Abstract

In this study, the natural antioxidant efficiency of the clove oil on the oxidative stability of waste cooking oil biodiesel was investigated. The oxidative stability was determined as for ASTM D7545 standart method for biodiesel added with 1,000, 2,000 and 3,000 ppm of additives by using oxifast device, and compared with the chemical antioxidant butylated hydroxy toluene (BHT) at the same concentrations. Samples were characterized by using Fourier transform infrared spectroscopy (FT-IR) and differential scanning calorimetry (DSC) techniques. Oxidation stability was determined by using ASTM D7545 by rapid oxidation test method. With the effect of antioxidant addition to biodiesel, the bond vibrations and transmittance % values of the FT-IR peaks changed. The crystallization temperatures (Tcr) of the samples were determined by using a DSC technique. It was concluded that Tcr values of samples with antioxidant were decreased compared to the non-antioxidant biodiesel sample (B100). The order of antioxidant power was B100BHT3 > B100C3 > B100C2 > B100BHT2 > B100C1 > B100BHT1 > B100. The oxidation times were determined as 29, 34, 40, 41, 46, 55, and 60 min respectively. The results show that the crystallization onset temperatures for B100, B100C3, and B100BHT3 were − 51.83, − 54.49, and − 54.15 °C respectively. Addition of natural antioxidant has a positive effect on biodiesel oxidative stability for all concentrations; in addition, natural clove oil showed a similar efficiency with the synthetic chemical antioxidant.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In the current century, the demand for environmentally friendly, sustainable, economical, and renewable energy sources has increased [1]. The main reasons for the increasing demand are the limited fossil fuel resources and the harmful emissions emitted by existing energy resources to the environment [2]. Emissions of traditional fossil fuels bring along many environmental problems such as air pollution, global warming, and climate change [3, 4].

Alternative fuels which have tremendous characteristics such as sustainability, cleanliness, and environmental friendliness are a new awareness tool to reduce the negative effects of conventional fuels. In this context, the use of biodiesel in diesel engines has come to the fore [5]. Biodiesels are methyl esters of fatty acids formed by the reaction of various seed oils, animal fats, or waste oils with catalysts and alcohol. The degree of saturation of these oils determines the biodiesel production capacity and efficiency [6].

Biodiesels contain large amounts of methyl esters of unsaturated fatty acids. The overabundance of methyl esters of unsaturated fatty acids (FAME) creates a vulnerable situation against autoxidation [7]. Autooxidation is an undesirable situation for biodiesel. Firstly, it reduces the shelf life of biodiesels by negatively affecting its storage properties. Secondly, it leads to the formation of oxidation products such as organic acids, aldehydes, ketones, alkanes, and various polymers. These products cause problems such as corrosion of the engine and its parts, blockages, engine power imbalance, and filtration problems. Therefore, the oxidation stability of biodiesel is important for both storage and engine performance [8]. Oxidation stability is one of the fundamental parameters used in the quality control of biodiesel. The oxidation of biodiesel is a complex process due to biodiesel’s high viscosity, water content, acidity, and peroxide degree. Moisture and metal content in biodiesel, exposure to heat, and light affect oxidation stability. These should be controlled [9]. The formation of hydroperoxide, which decomposes to form an array of secondary oxidation products like aldehydes, ketones, carboxylic acids, oligomers, polymers, gum, and sediment, can block fuel lines and pumps. Because of these reasons, the oxidation stability should be kept at an acceptable level in biodiesel industry [10].

The iodine value (IV), peroxide value (PV), oil stability index (OSI), and induction period (IP) values of biodiesel provide information about the oxidation stability of biodiesel [11]. The main techniques and standards used to determine these values are Rancimat, PetrOXY, and EN14112. Rancimat analysis is based on the increase in conductivity of the water in the sample known as the acceleration test. The increased conductivity is due to the oxidation of volatile fatty acids [12]. The other method, EN14112 standard, was originally used to determine the stability of oils, but now it is internationally accepted in determining the oxidation stability of biodiesel. According to this standard, the minimum induction time for biodiesel with Rancimat analysis at 110 °C is 6 h [13]. Another method similar to EN14112 is the ASTM D6751 standard. The PetrOXY method, which was developed as an alternative to the Rancimat method and according to the ASTM D7545 standard, is used to determine the induction time of pure oxygen in the atmosphere. Compared to the Rancimat method, the PetrOXY method can be made with less samples and gives results in a shorter time [14].

In addition to all these methods, differential scanning calorimetry (DSC) and Fourier transform infrared spectroscopy (FT-IR) are cheap and reliable methods used to determine oxidation stability of biodiesel. The crystallization onset temperature of biodiesel can be determined by DSC technique, and the products formed as a result of oxidation can be observed using the FT-IR technique [10].

Oxidation products are saturated structures as a result of the isomerization of double bonds in the structure of free fatty acids. These saturated structures with high molecular weight increase the density and viscosity values of biodiesel [15]. Some additives can be added to biodiesel in order to prevent or minimize the formation of the products that cause a decrease in oxidation stability. The oxidation process can be eliminated by addition of antioxidants [16]. Antioxidants are generally used as deoxidizers due to their mechanisms. The most active and common major antioxidants have phenolic groups. Antioxidants not only donate hydrogen and electrons, but also prevent the oxidation of fatty acids in the biodiesel structure thanks to their stable radicals [17].

Recently, the usage of natural additives in industrial products such as food, medicine, cosmetics, and fuel has come to the fore. These natural additives are minimizing or reducing the effects of harmful substances are antioxidants used for the purpose [18].

Antioxidants mainly consist of two categories as natural and synthetic. The traditional synthetic antioxidants such as tert-butyl hydroquinone (TBHQ), pyrogallol (PY), propyl gallate (PrG) [7], butylatedhydroxyanisole (BHA), and butylated hydroxy toluene (BHT) [10] have been used to improve the oxidation stability of biodiesel [19]. Additionally, natural antioxidants such as tocopherols, gossypol [20], quercetin, catechin, curcumin [21], oregano, basil, and bilberry [22] have also been indicated to increase the oxidation stability of biodiesel [23]. The many natural antioxidants are cheap from synthetic antioxidants. In addition, the natural antioxidants are easily accessible. The synthetic antioxidants are toxic and non-biodegradable. The natural antioxidants are eco-friendly. Consequently, the usage of natural antioxidants decreases the cost and increases the benefit in environment [21].

In the study conducted by Malayoğlu et al., they obtained from anise (Pimpinella anisum), rosemary (Rosmarinus officinalis), laurel (Laurus nobilis), clove (Syzygium aromaticum), thyme (Oreganum onites spp.), and cumin (Cuminum cyminum) plants by a steam distillation method and investigated the radical scavenging capacity and antioxidant activities of essential oils. The radical scavenging capacities and antioxidant activities of essential oils were determined by in vitro methods such as total phenol (TPA), 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging activity, and Trolox equivalent antioxidant capacity (TEAC). According to the findings, clove and thyme essential oils showed the highest radical scavenging activity (98.32%, 70.67%) and antioxidant capacity (421, 225 μM Trolox/100 g dry sample) due to their high eugenol and carvacrol contents. However, a high correlation was found between total phenol and DPPH (r = 0.97), total phenol, and TEAC (r = 0.99) values. As a result, this study demonstrated the antioxidant potential of essential oils during clove > thyme > laurel > rosemary > cumin > anise efficacy. In particular, clove and thyme essential oils can be used as natural antioxidant agents in medicine, food industry, and animal nutrition due to their high antioxidant activity [24].

Clove, whose Latin name is Syzygium aromaticum, comes from the Myrtaceae family. It is a budded plant commonly grown in Madagascar. Clove showed high antioxidant activity in terms of neutralizing free radicals [24].

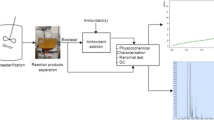

Accompanied by the available literature, oxidation stability is an important parameter in determining and preserving biodiesel quality. For this reason, this study aims to examine the influence of clove oil as a natural antioxidant and BHT as a synthetic antioxidant on the oxidation stability of biodiesel prepared from WCO using ASTM D7545, FT-IR, and DSC methods. All antioxidants were added to biodiesel in 3 different ratios; 1000, 2000, and 3000 ppm, respectively, and the effects of the type and concentration of antioxidants on oxidation stability were investigated.

2 Materials and Methods

2.1 Materials

Herein, waste cooking oil methyl ester (WCOME) was supported from Kolza Biodiesel Company in Turkey. The instrumental techniques for the determination of the biodiesel oxidative stability have been explained. Clove essential oil was provided as natural antioxidant. Butyl hydroxy toluene (BHT) was provided as synthetic traditional antioxidant to compare with the effects of clove oil.

2.2 Addition of antioxidants to WCOME

Clove essential oil was used as natural antioxidants in this study. Clove essential oils were obtained from Arifoğlu Company (İstanbul, Turkey). Clove oil content was analyzed by GC–MS technique; helium was used as the carrier gas. A 0.1-mL sample was injected with splitless mode. The results are exhibited Table 1. BHT was used as classical antioxidant to compare with clove oil. Samples were mixed certain amount of natural and chemical antioxidant at different concentrations between 1000 and 3000 ppm by centrifuge technique. The chemical formula of eugenol in clove oil and BHT is shown in Fig. 1. Antioxidants were added with WCOME at different ratios: 1000, 2000, and 3000 ppm. All antioxidants are dissolved in the WCOME biodiesel. Table 2 shows the prepared samples besides WCOME biodiesel (B100).

2.3 Biodiesel characterization

Physico-chemical properties of all samples were determined by Vitsan Inspection Corporation Laboratory, Kocaeli, Turkey.

In this study, B100, B100C1, B100C2, B100C3, B100BHT1, B100BHT2, and B100BHT3 were characterized by using Perkin Elmer Fourier transform infrared spectrometer (FT-IR). FT-IR spectra were obtained in the range of 4000–650 cm-1 and processed with a computer software program Spectrum Two. Sample amount is 0.5 mL, and ethanol was employed to clean the analysis surface for cleaning before the background collection.

B100, B100C1, B100C2, B100C3, B100BHT1, B100BHT2, and B100BHT3 were analyzed by TA Q-2000 DSC under the flow of nitrogen (N2). The DSC curves were obtained in a calorimeter model DSC Q20 with RCS90 coupled with a cooling system, both from TA Instruments. The analysis conditions are exhibited in Table 3. Each DSC analysis took approximately 15 min. All DSC thermograms were evaluated with the help of TA Orchestrator Version V7.2.2.1.

Oxidation stability was determined by using the ASTM D7545Standard Test Method for Oxidation Stability of Middle Distillate Fuels—Rapid Small Scale Oxidation Test (RSSOT). This fast method is proposed as an alternative to the ASTM D2274 and EN 14,112, which require longer times. In this analysis, 5-mL sample was placed in a tightly closed cell under pure oxygen atmosphere 140 ℃. The decreases in the maximum pressure registered for the system at induction time. The tests were carried out at 140 °C. Accelerated oxidation tests were carried by KLC Oxifast device.

3 Results and discussions

3.1 Physico-chemical properties of WCOME

The measurement standard methods and measured properties of biodiesel have been summarized in Table 4. As a result of the analysis processed according to TS EN 14,112 standard, the oxidation stability of biodiesel obtained from waste cooking oil (WCOME) without adding antioxidants was determined as approximately 10.4 h.

3.2 FT-IR analysis

FT-IR is an important technique for determining functional groups and bonds by absorbing the electromagnetic spectra of organic liquids such as oil, ester, and biodiesel in the infrared region [27]. When biodiesel samples come into contact with oxygen or moisture in the air, it is inevitable that various oxidation products are formed by degrading. As a result of this degradation, various organic molecules such as hydroperoxides, acids, aldehydes, alcohols, and ketones are formed in the unsaturated bond chain structures in biodiesel samples. Symmetrical and asymmetric methyl, methylene ν(C-H) bonds in biodiesel samples tend to oxidation process. In addition, oxidation stability in biodiesel samples can be monitored with carbonyl and carboxylic acid groups ν(C = O) as well as aldehydes and ketones in their structure. Various antioxidants are used in fuels to ensure good oxidation stability [28].

The effect of adding natural and synthetic antioxidants to biodiesel samples at different concentrations (1000 ppm, 2000 ppm, and 3000 ppm) is exhibited in Fig. 2 a and b. In Fig. 3, IR spectra of all the biodiesel samples indicate a decrease in the intensity of the bands with increasing antioxidant concentration at wavenumber 1020–1090 cm−1 (ν(-C-O)). Due to the increase in unsaturation, it shows that there is a lack of oxidative polymerization reaction [29]. Similarly, the antioxidant effect can be seen between wavenumbers 1210 and 1250 cm−1, 1370 and 1420 cm−1, and 2970 and 3020 cm−1 [30] [10].

3.3 Oxidation stability analysis

As a result of the tests performed according to the TS EN 14,112 and ASTM7545 method, it was seen in Table 5 that the oxidation stability increases with the increase in the antioxidant concentration in biodiesel. When compared to the synthetic antioxidant BHT, natural clove oil appears to have antioxidant activity. Clove oil exhibited antioxidant performance due to its chemical structures and other studies showed in literature. The order of antioxidant power was B100BHT3 > B100C3 > B100C2 > B100BHT2 > B100C1 > B100BHT1 > B100, which is consistent with their concentrations. The results showed that the clove oil has decent potential for replacement of synthetic antioxidant. In addition, the low cost of natural antioxidant substances allows for commercial use. Due to the electron acceptors in the phenol compound, clove oil and BHT exhibit antioxidant performance with induction effect. The better the electronegativity property of the substituents, the greater the inductive effect to the benefit of antioxidant activity [21].

3.4 DSC analysis

The crystallization onset temperatures of B100, B100C3, and B100BHT3 under N2 atmosphere were studied using DSC and are presented in Fig. 4. The results show that the crystallization onset temperatures for B100, B100C3, and B100BHT3 were − 51.83, − 54.49, and − 54.15 °C respectively. B100C3 and B100BHT3 crystallize lower than B100, hence the natural and synthetic antioxidant effects. The results were supported by accelerated oxidation stability analysis. The supporting of antioxidants to biodiesel decreases the concentration of saturated methyl esters which leads to a reduction in the crystallization onset temperature [10]. The results are consistent with the literature.

4 Conclusions

Clove oil proved antioxidant activity for waste cooking oil biodiesel. Oxidation stability has increased by increasing both natural and synthetic antioxidant concentrations. All samples were analyzed; B100BHT3 exhibited the highest antioxidant performance, followed by B100C3. The oxidation times were determined as 29, 34, 40, 41, 46, 55, and 60 min for B100BHT3, B100C3, B100C2, B100BHT2, B100C1, B100BHT1, and B100, respectively. The results show that the crystallization onset temperatures for B100, B100C3, and B100BHT3 were − 51.83, − 54.49, and − 54.15 °C, respectively. We conclude that clove oil can be added into biodiesel as natural antioxidants. The results showed that the clove oil has decent potential for replacement of synthetic antioxidant. In addition, the low cost of natural antioxidant substances allows for commercial use. The results are consistent with the literature.

References

Avila Orozco FD, Sousa AC, Araujo MCU, Domini CE (2020) A new flow UV–Vis kinetics spectrophotometric method based on a photodegradative reaction for determining the oxidative stability of biodiesel. Fuel 262:116197. https://doi.org/10.1016/j.fuel.2019.116197

Pandey A, Larroche C, Gnansounou E, Khanal, SK.,Dussap CG, Ricke, S. (2019) Biofuels: alternative feedstocks and conversion processes for the production of liquid and gaseous biofuels

Mirnezami SA, Zahedi A, Shayan Nejad A (2020) Thermal optimization of a novel solar/hydro/biomass hybrid renewable system for production of low-cost, high-yield, and environmental-friendly biodiesel. Energy 202:117562. https://doi.org/10.1016/j.energy.2020.117562

Sousa LS, Moura CVR, Moura EM (2021) Action of natural antioxidants on the oxidative stability of soy biodiesel during storage. Fuel 288. https://doi.org/10.1016/j.fuel.2020.119632

Devi A, Das VK, Deka D (2019) A green approach for enhancing oxidation stability including long storage periods of biodiesel via Thuja oreantalis L. as an antioxidant additive. Fuel 253:1264–1273. https://doi.org/10.1016/j.fuel.2019.05.127

Kpan JDA, Krahl J (2019) The impact of adsorbents on the oxidative stability of biodiesel and its influence on the deterioration of engine oil. Fuel 256:115984. https://doi.org/10.1016/j.fuel.2019.115984

Liu W, Lu G, Yang G, Bi Y (2019) Improving oxidative stability of biodiesel by cis-trans isomerization of carbon-carbon double bonds in unsaturated fatty acid methyl esters. Fuel 242:133–139. https://doi.org/10.1016/j.fuel.2018.12.132

Sundus F, Fazal MA, Masjuki HH (2017) Tribology with biodiesel: a study on enhancing biodiesel stability and its fuel properties. Renew Sustain Energy Rev 70:399–412. https://doi.org/10.1016/j.rser.2016.11.217

Yang J, He QS, Corscadden K, Caldwell C (2017) Improvement on oxidation and storage stability of biodiesel derived from an emerging feedstock camelina. Fuel Process Technol 157:90–98. https://doi.org/10.1016/j.fuproc.2016.12.005

Uğuz G, Atabani AE, Mohammed MN, Shobana S, Uğuz S, Kumar G, Muhtaseb AA,(2019) Fuel stability of biodiesel from waste cooking oil: a comparative evaluation with various antioxidants using FT-IR and DSC techniques. Biocatal Agric Biotechnol 21. https://doi.org/10.1016/j.bcab.2019.101283

Supriyono SH, Almeida MF, Dias JM (2015) Influence of synthetic antioxidants on the oxidation stability of biodiesel produced from acid raw Jatropha curcas oil. Fuel Process Technol 132:133–138. https://doi.org/10.1016/j.fuproc.2014.12.003

Pardauil JJR, Souza LKC, Molfetta FA et al (2011) Determination of the oxidative stability by DSC of vegetable oils from the Amazonian area. Bioresour Technol 102:5873–5877. https://doi.org/10.1016/j.biortech.2011.02.022

Jain S, Sharma MP (2010) Review of different test methods for the evaluation of stability of biodiesel. Renew Sustain Energy Rev 14:1937–1947. https://doi.org/10.1016/j.rser.2010.04.011

De Sousa LS, De Moura CVR, De Oliveira JE, De Moura EM (2014) Use of natural antioxidants in soybean biodiesel. Fuel 134:420–428. https://doi.org/10.1016/j.fuel.2014.06.007

Schirmann JG, Angilelli KG, Dekker RFH et al (2019) 3,3″,5,5″-Tetramethoxybiphenyl-4,4″-diol: a new antioxidant enhancing oxidative stability of soybean biodiesel. Fuel 237:593–596. https://doi.org/10.1016/j.fuel.2018.10.044

Kreivaitis R, Gumbyte M, Kazancev K et al (2013) A comparison of pure and natural antioxidant modified rapeseed oil storage properties. Ind Crops Prod 43:511–516. https://doi.org/10.1016/j.indcrop.2012.07.071

Bharti R, Singh B (2020) Green tea (Camellia assamica) extract as an antioxidant additive to enhance the oxidation stability of biodiesel synthesized from waste cooking oil. Fuel 262:116658. https://doi.org/10.1016/j.fuel.2019.116658

Basmacioǧlu H, Tokuşoǧlu Ö, Ergül M (2004) The effect of oregano and rosemary essential oils or alpha-tocopheryl acetate on performance and lipid oxidation of meat enriched with n-3 PUFA’S in broilers. S Afr J Anim Sci 34:197–210

Ismail SA, elmonem A, Ali RFM, (2016) Enhancing oxidative stability of biodiesel samples subjected to cations contamination during storage using Lantana camara L. (Verbanaceae) leaves extracts. Biochem Eng J 110:143–151. https://doi.org/10.1016/j.bej.2016.02.009

Moser BR (2012) Efficacy of gossypol as an antioxidant additive in biodiesel. Renew Energy 40:65–70. https://doi.org/10.1016/j.renene.2011.09.022

Freitas JPA, França FRM, Silva MS et al (2019) Cottonseed biodiesel oxidative stability in mixture with natural antioxidants. Korean J Chem Eng 36:1298–1304. https://doi.org/10.1007/s11814-019-0287-x

Silva de Sousa L, de Moura CVR, de Moura EM (2020) Influence of binary, ternary and quaternary mixtures on oxidative stability and study of kinetics and thermodynamic parameters of the degradation process of soybean biodiesel. Fuel 259:116235. https://doi.org/10.1016/j.fuel.2019.116235

França FRM, dos Santos FL, Ramos ALD et al (2017) Storage and oxidation stability of commercial biodiesel using Moringa oleifera Lam as an antioxidant additive. Fuel 203:627–632. https://doi.org/10.1016/j.fuel.2017.03.020

Malayoğlu H, Aktaş B, Çeliktaş Ö (2011) Total phenolic contents and antioxidant activities of the essential oils from some plant species. Ege Üniversitesi Ziraat Fakültesi Derg 48:211–215. https://doi.org/10.20289/eüzfd.40697

Ramos TCPM, Santos EPS, Ventura M et al (2021) Eugenol and TBHQ antioxidant actions in commercial biodiesel obtained by soybean oil and animal fat. Fuel 286:119374. https://doi.org/10.1016/j.fuel.2020.119374

Rizwanul Fattah IM, Masjuki HH, Kalam MA et al (2014) Performance and emission characteristics of a CI engine fueled with Cocos nucifera and Jatropha curcas B20 blends accompanying antioxidants. Ind Crops Prod 57:132–140. https://doi.org/10.1016/j.indcrop.2014.03.022

Tariq M, Ali S, Ahmad F et al (2011) Identification, FT-IR, NMR (1H and 13C) and GC/MS studies of fatty acid methyl esters in biodiesel from rocket seed oil. Fuel Process Technol 92:336–341. https://doi.org/10.1016/j.fuproc.2010.09.025

Arisoy K (2008) Oxidative and thermal instability of biodiesel. Energ Source Part A 30:1516–1522. https://doi.org/10.1080/15567030601082845

Garcia-Perez M, Adams TT, Goodrum JW et al (2010) DSC studies to evaluate the impact of bio-oil on cold flow properties and oxidation stability of bio-diesel. Bioresour Technol 101:6219–6224. https://doi.org/10.1016/j.biortech.2010.03.002

Mohamed Shameer P, Ramesh K (2017) FTIR assessment and investigation of synthetic antioxidant on the fuel stability of Calophyllum inophyllum biodiesel. Fuel 209:411–416. https://doi.org/10.1016/j.fuel.2017.08.006

Acknowledgements

The authors would like to thank Hasan Özcan in Kolza Biodiesel Company in Turkey for supporting WCOME biodiesel and the analysis. The author would like to thank to Dr. Nalan Türköz Karakullukçu in KİTAM, Ondokuz Mayis University, Samsun, Turkey, for the DSC analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Uğuz, G. Antioxidant effect of clove oil on biodiesel produced from waste cooking oil. Biomass Conv. Bioref. 13, 367–373 (2023). https://doi.org/10.1007/s13399-021-01679-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01679-4