Abstract

This study explores the use of a locally isolated yeast strain to enhance bioethanol production. The research investigates the impact of various parameters on bioethanol and glycerol production using the Algerian isolated yeast strain “Saccharomyces cerevisiae” in conjunction with sugarcane byproducts. Fermentation kinetic parameters were determined, and optimization was carried out using response surface methodology (RSM), focusing on sugar concentration (measured in Brix degrees) and inoculum volume (%). Logistic and adapted Gompertz kinetics models were utilized to analyze fermentation duration against bioethanol output. RSM identified optimal conditions with an inoculum size of 6.6% and 25°Bx. Kinetic parameters derived from the model include a peak ethanol concentration (Pm) of 73.55 g/L, a maximum ethanol generation rate (rp,m) of 2.61 g/L/h, and a latency phase duration (tL) of 1.47 h. The study showcases the significant potential of the locally isolated yeast strain in achieving substantial bioethanol yields from sugarcane molasses, paving the way for large-scale production efforts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The global economy continues to rise, leading to increased energy consumption and high levels of greenhouse gases in the atmosphere, thereby exacerbating climate change. This surge has occurred within the context of the primary energy supply, where fossil fuels make up 81%, nuclear energy 5%, and renewable energies 14%. Notably, biomass plays a significant role, constituting approximately 70% of the renewable energy sector [1].

In response to the urgent need for environmental protection and reduced reliance on finite fossil fuels, the world is firmly committed to promoting renewable energies, particularly biofuels. Although the production and utilization of these biofuels initially sparked widespread criticisms over their potential impact on food security and land exploitation [2], biomass now emerges as highly promising substitutes for traditional fossil fuels. Its predictable availability and abundance of third-generation resources make it a viable option for sustainable energy production. Moreover, bioenergy offers the added prospects for converting renewable organic waste into energy [3].

In line with global efforts, Algeria has embarked on a green energy initiative with an ambitious program aimed at developing renewable energies and enhancing energy efficiency. With a firm commitment to renewable energies, Algeria aims to provide comprehensive and sustainable solutions to global environmental challenges [4]. The energy sectors, in particular, will act as the driving force behind sustainable economic development, fostering a new paradigm of economic growth.

In the field of renewable energies, bioethanol emerges as the most popular alcoholic biofuel available on the current world market, offering several advantages as an alternative fuel. A broad variety of substrates can be utilized for ethanol bio-production, with each selected based on its cost-effectiveness, profitability, and ready availability [5]. However, despite these benefits, industrial ethanol production faces challenges related to factors such as temperature, sugar concentration, and yeast strains [6].

To address these challenges, indigenous yeast strains have drawn attention for their resilience and suitability for bioethanol production [7]. These strains, isolated from diverse sources [8,9,10,11], are recognized for their robustness and resilience to stress, making them attractive candidates for fermentation processes [12,13,14,15,16]. However, despite their resilience, environmental fluctuations and variations in yeast culture composition can still exert pressure on the strains, thereby affecting their growth and production [17].

This situation emphasizes the need for careful management of environmental conditions and yeast culture composition to ensure the success of fermentation processes. Despite these obstacles, using indigenous strains is crucial for sustainable bioethanol solutions. Their natural adaptability to local conditions provides significant benefits in production stability and performance. This underscores the importance of utilizing indigenous yeast strains, which have inherent qualities that allow them to thrive and remain productive even in difficult conditions [18].

Along with the use of indigenous yeast strains, efforts to optimize the efficiency of bioethanol production are essential. Statistical approaches such as response surface methodology (RSM) play a crucial role in this effort. By identifying and optimizing operational parameters, RSM allows researchers to maximize production efficiency and evaluate interactions between variables [19, 20]. The central composite design (CCD) is an essential component of RSM, which enhances experimentation efficiency [20, 21]. These statistical techniques not only complement the use of indigenous yeast strains, but also create synergy with them, collectively advancing the quest for efficient bioethanol production.

This study aims to not only optimize fermentation conditions to improve bioethanol yield and minimize glycerol formation, but also to further investigate the performance of the isolated yeast strain. Advanced modeling techniques will be utilized to gain a comprehensive understanding of how this indigenous yeast strain grows under different conditions. Furthermore, the study will assess the performance of the process under operational conditions, using the modified Gompertz model to accurately represent bioethanol production. The insights obtained from this multifaceted approach hold significant promise for informing the design and implementation of large-scale bioethanol plants in various feedstock processing industries, particularly through the use of indigenous yeast strains [22].

2 Materials and methods

2.1 Feedstock

Sugar cane molasses was used as the substrate, obtained from an Algerian sugar factory (CEVITAL), and stored at 4 °C until use.

2.2 Microorganism and inoculum preparation

A local yeast strain, S1 Saccharomyces cerevisiae, previously isolated for its ability to produce bioethanol from different saccharides, was used in this study. Active cultures for fermentation experiments were prepared by growing S1 in Yeast Malt Broth (YM medium) with the following composition in grams per liter: yeast extract 3, malt extract 3, peptone 5, and glucose 10. The pH was adjusted to 5.5 with 1 M sulfuric acid, and the culture was maintained at 30 °C for 24 h, until reaching the OD level of 1, all within a shaking incubator agitating at 120 rpm. The cells growing after 24 h were used as inoculum for subsequent runs.

2.3 Molasses pretreatment

Prior to fermentation, for 18 h, 0.5 M sulfuric acid (H2SO4) was added to molasses to reach a pH sample of 4.0.

The precipitate was subsequently removed, and fermentation was processed with pH 4 clear supernatant, a pH condition considered optimal for Saccharomyces cerevisiae growth [23].

2.4 Fermentation process

Fermentation was performed in 250-mL Erlenmeyer flasks, each containing 150 mL of pretreated sterile molasses. Concentrated molasses (83°Bx) is diluted with distilled water to obtain different concentrations. The medium was not enriched with any mineral supplementation, and the pH was adjusted to 4 with sulfuric acid 1 M. The incubator shaker was maintained at a constant temperature of 30 °C while being agitated at 120 rpm, and fermentation continued for 72 h. The batch fermentation was done in triplicate. Samples were collected at 4-h intervals and stored at − 20 °C for analysis.

2.5 Analytical methods

Sugarcane molasses was characterized by different methods of analysis. The percentage (W/V) of soluble solids (°Bx) was determined with a hand-held refractometer (Scihemtech;)(type Abbé). Protein concentration was determined by the Kjeldahl method and lipid concentration by the Soxhlet method. Ashes were quantified using a muffle oven at 550 °C (Afnor 1986). Phosphore was measured by the photometric method (Palintest 8000, England). Potassium was determined by atomic absorption spectroscopy; chloride was determined by a titrimetric method; pH was measured using an OHAUS STARTER 3100C pH meter.

After fermentation, cell density in each sample was measured with a UV-visible spectrophotometer (PerkinElmer, Lambda 25) at 620 nm for cell growth.

Measurements were performed immediately after centrifugation at 3000 rpm for 5 min, and pH was measured directly in the sample medium.

The supernatant was used to analyze ethanol, glycerol, and sugar concentrations by HPLC involving ions exclusion column HPX-87H column (300 × 7.8 mm, Bio-Rad, Hercules, CA, USA), kept at 45 °C (Oven Croco Cil™; Cluzeau-Info-labo, Ste Foy La Grande, France). The eluent for separation was sulfuric acid (0.01 M), applied at a flow rate of 0.7 mL.min−1. The column was coupled with a Shimadzu RIO-6A Refractive Index Detector (Japan) which was used for the detection of various compounds [24].

2.6 Fermentation efficiency

The ethanol yield, determined by the ratio of ethanol produced to the amount of sugar consumed (g/g), is calculated as follows:

The ethanol productivity (g/L/h) was calculated as the ratio of ethanol concentration (g/L) to fermentation time (h):

Fermentation efficiency was determined by the comparison of the percentage of actual ethanol yield to the theoretical one.

The yield of glycerol production (g/g) was defined according to the following equation:

The sugar consumption rate was calculated as the ratio of sugar consumption (g/L/h) at a given fermentation time.

2.7 Experimental design and statistical analysis

Response surface methodology (RSM) was used to optimize the bioethanol production process from sugar cane molasses and to investigate the influence of different variables on both bioethanol and glycerol yield. The central composite design CCD was applied to study process variables and to design experimental data.

Two independent variables such as Brix (X1) and inoculum volume (X2) were chosen according to literature results and preliminary experiments in our laboratory [25, 26].

The response variables selected were bioethanol and glycerol yield. Table 1 lists the independent variables with their corresponding coded and actual values.

A central composite design (CCD) with three center points was set up, 11 experiments were carried out with various combinations of the independent variables, and the results are gathered in Table 2. For convenience, analyses were performed using coded independent variables (− α, − 1, 0, + 1, + α) rather than actual values.

The response of the dependent variable was evaluated using second-order polynomial Eq. (6) with variance for each variable divided into linear, quadratic, and interactive components as described below:

where Y is the predicted response, x1 and x2 are the coded levels of independent variables, a0 is the offset term, a1 and a2 are the linear effects, a11 and a22 are the quadratic effects, and a12 is the interaction effect.

A positive relationship between the independent variable and the response is shown by a positive coefficient, while a negative coefficient indicates a negative relationship. Model quality was estimated by the coefficient of determination (R2).

The statistical significance of the quadratic model was evaluated by performing the F-test for analysis of variance (ANOVA). A confidence level greater than 95% or a p-value less than 0.05 was used to identify significantly influencing variables regarding ethanol and glycerol production.

2.8 Kinetic model of bioethanol production

The formation of products and byproducts during the fermentation process can be described by several mathematical models.

In most cases, bioethanol production is modeled using the modified Gompertz model.

For this purpose, the production of bioethanol in our study is estimated by the following equation:

Equation (7) relates the bioethanol concentration (p) to the potential maximum bioethanol concentration (Pm), maximum bioethanol production rate (rp,m), and the lag time (tL) where P is the bioethanol concentration (g/L), Pm is the potential maximum bioethanol concentration (g/L), rp,m is the maximum bioethanol production rate (g/L/h), and tL is the time from the beginning of fermentation to exponential bioethanol production (h).

3 Results and discussion

Before starting fermentation, chemical characterization of sugarcane molasses was carried out in order to decide whether or not to add a mineral supplement.

3.1 Chemical characterization of sugarcane molasses

The chemical composition and physicochemical properties of sugarcane molasses are summarized in Table 3.

As shown in Table 3, sugarcane molasses used in our study showed its richness in several components which led to its use without any additions; this composition is quite similar to those reported in several studies. However, some differences are noted in terms of mineral composition [27,28,29,30].

The small differences in molasses composition reported by various authors can be linked to factors such as the geographic origin of the feedstock, the type of molasses, and the processing conditions [31]. Molasses as a raw material contains significant quantities of various chemical components, which are necessary for yeast growth. Indeed, the sugar composition is in a readily fermentable form, making it an ideal feedstock for bioethanol production [27].

3.2 Experimental design and statistical analysis

A central composite design (CCD) with three center points was set up, and eleven experiments were carried out. Studied factors and levels are given in Table 4.

3.3 Statistical analysis

Based on CCD and experimental results, RSM was used to optimize fermentation process design factors (independent variables). The obtained experimental data were evaluated by ANOVA analysis and adjusted to a second-order polynomial equation by multiple regression analysis using JMP 7 Software. The regression equation characterizing the influence of different considered variables on bioethanol and glycerol process yields is as follows:

An ANOVA test was performed to assess the statistical significance of independent factors and their interactive effects on both bioethanol and glycerol production (Tables 5, 6, and 7).

Tables 5 and 6 show the regression coefficients, t-values, and p-values for the models representing bioethanol production (Eq. (8)) and glycerol formation (Eq. (9)). Concerning bioethanol production, we observed that the linear term of Brix degree (X1) was highly significant and had a strong positive effect on bioethanol production. Moreover, the linear effect of inoculum concentration (X2) was negative and significant at a 5% probability level. Regarding interactions between variables (X1X2), their effect on bioethanol production was positive but not statistically significant (p-value > 0.05). The quadratic effect of the Brix degree (X1) was negative and highly significant, while the quadratic effect of inoculum concentration (X2) was negative and not significant.

In relation to glycerol formation (Eq. (9)), Table 6 reveals that only the linear term of Brix degree (X1) was statistically significant and had a strong positive impact on glycerol formation. The linear effect of inoculum concentration (X2) was positive, but not statistically significant (p = 0.0591) suggesting that inoculum concentration may have some effect on the response variable, but it is not strong enough to be considered statistically significant at a significance level of 0.05. The quadratic effect of X2 was negative and not significant. As for the interaction between X1X2, the effect was positive but not statistically significant.

According to the results in Table 7, the model was statistically significant with an F-value of 42.92 and a low probability p-value of ≤ 0.0004.

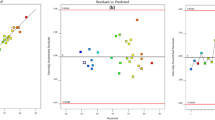

Furthermore, the evaluation of the model was also checked using the correlation coefficient (R2) and adjusted coefficient (R2adj); their values were found to be 0.98 and 0.95, respectively. These values indicate that 95% of the variability in response could be explained by the model with the elimination of 5% of the total variation in bioethanol production. Figure 1 shows the predicted versus the experimental value of response (bioethanol yield) for all runs. The high correlation coefficient (R2 = 0.98) observed in the graph indicates a strong positive correlation between the predicted and experimentally obtained values. This correlation demonstrates that the predicted values align closely with the actual experimental results, thus confirming the accuracy and reliability of the predictive model.

Regarding glycerol formation as the response variable, the ANOVA analysis showed that the regression model was highly significant. This is attested by the calculated Fisher’s “F” value, which stands at 31.12, and an associated probability p-value of 0.0009 (Table 8). A large F-value with a corresponding small p-value indicates a high significance of the respective coefficient.

Moreover, the values of R2 and R2adj were found to be 0.97 and 0.94, respectively. These values indicate that 94% of the response variability may be explained by the model.

While eliminating 6% of the total variation in glycerol production. Figure 2 shows the predicted versus experimental values of the response variable, glycerol yield, for all experimental runs.

It can be observed that there is a positive correlation (R2 = 0.94) between the predicted and experimental values, indicating good agreement between these values.

The results obtained in this study highlight the relationship between the considered variables, Brix degree, and inoculum concentration and their effect on both bioethanol production and glycerol formation.

In fact, in our study, when we started fermentation with an initial concentration of total sugars of 124 g/L (12.93°Bx), we obtained the lowest concentration of bioethanol and glycerol, 26.27 g/L and 3.54 g/L, respectively. These values reach their maximum at 256.98 g/L (27°Bx) of total sugars, and then, we obtain 71.24 g/L of ethanol and 6.4 g/L of glycerol.

These findings are in line with the established literature, which indicates that an increase in the sugar concentration results in an elevated production rate of bioethanol and glycerol [32, 33].

Zentou et al. [32] reported that fermentation with glucose concentrations varying between 25 and 250 g/L resulted in an increase in bioethanol and byproducts, particularly glycerol.

However, our results reveal that at certain high glucose concentrations, there is a reduction in ethanol levels and an increase in glycerol formation.

We obtained a reduction in ethanol production of 71.24 g/L when we attempted a high sugar concentration at 256.89 g/L, corresponding to 27°Bx.

According to Vučurović et al., substrate inhibition becomes significant at a sugar concentration higher than 175 g/L [34]. However, Beigbeder et al. observed a reduction in ethanol concentration when the sugar beet molasses concentration was higher than 225 g/L [35].

The reduction of ethanol production is probably due to the inhibitory effects of elevated glucose levels, which hinder the growth of yeast cells and the efficient utilization of carbon sources. This, in turn, results in increased osmotic stress, which requires additional glycerol, leading to reduced ethanol concentration and yield [36, 37].

Regarding the inoculum concentration, its impact is critical in bioethanol production as it can affect the fermentation process and the final ethanol yield [38, 39]. Our experimental outcomes corroborate these findings. Indeed, the present results demonstrate that, regardless of the Brix degree used in this study, there was a significant reduction in the rate of bioethanol production as the inoculum concentration increased suggesting that for our locally isolated yeast strain, an increase in inoculum concentration has a negative impact on bioethanol production. The results in Table 4 show that using 17.07% of the inoculum led to the production of 52.07 g/L of bioethanol, whereas using the same concentration of sugar notably 190.36 g/L and decreasing the inoculum volume to 2.93% produced a higher bioethanol concentration of 70.29 g/L.

In their study focusing on the use of sweet sorghum stalk juice to produce ethanol, Chauhan et al. [40] observed that using 5% yeast inoculum size resulted in higher ethanol yield as compared to 10% and 15%. Their findings align closely with the results obtained in our study.

Furthermore, our results also reveal that, as the ethanol yield decreases with the increase in yeast concentration, an increase in glycerol synthesis is observed. This phenomenon can be attributed to cellular behavior, which, at higher concentrations, tends to allocate metabolic resources to glycerol production as a stress response mechanism at high cell densities [38, 41]. This accumulation of glycerol, as an osmoprotectant, then competes with ethanol production, leading to a reduction in ethanol yield [42].

Chauhan et al. [40] and Laopaiboon et al. [43] have suggested that inoculum concentration may not affect considerably the final ethanol concentration. Nevertheless, it influences significantly the level of sugar consumption and the efficiency of ethanol production.

3.4 Optimization of bioethanol production: batch fermentation under optimum conditions

The desirability function was used to optimize the fermentation parameters in view to achieving the maximum bioethanol yield (Fig. 3).

As shown in Fig. 3, an optimal design with a desirability factor of 0.98 was attained at 25°Bx and 6.6% inoculum volume.

During the fermentation of synthetic molasses with Saccharomyces cerevisiae, Reddy et al. deduced optimal conditions that are very close to ours, namely, 300 g/L sugar and 2 g/L inoculum [44]

However, with a desirability factor of 0.817, Maiti et al. [45] predicted an ethanol concentration of 50.49 g/L under optimal conditions, namely, 220.7 g/L of total sugar concentration.

In this study, batch fermentation was conducted under optimized conditions determined through the application of the desirability function. The desirability function facilitated the identification of the ideal combination of fermentation parameters aimed at maximizing bioethanol yield from sugarcane molasses using Saccharomyces cerevisiae.

Under the optimized conditions, characterized by a sugar concentration of 237.95 g/L (25°Bx) in the molasses and an inoculum volume of 6.6%, the batch fermentation process demonstrated promising outcomes. The desirability factor of 0.98 indicated the attainment of an optimal design, maximizing bioethanol yield. The predicted maximum bioethanol concentration reached 75.08 g/L, while glycerol, a common byproduct of yeast fermentation, was produced at a concentration of 5.7 g/L. These findings underscore the efficacy of the optimization process in enhancing bioethanol production from sugarcane molasses.

During fermentation, Saccharomyces cerevisiae exhibits varied behaviors in consuming these sugars, as illustrated in Fig. 4 and supported by findings from Phowchinda and Strehaiano [46]. Despite a 3-day fermentation period, sugars were not entirely consumed, as shown in Fig. 1. Notably, sucrose hydrolysis into fructose and glucose occurred after 24 h. This process involves two mechanisms: extracellular invertase–mediated breakdown of sucrose into glucose and fructose, followed by facilitated diffusion into the cell via hexose transporters, or active transport into the cell, followed by intracellular hydrolysis [47, 48].

Saccharomyces cerevisiae demonstrates a preference for glucose over fructose [49]. Figure 4 indicates that not all sugars were fully utilized by the end of fermentation, suggesting the glucophilic characteristics of the isolated yeast strain. Similar observations were made in studies by Sudibyo et al. [50] and Tronchoni et al. [51].

As shown in Fig. 5, yeast growth continued until the end of the culture, reaching a final OD value of 2.97. Bioethanol production commenced at the first sampling, 12 h into fermentation, peaking at 75.1 g/L after 72 h of cultivation.

In addition to ethanol production, some studies have highlighted the coproduction of added-value compounds such as glycerol [52] and volatile compounds [53].

In the present study, glycerol production was observed after 24 h of fermentation, reaching 5.82 g/L by the end of fermentation. Phukoetphim et al. [54] also observed an increase in glycerol concentration with rising sugar concentration.

Furthermore, studies by Attfield [55] and Jiménez-Martí et al. [56] indicated that yeast cells, under specific environmental conditions, produce glycerol to counter osmotic stress caused by high sugar concentrations.

This section highlights the robustness of the fermentation process under optimized conditions, shedding light on the metabolic behavior of locally isolated Saccharomyces cerevisiae and its implications for bioethanol production. The success of batch fermentation processes relies not only on optimizing fermentation parameters but also on understanding and mitigating yeast stress factors. Changes in environmental conditions and yeast culture medium composition can induce stress at various levels, including macroscopic, microscopic, and molecular [17]. Factors such as the composition of the culture medium [57], osmotic pressure [58], ethanol accumulation [59], and temperature [60] contribute to yeast stress, affecting their growth capacities and production [61, 62].

During stress, yeast cells undergo metabolic changes, including an increase in intracellular glycerol concentration and a decrease in metabolic activity, leading to reduced glucose utilization and growth rates [63]. While glycerol plays a crucial role in maintaining the NAD + /NADH balance and initiating ethanol fermentation [64], its excessive production can have negative implications for the fermentation process. Glycerol consumption accounts for a significant portion of the carbon source, approximately 4%, in Saccharomyces cerevisiae fermentation [64]. Thus, minimizing glycerol formation is essential in bioethanol production to enhance ethanol yields, reduce costs, optimize resource utilization, and increase overall process efficiency [65]. Understanding the interplay between yeast stress, glycerol formation, and fermentation parameters is essential for maximizing bioethanol production efficiency. By addressing these factors, researchers can develop strategies to optimize fermentation conditions, mitigate yeast stress, and enhance bioethanol yields.

Moreover, we calculated the kinetic parameters of bioethanol production, including an ethanol yield of 0.33 g/g, ethanol productivity of 1.04 g/L/h, and an efficiency of 66%. These results align with those reported by Roukas [66], with an ethanol yield of 0.3 g/g. However, Hamouda et al. [10] obtained a higher ethanol yield (0.41 g/g), likely due to the inhibitory effect of other byproducts. In our study, a glycerol yield of 0.025 g/g was obtained, consistent with the findings of Jagtap et al. [67].

3.5 Fermentation kinetics of bioethanol production

The kinetics of bioethanol production under optimal conditions is illustrated in Fig. 6, showing both experimental and calculated values.

Fitting of the modified Gompertz models to the experimental results of bioethanol concentration (g/L) vs time (h). \(\begin{array}{c}{[\text{EtOH}]}= 73.55.\text{exp}\left.\left\{-\text{exp}\left[2.61 \left.\frac{{\text{exp}(1)}}{73.55}\right]\right.\right..\left(10.47-\left.t\right)\right.+1\right\}\\ {R}^{2}=99.89\%\end{array}\)

The adjustment was carried out with the modified Gompertz model. The coefficient of determination (R2) value of the model was found to be 0.9989, suggesting that the modified Gompertz equation is able to adequately describe ethanol production during the fermentation of sugarcane molasses.

The kinetic parameters of the proposed model were determined to be Pm = 73.55 g/L for the maximum ethanol, rp,m = 2.61 g/L/ h for its maximum production rate, and tL = 10.47 h for the lag phase. These results correspond well to experimental data confirming the good fit of our model.

Our results are similar to those of some authors in terms of maximum bioethanol production Pm, as shown in Table 9.

Indeed, Dodić et al. [68] obtained raw juice Pm = 73.31 g/L, and Priyadharsini et al. [69] produced a maximum ethanol corresponding to Pm = 69.07 g/L, with Kappaphycus alvarezii waste.

On the other hand, Abada et al. [70] reported a maximum ethanol concentration Pm = 49.81 g/L, while Salakkam et al. [71] achieved a maximum ethanol concentration Pm = 108 g/L.

We can also observe that there is a difference in the lag phase and maximum production rate between all the studies.

In our case, the obtained lag phase (tL) = 10.47 h is relatively longer than those reported in most of the works cited in Table 9, but not as long as those reported by Kularathne et al. [72] with tL = 17.56 h, suggesting that our yeast needs probably time to adapt to the initial high sugar concentration.

Indeed, it is reported that the difference in kinetic parameter values can be attributed to several factors, such as sugar concentration, substrate type, inoculum type and size, and working volume [73].

Through the kinetic parameters obtained, our results show the potential of the isolated yeast to achieve a higher maximum bioethanol concentration.

4 Conclusion

This study investigates the impact of various parameters on bioethanol and glycerol production from sugarcane molasses. Kinetic parameters of fermentation utilizing Saccharomyces cerevisiae, specifically an Algerian yeast strain that was locally isolated, were also determined. The promising performance of this strain in fermentable sugar transformation emphasizes its importance in the perspective of large-scale production.

Results obtained using response surface methodology (RSM) indicate effective optimization of fermentation parameters, with high values of R2 (0.98) and R2adj (0.95). Particularly, a maximum bioethanol concentration of 75.08 g/L at 25°Bx with a 6.6% inoculum rate demonstrated the robust potential of this local strain.

The Gompertz model, with a high precision of R2 at 0.99, strengthened result validity and highlighted the robustness of our approach.

These findings indicate that Saccharomyces cerevisiae strain S1 shows great potential for a transition to large-scale industrial production of bioethanol from sugarcane waste. Further exploration in larger-scale bioreactors is recommended to fully unlock the complete capabilities of this locally isolated yeast for industrial applications.

References

Popp J, Kovács S, Oláh J, Divéki Z, Balázs E (2021) Bioeconomy: biomass and biomass-based energy supply and demand. New Biotechnol 60:76–84

Bento AM, Kanbur R, Leard B (2012) Super-additionality: A neglected force in markets for carbon offsets. CEPR Discussion Paper No. DP8952, Available at SSRN: https://ssrn.com/abstract=2066325

Balat M, Ayar G (2005) Biomass energy in the world, use of biomass and potential trends. Energy Sources 27(10):931–940

Sefiane S, El Hoda MN, Ahmed H (2022) Financial or socio-economic feasibility? Potential assessment of renewable energy investment in Algeria. J Asian Energy Stud 6(1):48–58

Sarris D, Matsakas L, Aggelis G, Koutinas AA, Papanikolaou S (2014) Aerated vs non-aerated conversions of molasses and olive mill wastewaters blends into bioethanol by Saccharomyces cerevisiae under non-aseptic conditions. Ind Crop Prod 56:83–93

Hamouda HI, Nassar HN, Madian HR, Amr SSA, El-Gendy NS (2015) Statistical optimization of batch ethanol fermentation of sugarcane molasses by Candida tropicalis strain HSC-24. Int J ChemTech Res 8:878–889

Olawale BI, Iliyasu MY, Musa B, Abdulrahman A, Umar AF (2021) Production of bioethanol by co-culture of Aspergillus niger and Saccharomyces cerevisiae using watermelon peels as substrate. Traektoriâ Nauki= Path Sci 7(10):6001–6011

Lee YJ, Choi YR, Lee SY, Park JT, Shim JH, Park KH, Kim JW (2011) Screening wild yeast strains for alcohol fermentation from various fruits. Mycobiology 39(1):33–39

Boudjema K, Fazouane-Naimi F, Hellal A (2016) Isolation, identification of yeast strains producing bioethanol and improvement of bioethanol production on cheese whey. Turk J Biochem 41(3):157–166

Hamouda HI, Nassar HN, Madian HR, El-Sayed MH, El-Ghamry AA, El-Gendy NS (2016) Isolation of fermentative microbial isolates from sugar cane and beet molasses and evaluation for enhanced production of bioethanol. Energy Sources A: Recovery Util Environ Eff 38(15):2170–2180

Tenea GN, Veintimilla F (2021) Potential use of native yeasts to produce bioethanol and other byproducts from black sugarcane, an alternative to increment the subsistence farming in northern Ecuador. Sustainability 13(19):10924

Brooks AA (2008) Ethanol production potential of local yeast strains isolated from ripe banana peels. Afr J Biotechnol 7(20)

Hawaz E, Tafesse M, Tesfaye A, Kiros S, Beyene D, Kebede G, Muleta D (2023) Optimization of bioethanol production from sugarcane molasses by the response surface methodology using Meyerozyma caribbica isolate MJTm3. Ann Microbiol 73(1):2

Dmytruk KV, Kurylenko OO, Ruchala J, Abbas CA, Sibirny AA (2017) Genetic improvement of conventional and nonconventional yeasts for the production of first-and second-generation ethanol. Biotechnology of yeasts and filamentous fungi pp 1–38

Knauf M, Kraus K (2006) Specific yeasts developed for modern ethanol production. Sugar Ind/Zuckerindustrie 131(11):753–758

Ylitervo P, Franzén CJ, Taherzadeh MJ (2011) Ethanol production at elevated temperatures using encapsulation of yeast. J Biotechnol 56(1):22–29

Sainz J, Pizarro F, Pérez-Correa JR, Agosin E (2003) Modeling of yeast metabolism and process dynamics in batch fermentation. Biotechnol Bioeng 81(7):818–828

Panagan AT (2021) Indigenous yeast for bioethanol production. J Phys: Conf Ser IOP Publ 1940(1):012044

Latha S, Sivaranjani G, Dhanasekaran D (2017) Response surface methodology: a non-conventional statistical tool to maximize the throughput of Streptomyces species biomass and their bioactive metabolites. Crit Rev Microbiol 43(5):567–582

Asadi N, Zilouei H (2017) Optimization of organosolv pretreatment of rice straw for enhanced biohydrogen production using Enterobacter aerogenes. Bioresour Technol 227:335–344

Adnan NAA, Suhaimi SN, Abd-Aziz S, Hassan MA, Phang LY (2014) Optimization of bioethanol production from glycerol by Escherichia coli SS1. Renew Energy 66:625–633

Kechkar M, Sayed W, Cabrol A, Aziza M, Toudert AZ, Amrane A, Djelal H (2019) Isolation and identification of yeast strains from sugarcane molasses, dates and figs for ethanol production under conditions simulating algal hydrolysate. Braz J Chem Eng 36:157–169

Salari R, Salari R (2017) Investigation of the best Saccharomyces cerevisiae growth condition. Electron Physician 9(1):3592

Djelal H, Amrane A, Lahrer F, Martin G (2005) Effect of medium osmolarity on the bioproduction of glycerol and ethanol by Hansenula anomala growing on glucose and ammonium. Appl Microbiol Biotechnol 69(3):341–349

Faramarzi S, Anzabi Y, Jafarizadeh-Malmiri H (2019) Selenium supplementation during fermentation with sugar beet molasses and Saccharomyces cerevisiae to increase bioethanol production. Green Process Synth 8(1):622–628

Sherpa KC, Kundu D, Banerjee S, Ghangrekar MM, Banerjee R (2022) An integrated biorefinery approach for bioethanol production from sugarcane tops. J Clean Prod 352:131451

Abubaker HO, Sulieman AME, Elamin HB (2012) Utilization of Schizosaccharomyces pombe for production of ethanol from cane molasses. J Microbiol Res 2:36–40

Caldwell D (1998) Molasses in feeds. Adv Equine Nutr II:2000

Artmaktadır AAK (2010) Enhanced production of citric acid by Aspergillus niger M-101 using lower alcohols. Turk J Biochem-Turk J Biochem 35(1):7–13

Palmonari A, Cavallini D, Sniffen CJ, Fernandes L, Holder P, Fagioli L, Mammi L (2020) Characterization of molasses chemical composition. J Dairy Sci 103(7):6244–6249

El-Gendy NS, Madian HR, SSA Amr (2013) Design and optimization of a process for sugarcane molasses fermentation by Saccharomyces cerevisiae using response surface methodology. Int J Microbiol 2013. https://doi.org/10.1155/2013/815631

Zentou H, Zainal Abidin Z, Yunus R, Awang Biak DR, Abdullah Issa M, Yahaya Pudza M (2021) A new model of alcoholic fermentation under a byproduct inhibitory effect. ACS omega 6(6):4137–4146

Yi-Huang C, Ku-Shang C, Chien-Yu C, Hsu CL, Tsan-Chang C, Jang HD (2018) Enhancement of the efficiency of bioethanol production by Saccharomyces cerevisiae via gradually batch-wise and fed-batch increasing the glucose concentration. Fermentation 4(2)

Vučurović VM, Puškaš VS, Miljić UD (2019) Bioethanol production from sugar beet molasses and thick juice by free and immobilised Saccharomyces cerevisiae. J Inst Brew 125(1):134–142

Beigbeder JB, de Medeiros Dantas JM, Lavoie JM (2021) Optimization of yeast, sugar and nutrient concentrations for high ethanol production rate using industrial sugar beet molasses and response surface methodology. Fermentation 7(2):86

Laluce C, Tognolli JO, De Oliveira KF, Souza CS, Morais MR (2009) Optimization of temperature, sugar concentration, and inoculum size to maximize ethanol production without significant decrease in yeast cell viability. Appl Microbiol Biotechnol 83:627-637

Shaghaghi-Moghaddam R, Jafarizadeh-Malmiri H, Mehdikhani P, Alijanianzadeh R, Jalalian S (2019) Optimization of submerged fermentation conditions to overproduce bioethanol using two industrial and traditional Saccharomyces cerevisiae strains 8(1):157–162

Hashem M, Alamri SA, Asseri TA, Mostafa YS, Lyberatos G, Ntaikou I (2021) On the optimization of fermentation conditions for enhanced bioethanol yields from starchy biowaste via yeast co-cultures 13(4):1890

Sar T, Stark BC, Akbas MY (2019) Bioethanol production from whey powder by immobilized E. coli expressing Vitreoscilla hemoglobin: optimization of sugar concentration and inoculum size

Chauhan NM, Hajare ST, Mamo B, Madebo AA (2021) Bioethanol production from stalk residues of chiquere and gebabe varieties of sweet sorghum. Int J Microbiol 2021:1–16

Scanes KT, Hohmann S, Prior BA (1998) Glycerol production by the yeast Saccharomyces cerevisiae and its relevance to wine: a review 19(1)

Tse TJ, Wiens DJ, Reaney MJ (2021) Production of bioethanol—a review of factors affecting ethanol yield. Fermentation 7(4):268

Laopaiboon L, Thanonkeo P, Jaisil P, Laopaiboon P (2007) Ethanol production from sweet sorghum juice in batch and fed-batch fermentations by Saccharomyces cerevisiae. World J Microbiol Biotechnol 23:1497–1501

Reddy PK, Vijay M, Kusuma M, Ramesh KV (2021) Optimum parameters for production of ethanol from synthetic molasses by Saccharomyces cerevisiae. Mater Today: Proc 46:154–156

Maiti B, Rathore A, Srivastava S, Shekhawat M, Srivastava P (2011) Optimization of process parameters for ethanol production from sugar cane molasses by Zymomonas mobilis using response surface methodology and genetic algorithm. Appl Microbiol Biotechnol 385–395:90

Phowchinda O, Strehaiano P (1999) Utilization of mixed sugars for alcoholic fermentation by Saccharomyces cerevisiae. Thammasat Int J Sc Tech 4(2)

Stambuk BU, Batista AS, De Araujo PS (2000) Kinetics of active sucrose transport in Saccharomyces cerevisiae. J Biosci Bioeng 89(2):212–214

Batista AS, Miletti LC, Stambuk BU (2004) Sucrose fermentation by Saccharomyces cerevisiae lacking hexose transport. J Mol Microbiol Biotechnol 8(1):26–33

Guillaume C, Delobel P, Sablayrolles JM, Blondin B (2007) Molecular basis of fructose utilization by the wine yeast Saccharomyces cerevisiae: a mutated HXT3 allele enhances fructose fermentation. Appl Environ Microbiol 73(8):2432–2439

Sudibyo H, Jasman J, Petrus HTBM, Prasetya A, Widianto D, Hidayat C, Prijambada ID (2017) Simultaneous hydrolysis and fermentation of sweet sorghum varieties (FS501 and KCS105) into bioethanol using saccharomyces steineri–a kinetics study. Eng J 21(7):105–121

Tronchoni J, Gamero A, Arroyo-López FN, Barrio E, Querol A (2009) Differences in the glucose and fructose consumption profiles in diverse Saccharomyces wine species and their hybrids during grape juice fermentation. Int J Food Microbiol 134(3):237–243

Djelal H, Larher F, Martin G, Amrane A (2006) Effect of the dissolved oxygen on the bioproduction of glycerol and ethanol by Hansenula anomala growing under salt stress conditions 125(1):95–103

Sarris D, Kotseridis Y, Linga M, Galiotou‐Panayotou M, Papanikolaou S (2009) Enhanced ethanol production, volatile compound biosynthesis and fungicide removal during growth of a newly isolated Saccharomyces cerevisiae strain on enriched pasteasteurized grape musts. Eng Life Sci 9(1):29–37

Phukoetphim N, Salakkam A, Laopaiboon P, Laopaiboon L (2017) Improvement of ethanol production from sweet sorghum juice under batch and fed-batch fermentations: effects of sugar levels, nitrogen supplementation, and feeding regimes. Electron J Biotechnol 26:84–92

Attfield PV (1997) Stress tolerance: the key to effective strains of industrial baker’s yeast. Nature Biotechnol 15(13):1351

Jiménez-Martí E, Zuzuarregui A, Gomar-Alba M, Gutiérrez D, Gil C, Del Olmo M (2011) Molecular response of Saccharomyces cerevisiae wine and laboratory strains to high sugar stress conditions. Int J Food Microbiol 145(1):211–220

Wang FQ, Gao CJ, Yang CY, Xu P (2007) Optimization of an ethanol production medium in very high gravity fermentation. Biotechnol Lett 29(2):233–236

Yokozeki A (2006) Osmotic pressures studied using a simple equation-of-state and its applications. Appl Energy 83(1):15–41

Hirasawa T, Yoshikawa K, Nakakura Y, Nagahisa K, Furusawa C, Katakura Y, Shioya S (2007) Identification of target genes conferring ethanol stress tolerance to Saccharomyces cerevisiae based on DNA microarray data analysis. J Biotechnol 131(1):34–44

Aldiguier AS, Alfenore S, Cameleyre X, Goma G, Uribelarrea JL, Guillouet SE, Molina-Jouve C (2004) Synergistic temperature and ethanol effect on Saccharomyces cerevisiae dynamic behaviour in ethanol bio-fuel production. Bioprocess Biosyst Eng 26(4):217–222

Estruch F (2000) Stress-controlled transcription factors, stress-induced genes and stress tolerance in budding yeast. FEMS Microbiol Rev 24(4):469–486

Hohmann S (2002) Osmotic stress signaling and osmoadaptation in yeasts. Microbiol Mol Biol Rev 66(2):300–372

Martini S, Ricci M, Bonechi C, Trabalzini L, Santucci A, Rossi C (2004) In vivo 13C-NMR and modelling study of metabolic yield response to ethanol stress in a wild-type strain of Saccharomyces cerevisiae. FEBS Lett 564(1–2):63–68

Ribéreau-Gayon P, Glories Y, Maujean A, Dubourdieu D, Darriet P, Towey J (2006) The chemistry of wine: stabilization and treatments

Bideaux C, Alfenore S, Cameleyre X, Molina-Jouve C, Uribelarrea JL, Guillouet SE (2006) Minimization of glycerol production during the high-performance fed-batch ethanolic fermentation process in Saccharomyces cerevisiae, using a metabolic model as a prediction tool. Appl Environ Microbiol 72(3):2134–2140

Roukas T (1996) Ethanol production from non-sterilized beet molasses by free and immobilized Saccharomyces cerevisiae cells using fed-batch culture. J Food Eng 27(1):87–96

Jagtap RS, Mahajan DM, Mistry SR, Bilaiya M, Singh RK, Jain R (2019) Improving ethanol yields in sugarcane molasses fermentation by engineering the high osmolarity glycerol pathway while maintaining osmotolerance in Saccharomyces cerevisiae. Appl Microbiol Biotechnol 103(2):1031–1042

Dodić JM, Vučurović DG, Dodić SN, Grahovac JA, Popov SD, Nedeljković NM (2012) Kinetic modelling of batch ethanol production from sugar beet raw juice. Appl Energy 99:192–197

Priyadharsini P, Dawn SS (2023) Optimization of fermentation conditions using response surface methodology (RSM) with kinetic studies for the production of bioethanol from rejects of Kappaphycus alvarezii and solid food waste. Biomass Convers Bior 13(11):9977–9995

Abada S, Tebbouche L, Bessah R, Kechkar M, Berrached A, Saber M, Amrane A (2022) Experimental study and kinetic modelling of bioethanol production from industrial potato waste. Biomass Convers Biorefin 1–7:1–7

Salakkam A, Phukoetphim N, Laopaiboon P, Laopaiboon L (2023) Mathematical modeling of bioethanol production from sweet sorghum juice under high gravity fermentation: applicability of Monod-based, logistic, modified Gompertz and Weibull models. Electron J Biotechnol 64:18–26

Kularathne IW, Rathneweera AC, Kalpage CS, Rajapakshe S, Gunathilaka CA (2020) Optimization and kinetic parameter estimation of bioethanol production from freely available Sri Lankan fruits in batch fermentation. Ceylon J Sci 49(3):283–291

Moodley P, Kana EG (2019) Bioethanol production from sugarcane leaf waste: effect of various optimized pretreatments and fermentation conditions on process kinetics. Biotechnol Reports 22:e00329

Author information

Authors and Affiliations

Contributions

Madina Kechkar: conceptualization, methodology, formal analysis, investigation, writing original draft preparation, and resources. Majda Aziza: investigation and methodology. Rahma Bessah: supervision, review, and editing. Sabah Abada: investigation. Hayet Djelal: review and editing. Toudert Ahmed Zaid: review and editing. Abdeltif Amrane: review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kechkar, M., Aziza, M., Bessah, R. et al. Optimization and kinetic study of the bioethanol production by a locally isolated strain using response surface methodology. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05807-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05807-8