Abstract

Wastewater from the slaughterhouse industry is characterized by high levels of organic matter and nutrients. Due to this, it cannot be handled by a single or standalone treatment technique such as anaerobic digestion, as it does not provide effluent pollutant (organic matter and nutrients) concentrations that meet the desired discharge limits. The objective of this study was to develop an integrated biological wastewater treatment system that would take slaughterhouse wastewater, produce biogas in an anaerobic digestion unit by removing major organic matter, and remove most of the nutrients and residual organic matter in a microalgae photobioreactor. The integrated bench-scale treatment system indicated perceptible performance, with overall removal efficiencies of 99% of TCOD, SCOD, and BOD, 93–99% of TDS, 99% of TN, 98–99% of NH4+-N and PO4−3, 90–95% of NO3− and TP, and 97–98% of SO4−2. In addition, 189.5 mL/day of biogas and 128.4 mL/day of methane, with an average composition of 67.69%. Furthermore, from the Chlorella species, Scenedesmus species, and their co-cultures’ crude lipid, the biodiesel content of 72–79%, 67–78%, and 71–81%, respectively were obtained. The final effluent of the photobioreactor meets the minimum acceptable national environmental quality standards of Ethiopia. In general, from the lipid composition analysis of microalgae biomass in this study, all three (Chlorella sp., Scenedesmus sp., and co-cultures) strains cultivated in two-phase AD effluent can be noted as suitable feedstock for biodiesel.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Agro-processing industries are major contributors to the industrial pollution in the globe. Similarly, one of the biggest issues that developing countries like Ethiopia have to deal with is the management wastewater from agro-processing industries [1, 2]. Due to the lack of a suitable infrastructure for wastewater collection and treatment, rapid population increase, industrialization, and urbanization have resulted in the production of massive volumes of wastewater that are frequently released carelessly into the environment [3]. Untreated wastewater from slaughterhouse industry, on the other hand, is contaminated with microorganisms that are dangerous to both human health and the ecosystems that receive it [4,5,6]. Likewise, the increasing demand of meat in Ethiopia leads further expansions of slaughterhouses in the country which in turn resulted in a large number of wastewaters released to the environment [7, 8].

In their nature, slaughterhouses are categorized among industries characterized by water-consuming agro-processing industries. The wastewater is mainly composed of manure and urine, blood, stomach materials, and wash waters. Studies have presented that a composite slaughterhouse effluent has a high suspended solids (SS) (3,835.33 to 8,000 mg/L), insoluble and soluble organic concentrations that exhibit high chemical oxygen demand (COD) (4,000 to11,546.67 mg/L), and biological oxygen demand (BOD) (1,200 to 4,500 mg/L), and is categorized as strong wastewater [5, 9]. Moreover, it is also high in phosphorous (30 to 202 mg/L) and nitrogen (95.2 to 1,200 mg/L) contents [10, 11]. These high strengths of the slaughterhouse wastewater (SHWW) cause severe influence to the receiving environment [4, 7], eutrophication effects of nitrate and phosphate, and high oxygen demand of organic wastes, demand appropriate and an all-inclusive management approach [7].

Despite the risks associated with slaughterhouse wastewater, its abundant organic matter and nutrients might be utilized as valuable resources through producing renewable energy in the form of biogas, nutrients in the form of bio-compost (biomass residue or sludge) or supernatant (digestate) [12]. The complexity and variability of the pollutants present issues for such wastewater, necessitating the use of highly efficient technology to meet water quality regulations. In addition, the United Nations is urging everyone to have equitable access to safe and reasonably priced drinking water by 2030 under the Worldwide Sustainable Development Goals (SDGs), as the most recent data from the UN revealed that most nations are still making slow progress toward this objective. Consequently, the attainment of sustainable water provision for society is greatly aided by wastewater treatment. Because beneficial byproducts can be recovered or reused, wastewater management not only creates new business models but also opens up new paths for the circular economy [13, 14]. Therefore, the selection of the most appropriate treatment methods can be important factor to minimize the overall treatment cost. The use of a single type of treatment system such as biological [9] or physicochemical for agro-processing industries like slaughterhouse wastewater still leaves organic matter and nutrients at concentrations above the legal discharge limits [15] or secondary pollutants could potentially be created as a result of adding metal coagulants. Furthermore, cutting-edge technologies including membrane filtration, ion exchange resins, an electrolysis system, and reverse osmosis [16] are unsuitable for use in developing nations, costly, and require skilled personnel. Apart from their dependable treatment capacity and effluent quality, conventional wastewater treatment technologies based on the activated sludge process used in developed countries are typically not suitable for developing countries due to a number of factors, including high installation, maintenance, and operational costs [17]. Several treatment technologies, including physicochemical systems, biological systems (anaerobic or aerobic), constructed wetlands, electrochemical methods, membrane bioreactors, advanced oxidation processes or hybrid systems including two or more of the above-mentioned methods have been proposed and tested for agro-industrial wastewater treatment [17], which differ on their capital and operation cost. To meet allowable pollutants concentration limits and environmental sustainability requirements, agro-processing industries and municipalities requisite to employ proficient wastewater treatment routes [7, 15]. Due to this, different researchers [18, 19] also pinpointed the effectiveness of integrated biological treatment systems compared to conventional treatment schemes for agro-processing industrial wastewater. This is mainly due to the high pollutant removal efficiency and value added product generated from the integrated treatment systems or technologies [15]. Moreover, for the treatment of such a tough agro-processing industrial wastewater evidently preferably handled by integration of different biological processes [20], anaerobic digester or reactor mainly for organic matter removal and phytoremediation as a polishing unit for nutrients and residual organic matter [15]. Many typical post-AD treatment techniques based on physico-chemical and biological approaches address the organic matter and nutrients in the anaerobically treated effluent from the agro-processing industry using different combinations of aerobic and anoxic phases. Unfortunately, because to the high operational and investment costs in the sector [21] as well as the massive amount of sludge produced, these processes typically do not permit regular nutrient recovery. Recent research indicates that using different microalgae species to remediate wastewater from the agro-processing industry is becoming a practical and cost-effective solution. They have the ability to rapidly eliminate COD, total phosphorus (TP), and nitrogen (TN) by a process known as mixotrophic assimilation. When combined with microalgae phosphorus luxury uptake, this method produces high TN, TP, and COD removals at relatively short hydraulic retention times (HRT) [22]. Furthermore, these particular co-culture interactions among microalgae have numerous benefits for handling wastewater processes generated by the agro-processing industry, including slaughterhouses; they promote cell division, enhance or decrease nutrient consumption, introduce the production of allelochemicals, boost resistance to contaminants and predators, and combine single-cell organisms with floating ones to create a settleable system [23]. For biomass generation and nutrient recovery, the majority of study used artificial wastewater or microalgae culture media, such as Bold's Basal media (BBM) in flasks [24]. It is currently uncommon to combine two-phase AD with microalgae cultivation or growing in a photobioreactor [25]. Not much work has been done, though, to remove nutrients and organic matter from partially treated agro-processing industry effluent or to produce bioethanol and biodiesel using a co-culture of Scenedesmus dimorphus and Chlorella vulgaris for treating diluted municipal wastewater and Scenedesmus sgrown in anaerobic digester effluent [19, 26].

Therefore, the objective of this study was to develop and evaluate the pollutant removal efficiency and comparison of the parts of the integrated biological wastewater treatment encompassing AD and microalgae photobioreactors treating slaughterhouse wastewater.

2 Materials and Methods

2.1 The biological integrated experimental set-up

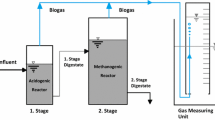

The biological integrated bench-scale system for the treatment of slaughterhouse wastewater established at the Center for Environmental Science consists of a two-phase anaerobic reactor and microalgae photobioreactor. Figure 1 shows the schematic diagram of the biological integrated bench-scale system used for the treatment of the slaughterhouse wastewater. The two anaerobic sequential batch reactors (ASBR) have a total volume of 40 L (36 and 4 L, working and headspace, respectively) and were connected in series with a pipe.

Microalgae were cultivated in a rectangular photobioreactor for the purpose of treating the wastewater after AD. The photobioreactor had the following measurements: 15 cm for height, 20 cm for breadth, and 30 cm for length. The photobioreactor had a working volume of 8* 103 cm3 and a total volume of 9* 103 cm3. The bioreactors were coated with clear plastic glass to prevent contamination. A pair of 20-W Philips fluorescent lamps were utilized as the light source, producing a maximum light intensity of 150–300 μmolm−2 s−1 above the photobioreactor's surface. At room temperature, the photoperiod was controlled by an electric timer switch with a 12:12 light/dark cycle. Air and CO2 were supplied via an aerator at 250 and 100 mL/minute, respectively. For twenty days, the microalgae culture was conducted in duplicate. Semi-continuous (draw and feed) mode was used to feed the photobioreactor with the effluent of the two-phase AD system. The photobioreactor's microalgae biomass was removed after a 20-day incubation period, and a fresh batch was fed. Before feeding, the effluent was filtered via 21-mm Whatman filter paper. The biomass of the microalgae was extracted by evaporation following the experiment's conclusion or after a twenty-day incubation period. After that, the effluent's physico-chemical characteristics were examined. Hence, the complete two-phase AD system had a total volume of 80 L, while the microalgae photobioreactor had a total volume of 9 L. The temperature of the two-phase AD system was maintained at 37.5 ± 0.1 °C using hot water circulated from a thermostatic water bath (Hangzhou West Tune Trading Co., Ltd, Zhejiang, China). The microalgae Chlorella and Scenedesmus species were isolated from freshwater sample, Awassa Lake, Awassa, Ethiopia, and conveyed to the laboratory.

2.2 Operating condition of the integrated system

The SHWW was fed to the HR at an OLR of 1879 mg of COD/L*day. The hydrolytic-acidogenic reactor effluent is then channeled into the MR then to the microalgae photobioreactor. The HR effluent operated at a 3-day HRT or OLR of 1879 mg of COD/L*day was used as a feedstock for the MR phase. The MR was operated at an OLR of 298 mg/L*day at HRT of 6 day. The description of the microalgae photobioreactors were indicated in detail in [6]. Feeding of both reactors (HR and MR) was once a day manually in a sequential manner in order to keep the semi-continuous mode. Initially, the MR effluent was discharged and fed to a microalgae photobioreactor or stored in collection tank. Then, an equal amount of HR effluent was fed to MR by opening the control valves. Lastly, the HR was fed with the same volume of SHWW. The volume discharged or fed to or from the reactors was calculated based on the OLR or HRT and the volume of the reactors in both phases. The performance of bench-scale integrated system treating slaughterhouse wastewater has been evaluated at optimal conditions.

2.3 Wastewater sampling and analysis

From the influent and effluent of each treatment units, triplicate samples were collected for SHWW characterization and performance evaluation of the AD system and microalgae photobioreactors. The analysis of the samples was performed using standard methods (APHA) for the following selected parameters that are considered to be harmful to the receiving environment: chemical oxygen demand (COD), total nitrogen (TN), ammonium nitrogen (NH4+-N), nitrate-nitrogen (NO3−-N) sulfides (S−2) and sulfate (SO4 2−). TS and VS were analyzed according to Standard Methods for the Examination of Water and Wastewater (APHA, 2017) using an oven at a temperature of 105 ℃ and 550 ℃, respectively. Accordingly, TCOD, SCOD, BOD5, TN, NH4+-N, NO3−, TP, PO4−3, SO4−2, and S−2 were following HACH instructions using a spectrophotometer (HACH DR/3900 HACH, Germany). Resistivity, salinity, electrical conductivity (EC), and total dissolved solids (TDS) were analyzed by a multi-meter (EUTECH Instruments, Madrid, Spain). pH and oxidation–reduction potential (ORP) were analyzed using a JENWAY pH meter (JENWAY, Manchester, UK). TVFA and TotA were analyzed using titration according to the standard method [27]. Total biogas production was measured by sucking the biogas collected in a 2-L glucose bag using a 100-mL airtight syringe while its composition was measured using a gas analyzer (Geotechnical Instrument Gas Analyzer, Leamington Spa, UK).

2.4 Data Analyses

The data generated from the sample analysis were entered into the MS Excel spreadsheet based on the objectives set for further statistical analysis. The statistical analysis for mean, standard deviation and one-way analysis of variance (ANOVA) at 95% confidence intervals was performed using Minitab statistical software to compare the performance of the two-phase AD system and microalgae photobioreactor, and Origin 2022 software were used to draw figures. All the sample values analyzed for the parameters under study were taken in at least triplicate.

3 Results and Discussions

The biological integrated treatment system performance efficiency as well as the association between the components (two-phase and microalgae photobioreactor) were presented in subsequent sections. The concentration of pollutants in SHWW and effluent of treatment units is presented in Table 1.

3.1 Organic Matter Removal Efficiency

The organic matter removal efficiency of the bench-scale integrated biological treatment system composed of the two-phase AD and a microalgae photobioreactor as a polishing step was above 90%. The final effluent BOD, SCOD, and TCOD concentrations found for the photobioreactor in which Chlorella sp., Scenedesmus sp., and their co-culture cultivated were 73.67 ± 6.51, 120.67 ± 6.51, and 62.67 ± 4.73 mg/L, respectively. The average overall BOD, SCOD, and TCOD removal efficiency found in this study for Chlorella species, Scenedesmus species, and the co-culture was 98.59, 98.68, and 98.75%; 99.17, 99.21, and 99.31%; 98.69, 97.86, and 98.89%, respectively. Similarly, the overall removal efficiency of TDS and turbidity of an integrated two-phase AD and microalgae photobioreactor system was 93.06, 92.91, 93.76%, and 99.66, 99.51, 99.7% by Chlorella species, Scenedesmus species, and co-culture, respectively (Fig. 2). The results showed that the organic pollutant removal efficacy of the integrated treatment system was found to be very high, demonstrating that the integrated biological system significantly reduced the organic matter to a level that meets the required environmental quality standards of the country (Ethiopia) [28].

Higher organic matter removal efficiency is typically indicated for AD effluent subjected to microalgae-based treatment systems in the literature. For example, [26, 27, 29, 30] reported comparable BOD, SCOD, and COD removal efficiency ranging between 90 and 98% by Chlorella species microalgae cultivated in anaerobically treated agro-processing industry effluent for safe discharge into the environment through substantial microalgae biomass production. In addition, many studies have demonstrated that microalgae can reduce nitrogen by up to 80% [31]. Moreover, several studies have also reported a higher COD removal efficiency of 80.0% to complete removal (100.0%) by Chlorella species [32]. For example, Chlorella vulgaris microalgae cultivated in swine manure digestate loaded with high COD and a microalgae cultivated in unsterilized dairy wastewater showed a COD removal efficiency between 84.18 and 89.70% in an eight-day incubation period at a lab-scale [33, 34]. Van den Hende et al., [35] and [36] also found a higher COD removal rate of 65 and 88.38 mg/L*day, respectively, for the microalgae cultivated in an anaerobically treated effluent. On the other hand, a lower COD removal efficiency of 34% was reported for AD microalgae-based agro-processing industrial wastewater treatment facilities [36]. In general, in many studies, it was concluded that Chlorella species microalgae are capable of instantaneous utilization of nutrients and COD removal when used in wastewater treatment [37, 38].

3.2 Nutrient Removal Efficiency

In recent decades, microalgae-based nutrient removal for AD effluent has become a much-attended concept both at a local and global level for treating domestic, agricultural, and industrial wastewater [39, 40]. Consequently, for evaluating the microalgae-based wastewater treatment system, the removal efficiency of the nutrient plays a key role. High-nutrient loaded anaerobically treated slaughterhouse wastewater has been supposed to be more appropriate for growing microalgae as it enables enhancement in microalgae biomass yield along with improved nutrient removal. The microalgae cells use the phosphorus and nitrogen nutrients from the wastewater for the synthesis of phospholipids, nucleic acids, and proteins [41]. The average final TN, NH4+-N, NO3−, TP, PO4−3, and SO4−2 effluent concentrations were 14 ± 3.61, 13.67 ± 1.53, 11 ± 2.65 mg/L; 3.67 ± 1.53, 7.67 ± 1.53, 2 ± 1 mg/L; 7 ± 1, 8 ± 2, 6.67 ± 1.53 mg/L; 5.67 ± 0.58, 10.67 ± 4.16, 6.67 ± 2.52 mg/L; 4.67 ± 1.53, 6.33 ± 3.21, 3.33 ± 1.53 mg/L, and 11.49 ± 7.38, 9.47 ± 6.51, 10.09 ± 4.74 mg/L by Chlorella, Scenedesmus, and co-culture, respectively (Table 1).

The nutrient RE (%) in terms of TN, NH4+-N, NO3−, TP, PO4−3, and SO4−2 by the integrated system was greater than 90%. More specifically, the TN, NH4+-N, NO3−, TP, PO4−3, and SO4−2 removal efficiencies by Chlorella, Scenedesmus, and Co-culture were 98.83, 98.86, 99.1; 98.92, 97.73, 99.41%; 98.46, 98.24, 98.53%; 94.6, 89.84, 93.65%; 92.51, 89.84, 94.66%, and 97.20, 97.69, 97.54%, respectively. The corresponding effluent concentration obtained by the integrated system for TN, NH4+-N, NO3−, TP, PO4−3, and SO4−2 was below the country’s slaughterhouse or meat processing effluent discharge limit [42].

The TN removal efficiency found in this study is consistent with the previous research results by different scholars such as Zenebe Yirgu et al. [26], and Mohammed et al. [43], who reported 94.36–96.08%, 99.20%, 91.90% of TN by Scenedesmus smicroalgae cultivated in AD effluent agro-processing industry wastewater. Literature also indicated that the removal efficiency of more than 90% to complete removal of NH4+-N attained by Chlorella species, Scenedesmus species, or the co-culture used or applied in tertiary agro-processing industry wastewater treatment [33]. Subramaniyam et al. [44] and Lu et al. [36] found a complete removal efficiency of PO4−3, while Ansari et al. [45] reported TP removal efficiency between 85–88% by Scenedesmus smicroalgae. Furthermore, different researchers [19, 26] also pinpointed the effectiveness of integrated biological treatment systems compared to conventional treatment schemes for agro-processing industrial wastewater. In several studies, it has been shown that microalgae can reduce nitrogen by up to 85% [46]. Similarly, [32, 47, 48] have also reported 80–100% nitrogen and 83.2–100.0% phosphorous removal, which discloses the high nutrient removal efficiency of Chlorella scultivated on anaerobic piggery digestate. In-line with this, Chlorella zofingiensis microalgae from freshwater sources employed to treat piggery wastewater removed 90–100% of TP [48]. Furthermore, for a dairy wastewater in which an integrated AD-microalgae phycoremediation was employed, a 93.0 ± 2.0% removal efficiency of both TP and TN was noted [33]. Again, [47, 49] found higher removal efficiency, which is comparable with this study’s results of greater than 97% for both NH4+-N and PO4−3-P using microalgae as a polishing step for AD effluent. Similarly, Chlorella vulgaris microalgae cultivated in swine manure digestate showed 97.2% and 99.7% removal efficiency for TN and TP, respectively [34]. Chlorella sorokiniana cultivated in AD digestate accomplished TN removal efficiencies of 95.3 ± 1% in 18 days of incubation [50]. Cultivation of microalgae at a lab-scale in unsterilized dairy wastewater showed 83.20–99.26% and 89.92–91.97% removal efficiency of NH4+-N and TP, respectively in eight-days of incubation [51]. However, studies have also reported removal efficiency as low as 50.2 and 65 for TN and TP in anaerobically treated agro-processing industry wastewater coupled with microalgae-based treatment techniques [31, 37]. Literature also concludes that the microalgae Chlorella species are capable of simultaneous utilization of nutrients and organic carbon during wastewater treatment [37]. In Qian et al., [31] it was found that the maximum removal efficiency of TN, NH4+ − N, and TP in the partially (anaerobically) treated piggery effluent was 58, 88, and 65%, respectively, at an initial pH of 9.0. The uptake of phosphate by microalgae is an active process that requires energy, which is stockpiled in the cells and is assimilated in the form of polyphosphate granules by microalgae [52]. Huo et al. [32] evaluated the feasibility of cultivating Chlorella zofingiensis using DW in outdoor ponds with pH regulation by CO2 and acetic acid achieved a maximum TN removal percentage of 51.7% in 5 days. The maximum TN and TP removal rates obtained in indoor cultivation conditions were 9.8–38.34 and 2.03 mg/L*day, respectively, by Van den Hende et al. [35]. The variations in the removal efficiency of TN, NH4+ − N, NO3−, TP, and PO4−3-P by microalgae in the anaerobically treated agro-processing industry may be attributed to the experimental conditions; media type, photoperiod, temperature, pH, microalgae type, and bioreactor type.

3.3 Comparison of the Two-Phase AD and Microalgae Photobioreactor Removal Efficiency

3.3.1 Organic matter removal efficiency

The organic matter such as TCOD, SCOD, BOD, TDS, and turbidity concentration of SHWW, two-phase AD effluent, and photobioreactor effluent in which Chlorella species was employed as a polishing unit were 5366.43 ± 83.80, 910 ± 7.82, 73.67 ± 6.51 mg/L; 4842.21 ± 83.81, 555.23 ± 106.25, 40.40 ± 10.67 mg/L; 2487.48 ± 594.54, 166.10 ± 51.40, 35.15 ± 13.88 mg/L; 1170.74 ± 399.84, 1011.41 ± 138.24, 81.28 ± 11.37 mg/L, and 566.5 ± 18.5, 11 ± 2.160, 1.95 ± 0.87 mg/L, respectively. The TCOD, SCOD, BOD, TDS, and turbidity concentrations of SHWW, two-phase AD effluent, and photobioreactor effluent treated by Scenedesmus swere, 5366.43 ± 83.80, 910 ± 7.82, 120.67 ± 6.51 mg/L; 4842.21 ± 83.81, 555.23 ± 106.25, 38.17 ± 7.66 mg/L; 2487.48 ± 594.54, 166.10 ± 51.40, 32.74 ± 42.03 mg/L; 1170.74 ± 399.84, 1011.41 ± 138.24, 83.01 ± 16.79 mg/L, and 566.5 ± 18.5, 11 ± 2.160, 2.77 ± 1.31 mg/L, respectively. Similarly, the average TCOD, SCOD, BOD, TDS, and turbidity concentrations of SHWW, two-phase AD effluent, and photobioreactor effluent with co-culture were 5366.43 ± 83.80, 910 ± 7.82, 62.67 ± 4.73 mg/L; 4842.21 ± 83.81, 555.23 ± 106.25, 33.59 ± 10.53 ± 7.66 mg/L; 2487.48 ± 594.54, 166.10 ± 51.40, 31.00 ± 8.78 mg/L; 1170.74 ± 399.84, 1011.41 ± 138.24, 73.00 ± 10.15 mg/L, and 566.5 ± 18.5, 11 ± 2.160, 1.72 ± 0.67 mg/L, respectively (Table 1). TCOD, SCOD, BOD, TDS, and turbidity removal efficiency of 82.87%, 88.53%, 93.32%, 73.35%, and 98.06%; 97.86–98.89%, 99.17–99.31%, 98.59–98.75%, 92.91–93.76%, and 99.51–99.70% were achieved at the two-phase AD and polishing steps by microalgae’s photobioreactor, respectively (Fig. 2). In all cases, the TCOD, SCOD, BOD, TDS, and turbidity concentration decreased as it moved from the AD to the microalgae-photobioreactor unit (Fig. 3). As denoted in Fig. 3 most of the organic matter (TCOD, SCOD, BOD, TDS, and turbidity) was removed in the two-phase AD, while their residues were removed at the polishing step in the microalgae photobioreactor. The variations of TCOD, SCOD, BOD, TDS, and turbidity removal efficiency in the two-phase AD system and microalgae’s photobioreactor were significant (p ≤ 0.05).

3.3.2 Nutrient removal efficiency

The TN, NH4+, NO3−, TP, PO4−3, and SO4−2 concentration of SHWW, two-phase AD effluent, and photobioreactor effluent with Chlorella swere 1198.45 ± 145.29, 367.33 ± 8.5, 14 ± 3.61 mg/L; 338.4 ± 58.13, 351.33 ± 18.72, 3.67 ± 1.53 mg/L; 453.58 ± 81.47, 94 ± 7, 7 ± 1 mg/L; 105 ± 12.15, 99 ± 6, 5.67 ± 0.58 mg/L; 62.333 ± 15.948, 71.33 ± 14.57, 4.67 ± 1.53 mg/L, and 410.33 ± 12.72, 135.50 ± 44.31, and 11.49 ± 7.38 mg/L, respectively. In the same way, for the integrated system in which Scenedesmus smicroalgae and the co-culture were used as the polishing step, TN, NH4+, NO3−, TP, PO4−3, and SO4−2 photobioreactor effluent concentrations were 13.67 ± 1.53, 11 ± 2.65; 7.67 ± 1.53, 2 ± 1; 8 ± 2, 6.67 ± 1.53; 10.67 ± 4.16, 6.67 ± 2.52; 6.33 ± 3.21, 3.33 ± 1.53, and 9.47 ± 6.51, 10.09 ± 4.74 mg/L, respectively (Table 1). Removal efficiency of 64.11, -13.01, 27.59, -20.97, 59.51, and -16.09% for TN, NH4+, NO3−, TP, PO4−3, and SO4−2, respectively, were attained in the two-phase AD system. Likewise, at the polishing phase by microalgae photobioreactor, a higher removal efficiency between 98.86–99.10, 97.73–99.41%, 98.24–98.53%, 89.84–94.60%, and 97.20–97.69% were obtained for TN, NH4+, TP, PO4−3, and SO4−2, respectively (Fig. 2). The concentrations of TN, NH4+, NO3−, TP, PO4−3, and SO4−2 decreased as we moved from the two-phase AD to microalgae’s photobioreactor (Fig. 4). As denoted in Fig. 4, TN, NO3−, TP, and SO4−2 removal efficiencies were low in the two-phase AD, and most of the TN, NO3−, TP, and SO4−2 were removed at the polishing step by the microalgae photobioreactor. In the contrary, negative removal efficiencies of NH4+-N and PO4−3 were observed in the two-phase AD system. The variations of TN, NH4+, NO3−, TP, PO4−3, and SO4−2 removal efficiency in a two-phase AD system and a microalgae photobioreactor in which Chlorella sp., Scenedesmus sp., and co-culture cultivated were significant (p ≤ 0.05). Furthermore, as low reductions of TN, NO3−, TP, PO4−3, and SO4−2 are usually expected in AD systems, but higher reductions in TN, NH4+, NO3−, TP, PO4−3, and SO4−2 were attained in the polishing (microalgae photobioreactor) step (Fig. 4). A little or no reduction of nitrate and sulfate was observed in a two-phase AD system, which can be attributed to a sulfate reduction and ammonification of the anaerobic microbial process in an oxygen-free environment. The decrease in the TN concentration in the effluent of the two-phase system is attributed to the conversion of nitrogen-containing compounds in the wastewater to NH4+-N in the AD system by the consortium of microorganisms in the system, and a decrease in concentration and subsequent increase in the TP concentration were attributed to conversion to PO4−3, which is consistent with the conclusion made by scholars [53, 54]. But the integration of microalgae’s photobioreactor into the two-phase AD system removed the higher TN, NH4+, NO3−, TP, PO4−3, and SO4−2 levels in AD to the level acceptable by the EPA of the country (Ethiopia) for slaughterhouse industry effluent before releasing it to the environment Table 1, Fig. 5, [55].

3.4 Bioenergy from the Integrated Biological System

The biogas and methane production rates were 189.5 and 128.4 mL/day, respectively. The methane and carbon dioxide contents of the biogas were 67.69% and 29.9%, respectively. The study findings revealed that biogas production was positively and highly correlated (R2 = 0.98) with total VS removed, implying that the process gained not only biogas production but also organic pollutant removal. The overall biogas produced versus mg of COD and VS reduced was 0.96 and 1.37 mL, respectively. The biodiesel produced from the crude microalgae lipid of Chlorella species, Scenedesmus species, and their co-culture was between 72–79%, 67–78%, and 71–81%, respectively. In general, from the lipid composition analysis of microalgae biomass in this study, all three (Chlorella sp., Scenedesmus sp., and co-culture) strains cultivated in two-phase AD effluent can be noted as suitable feedstock for biodiesel. Hence, integrating biological treatment systems add value to the waste and used as a raw material that can be improved for bioproducts that can contribute to the CE (value-added product and re-use), contribute to the clean water scarcity for the coming generation, and reduce various environmental impacts [46, 56]. The bioenergy from the integrated system is an indicator of circular bioeconomy strategy.

In general, the integrated wastewater treatment system combines the production of renewable energy with the treatment of wastewater, which can simultaneously improve sanitation and renewable energy availability. The biogas energy from an anaerobic digester promotes methane production, traps it, and then transforms it into heat and electricity energy, as well as fertilizer both in digestate and sludge form. Notably, biogas energy is taken into account in the circular carbon economy system diagram, which is characterized as a system that encompasses both the economic and environmental cycles. A circular bioeconomy is promoted by microalgae based bio-refineries, which not only benefit from efficient resource usage but also help to reduce waste and GHG emissions. This innovative strategy has a lot of potential for solving environmental problems and building a sustainable future. Additionally, it advances SDGs six (Clean Water and Sanitation) and seven (Affordable and Clean Energy). It can be concluded that the study results showed that the integrated wastewater consisting of phased AD system coupled with microalgae photobioreactor has dual importance: resource recovery and wastewater treatment.

4 Conclusions

The transformation from agricultural to agro-industrial development needs considerable attention from an environmental and sustainable development point of view in managing the byproducts from the sector. The result of the study showed that the AD system, integrated with microalgae-based treatment, achieved the highest removal efficiencies (ranging between 90 and 99.31%) for organic matter and nutrients. Specifically, the final BOD, SCOD, and TCOD TN, NH4+-N, NO3−, TP, PO4−3, and SO4−2 effluent concentrations of the integrated system were below the country’s slaughterhouse or meat processing effluent discharge limit. Substantial bioenergy in-terms of biogas (189.5 mL/day) with a methane content of (67.69%) and 67–81% biodiesel from the crude lipid microalgae biomass from the integrated system were obtained as a value-added product. Therefore, the established integrated biological treatment system composed of AD-microalgae photobioreactor showed promising result in converting effluent from the slaughterhouse industry into value-added products, such as biogas, biodiesel, and clean water, for use by the industries and nearby communities at least for domestic purposes, such as greenery, floor-washing, machine cleaning, irrigation, and re-using in the slaughtering process.

Data Availability

All the data and materials used in this manuscript are included in the document.

Abbreviations

- ANOVA:

-

Analysis of variance

- AD:

-

Anaerobic digestion

- APHA:

-

American Public Health Association

- ASBR:

-

Anaerobic sequential batch reactors

- BBM:

-

Bold’s basal medium

- BOD:

-

Biological oxygen demand

- COD:

-

Chemical oxygen demand

- EC:

-

Electrical conductivity

- HRT:

-

Hydraulic retention time

- NO3 —N:

-

Nitrate-nitrogen

- NH4-N:

-

Nitrogen ammonium

- OD:

-

Optical density

- OLR:

-

Organic loading rate

- ORP:

-

Oxidation-reduction potential

- RE:

-

Removal efficiency

- Rr:

-

Removal rate

- SCOD:

-

Soluble chemical oxygen demand

- SEM:

-

Scanning electron microscope

- SHWW:

-

Slaughterhouse wastewater

- S2– :

-

Sulfide

- SO4 –2 :

-

Sulfate

- TotA:

-

Total alkalinity

- TDS:

-

Total dissolved solid

- TCOD:

-

Total chemical oxygen demand

- TN:

-

Total nitrogen

- TSS:

-

Total suspended solids

- TN:

-

Total phosphorous

- UN:

-

United Nations

- USAB:

-

Upflow sludge bed

- TVFA:

-

Total volatile fatty acids

- VFA:

-

Volatile fatty acids

References

Ghangrekar SGRMM (2019) Comprehensive review on treatment of high - strength distillery wastewater in advanced physico - chemical and biological degradation pathways. Int J Environ Sci Technol 16(1):527–546. https://doi.org/10.1007/s13762-018-1786-8

Akpomie KG, Conradie J (2020) Banana peel as a biosorbent for the decontamination of water pollutants. A review. Environ Chem Lett 18(4):1085–1112. https://doi.org/10.1007/s10311-020-00995-x

Chan NW (2006) A comparative study of water resources usage by households in Georgetown-Malaysia and Pattaya-Thailand. Iranian J Environ Health Sci Eng. 3(4):223–228. http://journals.tums.ac.ir/abs/3377

Mulu A, Ayenew T (2015) Characterization-of-Abattoir-Wastewater-and-Evaluation-of-the-Effectiveness-of-the-Wastewater-Treatment.doc. Int J Sci Eng Res 6(4):1026–1040. https://www.researchgate.net/publication/284253828%0ACharacterization

Hailu AM, Asfaw SL, Tegaye TA (2020) Effect of carbon-rich-waste addition as co-substrate on the performance and stability of anaerobic digestion of abattoir wastewater without agitation. Bioresour Bioprocess 7:44. https://doi.org/10.1186/s40643-020-00333-7

Tsegaye D, Leta S (2023) Evaluation of biogas production and pollutant removal efficiency of two-phase anaerobic digestion treating slaughterhouse effluent. Biofuels 14(4):1–9. https://doi.org/10.1080/17597269.2023.2185728

Alayu E, Yirgu Z (2018) Advanced technologies for the treatment of wastewaters from agro-processing industries and cogeneration of by-products: a case of slaughterhouse, dairy and beverage industries. Int J Environ Sci Technol 15(7):1581–1596. https://doi.org/10.1007/s13762-017-1522-9

Rajagopal R, Saady NMC, Torrijos M, Thanikal JV, Hung YT (2013) Sustainable agro-food industrial wastewater treatment using high rate anaerobic process. Water (Switzerland) 5(1):292–311. https://doi.org/10.3390/w5010292

Mittal GS (2006) Treatment of wastewater from abattoirs before land application—a review. Bioresour Technol 97(9):1119–1135. https://doi.org/10.1016/J.BIORTECH.2004.11.021

Budiyono, Widiasa IN, Johari S, Sunarso (2011) Study on Slaughterhouse Wastes Potency and Characteristic for Biogas Production. Int. J. Waste Resour 1(2):4–7. https://doi.org/10.4172/2252-5211.1000102

Aleksić N, Nešović A, Šušteršič V, Gordić D, Milovanović D (2020) Slaughterhouse water consumption and wastewater characteristics in the meat processing industry in serbia. Desalin Water Treat 190:98–112. https://doi.org/10.5004/dwt.2020.25745

Senfter T et al (2021) Sludge thickening in a wastewater treatment plant using a modified hydrocyclone. Carbon Resour Convers 4:132–141. https://doi.org/10.1016/J.CRCON.2021.03.001

Fighir D, Teodosiu C, Fiore S (2019) Environmental and energy assessment of municipal wastewater treatment plants in Italy and Romania: A comparative study. Water (Switzerland) 11(8):1–13. https://doi.org/10.3390/w11081611

Di Maria F, Daskal S, Ayalon O (2020) A methodological approach for comparing waste water effluent’s regulatory and management frameworks based on sustainability assessment. Ecol Indic 118:106805. https://doi.org/10.1016/J.ECOLIND.2020.106805

Worku Zemene, Leta Seyom (2017) Anaerobic Digestion of Slaughterhouse Wastewater for Methane Recovery and Treatability. Int J Sustain Green Energy 6(5):84. https://doi.org/10.11648/j.ijrse.20170605.13

Vlyssides AG, Israilides CJ (1997) Detoxification of tannery waste liquors with an electrolysis system. Environ Pollut 97(1–2):147–152. https://doi.org/10.1016/S0269-7491(97)00062-6

Arthur MA et al (2022) Performance evaluation of a full-scale upflow anaerobic sludge blanket reactor coupled with trickling filters for municipal wastewater treatment in a developing country. Heliyon 8:8. https://doi.org/10.1016/j.heliyon.2022.e10129

Alemu T, Mekonnen A, Leta S (2019) Integrated tannery wastewater treatment for effluent reuse for irrigation: Encouraging water efficiency and sustainable development in developing countries. J Water Process Eng 30:100514. https://doi.org/10.1016/j.jwpe.2017.10.014

Alemu T, Mekonnen A, Leta S (2018) Post-treatment of tannery wastewater using pilot scale horizontal subsurface flow constructed wetlands (polishing). Water Sci Technol 77(4):988–998. https://doi.org/10.2166/wst.2017.613

Alayu E, Leta S (2020) Effectiveness of two-stage horizontal subsurface flow constructed wetland planted with Cyperus alternifolius and Typha latifolia in treating anaerobic reactor brewery effluent at different hydraulic residence times. Environ Syst Res 9:1. https://doi.org/10.1186/s40068-020-00183-4

Ruiz-Martinez A, Martin Garcia N, Romero I, Seco A, Ferrer J (2012) Microalgae cultivation in wastewater: Nutrient removal from anaerobic membrane bioreactor effluent. Bioresour Technol 126:247–253. https://doi.org/10.1016/J.BIORTECH.2012.09.022

Cai T, Park SY, Li Y (2013) Nutrient recovery from wastewater streams by microalgae: Status and prospects. Renew. Sustain. Energy Rev. 19(360–369):2013. https://doi.org/10.1016/j.rser.2012.11.030

Gururani, Bhatnagar, V. Kumar, M. S. Vlaskin, and A. V. Grigorenko (2022) “Algal Consortiums: A Novel and Integrated Approach for Wastewater Treatment,” Water (Switzerland) 14(22). https://doi.org/10.3390/w14223784.

Mamo TT, Mekonnen YS (2020) Microwave-Assisted Biodiesel Production from Microalgae, Scenedesmus Species, Using Goat Bone-Made Nano-catalyst. Appl Biochem Biotechnol 190(4):1147–1162. https://doi.org/10.1007/s12010-019-03149-0

Onay M (2018) Investigation of Biobutanol Efficiency of Chlorella sCultivated in Municipal Wastewater. J Geosci Environ Prot 06(10):40–50. https://doi.org/10.4236/gep.2018.610003

Yirgu Z, Leta S, Hussen A, Khan MM (2020) Nutrient removal and carbohydrate production potential of indigenous Scenedesmus sgrown in anaerobically digested brewery wastewater. Environ Syst Res 9(1):1–14. https://doi.org/10.1186/s40068-020-00201-5

APHA (2017) Standard methods for the examination of water and wastewater, 23rd edition. In: Rice EW, Baird RB, Eaton AD, Clesceri LS (eds) American public health association, American water works association and water environment federation, Washington, DC. https://doi.org/10.2105/SMWW.2882.002

Environmental Protection Agency (EPA) (2002) Effluent limitations guidelines and new source performance standards for the meat and poultry products point source category; proposed rule. (EPA/DC) EPA West, Room B102, 1301 Constitution Ave., NW., Washington, DC. Accessed Sept 2019

Sacristán de Alva M, Luna-Pabello VM, Cadena E, Ortíz E (2013) Green microalga Scenedesmus acutus grown on municipal wastewater to couple nutrient removal with lipid accumulation for biodiesel production. Bioresour Technol 146:744–748. https://doi.org/10.1016/J.BIORTECH.2013.07.061

Qin L et al (2016) Microalgae consortia cultivation in dairy wastewater to improve the potential of nutrient removal and biodiesel feedstock production. Environ Sci Pollut Res 23(9):8379–8387. https://doi.org/10.1007/s11356-015-6004-3

Qian J et al (2022) Enhancing Algal Yield and Nutrient Removal from Anaerobic Digestion Piggery Effluent by an Integrated Process-Optimization Strategy of Fungal Decolorization and Microalgae Cultivation. Appl Sci 12(9):4741. https://doi.org/10.3390/app12094741

Huo S, Wang Z, Zhu S, Zhou W, Dong R, Yuan Z (2012) Cultivation of Chlorella zofingiensis in bench-scale outdoor ponds by regulation of pH using dairy wastewater in winter, South China. Bioresour Technol 121:76–82. https://doi.org/10.1016/J.BIORTECH.2012.07.012

Kusmayadi A, Leong YK, Lu P-H, Huang C-Y, Yen H-W, Chang J-S (2022) Simultaneous Nutrients Removal and Biocompounds Production from Anaerobic Digestate of Dairy Wastewater with Chlorella Sorokiniana Su-1 Culture. SSRN Electron J. https://doi.org/10.2139/ssrn.4110667

Tao R, Kinnunen V, Praveenkumar R, Lakaniemi A-M, Rintala JA (2017) Comparison of Scenedesmus acuminatus and Chlorella vulgaris cultivation in liquid digestates from anaerobic digestion of pulp and paper industry and municipal wastewater treatment sludge. J Appl Phycol 29(6):2845–2856. https://doi.org/10.1007/s10811-017-1175-6

Van Den Hende S et al (2016) Technical potential of microalgal bacterial floc raceway ponds treating food-industry effluents while producing microalgal bacterial biomass: An outdoor pilot-scale study. Bioresour Technol 218:969–979. https://doi.org/10.1016/J.BIORTECH.2016.07.065

Lu W, Wang Z, Wang X, Yuan Z (2015) Cultivation of Chlorella susing raw dairy wastewater for nutrient removal and biodiesel production: Characteristics comparison of indoor bench-scale and outdoor pilot-scale cultures. Bioresour Technol 192:382–388. https://doi.org/10.1016/J.BIORTECH.2015.05.094

Kumar K, Krishna SV, Naidu SS, Verma K, Bhagawan D, Himabindu V (2019) Biomass production from microalgae Chlorella grown in sewage, kitchen wastewater using industrial CO2 emissions: Comparative study. Carbon Resour Convers 2(2):126–133. https://doi.org/10.1016/J.CRCON.2019.06.002

Silveira EO, Moura D, Rieger A, Machado ÊL, Lutterbeck CA (2017) Performance of an integrated system combining microalgae and vertical flow constructed wetlands for urban wastewater treatment. Environ Sci Pollut Res 24(25):20469–20478. https://doi.org/10.1007/s11356-017-9656-3

Mulbry W, Kondrad S, Pizarro C, Kebede-Westhead E (2008) Treatment of dairy manure effluent using freshwater algae: Algal productivity and recovery of manure nutrients using pilot-scale algal turf scrubbers. Bioresour Technol 99(17):8137–8142. https://doi.org/10.1016/J.BIORTECH.2008.03.073

Zamalloa C, Boon N, Verstraete W (2013) Decentralized two-stage sewage treatment by chemical–biological flocculation combined with microalgae biofilm for nutrient immobilization in a roof installed parallel plate reactor. Bioresour Technol 130:152–160. https://doi.org/10.1016/J.BIORTECH.2012.11.128

Yan C, Zhao Y, Zheng Z, Luo X (2013) Effects of various LED light wavelengths and light intensity supply strategies on synthetic high-strength wastewater purification by Chlorella vulgaris. Biodegradation 24(5):721–732. https://doi.org/10.1007/s10532-013-9620-y

EPA (2003) Standards for industrial pollution control in Ethiopia. Addis Ababa. Accessed 15 June 2018

Musa MA, Idrus S, Hasfalina CM, Daud NNN (2018) Effect of organic loading rate on anaerobic digestion performance of mesophilic (UASB) reactor using cattle slaughterhouse wastewater as substrate. Int J Environ Res Public Health 15:10. https://doi.org/10.3390/ijerph15102220

Subramaniyam V et al (2016) Cultivation of Chlorella on brewery wastewater and nano-particle biosynthesis by its biomass. Bioresour Technol 211:698–703. https://doi.org/10.1016/J.BIORTECH.2016.03.154

Ansari FA, Singh, Guldhe A, Bux F (2017) Microalgal cultivation using aquaculture wastewater: Integrated biomass generation and nutrient remediation. Algal Res. 21:169–177. https://doi.org/10.1016/J.ALGAL.2016.11.015

Rasoul-Amini S et al (2014) Removal of nitrogen and phosphorus from wastewater using microalgae free cells in bath culture system. Biocatal Agric Biotechnol 3(2):126–131. https://doi.org/10.1016/J.BCAB.2013.09.003

Jia H, Yuan Q (2018) Nitrogen removal in photo sequence batch reactor using algae-bacteria consortium. J Water Process Eng 26:108–115. https://doi.org/10.1016/J.JWPE.2018.10.003

Zhu L et al (2013) Nutrient removal and biodiesel production by integration of freshwater algae cultivation with piggery wastewater treatment. Water Res 47(13):4294–4302. https://doi.org/10.1016/J.WATRES.2013.05.004

Luo L et al (2019) Simultaneous nutrition removal and high-efficiency biomass and lipid accumulation by microalgae using anaerobic digested effluent from cattle manure combined with municipal wastewater. Biotechnol Biofuels 12(1):1–15. https://doi.org/10.1186/s13068-019-1553-1

Sayedin F, Kermanshahi-pour A, He QS, Tibbetts SM, Lalonde CGE, Brar SK (2020) Microalgae cultivation in thin stillage anaerobic digestate for nutrient recovery and bioproduct production. Algal Res 47:101867. https://doi.org/10.1016/J.ALGAL.2020.101867

Ding J et al (2015) Cultivation of Microalgae in Dairy Farm Wastewater Without Sterilization. Int J Phytoremediation 17(3):222–227. https://doi.org/10.1080/15226514.2013.876970

Larsdotter K (2006) Wastewater treatment with microalgae – a literature review. Vatten 62:31–38

Mburu N et al (2012) Simulation of carbon, nitrogen and sulphur conversion in batch-operated experimental wetland mesocosms. Ecol Eng 42:304–315. https://doi.org/10.1016/j.ecoleng.2012.02.003

Mohan SV, Rao NC, Prasad KK, Sarma N (2005) Bioaugmentation of an anaerobic sequencing batch biofilm reactor (AnSBBR) with immobilized sulphate reducing bacteria (SRB) for the treatment of sulphate bearing chemical wastewater. Process Biochem 40(8):2849–2857. https://doi.org/10.1016/j.procbio.2004.12.027

Bedane DT, Asfaw SL (2023) Microalgae and co-culture for polishing pollutants of anaerobically treated agro-processing industry wastewater: the case of slaughterhouse. Bioresour Bioprocess 10:1. https://doi.org/10.1186/s40643-023-00699-4

Li Y, Zhou W, Hu B, Min M, Chen P, Ruan RR (2011) Integration of algae cultivation as biodiesel production feedstock with municipal wastewater treatment: Strains screening and significance evaluation of environmental factors. Bioresour Technol 102(23):10861–10867. https://doi.org/10.1016/J.BIORTECH.2011.09.064

Acknowledgements

The authors wish to express their thanks to the Organic Export Abattoir PLC for allowing us to access the compound and take effluent sample and Center for Environmental Science for providing working space and laboratory facilities. Dejene Tsegaye thanks Addis Ababa University for funding the PhD study.

Funding

No funding received for this study.

Author information

Authors and Affiliations

Contributions

Dejene Tsegaye: Conceptualization, methodology, investigation, data curation, formal analysis, and original draft preparation, visualization, edited and approved the final manuscript. Seyoum Leta: Conceptualization, supervision, writing-review and editing, and validation. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Informed Consent

Not applicable (NA).

Institutional Review Board Statement

Not applicable (NA).

Conflicts of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bedane, D.T., Asfaw, S.L. Performance evaluation of a two-phase anaerobic reactor coupled with microalgae photobioreactors for slaughterhouse wastewater treatment in Ethiopia. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05498-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05498-1