Abstract

Exopolysaccharides or extracellular polymeric substances (EPS) has become an important resource and is being increasingly used in the biotechnology and biopharmaceutical industries. However, its production from glycerol under thermophilic conditions has not been reported. This study is aimed at isolating high-performance, EPS-producing bacteria under thermophilic conditions using glycerol as the substrate. Among the isolated microorganisms, Bacillus sonorensis strain NTV10 exhibited the highest EPS production. The optimum cultivation conditions in the enrichment medium (HS medium) were 1 g/L glycerol, 45 °C, and pH 7, with the highest EPS production of 15.97 mg/mL. We confirmed that NTV10 prefers thermophilic conditions for the highest EPS production. However, the utilization of glycerol was low because of the presence of yeast extracts and peptone in the HS medium. Therefore, the ability of glycerol conversion into EPS by NTV10 was evaluated using minimal medium (medium E*). We found that 15 g/L glycerol exhibited the highest EPS production (8.8 mg/mL). The monosaccharide composition of EPS from both media was similar, containing glucose, mannose, and rhamnose in a relative ratio of 5.1:2.2:1. The results of the IR spectrum showed the presence of mainly carboxyl and hydroxyl groups in the EPS product, which was in accordance with the monosaccharide composition. These properties can be applied in various industries such as food processing, cosmetics, and pharmaceuticals. The experimental knowledge derived from this study can be used to promote the use of glycerol as a renewable substrate for bioconversion into highly valuable products, such as EPS production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

One of the major environmental problems is the consumption of fossil fuels, especially in the transportation sector, which alone accounted for 24% of global carbon dioxide (CO2) emissions in 2019. Approximately 75% of total CO2 emissions in this sector are from commercial vehicles [1]. Biodiesel, which is primarily used in busses and commercial vehicles, has emerged as a promising alternative to fossil fuel resources. However, the increase in biodiesel production can become troublesome due to the extreme surplus of waste glycerol, about 10% (w/w) of which is generated from the transesterification reaction during the biodiesel production process. This problem directly affects the refined glycerol market and causes a significant reduction in the price of glycerol [2, 3]. Improper disposal of crude glycerol can have adverse environmental effects; further, the expensive nature of the glycerol refining process can be challenging, especially for small and medium-sized biodiesel plants [4]. Consequently, several efforts have been made to convert glycerol into a more valuable product, to reduce the cost of biodiesel production and the environmental problems associated with glycerol disposal [5, 6]. Moreover, most commercially available biotechnological products currently use sugars, starch, or molasses as feedstocks. In recent years, research has focused on the use of renewable and non-edible feedstocks as alternative raw materials. Therefore, glycerol can be considered a potential candidate for use as a renewable and low-cost substrate in biological production platforms.

Exopolysaccharides or extracellular polymeric substances (EPS) from prokaryotes are widely used as polysaccharide materials in many industries, such as food, pharmaceuticals, petrochemicals, and cosmetics. EPS can be homo- or heteropolysaccharides, each having different structures and specific properties depending on the type of bacteria and substrate used in its production. EPS has become an important resource and is being increasingly used in the biotechnology and biopharmaceutical industries [7]. The global market for hydrocolloids, which includes numerous polysaccharides, is still dominated by plant and algal polysaccharides, such as starch, galactomannans, and pectin. Considering the growth rate of the plants, eco-anxiety, and high extraction costs, EPS from microorganisms have the opportunity of becoming the dominant polysaccharide in the industry. Currently, some brands in the global market tend to use bacterial EPS such as xanthan, used in chromatographic media by Sigma-Aldrich Co. LLC.; alginate, used in Silvercel® antimicrobial alginate dressing by Johnson & Johnson; and dextran, used for the replacement of blood loss, plasma substitution, and volume expansion by Pharmacosmos [8].

The production of bacterial EPS normally uses different monosaccharides as substrates, such as glucose, fructose, and galactose, which is one of the reasons for their high production cost. Therefore, investigating the use of a low-cost substrate, such as glycerol, for EPS production is of interest. Some bacterial strains have been previously reported, which have the potential to produce EPS from glycerol under mesophilic conditions, such as Lactobacillus helveticus ATCC 15807 [9], Enterobacter A47 [10], Gluconacetobacter xylinus [11], and Acetobacter xylinum [12].

EPS production is commonly studied under mesophilic conditions (30–37 °C). However, some researchers have also investigated EPS production under thermophilic conditions (41–65 °C) [13-15]. The advantages of thermophilic conditions—extraordinarily high biochemical reaction rate, limit of bacterial contamination, and requirement of a smaller reactor volume—are attractive to investigate in the bio-production process [16]. These advantages are useful in industrial applications. However, EPS production from glycerol under thermophilic conditions has not been reported, because obtaining a remarkable isolated thermophile with high efficiency of EPS production from glycerol remains challenging. For a mixed culture source for microbial isolation in this study, a compost sample of synthetic food waste after 5 days of composting is considered as a potential resource. The composting temperature of synthetic food waste could reach 60 °C after 5 days of the process, and a high level of acetic acid accumulation occurred during this period [17]. Ua-Arak [18] et al. reported that acetic acid-producing bacteria have the ability to produce a high molecular weight EPS. Consequently, there is a possibility that EPS-producing thermophiles exist in the compost samples after day 5.

This study focused on EPS production from glycerol using an isolated thermophile. The challenge of this research was to identify bacteria that naturally prefer to produce EPS from glycerol under thermophilic conditions. After isolation and identification, the optimum conditions for maximizing EPS production, such as temperature, initial glycerol concentration, and pH, were evaluated. Finally, the EPS product was characterized by its monosaccharide content, structure, and properties, to determine its functions and usefulness in various applications.

2 Materials and methods

2.1 Isolation of EPS-producing bacteria using glycerol substrate, under thermophilic condition

A synthetic food waste sample, which was collected after 5 days of composting and potentially contained EPS-producing bacteria, was used as the source of a mixed culture. The Hestrin–Schramm (HS) medium [19], which contains 20.0 g/L glucose, 5.0 g/L yeast extract, 5.0 g/L peptone, 2.7 g/L Na2HPO4, 1.15 g/L citric acid, and 16 g/L bacto-agar, was modified by replacing the main carbon source from glucose with glycerol (20 g/L) and used for the isolation of EPS-producing bacteria. The culture conditions were 50 °C and shaking at 150 rpm. All microbial colonies with different morphologies were isolated, purified, and inoculated in liquid medium to evaluate their EPS production potential. After 48 h of incubation, EPS was extracted from the culture medium and measured using the phenol–sulfuric acid method [20]. The isolated bacterium with the maximum EPS yield was classified by 16S rRNA gene sequence analysis, and the optimal conditions for this reaction were determined.

2.2 Microbial identification by 16S rRNA sequence technique

Total genomic DNA of the isolated bacteria was extracted using a DNA extraction kit (ISOIL for Beads Beating, Nippon Gene Co. Ltd., Toyama, Japan), from the granule sample. The extracted DNA was used as template for the amplification of full-length 16S rRNA, using a universal primer, with TaKaRa PCR Thermal Cycler Dice™ (TP600, Takara Bio Inc., Shiga, Japan). The PCR product was purified using Wizard® SV Gel and PCR Clean-Up System (Promega, USA). Four primer sets (9F-GAGTTTGATCCTGGCTCAG, 515F-GTGCCAGCAGCCGCGGT, 785F-GGATTAGATACCCTGGTAGTC, and 1099F-GCAACGAGCGCAACCC) were used to read the sequences and derive high-accuracy sequencing results. Sequences were initially compared to the available databases using BLAST network services to determine their approximate phylogeny.

2.3 Optimization of the culture conditions and culture medium

Glycerol was used as the main carbon source in the HS medium. The suitable culture conditions—temperature (30–60 °C), glycerol concentration (0.5–20 g/L), and pH (5–8)—were investigated and optimized for EPS production.

Medium E* [21], a minimal medium, was modified and used to test EPS production from glycerol, by isolated EPS-producing bacteria. Modified medium E* was composed of (g/L): 1.0 glycerol, 1.0 nitrogen source, 5.8 K2HPO4, 3.7 KH2PO4, 10 mL MgSO4 solution (100 mM), and 1 mL microelement solution. This microelement solution contains (g/L of 1N HCl): 2.78 FeSO4·7H2O, 1.98 MnCl4·H2O, 2.81 CoSO4·7H2O, 1.67 CaCl2·2H2O, 0.17 CuCl2·2H2O, and 0.29 ZnSO4·7H2O. The effect of various nitrogen sources—yeast extract, peptone, urea, ammonium phosphate dibasic ((NH4)2HPO4), ammonium sulfate, ammonium chloride, and potassium nitrate—on EPS production was also investigated. Furthermore, glycerol concentration (1–20 g/L) was examined in the modified medium E*, to determine the optimum concentration, using (NH4)2HPO4 as the nitrogen source. Finally, the growth kinetics, glycerol utilization, and EPS production by the isolated bacteria, in the modified medium E*, were evaluated.

2.4 Characterization of the monosaccharides and functional groups in the EPS products

Exopolysaccharide (EPS) products were extracted from the culture medium after 48 h of incubation. The sample was heated at 80 °C for 10 min to inactivate the hydrolysis enzyme and then centrifuged at 9800 × g for 20 min at 4 °C. EPS was precipitated out from the cell-free supernatant by mixing it with cold ethanol (3:1) at 4 °C for 48 h. The sample was then centrifuged at 10,000 × g for 30 min at 4 °C; the obtained pellet was rinsed and dried by evaporating the ethanol. It was then dissolved in water, dialyzed using a Thermo Scientific™ SnakeSkin™ Dialysis Tubing (10 K MWCO, 22 mm) against distilled water at 4 °C for 48 h, and freeze-dried overnight. Protein in EPS was removed by dissolving the powder in 10% trichloroacetic acid, then dialyzed against distilled water at 4 °C for 120 h, and freeze-dried again.

The monosaccharide content of the purified EPS product was characterized after hydrolysis with 2 M trifluoroacetic acid at 120 °C for 1 h, using reverse-phase high-performance liquid chromatography (RP-HPLC) equipped with Shodex Asahipak NH2P-50 4E; 250 mM H3PO4 (aq.)/CH3CN (20:80 v/v) was used as the eluent. The major structural and functional groups were determined using Fourier transform infrared (FTIR) spectroscopy. The analyzed data was compared with standard substances and previous reports.

2.5 Fourier transform infrared (FTIR) spectroscopic analysis

FTIR spectroscopy can determine the major structural and functional groups present in the purified EPS products. The purified EPS was ground and mixed with spectroscopy-grade potassium bromide (KBr) and pressed to form pellets using the KBr disk technique. FTIR spectral data were recorded from 64 scans in the region 4,000–400 cm−1, at room temperature, using an FT/IR-610 JASCO spectrometer.

3 Results and discussion

3.1 Isolation and identification of EPS-producing bacteria

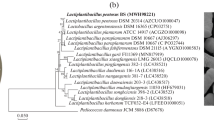

After the initial isolation, 18 colonies (NTV1–NTV18) with different morphologies were observed, selected, and purified (Supplement 1). All isolated bacteria were cultured in the modified HS medium to test their EPS-producing potential. Of the 18 isolated bacteria, NTV10 was selected as the representative of the isolated bacterium that produced the highest sugar content (Supplement 2). The results of 16S rRNA sequencing method (approximately 1500 bp) showed that NTV10 is closely related to Bacillus sonorensis (99.86% identity) (Accession number: MZ310519).

Bacillus sonorensis is a facultative anaerobic, gram-positive bacterium. Its growth temperature range is 15–55 °C (optimum, 30 °C). The growth can be inhibited by 5% NaCl and 0.001% lysozyme solutions. B. sonorensis can utilize citrate and propionate and hydrolyze casein and starch. Furthermore, this bacterium can reduce nitrate to nitrite and facilitate acid fermentation without gas production using glucose and other carbohydrates as substrates [22]. Previously, Bacillus sonorensis MJM60135, which was isolated from ganjang (fermented soy sauce), was reported to produce EPS from tryptic soy broth (TSB) medium containing glucose, under mesophilic conditions (37 °C) [23]. In contrast, the EPS in this study was obtained from a modified HS medium containing glycerol, by B. sonorensis strain NTV10, under thermophilic conditions. After optimizing the culture conditions, EPS was extracted, purified, and freeze-dried (Fig. 1). The purified EPS product was further identified with respect to its monosaccharide content and functional groups.

3.2 Optimization of culture conditions for EPS production in modified HS medium

First, the optimal temperature for EPS production was investigated in the modified HS medium, using 20 g/L of glycerol concentration and pH 6.27. Figure 2A shows that the highest EPS concentration (12.08 mg/mL) was obtained at 45 °C. This result confirmed that the B. sonorensis NTV10 strain preferred thermophilic over mesophilic conditions, for EPS production. However, microbial growth and EPS production declined gradually when the temperature was above 45 °C. Previously, Pediococcus pentosaceus and Lactobacillus amylovorus were isolated from tropical fruits of Thailand and studied for EPS production under thermophilic condition. These two bacteria preferred high temperatures (45 °C) for growth and EPS production [13]. However, some bacteria, such as Pseudomonas oleovorans NRRL B-14682, preferred mesophilic conditions and were studied to evaluate the influence of temperature (20–40 °C) on EPS production. The results showed that a temperature of 30 °C provided maximum cell growth and EPS production from glycerol [24]. The optimum temperature of 45 °C for the NTV10 strain offers several advantages, such as reducing the risk of contamination from mesophilic bacteria and increasing the biochemical reaction rate of fermentation [16]. Moreover, the reaction at 45 °C is energy-efficient as it reduces the cooling cost after the fermentation process.

Effect of physical parameters on EPS production from glycerol, in modified HS medium, by B. sonorensis NTV10 strain. (A) The effect of temperature (glycerol concentration 20 g/L, pH 6.27); (B) the effect of initial glycerol concentrations (temperature 45 °C, pH 6.27); and (C) the impact of pH (temperature 45 °C, glycerol concentration 1 g/L)

Second, the optimal glycerol concentration was evaluated at temperature 45 °C and pH 6.27 (Fig. 2B). The highest EPS concentration (14.17 mg/mL) was obtained with an initial glycerol concentration of 1 g/L. EPS production decreased with increasing glycerol concentrations. However, the EPS concentration at 0.5 g/L glycerol concentration was lower than that at 1 g/L. Enrichment substances such as yeast extract and peptone were preferred over glycerol. Therefore, to confirm the ability of B. sonorensis NTV10 strain to convert glycerol into EPS, the modified medium E* was used for further experiments. Moreover, the inhibition at high initial glycerol concentrations might have occurred due to the high osmotic pressure conditions. Torino et al. [9] reported that the EPS production, by Lactobacillus helveticus ATCC 15807, from glucose, was reduced because of the osmotic stress by adding 5% and 10% of glycerol concentration into the medium. The yield of EPS decreased 10-folds.

Finally, the optimal pH, which is an important factor for biological production processes, was evaluated (Fig. 2C). The highest EPS concentration (15.97 mg/mL) was obtained at an optimum pH of 7, for B. sonorensis. However, the optimal pH for EPS production depends on the specific bacterial strain. Lactobacillus helveticus ATCC 15807 could produce EPS in acidic conditions (pH 4.5), two-fold higher than that at pH 6.5 [9], whereas Bacillus licheniformis T14 prefers alkaline conditions (pH 8) for EPS production [25].

3.3 Optimization of EPS production in medium E*

Medium E*, a minimal medium, was used to evaluate the ability of B. sonorensis strain NTV10 to convert glycerol into EPS, and to assess the impact of nitrogen sources on EPS production. Figure 3A shows that organic nitrogen sources (except urea) provide superior EPS production compared to inorganic ones. EPS production did not vary significantly among the inorganic nitrogen sources. This result is similar to that of Moghannem et al. [26], who reported that yeast extract was the best nitrogen source for EPS production from sucrose, compared to peptone, urea, (NH4)2SO4, NH4Cl, and KNO3, by Bacillus velezensis KY471306. Gorret et al. [27] reported that yeast extract not only promoted microbial growth but also directly increased the biosynthesis of EPS.

To investigate the use of glycerol as the sole carbon source for EPS production by NTV10, ammonium phosphate dibasic, which was originally present in medium E*, was used for this experiment. We found that the highest EPS production (8.88 mg/mL) was observed at an initial glycerol concentration of 15 g/L (Fig. 3B). A higher glycerol concentration might cause high osmotic pressure, as previously described. NTV10 showed higher activity for glycerol conversion into EPS in medium E* than in modified HS medium, which contained yeast extract and peptone.

The dynamic relationship between microbial growth and EPS production in medium E* indicated that EPS production corresponded with growth, especially during the logarithmic phase (Fig. 4). This phenomenon was similar to the growth and EPS production of Klebsiella oxytoca [28], Chelatococcus daeguensis TAD1 [29], and Lactobacillus delbrueckii subsp. bulgaricus RR [30]. Thus, the enhancement of microbial growth may contribute in increasing the EPS production.

3.4 Characterization of the monosaccharides and determination of the structure of EPS products

The monosaccharide content in the purified EPS products obtained from the modified HS medium and medium E*, by the NTV10 strain, was identified. We found that the monosaccharide contents in the EPSs from both media were similar, containing glucose, mannose, and rhamnose in the ratio 5.1:2.2:1.0. This result indicated that the use of different media (enrichment and minimal media) had no effect on the monosaccharide composition of the EPS. A previous study on EPS production by B. sonorensis MJM60135 strain used tryptic soy broth (TSB) as a substrate, which contains glucose as a carbon source and tryptone and soytone as nitrogen sources. The results showed that only glucose and mannose were detected [23]. Although NTV10 and MJM60135 were similar species, their monosaccharide contents in the EPS were slightly different. Similarly, many previous studies used the same bacterial species and carbon sources, but the monosaccharide contents in EPS varied, as shown in Table 1. Enterobacter A47 was investigated for EPS production using medium E* containing glycerol, which was similar to the present study, but the monosaccharide content of the EPS was different. Therefore, the type of medium was not the determining factor for the monosaccharide content in EPS. In addition, Bacillus licheniformis strains T14 and KS-17 provide different monosaccharide compositions in EPS even when used with the same carbon source (sucrose) and nitrogen source (yeast extract) [25, 31]. Therefore, the monosaccharides in EPS might depend on the microbial strains, but the types of carbon and nitrogen sources might not affect the monosaccharide content.

Figure 5 shows the results of the IR spectrum in the 4000–400 cm−1 regions from FTIR spectroscopy that provided information on the major structural and functional groups of the EPS products of B. sonorensis NTV10 strain, in modified HS medium and medium E*. We found that there was no significant difference in FTIR results between EPS products of both media, which corresponded to the results of the monosaccharide composition. The characteristics of each band were assigned and are summarized in Table 2. The results of the FTIR spectrum of EPS in this study were similar to those assigned to the major bands of the EPS product from B. sonorensis MJM60135. In particular, the presence of carboxyl and hydroxyl groups is essential for binding divalent cations, which aid in enhancing flocculation [23, 32].

Together with the results of monosaccharide composition, the EPS product from NTV10 strain has the major monosaccharides—glucose, mannose, and rhamnose—mostly related to EPS (GalactoPol) from Pseudomonas oleovorans, which contains galactose, glucose, mannose, and rhamnose in the ratio 1:0.3:0.06:0.04, respectively [33]. The properties of EPS include flocculating, film-forming, and emulsifying capacities, which can be applied to food processes, cosmetics, pharmaceuticals, oil recovery, packaging, etc. [34]. The results of this study report the optimized culture conditions and efficiency of novel B. sonorensis NTV10 strain, for EPS production, from glycerol, under optimal thermophilic conditions. This will be beneficial for industrial EPS production and will facilitate the efficient utilization of glycerol, which, in turn, will have a positive effect on the biodiesel and glycerol industries.

4 Conclusions

Bacillus sonorensis strain NTV10 was isolated and selected as a representative of the EPS-producing bacterium, which can produce EPS from a glycerol-containing medium, under thermophilic conditions. The optimum culture conditions for EPS production by NTV10, using a modified HS medium, were initial glycerol concentration 1 g/L, temperature 45 °C, and pH 7. The highest EPS concentration obtained using the HS medium was 15.97 mg/mL. Glycerol utilization in the HS medium was low because of the presence of yeast extracts and peptones, which were preferred over glycerol. We found that yeast extract was the best nitrogen source for EPS production in minimal medium (medium E*) compared to other types of organic and inorganic nitrogen sources. The ability of glycerol conversion into EPS of NTV10 was evaluated in medium E* using ammonium phosphate dibasic as a nitrogen source. The most suitable glycerol concentration for EPS production in medium E* was 15 g/L, and the highest EPS concentration was 8.8 mg/mL. The kinetic data for EPS production showed that the growth of bacteria corresponded to the production of EPS. The monosaccharide compositions of EPS from both modified HS medium and medium E* were similar and contained glucose, mannose, and rhamnose. The IR spectra corresponded to the monosaccharide composition. The properties of EPS products obtained from NTV10 are applicable in many industries such as food, cosmetics, and pharmaceuticals.

Data availability

All data generated or analyzed during this study are included in this published article (and its supplementary information files).

References

Duque A, Álvarez C, Doménech P, Manzanares P, Moreno AD (2021) Advanced bioethanol production: from novel raw materials to integrated biorefineries. Processes 9:206. https://doi.org/10.3390/pr9020206

Yang F, Hanna MA, Sun R (2012) Value-added uses for crude glycerol–a byproduct of biodiesel production. Biotechnol Biofuels 5:13. https://doi.org/10.1186/1754-6834-5-13

Hejna A, Kosmela P, Formela K, Piszczyk Ł, Haponiuk JT (2016) Potential applications of crude glycerol in polymer technology–current state and perspectives. Renew Sustain Energy Rev 66:449–475. https://doi.org/10.1016/j.rser.2016.08.020

Yazdani SS, Gonzalez R (2007) Anaerobic fermentation of glycerol: a path to economic viability for the biofuels industry. Curr Opin Biotechnol 18:213–219. https://doi.org/10.1016/j.copbio.2007.05.002

Nicol RW, Marchand K, Lubitz WD (2012) Bioconversion of crude glycerol by fungi. Appl Microbiol Biotechnol 93:1865–1875. https://doi.org/10.1007/s00253-012-3921-7

Nwachukwu R, Shahbazi A, Wang L, Ibrahim S, Worku M, Schimmel K (2012) Bioconversion of glycerol to ethanol by a mutant Enterobacter aerogenes. AMB Express 2:20. https://doi.org/10.1186/2191-0855-2-20

Nicolaus B, Kambourova M, Oner ET (2010) Exopolysaccharides from extremophiles: from fundamentals to biotechnology. Environ Technol 31:1145–1158. https://doi.org/10.1080/09593330903552094

Andhare P, Chauhan K, Dave M, Pathak H (2014) Microbial exopolysaccharides: advances in applications and future prospects. In: Tewari R (ed) Biotechnology volume 3: microbial biotechnology, 1st edn. Studium Press LLC, pp 25. https://doi.org/10.13140/RG.2.1.3518.4484

Torino MI, H ébert EM, Mozzi F, Font de Valdez G, (2005) Growth and exopolysaccharide production by Lactobacillus helveticus ATCC 15807 in an adenine-supplemented chemically defined medium. J Appl Microbiol 99:1123–1129. https://doi.org/10.1111/j.1365-2672.2005.02701.x

Torres CA, Marques R, Ferreira AR, Antunes S, Grandfils C, Freitas F, Reis MA (2014) Impact of glycerol and nitrogen concentration on Enterobacter A47 growth and exopolysaccharide production. Int J Biol Macromol 71:81–86. https://doi.org/10.1016/j.ijbiomac.2014.04.012

Jalili Tabaii M, Emtiazi G (2015) Comparison of bacterial cellulose production among different strains and fermented media. Appl Food Biotechnol 3:35–41. https://doi.org/10.22037/afb.v3i1.10582

Jonas R, Farah LF (1998) Production and application of microbial cellulose. Polym Degrad Stab 59:101–106. https://doi.org/10.1016/S0141-3910(97)00197-3

Panthavee W, Noda M, Danshiitsoodol N, Kumagai T, Sugiyama M (2017) Characterization of exopolysaccharides produced by thermophilic lactic acid bacteria isolated from tropical fruits of Thailand. Biol Pharm Bull 40:621–629. https://doi.org/10.1248/bpb.b16-00856

Jachlewski S, Jachlewski WD, Linne U, Bräsen C, Wingender J, Siebers B (2015) Isolation of extracellular polymeric substances from biofilms of the thermoacidophilic archaeon Sulfolobus acidocaldarius. Front Bioeng Biotechnol 3:123. https://doi.org/10.3389/fbioe.2015.00123

Sardari RR, Kulcinskaja E, Ron EY, Björnsdóttir S, Friðjónsson ÓH, Hreggviðsson GÓ, Karlsson EN (2017) Evaluation of the production of exopolysaccharides by two strains of the thermophilic bacterium Rhodothermus marinus. Carbohydr Polym 156:1–8. https://doi.org/10.1016/j.carbpol.2016.08.062

Gebreeyessus GD, Jenicek P (2016) Thermophilic versus mesophilic anaerobic digestion of sewage sludge: a comparative review. Bioengineering 3:15. https://doi.org/10.3390/bioengineering3020015

Nakasaki K, Hirai H (2017) Temperature control strategy to enhance the activity of yeast inoculated into compost raw material for accelerated composting. Waste Manag 65:29–36. https://doi.org/10.1016/j.wasman.2017.04.019

Ua-Arak T, Jakob F, Vogel RF (2016) Characterization of growth and exopolysaccharide production of selected acetic acid bacteria in buckwheat sourdoughs. Int J Food Microbiol 19(239):103–112. https://doi.org/10.1016/j.ijfoodmicro.2016.04.009

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum. II. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345–352. https://doi.org/10.1042/bj0580345

DuBois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

Brandl H, Gross RA, Lenz RW, Fuller RC (1988) Pseudomonas oleovorans as a source of poly(beta-hydroxyalkanoates) for potential applications as biodegradable polyesters. Appl Environ Microbiol 54:1977–1982. https://doi.org/10.1128/aem.54.8.1977-1982.1988

Palmisano MM, Nakamura LK, Duncan KE, Istock CA, Cohan FM (2001) Bacillus sonorensis sp. nov., a close relative of Bacillus licheniformis, isolated from soil in the Sonoran Desert. Arizona Int J Syst Evol Microbiol 51:1671–1679. https://doi.org/10.1099/00207713-51-5-1671

Palaniyandi S, Damodharan K, Suh JW, Yang SH (2018) Functional characterization of an exopolysaccharide produced by Bacillus sonorensis MJM60135 isolated from Ganjang. J Microbiol Biotechnol 28:663–670. https://doi.org/10.4014/jmb.1711.11040

Freitas F, Alves VD, Pais J, Carvalheira M, Costa N, Oliveira R, Reis MAM (2010) Production of a new exopolysaccharide (EPS) by Pseudomonas oleovorans NRRL B-14682 grown on glycerol. Process Biochem 45:297–305. https://doi.org/10.1016/j.procbio.2009.09.020

Spanò A, Gugliandolo C, Lentini V, Maugeri TL, Anzelmo G, Poli A, Nicolaus B (2013) A novel EPS-producing strain of Bacillus licheniformis isolated from a shallow vent off Panarea Island (Italy). Curr Microbiol 67:21–29. https://doi.org/10.1007/s00284-013-0327-4

Moghannem SAM, Farag MMS, Shehab AM, Azab MS (2018) Exopolysaccharide production from Bacillus velezensis KY471306 using statistical experimental design. Braz J Microbiol 49:452–462. https://doi.org/10.1016/j.bjm.2017.05.012

Gorret N, Maubois JL, Engasser JM, Ghoul M (2001) Study of the effects of temperature, pH and yeast extract on growth and exopolysaccharides production by Propionibacterium acidi-propionici on milk microfiltrate using a response surface methodology. J Appl Microbiol 90:788–796. https://doi.org/10.1046/j.1365-2672.2001.01310.x

Moghannem SAM, Farag MMS, Shehab AM, Azab MS (2017) Media optimization for exopolysaccharide producing Klebsiella oxytoca KY498625 under varying cultural condition. Int J Adv Res Biol Sci 4:16–30. https://doi.org/10.22192/ijarbs.2017.04.03.002

Wei Z, Huang S, Zhang Y, Li H, Zhou S (2017) Characterization of extracellular polymeric substances produced during nitrate removal by a thermophilic bacterium Chelatococcus daeguensis TAD1 in batch cultures. RSC Adv 7:44265–44271. https://doi.org/10.1039/C7RA08147B

Kimmel SA, Roberts RF, Ziegler GR (1998) Optimization of exopolysaccharide production by Lactobacillus delbrueckii subsp. bulgaricus RR grown in a semidefined medium. Appl Environ Microbiol 64:659–664. https://doi.org/10.1128/AEM.64.2.659-664.1998

Song YR, Song NE, Kim JH, Nho YC, Baik SH (2011) Exopolysaccharide produced by Bacillus licheniformis strains isolated from Kimchi. J Gen Appl Microbiol 57:169–175. https://doi.org/10.2323/jgam.57.169

Agunbiade MO, Van Heerden E, Pohl CH, Ashafa AT (2017) Flocculating performance of a bioflocculant produced by Arthrobacter humicola in sewage wastewater treatment. BMC Biotechnol 17:51. https://doi.org/10.1186/s12896-017-0375-0

Jeong JP, Kim Y, Hu Y, Jung S (2022) Bacterial succinoglycans: structure, physical properties, and applications. Polymers (Basel) 14:276. https://doi.org/10.3390/polym14020276

Freitas F, Alves VD, Reis MA (2011) Advances in bacterial exopolysaccharides: from production to biotechnological applications. Trends Biotechnol 29:388–398. https://doi.org/10.1016/j.tibtech.2011.03.008

Acknowledgements

The authors would like to thank Assoc. Prof. Dr. Manabu Fujii, Department of Civil and Environmental Engineering, Tokyo Institute of Technology, for aiding in the use of the freeze-dryer. Moreover, the authors would also like to thank Prof. Dr. Masaki Kawano, Department of Chemistry, Tokyo Institute of Technology, for helping with the FTIR analysis.

Funding

This work received support from the Japan Society for the Promotion of Science (JSPS), JSPS Postdoctoral Fellowships (grant number: P17354).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Nunthaphan Vikromvarasiri. The first draft of the manuscript was written by Nunthaphan Vikromvarasiri. Supervision was done by Kiyohiko Nakasaki. All authors read, revised, and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vikromvarasiri, N., Nakasaki, K. Exopolysaccharide production from glycerol by Bacillus sonorensis NTV10 under thermophilic condition. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04402-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04402-7

HS) and medium E* (

HS) and medium E* (

E) in the range 4000–400 cm.−1

E) in the range 4000–400 cm.−1