Abstract

This research focused on the preparation of radish leaf protein concentrates (RLPC) by applying enzyme-assisted extraction, where α-amylase, protease, and xylanase were employed for the same. The α-amylase-assisted extraction showed maximum extraction yield (10.22%) and protein content (66.93%). Therefore, this method was optimized using response surface methodology where optimized conditions of extraction temperature (42.8 °C), amylase concentration (18,446 U), and extraction time (4.44 h) resulted in an extraction yield of 9.56% and protein content of 89.41% in the extracted RLPC. Fractionation of the protein concentrate demonstrated the maximum presence of glutelins followed by prolamins, albumins, and globulins. The apparent molecular weights of the RLPC and its isolated fractions ranged between 35 and 92 kDa. The RLPC showed a high in vitro protein digestibility (92.17%), considerable antioxidant activity (DPPH, FRAP, ABTS), and desirable structural and functional properties (water and oil holding capacity, emulsion capacity and stability, least gelation concentration, etc.). Threonine, methionine, and tryptophan were found to be the most abundant amino acids present in the RLPC. The microbial load of the stored RLPC was observed to be in acceptable range during 6 weeks of storage under ambient and refrigerated temperature conditions. Conclusively, α-amylase-extracted RLPC serves as a potential alternative edible plant-based protein fortification source for various food formulations.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Radish (Raphanus sativus) is one of the most widely cultivated and rapidly growing cold season root vegetable belonging to Cruciferae family. Leaves, seeds, and roots of radish plant confer a variety of health benefits and have been widely used in the treatment of various gastrointestinal, respiratory, and urinary disorders [1]. The world production of radish is ~ 7 million tonnes per year [2], where tonnes of leaves are wasted, constituting 30–50% of the total weight of a radish plant. The biological value of radish leaves, i.e., proportion of protein absorbed from the leaf that gets incorporated into the tissue of the organism, is considerably high (76.6) which is attributable to the presence of various amino acids and other bioactive constituents present in them [1].

Due to commonly growing consumer concerns about health and nutrition, interest in plant-derived proteins is continuously rising [3]. The leaves of various plants, usually considered to be the post-harvest waste, if properly harnessed and processed could diversify the utilization potential of the same [4]. The leaf protein should be given serious attention, as every year the yield per hectare of leaf proteins can be at least four times higher than that of seed proteins [5]. Generally, animal-based products including eggs, meat, fish, and various milk products have been used for preparing essential amino acid supplements. However, in the recent times, with the much popular vegan diet trend and an increasing human population, there is an urgent need for introducing safe yet sustainable alternative plant-based protein sources. By understanding the feasible role of leaf protein concentrates (LPCs) in combating protein deficiency, scientists have been suggesting the replacement of animal protein in the areas where it is expensive and inaccessible [6].

However, the consumption of enough quantities of leaves to meet protein needs of humans is largely impracticable because of the considerable amount of fiber present in plant leaves. Therefore, the major constraint for obtaining leaf protein is the composition of the leaf itself, where proteins are embedded in a fibrous matrix. Reported conventional methods for plant protein extraction include acid, alkaline, and other chemical solvents [7] which are not generally carried out under environmentally sustainable conditions. Heat coagulation methods have also been studied for LPC extraction [8], but the extraction yields and protein content in the obtained product were relatively lower. Enzyme-assisted extraction (EAE) of LPCs, on the other hand, has been found to be a preferred method to extract protein from plant leaves because it offers various advantages like better yield, high specificity, preserved protein properties, and environment sustainability [9]. This method, unlike the novel extraction techniques including microwave-assisted, pulsed electric field, or ultrasound-assisted extraction, is well researched and, therefore, technically scalable for industrial applications in by-product utilization, such as food industry, animal feed industry, and biorefineries [3, 10].

The EAE of radish leaf protein concentrates (RLPC) needs to be optimized to maximize protein content and extraction yield under certain parameters such as hydrolysis time, enzyme concentration, and extraction temperature. Response surface methodology (RSM) is an approach for statistical modelling and analysis of an experimental set based on regression analysis [11]. For incorporation of the extracted RLPCs into various products, it is necessary to understand their functionality in terms of absorption tendency, emulsifying capacity, and gelation and foaming capacity, among many others [12]. To date, there are not any specific studies available in literature related to EAE of radish leaf protein concentrates. Therefore, in order to determine the possibility of RLPC to be used as food/feed supplement, the present investigation was undertaken with the objectives of extracting protein using different enzymes; optimizing the process parameters of its enzymatic extraction; evaluating its physicochemical, structural, biological, and functional properties; and determining the storage stability of the same.

2 Materials and methods

2.1 Materials for preparation and analysis of radish leaf protein concentrates

The present investigation was carried out on the leaves of radish variety, Punjab Safed Mooli 2, procured from the fields of the Department of Vegetable Science, College of Horticulture and Forestry, Punjab Agricultural University, Ludhiana. The radish leaves were properly washed after separating them from their stalks and dried in a horizontal tray dryer (SFBD-200 Tray dryer, SF Engineering Works, Mumbai, India) at 50 °C for 8–10 h. The dried leaves were grinded into fine powder using a grinder (HL 7720 750-Watt 3-Jar Grinder, Philips India Ltd., Mumbai, India) which was stored in airtight containers at ambient room temperature until further use (3 months).

Food-grade α-amylase (20,000 U/g) and protease (500 U/mg) were purchased from Sisco Research Laboratories, Pvt. Ltd. (Mumbai, India), and xylanase (60 U/mg) was purchased from MP Biomedicals, Pvt. Ltd. (Mumbai, India). The reagents of analytical grade were used in the laboratory work.

2.2 Preparation of leaf protein concentrates

Different concentrations of xylanase, protease, and α-amylase were used to evaluate the maximum protein extraction from radish leaves. The leaf powder sample (10 g for each enzyme treatment) was added to double distilled water (100 ml) and stirred until a homogeneous slurry was obtained in order to aid proper solubilization of the extracted protein post the enzymatic action. The conditions of slurry were adjusted as follows: (1) pH 6.25 with 1.0 N HCl to which 0/2000/4000/8000/12000/16000/20000U of α-amylase were added; (2) pH 8.0 to which 0/1000/2000/3000/4000/5000 U of protease were added; and (3) pH 5.2 to which 0/120/240/360/480/600 U of xylanase were added. The enzyme containing slurries were homogenized; amylase-treated slurries were incubated at a constant temperature of 45 °C and shaken at 200 rpm for 3.5 h. The slurries treated with protease and xylanase were kept for incubation for 2 h at 37 °C and 55 °C, respectively. After the incubation, the slurries were centrifuged at 4000 rpm (using C-24 BL Remi Refrigerated Centrifuge, Mumbai, India) for 25 min at 4 ℃ to separate the soluble fraction from the residual one. The supernatant was subjected to isoelectric precipitation to separate the extracted solubilized proteins by adjusting its pH to 4.5, which was then centrifuged at 5000 rpm for 30 min at 4 ℃. The precipitates formed in the tube were then separated and washed properly using deionized water and then freeze-dried (using MSW-137 MAC Lyophilizer, Delhi, India). This final product, referred as RLPCs, were subjected to analysis for the determination of their yield and protein content.

2.3 Optimization of parameters for protein extraction

Since α-amylase catalysis extracted maximum amount of protein among all the tested enzymes, α-amylase-assisted extraction was employed for further optimization. Three process variables i.e., α-amylase concentration (4000–20,000 U), extraction time (2–6 h), and extraction temperature (35–55 °C) were selected. An experimental design was formed by availing the eleventh file version of Design Expert software (Stat-Ease Inc., Minneapolis, USA). The design was distinctively based on the three independent process variables and two discrete responses: yield (%) and protein content (%). In this software, response surface methodology (RSM) was adopted while considering a three variable design as suggested by Box and Behnken [13]. Analysis of variance (ANOVA) and coefficient of correlation (R2) detailed the adequacy of the model and specified its goodness of fit. Seventeen treatment combinations were generated based on the selected range of parameters, for which the resultant responses were experimentally obtained. Based on the responses, response surface plots were generated to study the interaction between independent process parameters. The software suggested optimum process parameters after analyzing the responses of all the experimental combinations which were then verified manually.

2.4 Estimation of protein content and extraction yield

Crude protein of RLPCs extracted by enzyme-assisted extraction was determined by the standard Kjeldahl method [14]. Yield of protein (%) in RLPCs was measured as the percentage of mass of RLPC obtained after extraction (g) from the total mass of radish leaf powder taken (g).

2.5 RLPC fractionation and electrophoretic profiling

The sequential solvent extraction of discrete protein fractions from RLPC was performed using the method followed by Kaur and Bhatia [15]. Proportion of protein present in the sequentially extracted fractions was estimated using the method developed by Lowry et al. [16]. Laemmli’s method [17] was followed for determining the apparent molecular weight of polypeptides of protein concentrate and its fractions by visualizing their electrophoretic profiles using sodium dodecyl polyacrylamide gel electrophoresis.

2.6 Determination of antioxidative properties and phenolic content

A methanolic extract of RLPC (0.5 g) was prepared by refluxing the sample at 80 ℃ for precisely 10 min. The extract was filtered and the supernatant was collected for estimation of DPPH (2,2-diphenyl-1-picrylhydrazyl) radical scavenging activity [18], ABTS (2,2′-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid)) radical scavenging activity [19] and FRAP (Ferric reducing/antioxidant power) activity [20]. Free phenols and flavonoids were estimated by the method described by Devi et al. [21].

2.7 In vitro digestion, color measurement, and mineral analysis

The triple simulated enzyme method described by Minekus et al. [22] was performed to determine in vitro digestibility of RLPC. Color measurement was carried out using Hunter colorimeter (ColorQuest XE, Hunter lab, Virginia, USA) [23]. For mineral analysis, the sample was digested using the di-acid method in Kjeldahl Infra Digestion System followed by quantitative evaluation by employing inductively coupled plasma optical emission spectroscopy [24].

2.8 SEM and FTIR analysis

The surface morphology of RLPC was analyzed by using scanning electron microscopy. The dried samples of RLPC were mounted on an aluminum stub with double-sided carbon tape, sputter coated with a 10-nm gold layer and examined in a SEM (JSM 6100, Jeol, Japan). The spectral analysis was done using an FTIR spectrometer (PerkinElmer Spectrum RX I, USA). The range of FTIR spectra lied between 4000 and 400 cm−1 at room temperature. The automatic signals gained were collected at a resolution of 1 cm−1 against a background spectrum recorded from the clean empty cell at 25 ℃.

2.9 Qualitative determination of amino acids and phenolic compounds

The presence of various amino acids and other organic compounds in amylase-extracted RLPC was determined where liquid chromatography mass spectrometry (LC–MS) was performed using Waters Micromass (Q-Tof Micro). This analytical instrument functioned under a mass range of 4000 amu in quadruple and 20,000 amu in ToF which was coupled with Waters 2795 HPLC facilitated with a quaternary pumping, precisely configured for flow rates from 0.05 to 5.0 ml/min. Formic acid-acetonitrile aqueous solution (0.1%) was taken as the mobile phase for chromatographic column separation.

2.10 Functional properties

To determine the organoleptic characteristics of RLPC various functional properties were studied. The method followed by Yu et al. [25] was used to determine protein solubility (PS). The methods described by Lin et al. [26] were followed to determine water holding capacity (WHC) as well as the oil holding capacity (OHC) of the RLPC. For the evaluation of foaming capacity (FC) and foaming stability (FS), the methods described by Yasumatsu et al. [27] were selected. The methods described by Sathe et al. [28] were used for measuring the emulsifying capacity (EC) and emulsion stability (ES). Determination of least gelation concentration was carried out as per the method followed by Huda et al. [29].

2.11 Storage studies to evaluate shelf life

The shelf life of RLPC extracted enzymatically, packed in low-density polyethylene zip lock bags of 25-micron thickness for storage, was determined for 6 weeks (42 days) under ambient (temperature, 31.1–42.6 ℃; relative humidity, 32–83%) and refrigerated (temperature, 4 ± 1 ℃; relative humidity, 90%) conditions. The microbial analyses (yeast/mold and total plate count) of RLPC were performed as per the method explained by Kaur and Bhatia [15] at an interval of 7 days. The plate counts were expressed in terms of log CFU ml−1.

2.12 Statistical analysis of results

The above-mentioned experiments were performed in triplicates, and the mean values for various respective analyses were determined using one way analysis of variance (ANOVA). The Statistical Analysis System Software (SAS 9.3 for Windows) was used for the statistical analyses. The data generated in Box-Behnken experimental design was interpreted using RSM analysis.

3 Results and discussion

3.1 Enzyme-assisted protein extraction

The effect of three different enzymes (α-amylase, protease, and xylanase) on the extraction of RLPCs from radish leaves is shown in Table 1. Addition of 0, 4000, 8000, 12,000, 16,000, and 20,000 U of amylase resulted in 2.07, 3.17, 5.98, 7.32, 8.91, and 10.22% yield of RLPC, respectively constituting 37.93, 39.25, 54.06, 66.93, 55.37, and 51.43% protein content. Maximum yield of protein (10.22%) was obtained when 20,000 U of amylase were added to the sample. However, maximum protein content (66.93%) was obtained when 12,000 U of amylase were employed for the RLPC extraction. Amylase is a carbohydrase which is a gainfully fast and an environmentally friendly approach to hydrolyze the starch component bound to the protein. It facilitates an effective protein extraction by disintegrating the cell wall polysaccharides, making the intracellular components, i.e., the protein, more accessible for extraction [9]. With an increase in amylase concentration, a significant increase in yield (%) was observed. Likewise, the protein content (%) displayed a significant increase, for amylase concentration ranging from 0 to 12,000 U. Beyond this concentration, the increase in protein content was not observed, which could be due to the extraction of intracellular components other than the proteins.

Addition of 0, 1000, 2000, 3000, and 4000 U of protease, a peptidase which breaks larger polypeptide chains into smaller peptides for easy extraction, to radish leaf powder resulted in 3.01, 4.38, 5.40, 6.01, and 8.13% yield of RLPC, respectively, with 36.25, 37.18, 41.05, 52.75, and 51.43% of protein content, respectively. Maximum yield (8.13%) was obtained at 4000 U of enzyme, whereas maximum protein content (52.75%) was obtained at 3000 U of protease. Evidently, a statistically significant increase in extraction yield and the corresponding protein content of RLPCs was observed with an increase in protease concentration. Xylanase is another glucoside hydrolase which depolymerizes the hemi-cellulose components of the cell wall to release the bound protein [9]. To check its effectiveness in protein extraction, supplementation of 0, 120, 240, 360, 480, and 600 U of xylanase was done which resulted in 5.22, 6.21, 6.34, 7.34, 11.8, and 11.25% yield of RLPC, respectively, with the respective protein content of 36.23, 37.43, 36.86, 34.29, 32.22, and 34.84%. Increasing the enzyme concentration did not exhibit any significant effect on RLPC protein content (with an exception of 480 U, where it declined). However, the yield of RLPC increased with an increase in xylanase concentration which might be because of the extraction of other intracellular components. Maximum yield (11.8%) of RLPC was obtained at 480 U, and maximum protein content (37.43%) of RLPC was achieved at 120 U of xylanase. The depolymerization carried out by these enzymes, after a certain concentration, resulted in the extraction of non-protein components from the radish leaf which eventually led to increased yield percent of the concentrate. The protein content in RLPC, however, does not increase significantly beyond a certain level because the optimal levels of extraction had already been achieved under the given conditions of extraction.

Since α-amylase-assisted extraction achieved maximum extraction of protein among the three above-mentioned enzymes, α-amylase was used for further optimization of process parameters. Design Expert software (version 11) was used to make an experimental design considering three independent variables: α-amylase concentration (4000–20,000 U), time of extraction (2–6 h), and extraction temperature (35–55 °C). The extraction of protein concentrates from radish leaves was optimized for protein concentrate yield and its percent protein content. The optimization experiment was performed in a random manner at different combinations of the selected parameters. The effects of varying levels of independent factors on the design responses are shown in Table 2 (a). The yield of RLPCs varied from 5.3 to 9.23% and protein content varied from 38.44 to 93.31%. Maximum yield (9.23%) of RLPCs was obtained using the conditions: 12,000 U of α-amylase at extraction temperature 45 °C and extraction time 4 h. Maximum protein content (93.31%) in RLPC was obtained when 20,000 U of amylase were added at an extraction temperature of 45 °C and extraction time of 6 h.

3.2 Fitting the models

The relationship between the selected process parameters in the experiments and their resultant response functions was studied in a regression analysis. Quadratic model so obtained during the analysis could be fit into the following equations for yield and protein content.

where A represents temperature of extraction (°C), B represents enzyme concentration (U), and C represents time of extraction (h).

Table 3 shows the results for analysis of variance for the experimental design where the probability value (P) exhibits the significance of model terms (at 95% confidence interval). Coefficient of determination, R2, which is an indication of degree of fit of the model has also been given in the table. If R2 value happens to be greater than 0.80, then the model chosen for the design of experiment is a good fit [30]. Since R2 value for extraction yield of RLPC was 0.808; therefore, the model design framed for the same was suitable, implying that 80.8% variations in the response could be elucidated by the fitted model. Similarly, the R2 value in the case of RLPC protein content was found to be 0.9602 which demonstrated that fitted model could very well determine 96.2% of the total variations in the given response. Therefore, it was proven that the developed models using Box-Behnken Design presented the interactive effects between dependent and independent process variables quite adequately.

3.3 Optimization of process variables

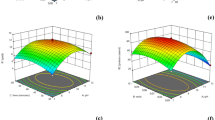

The overall model developed for the first response, extraction yield of RLPC, is significant with P ≤ 0.0001 (Table 3). Enzyme concentration and extraction temperature significantly contributed to maximize the yield of RLPC accredited to their low P values, but the time of extraction did not show any significance. The temperature-temperature and time-time interactive effects during amylase-assisted extraction of RLPC also portrayed a significant influence on the yield. The response surface plots from the experimental design were analyzed, which allowed the prediction of response function of the variables. As shown in Fig. 1a, b, and c, these plots illustrate the interactive effects of the independent process variables on extraction yield of RLPC. At constant time of extraction, concentration of enzyme showed a linear effect on the extraction yield, i.e., extensive disintegration of the protein bound carbohydrates leads to a higher protein extraction. However, under similar constraints, the extraction temperature displayed a quadratic effect on yield which attained an optimum maximum at 45 ℃. This was followed by a decline in the response with a further increase in the temperature (Fig. 1a). This transition might be a result of protein denaturation, structural destabilization and, therefore, decreased solubility at relatively higher temperatures [31]. Interactions between different process parameters have a great influence on the overall response of the treatment as suggested by Kaur and Bhatia [8] in their optimization studies of alkaline extraction of leaf protein concentrates. The influence of time and temperature of extraction at constant enzyme concentration has been illustrated in Fig. 1b, where the time of extraction maintained a linear effect while the temperature of extraction displayed a quadratic effect on the response. However, in Fig. 1c, both the independent variables, i.e., time of extraction and enzyme concentration depicted a linear effect on the response, keeping temperature of extraction constant.

The quadratic model exhibited in the design for protein content of RLPCs turned out to be evidently significant. The RLPC protein content was profusely affected by temperature of extraction and concentration of α-amylase, whereas the time of extraction did not show any statistical significance (Table 3). Up until an optimum level, the increase in protein content was seen with the increment in the extraction temperature as indicated by the response curve in Fig. 1d after which it declined with a further increase in temperature, thus suggesting its quadratic effect on the response. This could be due to the sensitivity of the enzyme to higher temperature conditions, leading to the destabilization in its structure as well as deformation of the active site, thereby explaining the decline in protein content. A similar interaction between concentration of enzyme and temperature at fixed time of extraction is depicted in Fig. 1e, whereas time-concentration interaction at constant temperature is shown in Fig. 1f.

3.4 Verification of results

The optimum conditions for α-amylase-assisted extraction of RLPC obtained by computer-generated response surfaces of the developed model are given in Table 2 which are as follows: (1) temperature of extraction, 42.8 °C; (2) concentration of α-amylase, 18,446 U; and (3) time of extraction 4.44 h. Under these conditions, a maximum response of RLPC yield of 9.09% and protein content of 87.07% were predicted. Experiments using the recommended optimum conditions were carried out to verify the predicted values. The experimental values so obtained were: 9.56% yield of RLPC and 89.41% protein with a variation 0.46% and 2.33%, respectively, indicating a non-significant difference between the predicted and experimental responses.

3.5 Isolation of protein fractions and SDS-PAGE profiling

The protein fractions were isolated from RLPC using sequential extraction method. Alkali-soluble protein fractions, glutelins, comprised major proportion of protein (42.58%), followed by ethanol soluble prolamins (23.57%), water-soluble albumins (20.08%), and salt-soluble globulins (13.74%) (Fig. 2). These results correspond with the findings of Kaur and Bhatia [8] where a similar distribution of protein fractions was observed in alkali-extracted protein concentrates from radish leaves. SDS-PAGE was employed to determine the apparent molecular weight distribution of RLPC and its protein fractions (Fig. 3). Bands ranging between 35 and 92 kDa were clearly observed. It can be observed that the apparent molecular weight distribution of albumin polypeptides recovered from RLPC has been represented by three distinct bands at 45, 50, and 57 kDa. A smear of bands between 47 and 60 kDa elucidated the polypeptide composition profile of globulins. Several distinct bands were observed for glutelins ranging between 40 and 66 kDa. A slightly faint band was observed at around 47 kDa representing prolamins. The improper separation of bands is mainly attributed to factors like limited solubility of the protein fraction in the buffer or the heterogeneity of the polypeptides in the sample [32]. Celik et al. [7] reported similar results in the electrophoretic profile of sour cherry kernel protein isolates and their fractions. These results were also consistent with reported researches on alfalfa soluble leaf proteins [33] and heat coagulated radish leaf protein concentrates [8].

3.6 Characterizing biochemical properties: antioxidant activity, phenolic and flavonoid content

The ferric reducing antioxidant activity (FRAP) of RLPC was observed to be 25.88% which was at par with the globulins but significantly lower than the prolamins and glutelins as presented in Table 4. The Moreover, DPPH+ and ABTS+ radical scavenging activities of the RLPC were 28.66 and 83.29%, respectively. Although the maximum ABTS+ activity was seen in the RLPC followed by glutelins and other fractions, DPPH+ activity of RLPC and three of the protein fractions (albumins, globulins and prolamins) were statistically at par with each other (Table 4). The presence of similar concentration of electron donating active compounds in the examined samples which could react with free radicals and terminate the chain radical reaction by converting them into relatively stable products is the possible reason for the non-significant antioxidant activities of RLPC and certain protein fractions [34]. The antioxidant activity may also be affected by various other parameters and conditions, such as a reduction in molecular weight, enhanced presence of ionizable groups, and outward localization of hydrophobic groups, therefore being more exposed [35]. The results were similar to the ones reported during the characterization of bean protein hydrolysates [36]. The ABTS+ method showed higher radical scavenging activity in case of RPLC as well as glutelins at the same concentrations of active compounds due to greater inhibition of ABTS•+ than that of DPPH• due to differences in the removal efficiency attributed to the solubility and diffusivity of radicals [37]. Table 5 shows the free flavonoid and free phenolic content (mg/g) in RLPC which are in comparable to the results reported for carrot leaf protein concentrates [38].

3.7 In vitro digestibility, color measurement, and mineral analysis

In vitro protein digestibility presented in Table 5 showed that the RLPC had digestibility of 92.17% which was higher than 64.7% for Moringa oleifera leaf protein isolate [39] and 30.50% for soybean flour [40]. However, the value was similar to that of 89.57% reported by Fasuan et al. [41] for sesame protein isolate. The high in vitro protein digestibility of the RLPC could be due to the higher amount of protein content (Table 2b). Therefore, higher availability of the peptide bonds of the proteins for enzymatic activities and lower amount of non-protein constituents, especially polysaccharides, attribute to the enzyme-assisted extraction of the protein concentrates [42].

The descriptive values for color characteristics of RLPC are shown in Table 5. The lightness value (L*) of RLPC was 45.8 which is lower than that of Bambara groundnut protein isolate [43] and commercial soy protein isolate [44] elucidating that the RLPC was comparatively darker than the other two. According to Pumilia et al. [45], the extraction of protein concentrates might degrade the chlorophyll pigment, thereby imparting darkness to the sample. The redness (a*) and yellowness (b*) of the RLPC were lower in comparison to Moringa leaf protein isolates and soy protein isolates [43, 44] which is considered to be desirable in the food industry [6]. This variation in the coloration of the protein concentrates/isolates is associated with the conditions of the extraction medium which basically determine the reactions of polyphenols, pigments, carbohydrates, and other constituents with the protein [46].

Table 5 also depicts the various concentrations of major and trace minerals present in radish leaf protein concentrates. The concentrations of Zn, Cu, Mn, and Cr in RLPC were observed as 12.16, 68.12, 53.00 and 11.56 mg/100 g. Fe was found to be the most abundant trace element with a concentration of 237.62 mg/100 g which is higher than that of Moringa oleifera leaf protein concentrate [47]. Major minerals including Ca, K, Mg, and P were also present in adequate amounts, where Ca was the most abundant major mineral with a concentration of 888.28 mg/100 g. The recommended daily allowance of Ca for both children and adults is reported to be 800 mg per day [48], which indicated that RLPC could furnish an individual with the requisite value of calcium.

3.8 Structural characterization of RLPC using FTIR

Fourier transform infrared spectroscopic analysis of RLPC was done where the peaks were recorded between the range of 4000 to 400 cm−1 (wavenumber). The spectrum of RLPC is presented in Fig. 4 depicting major peaks at the wavenumbers of 1617.67, 1636.38, 3237.77, 3414.34, 3473.32, and 3550.50 cm−1. The bands of spectral region between 1700 and 1600 cm−1 corresponds to the amide I linkage which is almost entirely due to CO stretch vibrations of the peptide linkages, weakly coupled with in-plane NH bending and CN stretching [49, 50]. It may have some contributions from CN stretching and CCN deformation [51]. Amide I bands were majorly representing β-sheets as secondary structures of RLPC since the wavenumbers ranged between 1615 and 1640 [49]. The IR bands at 3414 and 3473 cm−1 are attributed to the amide A and amide B linkages which are mainly derived from intermolecularly H-bonded NH groups [52]. The band at 3237 cm−1 is characterized by strong intramolecular C—O… N—H H-bonds compatible with α helical conformation [53].

3.9 Surface morphology of RLPC

Various attractive and repulsive forces influence the structure and morphology of a protein concentrate which are directly related to its extraction conditions [54]. Certain drastic alterations in the secondary, tertiary, and quaternary conformations of the protein structure are caused by the chemical modifications attributable to the enzymatic extraction. The SEM images of radish leaf protein concentrates are shown in Fig. 5. The concentrates were cloudy shaped having rough surfaces and irregularly formed networks. which might affect the oil retention and other emulsion properties [55]. The rough structure of the protein concentrates might be the result of chemical modifications attributed to enzymatic hydrolysis and pH alterations. Surface depressions on the microstructures arise due to the extraction treatment process which also might have led to changes in the functional properties of the concentrates [56].

3.10 Qualitative identification of amino acids and other organic compounds

The presence of various amino acids was detected using LC–MS equipped with chemical and electrospray ionization where the peaks of the spectrum obtained precisely depicted their m/z (mass to charge) ratio. The monoisotopic mass of the separated ions and the relative abundance of the identified compounds was interpreted from the m/z signals in the spectrum. The amino acids which have been identified in the amylase-extracted RLPC are presented in Fig. 6a where threonine, methionine, tryptophan, glutamic acid, and histidine were found to be the most abundant relatively. The presence of different phenolic (quinic acid, ferulic acid, cinnamic acid, chlorogenic acid, gentisic acid, etc.) and flavonoid compounds (kaempferol, catechin, certain flavones, and their derivatives) in the extracted RLPC is shown in Fig. 6b. Kaempferol and lutelon7-O-glucoside had higher relative abundance than the rest of the organic compounds detected qualitatively in the protein concentrate.

3.11 Functional properties

The water holding capacity (WHC) of the amylase-extracted RLPC came out to be 408% (Fig. 7) which was evidently greater than the values reported for soy protein isolate (130%) [57], cassava leaf protein concentrates (118–200%) [58], and sour cherry kernel protein isolate (242%) [7]. The value oil holding capacity (OHC) of RLPC was 335% (Table 5) which is higher than 207% OHC of sunflower flour [26], 110% in soy protein isolate [57], 254% in hyacinth bean protein isolate [59], and 191–227% in chickpea protein concentrate [60]. A higher value of OHC reflects the hydrophobic capacity of the protein concentrates [61]. The protein content of the RLPC might have an increased number of protein side chains with hydrophobic groups leading to a higher oil holding capacity [62].

Analysis of functional properties of α-amylase-extracted radish leaf protein concentrates (RLPC): a water holding capacity (WHC) and oil holding capacity (OHC) of RLPC. b Foaming properties: foaming capacity (FC) and foaming stability (FS), emulsifying properties: emulsifying capacity (EC) and emulsion stability (ES) and least gelation concentration (LGC) of RLPC. c Solubility profile of RLPC at pH ranging between 2 and 12

The foaming capacity (FC) of the RLPC was 14.9% evaluated at pH 7.4 (Fig. 5b) which is considerably lower than cowpea protein isolates (82–93%) [63] and mung bean protein isolates (26%) [3]. On the similar lines, the foaming stability (FS) of the RLPC (20%) was lower than that reported for the protein isolate of cashew [64], bayberry-kernel [65], and mung bean [3]. FS is known to affect the strength of protein films as well as their gas permeability [66]. The values of FC and FS as discussed were found to be relatively lower which indicates that the RLPCs extracted in this study were not appropriate to be used as foaming or whipping agents in products like ice creams, bakery products, and drinks.

The emulsion forming tendency of a protein measured as its emulsion capacity (EC) is an important functional characteristic just like its emulsion stability (ES) which is the ability of a protein to create a stable emulsion for a set period of time. The EC (44.3%) and ES (42.1%) of the RLPC (Fig. 7b) were significantly higher than 11% reported for wheat flour by Lin et al. [26] However, similar results were reported by Cano-Medina et al. [67] for soybean protein concentrates having 44% EC (at both acidic and alkaline pH), while ES was greater in acidic conditions pH (51%) than the alkaline ones (45%). Cassava leaf meals having 27.4% EC with 41.2% ES and cassava leaf protein concentrates demonstrating 32.5% EC with 42.9% EC as reported by Fasuyi and Aletor [58] were deemed suitable for enhancing the protein quality and stabilizing various cereal flours. These studies indicate that the RLPC also showed a high potential to be used as functional additives for the stabilization of emulsions in food products.

A critical concentration is required for a given protein in order to form a gel matrix which is referred to as the least gelation concentration (LGC). The minimum LGC evaluated for RLPC was 7% (w/v) as shown in Fig. 7b which was lower than that of pigeon pea protein concentrate, i.e., 12% [28]. Similarly, the LGC of RLPC was also lower than 14–16% found in chickpea protein concentrate [60] and 8% demonstrated in the case of sour cherry kernel protein concentrate [7]. Since lower LGC value depicts better gelation characteristics of protein isolate [7], it can be stated that amylase-extracted RLPC demonstrated superior gelation characteristics. Hence, it could be useful as an additive in food products for gel formation.

In the solubility profile of RLPC (Fig. 7c), a zig-zag pattern was observed where the solubility first decreased from 34.54% (pH 2) to 27.60% (pH 4) and then increased to 36.25% (pH 6) until it reached the maxima of 37.76% at pH 8. At pH 12, again a dip was seen and the solubility decreased to a value of 31.16%. The protein solubility results of mung bean protein isolates (MBPI) as reported by Du et al. [3] were comparable to the above observations, where minimum solubility of MBPI was observed at pH 4.6 and relatively higher solubility was observed at pH 2 and 8. Similar observations were reported for defatted peanut flour and peanut protein isolates [68] and black bean protein isolates [49]. The protein solubility profiles of leaf protein extracts of Vernonia amygdalina (bitter leaf), Solanum africana, Amaranthus hybridus (green tete), and Telfaria occidentalis (fluted pumpkins) also showed multiple maximum and minimum solubilities in both acidic and basic regions due to the presence of different amino acids which ionize at different pH levels [61]. The change in the pH of a protein’s environment causes observable changes in the solubility of the protein because of the. The solubility results generally indicated that leaf protein concentrates might find good use in foods having variable pH [69] such as protein rich carbonated beverages.

3.12 Analysis of microbial load in RLPC during storage

To demonstrate the storage stability of RLPC prepared using enzyme-assisted extraction, it was significant to measure its microbial load. Total plate count and yeast/ mold count were taken separately under different temperature conditions consecutively for 42 days at an interval of 7 days as shown in Table 6. It was observed that under room temperature/ambient storage conditions, the yeast/mold load elevated from 2.0 log CFU/ml (day 7) to 3.0 log CFU/ml (day 42). On the contrary, the counts were below the detection limit up to 14 days of storage under refrigerated temperature. The yeast/mold counts of amylase-extracted RLPC were evidently seen within acceptable range during the entire storage span under the given conditions of surrounding temperature. The total plate count remained below detection limit before 3 and 5 weeks of storage under ambient and refrigerated conditions, respectively. However, the total plate count reached a value of 4.0 log CFU/ml at day 28. This further increased to 4.60 log CFU/ml on day 42 at ambient conditions of temperature. At day 42, the total plate count was calculated as 4.0 log CFU/ml under refrigerated temperature which was lied within acceptable range as specified by FSSAI [70]. Similar results were reported by Kaur and Bhatia [15] during storage studies of protein concentrates prepared by chemical extraction method.

4 Conclusion

Radish leaf protein concentrates were prepared under optimized conditions of temperature (42.8 °C), amylase concentration (18,446 U) and time of extraction (4.44 h) which resulted in an extraction yield of 9.56% and protein content of 89.41%. The protein content and yield of RLPC increased both by temperature of extraction and amylase concentration, but time of extraction did not show any significant effect. Within the protein concentrate, the glutelin fraction was found to be maximum followed by globulins, albumins, and prolamins. The presence of several essential amino acids (threonine, methionine, tryptophan, etc.) and other organic compounds was observed in RLPC. A considerable protein digestibility, mineral content, desirable functional properties, and an acceptable microbial load in the isolated RLPC highlight their potential as functional food ingredients for incorporation in consumables. Future studies could be carried out to ensure that radish leaf protein concentrate is added to different food products such as energy bars, vegan cookies, and patties. The effects on the properties of the food product can be discovered and its sensory evaluation including taste, flavor, aroma, texture, etc. can be carried out.

Data availability

Available on request.

References

Ankita PK, Prasad K (2018) Characterization of dehydrated functional fractional radish leaf powder. Der Pharm Lett 7:269–279

CGIAR Genebank, Capacity building workshop on genetic resource policies for CGIAR scientists and partners in East Africa, 4–7 June 2019, ILRI Campus, Addis Ababa, Ethiopia (2019), https://cgspace.cgiar.org/handle/10568/106609

Du M, Xie J, Gong B, Xu X, Tang W, Li X, Xie M (2018) Extraction, physicochemical characteristics and functional properties of Mung bean protein. Food Hydrocoll 76:131–140. https://doi.org/10.1016/j.foodhyd.2017.01.003

Popoola JO, Wgwari LO, Bilewi Y, Omonigbehin E, Ogulana OO, Daramola F (2019) Proximate analysis and SDS-PAGE protein profiling of cassava leaves: utilization as leafy vegetable in Nigeria. MOJ Ecol Environ Sci 4:1–5. https://doi.org/10.15406/mojes.2019.04.00125

L. Telek, Leaf protein extraction from tropical plants, plants: the potentials for extracting protein 305 (1983).

Akyuz A, Ersus S (2021) Optimization of enzyme assisted extraction of protein from the sugar beet (Beta vulgaris L.) leaves for alternative plant protein concentrate production. Food Chem 335:127673. https://doi.org/10.1016/j.foodchem.2020.127673

Celik M, Melih G, Metin Y (2019) Effect of pH on protein extraction from sour cherry kernels and functional properties of resulting protein concentrate. J Food Sci Technol 6:3023–3032. https://doi.org/10.1007/s13197-019-03785-8

Kaur G, Bhatia S (2021) Characterization of radish leaf protein concentrates for biochemical, functional properties, antioxidant activity, mineral content and microbial stability. Int J Agric Sci 17:185–193. https://doi.org/10.15740/HAS/IJAS/17.2/185-193

Ahmadifard N, Mureta JHC, Abedian-Kenari A, Motamedzadegan A, Jamali H (2016) Comparison the effect of three commercial enzymes for enzymatic hydrolysis of two substrates (rice bran protein concentrate and soy-been protein) with SDS-PAGE. J Food Sci Technol 53:1279–1284. https://doi.org/10.1007/s13197-015-2087-6

Nadar SS, Rao P, Rathod VK (2018) Enzyme assisted extraction of biomolecules as an approach to novel extraction technology: A review. Food Res Int 108:309–330. https://doi.org/10.1016/j.foodres.2018.03.006

Choi H, Marufa N, Badrul A, Ahsan J, Alshammari FH, Kim S, Lee S (2022) Optimization of the extraction conditions of Nypa fruticans Wurmb using response surface methodology and artificial neural network. Food Chem 381:132086. https://doi.org/10.1016/j.foodchem.2022.132086

Daba SD, Morris CF (2022) Pea proteins: Variation, composition, genetics, and functional properties. Cer Chem 99:8–20. https://doi.org/10.1002/cche.10439

Box GE, Behnken DW (1960) Some new three level designs for the study of quantitative variables. Technometrics 2:455–475

AOAC, Official Methods of Analysis, 17th edn., Association of Official Analytical Chemists, Washington, D.C. (2000).

Kaur G, Bhatia S (2022) Radish leaf protein concentrates: optimization of alkaline extraction for production and characterization of an alternative plant protein concentrate. J Food Meas Charact. https://doi.org/10.1007/s11694-022-01411-4

Lowry OH (1951) Protein measurement with the Folin phenol reagent. J Biol, Chem 193:265–275

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685. https://doi.org/10.1038/227680a0

Lin CW, Yu CW, Wu SC, Yih KH (2009) DPPH Free-radical scavenging activity, total phenolic contents and chemical composition analysis of forty-two kinds of essential oils. J Food Drug Anal 17:386–395

Re R, Pellengrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26:1231–1237. https://doi.org/10.1016/S0891-5849(98)00315-3

Benzie FF, Strain JJ (1999) Ferric reducing/antioxidant power assay: direct measure of total antioxidant activity of biological fluids and modified version for simultaneous measurement of total antioxidant power and ascorbic acid concentration. Meth Enzymol 299:15–27. https://doi.org/10.1016/S0076-6879(99)99005-5

Devi J, Bhatia S, Alam MS, Dhillon TS (2018) Effect of calcium and salicylic acid on quality retention in relation to antioxidative enzymes in radish stored under refrigerated conditions. J Food Sci Technol 55:1116–1126. https://doi.org/10.1007/s13197-017-3027-4

Mineskus M, Marie A, Paula A, Simon B, Yorsten B, Claire B, Frederic C (2014) A standardised static in vitro digestion method suitable for food–an international consensus. Food Func 5:1113–1237. https://doi.org/10.1039/C3FO60702J

Schelkopf CS, Rice EA, Swenson JK, Hess AM, Geomaras I, Belk KE, Nair MN (2021) Nix Pro Color Sensor provides comparable color measurements to HunterLab colorimeter for fresh beef. J Food Sci Technol 58:3661–3665. https://doi.org/10.1007/s13197-021-05077-6

Sharma N, Singh VK, Lee Y, Kumar S, Rai PK, Pathak AK, Singh VK (2020) Analysis of mineral elements in medicinal plant samples using LIBS and ICP-OES. At. Spectrosc 41:234–241. https://doi.org/10.46770/AS.2020.06.003

Yu J, Ahmedna M, Goktepe I (2007) Peanut protein concentrate: Production and functional properties as affected by processing. Food Chem 103:121–129. https://doi.org/10.1016/j.foodchem.2006.08.012

Lin MJY, Humbert ES, Sosulski FW (1974) Certain functional properties of sunflower meal products. J Food Sci 39:2. https://doi.org/10.1111/j.1365-2621.1974.tb02896.x

Yasumatsu K, Sawada K, Moritaka S, Misaki M, Toda J, Wada T, Ishii K (1972) Whipping and emulsifying properties of soybean products. Agric Biol Chem 36:719–727. https://doi.org/10.1080/00021369.1972.10860321

Sathe SK, Deshpande SS, Salunkhe DK (1982) Functional properties of winged bean [Psophocarpus tetragonolobus (L) DC] protein. J. Food Sci. 47:503–509. https://doi.org/10.1111/j.1365-2621.1982.tb10112.x

Huda N, Abdullah A, Babji AS (2001) Functional properties of surimi powder from three Malaysian marine fish 36:401–406. https://doi.org/10.1046/j.1365-2621.2001.00473.x

Joglekar AM, May AT (1987) Product excellence through design of experiments. Cer Foods World 32:857–868

Lapornik B, Prosek M, Wondra AG (2005) Comparison of extracts prepared from plant by-products using different solvents and extraction time. J Food Eng 71:214–222. https://doi.org/10.1016/j.jfoodeng.2004.10.036

Adebiyi P, Adebiyi AO, Hasegawa Y, Ogawa T, Muramoto K (2009) Isolation and characterization of protein fractions from deoiled rice bran. Eur Food Res Technol 228:391–401. https://doi.org/10.1007/s00217-008-0945-4

Lamsal P, Koegel RG, Gunasekaran S (2007) Some physicochemical and functional properties of alfalfa soluble leaf proteins, LWT-. Food Sci Technol 40:1520–1526. https://doi.org/10.1016/j.lwt.2006.11.010

Xie Z, Huang J, Hu X, Jin Z (2008) Antioxidant activity of peptides isolated from alfalfa leaf protein hydrolysate. Food Chem 111:370–376. https://doi.org/10.1016/j.foodchem.2008.03.078

Y. Y. Wang, C. Y. Wang, S. T. Wang, Y. Q. Li, H. Z. Mo, J. X. He, Physicochemical properties and antioxidant activities of tree peony (Paeonia suffruticosa Andr.) seed protein hydrolysates obtained with different proteases, Food Chem. 345 (2021) https://doi.org/10.1016/j.foodchem.2020.128765.

JA do Evangelho, NL Vanier, VZ Pinto, JJ De Berrios, ARG Dias, E da Rosa Zavareze, Black bean (Phaseolus vulgaris L) protein hydrolysates: Physicochemical and functional properties. Food Chem 214 (2017) 460–467

Chiu C, Santoyo M, Lara E, Sanchez JA (2021) Jackfruit (Artocarpus heterophyllus Lam) leaf as a new source to obtain protein hydrolysates: physicochemical characterization, techno-functional properties and antioxidant capacity. Food Hydrocoll 112:106319. https://doi.org/10.1016/j.fochx.2021.100138

A. Sodamade, M. Raimi, A. D. Owonikoko, A. T. Adebimpe, nutritive evaluation, mineral composition and phytochemical analysis of leaf protein concentrates of Daucus carota, Braz. J. Sci. Technol. 36 (2019) 57–68, https://www.ijtsrd.com/papers/ijtsrd26427.pdf.

Benhammouche T, Melo A, Martins Z, Faria MA, Pinho SC, Ferreira IM, Zaidi F (2021) Nutritional quality of protein concentrates from Moringa Oleifera leaves and in vitro digestibility. Food Chem 348:128858. https://doi.org/10.1016/j.foodchem.2020.128858

Ali MA, El Tinay AH, Ahmed IA, Babiker EE (2009) Supplementation of pearl millet with soybean: changes in protein digestibility, amino acid composition and sensory quality during processing. Elec J Environ Agric Food Chem 8:1068–1076

Fasuan TO, Omobuwaio TO, Gbadamosi SO (2018) Optimization of simultaneous recovery of oil and protein from sesame (Sesamum indicum) seed. J Food Process Preserv 42:1–10. https://doi.org/10.1111/jfpp.13341

Adiamo OQ, Gbadamosi OS, Abiose SH (2016) Functional properties and protein digestibility of protein concentrates and isolates produced from Kariya (H ildergadia bateri) seed. J Food Process Preserv 40:979–989. https://doi.org/10.1111/jfpp.12678

Adewumi OO, Felix-Minnar JV, Jideani VA (2022) Functional properties and amino acid profile of Bambara groundnut and Moringa oleifera leaf protein complex. Processes 10:205. https://doi.org/10.3390/pr10020205

Toews R, Wang N (2013) Physicochemical and functional properties of protein concentrates from pulses. Food Res Int 52:193–198. https://doi.org/10.1016/j.foodres.2012.12.009

Pumilia G, Chicon MJ, Cooperstone JL, Guffrida D, Dugo G, Schwartz SJ (2014) Changes in chlorophylls, chlorophyll degradation products and lutein in pistachio kernels (Pistacia vera L) during roasting. Food Res Int 65:193–198. https://doi.org/10.1016/j.foodres.2014.05.047

Ozdal T, Capanoglu E, Altay F (2013) A review on protein–phenolic interactions and associated changes. Food Res Int 51:954–970. https://doi.org/10.1016/j.foodres.2013.02.009

A. Sodamade, O. S. Bolaji, O. Adeboye, proximate analysis, mineral contents and functional properties of Moringa oleifera leaf protein concentrate. J Appl Chem (2013) 47-51, 10.6084/M9.FIGSHARE.1097420.

National Research Council, Recommended dietary allowances (1989).

Kudre TG, Benjakul S, Kishimura H (2013) Comparative study on chemical compositions and properties of protein isolates from mung bean, blac k bean and bambara groundnut. J Food Sci Agric 93:2429–2436. https://doi.org/10.1002/jsfa.6052

Krimm S, Bandekar J (1986) Vibrational spectroscopy and conformation of peptides, polypeptides, and proteins. Adv Protein Chem 38:181–364. https://doi.org/10.1016/S0065-3233(08)60528-8

Akyuz S, Akyuz T, Celik O, Atak C (2018) FTIR spectroscopy of protein isolates of salt-tolerant soybean mutants. J Appl Spectrosc 84:1019–1023. https://doi.org/10.1007/s10812-018-0580-1

Chen X, Ru Y, Chen F, Wang X, Zhao X, Ao Q (2013) FTIR spectroscopic characterization of soy proteins obtained through AOT reverse micelles. Food Hydrocoll 31:435–437. https://doi.org/10.1016/j.foodhyd.2012.11.017

Liu CM, Peng Q, Zhong JZ, Liu W, Jhong YJ, Wang F (2018) Molecular and functional properties of protein fractions and isolate from cashew nut (Anacardium occidentale L.). Molecules 23:393. https://doi.org/10.3390/molecules23020393

Piotrowicz BB, Salas-Mellado MM (2017) Protein concentrates from defatted rice bran: preparation and characterization. Food Sci Technol 37:165–172. https://doi.org/10.1590/1678-457X.34816

Sun C, Tang X, Ren Y, Wang E, Shi L, Wu X, Wu H (2019) Novel antioxidant peptides purified from mulberry (Morus Atropurpurea Roxb.) leaf protein hydrolysates with hemolysis inhibition ability and cellular antioxidant activity. J Agric Food Chem 67:7650–7659. https://doi.org/10.1021/acs.jafc.9b01115

Sun X, Zhang W, Zhang L, Tian S, Chen F (2020) Molecular and emulsifying properties of arachin and conarachin of peanut protein isolate from ultrasound-assisted extraction 132:109790. https://doi.org/10.1016/j.lwt.2020.109790

Fernandez-Quintela MT, Del Macarulla AS, Barrio JA (1997) Martinez, Composition and functional properties of protein isolates obtained from commercial legumes grown in northern Spain. Plant Food Hum Nutr 51:331–341. https://doi.org/10.1023/a:1007936930354

Fasuyi O, Aletor VA (2005) Varietal composition and functional properties of cassava (Manihot esculenta, Crantz) leaf meal and leaf protein concentrates. Pak J Nutr 4:43–39. https://doi.org/10.3923/pjn.2005.43.49

Subagio A (2006) Characterization of hyacinth bean (Lablab purpureus (L.) sweet) seeds from Indonesia and their protein isolate. Food Chem. 95:65–70. https://doi.org/10.1016/j.foodchem.2004.12.042

Ghribi M, Gafsi IM, Blecker C, Danthine S, Attia H, Besbes S (2015) Effect of drying methods on physico-chemical and functional properties of chickpea protein concentrates. J Food Eng 78:179–188. https://doi.org/10.1016/j.jfoodeng.2015.06.021

Aletor O, Oshodi AA, Ipinmoroti K (2002) Chemical composition of common leafy vegetables and functional properties of their leaf protein concentrates. Food Chem 78:63–68. https://doi.org/10.1016/S0308-8146(01)00376-4

Damodaran S (1997) Protein-stabilized foams and emulsions. Food Sci Technol 70:54–66

Shevkani K, Singh N, Kaur A, Rana JC (2015) Structural and functional characterization of kidney bean and field pea protein isolates: a comparative study. Food Hydrocoll. 43:679–687. https://doi.org/10.1016/j.foodhyd.2014.07.024

Ogunwolu SO, Henshaw FO, Mock HP, Santros A, Awonorin SO (2009) Functional properties of protein concentrates and isolates produced from cashew (Anacardium occidentale L.) nut. Food Chem 115:852–858

Cheng J, Zhou S, Wu D, Chen J, Liu D, Ye X (2009) Bayberry (Myrica rubra Sieb. et Zucc) kernel: A new protein source. Food Chem 112:469–473

Garcia-Monero F, Solorzano E, Banhart J (2011) Kinetics of coalescence in liquid aluminium foams. Soft Matter 7:9216–9223. https://doi.org/10.1039/C1SM05831B

Cano-Medina A, Jimenez-Islas H, Dendooven L, Herrera RP, Gonzalez-Alatorre G, Escamilla-Silva EM (2011) emulsifying and foaming capacity and emulsion and foam stability of sesame protein concentrates. Food Res Int 44:684–692. https://doi.org/10.1016/j.foodres.2010.12.015

Wu H, Wang Q, Ma T, Ren J (2009) Comparative studies on the functional properties of various protein concentrate preparations of peanut protein. Food Res Int 42:343–348. https://doi.org/10.1016/j.foodres.2008.12.006

Fasuyi O (2006) Nutritional potentials of some tropical vegetable leaf meals: chemical characterization and functional properties. Afr J Biotechnol 5:49–53. https://doi.org/10.12691/jnh-3-1-3

FSSAI Specifications (2018) for dehydrated vegetable products. https://archive.fssai.gov.in

Acknowledgements

The authors acknowledge the Head, Department of Processing and Food Engineering and All India Coordinated Research Project on Post-harvest Engineering and Technology under ICAR, New Delhi, India, for providing facilities to carry out this research work.

Author information

Authors and Affiliations

Contributions

Methodology, laboratory research, investigation, data curation, writing (original draft preparation), Gurkanwal Kaur; conceptualization, supervision, writing (review and editing), Dr Surekha Bhatia.

Corresponding author

Ethics declarations

Ethical approval

This material is the authors’ own original work, which has not been previously published elsewhere.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• α-Amylase, protease, and xylanase were used to extract leaf protein concentrates from Raphanus sativus L. leaves.

• α-Amylase-assisted extraction showed maximum extraction yield (10.22%) and protein content (66.93%).

• Optimization of α-amylase-assisted extraction done using response surface methodology.

• At optimized extraction temperature (42.8 °C), amylase concentration (18446 U), and extraction time (4.44 h), a considerable extraction yield of 9.56% and protein content of 89.41% were obtained.

• High antioxidant activity, desirable functional properties, and acceptable microbial stability in protein concentrates.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaur, G., Bhatia, S. Alpha-amylase-assisted extraction of protein concentrates from Raphanus sativus L. leaves. Biomass Conv. Bioref. 13, 15051–15065 (2023). https://doi.org/10.1007/s13399-022-03611-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03611-w