Abstract

Sweet potato residue (SPR), a by-product of sweet potato starch extraction, is full of starch and cellulose and could be used as the starting material for bioethanol production. A novel one-step complex enzyme (including α-amylase, glucoamylase, cellulase, hemicellulase, and pectinase) hydrolysis approach was developed to liberate the fermentable carbohydrates present in SPR. The effects of pH, amount of enzymes, solid-to-liquid ratio, temperature, and enzyme reaction time on the reducing sugar yield were investigated. Experiment results showed that the optimum pH, solid-to-liquid ratio, amount of enzymes, enzymatic hydrolysis temperature, and time were 4.5, 1: 7, 0.32 g, 50 ℃, and 6 h, respectively. Under these optimum conditions, the experimental reducing sugar yield reached 65.06% ± 1.62%. Carbohydrate analysis of the enzymatic SPR showed that glucose accounted for the largest proportion of fermentable sugars at 58.91% ± 1.25%. In particular, 64.98% ± 0.11% of the cellulose was decomposed during the enzymatic hydrolysis. Finally, a concentration of 113.63 ± 1.35 g/L glucose was formed from the 17.2% (w/v) SPR substrate, and 46.9 ± 0.61 g/L ethanol was finally produced by an industrial diploid Saccharomyces cerevisiae strain at a yield of 27.27% ± 0.30% SPR. The proposed approach has great potential for industrial bioethanol production from SPR due to its high productivity, easy manipulation, and environmentally friendly characteristics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Bioethanol is a renewable fuel and can be used in gasoline–ethanol blends with 10 to 85% ethanol [1,2,3]. As one of the most promising alternatives to fossil fuels [4, 5], bioethanol production heavily relies on first-generation bioethanol where the fermentation sugar is derived from starch-based crops, such as corn, wheat, and cassava, which is relatively mature and widely used in countries around the world [6]. However, with the reduction in arable land and the increase in grain prices and ethanol consumption, the production of bioethanol from grains such as corn may cause a serious impact on its economic efficiency. Researchers began to focus on the second generation of bioethanol with waste or by-products as the main raw material, such as wheat straw, corn cobs, rice straw, and cassava starch residue. This way, public concerns about ethanol production from food sources and the rising price of bioethanol can be solved [7]. Therefore, the development of bioethanol from nonfood raw materials has become an inevitable trend of social development [8].

Sweet potato is one of the most adaptable and high-yield crops in the world, and its annual output has reached approximately 100 million tons in the past decades [9]. China is the largest sweet potato producer and can generate more than 71 million tons of sweet potatoes every year [4]. Sweet potato residue (SPR) is the byproduct of extracting starch from fresh sweet potatoes by crushing, washing, and filtering and mainly consists of starch, cellulose, and pectin [10, 11]. In China, most of the SPR cannot be utilized due to its high viscosity, and the utilized SPR is highly perishable and rancid. SPR contains abundant polysaccharides and proteins; when it turns rancid, it will release methane, the second most common greenhouse gas whose impact on climate change is 25 times greater than that of carbon dioxide [12, 13]. Moreover, the polysaccharides in SPR can be hydrolyzed into exploitable substances, such as monosaccharides and oligosaccharides [14], which can be used for fermentation to produce citric acid, lactic acid, and other high value-added products [15, 16]. Directly discarding SPR as waste will pose serious environmental pollution and reduce the economic value of this material.

SPR is rich in carbohydrates, making it a suitable substrate for bioethanol production. Saccharification is one of the most important steps in the production of ethanol from SPR [17]. Acid-catalyzed hydrolysis allows the release of polysaccharides from SPR into monosaccharides, but this method will corrode equipment and generate fermentation inhibitors [18]. Therefore, efficient enzymatic hydrolysis is preferred to obtain fermentable sugars from SPR. Pagana et al. [16] gelatinized starch granules in SPR and hydrolyzed them into glucose using glucoamylase alone; 83.56% of the available starch in SPR was converted into glucose, but the glucose from cellulose was not released. Xia et al. [9] used mixed enzymes comprising α-amylase, glucoamylase, cellulase, xylanase, and pectinase to hydrolyze SPR in two steps. The starch in SPR was initially hydrolyzed into glucose by α-amylase and glucoamylase, and the “de-starched” sample was pretreated with 1% (w/v) H2SO4, NaOH, or H2O2. Cellulase, xylanase, and pectinase were then added to release glucose from cellulose, and the highest cellulose conversion of 96.2% was reached after NaOH pretreatment. Although the starch and lignocellulose in SPR can be efficiently hydrolyzed by the two-step enzymatic hydrolysis, the process is time consuming and energy intensive. After pretreatment, alkalis reacting with lignocellulose may generate inhibitors, which may suppress subsequent microbial fermentation to produce ethanol [19].

In this study, the one-step complex enzyme hydrolysis method after gelatinization was developed to release fermentable sugars from SPR, where starch and cellulose were hydrolyzed simultaneously, and cellulose was not pretreated with acid or alkali. The chemical composition of SPR was first determined, and the effects of pH, temperature, amount of enzymes, solid-to-liquid ratio, and enzyme reaction time on the reducing sugar yield were then investigated. The optimal process derived from the single-factor test was also verified. Finally, the fermentation of the enzymatic hydrolysates of SPR to form bioethanol was investigated. The findings provide a convenient way to liberate fermentable sugars from SPR for bioethanol fermentation.

2 Materials and methods

2.1 Substrate, enzymes, and Saccharomyces cerevisiae strain growth conditions

SPR was provided by Luoyang Feed Factory of Henan Dongfang Zhengda Co., Ltd., China. The dried SPR was pulverized, passed through a 60-mesh sieve, and stored at room temperature. α-Amylase and glucoamylase were obtained from Beijing Aoboxing Biotechnology Co., Ltd. Cellulase, hemicellulase, and pectinase were obtained from Shanghai Yuanye Biotechnology Co., Ltd. The enzyme activities of α-amylase, glucoamylase, cellulase, hemicellulase, and pectinase were 3700, 100,000, 50,000, 20,000, and 500,000 U/g, respectively. The S. cerevisiae strain CCTCC M94055 was preserved in the laboratory and grown on YPD20 medium (10 g/L yeast extract, 20 g/L tryptone, 20 g/L D-glucose, and 20 g/L agar as needed). All other chemicals were of analytical reagents.

2.2 Chemical composition analysis of SPR

The contents of starch and cellulose were determined by 3, 5–dinitrosalicylic acid colorimetric (DNS) and anthrone colorimetry, respectively [20,21,22,23]. The content of hemicellulose was determined by using the Hemicellulose Content Assay Kit (Solarbio). The content of pectin was determined by carbazole colorimetry [24]. The contents of ash and protein were determined following previous reports [25, 26].

2.3 Determination of the enzymatic hydrolysis conditions of SPR

The necessity of gelatinization before SPR enzymatic hydrolysis was explored. The substrate (10 g of SPR mixed with 50 mL of distilled water) was first adjusted to pH 5.0 and then heated in boiling water for 15 min [27]. The mixed enzymes (0.13 g of α-amylase and 0.03 g of glucoamylase) were added to facilitate enzymatic hydrolysis at 200 rpm and 60 °C for 8 h after the sample had cooled down. The samples were heated in boiling water for 5 min to deactivate the enzymes. The supernatant was obtained by centrifugation and subjected to reducing sugar yield analysis [28,29,30]. Three independent replicates were performed.

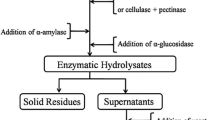

The effect of mixed enzyme ratio on the reducing sugar yield was studied by applying different mixed enzyme ratios following previous reports with some modifications. α-Amylase, glucoamylase, cellulase, hemicellulase, and pectinase were mixed in the ratios of 48 U: 300 U: 50 U: 5 U: 5 U [9, 31, 32] and 48 U: 300 U: 300 U: 300 U: 800 U [13, 33, 34]. The amount of mixed enzymes was 0.15 g, and the enzymatic hydrolysis reaction was carried out at 50 °C for 18 h. The resulting enzymatic hydrolysate was subjected to reducing sugar yield analysis [9]. Three independent replicates were performed.

2.4 Single-factor experiments

Single-factor experiments were conducted to investigate the effects of five factors on the reducing sugar yield. In the study of a certain factor, the other factors were set to their corresponding fixed values, i.e., 5.0 for pH, 50 °C for temperature, 0.15 g for amount of mixed enzyme addition, 1: 5 for solid-to-liquid ratio, and 6 h for enzymatic hydrolysis time. The factors and levels are shown in Table 1. The yield of reducing sugar in the enzymatic hydrolysate was determined by DNS, and the detailed procedure is described in the supplementary material. Three independent replicates were performed, and the results of all data from the single-factor experiments were shown in Table S1. “SAS” software package (Version 9.2) was used for one-way ANOVA to statistically analyze the single factor experiments.

2.5 Carbohydrates and scanning electron microscopy (SEM) analysis of the enzymatic hydrolysates of SPR

The sugar components in the enzymatic hydrolysates were derivatized following the method of Wu et al. with some modifications [35, 36] and then determined using an HPLC apparatus equipped with an Xtimate C18 column (4.6 × 200 mm, 5 μm). In brief, 0.05 M potassium dihydrogen phosphate solution (adjusted to pH 6.7 with NaOH solution) and acetonitrile were mixed in a ratio of 83: 17 to obtain the mobile phase; the flow rate was set as 1.0 mL/min at 30 ℃, and the detection wavelength was 250 nm [37, 38].

SEM (Hitachi HT7700) was used to observe the microstructure of SPR and saccharified residues. The samples were dried to a constant weight and then scanned at an accelerating voltage of 3 kV at 1000 × and 5000 × magnifications.

2.6 Ethanol production from the optimized enzymatic hydrolysates

The fermentation broth was obtained by optimal single-factor enzymatic hydrolysis process and concentrated by rotary evaporation at 85 °C. Single colonies of the CCTCC M94055 strain were obtained by streaking YPD20 plates from frozen glycerol stock, then inoculated in YPD20 liquid medium, and incubated overnight at 30 °C and 240 rpm. Afterward, 200 μL of the cultures were transferred to fresh medium to repeat the above procedure. Upon aerobic growth, the CCTCC M94055 cells were obtained by centrifugation at 12,000 rpm for 10 min, washed twice with sterilized distilled water, and inoculated into the SPR enzymatic hydrolysates at 0.5 g/L dry cell weigh inoculum. The correlation between dry cell weight and OD600 values was reported previously [39]. During the fermentation, the samples were taken every 4 h for OD600 determination and metabolite analysis. Two independent replicates were performed, and the results of all data from the ethanol fermentation experiment were shown in Table S2.

OD600 value was measured using a T2600 UV spectrophotometer. The glucose and ethanol concentrations were determined using a refractive index detector on LC-2030C HPLC with a Bio-Rad HPX-87H column. The column was eluted at 65 °C with 5 mM sulfuric acid at the flow rate of 0.6 mL/min [40]. Glucan conversion, glucose to ethanol conversion, SPR to ethanol yield, specific growth rates, specific glucose consumption rate, and specific ethanol production rates were calculated as previously described report [13, 41, 42].

3 Results and discussion

3.1 Analysis of the chemical composition of SPR

SPRs from different regions usually have different compositions, which affect the choice of enzymes for enzymatic hydrolysis. Therefore, the components of the SPR were analyzed to determine which helper enzyme needs to be added in this study. According to the standard curve (Fig. S1, Fig. S2, Fig. S3, and Fig. S4), the dried SPR is composed of 51.94% ± 0.55% starch, 18.22% ± 0.47% cellulose, 3.38% ± 0.02% hemicellulose, and 1.66% ± 1.31% pectin. As shown in Table 2, SPR also contains 2.92% ± 0.03% protein and 2.23% ± 0.01% ash. In agreement with previous studies, the SPR is high in starch, cellulose, and pectin but low in hemicellulose. Cellulose, hemicellulose, and pectin can cross-link with polymers and intertwine around starch, thus forming a complex network that restricts the access of hydrolases to substrates [13]. And the addition of enzymes such as pectinase and xylanase could help cellulose hydrolysis, and there was a synergistic effect between these cellulases and pectinases[9]. Therefore, the pectinase and hemicellulase were added to expose the starch and cellulose to the enzyme molecules [9].

3.2 Effects of gelatinization on the enzymatic hydrolysis of starch in SPR

In the conventional two-step enzymatic treatment of SPR, the thermostable α-amylase is added at high temperature and gelatinization is carried out simultaneously. However, in one-step enzymatic method, cellulase, hemicellulase, and pectinase cannot tolerate high temperature. Therefore, the SPR sample was gelatinized first, followed by the enzyme addition. As shown in Fig. 1, the yield of reducing sugar after gelatinization reached 60.79% ± 0.24%, and that without gelatinization was only 30.66% ± 0.56%. These results were consistent with a previous report stating that the thermal gelatinization of starch is required to increase substrate accessibility and hydrolysis rate [43]. Therefore, gelatinization before enzyme addition is necessary.

3.3 Effect of mixed enzyme addition amount on the one-step enzymatic hydrolysis of SPR

The amount of mixed enzymes has a substantial effect on the degree of enzymatic hydrolysis of SPR. Basing on previous studies, two different enzyme amounts and ratios were set, i.e., α-amylase, glucoamylase, cellulase, hemicellulase, and pectinase in the ratio of 48 U: 300 U: 50 U: 5 U: 5 U per gram of dry SPR matter or 48 U: 300 U: 300 U: 300 U: 800 U per gram of dry SPR matter. The final reducing sugar yield and cellulose and hemicellulose degradation rates were determined under the above two conditions. With an increasing enzyme addition level, the reducing sugar yield was increased from 60.94 ± 0.61 to 62.22% ± 0.29% (Fig. 2a). In addition, the cellulose and hemicellulose degradation rates were remarkably increased from 22.17 ± 0.96 and 44.67 ± 0.02 to 45.99% ± 0.53% and 55.03% ± 0.19%, respectively (Fig. 2b and c). These results indicated that increasing the amount of enzyme is beneficial to the degradation of cellulose and hemicellulose. The adjusted ratio was chosen for subsequent experiments.

Effect of mixed enzyme ratio on the enzymatic hydrolysis of SPR, where Set A is a mixture of α-amylase, glucoamylase, cellulase, hemicellulase, and pectinase in a ratio of 48 U: 300 U: 50 U: 5 U: 5 U and Set B is the same mixture at a ratio of 48 U: 300 U: 300 U: 300 U: 800 U. (a) Reducing sugar yield after enzymatic hydrolysis. (b) Cellulose degradation rates after enzymatic hydrolysis. (c) Hemicellulose degradation rates after enzymatic hydrolysis. **Significance at P < 0.01, *significance at P < 0.05

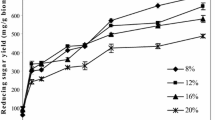

3.4 Results of single-factor experiments

3.4.1 Effects of pH on the yield of reducing sugar

The effects of pH on the yield of reducing sugar are shown in Fig. 3a. With the increase in pH from 4 to 6, the yield of reducing sugar increased first and then dropped sharply, indicating that the enzymatic hydrolysis of SPR preferred an acidic environment [16, 44]. The maximum value was observed at pH 4.5. Obviously, pH is a key parameter for the enzymatic hydrolysis of SPR.

Single-factor experiments. (a) Effect of pH on the yield of reducing sugar (P < 0.01). (b) Effect of temperatures on the yield of reducing sugar (P < 0.01). (c) Effect of mixed enzyme addition amount on the yield of reducing sugar (P < 0.01). (d) Effect of solid-to-liquid ratios on the yield of reducing sugar (P < 0.01). (e) Effect of reaction time on the yield of reducing sugar (P < 0.01)

3.4.2 Effect of temperatures on the yield of reducing sugar

As shown in Fig. 3b, temperature affected the yield of reducing sugar and showed a trend of increasing from 40 to 50 °C and then dropping from 50 to 60 °C. The optimum temperature of enzymatic hydrolysis of SPR is typically in the range of 37–90 °C in these studies [9, 13, 16, 44, 45]. The optimum temperature range of the α-amylase and glucoamylase reactions in the study was 50–70 ℃. And the optimum temperature ranges of the cellulase, hemicellulase, and pectinase reactions in the study were 40–60 ℃, 30–60 ℃, and 10–55 ℃. It is possible that the high temperature is not convenient for the action of pectinase, which, as a helper enzyme, has a significant effect on the conversion of glucan in SPRs [13]. Therefore, the optimum temperature was selected as 50 °C for the subsequent experiments.

3.4.3 Effect of the amount of mixed enzymes on the yield of reducing sugar

Figure 3c shows that with the increase in the mixed enzyme addition amount, the yield of reducing sugar increased and stabilized at the mixed enzyme addition amount of 0.3 g. Increasing the amount of enzyme within a certain range was beneficial to increasing the yield of reducing sugar, but an excessive amount of enzyme had no positive effect. Similar to pH, the mixed enzyme addition amount is also a key parameter for SPR hydrolysis and 0.32 g was chosen for the subsequent experiments.

3.4.4 Effect of solid-to-liquid ratios on the yield of reducing sugar

Figure 3d shows that the yield of reducing sugar increased significantly from the solid-to-liquid ratio of 1: 9 to 1: 7 and reached the highest value at 1: 7. The yield of reducing sugar gradually increased with the combination of the substrate containing the enzyme molecules in a certain concentration range. However, when the concentration exceeded a certain range, the high substrate content prevented the enzyme molecules to combine with the substrate or the substrate became an inhibitor; as a result, the yield of reducing sugar gradually decreased [46, 47]. The solid-to-liquid ratio 1: 7 was chosen for the subsequent experiments.

3.4.5 Effect of enzymatic hydrolysis time on the yield of reducing sugar

As shown in Fig. 3e, the yield of reducing sugar exhibited an upward trend when the enzymatic hydrolysis time was in the range of 2–6 h and then stabilized with the increasing reaction time. This finding can be attributed to the low content of polysaccharides in SPR in the subsequent enzymolysis [46]. Therefore, the effect of prolonged enzymolysis time on the yield of reducing sugar was not evident in the subsequent enzymolysis. The optimum reaction time was selected as 6 h for the next experiments.

3.5 Verification test

Under the optimum conditions of pH 4.5, solid-to-liquid ratio 1: 7, amount of mixed enzymes 0.32 g, enzymatic hydrolysis temperature 50 ℃, and time 6 h, the values of the yield of reducing sugar was 65.06% ± 1.62%, which was higher than the enzymatic hydrolysis at optimum values of one-factor experiments (62.79% ± 0.64%). Table 3 summarized effects of various enzymatic hydrolysis approach on the reducing sugar yield, cellulose degradation rate, and hemicellulose degradation rate. After one-factor experiments optimization, one-step enzymatic hydrolysis method achieved the highest reducing sugar yield (65.06) and cellulose and hemicellulose degradation rates (64.98% and 62.13%, respectively). Meanwhile, the SEM analysis of SPR before and after enzymatic hydrolysis showed that the round globular starch granules disappeared after the complex enzyme treatment and cellulose was still partially present (Fig. 4). The results showed that 51.94% of the starch in SPR was completely hydrolyzed, while the glucose content in the enzymatic hydrolysate of SPR was 58.91% (Table 4), indicating that only a small part of the cellulose was completely hydrolyzed to glucose.

3.6 Carbohydrates analysis of the enzymatic hydrolysis products of SPR after one-factor experiments optimization

Carbohydrate analysis was conducted to determine which type of sugar is present in the enzymatic hydrolysis product of SPR. As shown in Table 4, the glucose content far exceeded that of other sugars at 58.91%. Small amounts of other sugar types were also found, such as galactose and mannose. The content of hemicellulose in SPR was not high, and only some parts of the hemicellulose were degraded by one-step enzymatic method. Hence, the content of pentose, including xylose and arabinose, derived from hemicellulose was low.

3.7 Production of ethanol from enzymatic hydrolysates by CCTCC M94055 anaerobic fermentation

Carbohydrate analysis of the enzymatic hydrolysates of SPR revealed its potential use as an ethanol fermentation substrate. Hence, the industrial diploid yeast strain CCTCC M94055 was used to ferment SPR hydrolysates to directly produce ethanol without adding any nitrogen source or other nutrients. Table 5 shows that the initial glucose concentration after enzymatic hydrolysis was 113.6 g/L. All the glucose was completely utilized within 28 h, and the ethanol concentration finally reached 46.9 g/L, corresponding to the SPR to ethanol yield of 27.27%. Kinetic parameters during CCTCC M94055 anaerobic fermentation are shown in Fig. 5. The glucan conversion and glucose to ethanol conversion were 84.45% and 68.43%, respectively, both were higher than the previous report [13].

4 Conclusion

In this study, a one-step enzymatic hydrolysis approach for SPR was developed. The effects of the initial pH, temperature, amount of enzymes, solid-to-liquid ratio, and enzyme reaction time on the reducing sugar yield were systematically investigated. Single-factor experiments revealed that the optimum pH, temperature, amount of enzymes, solid-to-liquid ratio, and enzyme reaction time were 4.5, 50 °C, 0.32 g, 1: 7, and 6 h, respectively. Under these optimized conditions, the yield of reducing sugar reached 65.06% ± 1.62%. Maximum bioethanol concentration and SPR to ethanol yield of 46.9 g/L and 27.27%, respectively, were achieved by fermenting the SPR enzymatic hydrolysate. The one-step enzymatic hydrolysis method developed in this study provides a convenient way to release fermentable sugars from SPR for bioethanol production.

Data availability

All data generated or analysed during this study are included in this published article and its supplementary information files.

Code availability

This is not applicable.

References

Bušić A et al (2018) Bioethanol production from renewable raw materials and its separation and purification: a review. Food Technol Biotechnol 56(3):289–311

Saeed MA et al (2018) Concise review on ethanol production from food waste: development and sustainability. Environ Sci Pollut Res 25(29):28851–28863

Hill J et al (2006) Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc Natl Acad Sci USA 103(30):11206–11210

Banerjee S et al (2010) Commercializing lignocellulosic bioethanol: technology bottlenecks and possible remedies. Biofuels Bioproducts and Biorefining-Biofpr 4(1):77–93

Wang MY et al (2012) Cellulolytic enzyme production and enzymatic hydrolysis for second-generation bioethanol production. Biotechnol China III: Biofuels Bioenergy 128:1–24

Karmee SK (2016) Liquid biofuels from food waste: current trends, prospect and limitation. Renew Sustain Energy Rev 53:945–953

Matsakas L et al (2014) Utilization of household food waste for the production of ethanol at high dry material content. Biotechnol Biofuels 7(1):4

Littlewood J et al (2013) Techno-economic potential of bioethanol from bamboo in China. Biotechnol Biofuels 6(1):173

Xia J et al (2020) Synergism of cellulase, pectinase and xylanase on hydrolyzing differently pretreated sweet potato residues. Prep Biochem Biotechnol 50(2):181–190

Xu C et al (2016) Sweet potato residue as a substrate for microbial fermentation. Feed Industry 37(15):1–6

Yang SS, Ling MY (1989) Tetracycline production with sweet potato residue by solid state fermentation. Biotechnol Bioeng 33(8):1021–1028

Hao ZH et al (2014) Sweet potato starch residue as starting material to prepare polyacrylonitrile adsorbent via SI-SET-LRP. J Agric Food Chem 62(8):1765–1770

Wang FZ et al (2016) An environmentally friendly and productive process for bioethanol production from potato waste. Biotechnol Biofuels 9:50

Zeng X et al (2017) Research progress on fermentation utilization of sweet potato residue. South China Agric 11(34):39–41, 65

Aritonang A et al (2021) The production of citric-acid from Bilimbi (Averrhoa bilimbi) fruits through the fermentation process using Aspergillus niger. IOP Conf. Series: Earth and Environmental Science 782(3):032100

Pagana I, Morawicki R, Hager TJ (2014) Lactic acid production using waste generated from sweet potato processing. Int J Food Sci Technol 49(2):641–649

Nuanpeng S et al (2016) Ethanol production from sweet sorghum juice at high temperatures using a newly isolated thermotolerant yeast Saccharomyces cerevisiae DBKKU Y-53. Energies 9(4):253

Aziz NH, Mohsen GI (2002) Bioconversion of acid- and gamma-ray-treated sweet potato residue to microbial protein by mixed cultures. J Ind Microbiol Biotechnol 29(5):264–267

Yang L, Tan L, Liu T (2021) Progress in detoxification of inhibitors generated during lignocellulose pretreatment. Chin J Biotechnol 37(01):15–29

Ma J et al (2010) Determination of total starch content in feed by 3,5-dinitrosalicylic acid colorimetric method. China feed 14:38–40

Xiao H et al (2012) Metabolic engineering of D-xylose pathway in Clostridium beijerinckii to optimize solvent production from xylose mother liquid. Metab Eng 14(5):569–578

Sluiter JB et al (2021) Direct determination of cellulosic glucan content in starch-containing samples. Cellulose 28(4):1989–2002

An Y et al (2016) Determination of cellulose and hemicellulose content in potato stalk. Mod Agric Sci Technol 17:159–160

Ding J et al (2010) Determination of sisal pectin content by carbazole colorimetric method. Food Res Dev 31(11):138–140

Fang L et al (2020) The determination of moisture, total ash and acid-insoluble ash in fried myrrh. Anhui Chem Ind 46(01):100–102

Yuan J (2013) Optimum digestion temperature for determination of protein content by Kjeldahl method. Cereal Feed Ind 11:25–27

Luo C, Zhang C (2019) Study on hydrolysis of black soybean starch. J Shaanxi Univ Sci Technol 37(01):48–52

Idrees M et al (2013) Optimization of dilute acid pretreatment of water hyacinth biomass for enzymatic hydrolysis and ethanol production. EXCLI J 12:30–40

Ben Taher I et al (2017) Optimization of enzymatic hydrolysis and fermentation conditions for improved bioethanol production from potato peel residues. Biotechnol Prog 33(2):397–406

Li Y et al (2022) Forecasting of reducing sugar yield from corncob after ultrafine grinding pretreatment based on GM(1, N) method and evaluation of biohydrogen production potential. Bioresour Technol 348:126836

Wu Y et al (2014) Studies on technique of producing glucose from sweet potato residue by enzymes. J Agric Sci Technol 16(01):157–162

Wang S et al (2020) Optimization of cellulose hydrolysis from sweet potato residue by cellulase. Food Res Dev 41(08):179–182

Peng Z et al (2013) Optimization of conditions on dilute H2SO4 treatment to improve enzyme decomposition saccharify of lignocellulose from Chinese silvergrass treated by irradiation. J Anhui Agric Univ 41(31):2455–12457, 12461

Xie R, Li M, Long M (2020) The study on selective enzymatic hydrolysis of hemicellulose from Spartina anglica. J Jiangxi Normal Univ ( Nat Sci) 44(05):501–505

Wu X et al (2014) Analysis of the monosaccharide composition of water-soluble polysaccharides from Sargassum fusiforme by high performance liquid chromatography/electrospray ionisation mass spectrometry. Food Chem 145:976–983

Li PP et al (2021) Analysis of monosaccharide composition of water-soluble polysaccharides from Codium fragile by ultra-performance liquid chromatography-tandem mass spectrometry. J Sep Sci 44(7):1452–1460

Han J et al (2009) Analysis of monosaccharide compositions in Heterosmilax japonica polysaccharide by precolumn derivation HPLC. J Chin Med Mat 32(06):893–895

Ma XL et al (2017) Compositional monosaccharide analysis of Morus nigra Linn by HPLC and HPCE quantitative determination and comparison of polysaccharide from Morus nigra Linn by HPCE and HPLC. Curr Pharm Anal 13(5):433–437

Wang X et al (2019) Unraveling the genetic basis of fast l-arabinose consumption on top of recombinant xylose-fermenting Saccharomyces cerevisiae. Biotechnol Bioeng 116(2):283–293

Diao LY et al (2013) Construction of fast xylose-fermenting yeast based on industrial ethanol-producing diploid Saccharomyces cerevisiae by rational design and adaptive evolution. BMC Biotechnol 13:110

Succi M et al (2017) Sub-optimal pH preadaptation improves the survival of Lactobacillus plantarum strains and the malic acid consumption in wine-like medium. Front Microbiol 8:470

Meng J et al (2022) Cloning and characterization of sugar transporter genes of Kluyveromyces marxianus GX-UN120. Microbiol China 1–21

Baks T et al (2008) Effect of gelatinization and hydrolysis conditions on the selectivity of starch hydrolysis with alpha-amylase from Bacillus licheniformis. J Agric Food Chem 56(2):488–495

Zhang JH, Pakarinen A, Viikari L (2013) Synergy between cellulases and pectinases in the hydrolysis of hemp. Biores Technol 129:302–307

Wong DWS et al (2007) Synergistic action of recombinant a-amylase and glucoamylase on the hydrolysis of starch granules. Protein J 26:159–164

Wang J, Xing Y, Zhang L (2022) Optimization of enzymatic hydrolysis process and activity of Korean pine kernel polypeptide. China Oils and Fats 1–15

Frieden E, Walter C (1963) Prevalence and significance of the product inhibition of enzymes. Nature 198:834–837

Funding

This work was supported by the Doctoral Scientific Research Start–up Foundation from Henan University of Technology (No. 2018BS072), the Key scientific research projects of universities in Henan Province (No. 22A180015), and The Open competition Research Projects of Xuchang University (No. 2022JBGS06).

Author information

Authors and Affiliations

Contributions

Chenchen Gou: investigation, writing—original draft preparation, and writing—reviewing and editing. Xiao Wang: formal analysis and writing—original draft preparation. Yuxin Yu: investigation and writing—original draft preparation. Jihong Huang: project administration. Xin Wang: writing—original draft preparation, writing—reviewing and editing, and funding acquisition. Ming Hui: supervision.

Corresponding authors

Ethics declarations

Ethics approval

This paper is new, neither the entire paper nor any part of its content has been published or has been accepted elsewhere. It is not being submitted to any other journal.

Consent to participate

This is not applicable.

Consent for publication

This is not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gou, C., Wang, X., Yu, Y. et al. One-step enzymatic hydrolysis of sweet potato residue after gelatinization for bioethanol production by Saccharomyces cerevisiae. Biomass Conv. Bioref. 14, 15853–15862 (2024). https://doi.org/10.1007/s13399-023-03755-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-023-03755-3