material after metal loading; the easy recovery of the metals from the eluent and the expected concentrating effect are also critical parameters for improving the competitiveness of the process. In addition, stripping can be a very efficient step for enhancing the separation of metal ions in complex solutions. The choice of the eluent is thus an important issue for concluding on the feasibility of EIR processing.

Selection of eluent

Table 5 summarizes the tests of Au(III), Pd(II), and Pt(IV) stripping using a series of eluents. Water reveals completely inefficient at removing PGMs from IL-impregnated resins: only a negligible amount (i.e., 1.2%) of Pt(IV) was recovered through water stripping. This is interesting since some BMs, such as Cd(II) that were bound with similar systems (XAD-7/Cyphos IL101), were significantly stripped with water [51]: this can contribute to improved separation of PGMs from BMs. Pd(II) can be quite easily removed: with HNO3 (5 M), Na2SO3 (0.1 M), thiourea (1 M in 0.1 M HCl solution), and HClO4 (1 M), the metal is completely recovered, while stripping does not exceed 84% with HCl (8 M) solutions. Other PGMs were less easily removed from loaded EIR. For instance, Au(III) was poorly eluted from the EIR when using H2O, HCl (8 M), HNO3 (5 M), and HClO4 (1 M) (less than 8%); the stripping efficiency increases to 84% with Na2SO3; and only an acidic solution of thiourea succeeds in completely removing Au(III) ions. Gold (in its trivalent form) being quite easily reduced, metal stripping from loaded sorbent is frequently hindered by this reduction mechanism; here, despite the use of oxidizing eluents, the stripping efficiency is not especially improved and only a strong complexing agent (such as thiourea) can efficiently extract the metal from the saturated impregnated resin. The case of Pt(IV) is substantially different: Na2SO3 has a negligible effect on Pt(IV) stripping (less than 6%) and HCl (even at 8 M concentration) does not extract more than 23% of the metal-loaded EIR. Other eluents (nitric acid, perchloric acid, and acidic thiourea solution) have good stripping properties (in the range 82–86%), but none of them succeeds in completely removing Pt(IV) from loaded EIR.

Thiourea (in HCl solution) is the most efficient eluent for broad and unselective recovery of PGMs from the EIR. On the other hand, nitric acid and perchloric acid show good stripping properties for both Pd(II) and Pt(IV) while Au(III) is not significantly removed from metal-loaded EIR. Nitric and perchloric acids can be used to separate Au(III) from the two other PGMs.

Another “scenario” can be proposed for achieving a certain separation of PGMs: (a) a first treatment with HCl to remove most of Pd(II) and only a very small fraction of Pt(IV) (Au(III) remaining on the EIR), followed by (b) treatment with HNO3 or HClO4 to remove the residual amount of Pt(IV) (with traces of Pd(II) and even less of Au(III)), and (c) a final treatment with acidic thiourea to remove Au(III). Rinsing steps with 0.01 M HCl solutions can be intercalated between the different operations and can be applied at the end of the stripping process to re-condition the EIR (before the next sorption step).

Recycling of EIR

The recycling of the resin was tested for Au(III) recovery using thiourea solutions (1 M in 0.1 M HCl solution) for metal stripping. The results are summarized in Table 6. Gold recovery from metal-loaded EIR is quite efficient, exceeding 99%, and the extraction properties are maintained, under selected experimental conditions, at levels higher than 99%: Metal extraction is complete for the first three cycles and only begins to slightly decrease at the fifth cycle (99.4%). The EIR can be efficiently recycled for a minimum of five cycles, at least with pure synthetic solutions. Complementary steps with complex solutions would be necessary to definitively establish the regeneration properties of the sorbent.

Separation properties

Precious metals

An extraction step (not shown) was performed using multi-component solutions of Au(III), Pd(II), and Pt(IV) (at individual concentrations of 0.3 mM) under fixed experimental conditions (C(HCl), 0.1 M; SD, 2 g L−1; q IL, 391 mg IL g−1 EIR; contact time, 24 h). Gold extraction was complete, while extraction efficiency reaches 99.2% for Pd(II) and 95.2% for Pt(IV). XAD-1180/Cyphos IL101 is very efficient for the extraction of these metal ions from multi-component solutions. Based on these results, the affinity for selected metals can be ranked as follows: Au(III) ≈ Pd(II) > Pt(IV); however, these slight differences are not sufficient for making possible the selective separation of these metals within the series of PGMs.

Precious metals vs. base metals

A complementary test was performed using complex solutions, made of 0.3 mM solutions of Au(III), Pd(II), and Pt(IV) for PGMs, and Co(II), Ni(II), Cu(II), Fe(III), Zn(II), and Cd(II) for BMs. After an extraction test under selected conditions (reported in the caption of Table 7), a series of stripping operations (water washing followed by successive treatments with solutions of 8 M HCl, 5 M HNO3, and 1 M thiourea (in 0.1 M HCl)) was completed and the content of the different metals was determined in the different compartments: residual amounts in the EIR, in the washing solution, and in the different eluents. Table 7 reports the distribution of the different metals in the different compartments. The extraction step is almost selective of PGMs (recovery yield >86%). The BMs are extracted at a very low level (<8.5%), except Cd(II) that is adsorbed at a slightly higher level (18.7%). The selectivity against Co(II), Ni(II), and Cu(II) was expected since these metal ions are not supposed to form stable anionic complexes with chloride ions; on the opposite hand, Fe(III), Zn(II), and Cd(II) form chloro-anions in HCl solutions that could compete with PGM chloro-anions for metal extraction by Cyphos IL101 [51, 52], but under these conditions (especially 0.1 M HCl), these metals are not efficiently extracted. Both Au(III) and Pd(II) are almost completely removed from the solution, while a significant amount of Pt(IV) (about 13.5%) remains in the solution. This is globally consistent with previous studies: little preference for Au(III) over Pd(II) > Pt(IV). The second step (i.e., the washing with water) almost completely removes the amount of Cd(II) that was bound to the EIR; a negligible amount of Pd(II) (about 0.3%) is also recovered from the EIR. As expected, the treatment with HCl solution does not remove Au(III) while about two thirds of sorbed Pd(II) is released from the EIR; a little fraction of Pt(IV) (8.5%) is simultaneously desorbed. The treatment with nitric acid completely removes Pt(IV) (which remained on the EIR) with most of the remaining Pd(II) (a fraction, less than 2%, still remains on the EIR), and Au(III) is not eluted. The final treatment with acidic thiourea completely removes all remaining metals including Pt(IV) (0.4%), Pd(II) (1.8%), and Au(III) (99.0%).

Figure 8 reports the distribution of each individual metal in the different compartments. The initial solution after extraction contains more than 93% of BMs (plus 13.5% of Pt(IV) and 1.7% of Pd(II)). The washing solution contains 4% of BMs including 16.4% of Cd(II). The eluate produced by HCl solution contains 65% of Pd(II) and 8.5% of Pt(IV). The solution resulting from nitric acid elution contains 77.6% of Pt(IV) and 31.2% of Pd(II). Though some traces of Pd(II) and Pt(IV) can be detected in the eluate issued from the thiourea elution step, this solution is almost exclusively constituted of Au(III).

Relative distribution of individual elements in the different compartments for metal recovery (extraction/stripping/washing steps) from multi-metal solutions. Experimental conditions are reported in Table 7

The BMs are almost exclusively present in the treated solution and in the washing solution (97%). Gold is essentially recovered in the acidic thiourea solution (almost 99%). Palladium is mainly distributed in the HCl solution (65%) and in the HNO3 solution (30.3%). Platinum is essentially recovered in the HNO3 solution (77.6%) and in the HCl solution (8.4%) while a part of PGMs remained in the initial solution (non-adsorbed fraction, 13.5%).

These results confirm that the PGMs can be efficiently separated from BMs. A pre-separation (but incomplete) of PGMs is possible: gold composes more than 95% of the specific thiourea eluate; HCl essentially recovers Pd(II) and HNO3 mainly strips Pt(IV) (though in these last two cases, non-negligible amounts of Pt(IV) and Pd(II) are also released).

Improvement of Au(III) sorption properties with thiourea desorption cycles and pre-treatment

The observation of the resins during the extraction steps following the stripping treatment with acidic thiourea shows that the change in color of the EIR was much faster than with original EIRs. It appeared interesting comparing Au(III) extraction kinetics for different extraction cycles with different IL loadings (Fig. 9). The thiourea treatment clearly improves the extraction efficiency of the EIR: the equilibrium concentration progressively decreases with the recycling; in addition, the extraction kinetics are faster. The beneficial effect of thiourea is especially significant at low IL loading (i.e., q IL, 100 mg IL g−1 EIR): the enhancement continues over the second cycle while for other q IL the kinetic curves overlap for cycles 2 and 3. Table 8 reports the main characteristics of the different systems (apparent intraparticle diffusion coefficient and equilibrium sorption efficiency). The strict comparison of intraparticle diffusion coefficient is difficult since the pseudo-equilibrium reached after a few hours (with non-treated EIRs) overestimates D e.

Figure 10 compares the kinetic profiles of non-treated EIRs and thiourea-treated EIRs (TW) for q IL 100 and 592 mg IL g−1 EIR. The conditioning of the EIRs with thiourea consisted of the treatment of the resin with an acidic solution of thiourea (0.1 M in 0.1 M HCl solution) followed with a rinsing step with a 0.01 M HCl solution. The “thiourea washing” of the EIR significantly improves the efficiency of Au(III) extraction. Surprisingly, even the raw XAD-1180 (without IL impregnation) shows a significant improvement in sorption performance when washed with thiourea. The most probable explanation consists of the presence of thiourea in the porous network of the resin that contributes to metal binding and accumulation in the resin (and in the EIR).

Conclusion

The mesoporous styrene-divinylbenzene resin (Amberlite XAD-1180) impregnated with Cyphos IL101 (trihexyl(tetradecyl)phosphonium chloride) ionic liquid is very efficient for binding Au(III), Pd(II), and Pt(IV) from HCl solutions. The affinity of the IL for chloro-anions explains the strong extraction of PGMs in a wide range of HCl concentrations: Pd(II) is much more sensitive to HCl concentration than Au(III) and Pt(IV). At low HCl concentration, the stoichiometric ratio between the IL and the metal chloro-anions approaches 1 for Au(III) and Pd(II) and 2 for Pt(IV); the reaction involves the exchange of one chloride ion with one AuCl4 − or PdCl3 − and the exchange of two chloride ions with one PtCl6 2−. The Langmuir equation fits well extraction isotherms: maximum extraction capacity is proportional to IL loading. Extraction kinetics are controlled by the resistance to intraparticle diffusion. Increasing IL loading induces increasing resistance to diffusion: the filling of the porous network with the IL limits the diffusion of metal ions. When the porous volume of the resin is completely filled, the extraction kinetics are considerably slow. While the extraction is poorly selective among PGMs, BMs are almost not bound to the EIR: XAD-1180/Cyphos IL101 is selective for PGMs over BMs. The stripping of PGMs can be efficiently operated by nitric and perchloric acid, with sodium sulfite, and with thiourea (in HCl solution). The extraction step allows separating PGMs from BMs, while a series of different stripping steps (8 M HCl, 5 M HNO3, and acidic 1 M thiourea) allows recovering pure or highly enriched individual metal solutions. The extraction and stripping properties were maintained at a constant level for Au(III) over five sorption/desorption cycles.

References

Bigum M, Brogaard L, Christensen TH (2012) Metal recovery from high-grade WEEE: a life cycle assessment. J Hazard Mater 207–208:8–14. doi:10.1016/j.jhazmat.2011.10.001

Tuncuk A, Stazi V, Akcil A, Yazici EY, Deveci H (2012) Aqueous metal recovery techniques from e-scrap: hydrometallurgy in recycling. Miner Eng 25(1):28–37. doi:10.1016/j.mineng.2011.09.019

Zhang Y, Liu S, Xie H, Zeng X, Li J (2012) Current status on leaching precious metals from waste printed circuit boards. Procedia Environ Sci 16:560–568. doi:10.1016/j.proenv.2012.10.077

Syed S (2012) Recovery of gold from secondary sources—a review. Hydrometallurgy 115–116:30–51. doi:10.1016/j.hydromet.2011.12.012

Sheng PP, Etsell TH (2007) Recovery of gold from computer circuit board scrap using aqua regia. Waste Manage Res 25(4):380–383. doi:10.1177/0734242x07076946

Gupta B, Singh I (2013) Extraction and separation of platinum, palladium and rhodium using Cyanex 923 and their recovery from real samples. Hydrometallurgy 134:11–18. doi:10.1016/j.hydromet.2013.01.001

Jha MK, Gupta D, Lee J-C, Kumar V, Jeong J (2014) Solvent extraction of platinum using amine based extractants in different solutions: a review. Hydrometallurgy 142:60–69. doi:10.1016/j.hydromet.2013.11.009

Lee J-c, Pandey BD (2012) Bio-processing of solid wastes and secondary resources for metal extraction—a review. Waste Manag 32(1):3–18. doi:10.1016/j.wasman.2011.08.010

Alguacil FJ, Alonso M (2005) Liquid-liquid extraction of Au(I) by amberlite LA2 and its application to a polymer-immobilized liquid membrane system. Gold Bull 38(2):68–72. doi:10.1007/BF03215235

Kolekar SS, Anuse MA (2001) Rapid solvent extraction of gold(III) with high molecular weight amine from organic acid solution. Gold Bull 34(2):50–55. doi:10.1007/BF03214812

Alexandratos SD (2009) Ion-exchange resins: a retrospective from industrial and engineering chemistry research. Ind Eng Chem Res 48(1):388–398. doi:10.1021/ie801242v

Donia AM, Atia AA, Elwakeel KZ (2005) Gold(III) recovery using synthetic chelating resins with amine, thio and amine/mercaptan functionalities. Sep Purif Technol 42(2):111–116. doi:10.1016/j.seppur.2004.06.009

Alguacil FJ, Adeva P, Alonso M (2005) Processing of residual gold (III) solutions via ion exchange. Gold Bull 38(1):9–13. doi:10.1007/BF03215222

Parodi A, Vincent T, Pilsniak M, Trochimczuk AW, Guibal E (2008) Palladium and platinum binding on an imidazol containing resin. Hydrometallurgy 92(1–2):1–10. doi:10.1016/j.hydromet.2008.02.005

Sun PP, Lee JY, Lee MS (2012) Separation of platinum(IV) and rhodium(III) from acidic chloride solution by ion exchange with anion resins. Hydrometallurgy 113–114:200–204. doi:10.1016/j.hydromet.2011.12.009

Wołowicz A, Hubicki Z (2011) Investigation of macroporous weakly basic anion exchangers applicability in palladium(II) removal from acidic solutions—batch and column studies. Chem Eng J 174(2–3):510–521. doi:10.1016/j.cej.2011.08.075

Marinho RS, da Silva CN, Afonso JC, da Cunha JWSD (2011) Recovery of platinum, tin and indium from spent catalysts in chloride medium using strong basic anion exchange resins. J Hazard Mater 192(3):1155–1160. doi:10.1016/j.jhazmat.2011.06.021

Nguyen NV, Jeong J, Jha MK, Lee J-C, Osseo-Asare K (2010) Comparative studies on the adsorption of Au(III) from waste rinse water of semiconductor industry using various resins. Hydrometallurgy 105(1–2):161–167. doi:10.1016/j.hydromet.2010.09.003

Hubicki Z, Wołowicz A, Leszczyńska M (2008) Studies of removal of palladium(II) ions from chloride solutions on weakly and strongly basic anion exchangers. J Hazard Mater 159(2–3):280–286. doi:10.1016/j.jhazmat.2008.02.017

Pilśniak-Rabiega M, Trochimczuk AW (2014) Selective recovery of gold on functionalized resins. Hydrometallurgy 146:111–118. doi:10.1016/j.hydromet.2014.03.016

Van Nguyen N, Lee J-C, Kim S-K, Jha MK, Chung K-S, Jeong J (2010) Adsorption of gold(III) from waste rinse water of semiconductor manufacturing industries using Amberlite XAD-7HP resin. Gold Bull 43(3):200–208. doi:10.1007/BF03214987

Gurung M, Adhikari BB, Kawakita H, Ohto K, Inoue K, Alam S (2013) Recovery of gold and silver from spent mobile phones by means of acidothiourea leaching followed by adsorption using biosorbent prepared from persimmon tannin. Hydrometallurgy 133:84–93. doi:10.1016/j.hydromet.2012.12.003

Parajuli D, Kawakita H, Inoue K, Ohto K, Kajiyama K (2007) Persimmon peel gel for the selective recovery of gold. Hydrometallurgy 87(3–4):133–139. doi:10.1016/j.hydromet.2007.02.006

Santos Sopena LA, Ruiz M, Pestov AV, Sastre AM, Yatluk Y, Guibal E (2011) N-(2-(2-Pyridyl)ethyl)chitosan (PEC) for Pd(II) and Pt(IV) sorption from HCl solutions. Cellulose 18(2):309–325. doi:10.1007/s10570-010-9469-8

Kabay N, Cortina JL, Trochimczuk A, Streat M (2010) Solvent-impregnated resins (SIRs)—methods of preparation and their applications. React Funct Polym 70(8):484–496. doi:10.1016/j.reactfunctpolym.2010.01.005

Kondo K, Sawada M, Matsumoto M (2014) Adsorption and separation of palladium and platinum with microcapsules containing tri-n-octylamine hydrochloride. J Water Process Eng 1:115–120. doi:10.1016/j.jwpe.2014.04.002

Rovira M, Hurtado L, Cortina JL, Arnaldos J, Sastre AM (1998) Recovery of palladium(II) from hydrochloric acid solutions using impregnated resins containing Alamine 336. React Funct Polym 38(2–3):279–287. doi:10.1016/S1381-5148(98)00038-8

Saitoh T, Nakane F, Hiraide M (2007) Preparation of trioctylamine-impregnated polystyrene-divinylbenzene porous resins for the collection of precious metals from water. React Funct Polym 67(3):247–252. doi:10.1016/j.reactfunctpolym.2006.12.001

Saitoh T, Suzuki S, Hiraide M (2005) Solid phase extraction of some precious metals from hydrochloric acid to poly styrene-divinylbenzene porous resin impregnated with polyoxyethylene-type nonionic surfactant. J Chromatogr A 1097(1–2):179–182. doi:10.1016/j.chroma.2005.10.002

Tong Y, Yang H, Li J, Yang Y (2013) Extraction of Au(III) by ionic liquid from hydrochloric acid medium. Sep Purif Technol 120:367–372. doi:10.1016/j.seppur.2013.10.028

Lee J-M (2012) Extraction of noble metal ions from aqueous solution by ionic liquids. Fluid Phase Equilib 319:30–36. doi:10.1016/j.fluid.2012.01.033

Whitehead JA, Lawrence GA, Owen MP, McCluskey A (2006) A new route to precious metal recovery and subsequent electrodeposition using ionic liquids. In: Proceedings - Electrochemical Society, p 901–910

Cieszynska A, Wiśniewski M (2012) Extractive recovery of palladium(II) from hydrochloric acid solutions with Cyphos®IL 104. Hydrometallurgy 113-114:79–85. doi:10.1016/j.hydromet.2011.12.006

Cieszynska A, Wisniewski M (2010) Extraction of palladium(II) from chloride solutions with Cyphos ®IL 101/toluene mixtures as novel extractant. Sep Purif Technol 73(2):202–207. doi:10.1016/j.seppur.2010.04.001

Fischer L, Falta T, Koellensperger G, Stojanovic A, Kogelnig D, Galanski M, Krachler R, Keppler BK, Hann S (2011) Ionic liquids for extraction of metals and metal containing compounds from communal and industrial waste water. Water Res 45(15):4601–4614. doi:10.1016/j.watres.2011.06.011

Stojanovic A, Kogelnig D, Fischer L, Hann S, Galanski M, Groessl M, Krachler R, Keppler BK (2010) Phosphonium and ammonium ionic liquids with aromatic anions: synthesis, properties, and platinum extraction. Aust J Chem 63(3):511–524. doi:10.1071/CH09340

Mokhodoeva O, Myasoedova G, Kubrakova I, Nikulin A, Artyushin O, Odinets I (2010) New solid extractants for preconcentrating noble metals. J Anal Chem 65(1):12–16. doi:10.1134/s106193481001003x

Ciezynska A, Regel-Rosocka M, Wisniewski M (2007) Extraction of palladium(II) ions from chloride solutions with phosphonium ionic liquid Cyphos IL101. Pol J Chem Technol 9(2):99–101. doi:10.2478/v10026-007-0037-4

Regel-Rosocka M, Nowak L, Wisniewski M (2012) Removal of zinc(II) and iron ions from chloride solutions with phosphonium ionic liquids. Sep Purif Technol 97:158–163. doi:10.1016/j.seppur.2012.01.035

Regel-Rosocka M, Wisniewski M, Borowiak-Resterna A, Cieszynska A, Sastre AM (2007) Selective extraction of palladium(II) from hydrochloric acid solutions with pyridinecarboxamides and ACORGA®CLX50. Sep Purif Technol 53(3):337–341. doi:10.1016/j.seppur.2006.08.005

de los Rios AP, Hernandez-Fernandez FJ, Alguacil FJ, Lozano LJ, Ginesta A, Garcia-Diaz I, Sanchez-Segado S, Lopez FA, Godinez C (2012) On the use of imidazolium and ammonium-based ionic liquids as green solvents for the selective recovery of Zn(II), Cd(II), Cu(II) and Fe(III) from hydrochloride aqueous solutions. Sep Purif Technol 97:150–157. doi:10.1016/j.seppur.2012.02.040

Cui L, Cheng F, Zhou J (2015) Behaviors and mechanism of iron extraction from chloride solutions using undiluted Cyphos IL 101. Ind Eng Chem Res 54(30):7534–7542. doi:10.1021/acs.iecr.5b01546

Papaiconomou N, Svecova L, Bonnaud C, Cathelin L, Billard I, Chainet E (2015) Possibilities and limitations in separating Pt(IV) from Pd(II) combining imidazolium and phosphonium ionic liquids. Dalton Trans 44(46):20131–20138. doi:10.1039/c5dt03791c

van den Berg C, Roelands CPM, Bussmann P, Goetheer E, Verdoes D, van der Wielen LAM (2009) Preparation and analysis of high capacity polysulfone capsules. React Funct Polym 69(10):766–770. doi:10.1016/j.reactfunctpolym.2009.06.008

Blahusiak M, Schlosser S, Annus J (2015) Separation of butyric acid in fixed bed column with solvent impregnated resin containing ammonium ionic liquid. React Funct Polym 87:29–36. doi:10.1016/j.reactfunctpolym.2014.12.005

Blahušiak M, Schlosser Š, Marták J (2011) Extraction of butyric acid by a solvent impregnated resin containing ionic liquid. React Funct Polym 71(7):736–744. doi:10.1016/j.reactfunctpolym.2011.04.002

Abdolmohammad-Zadeh H, Galeh-Assadi M, Shabkhizan S, Mousazadeh H (2011) Sol-gel processed pyridinium ionic liquid-modified silica as a new sorbent for separation and quantification of iron in water samples. Arabian J Chem DOI. doi:10.1016/j.arabjc.2011.07.006

Liu Y, Zhu L, Sun X, Chen J, Luo F (2009) Silica materials doped with bifunctional ionic liquid extractant for yttrium extraction. Ind Eng Chem Res 48(15):7308–7313. doi:10.1021/ie900468c

Negrea A, Lupa L, Ciopec M, Negrea P, Voda R, Ianasi C (2013) Study of different impregnation methods of inorganic supports with ionic liquids. J Environ Prot Ecol 14(4):1785–1793

Lupa L, Negrea A, Ciopec M, Negrea P (2013) Cs+ removal from aqueous solutions through adsorption onto florisil (R) impregnated with trihexyl(tetradecyl)phosphonium chloride. Molecules 18(10):12845–12856. doi:10.3390/molecules181012845

Arias A, Saucedo I, Navarro R, Gallardo V, Martinez M, Guibal E (2011) Cadmium(II) recovery from hydrochloric acid solutions using Amberlite XAD-7 impregnated with a tetraalkyl phosphonium ionic liquid. React Funct Polym 71(11):1059–1070. doi:10.1016/j.reactfunctpolym.2011.07.008

Gallardo V, Navarro R, Saucedo I, Avila M, Guibal E (2008) Zinc(II) extraction from hydrochloric acid solutions using amberlite XAD-7 impregnated with Cyphos IL 101 (tetradecyl(trihexyl)phosphonium chloride). Sep Sci Technol 43(9–10):2434–2459. doi:10.1080/01496390802119002

Navarro R, Garcia E, Saucedo I, Guibal E (2012) Platinum(IV) recovery from HCl solutions using AMBERLITE XAD-7 impregnated with a tetraalkyl phosphonium ionic liquid. Sep Sci Technol 47(14–15):2199–2210. doi:10.1080/01496395.2012.697522

Navarro R, Saucedo I, Gonzalez C, Guibal E (2012) Amberlite XAD-7 impregnated with Cyphos IL-101 (tetraalkylphosphonium ionic liquid) for Pd(II) recovery from HCl solutions. Chem Eng J 185:226–235. doi:10.1016/j.cej.2012.01.090

Navarro R, Saucedo I, Lira MA, Guibal E (2010) Gold(III) recovery from HCl solutions using Amberlite XAD-7 impregnated with an ionic liquid (Cyphos IL-101). Sep Sci Technol 45(12–13):1950–1962. doi:10.1080/01496395.2010.493116

Hawkins CA, Momen MA, Garvey SL, Kestell J, Kaminski MD, Dietz ML (2015) Evaluation of solid-supported room-temperature ionic liquids containing crown ethers as media for metal ion separation and preconcentration. Talanta 135:115–123. doi:10.1016/j.talanta.2014.12.019

Myasoedova GV, Molochnikova NP, Mokhodoeva OB, Myasoedov BF (2008) Application of ionic liquids for solid-phase extraction of trace elements. Anal Sci 24(10):1351–1353. doi:10.2116/analsci.24.1351

Guibal E, Figuerola Piñol A, Ruiz M, Vincent T, Jouannin C, Sastre AM (2010) Immobilization of Cyphos ionic liquids in alginate capsules for Cd(II) sorption. Sep Sci Technol 45(12):1935–1949. doi:10.1080/01496395.2010.493113

Vincent T, Parodi A, Guibal E (2008) Pt recovery using Cyphos IL-101 immobilized in biopolymer capsules. Sep Purif Technol 62(2):470–479. doi:10.1016/j.seppur.2008.02.025

Vincent T, Parodi A, Guibal E (2008) Immobilization of Cyphos IL-101 in biopolymer capsules for the synthesis of Pd sorbents. React Funct Polym 68(7):1159–1169. doi:10.1016/j.reactfunctpolym.2008.04.001

Navarro R, Ruiz P, Saucedo I, Guibal E (2014) Bismuth(III) recovery from hydrochloric acid solutions using Amberlite XAD-7 impregnated with a tetraalkylphosphonium ionic liquid. Sep Purif Technol 135:268–277. doi:10.1016/j.seppur.2014.02.023

Lira MA, Navarro R, Saucedo I, Martinez M, Guibal E (2016) Influence of the textural characteristics of the support on Au(III) sorption from HCl solutions using Cyphos IL101-impregnated Amberlite resins. Chem Eng J 302:426–436. doi:10.1016/j.cej.2016.05.059

Brunauer S, Deming LS, Deming WE, Teller E (1940) On a theory of the van der Waals adsorption of gases. J Am Chem Soc 62(7):1723–1732. doi:10.1021/ja01864a025

Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60(2):309–319. doi:10.1021/ja01269a023

Barrett EP, Joyner LG, Halenda PP (1951) The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J Am Chem Soc 73(1):373–380. doi:10.1021/ja01145a126

de Boer JH (1958) The shape of capillaries. In: Everett DH, Stone FS (eds) The structure and properties of porous materials, vol 10. Vol Colston Papers. Butterworth, London, p 68

Puigdomenech I (2010) MEDUSA (Make equilibrium diagrams using sophisticated algorithms). 32 bit version edn. Royal Institute of Technology, Stockholm, Sweden

Cieszynska A, Wisniewski M (2011) Selective extraction of palladium(II) from hydrochloric acid solutions with phosphonium extractants. Sep Purif Technol 80(2):385–389. doi:10.1016/j.seppur.2011.05.025

Liu Y, Liu YJ (2008) Biosorption isotherms, kinetics and thermodynamics. Sep Purif Technol 61(3):229–242. doi:10.1016/j.seppur.2007.10.002

Tien C (1994) Adsorption calculations and modeling, Butterworth-Heinemann Series in Chemical Engineering. Butterworth-Heinemann, Newton

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, Oxford

Matsumiya M, Suda S, Tsunashima K, Sugiya M, Kishioka S-Y, Matsuura H (2008) Electrochemical behaviors of multivalent complexes in room temperature ionic liquids based on quaternary phosphonium cations. J Electroanal Chem 622(2):129–135. doi:10.1016/j.jelechem.2008.04.021

Kazama R, Matsumiya M, Tsuda N, Tsunashima K (2013) Electrochemical analysis of diffusion behavior and nucleation mechanism for Dy(II) and Dy(III) in phosphonium-based ionic liquids. Electrochim Acta 113:269–279. doi:10.1016/j.electacta.2013.09.082

Marcus Y (1997) Ion properties. Marcel Dekker, Inc, New York

Campos K, Vincent T, Bunio P, Trochimczuk A, Guibal E (2008) Gold recovery from HCl solutions using Cyphos IL-101 (a quaternary phosphonium ionic liquid) immobilized in biopolymer capsules. Solvent Extr Ion Exch 26(5):570–601. doi:10.1080/07366290802301572

Marták J, Schlosser Š (2007) Extraction of lactic acid by phosphonium ionic liquids. Sep Purif Technol 57(3):483–494. doi:10.1016/j.seppur.2006.09.013

Marták J, Schlosser Š (2016) New mechanism and model of butyric acid extraction by phosphonium ionic liquid. J Chem Eng Data 61(9):2979–2996. doi:10.1021/acs.jced.5b01082

Acknowledgements

The authors acknowledge the financial support from Guanajuato University (CIIC 1,049/2016) and PRODEP, SEP (Project: “Recuperación de metales preciosos contenidos en disoluciones acuosas provenientes de fuentes secundarias”). Cytec (Canada) is acknowledged for the gift of Cyphos IL101 sample. The authors thank Guanajuato University-CONACYT National Laboratory for SEM-EDX analysis.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

ESM 1

(DOCX 4351 kb).

Rights and permissions

About this article

Cite this article

Navarro, R., Lira, M.A., Saucedo, I. et al. Amberlite XAD-1180 impregnation with Cyphos IL101 for the selective recovery of precious metals from HCl solutions. Gold Bull 50, 7–23 (2017). https://doi.org/10.1007/s13404-016-0190-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13404-016-0190-8