Abstract

Crop residue management and curbing stubble burning is of global interest. For every tonne of rice harvested, approximately 1.4 tonnes of straw is left behind on the crops and a similar proportion applies for the other major crops as well. Direct on-farm burning remains the most common method in India to manage these huge volumes of crop residues. Generating biogas from the crop wastes could be an effective and environment friendly alternative. Biogas is a renewable source of energy, offers controlled waste management along with reducing greenhouse gases and harmful pollutants. The digested sludge when used as an organic fertiliser even completes a sustainable loop of recycling nutrients back into the soil. Crop residues due to their rich organic content have demonstrated excellent biogas potential. Most energy crops have shown methane yields of approximately 300 m3/t of organic matter. This gas could be used as a fuel or converted to electricity or even upgraded to bio-methane. To further optimise the process, different types of pre-treatment methods and co-digestion of the substrates have been identified. The current article aims at providing a perspective on the impact of stubble burning and replacing the practice by producing biogas instead, thus, providing information on the potential, limitations and methods for optimising methane generation from the crop residues.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

India is primarily an agriculture-based country and produces as much as 620 million tonnes (MT) of crop residues every year [1]. Crop residues are defined by the OECD (Organisation for Economic Co-operation and Development) as ‘plant material remaining after harvesting, including leaves, stalks, roots’ [2]. In some cases, by-products like husks and shells after the process of milling and even damaged crops are considered. Crop wastes are generated in India majorly from cereals like rice, wheat (in the form of husk and bran) and millet contributing nearly 70% of the total crop residues. Significant proportions are also generated from sugarcane (as bagasse and molasses), fibre crops, maize, pulses, oil seeds like rapeseed and mustard, coconut and groundnut shells, etc. [3, 4].

These carbon-rich crop residues could be excellent resources to produce energy and the United Nations Environment Program (UNEP) strongly recommends recovering the energy contained in them [5]. Estimates suggest that the available biomass in India has the potential of generating up to 18,000 MW electricity [6]. However, the real scenario is far from this since almost half of the crop residues is rather treated as waste and is burnt openly in the fields [1]. Stubble burning has increased with time due to the increased agricultural activities with the combine harvesters that leave behind long stalks which cannot be tilled back into the soil. Studies estimate that nearly 62% of the rice stubble is set ablaze [7] and alone from rice crop residues, nearly 90–140 MT are burnt each year [8]. States like Punjab and Haryana in north India known as ‘grain bowl of India’ set nearly 50% of the country’s rice stubble on open fire.

Collecting or storing such large quantities of waste become impossible and economically non-viable for the farmers. Besides, the availability of a short window of only ten to twenty days to dispose or utilise the leftover residues eventually encourages the farmers to burn the residues [9]. With improper management facilities and lack of public sector involvement, farmers are unable to afford proper disposal or finding a sustainable solution. Thus, burning away the residues becomes the easiest, cheap and non-labour-intensive method allowing preparation for the following crop cultivation.

1.1 Environmental impact of stubble burning

Extensive open burning of the millions of tonnes of crop residues in India unquestionably results in serious pollution issues. The consequence of such a practice remains a concern as the global and regional atmosphere chemistry of the air along with which the chemical, biological and physical properties of the soil are severely deteriorated [10, 11]. On-farm burning results in increasing the soil temperature to 33.8–42.2 °C that causes nitrogen loss between 20 and 70%, removes the organic material, thus, affecting the nutrient budget of the soil along with decreasing the microbial population in the soil until a depth of up to 2.5 cm [12]. When we think of the loss of nutrients, burning paddy straw alone has been reported to result in a loss of 3.85 million tonnes of organic carbon, 59,000 tonnes of nitrogen, 20,000 tonnes of phosphorous and 34,000 tonnes of potassium annually [10, 11]. Estimates present that burning 1 tonne of rice residue leads to the release of nearly 13 kg particulate matter, 60 kg CO, 1460 kg CO2, 3.5 kg NOx, 0.2 kg SO2 where almost 90% of N and S, and 15–20% of P and K are lost [13]. Greenhouse gases like CO2, CO, CH4, N2O, NOx, SO2, black carbon, aerosols, smoke, non-methyl hydrocarbons (NMHC), volatile organic compounds (VOC) and particulate matter (PM 2.5 and PM 10) are released that further disrupts the climate.

In India, air pollution due to stubble burning in winters has been declared as one of the worst environmental challenges prompting the announcement of public health emergency since the past few years. The government’s agency System of Air Quality and Weather Forecasting (SAFAR) in their findings have indicated direct impact of stubble burning in deteriorating Delhi’s air quality which qualifies as the world’s worst polluted in recent times. The particulate matter in the city has been more than 20 times beyond the safe limit majorly when the crops are set on fire every year [14]. It even found mention in the Union budget speech 2018–2019 as a ‘case of concern’ [15].

1.2 Economic impact of stubble burning

The National Academy of Agricultural Sciences reports that open burning in North-West India alone results in a loss of nearly 9.2 billion tonnes of C-equivalent, 1.4 × 105 tonnes of N (equivalent to Rs. 2 billion) every year [13]. As aforementioned, stubble burning dramatically pollutes the environment that invariably affects the human health which is costing the country’s health budget increasingly. The local residents have significantly demonstrated deteriorating health conditions that lower their productivity, thus impacting the economy indirectly as well. The International Food Policy Research Institute (IFPRI) estimated that the economic and health impacts arising due to the practice of stubble burning in North India (in Punjab, Haryana and Delhi) cost around $35 billion annually [16]. This amount is calculated to be thrice the amount the Union government spent in the health sector, a substantial fraction of the GDP [17].

1.3 Health impact of stubble burning

Open burning of crop residues pollutes the air releasing fine aerosol particles and carcinogenic dioxins that have negative impact on the health of millions of people. They pose risks such as asthma, bronchitis, tuberculosis, pneumoconiosis and other infections and decreasing lung function. Other issues include irritation in the eyes, skin, chest congestion and are especially dangerous for pregnant women and infants [7].

Rice is harvested during winters and the weather conditions further aggravate the health impact since there is poor dispersion and dilution of air. The poisonous airborne fine particulate matter PM2.5 enter deep into the lungs tissues and result in unrecoverable decrease in lung function, chronic asthma and emergency room visits, greater mortality risks and decreased life expectancy [18]. Chakrabarti et al. [19] presented in their study that nearly 14.4% of the acute respiratory illnesses were attributed directly to stubble burning. Individuals, particularly children (under 5 years of age) living in districts practicing crop residue burning were clearly observed to be more prone to acute respiratory infections. The risk becomes remarkably higher (three times more) when directly exposed to areas with extensive on-farm crop residue burning. A study determined that in 2015, stubble burning could be held responsible for nearly 66,000 deaths in India [20].

Despite the serious aftermaths, to date, open burning of crop residues remains the most common feature in India [9]. A certain need to come up with cost-effective, efficient and sustainable management methods not only is desirable, but is of extreme importance. Numerous researchers are exploring the use of crop residues as a source of renewable energy [13]. Energy-from-waste is a new exemplar and several studies report biogas to be a sustainable and efficient technology to produce fuel and organic fertilisers [4]. India being situated in a biogas conducive temperate zone is an added advantage and generation of biogas is a sustainable, cost-effective and more efficient use of the biomass waste [21].

2 Biogas for effective crop waste management and energy generation

Biogas is generated by anaerobic digestion (AD), a multistep biological process during which organic carbon is transformed mainly to methane and carbon dioxide along with traces of nitrogen, hydrogen, hydrogen sulphide and ammonia [22]. The AD process is an ancient yet proven technology to meet the energy demands for heating, electricity, fuel, etc. along with utilising low-cost feedstock or even municipal and industrial organic wastes; hence, proving to be economically viable [23].

2.1 Benefits of generating biogas

Biogas production has been evaluated as one of the most attractive, energy-efficient, non-toxic, and environment friendly pathway. It offers the advantage of being an almost carbon neutral renewable source of energy along with providing zero waste solutions for managing the organic wastes [24].

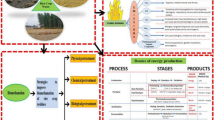

With a calorific value of nearly 10 kWh/Nm3, biogas has a high energy coefficient of about 20–40% of the lower heating value of the feedstock [25]. Rough estimates are that when 1 m3 of biogas is burnt, the heat generated is sufficient to boil 100 L of water or light a lamp with brightness of up to 100 W for 4.5 h [26]. As per the study by Riek et al. [21], a biogas plant of 2 m3 could supply a household with four members with the required cooking gas and lighting. To summarise, biogas can be utilised to cook and could even be upgraded to bio-methane that can further be used as vehicle fuel or even injected to natural gas gridlines [27]. It can also be directly used in spark ignition gas engines and gas turbines. Unlike gasification, biogas production does not require high temperatures and the operation is simple, thus, making it favourable for farmers and stake holders to utilise this with limited investments. Additionally, the digestate produced as a side product is rich in nutrients as organic fertilisers and can aid in enhancing crop production and reduce the usage of chemical fertilisers [28]. Figure 1 outlines the various benefits of considering crop wastes for biogas production.

2.2 Biogas production from different crop residues

Crop residues are abundant and inexpensive since they are discarded as waste. Different regional belts in India produce different types of agricultural wastes with rice, wheat, sugarcane and cotton as the major contributors (Table 1).

A well-run biogas digester fed with crop residues could generate about 200–400 m3 of biogas per day on an average [29, 30]. Numerous studies have been performed to determine the bio-methane potential of several crop wastes (outlined in Table 2). Rice straw has a high organic content of nearly 82% while maize and sugarcane have an even higher organic content of up to 92% [31]. Such rich organic and carbohydrate content qualify them as excellent substrates for biogas production capable of generating 50–55% methane on an average [37]. Microorganisms involved during fermentation favour carbohydrates since these are easier to degrade and the intermediate products such as lactic acid, acetic acid along with hydrogen are suitable for the methane producing bacteria [38].

Along with the organic matter, other factors such as trace metals and C/N ratio play a significant role in influencing the biogas production with different crop residues. Presence of trace metals such as calcium, iron, chromium in maize, paddy straw and sugarcane have clearly been linked with enhanced methane contents [39]. As for the C/N factor, a ratio of 25:1 has been recommended and the residues from crops such as rice, maize and sugarcane naturally bear high carbon contents compared to nitrogen, and hence provide an additional advantage when considered for biogas generation [40].

3 Process of generating optimal biogas with stubble

Biogas production involves complex biochemical reactions where different groups of microorganisms degrade and convert the organic matter under anaerobic conditions in a digester. This involves four individual phases, that is hydrolysis followed by formation of intermediate organic acids (like acetic, propionic, lactic, butyric acid), acetogenesis and finally methanogenesis where the energy-rich methane is generated [41]. Based on the temperature in the biogas digester, the process could be psychrophilic digestion at 10–20 °C which requires over 100 days of retention time, or the most favoured mesophilic digestion that occurs at temperatures between 20 and 40 °C with average retention time over 20 days or the faster thermophilic digestion that operates at 50–60 °C requiring shorter retention time over 8 days. However, thermophilic digesters need to be monitored carefully and are not advised for farm-scale biogas plants [42]. The various steps involved during production of biogas are outlined in Fig. 2.

A certain challenge when generating biogas from crop residues remains due to the complex lignocellulosic biomass that is composed of cellulose, hemicelluloses and lignin along with non-structural carbohydrates, proteins, lipids, extractives and pectin [37]. The utilisation of the strong and compact lignocelluloses, especially lignin is limited as the molecular structure is resistant to chemical and biological degradation and is poorly accessible by the microbes during anaerobic digestion [43]. Methods to overcome these shortcomings when utilising stubble from crops as substrates for biogas generation are described in the following sections.

3.1 Pre-treatment of crop residues for optimising the biogas production

Pre-treatment methods have been recognised to increase the substrate availability to the microorganism and improve the digestibility of crop residues for enhanced biogas production [44, 45]. Such methods result in increased surface area accessibility, decrease in crystallinity of cellulose and hemicellulose and reduced degree of polymerisation in the crop residues. When previously treated, agricultural wastes have demonstrated to overcome structural barriers of lignocellulosic characters leading to an increased methane yield [46]. Table 3 outlines the different pre-treatment methods that could be utilised for attaining improved biogas production with crop residues as substrates. A schematic representation for generating biogas after pre-treatment of crop residues is presented in Fig. 3.

Pre-treatment of crop residues to facilitate optimised biogas production. Adapted from Richard et al. [47]

3.1.1 Physical pre-treatment

While a range of pre-treatment methods have been determined, they can be broadly categorised as physical, chemical, biological and combined pre-treatments. Physical pre-treatment techniques include mechanical, thermal, ultrasound and electrochemical. Mechanical pre-treatment aids in reducing the particle size of the organic residues which have been associated with higher biogas yields [48]. The advantage of mechanical pre-treatment is that no inhibitory products are generated. Among such physical pre-treatments, milling is most commonly used where methane yield improvement by nearly 28% has been reported [49]. Milling has been found to be as efficient as shearing, as it improves the hydrolysis yield by exposing the surface area. Knife mills, hammer mills or shredders are commonly used to cut the crop residues as these are cheap and easy to handle. In thermal treatment, the substrates are heated typically between 125 and 190 °C under pressure and are held for nearly 1 h. It has been reported that biogas yields can be improved by 20–50% and the retention time can be shortened with this pre-treatment method [50].

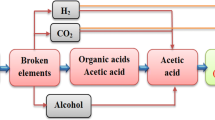

3.1.2 Chemical pre-treatment

Chemical pre-treatments employ acids, alkalis, solvents or oxidants [29]. Different chemicals mainly alkali and acid are considered at different concentrations under different conditions. Addition of alkali reagents like sodium hydroxide causes swelling of the lignocelluloses and partial lignin solubilisation. Such treatment breaks the bonds between hemicelluloses and lignin and increases the pore size, thus facilitating hydrolysis. Acid pre-treatments are not efficient in disrupting lignin, but are efficient in breaking down hemicelluloses and disrupting the ether bonds between lignin and hemicelluloses in combination with heat [42]. Acid treatment has been identified to be ideal for rice straw digestion as it breaks down the lignin component of the straw along with encouraging the growth of the methanogens which grow favourably under acidic conditions. An experiment with addition of acetic and propionic acid to rice straw demonstrated a 34% reduction in the lignin content further leading to a 36% increase in the methane content compared to untreated rice straw [51]. Pre-treatment with sodium chlorite and acetic acid mixture has been recognised as a commonly utilised delignification method increasing the biodegradability [52]. Addition of alcohol or weak organic acid for pre-treatment has also been reported to enhance the biogas production since these could be consumed by the anaerobes for additional methane formation [37]. Another effective pre-treatment method is the oxidative treatment with ozone or hydrogen peroxide. The oxidative agents affect the lignocelluloses by disrupting them and breaking the lignin. Song et al. [53] in their study report that such oxidative pre-treatment doubled the biogas production from rice straw. A specific limitation however remains that pre-treatment with chemicals demands excess energy inputs, chemicals, water and waste disposal issues associated with the digestate.

3.1.3 Biological pre-treatment

Biological methods involve microbes and enzymatic processes that breakdown the crop residues resulting in enhanced biomass degradation and an increased biogas production. These treatments are simpler and cost-effective [54]. Silaging is a widely utilised process and studies report enhanced biogas production with ensiled substrates due to the availability of the degraded and hydrolysed substrates for anaerobic digestion [55]. Addition of enzymes is also a widely utilised approach where cellulases, hemicellulases, lipases, amylases and proteases are used to break the bonds [37]. Biological pre-treatments are relatively simple and could involve two stages of digestion where the first two steps of anaerobic digestion (i.e., hydrolysis and acidogenesis) are separated from methanogenesis, the step where methane is produced. Such an approach leads to accumulation of intermediate volatile fatty acids and hence can speed up the process and generate more biogas. Enzymatic additives can also be added at different stages during anaerobic digestion, i.e. at the acidification vessel or during hydrolysis or by addition to a dedicated enzymatic pre-treatment vessel [46]. Aerobic microbial pre-treatments have found large applications as well. This is mainly since aerobic microbes produce cellulose, hemicelluloses and lignin degrading enzymes in large amounts which help solubilise the substrates. Successful utilisation of fungus like the white-rot fungi has also been explored to enable lignin degradation from agro-wastes [42].

In terms of application, mechanical and biological pre-treatment followed by chemical methods are favoured [48]. The cost-effective pre-treatment methods which produce less inhibitory by-products are generally more popular. The fourth category is the combined process which includes a combination of techniques like steam explosion, extrusion or thermo-chemical and thermal hydrolysis processes. In steam explosion, the substrates are more digestible and it involves a combination of heating and sudden change in pressure. The substrate is heated up to 220 °C leading to a rise in temperature. After retention of around 1 h, the pressure is abruptly released. This process has been reported to lead an increase of methane by 20% [42]. Compared to less chemical intensive thermal processes, the combined processes like thermo-chemical pre-treatments have been validated to be more effective albeit more complex.

3.2 Enhancing biogas production by co-digestion

Crop residues can either be digested alone or in co-digestion with other materials [29]. Co-digestion is defined as the simultaneous digestion of a mixture of two or more substrates preferred by farmers and also by industries to attain better biogas yields [37]. Improved biogas production and enhanced methane content (up to 70%) when crop residues are co-digested with other organic substrates has been reported by several studies. Animal manures like from cattle, pigs and chicken [56]; municipal solid wastes and sewage sludge [10, 11]; food wastes [57]; etc. are some of the widely utilised co-ferments that help attain process stability along with enhanced biogas yields especially in medium- and large-scale biogas plants (Fig. 4).

Co-digestion of crop residues with manures has been typically preferred due to their ability to provide an excellent buffer capacity, a diverse anaerobic microbial population, especially the methanogens [37]. Rice straw has been widely reported to result in an increased biogas production when co-digested with cattle dung [58]. Pig manure has been determined to carry a potential of increasing the biogas yield by about 30% [52]. Similar findings have been presented for other types of crop leftovers as well in full-scale industrial biogas plants [29]. Manures also balance the nitrogen content during digestion which is otherwise low in crop residues alone. Additional benefits of considering manure includes the presence of significant trace element and ammonia contents which contribute significantly in achieving the best balance between maximum biogas production and process stability [52, 59].

Other considerable advantages of co-digesting include dilution of components such as ammonia from protein-rich co-substrates, sodium ion and long chain fatty acids that are otherwise toxic for the microbes involved in biogas formation. Co-digesting crop residues have been reported to result in reduction of retention times, increase in methane content and production of a super quality sludge that contains essential nutrients to conserve the soil fertility and can be utilised as an organic fertiliser [45]. To further optimise the biogas production with crop residues, researchers propose considering a substrate-adapted inoculum that remarkably enhances the total biogas and methane yield from agricultural wastes [44, 60, 61].

4 Current status of biogas production in India

India stands as one of the countries with the largest number of biogas plants ranking ninth in terms of biogas production [62]. The country generates 2.07 billion m3 of biogas per year but the potential has been identified to be still largely unexplored [63, 64]. Like in other Asian countries, the focus has been largely on small-scale cattle dung-based biogas plants for cooking purposes especially in rural areas and this model has attained substantial success. In general, the Indian biogas systems have mainly been fairly simple, cheap and robust family-type digesters that are easy to design and operate with locally produced materials. The feed used for the digesters are from the household and their small farming activities. These types of reactors typically is a humble underground tank with a floating drum to collect the biogas while the effluent is collected from the bottom of the reactor [65]. As in 2012, 4.55 million such as biogas plants were operated in the country which carried a potential to mitigating global warming by 45 MT CO2 eq/year. Such small family sized biogas plants generating 1–10 m3 biogas daily can avail subsidies and financial aids from the government. A report presented by India’s MNRE (Ministry of New and Renewable Energy) details the investment costs and the expected returns from such small-scale plants and the payback period is calculated to be between 1.6 and 3.2 years [66].

Currently, there is a gradual shift towards utilising different organic materials including crop leftovers, dairy wastes, chicken manures and kitchen wastes in medium-/large-scale biogas reactors to generate methane that can further be converted to electricity [67]. In 2016, the Central Electricity Act was amended and the state electricity distribution companies (DISCOMS) were mandated to acquire 100% power generated from waste-to-energy (WtE) plants [63, 64]. The country reported operating 56 biogas-based power plants (BPP) mostly concentrated in the states of Maharashtra, Karnataka and Kerala. Through 400 off-grid biogas power plants, a total power generation capacity of 5.5 MW has already been prepared for decentralised applications [63, 64]. Growing interest to supply the energy requirements and increasing urban waste generation have led to an exponential increase in generation of biogas that further supports India’s action plan against climate change.

4.1 The National Biogas and Manure Management Programme

The government’s National Biogas and Manure Management Programme (NBMMP) launched since the 1970s is the driving force for constructing biogas plants in the country. It has focussed on setting-up family-type biogas plants for cooking and lighting purposes. In 2018, the programme announced to support setting-up 65,180 biogas plants annually for cooking, lighting and small power needs targeting remote, rural and semi-urban areas [68]. Meanwhile, the government’s MNRE under the NBMMP, in collaboration with UNDP also launched a project on ‘Removal of Barriers to Biomass Power Generation in India’. This project has effectively supported the schemes concerning biogas production targeting wastes from industries, agricultural sector as well as the urban wastes [10, 11]. Implemented under the ‘waste to energy mission’, small-scale biogas plants (each with a potential of 1–25 m3/day), nearly five million family biogas plants could be installed in the rural areas focussing to provide clean cooking fuel [3, 69].

4.2 Stubble burning and government’s recent interventions

Along with technological advancements, policy reforms continue to encourage biogas energy generation from agricultural crop leftovers in India [69]. It is a recent development that the authorities are recognising an urgent need to decipher ways to curb stubble burning and have attempted several interventions through numerous campaigns. Studies estimate crop residues having a potential of providing nearly 17% of the total energy consumed in the country [70]. The Indian Agricultural Research institute (IARI), Indian Ministry of New and Renewable Energy (MNRE) and several other research laboratories are actively involved with investigation and innovation in order to utilise crop residues and curtail stubble burning. MNRE launched the biogas -power generation (off-grid) and Thermal energy application Programme (BPGTP) in 2017 to promote decentralised medium-scale biogas plants (30–2500 m3/day) with power generation capacity of 3–250 kW. This scheme intends to meet the electrical and thermal energy demands in rural and semi-urban areas utilising paddy straw and other agricultural wastes.

The government continues to increasingly support plant waste–based bio-methane plants and substantial funds have been allocated lately to encourage biofuels from crop wastes. Another scheme to address the enormous volumes of crop wastes especially from paddy fields was the Sustainable Alternative Towards Affordable Transportation (SATAT), launched in 2018. This initiative targets the conversion of waste including agricultural and farm leftovers to compressed biogas as a vehicular fuel [71].

As a novel initiative by MNRE towards green energy in the state of Punjab which remains predominantly active in stubble burning, an example has been the rice straw–based bio-methanation plant set up in collaboration with commercial processing units and farms in a town named Fazilka [72]. The plant operates with nearly 10 tonnes of crop residues generating nearly 4000 m3 of biogas. Another successful privatised commercial biogas industry in the state has been designed to utilise 120,000 tonnes of stubble collected from around 15,000 farmers to generate 12 MW electricity where the farmers could generate an extra income of roughly Rs. 4 crores per power plant [73]. The farmers earn Rs. 600–1600 (8–23 $) per tonne of crop residues and the electricity generated could add an extra income. In India, such private enterprises are needed both in terms of generating green energy-from-waste as well as fulfil its potential of generating approximately 700,000 jobs in the agricultural sector [3]. A necessity for forming a conglomerate between government and private enterprises to develop a large-scale natural gas grid has been recognised.

The National Policy for Management of Crop Residue (NPMCR) is a recent addition to focus and address the stubble management issues. A thorough strategy to augment energy production from these discarded wastes keeping the millions of small- and large-scale farmers involved is expected to eventually discourage the practice of stubble burning. Such initiatives and policies are expected to bring a change in the way crop residues are handled in the country.

4.3 Future challenges forward in the biogas sector in India

The biogas sector in India has largely focussed on the small-scale digesters in rural areas with a limited scope [74]. The transition to identify biogas as a competent source of renewable energy and for managing organic wastes in an industrial-scale is relatively new. Regardless of the strong agricultural economy, abundant availability of agricultural wastes from crops and animals, schemes and support provided by the government and optimal weather conditions, the biogas sector still remains immature in the country. The reasons have been extensively analysed in various studies and the major factors include lack of advanced and appropriate technology to operate large-scale commercial biogas plants. Other causes include a deficiency of investor owned and professionally managed biogas units, financial constraints due to the high up-front installation costs, institutional elements and procedural delay in availing the support promised by the authorities, inadequate know-how to manage the biogas systems [63, 64, 74, 75] .

Generating biogas with crop residues pose additional challenges due to the elaborate cost, time and labour required for collecting the crop leftovers from large farm lands, packing the bulky volumes, handling, storing and transporting [3]. Additionally, crop residues with their complex structures demand specialised digester designs, pumps, pre-treatment or intervention of additives in order to attain favourable biogas production [23]. Competence, standardised methods and technology for optimally generating biogas plants with crop residues in practical scenarios still remain in its infancy. Besides, biogas digesters also come up with the risk of abrupt digester breakdowns owing to the fact that they involve numerous dynamic physico-chemical reactions, microbial processes and dependence on several parameters which require regular monitoring. An in-depth understanding, process monitoring, research and development to design efficient biogas systems and technology for optimal biogas production are few basic requirements before the stubble to biogas concept is successfully realised.

5 Conclusions

Managing the abundant supply of crop residues can be perceived both a challenge and an opportunity [13]. Farmers struggle to individually manage the crop residues and resort to stubble burning as an inexpensive alternative. Out of the various crop residues in India, millions of tonnes from rice, wheat and sugarcane which find limited use are majorly prone to such burning that further leads to severe environmental damage [70].

Generating biogas from the crop leftovers is a simpler and less cost- and energy-intensive method supporting the principles of circular economy. Biogas production from the crop residues and agricultural wastes not only offers a source of clean energy that can replace fossil fuels but also reduces methane and CO2 emissions; but these also reduce pathogen, odour and hygiene problems of the sludge and manure. Furthermore, they also treat the organic waste by turning it as a soil conditioner [76]. Straws from various major crops like paddy, wheat, oat, barley, sorghum, grass, millet, corn stover and sugar cane crop residues have been identified as competent substrates for bioenergy production [70]. They have been reported to bear a biogas potential ranging between 0.3 and 0.5 m3 per kg vs with a high methane content of up to 70% [3]. This gas could be utilised as a cooking or heating fuel or converted to electrical and heat energy using a combined heat and power (CHP) unit or could even be upgraded to be injected into natural gas gridlines or used as a vehicle fuel. Germany sets an optimistic example by demonstrating that nearly 0.6 TWh electricity is generated solely from crop residues [77].

For Indian context, launching community programmes is recommended that would assist in equipment rentals, transportation of agricultural leftovers, linking to the biogas industries where the crop residues could be utilised as raw materials. Thinking in financial terms, the biogas sector could help farmers generate extra revenues from the energy and organic fertilisers. Bioenergy has been reported to globally create nearly 3 million jobs where the annual turnover in Europe alone was €48 billion [78]. Thus, entrepreneurship development, business models for waste management and generation of renewable energy and governmental policies are certainly identified as essential elements to exploit the potential of these agricultural resources which otherwise are considered as waste in our country.

Further research is recommended to derive cost-effective biogas plant designs to direct economic benefits for the large number of small-scale farmers in India that resort to stubble burning. Future scopes include identifying efficient, sustainable and economically viable pre-treatment methods to encourage crop residues as favourable substrates for biogas generation.

References

Pratap Singh D, Prabha R (2018) Bioconversion of agricultural wastes into high value biocompost: a route to livelihood generation for farmers. Adv Recycl Waste Manag 02. https://doi.org/10.4172/2475-7675.1000137

Organisation for Economic Co-operation and Development (2001) Glossary of statistical terms. Environ Indic Agric:389–391

Bhuvaneshwari S, Hettiarachchi H, Meegoda JN (2019) Crop residue burning in India: policy challenges and potential solutions. Int J Environ Res Public Health 16. https://doi.org/10.3390/ijerph16050832

Devi S, Gupta C, Jat SL, Parmar MS (2017) Crop residue recycling for economic and environmental sustainability: the case of India. Open Agric 2:486–494. https://doi.org/10.1515/opag-2017-0053

United Nations Environment Programme (2016) UNEP Guide for Energy Efficiency and Renewable Energy Laws

Innovation Centre Denmark, India (2020) Biomass energy in India. https://indien.um.dk/en/innovation/sector-updates/renewable-energy/biomass-energy-in-india/#:~:text=India has a potential of,biomass for its energy needs. Accessed 08 Sept 2020

Singh J (2018) Paddy and wheat stubble blazing in Haryana and Punjab states of India: a menace for environmental health. Environ Qual Manag 28:47–53

Bisen N, Rahangdale C (2017) Crop residues management option for sustainable soil health in rice-wheat system: a review. Int J Chem Stud 5:1038–1042

Singh J, Singhal N, Singhal S, Sharma M, Agarwal S, Arora S (2018) Environmental implications of rice and wheat stubble burning in North-Western States of India. In: Advances in Health and Environment Safety. Springer Transactions in Civil and Environmental Engineering, Singapore

Kumar A, Kumar N, Baredar P, Shukla A (2015a) A review on biomass energy resources, potential, conversion and policy in India. Renew Sust Energ Rev 45:530–539. https://doi.org/10.1016/j.rser.2015.02.007

Kumar P, Kumar S, Joshi L (2015b) Socioeconomic and environmental implications of agricultural residue burning: a case study of Punjab, India

Gupta PK, Sahai S, Singh N, Dixit CK, Singh D (2004) Residue burning in rice-wheat cropping system: causes and implications. C Curr Sci India:1713–1715

NAAS (2017) Policy brief to reduce air pollution caused by rice crop residue burning. In: Natl. Acad. Agricutlural Sci

Worthington RP, McLean M, Doshi N (2017) Air pollution in India: questions of advocacy and ethics. Glob Secur Heal Sci Policy 2:76–83. https://doi.org/10.1080/23779497.2017.1398595

Union Budget (2018) Special scheme to manage crop residues. Indo Asian News Serv

International Food Policy Research Institute (2019) Air pollution from India’s stubble burning leads to USD 35 billion economic losses, poses significant health risk. In: South Asia IFPRI. https://southasia.ifpri.info/2019/03/04/new-study-air-pollution-from-indias-stubble-burning-leads-to-usd-35-billion-economic-losses-poses-significant-health-risk/. Accessed 25 Jun 2020

Sample D (2019) Air pollution from India’s stubble burning leads to USD 35 billion economic losses, poses significant health risk. In: Int. Food Policy Res. Inst. https://www.ifpri.org/news-release/new-study-air-pollution-indias-stubble-burning-leads-usd-35-billion-economic-losses. Accessed 18 Mar 2020

Chen J, Li C, Ristovski Z, Milic A, Gu Y, Islam MS, Wang S, Hao J, Zhang H, He C, Guo H, Fu H, Miljevic B, Morawska L, Thai P, LAM YF, Pereira G, Ding A, Huang X, Dumka UC (2017) A review of biomass burning: emissions and impacts on air quality, health and climate in China. Sci Total Environ 579:1000–1034. https://doi.org/10.1016/j.scitotenv.2016.11.025

Chakrabarti S, Khan MT, Kishore A, Roy D, Scott SP (2019) Risk of acute respiratory infection from crop burning in India: estimating disease burden and economic welfare from satellite and national health survey data for 250 000 persons. Int J Epidemiol 48:1113–1124. https://doi.org/10.1093/ije/dyz022

Watts K (2018) 75 percent of pollution deaths happen in rural India. Why is it thought of as an urban problem? Heal. Issues India

I. Riek, A. Rücker, T. Schall, M. Uhlig (2012) Renewable energy generation from biomass – biogas in India

Satpathy P, Steinigeweg S, Cypionka H, Engelen B (2016) Different substrates and starter inocula govern microbial community structures in biogas reactors. Environ Technol 37:1441–1450. https://doi.org/10.1080/09593330.2015.1118559

Achinas S, Achinas V, Euverink G (2017) A technological overview of biogas production from biowaste. Engineering 3:299–307. https://doi.org/10.1016/J.ENG.2017.03.002

Schoen MA, Sperl D, Gadermaier M, Goberna M, Franke-Whittle I, Insam H, Ablinger J, Wett B (2009) Population dynamics at digester overload conditions. Bioresour Technol 100:5648–5655. https://doi.org/10.1016/j.biortech.2009.06.033

Renewable Academy (2011) Biogas technology and biomass. In: RENAC. https://www.renac.de. Accessed 22 Jun 2020

IASRI (2014) Waste and by-product utilization. In: Indian Agric. Stat Res Inst. http://ecoursesonline.iasri.res.in/mod/page/view.php?id=1432. Accessed 07 Apr 2020

McKendry P (2002) Energy production from biomass (Part 1): overview of biomass. In: Bioresour Technol. p 37 46

Achinas S, Euverink GJW (2016) Theoretical analysis of biogas potential prediction from agricultural waste. Resour Technol 2:143–147. https://doi.org/10.1016/j.reffit.2016.08.001

Lehtomäki A (2006) Biogas production from energy crops and crop residues

Mshandete AM, Parawira W (2010) Biogas: sustainable alternative renewable energy of today and the future in Africa. Ann Arid Zone 49:217–239

Misri B (2016) Hay and crop residues in India and Nepal. In: Food Agric Organ. http://www.fao.org/docrep/005/x7660e/x7660e0q.htm. Accessed 12 Jul 2020

Weiland P (2010) Biogasproduction: current state and perspectives. Appl Microbiol Biotechnol 85:849.860–849.860. https://doi.org/10.1007/s00253-009-2246-7

Mehrdad Adl KS and AG (2010) Technical assessment of bioenergy recovery from cotton stalks through anaerobic digestion process and the effects of inexpensive pre-treatments. Appl Energy 93:251–269

Wolfsberger A (2008) Modelling and control of the anaerobic digestion of energy crops. Dissertation 221

Szerencsits M, Weinberger C, Kuderna M et al (2015) Biogas from cover crops and field residues: effects on soil, water, climate and ecological footprint. Int J Environ Ecol Eng 9:413–416

Chandratre S, Chaudhari V, Kulkarni B et al (2015) Biogas production from local agricultural waste by using laboratory scale digester. Res J Recent Sci 4:157–165

Horváth S, Tabatabaei I, Karimi K, Kumar R (2016) Recent updates on biogas production - a review. Biofuel Res J 3:394–402. https://doi.org/10.18331/brj2016.3.2.4

Elferink O, Krooneman J, Gottschal JC, Spoelstra SF, Faber F, Driehuis F (2001) Anaerobic conversion of lactic acid to acetic acid and 1,2-propanediol by Lactobacillus buchneri. Appl Environ Microbiol 67:125–132

Hinken L, Urban I, Haun E, Weichgrebe D, Rosenwinkel K-H (2008) The valuation of malnutrition in the mono-digestion of maize silage by anaerobic batch tests. Water Sci Technol 58:1435–1459

Dioha I, Ikeme CHNT (2013) Effect of carbon to nitrogen ratio on biogas production. Int Res J Nat Sci 1:1–10

Solli L, Håvelsrud OE, Horn SJ, Rike AG (2014) A metagenomic study of the microbial communities in four parallel biogas reactors. Biotechnol Biofuels 7:146

Montgomery L, Bochmann G (2014) Pretreatment of feedstock for enhanced biogas production. IEA Bioenergy:1–20. https://doi.org/10.1016/j.pecs.2014.01.001

Karuppiah T, Azariah V (2012) Biomass pretreatment for enhancement of biogas production. Interiors 395:116–124. https://doi.org/10.1016/j.colsurfa.2011.12.014

Amin FR, Khalid H, Zhang H, Rahman S, Zhang R, Liu G, Chen C (2017) Pretreatment methods of lignocellulosic biomass for anaerobic digestion. AMB Express 7:72. https://doi.org/10.1186/s13568-017-0375-4

Esposito G, Frunzo L, Giordano A, Liotta F, Panico A, Pirozzi F (2012) Anaerobic co-digestion of organic wastes. Rev Environ Sci Bio/Technology 11:325–341. https://doi.org/10.1007/s11157-012-9277-8

Pecorini I, Baldi F, Carnevale EACA (2016) Biochemical methane potential tests of different autoclaved and microwaved lignocellulosic organic fractions of municipal solid waste. Waste Manag 50(50):143–150

Richard EN, Hilonga A, Machunda RL, Njau KN (2019) A review on strategies to optimize metabolic stages of anaerobic digestion of municipal solid wastes towards enhanced resources recovery. Sustain Environ Res 1:1–13. https://doi.org/10.1186/s42834-019-0037-0

Mata-Alvarez J, Macé S, Llabrés P (2000) Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour Technol 74:3–16. https://doi.org/10.1016/S0960-8524(00)00023-7

Elbeshbishy E, Aldin S, Hafez H, Nakhla G, Ray M (2011) Impact of ultrasonication of hog manure on anaerobic digestability. Ultrason Sonochem 18:164–171. https://doi.org/10.1016/j.ultsonch.2010.04.011

Distefano TD, Ambulkar A (2006) Methane production and solids destruction in an anaerobic solid waste reactor due to post- reactor caustic and heat treatment. Water Sci Technol 53:33–41

Zhao R, Zhang Z, Zhang R, Li M, Lei Z, Utsumi M, Sugiura N (2010) Methane production from rice straw pretreated by a mixture of acetic-propionic acid. Bioresour Technol 101:990–994

Mussoline W (2013) Enhancing the methane production from untreated rice straw using an anaerobic codigestion approach with piggery wastewater and pulp and paper mill sludge to optimize energy conservation in farm-scale biogas plants. Universit´e Paris-Est

Song Z, Yang G, Guo Y, Zhang T (2012) Comparison of two chemical pretreatments of rice straw for biogas production by anaerobic digestion. BioResources 7:3223–3236

Hallenbeck PC (2011) Microbial technologies in advanced biofuels production. Springer Science and Business Media

Herrmann C, Heiermann M, Idler C (2011) Effects of ensiling, silage additives and storage period on methane formation of biogas crops. Bioresour Technol 102:5153–5161

Rao PV, Baral SS, Dey R, Mutnuri S (2010) Biogas generation potential by anaerobic digestion for sustainable energy development in India. Renew Sust Energ Rev 14:2086–2094. https://doi.org/10.1016/j.rser.2010.03.031

Anjum M, Qadeer S, Khalid A (2018) Anaerobic Co-digestion of catering and agro-industrial waste: a step forward toward waste biorefinery. Front Energy Res 6:116

Silvestre G, Gomez MP, Pascual A, Ruiz B (2013) Anaerobic co-digestion of cattle manure with rice straw: economic & energy feasibility. Water Sci Technol 67:745–755. https://doi.org/10.2166/wst.2012.616

Hinken L, Huber M, Weichgrebe D, Rosenwinkel KH (2014) Modified ADM1 for modelling an UASB reactor laboratory plant treating starch wastewater and synthetic substrate load tests. Water Res 64:82–93. https://doi.org/10.1016/j.watres.2014.06.044

Liu T, Sun L, Müller B, Schnürer A (2017) Importance of inoculum source and initial community structure for biogas production from agricultural substrates. Bioresour Technol 245:768–777. https://doi.org/10.1016/j.biortech.2017.08.213

Satpathy P (2016) Influence of lactate in anaerobic digestion and in the Anaerobic Digestion Model No. 1 (ADM1). Carl von Ossietzky University, Oldenburg, Germany

Surie G (2017) Achieving sustainability: insights from biogas ecosystems in India. Agriculture 7:1–15. https://doi.org/10.3390/agriculture7020015

Mittal S, Ahlgren EO, Shukla P (2018a) Barriers to biogas dissemination in India: a review. Energy Policy 112:361–379

Mittal S, Ahlgren EO, Shukla PR (2018b) Barriers to biogas dissemination in India: a review. Energy Policy 112:361–370. https://doi.org/10.1016/j.enpol.2017.10.027

Seadi TA, Rutz D, Prassl H et al (2008) Biogas Handbook. In: Big East Project. University of Southern Denmark Esbjerg, Esbjerg, pp 1–126

Ministry of New and Renewable Energy (MNRE) (2016) Solid state biogas plant: a boon for water scarce areas. Akshay Urja Renew Energy 9:16–21

Satpathy P (2017) Recent developments in biogas technology. In: Biogas: Production, Applications and Global Developments. pp 209–240

Ministry of New and Renewable Energy (MNRE) (2018) MNRE to set up 65,180 biogas plants in current year under the National Biogas and Manure Management Programme (NBMMP). Gov. India

Bharti VM of N and RE (2019) India’s programmes and incentives being implemented to support biogas systems

Hiloidhari M, Das D, Baruah DC (2014) Bioenergy potential from crop residue biomass in India. Renew Sust Energ Rev 32:504–512. https://doi.org/10.1016/J.RSER.2014.01.025

Ministry of Petroleum & Natural Gas (2018) Petroleum minister to launch SATAT initiative to promote compressed bio-gas as an alternative, green transport fuel

Ministry of New and Renewable Energy (MNRE) (2017) Energy Generation from paddy straw: an analysis of bioenergy models. Akshay Urja 22–27

Sood J (2015) Not a waste until wasted. Down to Earth

Shah A MA (2018) Jumpstarting Biogas in India. In: Gujarat Energy Res. Manag. Inst

Velusamy M, Speier CJ, Michealammal BRP, Shrivastava R, Rajan B, Weichgrebe D, Venkatachalam SS (2019) Bio-reserves inventory—improving substrate management for anaerobic waste treatment in a fast-growing Indian urban city, Chennai. Environ Sci Pollut Res 27:29749–29765. https://doi.org/10.1007/s11356-019-07321-1

Zhao Y, Yan Z, Qin J, Ma Z, Zhang Y, Zhang L (2016) The potential of residues of furfural and biogas as calcareous soil amendments for corn seed production. Environ Sci Pollut Res 23:6217–6226. https://doi.org/10.1007/s11356-015-5828-1

Lehtoma A, Huttunen SRJ (2007) Laboratory investigation on co-digestion of energy crops and crop residues with cow manure for methane production: effect of crop to manure ratio. Resour Conserv Recycl 51:591–609

Li WW, Yu H (2016) Advances in energy-producing anaerobic biotechnologies for municipal wastewater treatment. Eng Life Sci 2:438–446

Funding

The financial contribution to the first author was supported by the Dr. D.S. Kothari Postdoctoral Fellowship, UGC India, and is highly acknowledged. The authors are thankful to the Department of Science and Technology, Government of India and UGC for the financial support granted under DST-FIST and C.O.E to the P.G Department of Botany, Utkal University, Odisha, India.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Satpathy, P., Pradhan, C. Biogas as an alternative to stubble burning in India. Biomass Conv. Bioref. 13, 31–42 (2023). https://doi.org/10.1007/s13399-020-01131-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01131-z