Abstract

Gallic acid is a phenolic organic acid found in plants that has a wide range of applications, as a health-promoting agent and as a food preservative, due to its high antioxidant activity. Gallic acid can be obtained by acid hydrolysis of tannic acid or by the enzymatic action of tannase on tannic acid. A biorefinery approach to produce gallic acid was developed. A combination of grape pomace and soybean hull as support substrate was used for solid-state fermentation by Aspergillus niger and Aspergillus oryzae. The best conditions for the bioconversion of tannic acid to gallic acid were tested. Tannase and other relevant enzymes were produced in the same process. The gallic acid production was monitored and quantified by high-performance thin-layer chromatography (HPTLC). HPTLC was used to separate the phenolic extracts prepared, and bioautography by gel overlay was used to identify antioxidants and tyrosinase inhibitors directly on the plate. The best gallic acid producer was A. oryzae, and the best fermentation condition comprised soybean hull and grape pomace as support substrate, producing 0.36 g of gallic acid/g of tannic acid and 7.2 g/L of fermentation medium in 72 h of incubation. The value addition of these agricultural wastes through a green process to produce gallic acid was demonstrated, creating opportunities for solid waste usage.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Polyphenols are plant secondary metabolites found in fruits, vegetables, and seeds. The incorporation of these metabolites has been associated with lowering the risks related to chronic and age-related degenerative diseases. They have a wide range of applications as food, pharmaceutical, and cosmetic additives [1]. There is an increasing demand of natural food and cosmetic ingredients to replace the synthetic ones, and plant-derived bioactives such as polyphenols are excellent candidates as natural antioxidants. Also, some polyphenols have been reported as inhibitors of tyrosinase enzymes [2]. Tyrosinase (EC 1.14.18.1) is a copper-containing monooxygenase enzyme widely distributed in microorganisms, animals, and plants that produces enzymatic browning in fruits and vegetables; and excessive production of melanin in the human skin that can give rise to freckles, melasma, malignant melanoma, and degenerative diseases [3]. Tyrosinase inhibitors can be found in both synthetic [4] and natural sources [5], but the latter can have fewer constraints regarding their toxicity. In that sense, natural sources can provide novel and safe tyrosinase inhibitors for the food, cosmetic, and medicinal fields.

Polyphenols can be conveniently obtained from residual biomasses [1, 5, 6]. In particular, gallic acid (3,4,5-trihydroxybenzoic acid) is a low molecular weight triphenolic compound largely found in its free or bound form in gallnuts, oak bark, and tea leaves [7, 8]. Other sources include oak bark; berries, pomegranate, mango, and other fruits; vegetables; and beverages including wine [9]. Gallic acid is a precursor for the synthesis of trimethoprim, an antibacterial agent, and gallate esters, such as pyrogallol, that serve as preservatives in the food industry [10]. In addition, gallic acid has received much attention in the last decade, for its antioxidant, antibacterial, anticarcinogenic, antiallergic, and anti-inflammatory activities [11, 12]. Acid hydrolysis of tannic acid is the conventional method to produce gallic acid, but it presents some drawbacks regarding the cost and yield of the process [13]. Therefore, microbial and enzymatic conversions of tannic acid to gallic acid are attractive strategies for overcoming these drawbacks [14]. Tannase (EC 3.1.1.20) catalyzes the hydrolysis of tannic acid to produce glucose and gallic acid. Previous studies have shown the conversion of tannic acid to gallic acid in fermentation conditions in which tannase is produced by a microorganism. In some cases, substrate supplementation was required [15], or synthetic support was needed for fungi solid-state fermentation (SSF) [16]. In other cases, SSF was performed in tannin-rich biomasses, but the gallic acid yield is much lower than that retrieved from the conversion of tannic acid [14, 17].

The present study aimed to test a combination of both strategies, by using polyphenol-rich agri-food waste, soybean hull, and grape pomace, as support substrate for the conversion of tannic acid to gallic acid by tannase-producing filamentous fungi. In this biorefinery approach, gallic acid and relevant industrial enzymes are produced simultaneously. Aspergillus niger and Aspergillus oryzae were used for this purpose, and the production of tannase and carbohydrate-degrading enzymes was tested, including pectinase, cellulase, and α-amylase, which can help in the liberation of gallic acid and other polyphenols from the biomasses [18]. To visualize the potential bioactivities of the extracts, the resulting polyphenols were analyzed by high-performance thin-layer chromatography (HPTLC), in which plate development was followed by agar gel bioautography. By combining simultaneous chromatographic separation and localization of bioactivity patterns, we could confirm extracts’ potential as antioxidants and tyrosinase inhibitors.

2 Materials and methods

2.1 Materials

Grape pomaces of red wine grapes (Vitis vinifera L.) of Malbec and Tannat varieties were obtained from an Argentinian winery (Tunuyán, Mendoza Province) and used at a 1:1 ratio. Soybean (Glycine max) hull was obtained from a soybean crush plant (Molinos S.A, Santa Fe, Argentina). Aspergillus oryzae NRRL695 and Aspergillus niger NRRL3 (NRRL culture collection) were obtained from the National Center for Agricultural Utilization Research (ARS), United States Department of Agriculture (USDA), USA. Folin-Ciocalteu’s phenol reagent, ABTS (2,2′-azino-bis (3-ethyl-benzothiazoline-6-sulfonic acid) diammonium salt), gallic acid (GA), carboxymethylcellulose, pectin from citrus peel, and tannic acid (TA) were from Sigma-Aldrich (St. Louis, Missouri, USA). The growth culture medium of Potato Dextrose Agar (PDA) was from Britania Lab (CABA, Argentina).

2.2 Grape pomace and soybean hull preparation for the solid-state fermentation

Grape pomace (GP), consisting of residual grape seeds, pulp, and skins, was collected after winemaking fermentation in wineries and stored frozen at − 20 °C until processing in the laboratory. Grape pomace was dried in a drying oven at 60 °C (San-Jor, SL60SDB, San Andrés, Buenos Aires, Argentina) to reach a final moisture content of 5% and milled in coffee grinders to a particle size of 0.25–2.38 mm (sieved by mesh No. 60 and No. 8). The soybean hull (SH) was used as received after mechanical separation in the soybean processing plant, without any additional processing.

2.3 Propagation of fungi and inoculum preparation

A. niger and A. oryzae were grown in PDA culture media, supplemented with 0.01% w/v of tannic acid. Culture growth was performed at 30 °C for 5 days. Conidia were re-suspended in a Tween-80 solution at 0.02% v/v by magnetic stirring for 30 min. The count of conidia was performed in a Neubauer counting chamber.

2.4 SSFs of A. niger and A. oryzae using grape pomace and/or soybean hull as support substrate and preparation of extracts from cultures

Grape pomace, soybean hull, or a combination of both at a 1:1 ratio was used as support substrate for the SSF systems, and the moisture content was adjusted by the addition of aliquots of “Modified Czapex Dox” (NaNO3 0.25% w/v, KH2PO4 0.1% w/v de, MgSO4.7H2O 0.05% w/v, and KCl 0.05% w/v) adjusted at pH 5.50, as previously described (Treviño-Cueto et al., 2007). Glass flasks were employed as reactors by the addition of defined amounts of solid support substrate (2 g) and liquid medium (10 mL) to reach 84% of moisture content (considering the 5% moisture content of the grape pomace). The flasks were autoclaved at 121 °C for 20 min. After cooling down, tannic acid 2% w/v was added after sterilization by filtration with a 0.22-µm regenerated cellulose filter.

A. niger and A. oryzae were inoculated to reach a final concentration of 1 × 107 conidia/g of support substrate in each system, as previously reported as optimal for SSF of A. oryzae (Melnichuk et al., 2020). A control without inoculum was always run in parallel. The systems were incubated at a constant temperature of 30 °C for 72 h in a laboratory incubator (San Jor SL60SDB, San Andrés, Buenos Aires, Argentina).

After SSF, distilled water was added to the flasks to reach a solid:liquid ratio of 1:20, and the systems were incubated under continuous orbital agitation at 120 rpm at 45 °C (Infors HT incubation shaker, Ecotron model, Bottmingen, Switzerland) for 30 min. After the extraction, samples were filtered through a cloth fabric filter, centrifuged, and filtered with a 0.45-μm nylon syringe filter (Sartorius, Minisart NY, Goettingen, Germany).

2.5 Determination of tannase activity

Tannase enzyme activity was measured with the methanolic rhodanine method, which uses methyl gallate as a substrate, as previously described [19]. One tannase enzyme unit (U) is defined as the amount of enzyme which produces 1 µmol of gallic acid per min of reaction.

2.6 Determination of pectinase activity

Polygalacturonase activity was determined using pectin from citrus peel as substrate, and a second reaction was coupled to the main reaction to determine reducing sugars based on the 3,5-dinitrosalicylic acid (DNS) assay described by Miller [20]. The product generated is galacturonic acid. One enzyme unit (U) is defined as the amount of enzyme that releases 1 µmol of galacturonic acid per minute under the conditions of the assay [21].

2.7 Determination of cellulase activity

For endoglucanase determination, carboxymethyl cellulose (CMC) was used as a substrate. The product of the reaction was glucose, which was detected by the DNS assay [20]. The amount of enzyme that releases 1 µmol of glucose per minute under the conditions of the assay is defined as one enzyme unit (U) [22].

2.8 Determination of total phenolics

The Folin-Ciocalteu method was used for total phenolic determination as previously described [23]. In general, dilutions of the extracts between 1/5 and 1/20 were used for the assay. Determinations were made in triplicates, and results were expressed in g of gallic acid equivalents (GAE)/100 g of GP or GP + SH, denoted as solid substrate (SS).

2.9 Determination of antioxidant activity

The improved 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS) free radical scavenging assay was used [24]. In general, dilutions of the extracts between 1/5 and 1/20 were employed for the assay. The standard curve was prepared using Trolox. Determinations were made in triplicates, and results were expressed as mmol Trolox equivalents (TE)/100 g of GP or GP + SH, denoted as solid substrate (SS).

2.10 High-performance thin-layer chromatography (HPTLC) and quantification of gallic acid

HPTLC was carried out on TLC aluminum-backed silica gel 60 F254 plates of 7 cm height (Merck, Darmstadt, Germany). Samples were applied in 4-mm bands using a CAMAG Automatic HPTLC Sampler 4 (ATS 4) under air flux.

Development was performed in a twin-through chamber with a mixture containing ethyl acetate:methanol:acetic acid (100:30:10) that was modified from the phenolic acid technique [25] in order to maintain the gallic acid spot migration in an adequate area for quantification. The migration time was 15 min up to the migration distance of 70 mm from the lower edge of the plate. The chromatogram was dried in a stream of air for 20 min (hair dryer). After solvent evaporation, HPTLC images were captured under white light and UV light with a CAMAG HPTLC Visualizer. For gallic acid quantification, a calibration curve was prepared spotting increasing quantities of gallic acid (0.2–1.8 µg) on different lanes of the plate, and absorbance was determined at 273 nm.

2.11 ABTS and tyrosinase-based TLC bioautographies

In a typical 140 cm2 TLC-ABTS sheet, the staining solution for the antioxidant assay was prepared by dissolving agar (190 mg) at 90 °C in water (20 mL). The solution was allowed to cool to 40 °C and the ABTS radical solution was added (260 µL). ABTS was prepared as in Sect. 2.9 but avoiding dilution. Active compounds were visualized as clear spots on the blue-green background, TLC plates were scanned at 734 nm, and then plates were photographed at white light illumination.

In a typical 140 cm2 TLC-TYR sheet, the staining solution for the tyrosinase inhibition assay was prepared by dissolving agar (270 mg) at 90 °C in sodium phosphate buffer (20 mM, pH 6.8, 22.4 mL) (Paula García & Furlan, 2015). The solution was allowed to cool to 55 °C and the L-tyrosine solution (2.5 mM, 5.6 mL) was added. At 35 °C, tyrosinase solution (3800 U/mL, 260 µL) was added. Active compounds were visualized as clear spots on the brownish background, and TLC plates were photographed under white light and scanned at 475 nm for the best contrast.

2.12 Statistical analysis

All the experiments were performed in triplicates. A T-test was used to compare the means between the two groups. One-way ANOVA followed by multiple comparisons by the Tukey test was used to compare more than two groups. Two-way ANOVA followed by the Sidak multiple comparison test was used when necessary. Analyses were performed using GraphPad Prism version 8.00 for Windows, GraphPad Software, San Diego, CA, USA.

3 Results

3.1 SSFs of A. niger and A. oryzae using grape pomace and soybean hull as support substrate and tannic acid as tannase inductor

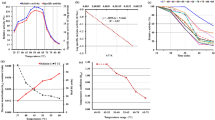

SSFs of A. niger and A. oryzae were conducted using a combination of grape pomace and soybean hull as support substrate (1:1), with an 84% moisture content, for 72 h at 30 °C. In these conditions, relevant enzymatic activities were induced, such as cellulase, pectinase, and α-amylase (Fig. 1). The production of cellulase by A. niger was significantly higher than that by A. oryzae when the combination of grape pomace and soybean hull was used as support substrate (p < 0.01). The inclusion of soybean hull favored the production of cellulase in both fungi. In the case of tannase, the addition of tannic acid at a concentration of 2% w/v induced its production in both fungi, and this induction was greater (p < 0.05) in the presence of grape pomace. A. oryzae produced more tannase than A. niger, although the differences found were not significant (p > 0.05). Regarding the production of pectinase, in the case of A. niger, it was significantly higher (p < 0.05) when soybean hull was used as support substrate with the addition of tannic acid 2% w/v, while in A. oryzae it was significantly higher (p < 0.05) when soybean hull and grape pomace were used as support substrate with the addition of tannic acid 2% w/v. No significant difference (p > 0.05) was observed between both fungi in the case of pectinase production. The production of α-amylase by both fungi was similar for all the support substrate tested, but A. oryzae production was significantly greater than that of A. niger (p > 0.05).

Enzymatic profile of the SSF system using grape pomace (GP), soybean hull (SH), or a combination of both with and without tannic acid (TA) addition. A Aspergillus niger. B Aspergillus oryzae. Different letters denote significant difference between groups (p < 0.05) for each enzymatic activity and fungus. A greater production of one enzyme by one of the fungi in a specific condition is indicated as follows: *p < 0.05; **p < 0.01. SS stands for solid substrate

When grape pomace and soybean hull were used as substrate support in the absence of tannic acid, the total phenolic content of the extracts after SSF was not increased (Fig. 2A). The addition of tannic acid at a concentration of 2% w/v gave rise to an increase in the total phenolic content (Fig. 2A) and antioxidant activity (Fig. 2B) of the extracts. This effect was observed with soybean hull as support substrate, but was only significant in the A. oryzae SSF extract (p > 0.05). When grape pomace was used as support substrate, alone or in combination with soybean hull, both fungi produced a significant increase in the total phenolic content and antioxidant activity (p > 0.05). This trend correlates with the production of the tannase enzyme.

Extraction yields of total polyphenols and antioxidant activity after A. niger and A. oryzae SSFs using as support soybean hull (SH), grape pomace (GP) or a combination of both, and tannic acid (TA). GAE, gallic acid equivalent; SS, solid substrate; TE: trolox equivalent. Different letters denote significant difference between groups (p < 0.05). SS stands for solid substrate

3.2 Quantification of gallic acid in SSF extracts by HPTLC

HPTLC was performed to identify and quantify the major component of the polyphenol extract. The resulting fingerprints of the samples are shown in Fig. 3A and B (detection at 365 and 266 nm, respectively). Gallic acid was run in parallel for the identification and quantification of the corresponding bands in the samples (GA, Rf = 0.8). Gallic acid was detected at a very low amount in cultures with no tannic acid. The results corresponding to gallic acid quantification in the SSFs with added tannic acid are shown in Fig. 4. In the case of A. oryzae SSFs, a significant increase is observed in gallic acid yield with respect to the corresponding controls in all the systems tested as solid support substrate. In the case of A. niger, a significant increase in gallic acid production was observed when grape pomace or grape pomace/soybean hull was used as support substrate, but not when soybean hull was used alone. The maximum yield of gallic acid—0.36 ± 0.02 mg/mg of tannic acid—was obtained in the SSF of A. oryzae using the combination of grape pomace/soybean hull.

Characterization of the extract composition by HPTLC-bioautography. (A) Detection at 365 nm. (B) Detection at 266 nm. (C) Bioautography detection of antioxidant compounds through ABTS radical scavenging assay at 734 nm. (D) Bioautography detection of tyrosinase inhibitors at 475 nm. SH, soybean hull; GP, grape pomace; GA, gallic acid; KA, kojic acid; TA, tannic acid

Although other few bands were also visualized at UV 365 and 266 nm (Fig. 3A and B), gallic acid was apparently one of the most abundant components in the SSFs with tannic acid. A. oryzae is a well-known producer of kojic acid, which has antioxidant and tyrosinase inhibitory properties. Therefore, we seeded the compound in the TLCs, but it was not detected in any of the samples (KA, Rf = 0.7), (Fig. 3A and B).

3.3 Bioautography detection of antioxidant compounds

The extracts obtained after SSFs showed increased antioxidant activity as described in Sect. 2.1. To identify the main compounds responsible for that activity, we conducted an effect-directed analysis of antioxidants. Once the plate was spotted and developed, the ABTS*+ radical was immobilized in agar gel and the bands corresponding to compounds with antioxidant activity appeared as white spots against the blueish-green background. As shown in Fig. 3C, the most outstanding antioxidant clear white spots correspond to gallic acid (Rf = 0.8). In those samples in which gallic acid was not produced at a high concentration, clear spots were found at the origin of the plate (Rf = 0.0). These spots are likely related to tannic acid or other phenolics of great MW from the extracts. Nonetheless, the antioxidant activity was more prominent in the bands corresponding to gallic acid, in accordance with the increase observed in the total antioxidant activity of the extracts (Fig. 2). Therefore, the biotransformation of the added tannic acid and the tannins present in the agro-industrial waste produced extracts with increased antioxidant activity, mainly related to the production of gallic acid.

3.4 Bioautography detection of tyrosinase inhibitors

In order to detect anti-tyrosinase activity in the extracts, we used the improved agar gel version of the assay with entrapped tyrosinase [26]. Gel containing tyrosinase covered the plate with a brownish background, and active compounds inhibiting tyrosinase appeared as white zones. As shown in Fig. 3D, inhibition was detected in the zones matching with the Rf of gallic acid (Rf = 0.8).

4 Discussion

The conventional process for the preparation of gallic acid entails acid-mediated hydrolysis of synthetic tannic acid or tannin-rich materials. This process presents some drawbacks regarding less purity, low yield, high cost, and the release of toxic effluents to the environment. Previous studies have reported the conversion of tannic acid to gallic acid through the fermentation of a tannase-producing microorganism. Sporidiobolus ruineniae was shown to produce 11.2 g/L gallic acid from 12.3 g/L tannic acid and 31.1 mU/mL of the tannse activity after 48 h of cultivation in a 1-L stirred tank fermenter, i.e., a 90% conversion. In this case, the culture medium was supplemented with 10 g/L yeast extract, 2 g/L (NH4)2SO4, 0.5 g/L Tween-80, 6.91 g/L glucose, and 1 g/L glutamate [15], all of which increase the cost of the process. A. niger Aa-20 produced 7.64 g/L gallic acid from 12.5 g/L tannic acid (60% conversion) with a maximum tannase activity of 2479 U/L in a SSF process using polyurethane matrices as support substrate [16]. These synthetic matrices can increase the cost of the process and its impact on the environment. Bioconversion of tannic acid to gallic acid by Aspergillus aculeatus DBF9 retrieved a yield of 6 g/L gallic acid from 30 g/L tannic acid in optimized conditions [27], i.e., a 20% conversion. Anaerobic fermentation of B. subtilis AM1 and Lactobacillus plantarum CIR1 in 10 g/L tannic acid and under non-optimized conditions resulted in maximum levels of tannase activity of 1400 and 1239 U/L and gallic acid contents of 2.41 and 2.37 g/L, respectively, around a 24% conversion in these cases [28]. When biomass was used as the source of tannins for gallic acid production in attempts to valorize agro-industrial wastes, lower amounts of gallic acid were obtained [14, 17]. This was attributed to the presence of sugars in the agro-industrial wastes that are more accessible and promote the growth of the fungus [29]. In addition, the tannin concentration may not be enough to reach the minimum necessary quantity for induction, which is between 1 and 2% v/w for tannic acid [30]. In light of our results, both Aspergillus spp. produced a very low level of tannase in the absence of tannic acid (Fig. 1A and B). With lower amounts of the inductor, lower amounts of tannase being produced and lower amounts of gallic acid obtained when agro-industrial wastes are used as the sole source of tannins.

An integrated strategy was evaluated, in which agro-industrial wastes, soybean hull and grape pomace, are used for a double purpose as support substrate, while tannic acid is added for its conversion. In this way, supplementation with costly ingredients and the usage of synthetic matrices were avoided. At the same time, high production of gallic acid was achieved. The biomass with an initial concentration of tannic acid of 20 g/L produced 7.2 g/L of gallic acid in the best condition—A. oryzae SSF in soybean hull + grape pomace + tannic acid, 72 h at 30 °C—i.e., 0.36 ± 0.03 g gallic acid/g tannic acid (Fig. 4). At the same time, the tannase enzyme is produced at a high yield, ca. 6000 U/mL. In addition, other relevant enzymes can be recovered from the extracts, including cellulase, pectinases, and α-amylases. The general scheme of the proposed biorefinery is shown in Fig. 5. Also, the enzymes, partially purified or in combination, could be used for direct treatment of grape pomace or soybean hull for the liberation of a variety of polyphenols as has been previously reported for tannase, cellulase, pectinase, and α-amylase in grape pomace and soybean hull [31,32,33].

The successful SSF of soybean hull and grape pomace mixed waste allowed to produce gallic acid, a phenolic compound with strong free radical scavenging activity. Previous studies have shown the inhibitory effect of gallic acid in mushroom tyrosinase activity with a low IC50 value (3.59 × 10−6 M) in comparison with kojic acid (59.72 × 10−6 M), with no cytotoxicity effect in the range of 50–400 µM [30]. The present study showed that gallic acid’s dual role as antimelanogenic and antioxidative agents are preserved in fungi extracts and can be assessed using TLC bioautographies. In this way, a process for the production of gallic acid–enriched polyphenol extracts through SSF and a practical method for bioactivity assessment is provided.

5 Conclusions

In this study, a biorefinery scheme was developed to produce gallic acid from tannic acid along with relevant industrial enzymes, based on the reutilization of soybean hull and grape pomace. The combination of SSF by tannase-producing fungi and aqueous extraction allowed us to obtain polyphenol extracts substantially enriched with gallic acid. The aqueous extracts showed increased antioxidant activity, and HPTLC-based bioautography showed high antioxidant activity and anti-tyrosinase activity that could be assigned to gallic acid. The gallic acid–enriched extract could be used as a natural ingredient with valuable bioactivities in foods and cosmetics. The process also leads to the production of a high yield of tannase and carbohydrase enzymes. The SSF is a process that can generally save energy, which is clean and reduces waste consumption. The procedure is an environmentally green approach that could be adapted to other by-product combinations.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Guerrini A, Burlini I, Huerta Lorenzo B et al (2020) Antioxidant and antimicrobial extracts obtained from agricultural by-products: strategies for a sustainable recovery and future perspectives. Food Bioprod Process 124:397–407. https://doi.org/10.1016/j.fbp.2020.10.003

Solimine J, Garo E, Wedler J et al (2016) Tyrosinase inhibitory constituents from a polyphenol enriched fraction of rose oil distillation wastewater. Fitoterapia 108:13–19. https://doi.org/10.1016/j.fitote.2015.11.012

Shi F, Xie L, Lin Q et al (2020) Profiling of tyrosinase inhibitors in mango leaves for a sustainable agro-industry. Food Chem 312:126042. https://doi.org/10.1016/j.foodchem.2019.126042

Cabezudo I, Ayelen Ramallo I, Alonso VL, Furlan RLE (2021) Effect directed synthesis of a new tyrosinase inhibitor with anti-browning activity. Food Chem 341:128232. https://doi.org/10.1016/j.foodchem.2020.128232

Maalej A, Elloumi W, Angelov I et al (2021) Pistacia lentiscus by-product as a promising source of phenolic compounds and carotenoids: purification, biological potential and binding properties. Food Bioprod Process 126:245–255. https://doi.org/10.1016/j.fbp.2021.01.011

Fonseca CS, da Silva NR, Ballesteros LF et al (2022) Penicillium brevicompactum as a novel source of natural pigments with potential for food applications. Food Bioprod Process 132:188–199. https://doi.org/10.1016/j.fbp.2022.01.007

Yilmaz Y, Toledo RT (2004) Major flavonoids in grape seeds and skins: antioxidant capacity of catechin, epicatechin, and gallic acid. J Agric Food Chem 52:255–260. https://doi.org/10.1021/jf030117h

Zhou X, Zeng L, Chen Y et al (2020) Metabolism of gallic acid and its distributions in tea (Camellia sinensis) plants at the tissue and subcellular levels. Int J Mol Sci 21:E5684. https://doi.org/10.3390/ijms21165684

Badhani B, Sharma N, Kakkar R (2015) Gallic acid: a versatile antioxidant with promising therapeutic and industrial applications. RSC Adv 5:27540–27557. https://doi.org/10.1039/C5RA01911G

AL Zahrani NA, El-Shishtawy RM, Asiri AM (2020) Recent developments of gallic acid derivatives and their hybrids in medicinal chemistry: a review. Eur J Med Chem 204:112609. https://doi.org/10.1016/j.ejmech.2020.112609

Choubey S, Goyal S, Varughese LR et al (2018) Probing gallic acid for its broad spectrum applications. Mini Rev Med Chem 18:1283–1293. https://doi.org/10.2174/1389557518666180330114010

Verma S, Singh A, Mishra A (2013) Gallic acid: molecular rival of cancer. Environ Toxicol Pharmacol 35:473–485. https://doi.org/10.1016/j.etap.2013.02.011

Bajpai B, Patil S (2008) A new approach to microbial production of gallic acid. Braz J Microbiol 39:708–711. https://doi.org/10.1590/S1517-838220080004000021

Treviño-Cueto B, Luis M, Contreras-Esquivel JC et al (2007) Gallic acid and tannase accumulation during fungal solid state culture of a tannin-rich desert plant (Larrea tridentata Cov.). Bioresour Technol 98:721–724. https://doi.org/10.1016/j.biortech.2006.02.015

Kanpiengjai A, Khanongnuch C, Lumyong S et al (2020) Co-production of gallic acid and a novel cell-associated tannase by a pigment-producing yeast, Sporidiobolus ruineniae A45.2. Microb Cell Factories 19:95. https://doi.org/10.1186/s12934-020-01353-w

Treviňo L, Contreras-Esquivel JC, Rodríguez-Herrera R, Aguilar CN (2007) Effects of polyurethane matrices on fungal tannase and gallic acid production under solid state culture. J Zhejiang Univ Sci B 8:771–776. https://doi.org/10.1631/jzus.2007.B0771

Saeed S, Aslam S, Mehmood T et al (2021) Production of gallic acid under solid-state fermentation by utilizing waste from food processing industries. Waste Biomass Valorization 12:155–163. https://doi.org/10.1007/s12649-020-00980-z

Teles ASC, Chávez DWH, Oliveira RA et al (2019) Use of grape pomace for the production of hydrolytic enzymes by solid-state fermentation and recovery of its bioactive compounds. Food Res Int 120:441–448. https://doi.org/10.1016/j.foodres.2018.10.083

Sharma S, Bhat TK, Dawra RK (2000) A spectrophotometric method for assay of tannase using rhodanine. Anal Biochem 279:85–89. https://doi.org/10.1006/abio.1999.4405

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Gupta MN, Dong G, Mattiasson B (1993) Purification of endo-polygalacturonase by affinity precipitation using alginate. Biotechnol Appl Biochem 18(Pt 3):321–327

Ncube T, Howard RL, Abotsi EK et al (2012) Jatropha curcas seed cake as substrate for production of xylanase and cellulase by Aspergillus niger FGSCA733 in solid-state fermentation. Ind Crops Prod 37:118–123. https://doi.org/10.1016/j.indcrop.2011.11.024

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic 16:144–158

Re R, Pellegrini N, Proteggente A et al (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26:1231–1237

Wagner H, Bladt S (1996) Plant drug analysis: a thin layer chromatography atlas. Springer Science & Business Media

García P, Furlan RLE (2015) Multiresponse optimisation applied to the development of a TLC autography for the detection of tyrosinase inhibitors. Phytochem Anal 26:287–292. https://doi.org/10.1002/pca.2562

Banerjee D, Mahapatra S, Pati BR (2007) Gallic acid production by submerged fermentation of Aspergillus aculeatus DBF9. Res J Microbiol 2:462–468. https://doi.org/10.3923/jm.2007.462.468

Aguilar-Zárate P, Cruz MA, Montañez J et al (2015) Gallic acid production under anaerobic submerged fermentation by two bacilli strains. Microb Cell Factories 14:209. https://doi.org/10.1186/s12934-015-0386-2

Aboubakr HA, El-Sahn MA, El-Banna AA (2013) Some factors affecting tannase production by Aspergillus niger Van Tieghem. Braz J Microbiol 44:559–567. https://doi.org/10.1590/S1517-83822013000200036

Meini M-R, Ricardi LL, Romanini D (2019) Novel routes for valorisation of grape pomace through the production of bioactives by Aspergillus niger. Waste Biomass Valorization. https://doi.org/10.1007/s12649-019-00844-1

Cabezudo I, Meini M-R, Di Ponte CC et al (2021) Soybean (Glycine max) hull valorization through the extraction of polyphenols by green alternative methods. Food Chem 338:128131. https://doi.org/10.1016/j.foodchem.2020.128131

Fernández K, Vega M, Aspé E (2015) An enzymatic extraction of proanthocyanidins from País grape seeds and skins. Food Chem 168:7–13. https://doi.org/10.1016/j.foodchem.2014.07.021

Meini M-R, Cabezudo I, Boschetti CE, Romanini D (2019) Recovery of phenolic antioxidants from Syrah grape pomace through the optimization of an enzymatic extraction process. Food Chem 283:257–264. https://doi.org/10.1016/j.foodchem.2019.01.037

Acknowledgements

The authors would like to thank Bodegas Salentein, Mendoza, Argentina, for supplying the grape pomace.

Funding

This work was supported by grants from the Consejo Nacional de Investigaciones Científicas y Técnicas, Argentina (PIP 11220200103120CO and PUE BD20160041CO), Universidad Nacional de Rosario (1BIO542, 80020190100061/111UR), and Agencia Santafesina de Ciencia Tecnología e Innovación (DTT-2021–065).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Ignacio Cabezudo, María-Rocío Meini, and Cecilia S. Galetto. The first draft of the manuscript was written by María-Rocío Meini and Ignacio Cabezudo, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cabezudo, I., Galetto, C.S., Romanini, D. et al. Production of gallic acid and relevant enzymes by Aspergillus niger and Aspergillus oryzae in solid-state fermentation of soybean hull and grape pomace. Biomass Conv. Bioref. 13, 14939–14947 (2023). https://doi.org/10.1007/s13399-022-03435-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03435-8