Abstract

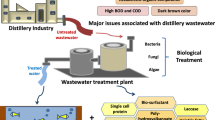

Fermentation distilleries produce a considerable volume of high-strength wastewater, known as stillage, having unconvertible organic fractions, lower pH and high percentage of dissolved organic and inorganic matters. Molasses stillage comprises higher level of chemical oxygen demand of 80–140 g/l, biochemical oxygen demand of 40–65 g/l, inorganic impurities and dark brown colour. Grain stillage contains comparatively lower chemical oxygen demand of 40–60 g/l. This stillage is acidic in nature (pH of 3.4–4.1) and exhibits considerable pollution potential upon discharge of untreated or partially treated wastewater into water body. Physical, chemical, biological and integrated processes for treatment of distillery stillage, which have been established by several researchers, are discussed in this review article. These treatment methods are discussed with focus on process details and current challenges, prospect and opportunities of future research and development. By utilizing distillery stillage as substrate in microbial fuel cell or integrated or combined fungal aerobic treatment followed by microbial fuel cell system, encouraging observations are demonstrated recently in terms of achieving the required treatment efficiency to meet the discharge standards, simultaneous bioelectricity generation and value-added products recovery. Such treatment system can offer a suitable solution for treatment of distillery wastewater in coming days.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Agro-processing industries contribute a potential thrive to the economic growth and human development generating a significant impact on industrial expansion and poverty reduction by providing various income opportunities, trade and employment. Despite of providing ample scope and prospects to overall agricultural development, the agro-processing industries generate organic waste that causes potential environmental pollution, if disposed untreated. Organic pollutants provide suitable substrate for bacterial proliferation, which induces threats by lowering the oxygen availability in the water body and due to increased turbidity and colour decreases photo-synthetic growth of stream biota. Wastewater generated by agro-processing industries is the major contributors of organic pollutants and contributes about 65–70% of the total industrial organic wastewater generated in India (Pachauri and Sridharan 1998) (Fig. 1). Among these, maximum pollution occurs from fermentation industries followed by pulp and paper industry as per NEERI ENVIS newsletter, January–March, 2016, Vol. 11, No. 1–3 (http://neerienvis.nic.in/). Most of the countries have stringent regulation and rigorous discharge norms for the disposal of agro-based industrial wastewaters. However, implementation of such norms is quite challenging in few cases, which insists to a steady infusion of cost-effective and innovative technologies with steady research efforts that could be adopted even by small treatment facilities.

Water consumption, wastewater generation and organic pollution load in agro-based industries (Pachauri and Sridharan 1998)

Fermentation industry generates the major volume of wastewater and contributes to highest pollution load among all agro-processing industries. Since 1980s, the technologies that have been developed and majorly practised by distilleries to treat such large volume of wastewater (12 m3/kilo litre of alcohol produced) comprise anaerobic digestion (biomethanation), composting and incineration. Around 70% removal and utilization of organic matter occur during biomethanation; however, overall three to four stages of cost-intensive wastewater treatment processes are practised by ethanol-producing industries to reduce down the level of organic load and achieve the effluent discharge limit. Hence, it is necessary to develop treatment processes that can demonstrate higher treatment efficiency, requiring lesser energy and footprint. Furthermore, in spite of quite a few efforts on knowledge contribution regarding high-strength ethanol distillery wastewater treatment, the present perspectives on complete bioremediation, wastewater recycling and zero discharge with multiple optimized process steps, to achieve maximum removal of organic pollutants, have never been discussed before. This review reports on recent development and advancement of distillery wastewater treatment, as different research groups started exploring possibilities of effective mineralization of highly concentrated organic matter present in distillery wastewater by physical, chemical, biological and integrated processes. Most of the case studies are reported although in laboratory scale, few technologies could demonstrate a proof of concept successfully and are certainly having potentials for field-scale applications.

Agro-industrial wastewater management

The major problem with agro-based industries is the higher demand of water consumption during the manufacturing processes, consequently generating a large volume of wastewater. This wastewater is predominantly loaded with organic matter, proteins, sugars, oils and grease, which upon disposal will increase the chemical oxygen demand (COD) of surface and ground water resulting in contaminating these water bodies and inviting human and animal health risks by severe environmental pollution. This type of wastewater is not readily biodegradable due to its high chemical stability and accumulation of bacterial end products of metabolism and sometimes requires extensive multiple-stage anaerobic–aerobic treatment process to generate effluent meeting required disposal standards, which reduces the economic feasibility of the overall process.

Conventional practice of multi-stage treatment process of high-strength agro-industrial wastewater includes pre-treatment in anaerobic digester or up-flow anaerobic sludge blanket (UASB) reactor for biogas recovery followed by aerobic oxidation processes for further removal of COD and volatile-suspended solids (VSS). Anaerobic treatment is not always effective for wastewater containing high level of organic pollutants. Lower efficiency of anaerobic reactors at such higher organic loading rates results in producing anaerobic effluent with much higher COD concentration. Aerobic post-treatment in stabilization ponds, lagoons and natural/artificial wetlands requires typically low organic loading rate (OLR, 0.01 kg of biochemical oxygen demand (BOD)/(m3 day)), higher retention time (few days to 100 days), large volume of reactors and more land area (Wang et al. 2005). The attractiveness of conventional anaerobic–aerobic treatment is decreased eventually due to reduced process efficiencies, large surplus sludge production and high energy consumption (Chan et al. 2009).

Characteristics of ethanol distillery wastewater

The level of pollutants and characteristics of distillery wastewater vary significantly depending on feedstock raw material used as substrate for ethanol production, its process efficiency and wastewater handling. The feedstock characteristics are largely dependent on availability of naturally occurring sugars, starch and cellulose (Table 1). Sugarcane or beet molasses fermentation produces aldehydes and ketones, which imparts distinct flavour (Sheehan and Greenfield 1980). Grain fermentation has economic advantages over using cellulose-based substrate as the spent grain can be utilized as feed for livestock; moreover, the generated wastewater is easily amenable to aerobic or anaerobic treatment processes; however, higher organic matter concentration still poses a challenge for treatment of this wastewater. Molasses and grain distillery wastewaters are comprised of high level of organic matter with biodegradable dissolved organic fractions, high nutrient content (sulphate, chloride, calcium, magnesium, potassium) and low pH (Nandy et al. 2002; Alkan-Ozkaynak and Karthikeyan 2011; Tang et al. 2007). This wastewater creates detrimental effect upon disposal in water body to human kind and aquatic life, causing severe land and water pollution. Winery wastewater typically consists of comparatively lower concentration of organic matter, but contains high amount of nutrients and poly-phenolic compounds (Melamane et al. 2007b).

Presently adopted practices for distillery wastewater treatment

The aqueous by-product of ethanol industries using starch-based raw materials (e.g. rice, barley, wheat, maize, potato) or cellulose-based raw material (sugarcane molasses) as substrates, contains higher percentage of less rapidly degrading organic matter. After ethanol recovery, the yeast-fermented slurry, also known as distillery stillage, comprises high concentration of organic matter, nutrient and suspended particles, which exhibit considerable pollution potential (Sheehan and Greenfield 1980; Kanimozhi and Vasudevan 2009). Methods to minimize the organic load achieved by Indian industries are (Fig. 2): (I) multi-stage anaerobic–aerobic treatment, (II) concentration and incineration and (III) zero-discharge system.

Multi-stage anaerobic–aerobic treatment

This is the most popular process for treatment of distillery wastewater, where the raw stillage is subjected first to decanter centrifuge for separating around 15–20% total suspended solids (TSS). The efficiency of solid separation can be increased; however, it has become one of the major challenges faced by industries due to its higher demand of energy consumption. The decanted thin stillage is sent to thermophilic UASB digester for biomethanation, a process of anaerobic conversion of organic compounds to methane and carbon dioxide, resulting in reduction of 85% of BOD and about 65% reduction in COD in the effluent, when operated under OLR of 49.3 kg COD/(m3 day) within a period of 92 days (Rajeshwari et al. 2000). During anaerobic treatment, it is difficult for micro-organisms to break down the composite structure of non-starchy polysaccharides (NSPs) present in distillery stillage, and hence, the COD reduction cannot be achieved by more than 70%. The generated biogas can be used in boiler as fuel, making this technology economically profitable. Biomethanation is followed by three-stage aeration treatment technology with clarifier for sludge recycling and finally after treatment in aerated lagoons or extended aeration, the final effluent can be used for ferti-irrigation (Wyman et al. 1992).

The limitations of this multi-stage anaerobic–aerobic treatment process are high power consumption for diffused aeration, huge land requirement for lagoon disposal, dilution required for disposal of final effluent to meet irrigation standards and pollution of groundwater and surrounding lands, which is associated with pollutants leaching while long-term storage in lagoons (Pant and Adholeya 2007a).

Concentration and incineration

Evaporation of distillery thin stillage recovers water, concentrating the wastewater and increasing the solid content to 55–60%. The concentrated mass is burnt in boiler to generate steam, which can be used to run turbine and generate electricity or used as fuel for evaporation. Ash produced from stillage mass in boiler is rich in pure inorganic salts such as phosphates, potassium and sulphates in high concentrations with moderately high level of calcium, nitrogen, iron, sodium and chlorides including other trace elements that can be applied as fertilizer or as a filler material in cement manufacturing. The process proposes zero effluent discharge, and the condensate from evaporation system can be recycled back to ethanol fermentation process. However, the process being highly energy intensive, it is not been widely adopted by distillery industries for wastewater treatment (Saha et al. 2005; Nandy et al. 2002).

Zero-discharge system

Grain stillage is introduced to decanter centrifuge to separate suspended particles and thin liquor. The thin liquor is concentrated in multiple effect evaporators (MEE) under vacuum pressure to recover maximum water per kg of steam energy supplied, and the recovered water is recycled to the fermentation process. Mixed solids, separated from decanter and MEE concentrate, are known as distiller’s wet grain stillage (DWGS), and they are rich in proteins and other nutrients, which can be used as animal feed. The moisture content of DWGS can be reduced further to less than 10% to produce distiller’s dry grain stillage (DDGS) (Thakur 2006). Zero-discharge limits can be achieved by this method through concentrating distillery thin liquor. The MEE process can be adopted only for treatment of grain distillery wastewater; however, biogas cannot be produced by this process, and hence, due to higher demand of steam energy for evaporation in MEE, the process is yet to be proved economical (Kahsay and Gabbiye 2015).

Recent advances in distillery wastewater treatment processes

Due to the presence of recalcitrant compounds in distillery effluents and their toxic effect on both human and environment, the wastewater treatment has become the most challenging issue. Such compounds are not effectively removed by conventional biological treatment processes. Hence, several physico-chemical, biological and integrated treatment processes for effective degradation of organic matter have been explored by scientists (Table 2) and described in the next section.

Physico-chemical treatment

Physico-chemical methods of distillery wastewater treatment combine physical and chemical processes, where the former process aids in removal of suspended materials and reduction of soluble COD can be achieved by the later process. Such processes involve coagulation or flocculation, adsorption, electrocoagulation, advanced oxidation processes, catalysis, radiation and membrane processes (Prajapati and Chaudhari 2015).

Coagulation, adsorption and absorption

Coagulation is a process of agglomeration of suspended particles present in wastewater under the effect of inorganic coagulants, such as CuSO4·5H2O, Alum, FeCl3, AlCl3 and FeSO4·7H2O, poly-aluminium chloride (PAC) or bioflocculants. Maximum 91 and 85% of respective COD and colour reduction was reported for treatment of grain distillery effluent using CuSO4·5H2O with 60 mM Cu2+ at optimum pH of 6, among all inorganic coagulants explored (Prajapati et al. 2015a). While treating molasses distillery effluent, coagulation/flocculation resulted in COD reductions of 55, 60 and 72% and colour reductions of 83, 86 and 92%, using 60 mM AlCl3, 60 mM FeCl3 and 30 ml/l PAC as coagulant, respectively, at their optimum initial pH. Chemical coagulation is a pH-dependent process, and for FeCl3, the optimum reaction pH is 3, whereas for both AlCl3 and PAC the optimum pH is 5.5; under such condition maximum COD and colour reduction of the biodigester effluent has been reported (Chaudhari et al. 2007). Ferrous sulphate (FeSO4·7H2O) in combination with lime was found to remove 78.5% COD with efficient colour removal (Pandey et al. 2003); however, during application of polyelectrolyte aid, Percol 47, the requirement of such coagulant was found to be reduced. Zhang et al. (2009) studied a novel bioflocculant poly-aspartic acid (PASP), extracted from marine algae with molecular formula: C4H6NO3 (C4H5NO3) m C4H6NO4, molecular weight: 1000–5000 Da and pH of 10–11 with 1% aqueous solution, for coagulation of wastewater derived from ethanol fermentation industry and the filtrate was aimed to recycle to the fermentation process. The ethanol production yield was comparable with the use of recycled wastewater to that of conventional process using tap water.

Investigation for the treatment of distillery vinasse in hybrid reactor combining ozone oxidation and adsorption by granular activated carbon (GAC) ensued 74.23 and 68% respective COD and colour removal at pH of 2 (Hadavifar et al. 2016); whereas, using low-cost activated carbon, prepared from coconut shell, the adsorption efficiency was increased, resulting in COD removal of around 95% (Lokeshwari and Joshi 2015). Organic–inorganic nanocomposite like chitosan-immobilized bentonite (CIB) as absorbent was studied for remediation of distillery wastewater, resulting in 83% of COD and 78% of colour removal with strong sorption capacity of clay minerals (El-Dib et al. 2016).

Electrocoagulation

Electrocoagulation is considered to be an in-expensive and effective alternate oxidation process of chemical coagulation for treatment of real wastewater loaded with electroactive pollutants, where, due to application of direct current, in situ metal coagulation is achieved (Kabdasl et al. 2012; Krishna et al. 2011). Up to 97% colour reduction with 54% COD removal and 70% combined NH4-N and NO3-N removal were achieved by Tsioptsias et al. 2015, while further treating biologically treated molasses distillery wastewater with iron/copper electrochemical reactions at optimized retention time of 3.5 h and current density of 33 mA/cm2, respectively, whereas, using aluminium plates as electrodes, the COD removal was found to be 72.3% (Krishna et al. 2010) and using iron electrodes for decolourization at 5 A of current input and 2 h of electrolysis time, 79% of colour reduction was achieved (David et al. 2015). COD and colour reduction from distillery wastewater of 89.62 and 92.24% were reported using titanium sponge anode and Ti/RuO2 cathode, respectively (Piya-Areetham et al. 2006). Around 50.5% COD removal and 97.3% average decolourization efficiency were achieved in another study at 44.65 A/m2 current density and 2.5 h of electrolysis time, while using iron electrodes (Kumar et al. 2009).

The major drawback of electrochemical coagulation is the production of chemical sludge, which requires additional measures for effective sludge handling, storage and utilization or disposal. Hence, an integrated treatment technology of distillery wastewater was developed, where the electrocoagulation process was combined with micro-filtration to remove the generated chemical sludge (Basu et al. 2015). Still the problem of chemical sludge thus removed remains, which will demand additional processing.

Advanced oxidation processes

Fenton’s oxidation, ozonation and wet oxidation are advanced oxidation processes that can be used to treat distillery wastewater. Fenton process is based on generation of hydroxyl radicals (·OH) with extremely high oxidation potential, through catalysis of H2O2 by Fe2+ ion under acidic conditions. A series of oxidation reactions occur when electrochemically active organic compounds are radicalized and react with oxygen, which consequently leads to mineralization of colour components and bioresistant fractions present in distillery and winery wastewater (Mishra et al. 1995; Beltran-de-Heredia et al. 2005a; Prajapati and Chaudhari 2015). Solar photo-Fenton’s oxidation process showed a significant removal of COD, dissolved organic carbon (DOC) and colour by 70 ± 3.3, 53 ± 3.7 and 75 ± 2.2%, respectively, and photo-Fenton process has been proved to be more effective as the polishing treatment step for winery wastewater (Ioannou and Fatta-Kassinos 2013; Ioannou et al. 2013; Hadavifar et al. 2010). In an electro-Fenton treatment process using iron electrodes for treatment of alcohol distillery wastewater as studied by Yavuz (2007), respective COD and total organic carbon (TOC) removal efficiencies of 92.6 and 88.7% were reported.

Ozone oxidation is a promising technology, where the direct oxidation with powerful oxidants like molecular ozone-generated secondary radicals and hydroxyl radicals seem effective for the treatment of molasses distillery wastewater. Pre-ozonation showed more than 99.5% settling ability of TSS, present in highly viscous wheat and sweet potato distillery wastewater (Tateda et al. 2004). It was also observed that ozone oxidation after aerobic treatment of wine distillery wastewater eliminates most of the biodegradable organic matter. The refractory and un-decomposed phenolic compounds and organic matter remaining after the aerobic treatment can be completely oxidized by ozone (Benitez et al. 1999; Beltrán et al. 1999). Few studies also explored the possibilities of complex wastewater treatment by wet-air oxidation process, which can be followed as a pre-treatment step to enhance the biodegradability and facilitate biogas generation in subsequent biological treatment processes (Padoley et al. 2012; Goto et al. 1998).

Catalytic thermolysis

Hydrothermal processes are proved to be effective for destruction of organic compounds and colour present in complex wastewater. Treatment of high-strength distillery wastewater with catalytic sub- and supercritical water in the presence of different homogeneous (MnSO4·7H2O, ZnSO4·7H2O) and heterogeneous (TiO2, CuO, MnO2) catalysts has been reported, where the initial pH of the reaction was found to have profound impact on mineralization (Chaudhari et al. 2008). Using CuO (10 wt%) and MnO2 (10 wt%) as catalyst at 400 °C with reaction time of 30 min, maximum COD removal efficiencies of 74.4 and 75.1% were achieved, respectively. However, using CuO catalyst, highest COD and colour removal efficiency of around 80% (with 5 wt% catalyst loading at 400 °C for 120 min) (Kazemi et al. 2015) and 72% (Prajapati et al. 2015b; Chaudhari et al. 2010), respectively, can be obtained.

Membrane separation processes

Membrane technology can be applied at different stages of distillery wastewater treatment to concentrate small organic solutes through reverse osmosis (RO), ultra-filtration (UF) or nanofiltration (NF) membrane module and recycle the treated effluent into the fermentation step. In order to produce reusable quality effluent, RO treatment could achieve 85% of COD removal, 91% of salinity removal and elimination of the anti-fermentation molecules, such as short-chain volatile fatty acids (VFA), hexanoic acids, 2,3-butanediol, furfural and phenyl-2-ethyl-alcohol (Thirugnanasambandham et al. 2016; Sagne et al. 2010; Couallier et al. 2006).

To achieve zero-discharge status, tertiary treatment of biologically treated distillery wastewater by membrane separation is proved as a promising technology. By employing NF membrane module, removal efficiencies of COD, total dissolved solids (TDS) and colour were in the range of 96–99.5%, 85–95 and 98–99.5%, respectively (Rai et al. 2008), whereas, ultra-filtration membrane separation could successfully achieve complete removal of SS from distillery effluent. Distillery condensate is generated in thin stillage evaporation process, containing low molecular weight volatile organic compounds, such as VFA, imparting much higher COD of around 3–3.5 g/l of condensate, which cannot be disposed off without further treatment. The water recovery process is expensive, while using RO or NF membranes, and this higher operating cost poses major challenge to wastewater processing plants to generate reusable quality effluent. For purification of condensate, application of MBR technology equipped with micro- or ultra-filtration membrane might be useful for large volume of permeate generation, which can be reused as dilution water in fermentation step (Fig. 3) (Prodanović and Vasić 2013; Satyawali and Balakrishnan 2008b; Vasić et al. 2013).

Biodegradation of distillery wastewater

Bioremediation of distillery wastewater includes degradation of organic pollutants in biological and natural pathways, where micro-organisms play a vital role in the process of biodegradation. Enzymes secreted by bacteria, fungi and algae individually or in symbiotic manner support the catalysis of toxic pollutants to less harmful reduced form.

Advanced bacterial metabolism

Anaerobic digestion Anaerobic digestion is a widely applied technology for the treatment of alcohol distillery and winery wastewater. The organic compounds present in wastewater are finally utilized by methanogens, following the acidogenesis and acetogenesis, reducing around 70% of COD and 80–90% of BOD with 85–90% recovery of biogas (around 60% CH4 and 40% CO2) in industrial scale (Sankaran et al. 2014). Anaerobic biodigestion process of winery wastewater could demonstrate around 56% of COD removal (Olvera et al. 2007), whereas more than 80% removal of soluble COD and 90–95% removal of total COD have been reported adopting high-rate anaerobic digestion technology (Melamane et al. 2007a; Thanikal et al. 2007; Moletta 2005). Anaerobic treatment of vinasses by a sequentially mixed moving bed biofilm reactor was followed, and the soluble COD removal efficiency was reported as 81.3–89.2% at an OLR of 29.6 g soluble COD/(l day) (Sheli and Moletta 2007); whereas, in another study using winery vinasses, the COD removal efficiency varied in the range of 70–92% in anaerobic inverse turbulent bed bioreactor at an OLR of 30.6 kg COD/(m3 day) with hydraulic retention time (HRT) of 11.1 h (Arnaiz et al. 2005).

Researchers proposed an appropriate treatment process for high-strength distillery wastewater adopting di-phasic anaerobic treatment technology with two anaerobic reactor configuration, where anaerobic contact filters were used in series and overall 73% COD removal was achieved (Vijayaraghavan and Ramanujam 2000; Ke et al. 2005). In a laboratory two-stage anaerobic digestion (AD) of corn bioethanol distillery wastewater, specific methane generation of 1092 l/(m3 day) was achieved at an OLR of 6.5 g total COD/(l day) with higher rate of methane yield during the second stage (Ráduly et al. 2016; Asha and Kumar 2007). Treatment of high-strength distillery spent wash was reported in continuously fed up-flow fixed-film column reactor under varying HRT and OLR and using different support materials such as charcoal, coconut coir and nylon fibres, out of which coconut coir was reported to give maximum of 64% COD reduction at an OLR of 23.25 kg COD/(m3 day) and 8 days of HRT with simultaneous biogas production of 7.2 m3/(m3 day) (Acharya et al. 2008; Bories et al. 1988).

Granular and fluidized bed anaerobic reactors

Performance evaluation of granular-bed anaerobic baffled reactor, which combines the advantages of both baffled reactor systems and UASB reactor, was carried out for treating high-strength whisky distillery wastewater, which resulted in up to 80% of COD and 90% of BOD removal at an OLR of 4.75 kg COD/(m3 day) (Akunna and Clark 2000). The reactor showed high solid retention efficiency, achieving about 80 mg/l of effluent SS concentration for all applied OLRs. Anaerobic fluidized bed reactor (AFBR), where high biomass concentration can be retained using small, porous and fluidized media, enables an operation at significantly reduced HRT. The process of fluidization aids in overcoming operating problems such as bed clogging and high pressure drop. This process demonstrates a feasible treatment process in various studies for treating high-strength industrial wastewater (Fernandez et al. 2008; Sowmeyan and Swaminathan 2008; Garcia-Morales et al. 2003).

Up-flow anaerobic sludge blanket reactor

Among all the different reactor configurations and treatment technology, the UASB reactor holds a significant effectiveness for continuous treatment of high-strength and non-diluted wastewaters, performing typically at higher OLRs and relatively shorter HRTs. The effectiveness lies in designing the gas–liquid–solid (GLS) separator, which enables proper settlement of sludge into the blanket, providing escape route for biogas and clear supernatant near to the top. UASB reactor requires lesser area and less input of external energy, where the required mixing can be achieved by the up-flowing of wastewater and the rising gas bubbles. The wastewater and the sludge residue can be well digested compared to other anaerobic reactors, thus requiring reduced sludge volume handling. The generated biogas is rich in methane, a valuable by-product (Laubscher et al. 2001; Goodwin et al. 2001). Study with UASB reactor for treating high-strength distillery wastewater at mesophilic temperature achieved maximum of around 70 and 90% of respective COD and BOD removals at HRT of 2 days and OLR of 15.34 kg COD/(m3 day) with rate of methane production within the range of 0.25–0.40 m3 CH4/ (kg COD removed) (Saner et al. 2016; Ince et al. 2005; Wolmarans and De Villiers 2002).

Anaerobic thermophilic digestion (50–55 °C) has also been investigated for treatment of distillery spent wash resulting in accelerated stabilization of the organic matter at lower HRT and higher OLRs, which leads to achieve higher BOD reduction and more efficient biogas production with higher percentage of methane present in it, than for mesophilic range of treatment. Thermophilic anaerobic digestion of wastewater from alcohol industries, having COD of 60 g/l, resulted the conversion of organic solids to CH4 by 70% at an OLR of around 6 kg COD/(m3 day) and HRT of 11 days, yielding 0.4 m3 methane/kg COD removed (Vlissidis and Zouboulis 1993; Perez-Garcia et al. 2005; Banu et al. 2007, 2006).

Advanced aerobic treatment

Although anaerobic digestion has gained much importance by the researchers to explore more efficient treatment processes for molasses distillery wastewater, aerobic biodegradation with thermo- and mesophilic bacteria is equally efficient for treatment of starch stillage (Krzywonos et al. 2009a). The effect of temperature during aerobic batch biodegradation of high-strength potato stillage has been investigated for temperature ranging from 20 to 65 °C using a mixed culture of genus Bacillus, resulting in around 90% COD reduction at the thermophilic range of temperature over 80 h of retention time (Krzywonos et al. 2008, 2010, 2009b). For anaerobically digested distillery wastewater, the treatment performance and influence of different OLRs for operating aerobic sequencing batch reactor (SBR) was investigated showing decrease in reactor performance when OLR was increased from 1.8 to 9 kg COD/(m3 day) for constant HRT of 24 h. The respective COD and BOD removal efficiency of 74 and 96% was achieved at 3.6 kg COD/(m3 day), which decreased to 43 and 84%, respectively, when OLR was increased to 9.0 kg COD/(m3 day) (Kanimozhi and Vasudevan 2014). It was also suggested that there are remote possibilities to reach safe disposal limits of distillery effluent by adopting presently adopted high-rate anaerobic treatment processes. Thus, an enriched culture of Pseudomonas sp. was tested to further degrade the organic compounds from anaerobically digested distillery wastewater resulting in 26.05% COD reduction further (Sankaran et al. 2014).

Aerobic membrane bioreactor (MBR) has developed quite a lot of interest among the researchers, as well as the industries. Compared to the old biofiltration processes, MBR process offers distinct advantages of reliable and efficient treatment performance with smaller footprint, reduced sludge generation and high treatability of distillery wastewater, recovering high-quality effluent (Robinson 2009; Satyawali and Balakrishnan 2008a; Melamane et al. 2007b). Effluent from UASB reactor treating distillery wastewater was treated further in a laboratory-scale MBR and found to achieve 92% of decolourization and 95% of COD reduction (Sundararaman et al. 2015). In another study for treatment of distillery spent wash with continuously fed MBR, equipped with submerged 30-μm nylon mesh filters and operated at OLR ranging from 3 to 5.7 kg COD/(m3 day), up to 41% COD removal was achieved (Satyawali and Balakrishnan 2008b); whereas, in the same reactor configuration with 2–8 micron submerged membrane made from waste fly ash, around 36 and 60% of COD and phenol removal were obtained, respectively (Gupta et al. 2008).

Biodegradation by filamentous fungi and recovery of valuable by-products

Technologies adopted for distillery wastewater treatment and resource recovery enable to minimize contaminants present in wastewater and generation of value-added by-products such as fungal mycelia, enzymes and lipids by fungal intervention (Mohana et al. 2013).

Distillery wastewater treatment

Novel mixed consortium with six fungal strains, comprising Penicillium pinophilum, Alternaria gaisen, Aspergillus flavus, Fusarium verticillioides, Aspergillus niger and Pleurotus florida, was developed for undiluted molasses distillery wastewater treatment, resulting in 61.5% colour and 65.4% of COD removal (Pant and Adholeya 2010; Ravikumar et al. 2011); whereas using white-rot fungi Phanerochaete chrysosporium, much effective aerobic degradation with higher removal efficiency of organic matter in terms of COD, BOD and colour was observed as 83.15, 85.70 and 88.25%, respectively (Hossain 2007). The fungal biodegradation technology was also suggested as an inexpensive process, where wastewater dilution was not required. For kinetic model equations for fungal biodegradation of distillery wastewater, pseudo-second-order rate expression has been obtained in the past studies (Mullai et al. 2007; Potentini and Rodriguez-Malaver 2006). Treatment with Aspergillus awamori resulted in total COD removal of 70.4% and soluble COD removal of 39.3% from grain-based distillery stillage (Ghosh Ray and Ghangrekar 2015). Hence, it is evident from the prior studies with distillery wastewater that depending upon the used yeast and fungal strain, batch aerobic fungal treatment processes are very effective and observed to remove more than 85% COD in single stage, although a cultivation time of 7–10 days is required to be given to achieve better removal of organic matter (Hossain 2007; Raghukumar et al. 2004; Moriya et al. 1990).

Biolipids and mycelia production

Around 17.3 U/ml of xylanase production was reported by using phyllosphere yeast Pseudozyma antarctica and bioethanol distillery wastewater as substrate and inexpensive source for production of biomaterials with simultaneous removal of DOC by 63% from wastewater (Watanabe et al. 2015). Another study with four white-rot fungi of Trametes pubescens, Ceriporiopsis subvermispora, Pycnoporus cinnabarinus and Phanerochaete chrysosporium at pH 5.0 demonstrated 71–77% COD and 87–92% phenolic compounds removal efficiencies with higher laccase activity of 1063 ± 26 U/l (Strong 2010). Fungi cultivation and corresponding laccase production by using it for enzymatic hydrolysis of winery wastewater were found to be an effective process for removal of COD, colour and phenolic compounds (Strong and Burgess 2008a; González et al. 2000; Strong and Burgess 2008b). Biolipid production has been studied by using oleaginous yeast Rhodosporidium toruloides for biodegradation of culture medium comprising of distillery wastewater, and 43.65 ± 1.74% of lipid content and 3.54 ± 0.04 g/l of lipid yield were achieved, associated with 86.11 ± 0.41% reduction of COD in the effluent (Ling et al. 2013). This work was further extended by reutilizing the spent culture medium, showing a significant and similar biomass and lipid production (Ling et al. 2016). Lipid productivity of mixed culture of Rhodosporidium toruloides and Chlorella pyrenoidosa achieved significantly increased lipid yield of 4.60 ± 0.36 g/l (lipid content of 63.45 ± 2.58%) with soluble COD removal efficiency of 95.34 ± 0.07% over 5 days of cultivation time (Ling et al. 2014).

Calvatia gigantea can be used as a source of food or traditional medicine, and hence, mycelia was cultivated using raw distillery wastewater as culture medium for 4.5 days at 26 °C operating temperature, which resulted in maximum mycelia biomass yield of 2.75 g/100 ml under optimized fermentation condition (Zhu et al. 2015). Another study reported biomass production of Candida utilis utilizing shochu wastewater with 62.9% removal of DOC (Watanabe et al. 2013). Intracellular enzymes can be recovered from fungal biomass, which can also be used as a source of protein-rich cattle feed, and biopolymer can also be recovered from the cell wall of fungal mycelia (Ghosh Ray and Ghangrekar 2016).

Algal bioremediation

Chlorella sorokiniana strain has been cultivated and used for phyco-remediation of distillery wastewater achieving increased rate of pollutant removal under short HRT of four days, and COD, nitrate, phosphate and sulphate removal efficiencies of 92.5%, more than 95, 77 and 35%, respectively, were reported (Solovchenko et al. 2014). Distillery wastewater after treatment in anaerobic filter was further treated in microalgae pond with HRT of 11 days and found to minimize COD and BOD5 by 83.2 and 88%, respectively (Travieso et al. 2008). Further assessment and determination of chlorophyll recovery were also done from the cultivated algal biomass.

Integrated or combined treatment processes

Single-stage anaerobic digestion processes are insufficient to achieve higher removal of organic matter; hence, it can be combined with single- or multi-stage aerobic or chemical oxidation treatment (Latif et al. 2011). Coupling of treatment processes can achieve improved efficiency of distillery wastewater treatment with improved COD and colour removal (Table 3). Sequential anaerobic–aerobic treatment was adopted comprising of microbial fuel cell (MFC) followed by rotating biological contactor (RBC). In the first stage of treatment in MFC, 64 and 61.2% of respective COD and BOD5 removal were observed with average current of 0.27 mA and power density of 18.35 mW/m2 with an influent feed COD concentration of 6.1 g/l. The COD and BOD5 were further reduced in the second-stage RBC by 84 and 81%, respectively (Anupama et al. 2013; Iscen and Ilhan 2008). In an experiment while treating malt whisky distillery wastewater using UASB reactor followed by batch aerobic degradation, in the first stage not more than 52% of COD and BOD removal was achieved, which was further reduced by 55 and 70%, respectively, in aerobic second stage (Uzal et al. 2003). A process was adopted for corn stover-based high-strength distillery wastewater treatment in combined thermophilic AFBR, comprising of aerobic airlift loop reactor (ALR) and biological aerated filter (BAF),which demonstrated overall more than 99% COD and BOD removal in three-stage process (Qiu et al. 2011; Kanhe et al. 2003). Another study of first-stage anaerobic digestion followed by ultraviolet (UV) photo-degradation achieved overall high COD removal efficiency of above 85% for molasses distillery wastewater and 88% colour removal from post-anaerobically digested distillery effluent in photo-degradation stage (Apollo et al. 2013).

Combination of fungal pre-treatment with Trametes pubescens followed by anaerobic digestion was adopted for removal of COD and phenolic compounds from wine distillery wastewater, where the fungal pre-treatment process achieved 53.3 and 72.5% reduction of COD and poly-phenolic compounds, respectively. Fungal pre-treated effluent of winery, supplemented with carbon and nutrient media, was further treated in anaerobic digester at HRT of 2 days, and the overall two-stage process was proved to reduce COD by 99.5% (Melamane et al. 2007c).

Ozone has higher potential for oxidation of organic and inorganic compounds, removal of suspended particles and disinfection and, hence, the combined pre- and post-ozonation with conventional aerobic oxidation (ozone-aerobic oxidation-ozone) of distillery wastewater achieved 79% COD reduction along with almost complete decolourization of effluent sample (Martins and Quinta-Ferreira 2014; Sangave et al. 2007a). Pre-ozonation was also found effective not only for the reduction of COD and TOC but also for enhancing the nitrogen removal and settling properties of sludge during subsequent aerobic biological process (Beltrán et al. 2000). Post-ozonation followed by aerobic treatment at HRT of 2 days of thermal pre-treated distillery wastewater could achieve 45.6% of COD reduction, where better oxidation was achieved during ozonation compared to ultra-sound (US) treatment (Sangave et al. 2007b).

Addition of powdered activated carbon (PAC) during MBR operation for treatment of high-strength distillery wastewater observed to offer several operational advantages, where PAC facilitated adsorption of recalcitrant components increasing the efficiency of aerobic biodegradation and membrane filtration of MBR and subsequent higher removal of colour and COD (Basu et al. 2015; Satyawali and Balakrishnan 2008a, 2009). A study with wine distillery wastewater combining fungal pre-treatment, submerged MBR and secondary digester, the fungal pre-treatment process not only reduced COD by 86 ± 4% but also aids to achieve higher soluble COD removal in the later process stages, achieving around 0.4 g/l of effluent COD concentration (Melamane et al. 2007d). Combined fungal biodegradation of grain-based distillery stillage with exo-enzymes of Aspergillus sp. followed by further treatment of fungal pre-treated effluent in anaerobic digester reduced overall 94% of total COD, whereas much higher efficiency of COD removal was observed by combining fungal biodegradation process with MFC technology, achieving around 99% reduction in COD and suspended solids and two times improvement in power production of MFC is reported using fungal pre-treated wastewater as feed (Ghosh Ray and Ghangrekar 2015, 2016) (Fig. 4).

Combination of different physico-chemical processes as stand-alone technology or clubbing it with advanced oxidation process has also proven to be an effective option for organic matter removal from distillery wastewater. Although processes based on membrane separation are quite expensive, hybrid NF-RO showed complete removal of colour from distillery spent wash by NF, which was followed by 99.9 and 99.8% removal of COD and TDS, respectively, during RO treatment. Nonetheless, the process could successfully achieve the effluent discharge specification as per the guidelines of World Health Organization (WHO) and Central Pollution Control Board (CPCB), India (Nataraj et al. 2006). Likewise, a combination of flocculation–ozonation–Fenton’s process established an effective alternative for treating distillery effluent (Martins et al. 2011); however, these processes are very expensive to operate.

The combined process of ultra-sound, enzymatic hydrolysis and aerobic biological oxidation was found to increase biodegradation efficiency of distillery wastewater (Sangave et al. 2007a, b). Two-stage process of aerobic biological oxidation followed by oxidation by Fenton’s reagent has shown better removal for polyphenolic and aromatic compounds (Beltran-de-Heredia et al. 2005b), whereas biological oxidation followed by ozonation resulted in 95 and 82% of respective BOD and COD removal, with lower degradation efficiency of polyphenols (Beltrán et al. 2001).

Alternative treatment processes

Distillery wastewater is typically characterized to contain high organic COD, low N/C and P/C ratio with higher concentration of recalcitrant constituents like polyphenol and lignin, which are difficult to degrade in single-stage process. Constructed wetland (CW) can offer an efficient low-cost and low energy-consuming treatment alternative to distillery and winery wastewater, which requires less maintenance during operation (Vymazal 2009). Although the process achieves high treatment efficiency, more area is required for this treatment plant comprising of CW. Continuous treatment of winery wastewater in full-scale subsurface flow CW with COD concentration of 14 g/l and having flow rate of 0.009 m3/(m2 of surface area day) resulted in more than 90% reduction of COD, producing effluent with COD concentration of 0.5 g/l. It was also reported that the treated effluent can be utilized for cash crop production (Mulidzi 2007; Grismer et al. 2003).

Pre-treated molasses distillery effluent, containing less BOD of 2.54 g/l and COD of 13.87 g/l, was further treated in four-celled horizontal subsurface flow CW, having effective surface area of 41.82 m2 and water retention capacity of 18 m3 showing considerable reduction of organic matter and nutrients as 64, 84, 59 and 79% for COD, BOD5, TKN and total phosphorus (TP), respectively, over 14.4 days of HRT, thus offering a potential technology for tertiary treatment of many high-strength industrial wastewater (Billore et al. 2001). Application of water hyacinth (Eichhomia crassipes) for treatment of highly acidic distillery effluent or wastewater from tanneries, pulp and paper industries and oil mills was found to be suitable for phyto-remediation (Jafari et al. 2006; Suppadit et al. 2009; Singhal and Rai 2003).

Chemical fertilizers are detrimental and often get washed out with storm water runoff and enter water body, and hence, biocompost made from the organic matter present in the distillery wastewater provides a healthy and environmental-friendly option for agriculture use (Ghosh et al. 2003; Chandra et al. 2009). Chitosan biopolymer was used to achieve effective adsorption of VFAs present in high amount in distillery wastewater and condensates, showing 93% decrease of COD in the effluent (Lalov et al. 2000).

Distillery wastewater remediation using bioelectrochemical systems

Bioelectrochemical processes are capable of converting the chemical energy stored in biodegradable organic materials to direct electrical current with catalytic activity of micro-organisms. Bioelectrochemical devices, with two major variants: MFC and microbial electrolysis cell (MEC), consist of anodic (oxidative) and cathodic (reductive) half cells, which consume electricity to facilitate recovery of chemically derived products by integrating the biochemical and electrochemical processes or produce electricity (Table 4). MFC utilizes electrochemically active bacteria (EAB) to catalyse the oxidation of organic electron donors in the anodic chamber and deliver electrons to the anode (Fig. 4). These electrons can be captured directly for bioelectricity generation, or value-added chemicals can be produced by supplying external power. In the last two decades, BES has drawn significant attention of the researchers due to its promising applications in scientific fields such as renewable energy recovery, bioremediation, by-products recovery and wastewater treatment (Rabaey et al. 2010; Kharayat 2012; Huang et al. 2011).

A study with distillery wastewater as substrate and permanganate as cathodic electron acceptor demonstrated 57% of COD removal and 36% of melanoidins decolourization in MFC with voltage generation of 1.165 V (5.40 mA) (Geetha and Raj 2015). While treating distillery wastewater, performance of MFC has been found to be maximum in terms of power generation as 202 ± 6 mW/m2 and COD removal as 63.5 ± 1.5%, at feed pH of 8 and with increased wastewater COD concentration, conductivity and area of proton exchange membrane (PEM) (Samsudeen et al. 2015a); whereas, under acidophilic (pH of 6) condition, enhanced COD degradation by 72.84% and colour reduction by 31.67% were achieved in fed-batch mode (Mohanakrishna et al. 2010). The reactor design can be attributed as one of the significant factors to enhance power generation in MFC using distillery wastewater.

A triple-chamber MFC was fabricated with two anodic and single cathodic compartments separated by PEM, exhibiting increase in power generation from 168 to 428 mW/m2, when the COD concentration of feed distillery wastewater was increased from 3.2 to 9.6 g/l (Samsudeen et al. 2015b). Working with a MFC having higher surface area of anode, which is made up of interlacing carbon yarn with stainless steel and arranged in a double-air cathode MFC configuration, it was observed to generate power density of 364 ± 11 mW/m2 from distillery wastewater and 58% reduction of COD concentration in the effluent (Sonawane et al. 2014). Authors also suggested that the complex chemical composition of distillery wastewater does not support the growth of electrochemically active bacterial community, imposing limitations to achieve higher power output, cation transport across PEM and COD removal in MFC.

Multiple anodes acting as baffles in MFC were found to achieve higher performance, and maximum power density of 597 mW/m2 was observed under recirculation mode with COD removal efficiency of 43% and Coulombic efficiency (CE) of 23%, while treating distillery wastewater (Sonawane et al. 2013). Carbon-based anodic surface impregnated with multi-walled nanotubes (MWCNT) and nanopowder (CNP) in single-chambered MFC treating distillery wastewater exhibited higher electrogenic activity with power generation of 267.77 mW/m2 for MWCNT-modified MFC and 168.45 mW/m2 for CNP-modified MFC (Mohanakrishna et al. 2012).

Using catalytic anode with ruthenium oxide modification in BES, optimal removal efficiencies for colour and COD of 83.31 and 39.66% with current density of 14.285 mA/cm2 were achieved, while treating 10% distillery spent wash at acidic pH of 5.5 (Prasad and Srivastava 2009). Like other thermophilic anaerobic treatment processes, thermophilic MFC exhibited higher current density of 2.3 A/m2 and power density of 1.0 W/m2, while treating distillery wastewater, achieving significantly high CE of 89% (Ha et al. 2012). Adopting cell-immobilization technology, it could achieve a significant increase in COD removal by 98% and power production of around 73 mW/m2 in MFC, which is 2.6 times higher than the control MFC, while treating high-strength distillery wastewater with COD concentration of 3.6 g/l (Lin et al. 2015).

Utilization of distillery wastewater and generation of value-added products

Distillery wastewater can be utilized as substrate and as sole source of carbon for cultivation of high-quality protein biomass of yeast, biodegradable polymer like poly-β-hydroxybutyrate (PHB) or fungal chitosan, fungal enzymes, algal lipids and biosurfactants, which are having high-end industrial applications. For fodder yeast production, residual ethanol, glycerol and reducing sugar in stillage were utilized as alternative substrate for biomass cultivation of yeast strain like Candida utilis (Martínez et al. 2004) and reduction of around 75% organic matter was reported (Rambla et al. 2008). Poly-β-hydroxybutyric acid has properties similar to chemically derived synthetic polymers, and it can be produced using grain distillery wastewater. From raw-rice grain-based spent wash 67% PHB yield was reported (Khardenavis et al. 2007).

Chitosan (poly-glucosamine) has wide industrial application as viscosity control agents, adhesives, paper-strengthening agents, flocculant, food additive, medicines and cosmetics. Industrial production of chitosan is carried out by deacetylation of shell-fish chitin; however, the process is restricted with seasonal supply of raw materials, high production cost and generation of highly toxic chemical sludge. It was proposed that high-quality chitosan can be produced from fungal strain, and in a study, Absidia atrospora, Gongronella butleri and G. Butleri fungal strains were cultivated using inexpensive substrate like barley-buckwheat-shochu distillery wastewater and sweet potato-shochu wastewater, which resulted in yielding fungal biomass and simultaneous treatment of the wastewater. Around 730 mg/l of chitosan was produced from the biomass, and 49% reduction of COD concentration in effluent was reported (Yokoi et al. 1998). In another study addressing simultaneous biodegradation and generation of biomass of fungi Aspergillus awamori in distillery thin stillage supernatant and recovery of chitosan by extraction from cell wall of the cultivated fungi, fungal biomass of 11.5 g/l and chitosan of 72–78 mg/g of dry mycelia were produced (Ghosh Ray and Ghangrekar 2016).

Shochu distillery wastewater was also used for production of valuable lipids polyunsaturated fatty acids (PUFA) like docosa-hexaenoic acid (DHA) and astaxanthin and pigments like xanthophylls from algal strain Schizochytrium sp., and 35% reduction of COD was observed (Yamasaki et al. 2006; Doušková et al. 2010). Production of fungal lignolytic enzymes was documented under solid-state fermentation using wheat straw and corncob with molasses distillery wastewater as moisturizing agent (Pant and Adholeya 2007b; Pant et al. 2006). Oyster mushroom was cultivated using solid substrate (wheat straw and bagasse) with anaerobically pre-treated distillery effluent. Pseudomonas aeruginosa was used for recovery of biosurfactant with improved surface-active properties from distillery wastewater (Dubey et al. 2005).

Discussion

Several methods and processes for treating alcohol distillery wastewater, containing high organic matter, dissolved and suspended solids and acidic pH are explored and implemented extensively in bench scale as well as in pilot scale. Among all advanced oxidation processes, ozonation is observed to be the most effective process for resulting in complete removal of suspended solids and biodegradation of un-decomposed polyphenols and other refractory compounds present in distillery wastewater. In zero-discharge system, membrane separation processes are found to be effective as tertiary treatment process for biologically treated distillery wastewater, resulting in more than 95% removal of COD, TDS and colour. However, these processes are expensive and energy intensive in terms of operation and maintenance for long-term applications and commercial implementation. Many of the biological treatment strategies need larger environmental footprints, skilled management, and moreover, the generated effluent cannot meet the inland disposal standards even after following three to four stages of combined physico-chemical and biological treatment processes such as anaerobic digestion-UV photodegradation, pre-ozonation-aerobic oxidation-post-ozonation, MFC-RBC combined reactor, UASB-aerobic batch degradation process, AFBR-ALR-BAF. Hybrid assembly of modified anaerobic process followed by two-stage aerobic processes can achieve considerable removal of organic matter and can achieve the disposal standards; however, higher energy consumption during the aerobic post-treatment makes this combined process economically infeasible and the robustness of the process is yet to be tested to make it ready for field-scale application. Fungal pre-treatment followed by anaerobic digestion is also found to be effective in considerable reduction of suspended solids and organic matter. Though fungal pre-treatment might lead to reduction in methane generation in anaerobic post-treatment, it will facilitate production of fungi-derived commercially valuable products, such as chitosan. From the perspective of treatment efficiency, this combination can also provide option for effective treatment of distillery wastewater.

Recent advancement in the bioelectrochemical processes provides another alternative, and it is worth investing research efforts on treatment of anaerobically treated distillery effluent to be further processed in bioelectrochemical systems. Implementation of such treatment process may render either energy recovery in the form of electricity or recovery of other value-added products in the form of organic chemicals. As demonstrated by the researchers, these bioelectrochemical processes offer advantages of phenolic compounds and lignin degradation from wastewater. Hence, these bioelectrochemical processes are expected to give superior performance as compared to other biological treatment (aerobic/anaerobic) processes. However, the proof of concept of application of bioelectrochemical processes like MFC or MEC, for treatment of distillery wastewater, has been formulated only for the study in laboratory-scale reactor. Therefore, further efforts are required for piloting these technologies to truly evaluate advantages and drawbacks of these systems in real-life applications. Reliability of such processes for assured treatment of the wastewater in long run to meet stipulated discharge norms also needs to be assessed.

Conclusion and outlook

MFC technology has been adopted as a single-stage treatment process with raw distillery wastewater or with anaerobically digested distillery effluent; however, the process failed to achieve more than 60% efficiency of COD removal, when operated under normal conditions without posing any modification in operating conditions and reactor design. Multi-stage processes involving pre-treatment with selective bacterial or fungal species have been followed by further treatment of pre-treated effluent in MFC. It could achieve almost complete removal of organic matter by demonstrating up to 99% COD removal, producing effluent having COD of less than 500 mg/l, which can meet the inland disposal quality standards. However, limited studies have been performed combining aerobic/anaerobic technologies with MFC technology. The major disadvantage of this bioelectrochemical process is the need of dilution water to reduce the organic matter present in the fungal pre-treated effluent, before further treatment in MFC. This effluent dilution may possibly be eliminated by following two repeated fungal co-cultivation process followed by treatment in MFC or by recycling the treated effluent. Hence, the future research should be focussed to develop such eco-friendly and economical treatment strategies in order to achieve higher treatment efficiency, effluent standards with lesser environmental footprints and reduce cost of overall treatment. Most importantly, apart from reducing suspended solids and organic matter, the possibility of recovering single cell protein, biopolymers, enzymes and many other derivatives from fermentation broth makes the fungal fermentation technology profitable for industrial implementation.

References

Acharya BK, Mohana S, Madamwar D (2008) Anaerobic treatment of distillery spent wash—a study on upflow anaerobic fixed film bioreactor. Bioresour Technol 99(11):4621–4626

Akunna JC, Clark M (2000) Performance of a granular-bed anaerobic baffled reactor (GRABBR) treating whisky distillery wastewater. Bioresour Technol 74(3):257–261

Alkan-Ozkaynak A, Karthikeyan KG (2011) Anaerobic digestion of thin stillage for energy recovery and water reuse in corn-ethanol plants. Bioresour Technol 102(21):9891–9896

Anupama S, Pradeep NV, Hampannavar US (2013) Anaerobic followed by aerobic treatment approaches for spentwash using MFC and RBC. Sugar Tech 15(2):197–202

Apollo S, Onyango MS, Ochieng A (2013) An integrated anaerobic digestion and UV photocatalytic treatment of distillery wastewater. J Hazard Mater 261:435–442

Arnaiz C, Elmaleh S, Lebrato J, Moletta R (2005) Start up of an anaerobic inverse turbulent bed reactor fed with wine distillery wastewater using pre-colonised bioparticles. Water Sci Technol 51(1):153–158

Asha B, Kumar VN (2007) Effect of hydraulic retention time for treating distillery effluent in diphasic anaerobic digester. J Ind Pollut Contr 23(1):25–30

Banu JR, Kaliappan S, Rajkumar M, Beck D (2006) Treatment of spent wash in anaerobic mesophilic suspended growth reactor (AMSGR). J Environ Biol 27(1):111–117

Banu R, Kaliappan S, Beck D (2007) Treatment of spent wash in anaerobic thermophilic suspended growth reactor (ATSGR). J Environ Biol 28(2):517

Basu S, Mukherjee S, Kaushik A, Batra VS, Balakrishnan M (2015) Integrated treatment of molasses distillery wastewater using microfiltration (MF). J Environ Manag 158:55–60

Beltrán FJ, García-Araya JF, Álvarez PM (1999) Wine distillery wastewater degradation. 1. Oxidative treatment using ozone and its effect on the wastewater biodegradability. J Agric Food Chem 47(9):3911–3918

Beltrán FJ, García-Araya JF, Alvarez PM (2000) Continuous flow integrated chemical (ozone)-activated sludge system treating combined agroindustrial-domestic wastewater. Environ Progr 19(1):28–35

Beltrán FJ, Álvarez PM, Rodríguez EM, García-Araya JF, Rivas J (2001) Treatment of high strength distillery wastewater (cherry stillage) by integrated aerobic biological oxidation and ozonation. Biotechnol Prog 17(3):462–467

Beltran-de-Heredia J, Dominguez JR, Partido E (2005a) Physico-chemical treatment for the depuration of wine distillery wastewaters (vinasses). Water Sci Technol 51(1):159–166

Beltran-de-Heredia J, Torregosa J, Dominguez JR, Partido E (2005b) Degradation of wine distillery wastewater by the combination of aerobic biological treatment with chemical oxidation by Fenton’s reagent. Water Sci Technol 51(1):167–174

Benitez F, Beltran-Heredia J, Real F, Acero JL (1999) Enhancement of the ozonation of wine distillery wastewaters by an aerobic pretreatment. Bioprocess Eng 21(5):459–464

Billore SK, Singh N, Ram HK, Sharma JK, Singh VP, Nelson RM, Das P (2001) Treatment of a molasses based distillery effluent in a constructed wetland in central India. Water Sci Technol 44(11–12):441–448

Bories A, Raynal J, Bazile F (1988) Anaerobic digestion of high-strength distillery wastewater (cane molasses stillage) in a fixed-film reactor. Biol Waste 23(4):251–267

Chan YJ, Chong MF, Law CL, Hassell DG (2009) A review on anaerobic-aerobic treatment of industrial and municipal wastewater. Chem Eng J 155:1–18

Chandra R, Bharagava RN, YadavS Mohan D (2009) Accumulation and distribution of toxic metals in wheat (Triticumaestivum L.) and Indian mustard (Brassica campestris L.) irrigated with distillery and tannery effluents. J Hazard Mater 162(2):1514–1521

Chaudhari PK, Mishra IM, Chand S (2007) Decolourization and removal of chemical oxygen demand (COD) with energy recovery: treatment of biodigester effluent of a molasses-based alcohol distillery using inorganic coagulants. Colloids Surf A 296(1):238–247

Chaudhari PK, Mishra IM, Chand S (2008) Effluent treatment for alcohol distillery: catalytic thermal pretreatment (catalytic thermolysis) with energy recovery. Chem Eng J 136(1):14–24

Chaudhari PK, Singh R, Mishra IM, Chand S (2010) Kinetics of catalytic thermal pretreatment (catalytic thermolysis) of distillery wastewater and bio-digester effluent of alcohol production plant at atmospheric pressure. Int J Chem React Eng 8(1):1–22

Cibis E, Krzywonos M, Miśkiewicz T (2006) Aerobic biodegradation of potato slops under moderate thermophilic conditions: effect of pollution load. Bioresour Technol 97(4):679–685

Couallier EM, Ruiz BS, Lameloise ML, Decloux M (2006) Usefulness of reverse osmosis in the treatment of condensates arising from the concentration of distillery vinasses. Desalination 196(1):306–317

David C, Arivazhagan M, Tuvakara F (2015) Decolorization of distillery spent wash effluent by electro oxidation (EC and EF) and Fenton processes: a comparative study. Ecotoxicol Environ Saf 121:142–148

Doušková I, Kaštánek F, Maléterová Y, Kaštánek P, Doucha J, Zachleder V (2010) Utilization of distillery stillage for energy generation and concurrent production of valuable microalgal biomass in the sequence: biogas-cogeneration-microalgae-products. Energy Convers Manag 51(3):606–611

Dubey KV, Juwarkar AA, Singh SK (2005) Adsorption–desorption process using wood-based activated carbon for recovery of biosurfactant from fermented distillery wastewater. Biotechnol Progr 21(3):860–867

El-Dib FI, Tawfik FM, Eshaq G, Hefni HHH, El Metwally AE (2016) Remediation of distilleries wastewater using chitosan immobilized Bentonite and Bentonite based organoclays. Int J Biol Macromol 86:750–755

Fernandez N, Montalvo S, Borja R, Guerrero L, Sanchez E, Cortes I, Colmenarejo MF, Travieso L, Raposo F (2008) Performance evaluation of an anaerobic fluidized bed reactor with natural zeolite as support material when treating high-strength distillery wastewater. Renew Energy 33(11):2458–2466

Garcia-Morales JL, Romero LI, Sales D (2003) Influence of operational conditions on biofilm specific activity of an anaerobic fluidized bed reactor. Water Sci Technol 47(5):197–200

Geetha K, Raj SA (2015) Biomass-electrochemical integrated system for distillery wastewater treatment with electricity generation using anaerobic mixed consortium in microbial fuel cells. Int. J. Environ. Waste Manag. 15(3):217–234

Ghosh Ray S, Ghangrekar MM (2015) Enhancing organic matter removal, biopolymer recovery and electricity generation from distillery wastewater by combining fungal fermentation and microbial fuel cell. Bioresour Technol 176:8–14

Ghosh Ray S, Ghangrekar MM (2016) Biodegradation kinetics of thin-stillage treatment by Aspergillus awamori and characterization of recovered chitosan. Appl Microbiol Biotechnol 100(4):1955–1965

Ghosh AK, Singh B, Bose N, Tiwari KK (2003) Biocomposting of distillery waste to control water pollution. OCEANS 2003. Proc IEEE 3:1194–1198

González T, Terrón MC, Yagüe S, Zapico E, Galletti GC, González AE (2000) Pyrolysis/gas chromatography/mass spectrometry monitoring of fungal-biotreated distillery wastewater using Trametes sp. I-62 (CECT 20197). Rapid Commun Mass Spectrom 14(15):1417–1424

Goodwin JAS, Finlayson JM, Low EW (2001) A further study of the anaerobic biotreatment of malt whisky distillery pot ale using an UASB system. Bioresour Technol 78(2):155–160

Goto M, Nada T, Ogata A, Kodama A, Hirose T (1998) Supercritical water oxidation for the destruction of municipal excess sludge and alcohol distillery wastewater of molasses. J Supercrit Fluids 13(1):277–282

Grismer ME, Carr MA, Shepherd HL (2003) Evaluation of constructed wetland treatment performance for winery wastewater. Water Environ Res 75(5):412–421

Gupta R, Satyawali Y, Batra VS, Balakrishnan M (2008) Submerged membrane bioreactor using fly ash filters: trials with distillery wastewater. Water Sci Technol 58(6):1281–1284

Ha PT, Lee T K, Rittmann B E, Park J, Chang I S (2012) Treatment of alcohol distillery wastewater using a Bacteroidetes-dominant thermophilic microbial fuel cell. Environ Sci Technol 46(5):3022–3030

Hadavifar M, Zinatizadeh AA, Younesi H, Galehdar M (2010) Fenton and photo-Fenton treatment of distillery effluent and optimization of treatment conditions with response surface methodology. Asia Pac J Chem Eng 5:454–464

Hadavifar M, Younesi H, Zinatizadeh AA, Mahdad F, Li Q, Ghasemi Z (2016) Application of integrated ozone and granular activated carbon for decolorization and chemical oxygen demand reduction of vinasse from alcohol distilleries. J Environ Manag 170:28–36

Hossain SM (2007) Aerobic treatment of distillery wastewater using Phanerochaete chrysosporium. Indian J Environ Prot 27(4):362–366

Huang J, Yang P, Guo Y, Zhang K (2011) Electricity generation during wastewater treatment: an approach using an AFB-MFC for alcohol distillery wastewater. Desalination 276(1):373–378

Ince O, Kolukirik M, Oz NA, Ince BK (2005) Comparative evaluation of full-scale UASB reactors treating alcohol distillery wastewaters in terms of performance and methanogenic activity. J Chem Technol Biotechnol 80(2):138–144

Ioannou L, Fatta-Kassinos D (2013) Solar photo-Fenton oxidation against the bioresistant fractions of winery wastewater. J Environ Chem Eng 1(4):703–712

Ioannou LA, Michael C, Vakondios N, Drosou K, Xekoukoulotakis NP, Diamadopoulos E, Fatta-Kassinos D (2013) Winery wastewater purification by reverse osmosis and oxidation of the concentrate by solar photo-Fenton. Sep Purif Technol 118:659–669

Iscen CF, Ilhan S (2008) Sequential (anaerobic-aerobic) treatment of beet molasses alcoholic fermentation wastewater. Fresenius Environ Bull 17(4):420

Jafari NG, Trivedy RK, Foroutan A (2006) Possible practical and environmental applications of water hyacinth (Eichhornia crassipes). Pollut Res 25(4):893

Kabdasl I, Arslan-Alaton I, Ölmez-Hanc T, Tünay O (2012) Electrocoagulation applications for industrial wastewaters: a critical review. Environ Technol Rev 1:2–45

Kahsay A, Gabbiye N (2015) Characterization and effects of scale formation on heat transfer system of multiple-effect evaporator units in cane sugar industry. Chem Eng Process Technol 6:255

Kanhe NM, Gupta R, Bhole AG (2003) Anaerobic digestion of distillery spentwash—a critical review of mesophilic and thermophilic digestion. J Ind Pollut Contr 19(1):97–109

Kanimozhi R, Vasudevan N (2009) An overview of wastewater treatment in distillery industry. Int J Environ Eng 2(1–3):159–184

Kanimozhi R, Vasudevan N (2014) Effect of organic loading rate on the performance of aerobic SBR treating anaerobically digested distillery wastewater. Clean Technol Environ 16(3):467–476

Kazemi N, Tavakoli O, Seif S, Nahangi M (2015) High-strength distillery wastewater treatment using catalytic sub-and supercritical water. J Supercrit Fluids 97:74–80

Ke S, Shi Z, Fang HH (2005) Applications of two-phase anaerobic degradation in industrial wastewater treatment. Int J Environ Pollut 23(1):65–80

Kharayat Y (2012) Distillery wastewater: bioremediation approaches. J Integr Environ Sci 9(2):69–91

Khardenavis AA, Kumar MS, Mudliar SN, Chakrabarti T (2007) Biotechnological conversion of agro-industrial wastewaters into biodegradable plastic, poly β-hydroxybutyrate. Bioresour Technol 98(18):3579–3584

Krishna BM, Murthy UN, Kumar BM, Lokesh KS (2010) Electrochemical pretreatment of distillery wastewater using aluminum electrode. J Appl Electrochem 40(3):663–673

Krishna BM, Murthy U, Kumar BM, Lokesh KS (2011) Investigation of the electrochemical treatment for distillery wastewater. J Environ Sci Eng 53(2):191–194

Krzywonos M, Cibis E, Miśkiewicz T, Kent CA (2008) Effect of temperature on the efficiency of the thermo-and mesophilic aerobic batch biodegradation of high-strength distillery wastewater (potato stillage). Bioresour Technol 99(16):7816–7824

Krzywonos M, Cibis E, Lasik M, Nowak J, Miśkiewicz T (2009a) Thermo-and mesophilic aerobic batch biodegradation of high-strength distillery wastewater (potato stillage)—utilisation of main carbon sources. Bioresour Technol 100(9):2507–2514

Krzywonos M, Cibis E, Miskiewicz T, Ryznar-Luty A (2009b) Utilization and biodegradation of starch stillage (distillery wastewater). Electron J Biotechnol 12(1):6–7

Krzywonos M, Cibis E, Ryznar-Luty A, Miśkiewicz T, Borowiak D (2010) Aerobic biodegradation of wheat stillage (distillery wastewater) at an elevated temperature—effect of solids separation. Biochem Eng J 49(1):1–6

Kumar M, Ponselvan FIA, Malviya JR, Srivastava VC, Mall ID (2009) Treatment of bio-digester effluent by electrocoagulation using iron electrodes. J Hazard Mater 165(1):345–352

Lalov IG, Guerginov II, Krysteva MA, Fartsov K (2000) Treatment of waste water from distilleries with chitosan. Water Res 34(5):1503–1506

Latif MA, Ghufran R, Wahid ZA, Ahmad A (2011) Integrated application of upflow anaerobic sludge blanket reactor for the treatment of wastewaters. Water Res 45(16):4683–4699

Laubscher ACJ, Wentzel MC, Le Roux JMW, Ekama GA (2001) Treatment of grain distillation wastewaters in an upflow anaerobic sludge bed (UASB) system. Water SA 27(4):433–444

Lin CW, Wu CH, Huang WT, Tsai SL (2015) Evaluation of different cell-immobilization strategies for simultaneous distillery wastewater treatment and electricity generation in microbial fuel cells. Fuel 144:1–8

Ling J, Nip S, Shim H (2013) Enhancement of lipid productivity of Rhodosporidium toruloides in distillery wastewater by increasing cell density. Bioresour Technol 146:301–309

Ling J, Nip S, Cheok WL, de Toledo RA, Shim H (2014) Lipid production by a mixed culture of oleaginous yeast and microalga from distillery and domestic mixed wastewater. Bioresour Technol 173:132–139

Ling J, Tian Y, de Toledo RA, Shim H (2016) Cost reduction for the lipid production from distillery and domestic mixed wastewater by Rhodosporidium toruloides via the reutilization of spent seed culture medium. Energy. https://doi.org/10.1016/j.energy.2016.04.008

Lokeshwari N, Joshi K (2015) Low cost adsorbent for reducing organic components. J Ind Pollut Contr 30(1):53–58

Martínez JA, Almazán O, Saura G, Otero MA (2004) Production of fodder yeast from stillage in Cuba—an environmental approach. Zuckerindustrie 129(2):92–95

Martins RC, Quinta-Ferreira RM (2014) A review on the applications of ozonation for the treatment of real agro-industrial wastewaters. Ozone Sci Eng 36(1):3–35

Martins RC, Pinto FL, Castro-Silva S, Quinta-Ferreira RM (2011) Flocculation, ozonation, and Fenton’s process in the treatment of distillery effluents. J Environ Eng 139(1):110–116

Melamane XL, Tandlich R, Burgess JE (2007a) Treatment of wine distillery wastewater by high rate anaerobic digestion. Water Sci Technol 56(2):9–16

Melamane XL, Strong PJ, Burgess JE (2007b) Treatment of wine distillery wastewater: a review with emphasis on anaerobic membrane reactors. S Afr J Enol Vitic 28(1):25

Melamane X, Tandlich R, Burgess J (2007c) Anaerobic digestion of fungally pre-treated wine distillery wastewater. Afr J Biotechnol 6(17):1990–1993

Melamane XL, Strong PJ, Tandlich R, Burgess JE (2007c) Submerged membrane bioreactor and secondary digestion in the treatment of wine distillery wastewater. Part II: the effect of fungal pre-treatment on wine distillery wastewater digestion. Fresenius Environ Bull 16(2):162–167

Mishra VS, Mahajani VV, Joshi JB (1995) Wet air oxidation. Ind Eng Chem Res 34(1):2–48

Mohana S, Acharya BK, Madamwar D (2013) Bioremediation concepts for treatment of distillery effluent, In Biotechnology for Environmental Management and Resource Recovery, Springer, India, 261 – 278

Mohanakrishna G, Venkata Mohan S, Sarma PM (2010) Bio-electrochemical treatment of distillery wastewater in microbial fuel cell facilitating decolorization and desalination along with power generation. J Hazard Mater 177(1–3):487–494

Mohanakrishna G, Mohan SK, Mohan SV (2012) Carbon based nanotubes and nanopowder as impregnated electrode structures for enhanced power generation: evaluation with real field wastewater. Appl Energy 95:31–37

Moletta R (2005) Winery and distillery wastewater treatment by anaerobic digestion. Water Sci Technol 51(1):137–144

Moriya K, Iefuji H, Shimoi H, Sato SI, Tadenuma M (1990) Treatment of distillery wastewater discharged from beet molasses-spirits production using yeast. J Ferment Bioeng 69(2):138–140

Mulidzi AR (2007) Winery wastewater treatment by constructed wetlands and the use of treated wastewater for cash crop production. Water Sci Technol 56(2):103–109

Mullai P, Sathian S, Sabarathinam P (2007) Kinetic modelling of distillery wastewater biodegradation using Paecilomyces variotii. Chem Eng World 42(12):98–106

Nandy T, Shastry S, Kaul SN (2002) Wastewater management in a cane molasses distillery involving bioresource recovery. J Environ Manage 65(1):25–38

Nataraj SK, Hosamani KM, Aminabhavi TM (2006) Distillery wastewater treatment by the membrane-based nanofiltration and reverse osmosis processes. Water Res 40(12):2349–2356

Olvera JDR, García FP, López ES, Gutiérrez AR, Martínez AG (2007) Factibility of treat wineyard wastewater through anaerobic biodigestion with a from cow’s waste. Revista Técnica de la Facultad de Ingeniería, Universidad del Zulia 30(2):128–135

Pachauri RK, Sridharan PV (eds) (1998) Looking back to think ahead: GREEN India 2047 (Growth with resource enhancement of environment and nature). TERI, New Delhi

Padoley KV, Tembhekar PD, Saratchandra T, Pandit AB, Pandey RA, Mudliar SN (2012) Wet air oxidation as a pretreatment option for selective biodegradability enhancement and biogas generation potential from complex effluent. Bioresour Technol 120:157–164

Pandey RA, Malhotra S, Tankhiwale A, Pande S, Pathe PP, Kaul SN (2003) Treatment of biologically treated distillery effluent—a case study. Int J Environ Stud 60(3):263–275

Pant D, Adholeya A (2007a) Biological approaches for treatment of distillery wastewater: a review. Bioresour Technol 98(12):2321–2334

Pant D, Adholeya A (2007b) Enhanced production of ligninolytic enzymes and decolorization of molasses distillery wastewater by fungi under solid state fermentation. Biodegradation 18(5):647–659

Pant D, Adholeya A (2010) Development of a novel fungal consortium for the treatment of molasses distillery wastewater. Environmentalist 30(2):178–182

Pant D, Reddy UG, Adholeya A (2006) Cultivation of oyster mushrooms on wheat straw and bagasse substrate amended with distillery effluent. World J Microbiol Biotechnol 22(3):267–275

Perez-Garcia M, Romero-Garcia LI, Rodriguez-Cano R, Sales-Marquez D (2005) High rate anaerobic thermophilic technologies for distillery wastewater treatment. Water Sci Technol 51(1):191–198

Piya-Areetham P, Shenchunthichai K, Hunsom M (2006) Application of electrooxidation process for treating concentrated wastewater from distillery industry with a voluminous electrode. Water Res 40(15):2857–2864

Potentini MF, Rodriguez-Malaver AJ (2006) Vinasse biodegradation by Phanerochaete chrysosporium. J Environ Biol 27(4):661–665

Prajapati AK, Chaudhari PK (2015) Physicochemical treatment of distillery wastewater—a review. Chem Eng Commun 202(8):1098–1117

Prajapati AK, Choudhary R, Verma K, Chaudhari PK, Dubey A (2015a) Decolorization and removal of chemical oxygen demand (COD) of rice grain-based biodigester distillery effluent (BDE) using inorganic coagulants. Desalin Water Treat 53(8):2204–2214

Prajapati AK, Chaudhari PK, Mazumdar B, Choudhary R (2015b) Catalytic thermal treatment (catalytic thermolysis) of a rice grain-based biodigester effluent of an alcohol distillery plant. Environ Technol 36(20):2548–2555

Prasad RK, Srivastava SN (2009) Electrochemical degradation of distillery spent wash using catalytic anode: factorial design of experiments. Chem Eng J 146(1):22–29

Prodanović JM, Vasić VM (2013) Application of membrane processes for distillery wastewater purification—a review. Desalin Water Treat 51(16–18):3325–3334

Qiu C, Jia X, Wen J (2011) Purification of high strength wastewater originating from bioethanol production with simultaneous biogas production. World J Microbiol Biotechnol 27(11):2711–2722

Rabaey K, Angenent L, Schroder U, Keller J (2010) Bioelectrochemical systems: from extracellular electron transfer to biotechnological application. In: LaBelle E, Bond DR (eds) Electrochemical techniques for the analysis of bioelectrochemical systems. IWA Publishing, London, pp 135–148

Ráduly B, Gyenge L, Szilveszter S, Kedves A, Crognale S (2016) Treatment of corn ethanol distillery wastewater using two-stage anaerobic digestion. Water Sci Technol 74(6):431–437

Raghukumar C, Mohandass C, Kamat S, Shailaja MS (2004) Simultaneous detoxification and decolorization of molasses spent wash by the immobilized white-rot fungus Flavodon flavus isolated from a marine habitat. Enzyme Microb Technol 35(2):197–202

Rai UK, Muthukrishnan M, Guha BK (2008) Tertiary treatment of distillery wastewater by nanofiltration. Desalination 230(1):70–78

Rajeshwari KV, Balakrishnan M, Kansal A, Lata K, Kishore VVN (2000) State-of-the-art of anaerobic digestion technology for industrial wastewater treatment. Renew Sustain Energy Rev 4(2):135–156