Abstract

Conventional sources of energy like fossil fuels are available in limited quantities and harm environment. So, for sustainable growth, renewable energy is the only way forward. Biomass-based energy has untapped potential and is one of the most economical and best-proven options among the various alternative energy sources available. To fully utilize the biomass, the estimation of the possible potential is much needed. A state-wise biomass database is valuable for localized bioenergy policy. However, in India, a state-level biomass resource database is inadequate. This paper assessed the state-wise potential of biogas from various of sources including crop residues, livestock and poultry wastes, municipal solid wastes, and wastewater (sewage and industrial). The overall estimated biogas potential from organic waste in India is 74.795 billion m3/year. Also, the state-wise current generation capacity of digesters installed under various schemes is assessed in this paper. Currently, digesters with a generation capacity of 3.635 billion m3/year are achieved in India. The results show that there is a massive gap between the potential and its utilization. Among all the states, Uttar Pradesh (14.73 billion m3/year) has the highest biogas potential, and Maharashtra (671.40 million m3/year) has the highest installed achievement. The statistics generated in this research is expected to be beneficial for decentralized biogas planning and management in the state.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In India, energy demand is increasing with rapid urbanization and industrialization. Energy demand is mostly met by conventional sources of energy, like oil and coal; however, its reserves are depleting [1]. Renewable energy sources, which include small hydro projects, urban and industrial waste power, solar, wind energy, etc., contribute only about 23.6% of total energy generation [2]. There is a necessity to increase the contribution of renewable energy. Compared to other renewable sources of energy such as hydro, solar, and wind, the biomass-based energy generation options require fewer capital investments and per-unit production cost, thus making it more economical [3].

Currently, 62 million tons of waste is being generated annually in India, less than 60% of these wastes are being collected, and around 15% processed. The unprocessed waste is usually sent to landfill directly for their disposal. The municipal solid waste (MSW) is piling up every day, with an average annual growth rate of 4%. In the current scenario, there is a requirement of 1240 hectares of land every year for setting up of landfill [4]. With landfills being the third-highest contributor to greenhouse gases (GHG), it is a severe threat to the environment. It also contaminates groundwater because of leachate production [5], so finding alternative solutions becomes a necessity. The processing of waste through anaerobic digestion is a more practical and feasible solution, having enormous potential, as 50% of the wastes generated are organic. Also, The GHG intensity of biogas energy is lower than fossil-based energy [6].

1.1 Anaerobic digestion and its potential in India

Anaerobic digestion (AD) is a biological transformation of the organic matter in the absence of oxygen with the help of microorganisms to produce biogas and digestate [7]. Biogas is primarily composed of methane (CH4) 55–65% and carbon dioxide (CO2) 35–45%. Other products like nitrogen, ammonia, and hydrogen sulphide are less than 1% [8]. AD takes place in four stages, namely, hydrolysis, acidogenesis (fermentation), acetogenesis, and methanogenesis. The yield from biogas can be maximized by optimizing the operating parameters such as (pH, total solids, temperature, hydraulic retention time, carbon to nitrogen ratio, agitation, and substrate to inoculum ratio) [9,10,11]. The biodegradability of the biomass feedstock is hugely dependent on its composition. It can be directly used for electricity generation or heating. Also, after purification, it can be upgraded to biomethane and used as a vehicle fuel [12]. The energy content of the biogas generated is often more than the energy used in running the plant. The benefits of AD to handle the waste of agricultural field, industries, and municipality increase its significance as a source of renewable fuel. The problems arising from solid wastes such as greenhouse gas emission, poor sanitation, and leachate generation are also taken care of. The by-product of AD is digested slurry, which can be used as soil conditioners, thus reducing the use of chemical fertilizers [13]. Almost 68% of the population of India resides in rural areas, and biomass constitutes about 32% of the country’s primary energy use [14]. The direct combustion of biomass, however, produces pollutants such as dust and acid rain gases. National Biomass cookstoves initiative was launched to introduce cookstoves with lower emissions, but they are not as efficient. An alternative to combustion, biomass can be used to produce biogas that can reduce indoor air pollution [15]. Thus, AD can be an effective solution to counteract significant problems in India, like pollution and energy demand. Furthermore, it can also generate employability to some extent, which can be considered an added advantage.

1.2 Overview of biogas development and utilization in India

In India, Mathunga Leper Asylum in Bombay (Mumbai) constructed anaerobic digester in 1897 and utilized human waste to generate gas, to meet its lighting needs [16]. Dr. S.V Desai first developed the first successful use of farm manure to produce biogas in the 1930s. In the 1950s, Jashu Bhai Patel developed a floating drum biogas plant, which was also known as the Gobar gas plant. In 1961, Khadi and Villages Industries Commission (KVIC) promoted the model developed by Jashu Bhai Patel for the utilization by Indian villagers. This model was promoted as the KVIC model [17]. A modified Chinese design was developed by the Planning Research and Action Division (PRAD), and it was promoted as a Janta fixed dome plant. The Janta design was cheaper by 30% than the KVIC design. In 1981–1982, the first national program was implemented, i.e., National Project on Biogas Development (NPBD). In 1984, Action for Food Production (AFPRO) developed the Deenbandhu model, which was an improvised version of the Janta model [18]. The Deenbandhu model was 30% cheaper than the Janta model and 45% less expensive than the KVIC model [19]. In 2006, NPBD was renamed as the National Biogas and Manure Management Program (NBMMP) with approved a biogas plant of 1 to 6 m3 capacity per day. To promote an off-grid decentralized renewable power generation, having the capacity range of 3 kW to 250 kW, an off-grid Biogas Power Generation Program (BPGP) was also initiated in 2006. After the 12th 5-year plan, BPGP was modified as Biogas Power Generation (Off-grid) and Thermal Energy Application Program (BPGTP). Also, NBMMP was redesigned and renamed as New National Biogas and Organic Manure Program (NNBOMP). Under the NNBOMP scheme, small family biogas plants of size 1m3 to 25m3 were installed for generating clean cooking fuel, lighting, and low power energy needs, mainly in rural and semi-urban areas [20]. In 2018, the Department of Drinking Water and Sanitation launched GOBAR (Galvanizing organic bio-agro resource)–DHAN scheme [21]. In 2018, the Ministry of Petroleum and Natural Gas began a Sustainable Alternative Towards Affordable Transportation (SATAT) initiative to promote compressed biogas (CBG) [22]. Under NPBD, NBMMP, and NNBOMP, until 2018–2019, a cumulative total of 50.28 lakh family/small size biogas plants have been installed in the country. A total of 389 power projects have been commissioned up to 2018–2019 under BPGP and BPGTP with a cumulative generation capacity of 8951.5 kW [23].

The production of biogas in India is still, however, quite low compared to its true potential. Many studies have accessed the biogas potential at the national level, for example, Rao et al. (2010) calculated the potential from different organic waste such as agricultural waste, animal waste, wastewater, and municipal solid waste [3]. Sukhesh and Rao (2018) calculated the methane potential from surplus agricultural residue (paddy, wheat and maize) [24]. Kaur et al. (2017) calculated the potential of livestock generated biomass for anaerobic digestion [25]. However, at the state level, it is limited to a few states. For example, Ramachandra et al. (2007) studied renewable energy potential (solar, wind, hydro, and bioenergy) in Karnataka [26]. Das and Jash (2009) did assessment of biomass resource from agricultural residue, biomass based industrial residue (rice mills and saw mills) and forest residue in West Bengal [27]. Singh et al., (2008) calculated the energy potential through agricultural biomass in Punjab [28]. Also, at the national level the estimates of potential in the previous literature are only limited to a few biomass. For example, Aich and Ghosh (2016) estimated anaerobic digestion energy generation potential from municipal solid waste in India [29]. Lata et al., (2002) estimated the biomethanation potential from industrial organic effluents in India [30]. Cardoen et al., (2015) estimated the quantity of biomass residue in agriculture sector [31]. Kshirsagar et al., (2012) estimated anaerobic co-digestion potential of animal waste and crop residue in India [32].

No study is found where the biogas estimate is done considering all biomass resource (agricultural residue, animal manure, municipal solid waste and waste water) at state level in India. Moreover, in earlier research, the production estimates are limited to the productions by the small-scale digesters installed under the NBMMP [33]. Hence, installed capacity from BPGTP and waste to energy plants is not included in any literature. So, this paper identifies the gap in the existing literature and discusses the difference between the current potential and utilization of biogas at the state level.

To determine the potential of biogas production using biomass as the principal source, a detailed region-by-region analysis must be done in order to create key guidelines and suggestions for appropriate biomass management technologies. Keeping this in mind, the objective of this study is to estimate the potential of biogas at state level in India. Also, this paper calculates the amount of biogas that is utilized at current scenario. The novelty of this study includes the biogas estimation at the state level of all states in India from biomass such as agricultural residue, animal manure, municipal solid waste and waste water (industrial and sewage). Moreover, the database on state-wise biogas utilization in India is not mentioned in any literature.

The breakdown of this study’s structure is as follows. The analysis methodologies used to evaluate the availability of various resources in this study are detailed in Section 2. This section also provides a complete explanation of the estimating process, as well as relevant dataset, data sources and assumptions used to calculate biogas potential. Section 3 details the biogas potential of various resources such as crop leftovers, animal manure, municipal solid waste, and waste water. This section also details the utilization of biogas potential currently. Furthermore, uncertainty and sensitivity analysis using Monte Carlo simulation is performed in this section. Study’s conclusion is presented in Section 4.

2 Materials and methods

Biomass is an organic matter which includes plants, animals, and microorganisms growing on land and water and their derivative. Biomass is utilized in several manners, for instance, combustion, gasification, pyrolysis, fermentation, and anaerobic digestion. In rural areas, energy generated from the biomass has been used as a source of heat (cooking) and light. Few sources of biomass feedstocks include:

-

1

Agricultural crop residue—More than 50% of the population’s livelihood in India is dependent on agriculture [34]. Even though energy crops are not explicitly cultivated for anaerobic digestion, there is a massive generation of crop residue (a by-product of crop production), which can be utilized [35]. The disposal of residue is a significant challenge, so farmers prefer in-situ burning. This leads to a loss of essential nutrients and, at the same time, pollutes the environment through the emission of greenhouse gases (CO2, CO, CH4, N2O, SO2), smoke, volatile organic compounds, aerosols, particulate matter, etc. [36].

-

2

Animal waste—India is home to one of the largest livestock populations (512.06 million), which includes 299.98 million bovine communities comprising of cattle, buffalo, mithun, and yak. On average, animal dung production per day is around 4–5% of the body weight [37]. The composition of animal waste is organic material, moisture, and ash. This indicates the massive production of animal manure, having the potential of biogas.

-

3

Municipal solid waste—This includes both organic and inorganic wastes. Typical composition of MSW waste remains vegetables, leaves, grass, paper, plastic, glass, ceramics, metal stones, ashes, etc. Main physical components are compostable (40–60%), recyclable (10–30%), and inert (30–50%) [33]. For Indian MSW, anaerobic digestion and composting are favoured over incineration because of the presence of high compostable fraction and high moisture content [38].

-

4

Wastewater—The wastewater is categorized into two fractions, depending on their characterizations and source, as described.

-

i)

Sewage—Discharge of sewage in watercourses is the most crucial water-polluting source in India. Currently, 61,948 MLD of sewage is generated in urban areas of India, while only 23,277 MLD (37.57%) of treatment capacity is installed. Wastewater sludge can be anaerobically digested and generate biogas [39].

-

ii)

Industrial—The effluent from the industries (sugar, distillery, dairy, pulp and paper, starch, etc.) usually have high BOD and, thus, possess a more significant threat to water pollution. The dairy sector is engaged in waste production through numerous operations such as silo washing, can and crate cleaning, plant rinsing, tanker rinsing, milk processing, and other dairy products. The value of BOD, COD, and solids of wastewater from these industries indicates the potential of biogas [40,41,42].

-

i)

2.1 Calculation methodology of biogas potential from different biomass

2.1.1 Agriculture crop residue

The agricultural residue generated from the cereal, pulses, oilseed, and horticulture can be used as the resources to produce biogas. First, the crop production of an ith crop at sth state (\({\mathrm{CP}}_{\mathrm{i},\mathrm{s}}\)) is estimated from the crop area of the ith crop at sth state (\({\mathrm{A}}_{\mathrm{i},\mathrm{s}}\)), and its corresponding crop yield (\({\mathrm{Y}}_{\mathrm{i},\mathrm{s}}\)) (Eq. 1). State-wise area under cultivation and an average yield of principal crops data available from the Ministry of Statistics and Program Implementation is a source for estimating the crop production (Table S.1 and Table S.2) [43]. Gross residue production of the ith crop at sth state (\({\mathrm{GRP}}_{\mathrm{i},\mathrm{s}}\)) is determined from crop production (\({\mathrm{CP}}_{\mathrm{i},\mathrm{s}}\)) and residue to crop ratio (RPRi) (Eq. 2). Surplus residue production of the ith crop at sth state (\({\mathrm{SRP}}_{\mathrm{i},\mathrm{s}}\)) is estimated from gross residue production (\({\mathrm{GRP}}_{\mathrm{i},\mathrm{s}}\)) and collection efficiency (\({\mathrm{CE}}_{\mathrm{i},\mathrm{s}}\)) of the ith crop at sth state (Eq. 3). Collection efficiency and RPR values are obtained from the Biomass Resource Atlas of India (BRAI). Hiloidhari et al., 2014 used a similar methodology to account for the surplus crop residue. Biogas potential (\({\mathrm{BP}}_{\mathrm{i},\mathrm{s}}\)) from crop residue is estimated by surplus residue production and biogas yield \({(\mathrm{BY}}_{\mathrm{i}})\) from each crop (Eq. 4). Ignoring the spatial variations, values of RPR, and biogas yield of various crops along with the sources is mentioned in Table 1. The biogas yield of different residues such as ragi straw, sesame stalk, nigerseed stalk, gram stalk, tur stalk, and jute stalk are not mentioned in any previous studies. So, these particular residues are not included in estimating the potential of biogas. Overall, the biogas potential of sth state \(({\mathrm{BPCR}}_{\mathrm{s}})\) is calculated by the addition of the potential of all crops considered for the study (Eq. 5).

2.1.2 Animal wastes

The dung of the animals such as cattle, goats, buffaloes, sheep, horses, pigs, and poultry has enormous potential for biogas generation. Firstly, the dung production of an ith animal at sth state (\({\mathrm{DP}}_{\mathrm{i},\mathrm{s}}\)) is estimated, which is dependent on the population of an ith animal at sth state (\({\mathrm{AP}}_{\mathrm{i},\mathrm{s}}\)) and average droppings per day of ith animal (\({\mathrm{DPD}}_{\mathrm{i}}\)) (Eq. 6). State-wise number of livestock poultry data, available from the Department of Animal husbandry and Dairying is used for estimating the dung production (Table S.3) [45]. Cattle excrement is extremely difficult to gather because they are allowed to graze in open fields. Hence, cattle dung can only be collected from the droppings at cattle sheds, which are typically located in rural locations. Then the surplus dung available (\({\mathrm{SDA}}_{\mathrm{i},\mathrm{s}}\)) is determined from the dung production (\({\mathrm{DP}}_{\mathrm{i},\mathrm{s}})\) and collection efficiency (\({\mathrm{CE}}_{\mathrm{i}}\)) of an ith animal (Eq. 7). Biogas potential of an ith animal at sth state \({(\mathrm{BP}}_{\mathrm{i},\mathrm{s}})\) is estimated from surplus dung available \({(\mathrm{SDA}}_{\mathrm{i},\mathrm{s}})\) and biogas yield of ith animal (\({\mathrm{BY}}_{\mathrm{i}}\)) (Eq. 8). Ignoring the spatial variation, average dropping per day, and biogas yields of animals included in the study are mentioned in Table 2. Overall, biogas’ potential of animal wastes (\({\mathrm{BPAW}}_{\mathrm{s}}\)) at sth state is estimated by the addition of biogas potential from each animal (Eq. 9).

2.1.3 Municipal solid waste

The available municipal solid waste (\({\mathrm{AMSW}}_{\mathrm{s}}\)) of sth state is estimated through the generation of municipal solid waste (\({\mathrm{MSW}}_{\mathrm{s}}\)) of sth state and collection efficiency (\({\mathrm{CE}}_{\mathrm{s}}\)) of sth state (Eq. 10). State-wise waste generation data is obtained from the Ministry of Housing and Urban Affairs (Table S.4) [46]. The organic fraction of municipal solid waste (\({\mathrm{OFMSW}}_{\mathrm{s}}\)) of sth state is estimated through the organic fraction (\({\mathrm{OF}}_{\mathrm{s}}\)) available in the available municipal solid waste (Eq. 11). Biogas potential of available municipal solid waste (\({\mathrm{BPAMSW}}_{\mathrm{s}}\)) of sth state is estimated by the product of the organic fraction of municipal solid waste and biogas yield of municipal solid waste (\({\mathrm{BY}}_{\mathrm{msw}}\)) (Eq. 12). Collection efficiency data is obtained from the annual report of Centre pollution control board (CPCB) [47]; however, data of Madhya Pradesh and Bihar is not available in the dataset, so the average values of the collection efficiency of reported states were considered in place of missing values. The values of various parameters considered in estimating the potential from MSW is mentioned in Table 3.

2.1.4 Wastewater

Sewage.

The biogas potential of sewage of sth state (\({\mathrm{BPS}}_{\mathrm{s}}\)) is estimated by multiplying the sewage generation (\({\mathrm{SG}}_{\mathrm{s}}\)), chemical oxygen demand (COD) of influents, COD removal efficiency (RE), and biogas yield factor (BY) (Eq. 13). The wastewater generation data available on the ENVIS Centre on Hygiene, Sanitation, Sewage Treatment Systems, and Technology is used for estimating the biogas potential of wastewater (Table S.5) [48]. It is assumed that sewage treatment is done through an up-flow anaerobic sludge blanket (UASB) as it is a sustainable technology. Also, COD removal efficiency is dependent on the post-treatment technology used [49]. The values of various parameters considered in assessing the potential from sewage are mentioned in Table 4.

Industrial wastewater.

The state-wise biogas potential from a different industry (sugar industry, distilleries, and dairy) is estimated in the same manner as in Sect. 2.4 (Eq. 14). Installed capacity of installed data of sugar and dairy industry is taken from Indiastat website (Table S.6 and Table S.7) [50]. The quantity and chemical composition of wastewater generated is dependent on the type of raw material and chemical process undergone [3]. Different parameter values used in this study for estimating the potential from various industries, such as the sugar industry, distilleries, and dairy, are mentioned in Table 5, Table 6, and Table 7, respectively.

2.2 State-wise and total biogas potential

Biogas produced from various biomass resource is summed up to estimate the overall state biogas potential (BPs) (Eq. 15).

where \({\mathrm{BP}}_{\mathrm{I}}\) is total biogas potential in India (Eq. 16).

2.3 Uncertainty calculation and sensitivity analysis

The influence of variability of biogas yield value of various substrate mentioned in literature on our biogas potential estimations was next investigated using a sensitivity analysis. It is a method of determining how different sources or input values of each variable affect a specific dependent variable. Global sensitivity analysis is defined as the variation of all input parameters (in our case biogas yield of each substrate) at the same time, and they are normally constructed according to a proper probability distribution. For a model, Monte Carlo (MC) simulation repeats the same operation (usually for hundreds or thousands of times) using inputs generated by suitable probability density functions [51]. In first step, the uncertainty of model input variables was determined in the MC simulation. Normal distribution of biogas yield (input variables) is assumed [52] with each input parameter’s uncertainty range is considered to have deviation of \(\pm\) 10% of its nominal value. An input sample (X) is thus produced as mentioned in Eq. 17. The desired output vector is obtained by computing Y (i.e., Eq. 18) for each row of matrix X (i.e., Eq. 17) [53]. The analysis was performed using (N = 10,000) trials.

where \({BP}^{1}\) is biogas potential obtained from particular biomass with input given by the row vector \({BY}_{1}^{(1)}\), \({BY}_{2}^{(1)}\), …, \({BY}_{r}^{(1)}\), and so on for the other row of matrix X (i.e., Eq. 17). The process is repeated for all biomass resources (i.e., agricultural residue, animal waste, municipal solid waste, and waste water). Furthermore, the simulation is extended to total biogas potential in India (i.e., Eq. 16)

With model input X and output Y, scatter plot is produced against N values of each r input factors. The sensitivity/uncertainty of the parameters was determined by graphing the input vs. output values, often known as a scatter plot. It is a handy tool for quickly determining the relationship between inputs and outcomes. If any factor has a significant effect on any dependent variable, a visible pattern should appear in the associated scatter plot; or in the absence of a distinguishing effect, little or no pattern should be expected [53].

2.4 State-wise biogas utilization

State-wise installed data of biogas plants under the NBMMP and NNBOMP is obtained from the annual report of the Ministry of Renewable Energy (MNRE) [54]. To estimate the biogas generation from various installed plants, it is assumed the average size of the plants installed under NBMMP and NNBOMP is 3m3, and the hydraulic retention time (HRT) is 40 days. Data of established state-wise biogas plants under the BPGTP is obtained from the MNRE website [23]. Also, the reports available on the Ministry of Power is used to estimate the state-wise installed waste to energy biogas and bio-CNG plants [55]. Total installed capacity in a state is determined by adding the biogas generating from plants installed in a state under different schemes such as NBMMP, NNBOMP, BPGTP, and waste to energy. State-wise utilization percentage of biogas is calculated by dividing the total installed capacity in a state by the potential of biogas that could be generated in a state (Eq. 19).

2.5 Economic analysis of different biogas system on the basis of end use:

For economic evaluation, indicators such as net present value (NPV) and internal return rate (IRR) are used (Eq. 20). Time value of expected cash flow (costs and benefits) is determined using NPV and its positive value of indicates that the investment is beneficial from economic perspective.

where \(CC\) is capital cost, \({OMC}_{t}\) is operational and maintenance costs, \({B}_{t}\) is benefits in lifespan of project (i.e., t = 20 years), r is discount rate which is assumed to be 15%. Discount rate at which NPV is zero is known as IRR. Land, buildings, and equipment are examples of fixed costs. Throughout the project’s life cycle, variable costs emerge on a regular basis. Raw material costs, power, salaries, diesel, packing, maintenance, and loan interest are all included. In this study, different biogas system on the basis of end usage (such as cooking fuel, electricity and vehicle fuel) is evaluated. The complete list of variables for aforementioned 3 types of biogas system, along with their price, which is used in the study, is mentioned in Table S8. Fixed and variable costs are all expected to rise by 2% every year. The interest amount (ia) on bank loan is calculated using (Eq. 21).

where ia is the interest amount, l \(\mathrm{a}\) is the loan amount, \(\mathrm{ir}\) is the interest rate, and ly is loan years. It is assumed that one half of the total investment is taken as a business loan for 5 years, where an ir of 18% is charged.

3 Results and discussions

3.1 Biogas potential from crop residues

Gross residue available in India from the principal crops is found to be 708.18 MT. The maximum amount of 392 MT is contributed by cereals, followed by sugarcane at 116 MT. Annually, 208.19 MT of surplus residue is available (29% of gross residue). Out of this, 88 MT is contributed by cereals. It is estimated that surplus crop residues from principal crops have biogas potential of around 39.07 billion m3/year. Contribution of cereals (rice, wheat, maize, bajra, barley, small millets, and jowar) is about 17.51 billion m3/year (45%) followed by sugarcane 15.97 billion m3/year (41%) at a crop group level (Fig. 1a). Even though the production of gross residue from paddy (rice) is most out of all the crops, it produces less surplus residue than sugarcane. This is owing to the fact that rice wastes have more competitive applications (feedstock, packaging material, and fuel) than sugarcane. The contribution of horticulture (banana and coconut) is 3.4 billion m3/year (9%), oilseed (mustard and rapeseed, linseed, soybean, safflower, sunflower, and groundnut) is 1.11 billion m3/year (3%), and others (cotton) are 1.07 billion m3/year (3%). In cereals, at individual crop levels, rice contribution is 9.04 billion m3/year (23%), followed by wheat 4.99 billion m3/year (13%) out of total potential. Table 1 shows that there is a considerable variation of biogas yield from different crop residues, so it is essential to account for these variations at crop level during estimation. For example, the Surplus residue of cotton (22MT) is observed to be more than banana (20 MT), but the estimated biogas potential from banana residue is more than cotton. It is because the biogas yield of banana is 165.3 m3/ton, and cotton is 48.98 m3/ton.

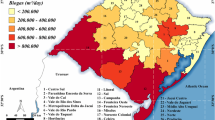

The variation of biogas potential is found significant among the states of India. Maximum contribution value of 9.31 billion m3/year (23.8%) is from Uttar Pradesh followed by Punjab and Maharashtra 4.91 billion m3/year (12.5%) and 4.4 billion m3/year (11.3%) respectively (Fig. 1b). In Uttar Pradesh, residues from sugarcane contribute 6.59 billion m3/year (16.87%) and from rice (straw and husk) 1.74 billion m3/year (2.92%). Together, sugarcane, rice, and wheat contribute 8.62 billion m3/year (which is 92.6% of biogas potential in the state and 22% of biogas potential in the country). In Punjab, mainly rice and wheat contribute 4.5 billion m3/year (91.8% of the state’s potential and 11.5% of the country’s potential). The combined potential of 8 states (Arunachal Pradesh, Goa, Manipur, Meghalaya, Mizoram, Sikkim, Nagaland, and Tripura) is found to be only 0.2 billion m3/year (0.58%).

The results shows a significant potential from agricultural residue, however collecting and transporting these leftovers for anaerobic digestion remains a barrier, but it may be doable provided the controlling agencies establish an adequate policy to ensure their effective usage. Also, residues are not available throughout the year, as crops are usually cultivated in two seasons, i.e., kharif and rabi. So, due to poor supply chains and low collection efficiency in India, there are concerns about feedstock supply and quality. Fluctuations in feedstock supply and quality might reduce the plant’s production efficiency, lowering its long-term profitability. Hence, to install the plants based on agricultural residue, proper planning must be done for storage facilities of feedstock throughout the year.

3.2 Biogas potential from animal wastes

Annually, total dung production from different livestock and poultry is about 1508.30 MT. Overall, biogas potential from surplus animal manure in India is found to be 29.141 billion m3/year. The maximum contribution is from cattle, which is around 13.92 billion m3/year (47.8%) and is followed by buffaloes 11.89 billion m3/year (40.8%). More than 90% of the total potential of livestock waste is from cattle, buffaloes, and poultry. Contribution of animals such as sheep, goats, pigs, horses, ponies, mules, donkeys, camels, yaks, and mithuns is only 1.90 billion m3/year (6.51%). Uttar Pradesh has a maximum biogas potential of 5.02 billion m3/year (17.23%) from animal waste, which is followed by Rajasthan and Madhya Pradesh having a possibility of 2.62 billion m3/year (9%) and 2.41 billion m3/year (8.28%) respectively (Fig. 2). Individually, the maximum potential of 3.35 billion m3/year (11.51%) is from buffaloes in Uttar Pradesh, followed by cattle in Madhya Pradesh 1.431 billion m3/year (4.91%).

Our calculations indicate a huge scope for biogas from animal waste, though major portion of plants based on animal dung are installed in rural areas. In such case the initial investment of the biogas plant is a major impediment to the adoption of biogas plants among rural communities. The financial incentive for establishing a small-scale biogas plant is now targeted at households with sufficient livestock ownership under the NBMMP scheme. A large proportion of rural households in the middle- and lower-income brackets are left out of this classification. To enhance biogas distribution in rural regions, a bottom-up method should be used [56].

3.3 Biogas potential from municipal solid wastes

The total estimated potential from the municipal solid waste in India is 2.20 billion m3/year. Out of total contribution, Maharashtra and Tamil Nadu have the possibility of 377.54 million m3/year (17%) and 241 million m3/year (11%), respectively (Fig. 3). Although MSW generation in Uttar Pradesh is more than in Tamil Nadu, its biogas potential is less. This is because the collection efficiency is 91.3% in Tamil Nadu and only 75% in Uttar Pradesh. Similarly, the generation of MSW is more in Rajasthan than Punjab, but the estimated biogas potential of Punjab is much more than Rajasthan. This is again because the collection efficiency of Punjab (99.53%) is more than Rajasthan (49.45%). These figures indicate that the states should increase their collection efficiency so that more organic waste is available for the generation of biogas. The estimated biogas potential from MSW is calculated as 3.37 billion m3/year [3]. The amount of gas generated from the organic fraction of MSW varies from plant to plant, depending on the plant’s design specifications as well as the properties of the feed materials. The gas yield of AD plants in India could be increased by changing the reactor architecture. When it comes to microbial development requirements in anaerobic digesters, MSW is generally inadequate in both nitrogen and phosphorus. Mixing waste water (sewage sludge, dairy waste and distillery waste) and other wastes can help AD plants run more efficiently. The above research, on the other hand, is based on the most cautious estimate of gas yield data from OFMSW AD reactors in Indian conditions. The estimated potential is lower than the previous studies because the collection efficiency of MSW in different states is accounted for in this study.

Despite having considerable promise of biogas from municipal solid waste there are several challenges involved in tapping the potential. For example, municipalities in cities have limited budget and technical competencies. As a result, the private industry has a critical role to play in expanding the use of biogas technology for organic treatment plants. The lack of private sector participation in the biogas sector in metropolitan areas has been identified as a major issue. The concerns connected with biogas technology are exacerbated by the unknown factors around waste quality and availability. Even in the case of public–private partnerships (PPPs), private actors bear these risks, which inhibits private investment in the industry.

3.4 Biogas potential from wastewater

The estimated potential of biogas from sewage in India is 1.25 billion m3/year. Maharashtra, with the possibility of 165.53 million m3/year (13.23%), is the top contributor, followed by Uttar Pradesh 144.81 million m3/year (11.57%) and Tamil Nadu 113.81 million m3/year (9.09%) (Fig. 4a). In the sugar and distillery industry, the estimated potential is 3.33 billion m3/year of biogas (Fig. 4b). The estimated biogas potential from the dairy industry is 28.76 million m3/year (Fig. 4c). The total estimated biogas potential from wastewater is 4.61 billion m3/year. Out of overall potential from wastewater, Maharashtra has the highest potential of 1.27 billion m3/year, followed by Telangana and Karnataka with a potential of 985.8 million m3/year and 509.8 million m3/year respectively. As a high-strength effluent producer, the distillery industry must adhere to stringent pollution control standards. As a result, the industry is being forced to employ wastewater treatment procedures in order to meet discharge standards prior to disposal. Distilleries are one of the most promising sites for energy generation using biomethanation in such a scenario. For industrial effluents, in order to meet the standards specified by the Central Pollution Control Board, a post-treatment process is still required following anaerobic digestion (CPCB). However, because most dairy operations use aerobic plants for effluent treatment, building an anaerobic plant after tearing down the existing aerobic unit is not an option. Furthermore, because they are in the small-scale sector, most of them do not believe it is economically possible to build a treatment plant, despite the fact that their high-strength effluent exceeds the pollution limitations [27].

3.5 Total estimated state-wise biogas potential from a different organic substrate

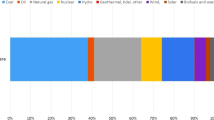

Total biogas potential from various organic substrate like agricultural residue, livestock waste, municipal solid waste, and wastewater in India is 74.795 billion m3/year. Out of this, the maximum contribution is from crop residue 38.84 billion m3/year (51.93%), followed by livestock waste 29.14 billion m3/year (38.96%) (Fig. 5). More than 90% contribution of total potential is from crop residue and livestock waste. There is a significant difference of biogas potential among the states of India. It ranges from the minimum value of 15.94 million m3/year in Sikkim to a maximum amount of 14,727.75 million m3/year in Uttar Pradesh. The reason is mainly that Uttar Pradesh is having the highest population of livestock and the highest surplus residue potential (38 MT). After Uttar Pradesh, Maharashtra (8.05 billion m3/year), Punjab (5.85 billion m3/year), Rajasthan (4.73 billion m3/year), Karnataka (4.72 billion m3/year), Madhya Pradesh (4.72 billion m3/year), and Tamil Nadu (4.63 billion m3/year) are major biogas potential states of India. The highest potential among the north-eastern states is of Assam (1.39 billion m3/year). It is observed that the finding of this study varies from previous research. For example, Rao et al. (2010) reported a biogas potential of (excluding wastewater) around 40.734 billion m3/year [3]. Nautiyal et al. (2015) reported that biogas potential 48.22 billion m3/year of from manure [57]. According to Kaur et al. (2017) the potential of biogas from livestock generated biomass (263.70 billion m3/year) [25]; Shivika et al. (2017) mentioned biogas potential in a range of 29–48 billion m3/year [58]. Sukhesh and Rao (2018) estimated the methane potential of 18.67 billion m3/year from surplus paddy, wheat, and maize residue [24]. The variations in estimation are mainly due to differences in consideration of various parameters. Hiloidhari et al. (2014) also reported that there is inconsistency in data of different parameters in documents from different agencies, and complete or transparent statistics are often not provided [44]. The bottom-up approach in this study, with consideration of each biomass separately, has attempted to overcome the limitation of previous findings.

3.6 Uncertainty and sensitivity analysis

From, Monte Carlo simulation (N = 10,000), uncertainty associated with various biomass’ biogas potential is presented in Fig. 6. It can be observed from the box whisker plot that the distribution is symmetric about mean. Inter quartile range (IQR) or middle 50% of box plot, is a measure of variability. IQR of biogas potential from crop residue, animal waste, MSW, sewage, and industrial wastewater is 2664.72, 2494.20, 298.34, 167.94 and 448.72 respectively. It shows that even after 10% deviation is considered in biogas yield from nominal value, the potential of biogas generation is still very high (Table 8). Total biogas potential from all biomass in India is (mean = 74.94 billion m3/year, std. dev = 2.71 billion m3/year, min = 64.63 billion m3/year, max = 84.85 billion m3/year). For sensitivity analysis, usually the scatter plots are used as starting point. In total, there were 34 scatter plots for presented in which shows the influence of each residue/biomass on total biogas potential (Fig. S1). However, for brevity purpose, only 9 of these residue/biomass plots are given in main text (Fig. 7). It can be clearly seen in Fig. 7e that Y (total biogas potential) is more sensitive to X10 than it is to any other input factors (biogas yield). Such a conclusion can be drawn as the pattern (or shape) presented in the plot for X10 is better than rest. Ordering of the top 5 influential substrate is mentioned in Eq. 20. Scatterplot with little or no shape, example (X2, X4, X26, X29) plot of which shows a very uniform cloud of points on the abscissa over the range of the input factor, is nearly always an indicator that the parameter is less influential than factor X10. Since R2 inform us how much the variation in output model is explained by variation in input to the model, so influential parameters can also be identified using the R2 of the scatter plot. Larger slope indicates the stronger correlation among the input and output parameters [51].

where X10 is sugarcane bagasse, X19 is cattle dung, X20 is buffalo dung, X1 is rice straw, and X3 is wheat straw.

Scatter plot of variation of biogas yield of various substrate input on abscissa vs variation of biogas potential on ordinate (Where X1 is rice straw, X2 is rice husk, X3 is wheat straw, X4 is maize stalk, X10 is sugarcane bagasse, X19 is cattle dung, X20 is buffalo dung, X26 is donkey dung, X29 is mithun dung)

The results indicate that variation of biogas yield from substrate can easily change overall potential. However, the overall potential in India is significant and should be immediately tapped into. Overall in India, major substrate that should be focused into is sugarcane residue, cattle dung, buffalo dung, rice straw and wheat straw. For cattle and buffalo dung, national policy such as NBMMP is already in effect. However, waste to energy program that focus on agricultural residue is still in its early phase and has very long way to go.

3.7 State-wise biogas utilization

Biogas generated from the installed biogas digesters in India is estimated at around 3.635 billion m3/year. Out of the total, 2.72 billion m3/year (75.04%) is quantified to be generated from family size digesters installed under NBMMP and NNBOMP. The maximum contribution is from Maharashtra (497.96 million m3/year), which is followed by Andhra Pradesh (303.04 million m3/year). Waste to energy biogas plants has a contribution of 875 million m3/year (24.06%); Uttar Pradesh has the maximum contribution of 206.05 million m3/year (Fig. 8). Least contribution is from the biogas plants installed under the BPGTP scheme (32.11 million m3/year) (Table 9). More than 55% of total installed capacity comes from the five states: Gujrat (306.65 million m3/year), Karnataka (326.52 million m3/year), Andhra Pradesh (384.25 million m3/year), Uttar Pradesh (448.70 million m3/year), and Maharashtra (671.40 million m3/year). The total installed capacity of states in the northeast region of India is 99.02 million m3/year (2.72%). Among the north-eastern states, Assam has the maximum installed achievement of 75.79 million m3/year.

The average utilization of biogas in India is 4.86%. Looking at the state-wise biogas utilization scenario, it can be seen that there is a massive gap between the estimated potential and installation. The maximum percentage of biogas potential is utilized by the Uttarakhand (32.93%) and is followed by Sikkim (31.07%) (Fig. 9). Uttar Pradesh, which has the highest biogas potential, utilizes only 3.05% of its available resource.

However, regardless of several national schemes, the results in this study indicate an inadequate utilization of potential and constrained diffusion. Economic limits in infrastructure construction, logistic challenges, antiquated and inefficient garbage disposal, collection, and management systems, and a general lack of acceptance of new ideas in favour of time-tested old waste disposal methods are some of the identified barriers. The need to maximize the use of India’s great potential for biomass-based energy generation while also alleviating the country’s severe power shortage necessitates the incorporation of bioenergy into national energy policy, allowing for the formation of a balanced energy mix. This, in turn, necessitates the advancement of bioenergy technologies beyond the phases of testing, innovation, and demonstration to implementation via proper funding methods. Between technological and profitable potential and realizable potential, there is a huge gap. Many things that are technically feasible are rejected for a variety of reasons, including environmental protection, a shortage of skilled personnel, economic possibilities, and even social/psychological factors. The barrier for dissemination or adoption of biogas technology ranges from different factors like financial, social, technical, and institutional [59]. Factors like high capital cost, bad design/installations, overfeeding of digesters, and leakage were found to be common [58]. In another study, Singh et al. (2020) found common issues such as market, operation, finance, and regulation. In market—organic manure market is missing, only limited players are present. In operation—non segregated waste supply, skilled labour availability, feedstock security. In finance—business viability insecurity, higher capital cost, and payback period. In regulation—inclination towards power based projects. These challenges can be mitigated through; in market—creating awareness, collaboration with academic institution; in operation—resource mapping, capacity building; in finance—market development, different financial models; in regulation—balance of centralized and decentralized technology [60]. Furthermore, the land and water requirements for biogas are increasingly posing a problem [61].

As discussed, there are numerous barriers in both launching and implementing AD technology. However if resources are fully utilized, AD technology may help to increase biogas outputs, notably methane, which can be used as a clean energy source in cooking, electricity or vehicle fuel. Animal waste based small-scale AD can help rural people save money on energy and lessen their reliance on firewood [62]. Usmani (2020) found that India has vast biomass resources and proposes that these resources be used in the transportation sector [63]. Compressed biogas (CBG) has the ability to offset up to 8.5% of India’s fossil fuel imports, boosting energy security significantly [64]. Using various biomass resources, 62 MTA of CBG can be produced [65]. In other few assessment studies, for example, Singh et al., (2020) concluded with the help of life cycle assessment study that sewage based biogas plant has beneficial impact on environment [66]. In another study, biogas based on MSW shows promising results and concluded that solid-state AD process is a viable option for pre-processed OFMSW [67]. This shows that biogas production in urban as well as rural areas using natively obtainable resources such as agricultural residues and livestock manure would aid in the achievement of numerous sustainable development goals, including gender equality and women’s empowerment (SDG 5), universal coverage to affordable and clean energy (SDG 7), sustainable cities and communities (SDG 11), responsible consumption and production (SDG 12), and combating climate change and its consequences (SDG 13). Aside from that, reducing regional air pollution will be aided by enacting strict regulations that prohibit crop leftovers burning, as well as monetary benefits for the acquisition and transit of residues from agricultural land to storage areas, thus ensuring a steady supply of raw material for bioenergy power plants. Biogas production from crop waste is a less expensive and energy intensive technology that adheres to the circular economy principles [68]. Renewable energy from OFMSW in decentralized waste processing facilities could be one of the finest choices for MSW treatment and disposal sustainability in India. The use of OFMSW from the MSW could reduce landfill space. Producing clean fuel from renewable feedstock while also conserving natural resources and lowering GHG emissions will be a significant benefit in dealing with India’s future MSW concerns. By removing the high-moisture organic waste from the MSW stream, the remaining portion will have a higher calorific value, allowing for incineration. Since, biogas has a number of societal advantages. Focus in India should be on expansion of biogas production as well as utilization.

3.8 Economic analysis

NPV of biogas plants used as cooking fuel, electricity, and vehicle fuel is 0.18, 478.89, and 168.05 respectively; thus, it is economically beneficial, according to the findings of this study. Even though NPV of various biogas system is positive, the maximum number of biogas plant (> 5 million) is installed under NBMMP whose main objective is to use biogas as a cooking purpose. Also, 75.04% total biogas generation in India is from plant installed under NBMMP scheme. Comparatively, BPGP (for electricity) and waste to energy (for vehicle fuel) programs are new and hence it can be seen that number of total plants installed and total biogas generated from these plants are also fewer than the NBMMP. IRR of three biogas system can be seen in Fig. 10, and it can be observed that it is considerably high. As economically, these plants are beneficially to install; hence, in future, the acceptability of plants under BPGP and waste to energy is also expected to increase.

3.9 Circular economy approach

The population is increasing, so is the demand for raw materials. The availability of critical raw resources, on the other hand, is limited. Furthermore, obtaining and using raw materials has a significant environmental impact. It also increases energy consumption and CO2 emissions. However, by optimizing the use of raw materials, CO2 emissions can be reduced. The circular economy is a production and consumption paradigm that encourages people to reuse and recycle existing materials and products for as long as feasible. In reality, this minimizes the overall requirement of the resource and consequently reduces waste.

In this study, it is observed that there is a huge potential to use different biomass (agricultural residue, animal waste, municipal solid waste, wastewater) to generate biogas. CO2 emissions from biomass such as crop residue and animal manure are not included. It is because in case of crop residue they were recently fixed by photosynthesis when plants were growing. The CO2 in biogas created from animal dung comes from the feed ingested by the animals [69]. As a result, the use of biogenic fuels has the added benefit of being environmentally friendly. Biogas is a promising biofuel that may be produced utilizing the AD process from biomass. Since no cultivation operations are required, biogas produced from waste has no negative effects on land use when compared to liquid biofuels (biodiesel and bioethanol). It is also observed that economically, different biogas system has high rate of return (Fig. 10). Overall, the use of biogas can not only solve the energy challenge to an extent but also it will stop the further environmental degradation (no open field burning, waste elimination and treatment and GHG reduction). Furthermore, direct and indirect jobs are created which will help in tackling social issues such as employability. Soil quality is also said to be improved by utilizing the digestate as organic fertilizer [68]. A circular economy based on biomass to biogas necessitates an integrated approach that addresses agricultural waste management, usage, and legislation. Biomass has been unable to achieve an economic value for which farmers and stakeholders are inspired and encouraged to participate in biomass waste based biogas circular economy due to supply chain flaws and a lack of technical understanding [70]. This can also be seen from low utilization of biomass resource in India as per calculation in this study. Different circular economy models such as co-digestion, recovery of multiple products, and combined bioprocess is proposed in previous study as a solution [71].

4 Conclusion

The present study estimated the biogas potential and biogas utilization from all primary biomass feedstocks (crop residue, livestock waste, municipal solid waste, and wastewater) for all states of India. The significant contributors from crop residue are sugarcane, rice, wheat, banana, and maize. Biogas potential from the crop residue is estimated highest in Uttar Pradesh (9.31 billion m3/year). Cattle and buffaloes are significant contributors to livestock wastes. The maximum contribution is by Uttar Pradesh (5.021 billion m3/year). For municipal solid waste and wastewater, in both categories, Maharashtra is leading with an estimated potential of 385.92 million m3/year and 1274.22 million m3/year, respectively. India has a total estimated potential of 74.795 billion m3/year, with a 90% contribution from crop residue (38.84 billion m3/year) and livestock waste (29.14 billion m3/year). Overall, Uttar Pradesh has the maximum potential of 14.73 billion m3/year. The estimated generation from the installed biogas digesters in India is 3.635 billion m3/year. The country’s average biogas utilization is 4.86%. Economic analysis shows positive NPV of three biogas system on the basis of end use. IRR of 29.39, 25.54, and 30.63% is observed with biogas used as cooking, electricity, and vehicle fuel respectively. State-wise estimation and current utilization scenario will help the local government in policy-making and decentralized energy planning.

Abbreviations

- MSW:

-

Municipal solid waste

- GHG:

-

Greenhouse gases

- AD:

-

Anaerobic digestion

- NPBD:

-

National Project on Biogas Development

- KVIC:

-

Khadi and Villages Industries Commission

- AFPRO:

-

Action for Food Production

- BPGP:

-

Biogas Power Generation Program

- BPGTP:

-

Biogas Power Generation (Off-grid) and Thermal Energy Application Program

- NBMMP:

-

National Biogas and Manure Management Program

- NNBOMP:

-

New National Biogas and Organic Manure Program

- SATAT:

-

Sustainable Alternative Towards Affordable Transportation

- HRT:

-

Hydraulic retention time

- MLD:

-

Million liter per day

- CPCB:

-

Centre pollution control board

- MT:

-

Million tonnes

- COD:

-

Chemical oxygen demand

- BOD:

-

Biological oxygen demand

- MNRE:

-

Ministry of Renewable Energy

- MC:

-

Monte Carlo

- \({\mathrm{CP}}_{\mathrm{i},\mathrm{s}}\) :

-

Crop production of an ith crop at sth state

- \({\mathrm{A}}_{\mathrm{i},\mathrm{s}}\) :

-

Crop area of the ith crop at sth state

- \({\mathrm{Y}}_{\mathrm{i},\mathrm{s}}\) :

-

Crop yield of ith crop

- \({\mathrm{GRP}}_{\mathrm{i},\mathrm{s}}\) :

-

Gross residue production of the ith crop at sth state

- \({\mathrm{RPR}}_{\mathrm{i}}\) :

-

Residue to crop ratio of ith crop

- \({\mathrm{SRP}}_{\mathrm{i},\mathrm{s}}\) :

-

Surplus residue production of the ith crop at sth state

- \({\mathrm{CE}}_{\mathrm{i},\mathrm{s}}\) :

-

Collection efficiency of the ith crop at sth state

- \({\mathrm{BY}}_{\mathrm{i}}\) :

-

Biogas yield of ith crop

- \({\mathrm{BP}}_{\mathrm{i},\mathrm{s}}\) :

-

Biogas potential of the ith crop at sth state

- \({\mathrm{BPCR}}_{\mathrm{s}}\) :

-

Biogas potential from crop residue at sth state

- \({\mathrm{DP}}_{\mathrm{i},\mathrm{s}}\) :

-

Dung production of ith animal at sth state

- \({\mathrm{AP}}_{\mathrm{i},\mathrm{s}}\) :

-

Animal population of ith animal at sth state

- \({\mathrm{DPD}}_{\mathrm{i}}\) :

-

Dung per day of ith animal

- \({\mathrm{SDA}}_{\mathrm{i},\mathrm{s}}\) :

-

Surplus dung available of ith animal at sth state

- \({\mathrm{CE}}_{\mathrm{i}}\) :

-

Collection efficiency of ith animal

- \({\mathrm{BPAW}}_{\mathrm{s}}\) :

-

Biogas potential from animal waste at sth state

- \({\mathrm{AMSW}}_{\mathrm{s}}\) :

-

Available municipal solid waste at sth state

- \({\mathrm{MSW}}_{\mathrm{s}}\) :

-

Municipal solid waste at sth state

- \({\mathrm{OFMSW}}_{\mathrm{s}}\) :

-

Organic fraction of municipal solid waste at sth state

- \({\mathrm{BPAMSW}}_{\mathrm{s}}\) :

-

Biogas potential from available municipal solid waste at sth state

- \({\mathrm{BPS}}_{\mathrm{s}}\) :

-

Biogas potential from sewage

- \({\mathrm{RE}}_{ww}\) :

-

Removal efficiency of wastewater

- \({\mathrm{BP}}_{\mathrm{I}}\) :

-

Total biogas potential of India

References

Thomas P, Soren N, Rumjit NP, George James J, Saravanakumar MP (2017) Biomass resources and potential of anaerobic digestion in Indian scenario. Renew Sustain Energy Rev 77:718–730. https://doi.org/10.1016/j.rser.2017.04.053

MoP, Power Sector at a Glance ALL INDIA | Government of India | Ministry of Power, (2020). https://powermin.gov.in/en/content/power-sector-glance-all-india (accessed August 10, 2020).

Rao PV, Baral SS, Dey R, Mutnuri S (2010) Biogas generation potential by anaerobic digestion for sustainable energy development in India. Renew Sustain Energy Rev 14:2086–2094. https://doi.org/10.1016/j.rser.2010.03.031

M. Swaminathan, How can India’s waste problem see a systemic change?, Econ. Polit. Wkly. (2018). https://www.epw.in/engage/article/institutional-framework-implementing-solid-waste-management-india-macro-analysis (accessed April 9, 2020).

Unnikrishnan S, Singh A (2010) Energy recovery in solid waste management through CDM in India and other countries. Resour Conserv Recycl 54:630–640. https://doi.org/10.1016/j.resconrec.2009.11.003

Styles D, Dominguez EM, Chadwick D (2016) Environmental balance of the of the UK biogas sector: an evaluation by consequential life cycle assessment. Sci Total Environ 560–561:241–253. https://doi.org/10.1016/j.scitotenv.2016.03.236

K. Ostrem, N.J. Themelis, Greening waste: anaerobic digestion for treating the organic fraction of municipal solid wastes., 2004.

Angelidaki I, Sanders W (2004) Assessment of the anaerobic biodegradability of macropollutants. Rev Environ Sci Biotechnol 3:117–129. https://doi.org/10.1007/s11157-004-2502-3

Krishania M, Kumar V, Vijay VK, Malik A (2013) Analysis of different techniques used for improvement of biomethanation process: a review. Fuel 106:1–9. https://doi.org/10.1016/j.fuel.2012.12.007

Kondusamy D, Kalamdhad AS (2014) Pre-treatment and anaerobic digestion of food waste for high rate methane production-a review. J Environ Chem Eng 2:1821–1830. https://doi.org/10.1016/j.jece.2014.07.024

Yadvika, Santosh TR, Sreekrishnan S, Kohli V. Rana (2004) Enhancement of biogas production from solid substrates using different techniques-a review. Bioresour Technol 95:1–10. https://doi.org/10.1016/j.biortech.2004.02.010

Scarlat N, Dallemand JF, Fahl F (2018) Biogas: developments and perspectives in Europe. Renew Energy 129:457–472. https://doi.org/10.1016/j.renene.2018.03.006

Iordan C, Lausselet C, Cherubini F (2016) Life-cycle assessment of a biogas power plant with application of different climate metrics and inclusion of near-term climate forcers. J Environ Manage 184:517–527. https://doi.org/10.1016/j.jenvman.2016.10.030

Motghare KA, Rathod AP, Wasewar KL, Labhsetwar NK (2016) Comparative study of different waste biomass for energy application. Waste Manag 47:40–45. https://doi.org/10.1016/j.wasman.2015.07.032

Sfez S, De Meester S, Dewulf J (2017) Co-digestion of rice straw and cow dung to supply cooking fuel and fertilizers in rural India: impact on human health, resource flows and climate change. Sci Total Environ 609:1600–1615. https://doi.org/10.1016/j.scitotenv.2017.07.150

S.K. Khanal, Anaerobic biotechnology for bioenergy production: principles and applications, 2011. https://books.google.co.in/books?hl=en&lr=&id=1RbyLx-GkSMC&oi=fnd&pg=PT7&dq=Khanal,+S.K.,+2008.+Anaerobic+biotechnology+for+bioenergy+production:+principles+and+applications.+John+Wiley+%26+Sons+Inc,+Ames,+Iowa,+United+States.&ots=oUU8ojbnRG&sig=F5Ktn1GJ9 (accessed August 10, 2020).

Abbasi T, Tauseef SM, Abbasi SA (2012) A brief history of anaerobic digestion and “biogas.” Biogas energy. Springer, New York, pp 11–23. https://doi.org/10.1007/978-1-4614-1040-9_2

Singh KJ, Sooch SS (2004) Comparative study of economics of different models of family size biogas plants for state of Punjab, India. Energy Convers Manag 45:1329–1341. https://doi.org/10.1016/j.enconman.2003.09.018

Kumar A, Mandal B, Sharma A (2015) Advancement in biogas digester. Green Energy Technol 201:351–382. https://doi.org/10.1007/978-81-322-2337-5_14

Schemes | Ministry of New and Renewable Energy, Government of India, (n.d.). https://mnre.gov.in/bio-energy/schemes (accessed August 10, 2020).

Swachh Bharat Mission-Gobar-Dhan, (n.d.). https://sbm.gov.in/Gobardhan/SLRM_AboutUs.aspx (accessed August 10, 2020).

MOP&NG, SATAT, (2018). https://www.iocl.com/Satat.aspx (accessed August 10, 2020).

MNRE, Current Status | Ministry of New and Renewable Energy, Government of India, (2020). https://mnre.gov.in/bio-energy/current-status (accessed August 10, 2020).

Sukhesh MJ, Rao PV (2018) Anaerobic digestion of crop residues: technological developments and environmental impact in the Indian context, Biocatal. Agric. Biotechnol 16:513–528. https://doi.org/10.1016/j.bcab.2018.08.007

Kaur G, Brar YS, Kothari DP (2017) Potential of livestock generated biomass: untapped energy source in India. Energies 10:1–15. https://doi.org/10.3390/en10070847

Ramachandra TV, Shruthi BV (2007) Spatial mapping of renewable energy potential. Renew Sustain Energy Rev 11:1460–1480. https://doi.org/10.1016/j.rser.2005.12.002

Das S, Jash T (2009) District-level biomass resource assessment: a case study of an Indian State West Bengal. Biomass Bioenerg 33:137–143. https://doi.org/10.1016/j.biombioe.2008.05.001

Singh J, Panesar BS, Sharma SK (2008) Energy potential through agricultural biomass using geographical information system-a case study of Punjab. Biomass Bioenerg 32:301–307. https://doi.org/10.1016/j.biombioe.2007.10.003

Aich A, Ghosh SK (2016) Organic fraction of municipal solid waste–a valuable source of green energy in India. Int J Energy Sect Manag 10:526–545. https://doi.org/10.1108/IJESM-06-2015-0001

Lata K, Kansal A, Balakrishnan M, Rajeshwari KV, Kishore VVN (2002) Assessment of biomethanation potential of selected industrial organic effluents in India. Resour Conserv Recycl 35:147–161. https://doi.org/10.1016/S0921-3449(01)00112-4

Cardoen D, Joshi P, Diels L, Sarma PM, Pant D (2015) Agriculture biomass in India: part 1. Estimation and characterization. Resour Conserv Recycl 102:39–48. https://doi.org/10.1016/j.resconrec.2015.06.003

Kshirsagar MP, Arora A, Chandra H (2012) Estimation of anaerobic codigestion potential of agri-waste in India and comparative financial analysis. Int J Sustain Energy 31:175–188. https://doi.org/10.1080/1478646X.2011.555819

Dhar H, Kumar S, Kumar R (2017) A review on organic waste to energy systems in India. Bioresour Technol 245:1229–1237. https://doi.org/10.1016/j.biortech.2017.08.159

Vadrevu K, Lasko K (2015) Fire regimes and potential bioenergy loss from agricultural lands in the Indo-Gangetic Plains. J Environ Manage 148:10–20. https://doi.org/10.1016/j.jenvman.2013.12.026

Ravindranath NH, Somashekar HI, Nagaraja MS, Sudha P, Sangeetha G, Bhattacharya SC, Abdul Salam P (2005) Assessment of sustainable non-plantation biomass resources potential for energy in India. Biomass Bioenergy. 29:178–190. https://doi.org/10.1016/j.biombioe.2005.03.005

Lohan SK, Jat HS, Yadav AK, Sidhu HS, Jat ML, Choudhary M, Peter JK, Sharma PC (2018) Burning issues of paddy residue management in north-west states of India. Renew Sustain Energy Rev 81:693–706. https://doi.org/10.1016/j.rser.2017.08.057

Mittal S, Ahlgren EO, Shukla PR (2019) Future biogas resource potential in India: a bottom-up analysis. Renew Energy 141:379–389. https://doi.org/10.1016/j.renene.2019.03.133

Breitenmoser L, Dhar H, Gross T, Bakre M, Huesch R, Hugi C, Wintgens T, Kumar R, Kumar S (2018) Methane potential from municipal biowaste: insights from six communities in Maharashtra, India. Bioresour Technol 254:224–230. https://doi.org/10.1016/j.biortech.2018.01.074

Elango D, Pulikesi M, Baskaralingam P, Ramamurthi V, Sivanesan S (2007) Production of biogas from municipal solid waste with domestic sewage. J Hazard Mater 141:301–304. https://doi.org/10.1016/j.jhazmat.2006.07.003

Acharya BK, Mohana S, Madamwar D (2008) Anaerobic treatment of distillery spent wash-a study on upflow anaerobic fixed film bioreactor. Bioresour Technol 99:4621–4626. https://doi.org/10.1016/j.biortech.2007.06.060

Thompson G, Swain J, Kay M, Forster CF (2001) The treatment of pulp and paper mill effluent: a review. Bioresour Technol 77:275–286. https://doi.org/10.1016/S0960-8524(00)00060-2

Shukla GL, Prabhu KA (1995) Bio-gas production from sugarcane biomass and agro-industrial waste. Sugarcane Agro-Industr Altern 1:157–170

MoSPI, AGRICULTURE - Statistical Year Book India 2018 | Ministry of Statistics and Program Implementation | Government Of India, (2018). http://mospi.nic.in/statistical-year-book-india/2018/177 (accessed December 2, 2019).

Hiloidhari M, Das D, Baruah DC (2014) Bioenergy potential from crop residue biomass in India. Renew Sustain Energy Rev 32:504–512. https://doi.org/10.1016/j.rser.2014.01.025

DADF, Chapter 1 Technical note on the 19th livestock census, (2012). http://dadf.gov.in/sites/default/filess/VolumeI.pdf (accessed August 10, 2020).

MoHUA, State-wise status of implementation of various components under SBM upto January 2020, (2020). http://swachhbharaturban.gov.in/writereaddata/Statewise_status_of_implementation.pdf (accessed August 10, 2020).

CPCB (2017) Annual Review Report 2015–16, Cent. Pollution Control Board. Minist Environ For Clim Chang 24:1–28

MoE&F, National status of waste water generation & treatment: SulabhENVIS Centre, (2021). http://www.sulabhenvis.nic.in/Database/STST_wastewater_2090.aspx (accessed August 10, 2020).

Khan AA, Gaur RZ, Mehrotra I, Diamantis V, Lew B, Kazmi AA (2014) Performance assessment of different STPs based on UASB followed by aerobic post treatment systems. J Environ Heal Sci Eng 12:43. https://doi.org/10.1186/2052-336X-12-43

Indiastat, Socio-economic statistical data and facts about India : Indiastat, (2021). https://www.indiastat.com/ (accessed July 21, 2021).

Turgut SS, Feyissa AH, Küçüköner E, Karacabey E (2021) Uncertainty and sensitivity analysis by Monte Carlo simulation: recovery of trans-resveratrol from grape cane by pressurised low polarity water system. J Food Eng 292:110366. https://doi.org/10.1016/j.jfoodeng.2020.110366

Gebrezgabher SA, Meuwissen MPM, Oude Lansink AGJM (2012) Energy-neutral dairy chain in the Netherlands: an economic feasibility analysis. Biomass Bioenergy 36:60–68. https://doi.org/10.1016/j.biombioe.2011.10.006

Saltelli A, Ratto M, Andres T, Campolongo F, Cariboni J, Gatelli D, Saisana M, Tarantola S (2008) Global Sensitivity Analysis The Primer. https://doi.org/10.1002/9780470725184

MNRE (2018) Ministry of New and Renewable Energy Annual Report 2018–19. https://doi.org/10.1355/9789812308702-004.

MoP, Ministry of Power, (2018) 5–14. https://powermin.nic.in/sites/default/files/uploads/ (accessed December 1, 2019).

Raha D, Mahanta P, Clarke ML (2014) The implementation of decentralised biogas plants in Assam, NE India: the impact and effectiveness of the National Biogas and Manure Management Programme. Energy Policy 68:80–91. https://doi.org/10.1016/j.enpol.2013.12.048

Nautiyal S, Goswami M, Manasi S, Bez P, Bhaskar K, Khan YDI (2015) Potential of manure based biogas to replace conventional and non-conventional fuels in India: Environmental assessment for emission reduction. Manag Environ Qual An Int J 26:3–20. https://doi.org/10.1108/MEQ-04-2013-0034

Mittal S, Ahlgren EO, Shukla PR (2018) Barriers to biogas dissemination in India: a review. Energy Policy. https://doi.org/10.1016/j.enpol.2017.10.027

Schmidt TS, Dabur S (2014) Explaining the diffusion of biogas in India: a new functional approach considering national borders and technology transfer. Env Econ Policy Stud 16:171–199. https://doi.org/10.1007/s10018-013-0058-6

Singh B, Szamosi Z, Siménfalvi Z, Rosas-Casals M (2020) Decentralized biomass for biogas production. Evaluation and potential assessment in Punjab (India). Energy Reports 6:1702–1714. https://doi.org/10.1016/J.EGYR.2020.06.009

Kothari R, Vashishtha A, Singh HM, Pathak VV, Tyagi VV, Yadav BC, Ashokkumar V, Singh DP (2020) Assessment of Indian bioenergy policy for sustainable environment and its impact for rural India: strategic implementation and challenges. Environ Technol Innov 20:101078. https://doi.org/10.1016/j.eti.2020.101078

Gross T, Breitenmoser L, Kumar S, Ehrensperger A, Wintgens T, Hugi C (2021) Anaerobic digestion of biowaste in Indian municipalities: effects on energy, fertilizers, water and the local environment. Resour Conserv Recycl 170:105569. https://doi.org/10.1016/J.RESCONREC.2021.105569

Usmani RA (2020) Potential for energy and biofuel from biomass in India. Renew Energy 155:921–930. https://doi.org/10.1016/J.RENENE.2020.03.146

Jagtap NJ, Dalvi VH (2021) Feasibility study of bio-methane economy in India. Biomass Bioenerg 149:106059. https://doi.org/10.1016/J.BIOMBIOE.2021.106059

Nouni MR, Jha P, Sarkhel R, Banerjee C, Tripathi AK, Manna J (2021) Alternative fuels for decarbonisation of road transport sector in India: options, present status, opportunities, and challenges. Fuel 305:121583. https://doi.org/10.1016/J.FUEL.2021.121583

Singh AD, Upadhyay A, Shrivastava S, Vivekanand V (2020) Life-cycle assessment of sewage sludge-based large-scale biogas plant. Bioresour Technol 309:123373. https://doi.org/10.1016/j.biortech.2020.123373

Tyagi VK, Kapoor A, Arora P, Banu JR, Das S, Pipesh S, Kazmi AA (2021) Mechanical-biological treatment of municipal solid waste: case study of 100 TPD Goa plant, India. J Environ Manage 292:112741. https://doi.org/10.1016/J.JENVMAN.2021.112741

Satpathy P, Pradhan C (2020) Biogas as an alternative to stubble burning in India. Biomass Convers Biorefinery 1:1–12. https://doi.org/10.1007/s13399-020-01131-z

S. Bruun, L. Jensen, S.S.-R. and S. Energy, U. 2014, Small-scale household biogas digesters: an option for global warming mitigation or a potential climate bomb?, Renew. Sustain. Energy Rev. (2014). https://www.sciencedirect.com/science/article/pii/S1364032114001543?casa_token=49ULDCHDhyIAAAAA:DAtwesGU5gcBaCSrAjgknutCC79KmrQ7qnV9wl-7bE9CZ9t2ibbbMVPuPQTkWqo76IfKivmH (accessed November 24, 2020).

Kapoor R, Ghosh P, Kumar M, Sengupta S, Gupta A, Kumar SS, Vijay V, Kumar V, Kumar Vijay V, Pant D (2020) Valorization of agricultural waste for biogas based circular economy in India: a research outlook. Bioresour Technol 304:123036. https://doi.org/10.1016/J.BIORTECH.2020.123036

Wainaina S, Awasthi MK, Sarsaiya S, Chen H, Singh E, Kumar A, Ravindran B, Awasthi SK, Liu T, Duan Y, Kumar S, Zhang Z, Taherzadeh MJ (2020) Resource recovery and circular economy from organic solid waste using aerobic and anaerobic digestion technologies. Bioresour Technol 301:122778. https://doi.org/10.1016/J.BIORTECH.2020.122778

Zhang R, Zhang Z (1999) Biogasification of rice straw with an anaerobic-phased solids digester system. Biores Technol 68:235–245

Haryanto A, Sugara BP, Telaumbanua M, Rosadi RAB (2018) Anaerobic co-digestion of cow dung and rice straw to produce biogas using semi-continuous flow digester: effect of urea addition. IOP Conf Ser: Earth Environ Sci 147:012032

Contreras LM, Schelle H, Sebrango CR, Pereda I (2012) Methane potential and biodegradability of rice straw, rice husk and rice residues from the drying process. Water Sci Technol 65:1142–1149

Wang G (2010) Biogas production from energy crops and agriculture residues

Aqsha A, Tijani MM, Mahinpey N (2014) Catalytic pyrolysis of straw biomasses (wheat, flax, oat and barley straw) and the comparison of their product yields. WIT Trans Ecol Environ 2:1007

Deepanraj B, Sivasubramanian V, Jayaraj S (2014) Biogas generation through anaerobic digestion process-an overview. Res J Chem Environ 18:5

Kumar S, Gandhi P, Yadav M, Paritosh K, Pareek N, Vivekanand V (2019) Weak alkaline treatment of wheat and pearl millet straw for enhanced biogas production and its economic analysis. Renewable Energy 139:753–764

Murphy J, Braun R, Weiland P, Wellinger A (2011) Biogas from crop digestion

Balsari P, Menardo S, Airoldi G (2011) Effect of physical and thermal pre-treatments on biogas yield of some agricultural by-products yield of some agricultural by-products

Biogas App - Indian Biogas Association n.d. https://biogas-india.com/service/biogas-app/ (accessed August 11, 2020).

Zhang Z, Zhang G, Li W, Li C, Xu G (2016) Enhanced biogas production from sorghum stem by co-digestion with cow manure. Int J Hydrogen Energy 41:9153–9158

Lehtomäki A, Viinikainen TA, Rintala JA (2008) Screening boreal energy crops and crop residues for methane biofuel production. Biomass Bioenerg 32:541–550

Wang C, Hong F, Lu Y, Li X, Liu H (2017) Improved biogas production and biodegradation of oilseed rape straw by using kitchen waste and duck droppings as co-substrates in two-phase anaerobic digestion. PLOS ONE 12:e0182361

Braun R, Weiland P, Wellinger A (n.d.) Biogas from energy crop digestion task 37-energy from biogas and landfill gas

Deng Y, Dai B, Xu J, Liu X, Xu J (2018) Anaerobic co-digestion of rice straw and soybean straw to increase biogas production by pretreatment with trichoderma reesei RUT C30. Environ Progr Sustain Energy 37:1050–1057

Kovacic D, Kralik D, Rupcic S, Jovicic D, Spajic R, Tišmac M (2017) Soybean straw, corn stover and sunflower stalk as possible substrates for biogas production in Croatia: a review. Chem Biochem Eng Q 31:187–198

Awulu JO, Omale PA, Wonov TJ (2020) Comparative study of methane production from groundnut straw, bambaranut straw and milkweed plant vol. 4

Eshore S, Mondal C, Das A (2017) Production of biogas from treated sugarcane bagasse. International Journal of Scientific Engineering and Technology 6:224

Salomon FotsoSimo W, Nso Jong E, Kapseu C (2016) Improving biogas production of sugarcane bagasse by hydrothermal pretreatment. Chem Biomol Eng 1:21–5

Zhang H, Ning Z, Khalid H, Zhang R, Liu G, Chen C (2018) Enhancement of methane production from cotton stalk using different pretreatment techniques. Sci Rep 8:3463

Yuan X, Ma L, Wen B, Zhou D, Kuang M, Yang W et al (2016) Enhancing anaerobic digestion of cotton stalk by pretreatment with a microbial consortium (MC1). Biores Technol 207:293–301

Kunchikannan LKNV, Mande SP, Kishore VVN, Jain KL (2007) Coir Pith: A potential agro residue for anaerobic digestion. Energy Sources A Recov Utiliz Environ Effects 29:293–301

Pisutpaisal N, Boonyawanich S, Saowaluck H (2014) Feasibility of biomethane production from banana peel. Energy Procedia 50:782–788

Biogas-Vikaspedia n.d. https://vikaspedia.in/energy/energy-production/bio-energy/biogas (accessed August 11, 2020).

Kanwar SS, Kalia AK (1993) Anaerobic fermentation of sheep droppings for biogas production. World J Microbiol Biotechnol 9:174–175

Khoiyangbam R, Gupta N, Kumar S (2011) Biogas Technology: towards sustainable development. TERI Press, New Delhi

Friman R (1984) Monitoring anaerobic digesters on farms. J Agricult Eng Res 29:357–365

Hennessy J, Eriksson O (2015) Energy and nutrients from horse manure: life-cycle data inventory of horse manure management systems in Gävleborg, Sweden

MitikuTeferra D, Wubu W (2019) Biogas for clean energy. Anaerobic Digestion. IntechOpen, London

Mule dung to replace LPG - Early Times Newspaper Jammu Kashmir n.d. http://earlytimesnews.com/newsdet.aspx?q=86999 (accessed August 11, 2020).

Uche OAU (2007) The effect of donkey-dung on the properties of lateritic soilcrete blocks. J Eng Technol 2:45–54

Camel dung fuels cement production in northern UAE - Reuters n.d. https://www.reuters.com/article/us-emirates-energy-camels/camel-dung-fuels-cement-production-in-northern-uae-idUSKCN1UG0GR (accessed August 11, 2020).

Laskri N, Mizi A, Daas D, Nedjah N, Baccouche M (2016) Biogas production from the anaerobic digestion of lignocellulosics wastes. Pollut Res 35:247–252

Rhode D, Madsen DB, Jeffrey Brantingham P, Dargye T (2007) Yaks, yak dung, and prehistoric human habitation of the Tibetan Plateau. Develop Quater Sci 9:205–224

Joshi R, Ahmed S (2016) Status and challenges of municipal solid waste management in India: a review. Cogent Environ Sci 28:1139434

Resource Assessment for Livestock and Agro-Industrial Wastes-India Prepared for: The GlobalMethaneInitiative2011.https://www.globalmethane.org/documents/ag_india_res_assessment.pdf (accessed August 11, 2020).

Tanksali AS (2013) Treatment of sugar industry wastewater by upflow anaerobic sludge blanket reactor | Request PDF. Int J ChemTech Res 5:1246–1253

Sahu O, Rao DG, Gopal R, Tiwari A, Pal D (2017) Treatment of wastewater from sugarcane process industry by electrochemical and chemical process: aluminum (metal and salt). Journal of Water Process Engineering 17:50–62

By-products of Sugarcane n.d. http://content.indiainfoline.com/wc/archives/sect/suin/ch10.html (accessed August 11, 2020).

Mohana S, Acharya BK, Madamwar D (2009) Distillery spent wash: treatment technologies and potential applications. J Hazard Mater 163:12–25

Kharayat Y (2012) Distillery wastewater: bioremediation approaches. J Integr Environ Sci 9:69–91

Mohan N (2021) Prospects of ethanol & its costing. National Sugar Institute, Kanpur

Shete BS, Shinkar NP (2017) Anaerobic digestion of dairy industry waste water-biogas evolution-a review. Int J Appl Environ Sci 12:1117–1130

Kolev SA (2017) General characteristics and treatment possibilities of dairy wastewater–a review. Food Technol Biotechnol 55:28

Acknowledgements

The authors would like to thank Mr. Siddhant Dash and Mr. Ankit Pratim Goswami, Department of Civil Engineering, Indian Institute of Technology Guwahati, Assam (India), for giving valuable comments and proof read which helped in improving the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Singh, P., Kalamdhad, A. A comprehensive assessment of state-wise biogas potential and its utilization in India. Biomass Conv. Bioref. 13, 12557–12579 (2023). https://doi.org/10.1007/s13399-021-02001-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02001-y