Abstract

Waste-to-energy technologies from anaerobic digestion (WtE-DA) are successfully used in European countries for electricity generation. In Mexico, the application of these processes is limited due to their design and operation complexity, high required investment, high operations and maintenance costs, and low government support, which hinders their economic competitiveness. This work conducted a study to determine the best conditions of electricity generation through WtE-DA processes to be competitive compared with the conventional process. An industrial-scale process was designed regarding the co-digestion of fruit and vegetable waste from a food supply center with slaughterhouse waste from the Monterrey Metropolitan Area in Mexico. Analysis scenarios were strategically proposed considering different sizes of the WtE-DA plant, transport distance from the source of waste to the process, and the degree of government participation through economic subsidies granted to clean energy production. The environmental performance of the plant was evaluated via the climate change indicator (CCI) following a life cycle analysis approach, and the net present value (NPV) was used as an economic criterion. The results show that the CCI has a high sensitivity to the waste transport distance, having a maximum of 130 km to ensure environmental success. The sensitivity analysis performed on the management capacity and NPV indicates that plants smaller than 72,000 t year−1 are economically unviable and require governmental financial support like that granted in European countries. This work provides reliable operating, eco-efficiency criteria, and subsidy schemes to support decision-making for proper investment in bioenergy projects.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Waste-to-energy (WtE) technologies have become an attractive option for countries seeking to minimize the environmental impact of landfills as a final waste disposal strategy [1, 2]. The European Union classifies the anaerobic digestion of organic waste as one of the main promising WtE options, together with waste incineration in combustion plants and indirect incineration after a pyrolysis or gasification step [3]. As a complement to waste management, the anaerobic digestion waste-to-energy (WtE-AD) systems can produce biogas (60% CH4 and 40% CO2) and digestate, which can be used to produce clean energy and biofertilizers, respectively [4].

In Mexico, WtE-AD technologies can play an essential role in achieving the national climate change strategy implemented in 2013 [5, 6], which aims to comply with the ratified Paris Agreement goals. The importance of those processes lies in minimizing the environmental impact of organic waste management and reducing greenhouse gas (GHG) emissions while producing clean electricity [7]. Tsydenova et al. [6] analyzed the feasibility of WtE-AD of municipal solid waste in Mexico City through life cycle assessment (LCA), using as a functional unit (FU) 1 kg of waste generated in a metropolitan food supply center (FSC), determining a climate change indicator (CCI) of 4.01 kg CO2 eq t−1, 99.5% less than the landfill strategy.

The successful application of WtE-AD is influenced by the variation and composition of raw materials (energy crops and organic waste), operating conditions [7], government subsidies and incentives [8], revenues from organic waste management, and the potential use of coproducts (energy and biofertilizer) [9]. In addition, these waste management technologies in Mexico can be subject to carbon offset certificates, increasing the economic success possibility [6].

In Latin America, WtE-AD is commonly used to treat manure in dairy and pig farms through covered anaerobic lagoons installed in decentralized small- and medium-scale plants. In these facilities, biogas and digestate are generally not adequately monitored due to the region’s budgetary and technological limitations; consequently, biogas and electricity production is also limited. Low biogas production is associated with using manure as a single substrate [10] since the content of organic material makes it hard to biodegrade [11, 12]. Pöschl et al. [13] found that mono-digestion is unsustainable for large-scale biogas plants. In Germany, most WtE-AD plants use co-digestion between three to five substrates [14] from farms, municipal slaughterhouses, food packers, and FSC. Notably, the FSC represent localized sites for food and loose waste generation. In Latin American metropolitan areas, extensive FSC represents localized waste generation sites. Mexico City generates around 326,675 t year−1 organic waste [15], which brings opportunities to implement profitable WtE-AD strategies.

In Latin America, no studies analyze the technical–economic and environmental feasibility of WtE-AD together. The few existing ones analyze these issues separately. In a medium-sized city in Argentina, Morero et al. [16] analyzed the environmental and energy performance of a WtE-AD plant of sewage sludge and the organic fraction of municipal solid waste following an LCA approach. The authors considered two valorization scenarios: biogas to substitute natural gas or electricity. In both alternatives, the problems related to landfill disposal can be solved, showing greenhouse gas emissions of − 1.02 and 3.2 × 10−4 kg CO2 eq t−1, respectively, demonstrating the environmental advantages of WtE-AD technologies. In Brazil, Velasquez-Piñas et al. [17] analyzed the effect of different WtE-AD plant sizes on the economic and energetic criteria, considering different schemes of mono and co-digestion of cow manure, corn, and grass silage. Their results indicated that plants with an electricity generation of less than 1000 kW are viable only for the mono-digestion of cow manure. Co-digestion plants with a generation greater than 1000 kW can be economically viable if the substrate’s costs are equal to or less than 11.49 USD t−1 for corn and 12.40 USD t−1 for grass silage. Two restrictions must be met to achieve economic competitiveness: electricity sale prices must be above 0.10 USD kWh−1 and government subsidies greater than 0.03 USD kWh−1. In Mexico, Gutiérrez et al. [18] evaluated the effect of mono and co-digestion of pig manure and elephant grass, different biogas uses, and government subsidies for infrastructure construction, on the economic viability of a centralized WtE-AD. The authors concluded that co-digestion is the best management alternative due to increased methane production. Also, it was found that electricity generation is the best option for biogas valorization and that economic success is accomplished when the electricity has a minimum tariff of 0.129 and 0.114 USD kWh−1 with and without subsidy.

The state-of-the-art review shows the absence of multi-criteria studies that contemplate under what conditions a WtE-AD plant can be competitive, limiting itself to evaluating processes with fixed waste treatment capacities, without determining the role played by different levels of government participation (through subsidies for the generation of clean electricity), nor the effect of waste transport distances, to jointly achieve the sustainability of these processes in Mexico. This work aims to conduct a techno-economic and environmental analysis to fill this knowledge gap, supplying ecoefficiency criteria to support decision-making for financial investment in bioenergy projects. This study’s methodology approach and results can be helpful in other Latin American countries with high fossil fuel dependence and waste management systems based on final disposal sites.

2 Materials and methods

2.1 Electricity and biofertilizer production from waste-to-energy anaerobic digestion plant

2.1.1 General features

The Monterrey Metropolitan Area (MAM), located in the Nuevo León state in Northeast Mexico, was considered a case study. The MAM is the second-largest city in the country, with a population of 5.34 million [19]. This city houses the largest FSC in the northeast of the country, generating around 33 t day−1 of waste, made up of 85% of fruits and vegetable waste (FVW), and,as is the case in most Latin American countries, are confined to final disposal sites: landfills and open dumps. Considering these wastes’ high availability and localized generation, a WtE-AD plant operated under an FVW and slaughterhouse waste (SHW) co-digestion regime in a 1:1 VS ratio was proposed as recommended by Miramontes-Martínez et al. [20], corresponding to a fresh mass ratio of 1.28 FVW:SHW (the waste characterizations of these substrates are given in Table S1 of the Supplementary Material Section). This proportion grants high yields and adequate process stability, allowing the WtE-AD to operate successfully during the life of the process.

This work proposed five analysis scenarios based on the waste management capacity. Scenario 1 corresponds to a WtE-AD process that manages 18,177 t year−1, made up of FVW in co-digestion with SHW (it was assumed to be a constant supply without variations in the waste composition during the useful life of the WtE-AD plants, 25 years). The anaerobic digestion process was carried out in two digesters with individual operating volumes of 1000 m3 (design specifications are given in Section 2.1.2). Scenarios 2 to 5 considered proportional increases in the management capacity and the number of digesters concerning scenario 1; i.e., scenario 2 manages 36,354 t year−1 in four digesters, while scenario 5 operates with 90,885 t year−1 in ten digesters.

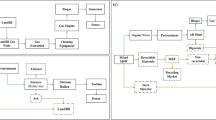

The diagram of the plant and its main characteristics are shown in Fig. 1 and Table S2, respectively. Some authors have suggested a maximum distance of 25 km from waste transport to centralized WtE-AD [21]. In this work, 20 km was used as a base distance. However, the environmental impact at higher distances was analyzed (Section 3.2). The transport of FVW was carried out in heavy truck class 7 (weight capacity 11.8–15 t and dimensions of width 2.44 m, height 3.18–3.43 m, and length 5.33–5.8 m) and the SHW in refrigerated trucks (weight capacity 11.8–15 and dimensions of width 2.59 m, height 2.64 m, and length 9.16 m), as established by Mexican standards [22]. All trucks operate under the Euro 5 emission regulations.

2.1.2 Biogas pre-treatment and production module

The waste entering the process is ground and mixed through a hammer crusher and a mixing tank. In this stage, water is added until the concentration of the substrates is reduced to 87.5 kg VS m−3. The added water comes from the tap water network and the digestate drying stage. The biogas production stage consists of stirred tank digesters in semi-continuous operation with an operating volume of 1000 m3, as described in Table S2. This volume was selected because it is usually used as a minimum for considering digesters on an industrial scale [23].

The AD phenomenon was simulated using the Anaerobic Digestion Model No. 1 (ADM1) [24] coupled with a co-digestion model proposed by Miramontes-Martínez et al. [12]. The numerical resolution of ADM1 was carried out according to the methodology of Rivas-García et al. [25]. Table S3 shows the initialization values of the model, which are based on the characterization of substrates (Table S1). The ADM1 allows for quantifying the concentration of ammoniacal and organic N in the digestate, which helps evaluate the biofertilizer quality.

2.1.3 Coproducts generation

The biogas generated in the digesters is fed to the cogeneration heat and power (CHP) unit, which has 38% and 48% electrical and thermal efficiency, respectively [26]. The internal electricity consumption in the plant is self-supplied, and the surplus is exported to the national electricity distribution network. Part of the heat generated is used to maintain isothermal conditions in the digesters (through the methodology proposed by Passos and Ferrer [27]), and the remainder is released into the environment.

The digestate removed from the reactors receives a drying treatment using a decanter and a drum-type dryer to reduce biological activity and increase the concentration of N–NH3. The decanter recovers some water from the digestate, reincorporated into the digesters, as mentioned at the beginning of Section 2.1.2. The effluent from the decanter is sent to the drum-type dryer to reduce its humidity from 80 to 15%. The resulting biofertilizer is sold in the study region.

2.2 Life cycle assessment implementation

2.2.1 Aim and scope definition

The LCA aims to quantify the environmental impact of the management of FVW from the food supply center through a WtE-DA plant to produce electricity and biofertilizer. The system boundary is shown in Fig. 1. Within the boundaries, the production of all the necessary mass and energy supplies in each life cycle stage was considered. The activities associated with the manufacture and final disposal of transports and construction and demolition of facilities were not considered in the analysis. The activities of electricity transmission through the national distribution network and those related to the transport and biofertilizer application were considered outside the study’s aims and scope. Given the remoteness and dispersion of the agricultural production fields and the lack of a properly established market for biofertilizers in the city, the activities related to its distribution and use have substantial uncertainty. Other LCA studies in biogas production plants from organic waste implement a similar scope in considering the fertilizers study [28, 29].

The FU was defined as the management of 1 t of FVW (wet base) from the FSC with the characteristics presented in Table S1. Since it is a co-digestion process, the FU encompasses the environmental impacts derived from the valorization of FVW and SHW.

2.2.2 Life cycle inventory analysis

Inventory of intermediate product flows

The diesel consumption was determined considering the transport performance and the distance traveled from the source of waste generation and the WtE-AD plant (Section 2.2.1). The electricity consumption for the pre-treatment and by-product generation modules was obtained from the equipment’s technical specifications. The digesters’ electrical consumption was calculated using Passos and Ferrer’s methodology [27]. The water required in the digesters was estimated using a mass balance (Sections 2.1.2 and 2.1.3). Finally, the consumption of lubricant by the digesters and the CHP was obtained from the Ecoinvent 3.3 database [30].

It was considered that the electricity supplied to the national electricity distribution network replaces conventional electricity in the same proportion. The biofertilizer substitutes commercial urea fertilizer based on its total N content (ammoniacal and organic).

Inventory of elementary flow emissions

GHG emissions generated by waste transportation were estimated using The Greenhouse gases, Regulated Emissions, and Energy use in Technologies Model [31]. For the biogas pre-treatment and production module, only emissions from methane leaks from the digesters equivalent to 1% of methane production are considered, according to the estimation from the European Environment Agency [32]. Fugitive C–CO2 emissions from digesters and electricity generation were not considered in evaluating the CCI due to their biogenic origin [33].

Emissions coming from the electricity generation stage from the CHP were obtained from the Ecoinvent 3.3 database [30]. This work considered the environmental impact of the WtE-AD plant for 25 years (since this horizon is a typical lifetime of the FVW and SHW management process), as well as the equipment’s efficiencies and its emissions not changing over time. GHG emissions in biofertilizer production come from the decanter and the drum-type dryer (Section 2.1.3). Direct N–N2O emissions are released in the decanter [34]. The effluent from the decanter was fed in a mechanical drum drier, where temperature and contact surface are high, fostering that a considerable amount of N–NH4+ is emitted as NH3 [34]. In this work, it was assumed that 85% of the available NH4+ is emitted as NH3. The ADM1 model simulated the NH4+ concentration in the sludge. This methodology can be reviewed in detail in Rivas-García et al. [35]. Indirect N2O emissions from NH3 volatilization were determined using the Guidelines for National Greenhouse Gases Inventories, Chapter 11 [33].

2.2.3 Life cycle impact assessment

The life cycle impact assessment (LCIA) was carried out under an attributional approach, and the analysis model was implemented using SimaPro® 7.3.3 software [36]. The data concerning to production of materials and energy considered in the life cycle inventory were taken from the Ecoinvent database v 3.3 [30]. The environmental performance of the WtE-AD was determined using the midpoint CCI using the Intergovernmental Panel on Climate Change 2013 GWP 100y method, as suggested by Eriksson et al. [37].

2.3 Economic assessment

Scenarios 1–5 were employed to conduct the economic assessment of the WtE-AD plant. The economic evaluation was carried out by analyzing the net present value (NPV) after taxes taking 2021 as the reference year. The assessment assumed a minimum attractive return of 8.4%, inflation of 4.89% [38], and a project lifetime of 25 years. Funding of 50% in the initial investment of the plant was considered through a bank loan with an annual interest rate of 7.75% with a 10 years time horizon, without the option of refinancing [38]. The investment and operation and maintenance (O&M) costs of the WtE-AD plant were quantified utilizing a correlation with other AD systems’ organic waste management capacity on an industrial scale (Fig. 2). O&M costs were considered to increase proportionally to annual inflation. The depreciation of equipment and transportation was estimated at 10 and 15% per year, respectively.

Relationships between investment and O&M costs and management sizes of anaerobic digestion plants on an industrial scale. The regressions were constructed via Tsilemou and Panagiotakopoulos’ [39] information

Economic revenue from the sale of electricity and biofertilizer was considered; 79 USD t−1 [16] and 0.141 USD kWh−1, respectively [40]. Table 1 shows the data used in the economic assessment, including investment and O&M costs, taxes, and economic revenue (taking as an example investment, O&M, and vehicle costs in scenario 1). Economic revenue was increased annually in line with inflation.

Table 1 also shows the economic revenue for managing FVW and SHW in the WtE-AD plant. This work assumes it is equivalent to that of their management in the city’s sanitary landfill. Table S4 shows revenues from organic waste management in several WtE-AD plants reported in the literature, which are relatively higher than those used in this study. The low costs of waste management in Mexico are due to the absence of legislation that restricts sanitary landfills use. In Europe, environmental regulations and government taxes on organic waste management are the leading cause of the rise of WtE-AD technologies [42].

The models for the WtE-AD plant design, the economic model, and the sensibility analysis (except the environmental evaluation) were developed in Microsoft Excel®.

3 Results

3.1 Technical results of the waste-to-energy anaerobic digestion plant

The operating conditions and the digester performance results are shown in Table S5. The digesters have an individual biogas productivity of 1.12 m3 m−3 day−1, equivalent to 35.5 m3 FU−1, with an average of 59% methane. Similar average results are observed in the same table for processes of this type according to the smart European biogas sustainable energy program [43].

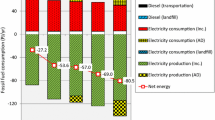

For all scenarios, the biogas produced through the CHP unit produces 141 and 178 kWh FU−1 of electricity and heat, respectively; 17.7% of the electricity is used for the plant’s internal consumption, and the surplus is injected into the national electricity grid (Fig. 3). Gebrezgabher et al. [44] determined an electrical performance of 222.3 kWh t−1 of substrate formulated in co-digestion (pig and chicken manure, food residues, corn, and flower bulbs), which is related to higher hydraulic retention time and temperature of operation (40 d and 40 °C, respectively). On the other hand, Akbulut [45] reports a lower electricity production, 81.36 kWh t−1 of managed waste (cow and sheep manure) for a plant with similar characteristics (organic loading rate of 2.51 kg m3 day−1 and 39% CHP efficiency). This difference may be due to the low productivity of cow (0.68 m3 m−3 day−1) and sheep manure (0.198 m3 m−3 day−1) compared to the productivity obtained in this study (1.12 m3 m−3 day−1). The plant also generates 1.65 t FU−1 of digestate, which is dried until obtaining 0.1857 t FU−1 of biofertilizer with a 20.72 kg N–NH3 UF−1 concentration (Fig. 3).

3.2 Life cycle assessment

Figure 3 shows the inputs and outputs flow of the WtE-AD plant (scenario 1 was chosen for widespread discussion). This figure also shows that biogas pre-treatment and production are the major contributors to methane emissions from the process due to biogas leaks in the digester. The thermal drying process in biofertilizer production releases the highest N2O and NH3 emissions from the life cycle. The loss of N in this process is 0.023 kg N UF−1, 76% as N2O and 24% as NH3.

Table 2 shows the CCI of the modules of the WtE-AD plant scenarios. All scenarios show a CCI of − 71.12 kg CO2 eq FU−1, equivalent to − 0.504 kg CO2 eq per kWh generated, is mainly due to conventional electricity substitution. In WtE-AD plants, the literature reports − 0.21 to − 1.07 kg CO2 eq kWh−1 for AD processes of corn, manure, or co-digestion with manure [7]. These values depend on the substrate nature (energy crop or residue), the transport distance between the substrate source and the utilization plant, the efficiency of the CHP, and the energy mix to be replaced. In Mexico, electricity generation has a high CCI, 0.61 kg CO2 eq kWh−1, and its energy sources are fossil fuels (77.33%), hydroelectric (15.76%), nuclear energy (3.74%), renewable energy (3.15%), and from waste (0.02%) [46, 47]. WtE-AD technologies could be an attractive alternative to mitigate environmental impacts in the Mexican electricity sector.

The transport distance and its influence on greenhouse gas emissions in the WtE-AD plant were analyzed by increasing the kilometers traveled by waste transports. Table 2 also shows that waste transport distance substantially influences the CCI of WtE-AD, making it noticeable that the environmental impacts increase substantially due to the number of trips required to supply the plant (Table S6). Ruiz et al. [48] established 60 km for transporting FVW, SHW, and food waste for similar AD processes in Europe (Table 3). For this study, using such distance, GHG emissions from transport increase to 38.81 kg of CO2 eq FU−1 and the CCI of the process goes from − 71.12 to − 45.24 kg of CO2 eq FU−1. The analysis reveals that at waste transport distances greater than 130 km, WtE-AD shows GHG emissions greater than zero. This analysis can be helpful as the basis for more exhaustive evaluations, which determine the optimal location of the WtE-AD plant by employing mathematical tools such as multi-objective optimization problems, involving cost studies, environmental evaluation, safety, vehicular traffic, legislation, and social acceptance (since the local population usually rejects waste management technologies). In addition, an essential gap in Latin America is limited and unclear regulation on waste transport.

The environmental benefits of managing FVW and SHW in the proposed scenarios of the WtE-AD plant vary depending on the amount of waste and its transport. The most extensive GHG mitigation was obtained at a transport distance of 20 km, generating 141 kWh FU−1 and 0.186 t FU−1 of biofertilizer, with a CCI of − 71.12 t CO2 eq FU−1. The environmental impact associated with managing these wastes in the sanitary landfill was estimated through the Mexican Biogas Model [55] at 15,760 t CO2 eq y−1 for scenario 1. The alternative to valorize these wastes in the proposed WtE-AD plants represents considerable reductions in GHG emissions, increasing the useful life of the landfill and decreasing the need to open new sites. However, the economics of these plants must be analyzed since WtE-AD plants have higher capital and O&M costs than landfills.

3.3 Economic feasibility assessment

The economic and environmental assessment results of the studied WtE-AD scenarios are shown in Table 4, where the economy of scale is evident. One of the strategies to make the WtE-AD alternatives more competitive is the external support given by governments to produce clean energy. Without government support, no scenario presented economic benefits (positive NPV). Therefore, a sensitivity analysis was developed to determine the influence of subsidies on the economy of the WtE-AD process.

Table 5 shows various subsidy schemes granted for electricity generation in various countries, which depend on the maximum installed capacity of the CHP and the substrate used. Germany, for example, one of the leading countries in WtE-AD, has the highest subsidies. In this work, a sensitivity analysis was carried out to evaluate the effect of the subsidies (0.1–0.4 USD kWh−1) on the NPV of the WtE-AD plants. Figure 4 shows that the subsidies required to obtain a positive NPV decrease with more management capacity. Economic benefits (positive NPV) were achieved with subsidies of 0.3 and 0.4 USD kWh−1 with management capacities corresponding to scenarios 4 and 5. The subsidy of 0.3 USD kWh−1 is in the range of support granted by Germany (0.176–0.311 USD kWh−1) (Table 5). Considering this subsidy, a minimum management capacity of 90,885 t year−1 is required to achieve financial benefits.

Figure 4 highlights the strong influence that government subsidies have on the financial success of the WtE-AD process. Renewable energy policies based on waste recovery (which grant subsidies for producing clean energy from alternative options to the landfill) must consider the conditions for WtE-AD technologies to be competitive within the national production electricity market. In countries where this means a challenge, such as Mexico and Latin American countries, the prioritization of renewable energy policies and prohibitions aimed at reducing the use of landfills, like the European context, could encourage emerging markets based on waste valorization via WtE technologies.

This study provides the basis for future works, emphasizing that the uncertainties of the economic parameters should be considered to have more detailed evaluations.

4 Conclusions

This work analyzed the techno-economic and environmental footprint of a Mexican waste-to-energy anaerobic digestion (WtE-AD) plant from co-digestion of slaughterhouse waste (SHW) and fruit and vegetable wastes (FVW), considering the influence of plant size, government subsidies for clean electricity production, and waste transport distance from source to the processing plant. The scenarios analyzed for the WtE-AD plant contemplated a waste management capacity of 18,177–90,885 t year−1 of organic waste, which exhibits the greatest savings in greenhouse gas emissions (− 71.12 t CO2 eq t−1 FVW); this concern is mainly due to the generation of 141 kWh t−1 FVW of electricity and 0.186 t of biofertilizer t−1 FVW. The study even found that waste transport has a strong effect on the plant's environmental impact, especially when the waste requires refrigeration (as in the case of SHW) and more transport distance; when the transport distance is three times higher, GHG emissions of transportation are increased by 300%. The economic evaluation resolved that plant sizes with processing below 72,000 t of waste (56% of FVW and 44% of SHW) are economically unfeasible (negative net present values). A sensitivity analysis that considers the plant processing size and government subsidies together indicated that economic success could be achieved from a capacity of 72,000 t of waste and subsidies like those provided by various European countries (~ 0.17 USD kWh−1). At the largest size plant, the needed subsidies diminish drastically.

Data availability

Not applicable.

References

Capson-Tojo G, Rouez M, Crest M, Steyer JP, Delgenès JP, Escudié R (2016) Food waste valorization via anaerobic processes: a review. Rev Environ Sci Biotechnol 15(3):499–547. https://doi.org/10.1007/s11157-016-9405-y

Achinas S, Achinas V, Euverink GJW (2017) A technological overview of biogas production from biowaste. Eng 3(3):299–307. https://doi.org/10.1016/J.ENG.2017.03.002

European Commission (2017) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions - The role of waste-to-energy in the circular economy COM/2017/0034. https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52017DC0034. Accessed 1 May 2020

Al Seadi T, Lukehurst C (2012) Quality management of digestate from biogas plants used as fertilizer. IEA Bioenergy Task no. 37-Energy from Biogas. http://www.iea-biogas.net/files/daten-redaktion/download/publi-task37/digestate_quality_web_new.pdf. Accessed 15 June 2020

ENCC (2013) Estrategia Nacional de Cambio Climático Visión 10–20–40. Gobierno de la República. https://www.gob.mx/cms/uploads/attachment/file/41978/Estrategia-Nacional-Cambio-Climatico-2013.pdf. Accessed 20 June 2020

Tsydenova N, Morillas AV, Hernández ÁM, Soria DR, Pehlken WC, A, (2019) Feasibility and barriers for anaerobic digestion in Mexico City. Sustain 11(15):1–21. https://doi.org/10.3390/su11154114

Bacenetti J, Fiala M (2015) Carbon footprint of electricity from anaerobic digestion plants in Italy. Environ Eng Manag J 14(7):1495–1502. https://doi.org/10.30638/eemj.2015.161

Edwards J, Othman M, Burn S (2015) A review of policy drivers and barriers for the use of anaerobic digestion in Europe, the United States and Australia. Renew Sustain Energy Rev 52:815–828. https://doi.org/10.1016/j.rser.2015.07.112

Vasco-Correa J, Khanal S, Manandhar A, Shah A (2018) Anaerobic digestion for bioenergy production: global status, environmental and techno-economic implications, and government policies. Bioresour Technol 247(September):1015–1026. https://doi.org/10.1016/j.biortech.2017.09.004

Garfí M, Martí-Herrero J, Garwood A, Ferrer I (2016) Household anaerobic digesters for biogas production in Latin America: a review. Renew Sustain Energy Rev 60:599–614. https://doi.org/10.1016/j.rser.2016.01.071

Rivas-García P, Botello-Álvarez JE, Miramontes-Martínez LR, Cano-Gómez JJ, Rico-Martínez R (2020) New model of hydrolysis in the anaerobic co-digestion of bovine manure with vegetable waste: modification of anerobic digestion model No. 1. RMIQ 19(1):109–122. https://doi.org/10.24275/rmiq/Bio557

Miramontes-Martínez LR, Gomez-Gonzalez R, Botello-Álvarez JE, Escamilla-Alvarado C, Albalate-Ramírez A, Rivas-García P (2020) Semi-continuous anaerobic co-digestion of vegetable waste and cow manure: a study of process stabilization. RMIQ 19(3):1117–1134. https://doi.org/10.24275/rmiq/proc920

Pöschl M, Ward S, Owende P (2010) Evaluation of energy efficiency of various biogas production and utilization pathways. Appl Energy 87(11):3305–3321. https://doi.org/10.1016/j.apenergy.2010.05.011

Wagner AO, Lins P, Malin C, Reitschuler C, Illmer P (2013) Impact of protein-, lipid- and cellulose-containing complex substrates on biogas production and microbial communities in batch experiments. Sci Total Environ 458–460 (2013): 256–266. https://doi.org/10.1016/j.scitotenv.2013.04.034

Garcia-Peña EI, Parameswaran P, Kang DW, Canul-Chan M, Krajmalnik-Brown R (2011) Anaerobic digestion and co-digestion processes of vegetable and fruit residues: process and microbial ecology. Bioresour Technol 102(20):9447–9455. https://doi.org/10.1016/j.biortech.2011.07.068

Morero B, Vicentin R, Campanella EA (2017) Assessment of biogas production in Argentina from co-digestion of sludge and municipal solid waste. Waste Manag 61:195–205. https://doi.org/10.1016/j.wasman.2016.11.033

Velásquez Piñas JA, Venturini OJ, Silva Lora EE, del Olmo OA, Calle Roalcaba OD (2019) An economic holistic feasibility assessment of centralized and decentralized biogas plants with mono-digestion and co-digestion systems. Renew Energy 139:40–51. https://doi.org/10.1016/j.renene.2019.02.053

Gutierrez EC, Xia A, Murphy JD (2016) Can slurry biogas systems be cost effective without subsidy in Mexico? Renew. Energy 95:22–30. https://doi.org/10.1016/j.renene.2016.03.096

INEGI (2020) Instituto Nacional de Estadística y Geografía. https://www.inegi.org.mx/app/areasgeograficas/?ag=19. Accessed 12 May 2020

Miramontes-Martínez LR, Rivas-García P, Albalate-Ramírez A, Botello-Álvarez JE, Escamilla-Alvarado C, Gomez-Gonzalez R, Alcalá-Rodríguez MM, Valencia-Vázquez R, Santos-López IA (2021) Anaerobic co-digestion of fruit and vegetable waste: synergy and process stability análisis. J Air Waste Manage Assoc 71(5):620–632. https://doi.org/10.1080/10962247.2021.1873206

Polifacio M, Murphy JD (2007) Anaerobic digestion in Ireland: decision support system. Department of Civil, Structural and Environmental Engineering. Cork Institute of Technology, Ireland

NOM-043-SCT-2003 Norma Mexicana Dirección General de Normas (2003) Documento de embarque de substancias, materiales y residuos peligrosos. https://dof.gob.mx/nota_detalle_popup.php?codigo=684641. Accessed 14 Jan 2020

Galván-Arzola U, Miramontes-Martínez LR, Escamilla-Alvarado C, Botello-Álvarez JE, Alcalá-Rodríguez MM, Valencia-Vázquez R (2022) Rivas-García P (2022) Anaerobic digestion of agro-industrial waste: anaerobic lagoons in Latin America. RMIQ 2((2022)):IA2680. https://doi.org/10.24275/rmiq/IA2680

Batstone DJ, keller J, Angelidaki I, Kalyuzhnyi SV, Pavlostathis SG, Rozzi A, Sanders WTM, Siegrist H, Vavilin VA (2002) The IWA Anaerobic Digestion Model No 1(ADM1) scientific and technical report No. 13. London

Rivas-García P, Botello-Álvarez JE, Estrada-Baltazar A, Navarrete-Bolaños JL (2013) Numerical study of microbial population dynamics in anaerobic digestion through the Anaerobic Digestion Model No. 1 (ADM1). Chem Eng J 228:87–92. https://doi.org/10.1016/j.cej.2013.05.013

Scano EA, Asquer C, Pistis A, Ortu L, Demontis V, Cocco D (2014) Biogas from anaerobic digestion of fruit and vegetable wastes: experimental results on pilot-scale and preliminary performance evaluation of a full-scale power plant. Energy Convers Manag 77:22–30. https://doi.org/10.1016/j.enconman.2013.09.004

Passos F, Ferrer I (2015) Influence of hydrothermal pretreatment on microalgal biomass anaerobic digestion and bioenergy production. Water Res 68:364–373. https://doi.org/10.1016/j.watres.2014.10.015

Mezzullo WG, McManus MC, Hammond GP (2013) Life cycle assessment of a small-scale anaerobic digestion plant from cattle waste. Appl Energy 102:657–664. https://doi.org/10.1016/j.apenergy.2012.08.008

Ramírez-Arpide FR, Demirer GN, Gallegos-Vázquez C, Hernández-Eugenio G, Santoyo-Cortés VH, Espinosa-Solares T (2018) Life cycle assessment of biogas production through anaerobic co-digestion of nopal cladodes and dairy cow manure. J Clean Prod 172:2313–2322. https://doi.org/10.1016/j.jclepro.2017.11.180

Ecoinvent Center (2014) Ecoinvent data version 3.3. Swiss Centre for Life Cycle Inventories. Dübendorf, Switzerland. http://www.ecoinvent.org/

GREET (2016) The greenhouse gases, regulated emissions, and energy use in transportation. Chicago: Argonne National Laboratory. https://greet.es.anl.gov/

EEA (2020) European Environment Agency. https://www.eea.europa.eu. Accessed 29 May 2020

IPCC (2006) Guidelines for national greenhouse gases inventories. Hayama: Intergovernmental Panel on Climate Change (IPCC). https://www.ipcc.ch/

Rehl R, Lansche J, Müller J (2012) Life cycle assessment of energy generation from biogas - attributional vs consequential approach. Renew Sustain Energy Rev 16(6):3766–3775. https://doi.org/10.1016/j.rser.2012.02.072

Rivas-Garcia P, Botello-Álvarez JE, Abel-Seabra JE, da Silva Walter AC, Estrada-Baltazar A (2015) Environmental implications of anaerobic digestion for manure management in dairy farms in Mexico: a life cycle perspective. Env Technol April: 1–38 https://doi.org/10.1080/09593330.2015.1024758

PReConsultants. SimaPro 7.3.3® software (2019). Amrersfoort, The Netherlands. https://pre-sustainability.com/

Eriksson M, Strid I, Hansson PA (2015) Carbon footprint of food waste management options in the waste hierarchy – a Swedish case study. J Clean Prod 93:115–125. https://doi.org/10.1016/j.jclepro.2015.01.026

BM (2020) Banco de México. https://www.banxico.org.mx/. Accessed 20 June 2020

Tsilemou K, Panagiotakopoulos D (2006) Approximate cost functions for solid waste treatment facilities. Waste Manag Res 24(4):310–322. https://doi.org/10.1177/0734242X06066343

CFE (2019) Comisión Federal de Electricidad. https://www.cfe.mx/Pages/Index.aspx. Accessed 3 June 2020

SAT (2020) Ley de impuesto al valor agregado. https://www.sat.gob.mx/ordenamiento/37585/ley-del-impuesto-al-valor-agregado. Accessed 12 June 2020

Yousuf A, Khan MR, Pirozzi D, Ab Wahid Z (2016) Financial sustainability of biogas technology: barriers, opportunities, and solutions. Energy Sources Part B Econ Plan Policy 11(9):841–848. https://doi.org/10.1080/15567249.2016.1148084

Biogas3 Proyect (2020) Sustainable small-scale biogas from agri-food waste for energy self-sufficiency Intelligent Energy Europe Programme. http://www.biogas3.eu/esp/index.html

Gebrezgabher SA, Meuwissen MPM, Prins BAM, Lansink AGJMO (2010) Economic analysis of anaerobic digestion-a case of Green power biogas plant in the Netherlands. NJAS - Wageningen J Life Sci 57(2):109–115. https://doi.org/10.1016/j.njas.2009.07.006

Akbulut A (2012) Techno-economic analysis of electricity and heat generation from farm-scale biogas plant: Çiçekdaĝi case study. Energy 44(1):381–390. https://doi.org/10.1016/j.energy.2012.06.017

Itten R, Frischknecht R, Stucki M (2014) Life cycle inventories of electricity mixes and grid. Paul Scherrer Inst. June: 1–229. www.lc-inventories.ch

INECC (2018) Inventario nacional de emisiones de gases y compuestos de efecto invernadero. Instituto Nacional de Ecología y cambio climático. https://www.gob.mx/cms/uploads/attachment/file/312045/INEGYCEI6CN_26_marzo_2018.pdf. Accessed 25 Apr 2020

Ruiz D, San Miguel G, Corona B, Gaitero A, Domínguez A (2018) Environmental and economic analysis of power generation in a thermophilic biogas plant. Sci Total Environ 633:1418–1428. https://doi.org/10.1016/j.scitotenv.2018.03.169

Li Y, Manandhar A, Li G, Shah A (2018) Life cycle assessment of integrated solid state anaerobic digestion and composting for on-farm organic residues treatment. Waste Manag 76:294–305. https://doi.org/10.1016/j.wasman.2018.03.025

Patterson T, Esteves S, Dinsdale R, Guwy A (2011) Life cycle assessment of biogas infrastructure options on a regional scale. Bioresour Technol 102(15):7313–7323. https://doi.org/10.1016/j.biortech.2011.04.063

Michel J, Weiske A, Möller K (2010) The effect of biogas digestion on the environmental impact and energy balances in organic cropping systems using the life-cycle assessment methodology. Renew Agric Food Syst 25(03):204–218. https://doi.org/10.1017/S1742170510000062

Tonini D, Albizzati PF, Astrup TF (2018) Environmental impacts of food waste: Learnings and challenges from a case study on UK. Waste Manag 76:744–766. https://doi.org/10.1016/j.wasman.2018.03.032

Bedoi R, Cucek L, Cosic B, Krajnc D, Smoljanic G, Kravanja Z, Ljubas D, Puksec T, Duic N (2019) Green biomass to biogas – a study on anaerobic digestion of residue grass. J Clean Prod 213:700–709. https://doi.org/10.1016/j.jclepro.2018.12.224

Evangelisti S, Lettieri P, Borello D, Clift R (2014) Life cycle assessment of energy from waste via anaerobic digestion: a UK case study. Waste Manag 34(1):226–237. https://doi.org/10.1016/j.wasman.2013.09.013

SCS Engineers (2009) User’s Manual Mexico Landfill Gas Model Version 2.0. USEPA. http://www.epa.gov/lmop/documents/pdfs/manual_del_%0Ausuario_modelo_mexicano_de_biogas_v2_2009.pdf. Accessed 22 Feb 2020

Battista F, Frison N, Bolzonella D (2019) Energy and nutrients’ recovery in anaerobic digestion of agricultural biomass: an Italian perspective for future applications. Energies 12 (17) https://doi.org/10.3390/en12173287

Torrijos M (2016) State of development of biogas production in Europe. Procedia Environ Sci 35:881–889. https://doi.org/10.1016/j.proenv.2016.07.043

O’Connor S, Ehimen E, Pillai SC, Lyons G, Bartlett J (2020) Economic and environmental analysis of small-scale anaerobic digestion plants on Irish dairy farms. Energies 13 (3) https://doi.org/10.3390/en13030637

Zheng L, Chen J, Zhao M, Cheng S, Wang L, Mang HP, Li Z (2020) What could China give to and take from other countries in terms of the development of the biogas industry? Sustain 12(4):1–22. https://doi.org/10.3390/su12041490

Funding

The Autonomous University of Nuevo Leon supported this work through PAICYT grant 573-IT-2022 and 591-IT-2022.

Author information

Authors and Affiliations

Contributions

Conceptualization: Pasiano Rivas-García, Luis Ramiro Miramontes-Martínez; data curation: Luis Ramiro Miramontes-Martínez, Pasiano Rivas-García, Rafael Arturo Briones-Cristerna; formal analysis: Luis Ramiro Miramontes-Martínez, Pasiano Rivas-García, José Enrique Botello-Álvarez; funding acquisition: Pasiano Rivas-García; investigation: Luis Ramiro Miramontes-Martínez, Rafael Arturo Briones-Cristerna; methodology: Luis Ramiro Miramontes-Martínez, Rafael Arturo Briones-Cristerna; project administration: Pasiano Rivas-García; resources: Pasiano Rivas-García; software: Luis Ramiro Miramontes-Martínez, Rafael Arturo Briones-Cristerna, Pasiano Rivas-García; supervision: Pasiano Rivas-García; validation: Pasiano Rivas-García, José Enrique Botello-Álvarez, Joaquim Eugenio Abel-Seabra, Alejandro Padilla-Rivera, Mónica María Alcalá-Rodríguez, Annie Levasseur; visualization: Luis Ramiro Miramontes-Martínez, Pasiano Rivas-García; writing—original draft: Luis Ramiro Miramontes-Martínez, Pasiano Rivas-García, José Enrique Botello-Álvarez, Alejandro Padilla-Rivera; writing—review and editing: Pasiano Rivas-García, Joaquim Eugenio Abel-Seabra, Alejandro Padilla-Rivera, Mónica María Alcalá-Rodríguez, Annie Levasseur.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Miramontes-Martínez, L.R., Rivas-García, P., Briones-Cristerna, R.A. et al. Potential of electricity generation by organic wastes in Latin America: a techno-economic-environmental analysis. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-03393-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-03393-1