Abstract

Food wastes are one of the great deals of ever-growing world population. Among them, chitinous wastes are precious for being used as a substrate to produce value-added commodities. In the present work, the deproteinization of shrimp waste together with the production of alkaline protease enzyme by obligate alkalophilic Bacillus marmarensis was investigated. First, we determined optimum conditions including inoculum ratio, temperature, shrimp waste concentration, and fermentation time for alkaline protease production. The highest protease activity (269.48 ± 2.19 U/mL) was obtained with 5% sole shrimp waste pretreated by heating at 100 °C for 20 min at 35 °C and pH 10.0 with inoculum ratio of 6%. Under optimized conditions, B. marmarensis showed a deproteinization capacity of 70.62% at pH 10.0 and 56.52% at pH 12.0, respectively, and the Fourier transform infrared spectroscopy spectrum of chitin obtained from deproteinization by B. marmarensis presented the characteristics of chitin compared to literature. Furthermore, the production of alkaline proteases was performed by using different carbon and nitrogen sources in comparison with the enzyme produced solely from shrimp waste. Among the carbon and nitrogen sources used, the highest activity was obtained from sucrose together with peptone from meat as 239.87 ± 28.35 U/mL, which was lower than the activity obtained from sole shrimp waste. Thus, this work indicates that obligate alkalophilic B. marmarensis can be used to develop sustainable bioprocess to produce alkaline proteases from sole shrimp waste and deproteinization of it. To our knowledge, this is the first work for the valorization of shrimp waste by obligate alkalophilic bacteria.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Environmental pollution and global warming caused by uncontrolled waste disposal can lead to the mass destruction of human life and the environment. Therefore, the development of waste management strategies, to recycle and reuse wastes generated by different sources and industries, is very crucial for sustainability and circular economy [1].

Among different industries, the food sector generates a huge amount of waste, which leads to 8–10% of global greenhouse gas emissions. Crustaceans are important animals in the sea food industry with high protein content. Shrimp, the best-known crustacean, is extensively consumed in all countries. Annual shrimp sale is boosted due to the flavor and nutraceutical benefits of shrimp and its products. Overall, the shrimp industry had a capacity of 5.03 million tonnes in 2020 and is expected to reach 7.28 million tonnes by 2025 with a 6.1% CAGR (compound annual growth rate) between 2020 and 2025 [2]. Approximately 60% of shrimp weight is considered waste and a tremendous amount of this waste is discarded into the environment [2,3,4,5,6]. These wastes can cause a negative impact such as foul odor and infectious diseases. However, valorization and reuse of waste sourced from the seafood industry to produce value-added biological materials such as proteins, collagen, and chitin are not very common [7,8,9]. The valorization of shrimp waste supports the construction of a circular economy as well as distinguishable environmental benefits by clean and economical bioprocesses [9, 10]. The shrimp wastes include calcium carbonate (20–50%), protein (20–40%), and chitin (15–40%) with lower amounts of carotenoids and lipids [11], a biocompatible and biodegradable polymer that can be extracted from shrimp wastes. Chitin, with antimicrobial, antitumor, and antioxidant activities, has diverse applications in many areas, like wastewater treatment, agriculture, cosmetics, paper, textile industry, chromatography, and biomedicine [9, 10, 12, 13].

Although the extraction of chitin can be achieved from natural sources by strong acids and bases, these extraction processes are not cost-effective and are harmful to the environment [14, 15]. Therefore, eco-friendly alternative methods such as microbial processes have been used to deproteinize shrimp waste and to extract chitin from shrimp waste while producing proteases [8, 16]. Moreover, deproteinization of shrimp wastes is a safer way to protect the structural conformation of chitin, and microbial processes prevent depolymerization and deacetylation of chitin when compared to conventional chemical extraction methods [8, 15]. Hence, microbially extracted chitin is more favorable. For instance, chitin from shrimp shells was used to produce highly immunogenic nasal spray for hay fever [11].

Deproteinization of shrimp waste has been achieved by different microorganisms like Pseudomonas aeruginosa K-187, Pseudomonas maltophilia LC-102, Candida parapsilosis, and Bacillus subtilis. In addition, lactic acid bacteria were also used in the demineralization process; and shrimp wastes were evaluated as a carbon source of lactic acid fermentation [17]. Since the deproteinization of shrimp waste is achieved by protease enzyme produced from microorganisms, shrimp waste can also be evaluated as a raw material for a cost-effective enzyme, specifically protease production [14, 18]. Particularly, the majority of the microbial alkaline proteases are produced by Bacillus species which can be active at pH 9.0–11.0 [7, 16, 19,20,21]. Alkaline proteases are the most studied enzymes for their utilization in diverse industries such as pharmacy, food, leather, photography, and detergents to replace noxious and unhealthy chemicals, and according to Protease Market Report, the global market size of proteases was worth 3.454 billion USD in 2020 and it is estimated to reach 5.762 billion USD in 2030 with 5.4% annual growth rate between 2021 and 2030 [22]. Microbial proteases are the dominant enzymes that surpass animal-, plant-, or fungi-derived equivalents and they almost reach half of the total enzyme market. Moreover, these microbial proteases have advantages over other sources due to their high yield, low-cost production, and easy genetic manipulation chance of microorganisms, which produce proteases.

Recently, obligate alkaliphilic B. marmarensis has been reported as alkaline protease producer. B. marmarensis can live between pH 8.0–12.5 and 15–45 °C and it has an ability to degrade Tween 80 [23]. B. marmarensis GMBE 72 T protease resembles to chymotrypsin enzyme and has a molecular weight of 26.4 kDa. The optimum pH and temperature of the alkaline protease synthesized by strain GMBE 72 T were reported as 11.0 and 60 °C, respectively [24]. It is known that the alkaline protease–producing microorganisms can utilize the shrimp waste as carbon and nitrogen sources, and alkaline proteases can deproteinize shrimp to extract chitin [25]. Therefore, the main objective of this present work was to investigate the suitability of obligate alkaliphilic B. marmarensis to valorize shrimp wastes for the simultaneous production of alkaline protease and the deproteinization of this waste. Since a more sustainable way to the valorization of waste using microbial fermentation processes is not only a valuable approach but also crucial for designing biorefinery concepts, based on our knowledge, obligate alkaliphilic B. marmarensis is being used for the first time to valorize shrimp waste using an eco-friendly approach.

2 Materials and methods

2.1 Microorganism, biological material, and chemicals

An extreme alkaliphilic bacterium, B. marmarensis strain DSM 21,297, isolated from mushroom compost, was obtained from DSMZ (Braunschweig, Germany). All chemicals used in the experiments were purchased from Sigma-Aldrich and Merck, unless otherwise noted. Shrimp waste (Shr-waste) was kindly obtained from a local fish market and restaurants in Istanbul, Turkey.

2.2 Pretreatment methods of Shr-waste

To develop an efficient valorization process, heating steps and sterilization can be applied for the inactivation of the endogenous enzymes and to remove bad odor and microbial contaminants, respectively [26,27,28]. Therefore, in the present work, Shr-waste containing mostly shrimp shell and a small number of head collected from a local restaurant was transferred to the laboratory, and subsequent washing with tap water and pretreatment were applied. For pretreatment, shrimp waste was heated at 100 °C for 30 min (Shr1) and 20 min (Shr2) to inactivate endogenous enzymes. Additionally, to eliminate the negative effect of possible contaminating microorganisms present in the Shr-waste, samples were also autoclaved for 15 min at 121 °C (Shr3). After each treatment step, all samples were dried and grinded, and each sample belonging to each pretreatment step was mixed separately to ensure the usage of the sample having the same composition. Then, the valorization of Shr-waste by obligate alkaliphilic B. marmarensis was evaluated using pretreated waste as a raw material to produce an alkaline protease enzyme.

2.3 Valorization of Shr-waste by B. marmarensis and comparison with different carbon and nitrogen sources

Alkaline nutrient broth (5 g L−1 peptone and 3 g L−1 meat extract) supplemented with (w/v) MgSO4 (0.040%), KH2PO4 (0.042%), and NaCl (4%) at pH 9.8 was used to preserve strain DSM 21,297 and to prepare the preculture medium [29]. Fifty milliliters of alkaline nutrient broth in 250-mL Erlenmeyer flask was inoculated with 2% (v/v) of glycerol stock of strain DSM 21,297 and incubated for 16 h in an orbital shaker at 30 °C and 180 rpm for preculture preparation.

To investigate the valorization of Shr-waste, nitrogen sources like peptone and meat extract in basal medium (w/v; peptone 0.5%, meat extract 0.3%, MgSO4 0.040%, KH2PO4 0.042%, and NaCl 4%) were removed, and Shr-waste was added at an equal concentration of the total amount of organic nitrogen sources (0.8%). The pH of the medium was adjusted to 9.8 by 12% (v/v) Na-sesquicarbonate solution, and a 50 mL medium in 250-mL Erlenmeyer flask was autoclaved for 15 min at 121 °C. Then, the cultivation medium was inoculated by preculture at a ratio of 1% (v/v). The cultivation was carried out for 24 and 48 h at 30 °C and 180 rpm.

Primarily, the effect of pretreatment methods was evaluated by using pretreated Shr-wastes as Shr1, Shr2, and Shr3. Since the alkaline protease activity (U/mL) was higher in Shr1 and Shr2 compared to Shr3, the effect of the concentration of Shr1 and Shr2 on alkaline protease synthesis was further investigated at concentrations ranging from 0.5 to 5%. The effects of temperature in the range of 30–45 °C, pH between 9.0 and 12.0, and inoculation ratio of 1%, and 10% were also analyzed.

To analyze the feasibility of Shr-waste, the production of alkaline protease was also investigated by supplementing the basal medium with different carbon sources (glucose, sucrose, maltose, and molasses) at the concentration of 1% (w/v) and replacing peptone and meat extract with sole nitrogen sources (yeast extract, beef extract, malt extract, peptone from meat, skim milk powder, and whey) at a concentration of 0.8% (w/v). All culture media were prepared with 50 mL working volume in 250-mL Erlenmeyer flasks and the pH of the media was adjusted to 9.8 with 12% (v/v) filter-sterilized Na-sesquicarbonate solution. After inoculation with 1% preculture, the cultivation was carried out for up to 48 h at 30 °C and 180 rpm. Samples were taken for 24-h intervals to determine the protease activity. All experiments were performed in triplicate.

2.4 Deproteinization capability of B. marmarensis to obtain chitin

After the optimization of process parameters (pH, temperature, inoculation ratio, and Shr-waste concentration), deproteinization of Shr-waste was investigated to obtain chitin. For this purpose, 1L production medium containing (w/v) Shr2 (5%), MgSO4 (0.040%), KH2PO4 (0.042%), and NaCl (4%) in 5-L Erlenmeyer flasks was used. The production was carried out at an initial pH of 10.0 and 12.0, and 6% (v/v) inoculation was used as the optimal inoculum ratio. Fermentation of Shr2 was carried out at 35 °C and 180 rpm. After 48 h of incubation, the fermentation broth was centrifuged and the solid part including bacteria and deproteinated Shr2 was used to analyze the presence of chitin in the sample, while the deproteinization of Shr-waste was determined by measuring protease activity and protein concentration of supernatant.

Deproteinization percentage was calculated by using the following equation [30, 31].

where PO and PR were the protein contents before and after the fermentation process while O and R were the masses of shrimp waste (g) before and after deproteinization, respectively. The total nitrogen content was performed by commercial customer services of the commercial company by Kjeldahl method and protein content (%) was calculated by multiplying 6.25 [32].

For chitin analysis, the solid sample was treated with 70% ethanol solution at a 2:1 ratio for 30 min using a modified method and then washed with distilled water to remove impurities [33]. After that, the sample was dried at 60 °C for 24 h and the functional groups were analyzed by Fourier transform infrared (FTIR) spectroscopy. FTIR analysis was performed by commercial customer services of the Center for Nanotechnology and Biomaterials Applications and Research at Marmara University. FTIR analysis of the sample was carried out using a JASCO FT/IR-4700 (Japan) spectrophotometer in the range of 400–4000 cm−1 with sixteen scans per measurement.

2.5 Determination of alkaline protease activity and protein concentration

Alkaline protease activity was determined by using the modified method described by Bose et al. [34]. The reaction mixture contained 0.5 mL enzyme and 2.5 mL 0.6% (w/v) casein prepared in NaOH-glycine buffer (50 mM, pH 10.5) as a substrate was mixed and the mixture was incubated at 30 °C for 20 min. The blank solution containing 0.5 mL NaOH-glycine buffer (50 mM, pH 10.5) and 2.5 mL 0.6% casein was also kept at the same conditions. At the end of 20 min, the reaction was terminated by the addition of 2 mL of trichloroacetic acid (TCA) solution (consisting of 0.11 M TCA, 0.22 M CH3COONa.3H2O, and 0.33 M CH3COOH) and unreacted proteins were removed by centrifugation at 13,000 rpm (13517 g) for 15 min by using a pre-cooled centrifuge (CAPP CR1512, Wolflabs). After that, the tyrosine concentration was determined by measuring OD at 280 nm using a tyrosine standard curve. One unit of alkaline protease activity was defined as the amount of enzyme required to liberate 1 µg of tyrosine per minute at pH 10.5 and temperature at 30 °C. The protein concentration of all samples was determined by the Bradford method using bovine serum albumin as the standard solution [35].

3 Results and discussion

3.1 Valorization of shrimp waste by B. marmarensis

The valorization of Shr-waste by B. marmarensis was investigated by evaluating the alkaline protease produced from Shr-waste. Therefore, firstly, the effect of the pretreatment step on valorization was analyzed. Considering the alkaline protease activity presented in Fig. 1, prolonged cultivation of B. marmarensis with Shr1, Shr2, and Shr3 caused an increase as 1.6 times of activity, and the highest protease activity as 87.41 ± 0.73 U/ml was obtained after 48 h of cultivation with 30-min heating (Shr1). Reducing the heating period from 30 min (Shr1) to 20 min (Shr2) caused to reduce the activity slightly from 87.41 ± 0.73 to 79.01 ± 5.3 U/mL. Regarding the sterilization of the shrimp waste (Shr3), the lowest enzyme activities as 46.71 ± 0.07 and 69.05 ± 1.46 U/mL were observed for 24 and 48 h of B. marmarensis cultivation. This reduction due to pretreatment for 15 min at 121 °C (Shr3) can be explained by the negative effect of excess heat on the protein content of Shr-waste, namely, by the denaturation of the protein content of the shell material due to the excess heat. Since sterilization was also applied before enzyme production from Shr3, shrimp waste was exposed to 121 °C twice compared to Shr1 and Shr2. Although the whole protein of Shr3 could not be completely denatured at 121 °C because of a tight matrix of chitin, protein, and calcium in the shrimp shell [26], protein content could be reduced compared to Shr1 and Shr2. Therefore, alkaline protease produced from Shr3 was lower compared to Shr1 and Shr2. As a result, Shr-waste obtained after heating at 100 °C for 30 (Shr1) and 20 min (Shr2) was used to evaluate the valorization of Shr-waste by B. marmarensis.

Different Shr1 and Shr2 concentrations (0.5%, 1%, 2%, 3%, and 5%) were added to the basal medium (w/v: 0.040% MgSO4, and 0.042% KH2PO4) to determine the optimal concentration of waste to yield the highest alkaline protease. The effect of the concentration of Shr1 and Shr2 on valorization can be seen in Fig. 2. Generally, increasing waste concentration for both Shr1 and Shr2 caused an increase in protease activity. Compared to Shr2, Shr1 yielded higher protease activity up to 2% concentrations. However, above 2% concentrations, the protease activity obtained from Shr2 was higher than Shr1 and the maximum protease activity as 226.55 ± 8.78 U/mL was obtained with 5% Shr2 after 48 h of cultivation. There are many studies related to the application of shrimp waste as a cheap substrate to yield proteases from different microorganisms like Aspergillus niger, Paenibacillus elgii, Paenibacillus sp. TKU042, and Bacillus cereus HMRSC30 [16, 18, 36, 37]. Doan et al. [18] used demineralized crab shell, demineralized shrimp shell, shrimp head, shrimp shell, and squid pen as waste materials, and the highest activity was reported as 2.98 U/mL from 0.5% of shrimp head powder. Although the highest protease activity from Paenibacillus sp. TKU042 was obtained at lower shrimp waste concentrations compared to our results, protease activity produced from Shr-waste by B. marmarensis was very high compared to Paenibacillus sp. TKU042. Similarly, protease activity obtained from Paenibacillus elgii [16] from cooked and fresh shrimp waste as 60 and 70 U/mL was lower than that obtained in this work.

Additionally, Liu et al. [31] studied the production of protease from shrimp shell by two steps fermentation. They used Lactobacillus rhamnoides for demineralization and Bacillus amyloliquefaciens for the deproteinization and reported 701.3 U/mL protease activity after the demineralization and the deproteinization steps. Although this value is higher than our results, considering the one-step protease production, B. marmarensis showed promising results for the valorization of Shr-wastes. Due to the highest protease activity, 5% Shr2 was chosen as the best waste concentration for protease production.

Since the inoculation ratio, initial pH, and temperature are substantial parameters for bioprocess development, the effect of these parameters on the valorization of Shr2 by B. marmarensis was evaluated. To figure out the best inoculation ratio for higher production, the inoculation ratios between 1.0 and 10.0% (v/v) were investigated at 30 °C and pH 9.8. Remarkably, the inoculation ratio of 6.0% (v/v) led to the highest alkaline protease activity (269.48 ± 2.19 U/mL) and protein concentration (0.44 mg/mL) from shrimp wastes (Fig. 3(a)). While increasing the inoculation ratio slightly increased protease activity, it caused a decrease in total protein concentration. Similar to our results, Liu et al. [31] stated that 6.0% (v/v) was the best inoculation ratio for deproteinization of shrimp waste. Additionally, the results reported by Avcı et al. [38] are in agreement with our results showing that increasing inoculation ratio from 5.0% (v/v) to 10 and 15% induced a change in the negative direction in Bacillus subtilis ZBP4 alkaline protease activity. However, different inoculation levels for different Bacillus strains such as 2.0% for Bacillus mojavensis strain were informed since the optimum inoculation ratio is strongly related to the choice of microorganism and substrate.

To investigate the effect of initial pH on the valorization of Shr-waste by B. marmarensis, pH values above 9.0 were studied since B. marmarensis is an obligate alkaliphilic strain and it has an ability to grow at pH between 8.0 and 12.5 [23]. As seen in Fig. 3(b), protein concentration was increased with increasing pH values, while maximum protease activity was observed at pH 10.0. Increasing pH from 10.0 to 11.0, and 12.0 caused to a decrease in protease activity while protein concentration was increased. The increase in protein concentration at higher pH values can be explained by the deproteinization effect of B. marmarensis protease at higher pH values [16], since B. marmarensis protease is active at wide range of pH values [24]. Many studies demonstrated that the alkaline conditions between pH 9.0 and 11.0 are favorable choices for alkaline proteases of Bacillus species [39]. For instance, Jadhav et al. [40] showed that pH 11.0 led to superior enzyme production (87.99 U/mL) via Bacillus cereus HP_RZ17 while the strain Paenibacillus xylanilyticus HP_RZ19 had greater protease yield (73.23 U/mL) at pH 10.0.

Since the incubation temperature is a highly influential factor due to the induction of metabolic activities, the valorization of Shr-waste was investigated at a temperature between 35 and 45 °C. As seen Fig. 3(c), alkaline protease activity increased when the temperature increased from 30 to 35 °C and decreased beyond; conversely, protein concentration decreased with the increasing temperature from 30 to 35 °C and increased beyond.

For alkaline protease production from Shr-waste by Bacillus marmarensis, the incubation temperature of 35 °C is the best choice and above 35 °C, protease activity relative to activity at 35 °C was 69% at 40 °C and 43% at 45 °C. This is in agreement with the thermal stability of protease above 40 °C, since B. marmarensis protease lost its activity at a temperature above 35 °C [24]. Opposite to the protease activity, protein concentration was slightly reduced from 0.24 to 0.20 mg/mL by increasing temperature from 30 to 35 °C and then, it increased with raising temperature from 35 to 45 °C and reached to 0.31 mg/mL at 45 °C. The increase in protein concentration with increasing temperature could be explained with the specificity of alkaline protease against proteins at elevated temperatures, since increasing temperature caused to increase protein hydrolysis by B. marmarensis protease, and its optimum temperature was reported as 60 °C [24]. Similar to our results, Ooi et al. [37] stated that 35 °C is the best choice for protease production from shrimp waste. Additionally, the best temperature for deproteinization of shrimp shell by Bacillus amyloliquefaciens was reported as 37 °C which is very close to our results.

To evaluate the efficacy of sole Shr2 as carbon and nitrogen sources, we analyzed the production of alkaline protease by using different carbon and nitrogen sources (Table 1). Among diverse carbon sources, sole carbohydrates like glucose, sucrose, and maltose, and agricultural by-products (wheat bran, corn bran, corn starch, rice bran, wheat flour, orange peels, and soybean) and sugar industry by-product as molasses are greatly utilized to produce alkaline proteases [41]. Moreover, the nitrogen source is an important factor for the growth of microorganisms and the induction of protease production, and organic nitrogen sources are more effective on the induction of protease production, while inorganic sources lead to the suppression of enzyme synthesis in Bacillus sp. due to the quick discharge of ammonia [41, 42]. In the light of these information, glucose, sucrose, maltose, and molasses as carbon sources, and yeast extract, beef extract, peptone from meat, skim milk powder, and whey as nitrogen sources were tested for alkaline protease production from B. marmarensis and compared with sole Shr2. As seen in Table 1, molasses induced the lowest alkaline protease activity (97.05 U/mL) when it was compared with glucose, maltose, and sucrose. The highest protease activity as 239.87 ± 28.35 U/mL, which is almost 2.5 times higher than the activity obtained from molasses, was obtained with sucrose together with peptone from meat. The other highest value as 179.48 ± 9.51 U/mL was obtained when glucose and yeast extract were used as the carbon and nitrogen sources, respectively. In the literature, it was shown that different Bacillus species enhanced protease activities by using glucose as the carbon source [41]. In agreement with these results, previous reports stated that peptone from meat and yeast extract are efficient complex organic nitrogen sources for protease production and 1% (w/w) supplementation of these nitrogen sources can increase activities up to 587.2 U/mL [43]. These complex nitrogen sources contribute to alkaline protease production by serving all required amino acids for enzyme synthesis. Higher yields of alkaline protease were observed with Bacillus sp. SB12 and B. subtilis FBL-1 when yeast extract and peptone were used as main nitrogen sources [40]. In addition, it was reported that high mineral composition of yeast extract (especially potassium and phosphorus) is essential for microbial physiology and growth [44].

Overall, our results demonstrated that sucrose was the best carbon source (239.87 ± 28.35 U/mL as protease activity) followed by glucose, maltose, and molasses. Peptone from meat is the most effective nitrogen source with activity reaching almost 300 U/mL. The lowest values of enzymatic activity (11.77 ± 3.48U/ml and 15.19 ± 1.37 U/mL) were acquired with skim milk-glucose and whey-sucrose combinations, respectively. Avcı et al. [38] also stated whey as the least effective nitrogen source with an activity of 206 ± 17.7 U/mL. Especially, the coupling of various carbon and nitrogen sources is an important step for the induction or suppression of protease production by different microorganisms [45]. Therefore, enzyme activities with different combinations of carbon and nitrogen sources are expected to be different. In general, our results showed that skim milk powder and whey did not enhance protease activity compared to peptone from meat and yeast extract (Table 1), because of the high protein content of yeast extract (around 65%) and beef extract (around 41%) compared to skim milk powder (35.5%) and whey (0.8%).

Comparing the highest enzyme production (239.87 ± 28.35 U/mL) obtained by 1.0% sucrose and 0.08% peptone from meat with protease from 5% Shr2 at optimized conditions (269.48 ± 2.19 U/mL), Shr-waste could be a suitable source for protease production. Furthermore, deproteinized Shr-waste can be used as a source of the chitin biopolymer. At this point, a cleaner production route for alkaline proteases and chitin can be achieved with lower prices and energy input.

3.2 Alkaline protease production and deproteinization potential of B. marmarensis

Chitin is an abundant natural polysaccharide found in different crustaceans. The first step for chitin production from crab and shrimp wastes is the deproteinization. Although chemical treatment is widely used for deproteinization processes, proteolytic microorganisms or their enzymes are preferred to develop cost-effective and environmentally friendly processes [28]. For that reason, we deproteinized Shr2 at 5.0% concentrations by B. marmarensis with a 6.0% inoculation ratio at 35 °C and at pH 10.0 and 12.0, since the highest activity and highest protein content were obtained at pH 10.0 and 12.0, respectively. After the deproteinization step, the fermentation broth was analyzed for alkaline protease activity, and the solid residues were analyzed by FTIR to determine the functional groups related to chitin, and protein percentage based on total nitrogen content.

The results showed that pH 10.0 is the better option to enhance alkaline protease activity and deproteinization capacity. The highest protease activity as 321.98 U/mL and deproteinization capacity as 70.62% was obtained at pH 10.0 after 48 h of incubation. At pH 12.0, protease activity and deproteinization percentage determined were 244.91 U/mL and 56.52%, respectively. Similar to our previous results, increasing pH from 10.0 to 12.0 decreased activity from 321.98 to 244.91 U/mL, while protein concentration increased from 0.159 to 0.831 mg/mL. However, deproteinization capacity at pH 10.0 was higher than at pH 12.0, based on total nitrogen content of solid samples.

Comparing our data with the literature, deproteinization at pH 10.0 without demineralization yielded promising results. The deproteinization capacity of B. marmarensis obtained at pH 10.0 was lower than that obtained by Paenibacillus elgii which is over 94% [16], and by Bacillus amyloliquefaciens that is 96.8% [31]. For alkaline protease activity, although protease activity obtained by B. marmarensis was lower than that reported by Bacillus amyloliquefaciens as 701.3 U/mL [31], our data was higher than that obtained from fresh shrimp waste by Paenibacillus elgii as 70 U/mL [16].

Besides microorganisms, crude and commercial proteases were also tested for deproteinization of shrimp waste. Alcalase, pepsin, and crude protease were used to remove proteins, and the deproteinization yields of 93.41%, 92%, and 88.8% were obtained by using shrimp, white shrimp shell, and shrimp shell, respectively [46]. Cui et al. [32] reported the deproteinization of chitin together with heating by microwave for 10 min at 60 °C, and a deproteinization yield of 92% was reported with 4000 U enzyme/g substrate. Although the highest deproteinization yield obtained by B. marmarensis (70.62%) was lower than that reported by Mathew et al. [46] and Cui et al. [32], B. marmarensis showed promising results for the deproteinization of shrimp waste at pH 10.0 since the usage of proteolytic microorganisms for the deproteinization of shrimp waste is less expensive compared to crude or commercial enzymes [46].

Additionally, Maruthiah and Palavesam [47] reported different data related to shrimp waste utilization for protease production by different Bacillus species as B. halodurans CAS 6 (2% Shr-waste, 473.3 U), B. firmus CAS 7 (1% Shr-waste, 2289 U), B. alveayuensis CAS 5 (1% Shr-waste, 2872 U), Bacillus sp. APCMST-RS7 (4% Shr-waste, 140 U), B. pumilus A1 (5% Shr-waste, 1267 U), and B. cereus SV1 (5% Shr-waste, 1152 U), B. marmarensis could be used effectively for the valorization of Shr-wastes at both pH 10.0 and 12.0. Additional research showed that Bacillus luteus H11 produced alkaline protease (120 U/mL) with 2.5% (w/v) shrimp waste as the main substrate [48] and Bacillus cereus SV1 had maximal protease production (5.900 U/mL) when 4.0% shrimp waste used as a carbon source [49]. These results imply that B. marmarensis may hold great potential in the valorization of shrimp waste for alkaline protease production and deproteinization.

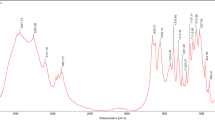

3.3 FTIR analysis of crude chitin obtained after fermentation of Shr-waste by B. marmarensis

The impurities were removed from the solid sample obtained after Shr2 fermentation and then subjected to FTIR analysis to determine the quality of crude chitin prepared without any demineralization and decolorization, and spectrum of crude chitin compared with the literature data [16, 31]. In the present work, the decolorization and demineralization steps were excluded in order to develop eco-friendly process and to investigate the effect of the alkaline character of B. marmarensis on chitin purity.

When the FTIR spectrum of the deproteinized Shr2 at pH 10.0 and 12.0 (Fig. 4 and Table 2) was evaluated, the intensities of all peaks related to pH 12.0—specifically the peaks of sample at 3261.04, 1309.42, and 1376.93 cm−1 were lower than that obtained at pH 10.0 (specifically at 3261.03, 1309,43, 1376.93 cm−1). This may also be an indication of the higher deproteinization efficiency at pH 10.0.

As shown in Fig. 4 and Table 2, the deproteinized Shr2 at pH 10.0 and 12.0 could be an alpha chitin based on the NH stretching vibration at 3261.03 and 3261.04 cm−1, respectively [16]. Symmetric stretching vibrations of CH and CH3 and the asymmetric stretching vibration of CH2 at 2890.77 to 2962.13 cm−1, and the wagging of CH (Amide III) at 1309.43 cm−1 indicated that the deproteinized sample at pH 10.0 and 12.0 included alpha chitin [16]. The peaks of sample at 1619.91 (pH 10.0) and 1621.8 cm−1 (pH 12.0) is a representation of amide I region and a specific peak at 1376.93 cm−1 of two samples is related with C-H stretching of chitin [31]. Additionally, the peak at 1554.34 for both samples obtained at pH 10.0 and 12.0 corresponded to amide II region. Importantly, there was no signal at 1540 cm−1 which is specific to proteins, so we can ensure about the effectiveness of deproteinization of shrimp waste at pH 10.0 and 12.0 [25, 29]. Furthermore, chitin characteristic peaks between 952.66 and 1203.36 cm−1 (C–O–C and C-O) were also observed in the deproteinized Shr2 at pH 10.0 and 12.0.

4 Conclusion

Globally, a huge amount of shrimp waste (head, tail, and shells) is produced every year and these wastes are precious sources as a substrate for the production of value-added commodities. Thus, in the present work, the production of the alkaline protease from B. marmarensis on sole Shr-waste and deproteinization capacity were investigated. The results demonstrated that shrimp waste is a more advantageous source when compared with costly carbon and nitrogen sources, and B. marmarensis has an ability to utilize sole shrimp waste for alkaline protease production. Furthermore, one-step deproteinization by B. marmarensis is found to be promising economically, and the chitin can be prepared by deproteinization of shrimp waste using B. marmarensis. Moreover, its FTIR spectrum showed similar patterns to that reported in the literature. The valorization of shrimp waste with microbial fermentation processes is a beneficial approach to constructing a sustainable biorefinery, and B. marmarensis could be an excellent candidate for the development of biorefinery to valorize shrimp waste for both alkaline protease and chitin production. By the application of a cleaner production route through the valorization of shrimp wastes, the environmental impact of chemical processes could be diminished.

Data availability

The authors confirm that the data and materials that support the findings of this study are available within the manuscript.

Code availability

Not applicable.

References

Awasthi A, Cheela VRS, D’Adamo I, Iacovidou E, Islam MR, Johnson M, Li J (2021) Zero waste approach towards a sustainable waste management. Resour Environ Sustainability 3:100014. https://doi.org/10.1016/j.resenv.2021.100014

Nirmal NP, Santivarangkna C, Rajput MS, Benjakul S (2020) Trends in shrimp processing waste utilization: an industrial prospective. Trends Food Sci Technol 103:20–35. https://doi.org/10.1016/j.tifs.2020.07.001

Aneesh PA, Anandan R, Kumar LR, Ajeeshkumar KK, Kumar KA, Mathew S (2020) A step to shell biorefinery—extraction of astaxanthin-rich oil, protein, chitin, and chitosan from shrimp processing waste. Biomass Convers Biorefin 1-10. https://doi.org/10.1007/s13399-020-01074-5

Cabanillas-Bojórquez LA, Gutiérrez-Grijalva EP, González-Aguilar GA, López-Martinez LX, Castillo-López RI, Bastidas-Bastidas PDJ, Heredia JB (2021) Valorization of fermented shrimp waste with supercritical CO2 conditions: extraction of astaxanthin and effect of simulated gastrointestinal digestion on its antioxidant capacity. Molecules 26:4465. https://doi.org/10.3390/molecules26154465

Santos VP, Marques NS, Maia PC, Lima MABD, Franco LDO, Campos-Takaki GMD (2020) Seafood waste as attractive source of chitin and chitosan production and their applications. Int J Mol Sci 21:4290. https://doi.org/10.3390/ijms21124290

Zhou Y, Guo N, Wang Z, Zhao T, Sun J, Mao X (2021) Evaluation of a clean fermentation-organic acid method for processing shrimp waste from six major cultivated shrimp species in China. J Clean Prod 294:126135. https://doi.org/10.1016/j.jclepro.2021.126135

Kumar PA, Suresh PV (2014) Biodegradation of shrimp biowaste by marine Exiguobacterium sp. CFR26M and concomitant production of extracellular protease and antioxidant materials: production and process optimization by response surface methodology. Mar Biotechnol 16:202–218. https://doi.org/10.1007/s10126-013-9531-2

Lopes C, Antelo LT, Franco-Uría A, Alonso AA, Pérez-Martín R (2018) Chitin production from crustacean biomass: sustainability assessment of chemical and enzymatic processes. J Clean Prod 172:4140–4151. https://doi.org/10.1016/j.jclepro.2017.01.082

Mao X, Guo N, Sun J, Xue C (2017) Comprehensive utilization of shrimp waste based on biotechnological methods: a review. J Clean Prod 143:814–823. https://doi.org/10.1016/j.jclepro.2016.12.042

Mathew GM, Sukumaran RK, Sindhu R, Binod P, Pandey A (2021) Green remediation of the potential hazardous shellfish wastes generated from the processing industries and their bioprospecting. Environ Technol Innov 24:101979. https://doi.org/10.1016/j.eti.2021.101979

Mathew GM, Mathew DC, Sukumaran RK, Sindhu R, Huang CC, Binod P, Sirohi R, Kim SH, Pandey A (2020) Sustainable and eco-friendly strategies for shrimp shell valorization. Environ Pollut 267:115656. https://doi.org/10.1016/j.envpol.2020.115656

Rahimi M, Mir SM, Baghban R, Charmi G, Plummer CM, Shafiei-Irannejad V, Soleymani J, Pietrasik J (2022) Chitosan-based biomaterials for the treatment of bone disorders. Int J Biol Macromol 215:346–367. https://doi.org/10.1016/j.ijbiomac.2022.05.006

Zewude DA, Noguchi T, Sato K, Izawa H (2022) Production of chitin nanoparticles by bottom-up approach from alkaline chitin solution. Int J Biol Macromol 210:123–127. https://doi.org/10.1016/j.ijbiomac.2022.06.079

Yadav M, Goswami P, Paritosh K, Kumar M, Pareek N, Vivekanand V (2019) Seafood waste: a source for preparation of commercially employable chitin/chitosan materials. Bioresour Bioprocess 6:1–20. https://doi.org/10.1186/s40643-019-0243-y

Younes I, Rinaudo M (2015) Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar Drugs 13:1133–1174. https://doi.org/10.3390/md13031133

Lee DH, Doan CT, Tran TN, Nguyen VB, Nguyen AD, Wang CL, Wang SL (2021) Proteases production and chitin preparation from the liquid fermentation of chitinous fishery by-products by Paenibacillus elgii. Mar Drugs 19:477. https://doi.org/10.3390/md19090477

Sorokulova L, Krumnow A, Globa L, Vodyanoy V (2009) Efficient decomposition of shrimp shell waste using Bacillus cereus and Exiguobacterium acetylicum. J Ind Microbiol 36:1123–1126. https://doi.org/10.1007/s10295-009-0587-y

Doan CT, Tran TN, Wen IH, Nguyen VB, Nguyen AD, Wang SL (2019) Conversion of shrimp head waste for production of a thermotolerant, detergent-stable alkaline protease by Paenibacillus sp. Catalysts 9:798. https://doi.org/10.3390/catal9100798

Liang TW, Hsieh JL, Wang SL (2012) Production and purification of a protease, a chitosanase, and chitin oligosaccharides by Bacillus cereus TKU022 fermentation. Carbohydr Res 362:38–46. https://doi.org/10.1016/j.carres.2012.08.004

Razzaq A, Shamsi S, Ali A, Ali Q, Sajjad M, Malik A, Ashraf M (2019) Microbial proteases applications. Front Bioeng. Biotechnol 7:110. https://doi.org/10.3389/fbioe.2019.00110

Singh S, Bajaj BK (2017) Potential application spectrum of microbial proteases for clean and green industrial production. Energy Ecol Environ 2:370–386. https://doi.org/10.1007/s40974-017-0076-5

Protease Market (2022) Protease market by source and application: global opportunity analysis and industry forecast, 2021–2030. https://www.alliedmarketresearch.com/protease-market-A12830. Accessed 12 August 2022

Denizci AA, Kazan D, Erarslan A (2010) Bacillus marmarensis sp. Nov., an alkaliphilic, protease-producing bacterium isolated from mushroom compost. Int J Syst Evol 60:1590–1594. https://doi.org/10.1099/ijs.0.012369-0

Öner MNK (2009) Purification and characterization of an alkaline protease which isolated from an obligate alkaliphilic Bacillus marmarensis GMBE 72. Ph.D. thesis, Kocaeli University

Haddar A, Hmidet N, Ghorbel-Bellaaj O, Fakhfakh-Zouari N, Sellami-Kamoun A, Nasri M (2011) Alkaline proteases produced by Bacillus licheniformis RP1 grown on shrimp wastes: application in chitin extraction, chicken feather-degradation and as a dehairing agent. Biotechnol Bioprocess Eng 16:669–678. https://doi.org/10.1007/s12257-010-0410-7

Aye KN, Stevens WF (2004) Improved chitin production by pretreatment of shrimp shells. J Chem Technol Biotechnol 79:421–425. https://doi.org/10.1002/jctb.990

Mechri S, Sellem I, Bouacem K, Jabeur F, Laribi-Habchi H, Mellouli L, Hacène H, Bouanane-Darenfed A, Jaouadi B (2020) A biological clean processing approach for the valorization of speckled shrimp Metapenaeus monoceros by-product as a source of bioactive compounds. Environ Sci Pollut Res 27:15842–15855. https://doi.org/10.1007/s11356-020-08076-w

Younes I, Hajji S, Frachet V, Rinaudo M, Jellouli K, Nasri M (2014) Chitin extraction from shrimp shell using enzymatic treatment. Antitumor, antioxidant and antimicrobial activities of chitosan. Int J Biol Macromol 69:489–498. https://doi.org/10.1016/j.ijbiomac.2014.06.013

Özgören T, Pinar O, Bozdağ G, Denizci AA, Gündüz O, Hatır PÇ, Kazan D (2018) Assessment of poly (3-hydroxybutyrate) synthesis from a novel obligate alkaliphilic Bacillus marmarensis and generation of its composite scaffold via electrospinning. Int J Biol Macromol 119:982–991. https://doi.org/10.1016/j.ijbiomac.2018.08.014

Doan CT, Tran TN, Vo TPK, Nguyen AD, Wang SL (2019) Chitin extraction from shrimp waste by liquid fermentation using an alkaline protease-producing strain, Brevibacillus parabrevis. Int J Biol Macromol 131:706–715. https://doi.org/10.1016/j.ijbiomac.2019.03.117

Liu Y, Xing R, Yang H, Liu S, Qin Y, Li K, Yu H, Li P (2020) Chitin extraction from shrimp (Litopenaeus vannamei) shells by successive two-step fermentation with Lactobacillus rhamnoides and Bacillus amyloliquefaciens. Int J Biol Macromol 148:424–433. https://doi.org/10.1016/j.ijbiomac.2020.01.124

Cui D, Yang J, Lu B, Deng L, Shen H (2022) Extraction and characterization of chitin from Oratosquilla oratoria shell waste and its application in Brassica campestris L.ssp. Int J Biol Macromol 198:204–213. https://doi.org/10.1016/j.ijbiomac.2021.12.173

Hongkulsup C, Khutoryanskiy VV, Niranjan K (2016) Enzyme assisted extraction of chitin from shrimp shells (Litopenaeus vannamei). J Chem Technol Biotechnol 91:1250–1256. https://doi.org/10.1002/jctb.4714

Bose A, Pathan S, Pathak K, Keharia H (2014) Keratinolytic protease production by Bacillus amyloliquefaciens 6B using feather meal as substrate and application of feather hydrolysate as organic nitrogen input for agricultural soil. Waste Biomass Valor 5:595–605. https://doi.org/10.1007/s12649-013-9272-5

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. https://doi.org/10.1016/0003-2697(76)90527-3

Cahyaningtyas HAA, Suyotha W, Cheirsilp B, Prihanto AA, Yano S, Wakayama M (2022) Optimization of protease production by Bacillus cereus HMRSC30 for simultaneous extraction of chitin from shrimp shell with value-added recovered products. Environ Sci Pollut Res 29:22163–22178. https://doi.org/10.1007/s11356-021-17279-8

Ooi CK, Rasit N, Absullah WRW (2021) Optimization of protease from Aspergillus niger under solid-state fermentation utilizing shrimp shell substrate. Biointerface Res Appl Chem 11:14809–14824. https://doi.org/10.33263/BRIAC116.1480914824

Avcı A, Değirmen M, Akcay FA (2022) Investigation of lentil flour utilization for the production of protease by Bacillus subtilis ZBP4. Biocatal Biotransformation 40:75–81. https://doi.org/10.1080/10242422.2020.1870109

Rejisha RP, Murugan M (2021) Alkaline protease production by halophilic Bacillus sp. strain SP II-4 and characterization with special reference to contact lens cleansing. Mater Today: Proc 45:1757–1760. https://doi.org/10.1016/j.matpr.2020.08.624

Jadhav HP, Sonawane MS, Khairnar MH, Sayyed RZ (2020) Production of alkaline protease by rhizospheric Bacillus cereus HP_RZ17 and Paenibacillus xylanilyticus HP_RZ19. Environmental Sustainability 3:5–13. https://doi.org/10.1007/s42398-020-00096-z

Kaur I, Sharma AD, Joshi N, Kocher GS (2020) Alkaline proteases: a review on production optimization parameters and their physicochemical properties. Res Rev Biotechnol Biosci 7:33–59. https://doi.org/10.5281/zenodo.3748473

Pal K, Rakshit S, Mondal KC, Halder SK (2021) Microbial decomposition of crustacean shell for production of bioactive metabolites and study of its fertilizing potential. Environ Sci Pollut Res 28:58915–58928. https://doi.org/10.1007/s11356-021-13109-z

Espoui AH, Larimi SG, Darzi GN (2022) Optimization of protease production process using bran waste using Bacillus licheniformis. Korean J Chem Eng 39:674–683. https://doi.org/10.1007/s11814-021-0965-3

Taokaew S, Zhang X, Chuenkaek T, Kobayashi T (2020) Chitin from fermentative extraction of crab shells using okara as a nutrient source and comparative analysis of structural differences from chemically extracted chitin. Biochem Eng 159:107588. https://doi.org/10.1016/j.bej.2020.107588

Gimenes NC, Silveira E, Tambourgi EB (2021) An overview of proteases: production, downstream processes and industrial applications. Sep Purif Rev 50:223–243. https://doi.org/10.1080/15422119.2019.1677249

Mathew GM, Huang CC, Sindhu R, Binod P, Sirohi R, Awsathi MK, Pillai S, Pandey A (2021) Enzymatic approaches in the bioprocessing of shellfish wastes. 3 Biotech 11:367. https://doi.org/10.1007/s13205-021-02912-7

Maruthiah T, Palavesam A (2017) Characterization of haloalkalophilic organic solvent tolerant protease for chitin extraction from shrimp shell waste. Int J Biol Macromol 97:552–560. https://doi.org/10.1016/j.ijbiomac.2017.01.021

Kalwasińska A, Jankiewicz U, Felföldi T, Burkowska-But A, Brzezinska MS (2018) Alkaline and halophilic protease production by Bacillus luteus H11 and its potential industrial applications. Food Technol Biotechnol 56:553. https://doi.org/10.17113/ftb.56.04.18.5553

Manni L, Jellouli K, Ghorbel-Bellaaj O, Agrebi R, Haddar A, Sellami-Kamoun A, Nasri M (2010) An oxidant-and solvent-stable protease produced by Bacillus cereus SV1: application in the deproteinization of shrimp wastes and as a laundry detergent additive. Appl Biochem Biotechnol 160:2308–2321. https://doi.org/10.1007/s12010-009-8703-z

Funding

The authors acknowledge the financial support received from Marmara University, Scientific Research Project Unit with the project number FYL-2022–10331.

Author information

Authors and Affiliations

Contributions

Investigation: Merve Canpulat, writing—original draft preparation: Merve Canpulat, Orkun Pinar, Zeynep Yilmaz-Sercinoglu, Dilek Kazan, validation: Merve Canpulat, visualization: Orkun Pinar, writing—reviewing and editing: Orkun Pinar, Zeynep Yilmaz-Sercinoglu, Dilek Kazan, formal analysis: Orkun Pinar, Dilek Kazan, resources: Dilek Kazan, project administration: Dilek Kazan, conceptualization: Merve Canpulat, methodology: Orkun Pinar, Dilek Kazan, funding acquisition: Dilek Kazan, supervision: Zeynep Yilmaz-Sercinoglu, Dilek Kazan.

Corresponding author

Ethics declarations

Ethics approval

The manuscript does not contain experiments using animals and human studies. No ethical approval is necessary for this article.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Canpulat, M., Pinar, O., Yilmaz-Sercinoglu, Z. et al. Valorization of shrimp waste by obligate alkaliphilic Bacillus marmarensis. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-03684-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-03684-7