Abstract

Brewers’ spent grains (BSGs) represent the largest quantity of solid waste from brewing, while xylooligosaccharides (XOS) produced from BSG show promising applications in food, beverage and health products. Production of XOS from a Weiss and malt BSG was scaled-up in steam explosion hydrothermal treatment using process conditions from bench-scale liquid hot water optimisations in stirred batch reactors. Three levels of moisture (15, 25 and 32% dry matter) achieved by screw press dewatering were evaluated by varying the treatment temperatures and times. Results show the highest XOS yields (> 73.1%) were obtained, for both BSGs, at process condition selected (180 °C, 10 min) with 25% initial dry matter content. These yields were higher than reported bench-scale optimisations (61%), but obtained using 60% less water; hence, initial dry matter content was an important variable affecting XOS yield. The pilot-scale steam explosion results provide a departing point for a cost-effective commercial production of XOS from BSG.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Worldwide, around 40 million tonnes of brewers’ spent grains (BSGs) is produced annually [1], and it comprises of up to 85% of the solid waste produced by breweries [2]. BSG has a high moisture content (about 75 to 85%) and is typically disposed off without drying, mostly as a cheap ruminant feed supplement [3, 4]. Regulations regarding animal feeds are becoming increasingly stringent, compelling breweries to consider alternative solutions for BSG disposal and valorisation [4].

Recently, higher value food product applications from processed BSG have been reported such as health-promoting, indigestible, soluble polysaccharides, i.e. xylooligosaccharides (XOS) [1, 5]. BSG is reported to be well suited for the production of XOS since it contains fibre (ca. 70%) that is high (with up to 40%) in xylan polymers [6,7,8]. Xylan is the major component of the hemicellulose fraction in BSG and is more amorphous and accessible than cellulose or lignin [8, 9]. Thus, xylan can be fractioned through selective solubilisation and depolymerisation by hydrothermal treatment (HTT) to produce XOS of varying degrees of polymerisation (DP) and substitution with arabinan, uronic acid, phenolic acid and acetyl groups [6,7,8]. Short-chain (DP < 10) XOS are valued for their prebiotic effect, in particular XOS substituted with arabinan or arabino-oligosaccharide (ArOS) [8]. Applications of XOS are found in functional food products as low-calorie sweeteners, prebiotics and texturisers, and are also marketed as supplements [10,11,12,13,14,15,16].

HTT processes reported for lignocelluloses are applied, with or without catalysts, in various reactor systems such as stirred batch [8], stationary flow-through [17], plug flow [18] or continuous process mode [19], while using steam injection, conductive or microwave heating [20]. The reactions take place using water mainly in the liquid phase, such as in stirred [8] or unstirred batch vessels [21], in single-phase steam [22] or in mixed liquid water and vapour phase such as in steam explosion [20, 23,24,25].

Steam explosion (SE) is widely reported as an efficient HTT method specifically to maximise the production of XOS from barley husk [20], corncobs [26] and bagasse [27]; however, no such optimisations of XOS production from BSG are reported. Recent SE HTT studies of BSG focus on improving digestibility [28, 29]. Another study optimised total xylan recovery [30]. In the study, a maximum of 47% xylan yield (33.5% XOS yield) was reported at 173 °C and 15.5 min. The best XOS yields reported from BSG are from optimisations in autocatalytic liquid hot water (LHW) HTT studies in stirred batch reactors with less than 11% dry matter, with a maximum XOS yield of up to 77% in nonisothermal LHW HTT up to 200 °C [8] and ca. 61% from isothermal (ca. 190 °C and 5 min) LHW HTT optimisations [6, 31]. However, it was shown that isothermal HTT at even lower temperatures, with equivalent severity, T = 180 °C for t = 12.2 min (severity factor = 3.65), increased the overall yield of XOS substituted with arabinan (ArOS) [8]. Therefore, this preferred process condition for BSG for production of XOS high in ArOS can be used as a guide for a scale-up in more efficient high solids pilot SE. In order to investigate SE at higher solids loadings than previous studies, an appropriate pilot-scale method of dewatering efficiently had to be applied. Mechanical dewatering of BSG with a screw press was selected on the basis of several process benefits [32, 33]: (i) reduced energy requirements compared to conventional drying, (ii) removal of the protein fraction into a separate by-product and (iii) increase in the fibre fraction of the residual BSG, which is then more suitable for XOS production. Additionally, the screw press could enhance the SE HTT for XOS production by three mechanisms. Firstly, the mechanical shear action of the screw press can cause defibrillation and shortening of fibres of the biomass, resulting in increased surface area [34]. Secondly, screw press dewatering can increase acidification of HTT of the biomass by the reduced acid neutralisation (buffering) capacity in the pressed biomass, as a result of removed components in the water fraction, such as soluble salts or ash [35], and reduction of the biomass proteinaceous compounds [36]. Thirdly, screw press dewatering can increase the rate of hemicellulose depolymerisation by acidification in HTT by the increase in H+ concentration as a result of water reduction in the biomass [37].

Therefore, this study investigated the impact of screw press dewatering on the XOS yield obtained from subsequent autocatalytic SE HTT using two types of BSG, namely, Weiss and pure pale malt brew (WBSG and PBSG respectively). Three levels of moisture contents were applied in such SE HTT, i.e. raw BSG (15% dry matter) and screw pressed BSGs at 25 and 32% dry matter, for both types of BSG. The pH values of the resulting hydrolysates were also used to compare acidification in the SE HTT between the different BSG types and screw press moisture levels, as based on the mol H+ per gram dry BSG. Additionally, air-dried BSG (90% dm) was used to benchmark for acidification in SE. Besides autocatalytic SE HTT of the various BSGs, the acidification and the depolymerisation rate of xylan were also enhanced by the addition of external catalysts. SE treatments of BSG with SO2 catalyst were done at the conditions for highest XOS yield to compare XOS yields, and yields of short-chain XOS oligomers xylobiose (X2) and xylotriose (X3) in the XOS hydrolysate.

2 Materials and methods

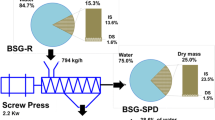

2.1 Raw material and screw press

BSG was sourced from a local brewery in Newlands (Cape Town, South Africa) in fresh 1 m3 lots, either as a single brew from a WBSG recipe consisting of 50/50 barley/wheat or a PBSG made of a single brew from a pure malt recipe. A 2.2-kW single screw press (NEW Eco-tec Verfahrenstechnik GmbH, Germany), with a screen cage of 0.3 m long × 0.15 m diameter and 0.6 mm slotted opening, was used to reduce the moisture contents in the two types of BSG. An adjustable opening at the press outlet which allowed for a measure of flow control was used to regulate the extent of pressure build-up in the screw press as well as the resulting water removal and dry mass content of the solid product. Triplicate runs were conducted to compare the screw press operation with respect to flow rate of each BSG type and the resulting moisture contents. Selected feed samples were taken randomly of raw feedstocks and pressed products (25 and 32% dry matter), aliquoted in sealed vacuum bags and stored frozen at − 20 °C until required. Samples were defrosted in a water bath at 25 °C before use [38].

2.2 Steam explosion fractionation of BSG

SE experiments were carried out in a pilot-scale 19-L capacity “steam gun” system that is well described elsewhere [39]. BSG was loaded manually at a top valve-operated opening of a cylindrical high-pressure reactor vessel, and saturated steam from an electrical boiler was used to heat the material to the required temperature. An explosive flash discharge cooled and released the BSG hydrolysate slurry into a flash tank once the required treatment time had been reached. The slurry of residue was collected from the flash tank and centrifuged to separate a liquid fraction for analysis. The resulting solids fraction was washed with distilled water and stored at − 20 °C before analysis. The SE reactor vessel was preheated to the required temperature by saturated steam and loaded with a sample of 1 kg dry mass of BSG.

SE treatment times and temperatures of the two BSG feedstocks are given in Table 1: for WBSG (runs A-1–A-12) and for PBSG (runs B-1–B-7). These HTT conditions used include 180 °C and 15 min which showed highest XOS yields in autocatalytic LHW HTT using WBSG (15% dry matter) (Table 3(b)). Preferred process conditions were selected from reported optimisations for maximum XOS + ArOS yields: (i) 180 °C and 10 min from multivariate optimisations in LHW HTT (11% dry matter) and (ii) 200 °C and 5 min (SF of 3.65) from nonisothermal LHW HTT optimisation in stirred batch reactors (11% dry matter) at 195 °C (SF of 3.65) [8]. Catalysed SE HTT runs (A-11/12 and B-7) with SO2 were conducted at process conditions for highest XOS yield obtained in uncatalysed SE [39]. To achieve the desired SO2 loading in the BSG, a 4.5 wt.% SO2 was added in BSG prior to SE (runs A-11 and B-7); however, in run A-12, potassium metabisulphite (K2S2O5) was added (57% wt.% equivalent SO2) to reach the 30 mg equivalent SO2/g dry feedstock (Table 1). Air-dried feedstock (WBSG-90%) was also prepared for run A-9 from WBSG-25% for SE benchmarking control run A-7.

SE HTT results of hemicellulose, gluco-oligosaccharide (GlcOS), XOS, arabino-oligosaccharides (ArOS), monomeric sugars and degradation products (acetic acid, formic acid, hydroxymethylfurfural [HMF] and furfural) were used to characterise the effects of screw press dewatering, SE treatment time and temperature; these were compared to bench-scale optimisation obtained under LHW HTT conditions from literature [6, 8, 31]. GlcOS, XOS and ArOS yields after SE treatment were calculated as the weight fraction of each of the starting polysaccharides (glucan, xylan or arabinan, depending on which yield) in the feedstock BSG recovered in the liquid hydrolysate as oligosaccharides [6, 8]. Hemicellulose yield was calculated as the fraction of the starting amount of hemicellulose that was recovered as pentose sugars and oligosaccharides in the liquid products. Inhibitor yields were calculated as mass yields relative to the dry mass starting feedstock. The total oligosaccharide equivalent (TXeR) weight recovered is the mass equivalent of reducing sugars and oligosaccharides recovered in the hydrolysate liquid after treatment [21]. Yields of xylobiose (X2) and xylotriose (X3) were calculated as a fraction of the XOS in the hydrolysate. The oligosaccharide yields relative to reducing sugar yield (GlcOS%, ArOS% and XOS%) were calculated as the mass oligosaccharides recovered relative to TXeR or sum total oligosaccharide and reducing sugars as equivalent weight recovered.

Additionally, a combined severity factor (CSF) was calculated for SE HTT, using the resulting pH in the slurry product, for comparison of HTT results. The CSF is log R′0 = log R0 – pH, where R0 = t.exp ((Tr − 100)/14.75) and that combines time (t) and temperature (Tr), and incorporates pH to include the contribution of added catalysts on biomass HTT [40]. The contribution of increased dry matter content to changes in pHs with HTT was considered using the resulting ratio as R[H+], of mol H+ per gram BSG at the same process condition from one dry matter content with another.

2.3 Analytical methods

Compositions of all solids, i.e. raw feedstock, screw press products, residue from SE HTT and its moisture content, were determined according to standard laboratory analytical procedures (LAP) for biomass analysis from the National Renewable Energy Laboratory (NREL, USA) [41]. Bulk densities of all feedstocks were determined by measurement in a graduated cylinder according to QAS/11.450 [42]. The BSG total starch and residual starch were determined before and after NREL extractives using a starch kit from Megazyme (K-TSTA, Ireland) [43]. Nitrogen content of samples was determent by crude nitrogen determination by the Kjeldahl method (D-3 Velp, Italy), where N × 6.25 was applied [44]. Amino acids were determined using a Waters Acquity (Milford, USA) ultra-performance liquid chromatograph (UPLC) separator with ultraviolet (UV) or fluorescence detection after derivation with 6-aminoquinolyl-N-hydroxysuccinimidyl carbamate (AQC).

Liquid fractions were analysed by high-pressure liquid chromatography (HPLC) using an Aminex HPX-87H Ion Exclusion Column equipped with a Cation-H cartridge (Bio-Rad, Johannesburg, South Africa), to determine the concentrations of short-chain oligomers (X2 and X3), sugars (glucose, xylose and arabinose) and inhibitors (acetic acid, formic acid, HMF and furfural) [39]. Additionally, oligosaccharide concentrations (GlcOS, XOS and ArOS) were determined as the difference in the monomeric sugar concentration before and after acid hydrolysis [27]. Correction factors of 0.9 for pentose and 0.88 for hexose to anhydrous oligomers were used [8, 21]. Difference in degradation products HMF and furfural was corrected to glucose and xylose respectively with correction factors 1.286 of 1.375 and for acetic acid to acetyl group by 0. 0.717 factor. All samples were analysed at least in triplicate.

3 Results and discussion

Two types of BSG, from a malt (PBSG) and Weiss (WBSG) brew, were used as raw materials to investigate pilot-scale SE HTT for XOS production. In particular, a screw press was used to dewater the BSG both from 15 to 25 and 32% dry matter contents prior to SE. A selection of process conditions from optimised bench-scale LHW HTT investigations for XOS production reported by [8] at 11% dry matter content, and confirmed at dry matter contents up to 15% (data not shown), was applied in the SE HTT. Results were evaluated for the extent of hemicellulose solubilisation from BSG and the recovery of XOS and associated oligosaccharides in the hydrolysate.

3.1 Screw press operation in dewatering WBSG and PBSG

The throughput rate (kg/h) of the equipment decreased with increases in dry matter content of the resulting pressed BSG (Supplementary Data). The energy requirement for processing PBSG from a starting 15 to 36.6% dry matter (maximum achieved) was 66.1 kWh/t BSG, similar to reported values of 40 to 53 kWh/t BSG [45, 46]. Additionally, the type of BSG used in the screw press had a significant influence on the screw press operation, as the results show a higher throughput rate of 794.7 ± 51.9 kg wet WBSG/h was achieved compared to PBSG (282.2 ± 32.4 kg wet PBSG/h) to dewater the raw BSG to ca. 25% dry matter content (Supplementary Data). Literature reports that fine particles (0.2–0.8 μm) present in BSG from adjuncts, like corn grits, or fines in the malt, can affect screw press dewatering significantly by giving an elastic or dough-like property to the BSG [47].

3.2 Characteristics of screw press–dried BSG product

Screw press–dried solids from WBSG and PBSG, of ca. 25% and 32% dry matter, were selected in addition to the unpressed feedstocks (15% dm), effectively creating 6 different BSGs for subsequent use in SE treatment (Table 2). The screw pressing operation did not compact the press-dried BSG; on the contrary, bulk density declined on a wet and dry basis (Table 2). On a dry basis, bulk volume reduced from 0.15 kg/L for wet WBSG-15% to 0.11 kg/L with WBSG-32%, which indicate an increased bed porosity and large void fraction created in the screw pressed material as a result of the removal of water, fines and soluble materials.

The compositional analysis shows total starch content on a dry mass basis in raw WBSG-15% was 12.9%, nearly 3 times that of PBSG-15% (Table 2). The screw press operation reduced total starch in both types of BSG (by ca. 33% in WBSG-25% and PBSG-25%), though WBSG-32% still contained 7.6% total starch. The reduction of starch was a result of the selective removal of fine suspended starch particles and soluble starch within the large water fraction removed with the press liquid [48, 49]. Together with the starch, fine particles high in protein were removed with the press liquid fraction in the screw press dewatering of raw PBSG and WBSG, which decreased the crude protein for the solid press products (Table 2). The fine insoluble particles in the press liquid removed from WBSG and PBSG showed 35.5 and 46.5% crude protein content (and 43.0 and 50.6% amino acids), respectively, obtained at 25% dry matter pressings (Supplementary Data). The lowering of starch and protein content with the screw press dewatering increased the lignocellulose and hemicellulose fractions present in both types of BSG; hemicelluloses increased in both WBSG (18.9 to 23.1%) and PBSG (20.8 to 24.1%) (Table 2). Raw PBSG showed a higher starting xylan content (13.2%) compared to WBSG (11.7%); nonetheless, screw pressing increased xylan fractions in both BSGs. Importantly, the screw press dewatering did not significantly change the composition of the BSGs since the values found for components of the 6 feedstocks from WBSG and PBSG are within ranges of other compositional values reported in literature, for hemicellulose (19.2 to 41.9%), cellulose (0.3 to 33%), starch (1 to 12%), protein (14.2 to 31%), lignin (11.5 to 27.8%), lipids (3 to 13%) and ash content (1.1 to 13%) [1]

3.3 XOS production scale-up in SE by using optimised bench-scale LHW process conditions and comparison of CSF

Bench-scale LHW optimisations in stirred batch reactors provide good starting points for process conditions to scale-up in SE HTT. Firstly, from the LHW HTT process, conditions for the highest XOS yield (78.0%) obtained using WBSG-15% (180 °C and 15 min) did provide process conditions resulting in similar high XOS yields (75.1%) in SE HTT (run A-5) at the same process condition using 25% dry matter (Fig. 1a). However, by a comparison of all the SE runs using CSF as shown in Fig. 1, the preferred process conditions of 10 min at 180 °C selected from reported optimisations in LHW HTT (11% dry matter) obtained the highest XOS yields (> 73%) for both types of BSGs (25% dry matter) at a CSF of ca. − 0.48 (run A-4 and run B-2). XOS yields increased with increasing CSF from − 2.5 to around − 0.48 to achieve the highest yields. From a CSF of around 0, a further increase resulted in significantly increased xylose formation from increased XOS depolymerisation. Both BSGs show a turning point at CSF of ca. − 0.48 for fractionating a large XOS fraction from BSG (> 73%) with minimal xylose formed (Fig. 1). Moreover, the preferred process conditions of 10 min at 180 °C selected provided the highest ArOS yield (Fig. 2a). An increased treatment time from 10 to 15 min resulted in a reduction in ArOS yields (Fig. 2a), while degradation by-product formation increased significantly from 0.81 and 1.10 g/100 to 1.48 and 1.68 g/100 g dm, for WBSG and PBSG, respectively (Fig. 2b). Therefore, both the reported (11% dry matter) optimal process conditions for maximum XOS production (XOS + ArOS) from bench-scale multivariate optimised LHW HTT of BSG [8] and process conditions found with highest XOS yield in LHW HTT using 15% dry matter content did provide process conditions for use in scale-up in SE HTT. This is in agreement with literature that demonstrated the use of bench-scale HTT optimisations for total xylan yield from corn stover in HTT scale-up [24]. This study showed that less costly smaller bench-scale HTT optimisations, even from literature, can be useful to assist process condition in scaling up to larger HTT systems like SE.

A comparison of steam explosion results ordered in increasing CSF achieved. a WBSG and b PBSG using combined severity factor (CSF): [  ] insoluble solid residue, [

] insoluble solid residue, [  ] XOS yield, [

] XOS yield, [  ] xylose yield, [

] xylose yield, [  ] hemicellulose yield, [

] hemicellulose yield, [  ] CSF (right axes) (experimental 95% confidence error bars of triplicate run B-2) (lines show trends)

] CSF (right axes) (experimental 95% confidence error bars of triplicate run B-2) (lines show trends)

3.4 Effect of variations in chemical composition of BSG on XOS production in SE HTT

The XOS production scale-up in SE was not significantly affected by small differences in chemical compositions. Applying a selected/preferred set of conditions to different types of BSGs resulted in yields and XOS product qualities that were comparable. The highest XOS yields for both Weiss-(WBSG) and malt-based (PBSG) BSGs were obtained at the same process condition of 180 °C and 10 min using 25% dry matter (Fig. 1a, b). Differences in composition between WBSG and PBSG only led to significant differences in yields of degradation products, acetic and formic acid. Moreover, the significantly higher starch content in WBSG did not have a significant effect on HMF yields from WBSG compared to PBSG (Fig. 2b). These comparable HTT results can also be found between various reported LHW HTT optimisation studies for BSGs where similar process conditions obtained comparable (ca. 60%) high XOS yields [6, 31]. Additionally, comparing the XOS and xylose yields across reported LHW HTT from BSG [6] with SE HTT shows similar trends for xylose and XOS formation when using CSF that incorporates the resulting pH obtained from the HTT (Fig. 3). The xylose yield increased significantly from a CSF of ca. − 0.5, at the conditions of highest XOS yield, for both WBSG run A-4 and PBSG run B-2 and the optimised process condition in LHW HTT reported (Fig. 3). Therefore, as this study showed, optimal process conditions from bench-scale HTT studies in literature that use other BSGs, with small differences in chemical compositions, can be useful to find preferred process conditions from scale-up.

Combined severity factor for steam explosion and LHW HTT. Steam explosion of [  ] WBSG and [

] WBSG and [  ] PBSG; and reported HTT of BSG, [

] PBSG; and reported HTT of BSG, [  ] 11% dm autocatalytic LHW [6] (highest XOS yield runs indicated)

] 11% dm autocatalytic LHW [6] (highest XOS yield runs indicated)

3.5 Increasing solids loadings with screw press dewatering for higher XOS yields in SE XOS production

Higher dry matter concentrations (> 11% dm) in HTT can lead to higher product yields. Based on literature [50], it is to be expected that higher dm in HTT will have negative effects on product yields, while increasing degradation by-product formation. Yet, contrary to that expected, using 25% dm for both WBSG (run A-4) and PBSG (run B-2) in SE HTT increased the XOS yield > 73% at 180 °C and 10 min compared to only 21.1% and 50.0% using 15% dm for WBSG and PBSG respectively (Fig. 4a1). The higher XOS yields from 25% dm BSGs were obtained even with slightly higher xylan contents in the 25% dm BSGs compared to the 15% dm (Table 2). Nevertheless, these SE HTT findings of increasing XOS yields from 15 to 25% dry matter BSG are in agreement with studies of barley husks in SE that reported increasing dry matter from 20 to 30% resulted in increased xylan recovery [20] and in unstirred autocatalytic LHW of bagasse at 170 °C, where XOS yield increased from 34 to 43% with increased dry matter content of 10 to 25% at the same treatment time [21]. The increase in XOS yield in SE HTT of screw pressed BSG observed in this study can be as a result of a combination of the effect of reduced moisture content and buffering capacity, decreasing the resultant pH in the SE HTT [37]. Additionally, the screw press dewatering increased BSG bed porosity (reduced bulk density; Table 2), increasing steam penetration during heating in a screw press–dried BSG compared to the raw BSG, creating faster and more uniform heating patterns [51]. Since temperature is a key factor in HTT, efficient exposure at the required temperature permits improved HTT of biomass since improved steam penetration will allow better temperature control, including more rapid heat-up and more accurate control at the set point [52, 53]. Therefore, the increasing yields obtained with increasing solids loading in SE HTT in this study support the inclusion of dry matter content or moisture as an additional optimisation parameter with time and temperature in HTT.

SE treatment results for WBSG and PBSG. a 180 °C and 10 min. b At 200 °C and 5 min. (1) Product yield and (2) inhibitors yield (g/100 g dry BSG) ([  ] 15% dm, [

] 15% dm, [  ] 25% dm, [

] 25% dm, [  ] 32% dm and [

] 32% dm and [  ] 90% dm WBSG and [

] 90% dm WBSG and [  ] 15% dm, [

] 15% dm, [  ] 25% dm and [

] 25% dm and [  ] 32% dm PBSG) (experimental 95% confidence error bars of triplicate run B-2 PBSG-25%)

] 32% dm PBSG) (experimental 95% confidence error bars of triplicate run B-2 PBSG-25%)

3.6 Screw press dewatering for optimising product yields in SE HTT

The use of higher dry matter concentrations (> 11% dm) in HTT can have significant process advantages if the negative effects of increased degradation by-product formation on process yields can be mitigated with effective optimisation strategies. Screw press dewatering of BSG can enable optimisation of XOS production in SE HTT by maximising the XOS yield as seen from the results at the preferred process condition of 180 °C and 10 min for both BSGs (Fig. 4a1). XOS yields of WBSG-15% (21.1%) increased to 75.3% for WBSG-25% and then decreased to 48.3% for WBSG-32% (Fig. 4a1). Similarly, for PBSG, the XOS yield increased at 180 °C and 10 min, from 50.0%, for PBSG-15%, to 73.1% (highest XOS yield) for PBSG-25%, and this decreased again to 64.8% with PBSG-32%. Degradation by-product formation supports this optimisation, as the acetic and formic acid formation increased with dry mater content of BSG between 15 and 25% dry matter and decreased between 25 and 32% dry matter, for both types of BSG (Fig. 4a2). However at 200 °C, the further increase in dry matter content to 32% further increased degradation by-product formation from 1.54 to 1.57 g/100 g dm and from 2.06 to 2.46 g/100 g dm for WBSG and PBSG, respectively (Fig. 4b2), contributing in reduced XOS yields. Moreover, at 200 °C, a significant negative effect of increased dry matter content on XOS yield is evident from the treatment of the air-dried 90% dry matter WBSG (original 25% dry matter) where the SE yield of XOS dropped from 60.6%, with 25% dry matter WBSG, to 9.8%, with 90% dry matter (air-dried WBSG-90%). From the results, it is clear that moisture content significantly affects product and degradation by-product formation in SE HTT and needs to be optimised in the HTT in combination with time and temperature.

3.7 Overall XOS production process intensification by screw press dewatering

Using higher dry matter concentrations (> 15%) of BSG through screw press dewatering in a SE HTT process can provide significant HTT process improvements for the intensification of the production of XOS. This is achieved through the following: (i) achieving similarly high (> 73%) XOS yields in SE HTT compared to reported nonisothermal (200 °C) optimised LHW studies [8] and increasing (> 10%) XOS yields from reported isothermal (190 °C and 5 min) optimised LHW studies [6, 31]; (ii) together with a reduction in the required process water in HTT of more than 60% by processing 25% dry matter BSG in SE compared to 9–11% dry matter in reported LHW studies. (iii) Additionally, reduced HTT process temperatures by up to 20 °C were achieved compared to the reported LHW HTT optimisations [6, 8, 31] while maintaining or increasing product yields. (iv) Another is a further reduction in degradation by-product formation compared to stirred batch work as was shown in the application of appropriate high solids HTT processing of BSG in SE at 25% dm (75.3% XOS yield) that resulted in degradation by-product formation of only 0.81 g/100 g dm compared to 1.50 g/100 g dm with 15% dm and 1.89 g/100 g dm reported at optimised conditions (190 °C and 5 min) in stirred batch reactors [6], conducted with 11% dm (61% XOS yield). (v) Moreover, overall product recovery increased. Compared to the reported SE HTT optimisation by Rojas Pérez (2018) on BSG for maximum (47.0%) total xylan yield (XOS + xylose), this SE HTT study achieved significantly higher (> 30%) total xylan yields at the preferred process conditions for both WBSG and PBSG.

Thus, the combination of effects of higher XOS product yield and concentrations, lower water usage, lower processing temperature requirements and lower degradation by-product formation achieved in this study could lower process energy and reduced equipment requirements that when combined may contribute to making BSG valorisation at small-scale economically feasible.

3.8 XOS depolymerisation to short-chain XOS with SO2 addition and high severity SE HTT

XOS is reported to be a functional food ingredient and an antioxidant and, more importantly, short-chain XOS oligomers with DP < 7 are reported to be prebiotic with bifidogenic activity of which the xylobiose (X2) and xylotriose (X3) obtained from BSG showed the most activity [8]. However, BSG SE results showed that, at conditions for the highest XOS yield (180 °C at 10 min with 25% dm), the XOS obtained contained low combined fractions (< 10%) of these two short-chain XOS from both types of BSGs (Fig. 5a). As an alternative to increase this fraction, by increasing the CSF at the SE condition for the highest XOS yield, SO2 catalyst additions were tested. Direct SO2 dosing in run A-11 for WBSG-25% (Fig. 1a) produced a significantly higher CSF (0.68) compared to the K2S2O5 addition (− 0.01) in run A-12. In run A-11 for WBSG-25%, direct SO2 solution dosing, 25 mg SO2/g dry feedstock, increased the combined X2 and X3 fraction to 16.5% (Fig. 5a) and obtained the highest yield of hemicellulose (77.1%) and highest xylose yield (23.3%) from WBSG (Fig. 1a). The 35 mg SO2/g dry feedstock dosing in SE of PBSG-25%, run B-7, increased the CSF to 0.83 (from − 0.49 without SO2) which increased the combined X2 and X3 fraction to 25.3% in run B-7 for PBSG (Fig. 5a). However, the SO2 catalyst addition reduced XOS yield from 73.1 to 33.6% as a result of increased severity from the SO2 catalyst. Yet, without additional chemical use, by only increasing the SE HTT process conditions to 200 °C and 5 min (25% dm), a similar increase of the combined fraction of X2 and X3 (27.0%) with an overall better XOS yield (49.7%) was achieved. Additionally, the screw pressed PBSG-32% obtained the highest fraction of 31.3% at 200 °C and 5 min that also show the increased severity effect from the screw press dewatering step. These findings are significant as a possible single production step of XOS with SE that could provide a large portion of prebiotic X2 and X3, either at high severity (200 °C and 5 min) or aided with SO2 catalyst.

a XOS composition: [  /

/  ] xylobiose (X2) and [

] xylobiose (X2) and [  /

/  ] xylotriose (X3) from steam explosion of 25 and 32% dm (left axis: yield in XOS, dashed

] xylotriose (X3) from steam explosion of 25 and 32% dm (left axis: yield in XOS, dashed  /

/  for WBSG and solid [

for WBSG and solid [  /

/  ] for PBSG; right axis: [

] for PBSG; right axis: [  ] CSF, [

] CSF, [  ] XOS yield and [

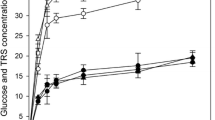

] XOS yield and [  ] xylan eq yield). b Monomeric xylose and glucose formation relative to oligomers in HHT: steam explosion of [

] xylan eq yield). b Monomeric xylose and glucose formation relative to oligomers in HHT: steam explosion of [  ] WBSG and [

] WBSG and [  ] PBSG (experimental 95% confidence error bars of triplicate run B-2 PBSG-25%) (lines show trends); and WBSG in liquid hot water, [

] PBSG (experimental 95% confidence error bars of triplicate run B-2 PBSG-25%) (lines show trends); and WBSG in liquid hot water, [  ] autocatalytic and [

] autocatalytic and [  ] extremely low acid (ELA) catalysed

] extremely low acid (ELA) catalysed

3.9 Effect of screw press dewatering on HTT, acidification and the resulting hydrolysate pH

Screw press dewatering of BSG in SE was shown to have a significant effect on the HTT process, affecting the hemicellulose xylan solubilisation, XOS yields, resulting pH and CSF (Table 3). Similar to the increased xylan solubilisation obtained in SE HTT at 180 °C and 10 min by screw press dewatering BSG from 15% and 25% dm, screw press dewatering also accelerated starch hydrolysis in SE HTT with reducing the residual starch in the remaining insoluble solid from WBSG-15%, from 8.1 to 0.8% with the pressed WBSG-25% and from 2.2 to 0.1% with the PBSG-25% at the same process conditions (Supplementary Data). Yet in HTT, the rate of solubilisation and depolymerisation of xylan and glucan polysaccharides is related proportionally to the H+ concentration in the hydrolysate [37]. In autocatalytic HTT, the effect of water as a weak acid is the main catalyst affecting the H+ concentration and, during HTT, acidification can be accelerated through the release of acetic, furanic, uronic and phenolic acids [9, 54]. External catalysts such as H2SO4 or SO2 can be added to increase the H+ concentrations in autocatalytic HTT such with ELA (extremely low acid) dosing.

R[H+] basis of gram dry BSG

3.10 Screw press dewatering modification of polysaccharide solubilisation and depolymerisation in SE HTT

The autocatalytic HTT solubilisation and depolymerisation of hemicellulose xylan and starch (glucan) in the steam explosion and LHW are comparable. Xylan and glucan depolymerisation yields change proportionally, even considering the small differences in the compositions of WBSG and PBSG, and modifications with the screw press dewatering (Fig. 5b). However, the addition of SO2 catalyst in SE (runs A-12 and B-7) changed the xylan and glucan depolymerisation significantly compared to autocatalytic HTT with catalyst additions resulting in significantly more glucose formation relative to xylose. Autocatalytic depolymerisation even with the highest CSF 1.25, in run A-10, from the 90% air-dried WBSG (original WBSG-25%) obtained xylan and glucan depolymerisation results similar to other more dilute and less severe autocatalytic SE runs of WBSG and PBSG (Fig. 5b). This is consistent with literature that showed, for straw, that mainly HTT reactions are activated with temperatures of up to 200 °C, even at high dry matter content (< 80%) [9]. This suggests that the effect of compositional modifications with screw press dewatering on BSG could affect rates of polysaccharide solubilisation and depolymerisation similar to moisture reductions. Screw press dewatering is effective to modify the rate of polysaccharide solubilisation and depolymerisation in autocatalytic HTT.

3.11 Screw press dewatering and initial dry matter content to adjust H+ concentration, pH and CSF in autocatalytic SE HTT

As expected, the screw press dewatering and temperature played a significant role in SE HTT hydrolysate acidification from both types of BSGs. Two distinct trends were found when looking at the effects of screw press dewatering on hydrolysate acidification (mol H+ per gram dry BSG) in SE HTT from WBSG and PBSG (Fig. 6). Firstly at 180 °C, increasing screw pressed dry matter content from 25 to 32% resulted in reduced acidification of between 35 and 57% in autocatalytic SE HTT for both BSGs (Fig. 6) when compared to 25% dm and accounting for the resulting dilution effect of SE in the hydrolysates (Supplementary Data). This reduction in acidification is also shown in the ratio of R[H+] 0.43 for PBSG 32%/25% and R[H+] of 0.66 for WBSG 32%/25% (Table 3), even though with 32% dm WBSG the hydrolysate H+ concentration increased slightly (lowered pH). This reduced acidification at 32% dm for both WBSG and PBSG can explain the reduced XOS yields from 60.6 to 9.8% obtained with the 32% dry matter BSGs in this study (Table 3), compared to 25% dm. This is in agreement with reported findings where rate of xylan solubilisation reduced by 66% with a doubling in dry matter content in HTT [55].

The effect of screw press dewatering on acidification in HTT of a WBSG and b PBSG: steam explosion at [  ] 180 °C for 10 min and [

] 180 °C for 10 min and [  ] 200 °C for 5 min and; stirred batch reactor at [

] 200 °C for 5 min and; stirred batch reactor at [  ] 150 °C for 10 min and [

] 150 °C for 10 min and [  ] 180 °C for 5 min and [

] 180 °C for 5 min and [  ] 15 min (experimental 95% confidence error bars of triplicate run B-2 PBSG-25%)

] 15 min (experimental 95% confidence error bars of triplicate run B-2 PBSG-25%)

Secondly, at 200 °C, the same dewatering increased hydrolysate acidification in HTT (Fig. 6). Increased screw pressed dry matter content from 25 to 32% dry matter leads to increased acidification compared to 180 °C and 10 min for both BSGs with R[H+] for WBSG-32%/25% at 200 °C relative to 180 °C being 1.75 (1.15/0.66) and for PBSG 32%/25% being 2.15 (0.92/0.43) (Table 3). This significant increased acidification at 200 °C compared to 180 °C could be as a result of more exothermic hydrothermal carbonisation reactions activated from temperatures around 200 °C accelerating HTT acidification [9]. This increasing acidification at 200 °C with dry matter was also found to be similar for screw press dewatering and moisture reduction.

The screw press dewatering of BSG could be considered as a moisture reduction step, since the acidification (mol H+ per gram dry BSG) in the hydrolysate from screw pressed BSG in autocatalytic SE HTT was not significantly different from that obtained by moisture reduction alone. A reduced water content or increasing the dry matter content from 25 to 90% dm (air-dried) process at the same conditions (5 min and 200 °C) in the SE HTT resulted in a significant reduction in hydrolysate pH (from pH 3.33 in run A-7 to pH 2.43 in run A-10) (Table 3), which increased severity in SE HTT with increased CSF (from 0.36 (A-7) to 1.25 (A-10)). However, this increased acidification at 200 °C and 5 min for WBSG-90% (air-dried) was proportional to the increased acidification with WBSG-32% (screw pressed) by the reduction in water (Fig. 6a). Therefore, the H+ concentration obtained and H+ released during SE HTT of screw pressed BSG seem related to the reduced water content, and the fractionation of components including starch, protein and buffering components did not show a significant effect. Similarly, the autocatalytic LHW HTT in stirred batch reactors found similar acidification (mol H+ per gram dry BSG) raw and pressed WBSG-25%.

3.12 Screw press dewatering in pilot-scale autocatalytic SE HTT compared to bench-scale autocatalytic LHW

The stirred batch was more suitable for lower (up to 15% dm) solids loading autocatalytic HTT of BSG compared to unstirred SE since the acidification (mol H+ per gram dry BSG) was almost constant in stirred reactors, while SE HTT was better suitable for higher (ca. 25% dm) solids loadings (Fig. 6a). SE HTT of WBSG-15% at 180 °C for 10 min (run A-1) achieved only 29% of the acidification of 5 min autocatalytic LHW HTT in a stirred batch reactor (Table 3). However, the screw press dewatering of WBSG-15% to WBSG-25% improved acidification in the pilot-scale SE HTT that was more beneficial to XOS production in comparison with the bench-scale LHW HTT since this increased acidification with dewatering increased XOS yields in SE (Table 3). SE HTT screw pressed WBSG-25% at the preferred process conditions (run A-4) achieved 73% acidification and similar CSF conditions than LHW (run AH-A3) of raw WBSG-15% in the stirred batch Parr reactor (Table 3), treatments that both resulted in maximum XOS yields (78.0% and 75.3%). This observation could be attributed to the screw press process creating large void fractions, increasing the bed porosity of WBSG-25%, resulting in increased steam permeability, more efficient heating with a reduction in moisture content, summing up to a significantly improved autocatalytic effect in the SE HTT process [51,52,53]. In summary, a high dry matter content (WBSG-25%) in a SE HTT is as effective in the production of XOS as a low dry matter content (WBSG-15%) in a LHW HTT process.

3.13 Effect of screw press dewatering on SE hydrolysate purity

Hydrolysed starch, proteins and other soluble by-products including degradation products formed from components during SE of BSG negatively affect the purity of the XOS produced. Purification of the hydrolysate for XOS is the largest cost component in XOS production and improving the purity needs to be considered [56].

Higher oligosaccharide fractions in total dissolve solids (TDS) were obtained from SE HTT with short residence times, lower temperatures and high dry matter content screw pressed BSGs (Table 4). The total oligosaccharide (OS) fraction (XOS and ArOS) increased in the TDS of the SE hydrolysates from screw pressed BSGs through selective removal of water-soluble materials and impurities which include minerals, starch and proteins. Results show the highest OS/TDS of 51.9% and 42.2% was obtained for WBSG (32% dm) and PBSG (32% dm), respectively, both at 180 °C and 10 min (the preferred HTT process conditions) (Table 4). To improve on the process minimising purification cost, through increasing the purity of XOS, the screw press could be used to dry the BSG to the minimum moisture content of ca. 40% dry matter and then, the water content can be readjusted to the dry matter content required (25% dm) for optimum yield of the XOS. Additionally, such increased screw press intensity can result in higher recovery of protein in the press water as a valuable by-product.

The addition of SO2 catalysts at the process conditions for the highest XOS yield resulted in increased soluble components in the hydrolysate that reduced OS/TDS from 37.1% for WBSG (run A-4) without catalyst addition to between 23.9 and 25.9% (Table 4). Therefore, the catalyst addition at the tested conditions did not improve XOS purity or yield in autocatalytic SE process mainly since it increased depolymerisation.

3.14 BSG protein in SE hydrothermal treatment

WBSG compared to PBSG had similar amounts of essential amino acids (37.3% and 36.8%); the hydrophilic amino acids in WBSG was higher (44.2%) compared to PBSG (40.3%). The screw press protein fractions separated, for both PBSG and WBSG, show selectivity to the non-essential amino acid proline and glutamine (Supplementary Data). The overall protein balance of the process for SE conditions of highest XOS yield (run B-2), using the crude protein contents for the starting PBSG and SE residue, shows up to 73.6% of PBSG protein can be recovered as insoluble residue (press liquid and SE residue). The SE of PBSG-25%, aided with addition of SO2 catalyst, removed more proteins compared to autocatalytic SE. Low severity SE HTT had a better recovery of PBSG proteins in the remaining solids. SE process conditions at 200 °C and 5 min removed 32.3% from the overall crude protein of raw PBSG-15% compared to 26.4% at 180 °C and 10 min. While lower severity is preferred, SE of BSG can recover protein (rich in essential amino acids) in the remaining solid fraction. However, the SE residue composition at the near optimal conditions for PBSG-25% (run B-2) results shows 81.7% of the nitrogen of PBSG-25% removed in SE was accounted for in the hydrolysate. The hydrolysate for run B-2 showed 15.3% crude nitrogen in TDS, of which 66.2% was accounted for as amino acids (Supplementary Data). The solubilised crude nitrogen made up 53.4% of other components non-determined, which is similar to reported autocatalytic LHW optimised conditions for XOS production [8].

BSG proteins degrade in SE. The crude protein from the SE residues was consistently higher than the total amino acids even though tryptophan and cysteine amino acids were not quantified (reportedly < 2% combined content in total BSG amino acids) as shown in the Supplementary Data. The solid residue from SE run B-4 at 200 °C showed a crude protein of 19.6% while the amino acid total was 14.4%. That shows that almost 20% of the nitrogen was degraded in the insoluble residue in the SE HTT. Acid insoluble (AI) fractions from raw WBSG and PBSG (22.4% to 24.5%) showed an increase of up to 32.3 to 34.5% respectively in residues from SE treatment (Supplementary Data). The AI fraction from SE run B-2 at 180 °C for the highest XOS yield contained 39.6% crude protein, and the addition of SO2 in SE reduced the crude protein fraction in the acid insoluble fraction to 35.7%. Reports have shown that BSG proteins degrade in SE by aggregation, combined with heat-induced cross-linking, which remain insoluble [28, 57]. BSG proteins can also bind with lignin in SE HTT as pseudo-lignin that increase the insoluble lignin fraction [57].

4 Conclusions

XOS production from BSG for application in novel food and beverages can reduce brewery waste streams and increase resource efficiency. XOS production optimisations reported in bench-scale LHW HTT of BSG can be used for scale-up to pilot-scale SE, achieving similar and higher XOS yields (> 73%) by using > 60% less water. Moisture content was shown as an important HTT optimisation variable. Small variations in BSG compositions did not significantly affect near optimal conditions. SE severity adjustment through SO2, catalyst addition or process conditions can increase the valuable short-chain X2 and X3 oligomers in the XOS up to 31.3%.

References

Lynch KM, Steffen EJ, Arendt EK (2016) Brewers’ spent grain: a review with an emphasis on food and health. J Inst Brew 4:553–568. https://doi.org/10.1002/jib.363

Nigam PS (2017) An overview: recycling of solid barley waste generated as a by-product in distillery and brewery. Waste Manag 62:255–261. https://doi.org/10.1016/j.wasman.2017.02.018

Mussatto SI (2014) Brewer’s spent grain: a valuable feedstock for industrial applications. J Sci Food Agric 94:1264–1275. https://doi.org/10.1002/jsfa.6486

Kerby C, Vriesekoop F (2017) An overview of the utilisation of brewery by-products as generated by British Craft Breweries. Beverages 3:1–12. https://doi.org/10.3390/beverages3020024

Ikram S, Huang L, Zhang H, Wang J, Yin M (2017) Composition and nutrient value proposition of brewers spent grain. J Food Sci 00:1–11. https://doi.org/10.1111/1750-3841.13794

Carvalheiro F, Esteves MP, Parajo JC et al (2004) Production of oligosaccharides by autohydrolysis of brewery’s spent grain. Bioresour Technol 91:93–100. https://doi.org/10.1016/S0960-8524(03)00148-2

Gullón P, González-Muñoz MJ, Parajó JC (2011) Manufacture and prebiotic potential of oligosaccharides derived from industrial solid wastes. Bioresour Technol 102:6112–6119. https://doi.org/10.1016/j.biortech.2011.02.059

Gómez B, Miguez B, Veiga A et al (2015) Production, purification, and in vitro evaluation of the prebiotic potential of arabinoxylooligosaccharides from brewer’s spent grain. J Agric Food Chem 63:8429–8438. https://doi.org/10.1021/acs.jafc.5b03132

Ibbett R, Gaddipati S, Davies S, Hill S, Tucker G (2011) The mechanisms of hydrothermal deconstruction of lignocellulose: new insights from thermal – analytical and complementary studies. Bioresour Technol 102:9272–9278. https://doi.org/10.1016/j.biortech.2011.06.044

Fărcaş AC (2014) Research regarding the identification and exploitation of biologically active compounds from brewers’ spent grain by-product. University of Agricultural Sciences and Veterinary Medicine CLUJ-NAPOCA

Steiner J, Procopio S, Becker T (2015) Brewer’s spent grain: source of value-added polysaccharides for the food industry in reference to the health claims. Eur Food Res Technol 303–315. https://doi.org/10.1007/s00217-015-2461-7

Brink M (2004) Market and product assessment of prebiotics and probiotics strains for commercial use. University of Pretoria

Collins S, Reid G (2016) Distant site effects of ingested prebiotics. Nutrients 8:1–20. https://doi.org/10.3390/nu8090523

NutraSource I (2013) GRAS Notification (GRN) No 458 for Shangdong Longlive Biotechnology, Ltd.’s Xylooligosaccharides

Steele EA (2010) Wheat Bran Extract: GRAS Notice 000343

Rastall RA, Gibson GR (2015) Recent developments in prebiotics to selectively impact beneficial microbes and promote intestinal health. Curr Opin Biotechnol 32:42–46. https://doi.org/10.1016/j.copbio.2014.11.002

Yang B, Gray MC, Liu C, et al. (2004) Unconventional relationships for hemicellulose hydrolysis and subsequent cellulose digestion. In: Lignocellulose biodegradation. American Chemical Society

Church JA, Wooldridge D (1981) Continuous high-solids acid hydrolysis of biomass in a 11/2-in. plug flow reactor. Ind Eng Chem Prod Res Dev 20:371–378. https://doi.org/10.1021/i300002a027

Heitz M, Capek-Ménard E, Koeberle PG, Gagné J, Chornet E, Overend RP, Taylor JD, Yu E (1991) Fractionation of Populus tremuloides at the pilot plant scale: optimization of steam pretreatment conditions using the STAKE II technology. Bioresour Technol 35:23–32. https://doi.org/10.1016/0960-8524(91)90078-X

Roos AA, Persson T, Krawczyk H, Zacchi G, Stålbrand H (2009) Extraction of water-soluble hemicelluloses from barley husks. Bioresour Technol 100:763–769. https://doi.org/10.1016/j.biortech.2008.07.022

Vallejos ME, Zambon MD, Area MC, Curvelo AA d S (2012) Low liquid–solid ratio (LSR) hot water pretreatment of sugarcane bagasse. Green Chem 14:1982. https://doi.org/10.1039/c2gc35397k

Allen SG, Schulman D, Lichwa J, Antal MJ, Jennings E, Elander R (2001) A comparison of aqueous and dilute-acid single-temperature pretreatment of yellow poplar sawdust. Ind Eng Chem Res 40:2352–2361

Brownell HH, Saddler JN (1987) Steam pretreatment of lignocellulosic material for enhanced enzymatic hydrolysis. Biotechnol Bioeng 29:228–235. https://doi.org/10.1002/bit.260290213

Lischeske JJ, Crawford NC, Kuhn E, Nagle NJ, Schell DJ, Tucker MP, McMillan JD, Wolfrum EJ (2016) Assessing pretreatment reactor scaling through empirical analysis. Biotechnol Biofuels 9:213. https://doi.org/10.1186/s13068-016-0620-0

Olsson L (2007) Biofuels

Wang L, Fan X, Tang P, Yuan Q (2013) Xylitol fermentation using hemicellulose hydrolysate prepared by acid pre-impregnated steam explosion of corncob. J Chem Technol Biotechnol 88:2067–2074. https://doi.org/10.1002/jctb.4070

Carvalho AFA, Marcondes WF, de Oliva NP et al (2018) The potential of tailoring the conditions of steam explosion to produce xylo-oligosaccharides from sugarcane bagasse. Bioresour Technol 250:221–229. https://doi.org/10.1016/j.biortech.2017.11.041

Kemppainen K, Rommi K, Holopainen U, Kruus K (2016) Steam explosion of Brewer’s spent grain improves enzymatic digestibility of carbohydrates and affects solubility and stability of proteins. Appl Biochem Biotechnol 180:1–15. https://doi.org/10.1007/s12010-016-2085-9

Qihua D, Li F, Deliang W et al (2010) Research into pretreatment methods of brewer’s spent grain (Chinese). Food Ferment Ind 36:116–121

Rojas Pérez LC (2018) Valorisation of brewers spent grains in the production of xylitol (Spanish). Universidad Nacional de Colombia

López-Linares JC, García-Cubero MT, Lucas S, González-Benito G, Coca M (2019) Microwave assisted hydrothermal as greener pretreatment of brewer’s spent grains for biobutanol production. Chem Eng J 368:1045–1055. https://doi.org/10.1016/j.cej.2019.03.032

Ishiwaki BN, Murayama H, Awayama H et al (2000) Development of high value uses of spent grain by fractionation technology quarterly. MBAA Tech Q 37:261–265

Blinkov SD, Nemoytin JBBM, Fedorov AL (1999) Method for processing vegetal raw materials in order to produce pentose hydrolysates essentially containing xylose

Yan Q, Miazek K, Grande PM, Domínguez de María P, Leitner W, Modigell M (2014) Mechanical pretreatment in a screw press affecting chemical pulping of lignocellulosic biomass. Energy Fuel 28:6981–6987. https://doi.org/10.1021/ef501706w

Jacobsen SE, Wyman CE (2000) Cellulose and hemicellulose hydrolysis models for application to current and novel pretreatment processes. Appl Biochem Biotechnol 84–86:81–96. https://doi.org/10.1385/ABAB:84-86:1-9:81

Liao W, Liu Y, Liu C, Chen S (2004) Optimizing dilute acid hydrolysis of hemicellulose in a nitrogen-rich cellulosic material - Dairy manure. Bioresour Technol 94:33–41. https://doi.org/10.1016/j.biortech.2003.11.011

Mosier NS, Ladisch CM, Ladisch MR (2002) Characterization of acid catalytic domains for cellulose hydrolysis and glucose degradation. Biotechnol Bioeng 79:610–618. https://doi.org/10.1002/bit.10316

Bartolomeé B, Santos M, Jiménez JJ et al (2002) Pentoses and hydroxycinnamic acids in brewer’s spent grain. J Cereal Sci 36:51–58

García-Aparicio M, Parawira W, Van Rensburg E et al (2011) Evaluation of steam-treated giant bamboo for production of fermentable sugars. Biotechnol Prog 27:641–649. https://doi.org/10.1002/btpr.580

Chum HL, Johnson DK, Black SK, Overend RP (1990) Pretreatment-catalyst effects and the combined severity parameter. Appl Biochem Biotechnol 24–25:1–14. https://doi.org/10.1007/BF02920229

Sluiter JB, Ruiz RO, Scarlata CJ, Sluiter AD, Templeton DW (2010) Compositional analysis of lignocellulosic feedstocks. 1. Review and description of methods. J Agric Food Chem 58:9043–9053. https://doi.org/10.1021/jf1008023

WHO (2012) S.3.6. Bulk density and tapped density of powders QAS/11.450 FINAL

Robertson JA, I’Anson KJA, Treimo J et al (2010) Profiling brewers’ spent grain for composition and microbial ecology at the site of production. LWT Food Sci Technol 43:890–896. https://doi.org/10.1016/j.lwt.2010.01.019

Pires EJ, Ruiz HA, Teixeira JA, Vicente AA (2012) A new approach on brewer’s spent grains treatment and potential use as lignocellulosic yeast cells carriers. J Agric Food Chem 60:5994–5999. https://doi.org/10.1021/jf300299m

Weger A, Binder S, Franke M, Hornung A (2014) Solid biofuel production by mechanical pre-treatment of brewers’ spent grain. Chem Eng Trans 37:661–666. https://doi.org/10.3303/CET1437111

Weber B, Stadlbauer EA (2017) Sustainable paths for managing solid and liquid waste from distilleries and breweries. J Clean Prod 149:38–48. https://doi.org/10.1016/j.jclepro.2017.02.054

Huige NJ (1994) Handbook of brewing: In Food science and technology. In: Hardwick WA (ed) Marcel Dekker Inc. CRC Press, pp 501–550)

Jay AJ, Parker ML, Faulks R, Husband F, Wilde P, Smith AC, Faulds CB, Waldron KW (2008) A systematic micro-dissection of brewers’ spent grain. J Cereal Sci 47:357–364. https://doi.org/10.1016/j.jcs.2007.05.006

Stiles RS, Herbert HS (1977) Centrifugal separation, isolation and characteristics of brewery spent grains and press liquor. MBAA Tech Q 14:21–34

Modenbach AA, Nokes SE (2012) The use of high-solids loadings in biomass pretreatment-a review. Biotechnol Bioeng 109:1430–1442. https://doi.org/10.1002/bit.24464

Brownell HH, Yu EKC, Saddler JN (1986) Steam explosion pretreatment of wood: effect of chip size, acid, moisture content and pressure drop. Biotechnol Bioeng 28:792–801. https://doi.org/10.1002/bit.260280604

Cullis IF, Saddler JN, Mansfield SD (2004) Effect of initial moisture content and chip size on the bioconversion efficiency of softwood lignocellulosics. Biotechnol Bioeng 85:413–421. https://doi.org/10.1002/bit.10905

Sui W, Chen H (2015) Study on loading coefficient in steam explosion process of corn stalk. Bioresour Technol 179:534–542. https://doi.org/10.1016/j.biortech.2014.12.045

Negahdar L, Delidovich I, Palkovits R (2016) Aqueous-phase hydrolysis of cellulose and hemicelluloses over molecular acidic catalysts: Insights into the kinetics and reaction mechanism. Appl Catal B Environ 184:285–298

Morinelly JE, Jensen JR, Browne M, Co TB, Shonnard DR (2009) Kinetic characterization of xylose monomer and oligomer concentrations during dilute acid pretreatment of lignocellulosic biomass from forests and switchgrass. Ind Eng Chem Res 48:9877–9884. https://doi.org/10.1021/ie900793p

Amorim C, Silvério SC, Rodrigues LR (2019) One-step process for producing prebiotic arabino-xylooligosaccharides from brewer’s spent grain employing Trichoderma species. Food Chem 270:86–94. https://doi.org/10.1016/j.foodchem.2018.07.080

Rommi K, Niemi P, Kemppainen K, Kruus K (2018) Impact of thermochemical pre-treatment and carbohydrate and protein hydrolyzing enzyme treatment on fractionation of protein and lignin from brewer’s spent grain. J Cereal Sci 79:168–173. https://doi.org/10.1016/j.jcs.2017.10.005

Funding

This work was supported by funds from the Council for Scientific and Industrial Research (CSIR) of South Africa.

Author information

Authors and Affiliations

Contributions

Lukas J. Swart: conceptualisation, methodology, investigation and writing-original draft. Oscar K.K. Bedzo: writing, review and editing. Eugéne van Rensburg: review and editing. Johann F. Görgens: project administration, supervision, writing-review and editing.

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• High solids loading (15, 25 and 32% dry matter) BSG hydrothermal treatment

• Simple screw press dewatering for XOS production intensification

• Scale-up to pilot steam explosion by using reported optimal conditions from bench stirred batch reactors

Electronic supplementary material

ESM 1

(DOCX 287 kb)

Rights and permissions

About this article

Cite this article

Swart, L.J., Bedzo, O.K.K., van Rensburg, E. et al. Pilot-scale xylooligosaccharide production through steam explosion of screw press–dried brewers’ spent grains. Biomass Conv. Bioref. 12, 1295–1309 (2022). https://doi.org/10.1007/s13399-020-01099-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01099-w

/

/  ] WBSG and 10/15 min [

] WBSG and 10/15 min [  /

/  ] PBSG) (experimental 95% confidence error bars of triplicate run B-2)

] PBSG) (experimental 95% confidence error bars of triplicate run B-2)