Abstract

In the present study, the valorization of cheese whey (CW) as an electron donor in an air-cathode single-chamber microbial fuel cell (MFC) was studied. Filter-sterilized raw and pretreated-acidified diluted CW (after 48 h of fermentation at mesophilic temperature) were used as substrates, in order to investigate the effect of the two different handlings on the MFC performance. The pretreatment-acidification experiments were performed under different operational conditions (initial dilutions giving chemical oxygen demand (COD) concentrations of 2 and 4 g/L as well as initial pH adjusted to 6.7 and without pH adjustment) in order to obtain maximum acidification efficiency and energy recovery, in the form of hydrogen. The effect of organic load on the efficiency of the MFC was studied, aiming at exploring the possibility of achieving a successful operation at the highest possible initial concentration of CW (smallest dilution). The experimental results showed that CW is a suitable and promising substrate for electricity production using MFC, with a maximum power density of 3.26 W/m3 (0.33 MJ/kg COD) for filter-sterilized CW diluted to an initial concentration of 0.8 g COD/L. Combining MFC technology with the pretreatment/acidification process, during which hydrogen is also produced, a total energy of 2.37 MJ/kg COD could be recovered.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Decision 97/80/EC, which sets the provisions for the implementation of Council Directive 96/16/EC regarding the statistical surveys of milk and its products, defines whey as the by-product obtained during the manufacturing of cheese or casein. Cheese whey (CW) contains on average 4.8% lactose, 0.8% protein and 0.2% fats (w/v), corresponding to the residual organic content after removal of casein and most of the fats from the milk [1]. The proportion of its ingredients varies according to the type of milk used and the type of cheese made. Generally, CW coming from goat milk is expected to have higher concentrations of total solids than the respective coming from cow milk. Due to its high organic content, CW has a strong organic load, with the values of biochemical oxygen demand (BOD) and chemical oxygen demand (COD) ranging from 27 to 60 and from 50 to 102 kg/m3, respectively [2].

Due to its large production volumes (9 kg of CW is generated per kg of cheese) and the number of cheese manufacturing units, CW handling is a serious environmental challenge, especially in countries where the cheese-making sector is highly developed. Today, the annual amount of cheese produced in EU 27 exceeds 10.2 million tons and has an upward trend of around 3% per year.

Ιn Greece, there are numerous small private cheese-manufacturing units scattered throughout the country, producing more than 160,000 tons of cheese (data for 2007 by Hellenic Statistical Authority, ELSTAT 2009–2010) and more than 700,000 tons of CW annually. Out of this amount, approximately 250,000 tons are used for the production of the secondary white cheese called “mizithra”, 50,000 tons for animal feed, and the rest is inappropriately discarded into rivers, lakes, or other water bodies, resulting in severe water pollution. Up to now, in Greece, no specific strategies have been adopted for the treatment and disposal of CW [1]. However, legislation has recently become stricter, forcing the cheese factories to treat their wastewaters, by developing facilities for this purpose on their premises, causing an increase in the capital and cheese production cost [3]. In this respect, the possibility of exploiting the components such as lactose or proteins contained in CW for producing useful products or energy should add value to this by-product, ensuring its treatment and safe disposal while simultaneously reducing the cheese production cost.

Anaerobic biological processes such as biogas or hydrogen production [4,5,6,7] are alternative technologies to other methods employed in CW management, such as animal feeding or recovery of proteins or other compounds [1]. However, due to the low bicarbonate alkalinity and high COD value, anaerobic treatment of CW is not always efficient since CW exhibits a tendency to get rapidly acidified [7]. CW management with simultaneous energy recovery using MFCs represents a promising approach [8], since it operates at neutral pH values and low organic loadings, where tendency for acidification is hardly observed.

MFCs are bio-electrochemical systems producing bioelectricity providing the dual benefit of energy production and simultaneous wastewater/waste treatment [9]. In MFCs, microorganisms oxidize the organic compounds, producing carbon dioxide, protons, and electrons, which are transferred to an electrode (final electron acceptor of their metabolism). The electrons are transferred to a current collector and then migrate through an external resistor to the cathode, where oxygen is reduced to water, generating electric current. Power generation depends on the materials employed, the design of the MFC and the capabilities of the electroactive bacteria to use the anode as solid electron acceptor [10, 11]. In this respect, the concept of an air-cathode single-chamber MFC containing graphite granules to support biofilm formation is considered promising [12], offering the possibility of enhanced power generation, while treating different kind of substrates [13]. The use of CW as an electron donor in such a single-chamber MFC, operating in continuous mode, is quite appealing. Up to now, batch operation of bioelectrochemical systems for producing either electricity [6, 10, 14] or hydrogen [15] from CW has extensively been investigated. For instance, Ghasemi et al. [14] operated a two-chamber MFC, producing 188.8 mW/m2, when whey at a concentration of 50 g lactose/L was used as substrate, while Kelly and He [16] observed an average power density of 0.4 W/m3 when CW was used as a substrate in a tubular MFC, operated in batch mode. On the other side, two-chamber continuous systems, packed with graphite granules, were used for treating undiluted dairy wastewater collected from the flotation unit of a large cheese factory with an initial COD of 0.65–3.00 g/L, recovering a maximum power density of almost 27 W/m3 [17, 18].

In the present study, a four-air cathode single-chamber MFC with MnO2 as cathode catalyst and a packed bed as anode was studied, aiming at the continuous treatment of diluted, filter-sterilized CW. The MFC performance was assessed under two different organic loadings (0.8 and 1.6 g COD/L.d, at a hydraulic retention time (HRT) of 24 h) in order to determine the optimal initial CW concentration. The use of filter-sterilized CW instead of raw CW in this study was based on previous experiments where raw diluted CW, without any treatment was used as substrate in a two-chamber MFC [8]. In that study, it was found that although electricity production was possible with a high COD reduction efficiency, the coulombic efficiency (CE) was very low, only 1.9%. This was attributed to a significant substrate bioconversion in the bulk of the anode. Indigenous non-electrogenic microorganisms (possibly Lactobacillus sp.) contained in the CW used the organic matter in the bulk, rather than on the electrode, where the electrogenic biofilm was established. These results indicated that a pretreatment step of raw CW was essential prior to use, and thus, Stamatelatou et al. [6] used CW after filtration in order to eliminate solids and microorganisms, in a dual-chamber MFC, with promising results.

Following the experiments with the diluted filter-sterilized CW, acidified CW (the rich in acids effluent of dark fermentation (DF) process for hydrogen production), properly diluted, was used as alternative electron donor in the MFC. Thus, a two-stage process was developed, where anaerobic DF (acidification) of CW was carried out as a first step, generating hydrogen and fatty acids, while in the second step, the effluent of the first process was used as substrate in the MFC. Such a two-stage process (DF-MFC) has been used for other types of effluents [19]. CW has been efficiently used as substrate when DF was integrated with other bioelectrochemical systems such as microbial electrolysis cell (MEC) for hydrogen production (DF-MEC concept) by Rivera et al. [20]. In the present work, CW was used as substrate in a DF-MFC concept for the first time. With this approach, the effect of acidification on the MFC performance is assessed and this is important, given the tendency of CW to get acidified by its indigenous microbial consortium. Finally, in the two-stage process, a dual benefit of hydrogen and electricity production is achieved.

2 Materials and methods

2.1 CW used

A cheese-making factory (producing the traditional Greek white cheese “feta”), located in the Achaia prefecture, Western Greece, supplied the CW used in this study. In Table 1, the mean values of its main characteristics are presented.

2.2 Pretreatment-acidification process

Acidification experiments were carried out in duplicate in 160-mL serum bottles with a working volume of 50 mL, without inoculum addition, but using the indigenous microbial consortium contained in CW, a practice that was previously followed for producing biohydrogen from CW, in continuous reactors [4, 5]. The effect of initial organic concentration (2 and 4 g COD/L) by performing appropriate dilutions and of initial pH was studied. Specifically, the initial pH was set to 6 and 7 using phosphate buffer solutions (K2HPO4, 7.928 g/L and KH2PO4, 18.6 g/L for pH 6 and K2HPO4, 15.493 g/L and KH2PO4, 8.2285 g/L for pH 7), while experiments with no pH adjustment were also carried out, at both initial concentrations of 2 and 4 g COD/L. The experiments were performed at 35 °C for 48 h. The content of the vials was gassed with a mixture of N2/CO2 (80/20 v/v) in order to secure anaerobic conditions and sealed with butyl rubber stoppers and aluminum crimps. The volume of generated biogas was measured via a syringe, adjusted to the rubber stoppers. Hydrogen as well as liquid products (volatile fatty acids (VFAs), lactic acid, and ethanol), remaining carbohydrates, COD, and pH were monitored at 0, 24, and 48 h, respectively.

2.3 Electricity production through MFC

2.3.1 MFC apparatus

The experiments were performed using a single-chamber four air–cathode MFC, similar with the respective of Tremouli et al. [12] and Antonopoulou et al. [13], but slightly modified in terms of geometry. Specifically, the anode consisted of a cylinder made of Plexiglas, with an internal diameter of 12.1 cm and a height of 16.9 cm, with a conical base, with 3.1 cm height. Four tubes, with internal diameter of 2 cm, also made of Plexiglas, were placed in the anode. The tubes were homogenously drilled with holes (with internal diameter of 2.5 mm, so as the total geometrical surface area of each tube being 164 cm2). The internal side of the tubes was covered by GORE-TEX® cloth coated with MnO2 at a loading of 213.3 mg/cm2, as described in Zhuang et al. [21], serving as cathode.

The reactor had a volume of 1943 mL and was filled with conductive graphite granules (0.904 ± 0.0303 g/mL density), serving as anode and also as carrier for the biofilm support. Graphite granules, properly treated with HCl as described in Antonopoulou et al. [13], were connected to the circuit using a graphite rod. The graphite rod and the four cathodes were connected via copper wires, with a 100 Ω external resistor, to close the electrical circuit.

The MFC was placed in a constant temperature chamber and a temperature of 28 °C was maintained throughout the experimental period. The MFC potential (Ucell) was recorded every 50 s, using a data acquisition system (ADAM-4017), while the current through the cell was recorded using a precision multimeter (Mastech, MY64). Power density was calculated using the polarization curves, obtained by changing the external resistance of the circuit from 0.1 to 1000 kΩ and recording the potential and current values (normalized with the reactor volume). The coulombic efficiency, CE (%), defined as the ratio of total charge actually transferred to the anode from the substrate to the maximum theoretical charge that would result if all the substrate removal produced current, was determined according to Eq. (1):

where I is the current (A), M = 32 is the molecular weight of oxygen, F is the Faraday’s constant (96,485 C/mol-e), b = 4 is the number of electrons exchanged per mol of oxygen, q is the volumetric rate (L/s), and Δ(COD) is the change in s-COD.

2.3.2 MFC operation

The acclimation phase was performed for four successive cycles in batch mode, until an electrogenic microbial consortium was established in the cell, as described in Antonopoulou et al. [13]. Briefly, glucose at an initial concentration of 0.8 g COD/L also supplemented with a buffer solution (for pH 7) of Na2HPO4·2H2O: 3.4472 g/L and NaH2PO4: 3.668 g/L, NaHCO3: 5 g/L, KCl: 0.16 g/L, a solution of 10 mL/L with trace metals and methanogenic sludge in 10% (v/v), were added in the MFC, which operated as a sequencing batch reactor, for four cycles. At the end of each cycle, the liquid contents were emptied and the MFC was refilled with fresh medium.

Methanogenic sludge was obtained from the wastewater treatment plant of Metamorphosis, Attica, Greece, with the following characteristics: pH = 7.40 ± 0.10, total COD (T.COD) = 21.23 ± 0.15 g/L, dissolved (d.COD) = 1.09 ± 0.14 g/L, total suspended solids (TSS) = 37.42 ± 0.29 g/L, and volatile suspended solids (VSS) = 16.45 ± 0.21 g/L.

Following the acclimation phase, the reactor operation was shifted to continuous mode, using a glucose-based synthetic medium with an initial concentration of ~ 0.8 g COD/L (0.78 ± 0.03 g COD/L) (organic loading rate (OLR) 0.8 g COD/L.d) at an HRT of 24 h. The glucose-based medium was also supplemented with the buffer solution, NaHCO3, KCl, and trace metal solution, as described above and in Antonopoulou et al. [13]. In the sequel, diluted, filter-sterilized CW, also supplemented with the buffer solution, NaHCO3, KCl, and trace metals solution, was used as electron donor, initially at a concentration of ~ 0.8 g COD/L (0.86 ± 0.04 g COD/L) (OLR: ~ 0.8 g COD/L.d) and then at a concentration of ~ 1.6 g COD/L (1.60 ± 0. 09 g COD/L) (OLR: ~ 1.6 g COD/L.d). Finally, pretreated, acidified CW (the effluent of the acidification process), which was filtered and properly diluted, at a concentration of ~ 1.6 g COD/L (1.53 ± 0.09 g COD/L) (OLR: ~ 1.6 g COD/L.d) and supplemented with the buffer solution, NaHCO3, KCl, and trace metal solution, was used as substrate, in order to assess the effect of acidification as a pretreatment of CW on MFC performance, due to the tendency of CW to get acidified, owing to its indigenous microbial consortium. The main characteristics of filter-sterilized CW (prior to dilutions) were: d.COD = 66.895 ± 1.185 mg/L, sugars = 52.320 ± 850 mg/L, while the respective of diluted pretreated-acidified CW used, were: d.COD = 1535 ± 90 mg/L, sugars = 29.19 ± 0.01 mg/L, acetic acid: 276.49 ± 29.75 mg/L, butyric acid: 455.41 ± 51 mg/L, lactate: 157.96 ± 4.2 mg/L, and ethanol: 106.25 ± 5.3 mg/L. The use of raw diluted CW (contained mainly lactose) and acidified CW (contained mainly acids) as substrates on the MFC was performed in order to assess the effect of different electron donors on its performance and on energy recovery.

2.4 Analytical methods

The measurements of TSS, VSS, d.COD and T.COD were carried out according to standard methods [22]. For the quantification of the total and soluble carbohydrates, the method of DuBois et al. [23] was used, while reducing sugar concentration was estimated by the DNS (3,5-dinitrosalicylic acid) method and was expressed as glucose equivalents [24]. For total phosphorus determination, the persulfate digestion method and the ascorbic acid method were used [22], while total kjeldahl nitrogen (TKN) was determined according to standard methods [22].

The hydrogen content of the produced gas was quantified with a gas chromatograph (SRI 8610c MG#1) (two columns in series: molecular sieve column, 6 ft., O.D. 1/8 in., I.D. 2.1 mm and silica gel column, 6 ft., O.D. 1/8 in) equipped with a TCD (thermal conductivity detector). The column oven temperature was 80 °C, the injector valve 90 °C, and the TCD oven 100 °C. Nitrogen was used as carrier gas at 20 mL/min. Detection of methane was also carried out, using the same method, but helium was used as carrier gas. Determination of liquid metabolites (VFAs, ethanol, lactic acid) was performed as presented in Antonopoulou et al. [25].

2.5 Statistical analysis

A two-sample t test with a threshold p value of 0.05 was applied in order to analyze statistically the effect of organic loading on the hydrogen yields, expressed as mol H2/mol consumed sugars, at the same pH value.

3 Results and discussion

3.1 Pretreatment-acidification of CW

In order to obtain maximum energy recovery in the form of hydrogen and acids, different operational conditions were tested, i.e., the initial organic concentration and pH value. In Fig. 1, hydrogen yields in terms of L/LCW (Fig. 1a) and mol/mol consumed sugars (Fig. 1b), at different pH values (6 and 7 and without pH adjustment) at both initial concentrations of CW, are presented. It is obvious that both COD concentrations led to high hydrogen yields, e.g., the highest was 13.16 L/LCW, for pH 7 and initial organic loading of 4 g COD/L and the lowest was 9.73 L/LCW, for initial organic loading of 2 g COD/L, without pH adjustment.

A t test of the hydrogen yields, under the two organic loadings, showed that at the same pH value, the average yields were not affected significantly (p = 0.84, 0.99, and 0.36 > 0.05 for pH = 6, for pH = 7, and no pH addition, respectively), which in turn implies that there is no inhibition or kinetic limitation, under the conditions tested.

From Fig. 1b, it can be seen that the yields expressed in terms of mol H2/mol consumed sugars are very high, compared to the maximum theoretical ones, i.e., 4 mol/mol, when acetic acid is the final metabolic product and 2 mol/mol when butyric acid is the final metabolite [25]. The highest hydrogen yield was obtained in the case of no pH adjustment and was approximately 2.65 mol/mol at both organic loadings, while a high hydrogen yield of 2.36 mol/mol was also obtained, when the pH was initially adjusted to 7 at an initial organic loading of 4 g COD/L.

In Table 2, the main characteristics of the pretreatment-acidification experiments after 48 h of fermentation are presented. Both parameters, such as the initial pH and initial COD concentration, influenced the acidification efficiency and the final metabolic products distribution, as presented in Fig. 2 and Table 2. The acidification efficiency is defined as the ratio of the sum of COD of the metabolic products detected in the fermentation broth (ethanol, lactic, butyric, propionic, and acetic acids) to the experimentally measured COD. The difference in these two values corresponds to the COD of non-consumed carbohydrates measured as glucose units as well as to the non-identified metabolic products during fermentation. Since the main metabolic products of CW fermentation were determined (approximately 80–90%), the main contribution to the low acidification efficiency in the case of no pH adjustment could be attributed to the non-consumed carbohydrates, i.e., 681.35 ± 20.25 mg sugars/L (50.9% acidification efficiency, 60.8% carbohydrate consumption efficiency) and 907.09 ± 85.35 mg sugars/L (57.9% acidification efficiency, 67.7% carbohydrate consumption efficiency) for the initial concentration of 2 and 4 g COD/L, respectively. Under these conditions, the pH at the end of the experiments was also low, almost 4. These results are in agreement with other studies in which the effect of pH (6.5–3.5) on hydrogen production during DF of sweet sorghum extract was investigated [26]. In that study, it was shown that microorganisms under low pH values were unable to consume high amounts of carbohydrates contained in sweet sorghum extract. Specifically, while the efficiency of total carbohydrate consumption in glucose equivalents was higher than 97% at the pH range of 6.5–4.6, this value decreased to 72.9% when the pH dropped to 3.5. In the present study, the low carbohydrate removal efficiency at this low pH value could justify the high hydrogen yields in terms of consumed sugars, since the hydrogen production efficiency was high, even in the case that only 50.9 and 57.9% of the carbohydrates were transformed to acids/ethanol, respectively, at 2 and 4 g COD/L.

From Fig. 2, it is obvious that the main metabolic products, for the majority of the experiments, were acetic and butyric acids, which, based on the metabolic reactions of glucolysis, favor hydrogen production. For the experiments with initial pH of 7, a mixed acid fermentation occurred, and especially in the case of low organic loading (2 g COD/L), lactic acid, ethanol, and acetic acid were produced at high concentrations (500 mg/L, 330 and 507 mg/L, respectively), while butyric acid concentration was very low (only 50.5 mg/L) compared to the other experiments. Under the latter conditions, the pH was 6.29, a value in which the generation of more reduced end products such as lactate and ethanol is favored. Lactate and ethanol are known as metabolites generated in zero-hydrogen balance pathways, which is consistent with the lower hydrogen production yields, obtained in this experiment (1.9 ± 0.2 mol/mol).

A significant parameter for the process, is the ratio of the experimentally measured hydrogen production (nH2) to the theoretical calculated hydrogen based on the stoichiometric reactions (R1)–(R3), Υexp/theor (Table 2). The theoretically calculated hydrogen corresponds to the sum of 2 mol H2 per 1 mol of acetic acid (nacetic), 2 mol H2 per 1 mol of butyric acid (nbuturtic), minus 1 mol of H2 per 1 mol of propionic acid produced (npropionic):

From this ratio, the metabolic pathways which may have been followed by the implicated microorganisms could be assumed, elucidating the basic biochemical reactions which might take place. From Table 2, it is obvious that for almost all the experiments, the experimentally measured hydrogen production is lower than the theoretically calculated one. In the case of the initial COD concentration of 2 g/L, the ratio ranged from 71.13 to 78.99%, while for the higher concentration of 4 g COD/L, the ratio was 76%. The difference between the two values could be attributed to other reactions which may have taken place, i.e., hydrogen consumption towards acetate from homoacetogenic bacteria (R4) or glucose degradation towards acetate without hydrogen production (R5) [26].

From these results, it is obvious that pH adjustment is crucial for obtaining maximum acidification efficiency and hydrogen production recovery. Given though that CW was used as seed inoculum, without addition of extra microbial source, a practice that has also been applied in the past, in the continuous DF of CW at lab and full scale [5, 6], it is very important for the operation of a full-scale plant suggesting that no extra energy will be required either for the start-up of the reactor or for the pasteurization or sterilization of the influent. Taking into account that the effluent of this process will be used for electricity production in a MFC operating at an adjusted pH of 7 and developing a two-stage process for the exploitation of CW at the higher organic loading, the concentration of 4 g COD/L and the initial pH of 7 were selected as optimum operational conditions for the acidification process.

3.2 Electricity production through MFC

3.2.1 Acclimation phase

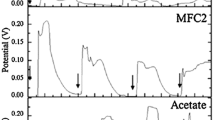

The MFC was initially operated in batch mode using anaerobic methanogenic sludge and a synthetic nutrient glucose-based medium, where acclimation of the mixed anaerobic microbial culture in the novel air-cathode MFC system was conducted. In Fig. 3, the voltage output and COD consumption during the four successive cycles of acclimation phase are presented.

As seen in Fig. 3, in the first cycle, a few hours after glucose addition, the voltage reached approximately 0.2 V, which implied that electrochemically active bacteria were contained in the inoculum used in this study. The COD removal efficiency for the first cycle of the acclimation phase was 61.5%, with a duration time of almost 300 h. Therefore, a fresh medium with glucose and anaerobic sludge was added after draining the previous one and the voltage increased rapidly to 0.409 V and then to 0.469 V. The duration of the cycle was shorter, i.e., 150 h. In the third cycle of the acclimation phase with glucose and inoculum addition, the voltage and the COD removal efficiency increased to 0.550 V and 68.4%, respectively. Finally, in the fourth cycle, the voltage and the COD removal efficiency were approximately the same with those of the third cycle (0.572 V and 69.0%, respectively). These observations are in accordance with the literature, where anaerobic sludge has been used as seed sludge for electricity generation [13].

3.2.2 Continuous operation

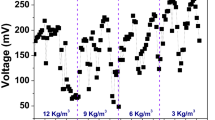

Following the enrichment of the MFC with electrochemically active bacteria contained in the anaerobic sludge, the reactor operation was shifted to continuous mode using initially glucose-based synthetic medium, at initial concentration of ~ 0.8 g COD/L. The use of synthetic substrate was performed for comparative reasons, with the respective CW. Thereafter, diluted, filter-sterilized raw CW at the same concentration was used and, when a steady state was reached, the concentration of CW in the feed increased to ~ 1.6 g COD/L. Finally, acidified diluted CW, which was the effluent of the pretreatment-acidification experiments (DF), after filtration, was used as substrate, at a concentration of approximately 1.6 g COD/L, in order to assess the effect of acidification, as a pretreatment method, developing thus a two-stage process, for hydrogen and electricity production, in DF-MFC concept.

The cell voltage (Ucell) and the COD of the effluent, as well as the main characteristics of the MFC at all steady states are presented in Fig. 4 and Table 3, respectively. In Fig. 5, the polarization curves, i.e., the fuel cell voltage vs. current density and the power density vs. current density, at all conditions tested, are presented. As shown in Fig. 4, the MFC voltage varied from 0.40 V, when glucose was used as electron donor, to 0.30 V (last handling), when pretreated-acidified CW was used. Specifically, when glucose was replaced by diluted filter-sterilized CW at the same approximately concentration, the voltage slightly decreased, i.e., from 0.4 to 0.38 V. This could be attributed to the fact that glucose and diluted CW had a different composition, since sugars represent almost 72% of the COD of CW, with the rest 28% being other soluble compounds. These voltage values of approximately 0.5–0.4 V are typical for single chamber MFCs, under similar working conditions (R = 100 Ω) [27]. However, when the COD concentration increased, the voltage output decreased to 0.31 V and remained almost constant (0.30 V) when pretreated-acidified CW was fed, at approximately the same organic loading.

Comparing glucose and CW at similar conditions, it is clear that the COD removal efficiency was quite high (over 76%) in both cases (Table 3), which indicates that CW consisted of biodegradable compounds, which were consumed by the microbial consortium established in the MFC and that the hydrolysis of lactose, which is the main component of CW, was not the limiting rate step. Similar COD removal efficiencies have also been reported in previous studies using filtered CW as an electron donor, in a typical two-chamber MFC [6, 28] or using similar MFC design, but different kinds of wastes/wastewaters [12, 13]. Increasing the organic loading to ~ 1.6 g COD/L (Table 3), the COD removal efficiency slightly decreased, from 76.9 to 69.3% (filter-sterilized CW) and 63.6% (pretreated-acidified CW), respectively, which indicates that a kinetic limitation might have occurred. These results are in accordance with previous studies in similar MFC designs, when diluted household food waste extract was used at escalating initial concentrations, i.e., 0.64, 1.23, and 2.13 g COD/L, respectively [13]. In that study, it was observed that for an organic loading of 1.23 g COD/L, the COD removal efficiency was 71.3%, but when the concentration increased to 2.13 g COD/L, the COD removal efficiency was only 55.7%.

The maximum power density, Pmax, was 3.26 W/m3 for filter-sterilized, diluted CW, at a similar organic loading with glucose (3.53 W/m3). The CE slightly decreased from 9.2%, in the case of glucose, to 8.2% in the case of CW. Increasing diluted CW organic loading to ~ 1.6 g COD/L, the CE decreased to 4.1% and the Pmax also decreased to 1.85 W/m3. Both values were the half of the respective CE and power output of filter-sterilized, diluted CW, at a half initial concentration. When filter-sterilized CW was replaced by acidified-pretreated CW at the same initial concentration, the MFC performance was not influenced significantly, since the CE was 4.4% and the Pmax, 1.57 W/m3. This implies that the performance is not influenced by the specific compounds (glucose or acids) which are fed in the MFC, in the case that they are biodegradable. This is very important due to the natural tendency of CW to get acidified, since either CW or acidified CW could be used as electron donors in the MFC, without influencing the process performance.

It should be noted that the Pmax produced by this MFC is within the range of the power densities reported in previous studies using air-cathode systems, varying from 2.83 to 50.2 W/m3 [13, 29, 30]. Kim et al. [31] reported power densities of 6.9–24.9 W/m3 when using milk-processing wastewater with a COD content of 1375 ± 101 mg/L, collected from the primary clarifier effluent of a wastewater treatment plant, in an MFC operating at an HRT range of 1–6 h. It should be mentioned that in that study, very low COD removal efficiencies were observed, i.e., 13.1% at the HRT 6 h and 5.1% at the HRT of 1 h.

The low CEs accompanied by high COD removal efficiencies observed in this study imply that other biochemical reactions, competitive to the electrogenesis, are taking place in the reactor, reducing the MFC performance. Since no methane was detected in the gas phase of the MFC (measurements were performed at different time intervals), partial oxidation of the substrate might have occurred, using the oxygen which might have been passed through the pores of the cathode material (GORE-TEX® cloth). The cathode material is in general a breathable material, permitting oxygen transition from the environment to the anode [30, 32]. This biochemical reaction of partial oxidation of the substrate is competitive to the electrogenic reactions, leading thus to low CEs. Permeability of oxygen into the reactor volume, might have also a negative effect on the anaerobic exo-electrogenic microflora, contributing also to the low CEs. Periodic sparging of the reactor with an inert gas can be a possible solution in order to maintain anaerobic conditions.

Regarding the microbial species which are usually implicated in bioelectrochemical systems such as MFCs, it is well known that they transfer electrons to the anode, using bacteria respiration, via three different transfer pathways: indirect electron transfer (IET), mediated electron transfer (MET), and direct electron transfer (DET) [33]. The facultative anaerobic bacterium Shewanella sp., which is among the most frequently used in MFCs, follows the DET pathway via outer membrane c-type cytochromes and nanowires and the MET pathway, via endogenously secreted flavins. In contrast with Shewanella, Geobacter utilizes only DET pathways (via nanowire and/or c-type cytochromes). In the case of biofilms, bacteria may transfer electrons by the MET and DET pathways [33], forming communities, where microorganisms either cooperate or compete with each other [34]. It should be noticed that all bacteria in biofilms are not electroactive, but may secrete molecules which facilitate electron transfer or may degrade organic compounds into smaller molecules, easily degradable by exoelectrogenic bacteria.

Another aspect that should be taken into account for low CEs in such MFCs is the use of graphite granules as 3-D electrodes. It is reported that due to their structure and shape, they form significant dead volumes into the reactor volume, decreasing the available surface of the electrodes for the contact between microorganisms and substrate [35]. For this reason, a recirculation of the reactor liquid content might probably enhance its performance, achieving higher organic removal efficiencies and also higher power densities. Finally, the internal resistance of the MFC could be estimated from the polarization experiments. This value corresponds to the external resistance where the maximum power density occurs [36]. As also confirmed by previous studies using the similar MFC systems [12, 13], this value was very low (almost 20 Ω) and could be associated with the advanced design characteristics of the MFC (geometry, cathode material, etc).

3.2.3 Perspective

From the energy yield values corresponding to Pmax at each organic loading (Table 3), it can be seen that the lower concentration of COD in the feed resulted to a higher yield of energy (0.33 MJ/kg COD), which was similar to that of glucose (0.39 MJ/kg COD). The energy yield decreased to 0.10 MJ/kg COD when the COD concentration in the feed increased to 1.6 g/L and to 0.09 MJ/kg COD for acidified CW. Energy yield values in the range of 1.16–2.17 MJ/kg d.CODremoved were reported by Kim et al. [31], when using milk-processing wastewater in a air-cathode MFC operating at the HRTs of 1–6 h.

Based on the hydrogen which was produced during the pretreatment-acidification experiments conducted in the present study (13.16 L/LCW) and the T.COD concentration of CW, the hydrogen and energy yields can be calculated: 179.5 LH2/kg COD, which corresponds to an extra energy of 2.28 MJ/kg COD. Thus, a total of 2.37 MJ/kg COD could be recovered from the two-stage process (DF-MFC), in the form of hydrogen and electricity, compared with only 0.33 MJ/kg COD, in the case CW is used directly as an electron donor in an MFC, in a single stage process. The fact that the MFC performance of raw, filter-sterilized, diluted CW and that of pretreated-acidified, at the same organic concentration, was similar and independent of the type of substrate (raw or pretreated) suggests that such a two-stage process is highly efficient.

Comparing the energy recovery of both individual processes, it should be pointed out that the energy from the MFC was very low, compared with the respective obtained in the form of hydrogen, from the first step of the process. In this respect, establishing a MFC after a DF process, seems not to be beneficial for economical point of view, taking into account the fixed and operational cost of the MFCs and simultaneously the low energy recovery. Another drawback of the proposed processes is the very low initial concentration and thus the high dilution required for feeding the CW to the MFC. In order to avoid the use of huge amounts of water for CW dilution, the MFC technology could not be a stand-alone process. In order to improve the process economy, MFC could be used as a post-treatment step, since it could be installed after an anaerobic digester (AD) (producing biogas) or after a two-stage process (DF-AD), producing hydrogen and then biomethane (during AD), producing electricity from the remaining COD. Establishing a MFC after e.g. a DF-AD or AD system, might have the advantage of increased CW treatment efficiency, decreasing further the COD of the AD effluent, at levels close to the legal limits. In this respect, a MFC could be beneficial for the treatment of CW, even in the case that leads to low energy recovery, in the form of electricity. Such a process (AD-MFC or DF-AD-MFC) might be conducted on the premises of a cheese-making factory, since it is simple, not energy intensive, without requiring experienced labor, or specific equipment. However, these assumptions need further technical and economical analysis and experimental demonstration at lab, pilot, and full scale.

4 Conclusions

In the present study, cheese whey (CW) was used as an electron donor in an air-cathode single chamber microbial fuel cell (MFC). The pretreatment-acidification experiments showed that fermentative hydrogen production and acidification efficiency depended on the initial pH and the initial COD concentration. A high hydrogen yield of 13.16 L/LCW was obtained for 4 g COD/L and initial pH 7, corresponding to a high acidification efficiency and sugar consumption. Operation of the MFC under different handlings showed that acidified CW and filter-sterilized, diluted CW exhibited similar performances, in terms of their main electrochemical and biochemical characteristics, at the same organic loadings. Maximum power density of 3.26 W/m3 was observed for diluted raw CW at an initial concentration of ~ 0.8 g COD/L, corresponding to an energy yield of 0.33 MJ/kg COD. The later value is lower than the energy that could be recovered from a two-stage process, where in the first stage pretreatment-acidification with simultaneous hydrogen production is carried out and then electricity is generated from the acidified CW, in the second step (2.37 MJ/kg COD in total).

References

Valta K, Damala P, Angeli E, Antonopoulou G, Malamis D, Haralambous KJ (2017) Current treatment technologies of cheese whey and wastewater by Greek cheese manufacturing units and potential valorisation opportunities. Waste Biomass Valor 8(5):1649–1663. https://doi.org/10.1007/s12649-017-9862-8

Prazeres AR, Carvalho F, Rivas J (2012) Cheese whey management: a review. J Environ Manag 110:48–68. https://doi.org/10.1016/j.jenvman.2012.05.018

Kasmi M (2018) Biological processes as promoting way for both treatment and valorization of dairy industry effluents. Waste Biomass Valor 9:195–209. https://doi.org/10.1007/s12649-016-9795-7

Antonopoulou G, Stamatelatou K, Venetsaneas N, Kornaros M, Lyberatos G (2008) Biohydrogen and methane production from cheese whey in a two–stage anaerobic process. Ind Eng Chem Res 47(15):5227–5233. https://doi.org/10.1021/ie071622x

Venetsaneas N, Antonopoulou G, Stamatelatou K, Kornaros M, Lyberatos G (2009) Using cheese whey for hydrogen and methane generation in a two-stage continuous process with alternative pH controlling approaches. Bioresour Technol 100:3713–3717. https://doi.org/10.1016/j.biortech.2009.01.025

Stamatelatou K, Antonopoulou G, Tremouli A, Lyberatos G (2011) Production of gaseous biofuels and electricity from cheese whey. Ind Eng Chem Res 50:639–644. https://doi.org/10.1021/ie1002262

Stamatelatou K, Giantsiou N, Diamantis V, Alexandridis C, Alexandridis A, Aivasidis A (2014) Biogas production from cheese whey wastewater: laboratory- and full-scale studies. Water Sci Technol 69(6):1320–1325. https://doi.org/10.2166/wst.2014.029

Antonopoulou G, Stamatelatou K, Bebelis S, Lyberatos G (2010) Electricity generation from synthetic substrates and cheese whey using a two chamber microbial fuel cell. Biochem Eng J 50:10–15. https://doi.org/10.1016/j.bej.2010.02.008

Chen S, Patil SA, Brown RK, Schröder U (2019) Strategies for optimizing the power output of microbial fuel cells: transitioning from fundamental studies to practical implementation. Appl Energy 233-234:15–28. https://doi.org/10.1016/j.apenergy.2018.10.015

Christwardana M, Frattini D, Duarte KDZ, Accardo G, Kwon K (2019) Carbon felt molecular modification and biofilm augmentation via quorum sensing approach in yeast-based microbial fuel cells. Appl Energy 238:239–248. https://doi.org/10.1016/j.apenergy.2019.01.078

Li C, Cheng S (2019) Functional group surface modifications for enhancing the formation and performance of exoelectrogenic biofilms on the anode of a bioelectrochemical system. Crit Rev Biotechnol 39(8):1015–1030. https://doi.org/10.1080/07388551.2019.1662367

Tremouli A, Martinos M, Bebelis S, Lyberatos G (2016) Performance assessment of a four-air cathode single-chamber microbial fuel cell under conditions of synthetic and municipal wastewater treatments. J Appl Electrochem 46:515–525. https://doi.org/10.1007/s10800-016-0935-3

Antonopoulou G, Ntaikou I, Pastore C, di Bitonto L, Bebelis S, Lyberatos G (2019) An overall perspective for the energetic valorization of household food waste using microbial fuel cell technology of its extract, coupled with anaerobic digestion of the solid residue. Appl Energy 238:239–248. https://doi.org/10.1016/j.apenergy.2019.03.082

Ghasemi M, Ahmad A, Jafary T, Azad AK, Kakooei S, Wan Daud WR, Sedighi M (2017) Assessment of immobilized cell reactor and microbial fuel cell for simultaneous cheese whey treatment and lactic acid/electricity production. Int J Hydrog Energy 42(14):9107–9115. https://doi.org/10.1016/j.ijhydene.2016.04.136

Moreno R, Escapa A, Cara J, Carracedo B, Gomez X (2015) A two-stage process for hydrogen production from cheese whey: integration of dark fermentation and biocatalyzed electrolysis. Int J Hydrog Energy 40(1):168–175. https://doi.org/10.1016/j.ijhydene.2014.10.120

Kelly PT, He Z (2014) Understanding the application niche of microbial fuel cells in a cheese wastewater treatment process. Bioresour Technol 157:154–160. https://doi.org/10.1016/j.biortech.2014.01.085

Callegari A, Cecconet D, Molognoni D, Capodaglio AG (2018) Sustainable processing of dairy wastewater: long-term pilot application of a bio-electrochemical system. J Clean Prod 189:563–569. https://doi.org/10.1016/j.jclepro.2018.04.129

Cecconet D, Molognoni D, Callegari A, Capodaglio AG (2018) Agro-food industry wastewater treatment with microbial fuel cells: energetic recovery issues. Int J Hydrog Energy 43:500–511. https://doi.org/10.1016/j.ijhydene.2017.07.231

Fradler KR, Kim JR, Shipley G, Massanet-Nicolau J, Dinsdale RM, Guwy AJ, Premier GC (2014) Operation of a bioelectrochemical system as a polishing stage for the effluent from a two-stage biohydrogen and biomethane production process. Biochem Eng J 85:125–131. https://doi.org/10.1016/j.bej.2014.02.008

Hydrogen production in a microbial electrolysis cell fed with a dark fermentation effluent. J Appl Electrochem 45:1223–1229. https://doi.org/10.1007/s10800-015-0864-6

Zhuang L, Zhou S, Wang Y, Liu C, Geng S (2009) Membrane-less cloth cathode assembly (CCA) for scalable microbial fuel cells. Biosens Bioelectron 24:3652–3656. https://doi.org/10.1016/j.procbio.2010.02.014

APHA, AWWA, WPCF (1995) In: Franson MA (ed) Standard methods for the examination of water and wastewater. American Public Health Association, Washington, DC

DuBois M, Gilles K, Hamilton J, Rebers P, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Antonopoulou G, Gavala HN, Skiadas IV, Angelopoulos K, Lyberatos G (2008) Biofuels generation from sweet sorghum: fermentative hydrogen production and anaerobic digestion of the remaining biomass. Bioresour Technol 9(1):110–119. https://doi.org/10.1016/j.biortech.2006.11.048

Antonopoulou G, Gavala HN, Skiadas IV, Lyberatos G (2010) Influence of pH in fermentative hydrogen production from sweet sorghum extract. Int J Hydrogen Energy 35:1921–1928. https://doi.org/10.1016/j.ijhydene.2009.12.175

Kumar R, Singh L, Zularisam AW, Hai FI (2018) Microbial fuel cell is emerging as a versatile technology: a review on its possible applications, challenges and strategies to improve the performances. Int J Energy Res 42:369–394. https://doi.org/10.1002/er.3780

Tremouli A, Antonopoulou G, Bebelis S, Lyberatos G (2013) Operation and characterization of a microbial fuel cell fed with pretreated cheese whey at different organic loads. Bioresour Technol 131:380–389. https://doi.org/10.1016/j.biortech.2012.12.173

You S, Zhao Q, Zhang J, Jiang J, Wan C, Du M, Zhao S (2007) A graphite-granule membrane-less tubular air-cathode microbial fuel cell for power generation under continuously operational conditions. J Power Sources 173:172–177. https://doi.org/10.1016/j.jpowsour.2007.07.063

Zhuang L, Feng C, Zhou S, Li Y, Wang Y (2010) Comparison of membrane- and cloth-cathode assembly for scalable microbial fuel cells: construction, performance and cost. Process Biochem 45:929–934. https://doi.org/10.1016/j.procbio.2010.02.014

Kim H, Kim B, Yu J (2015) Power generation response to readily biodegradable COD in single-chamber microbial fuel cells. Bioresour Technol 186:136–140. https://doi.org/10.1016/j.biortech.2015.03.066

Fan Y, Hu HU, Liu H (2007) Sustainable power generation in microbial fuel cells using bicarbonate buffer and proton transfer mechanisms. Environ Sci Technol 41:8154–8158. https://doi.org/10.1021/es071739c

Rabaey K, Boon N, Siciliano SD, Verhaege M, Verstraete W (2004) Biofuel cells select for microbial consortia that self-mediate electron transfer. Appl Environ Microbiol 70:5373–5382. https://doi.org/10.1128/AEM.70.9.5373-5382.2004

Matz C (2011) Competition, communication, cooperation: molecular crosstalk in multi-species biofilms. In: Springer Berlin Heidelberg, pp 29–40. https://doi.org/10.1007/978-3-642-19940-0_2

Cecconet D, Bolognesi S, Molognonia D, Callegari A, Capodaglio AG (2018) Influence of reactor’s hydrodynamics on the performance of microbial fuel cells. J Water Process Eng 26:281–288. https://doi.org/10.1016/j.jwpe.2018.10.019

Logan BE, Hamelers B, Rozendal R, Schroeder U, Keller J, Freguia S, Aelterman P, Verstraete W, Rabaey K (2006) Microbial fuel cells: methodology and technology. Env Sci Technol 40:5181–5192. https://doi.org/10.1021/es0605016

Funding

This research about MFCs has been co-funded by the European Union (_European_Regional_Development Fund_-ERDF) and Greek national funds through the Operational Program “Competitiveness, Entrepreneurship and Innovation 2014-2020” of the National Strategic Reference Framework (NSRF)-Research Funding Program: WE-MET research project “Sustainable wastewater treatment combined with energy recovery with microbial electrochemical technologies”. The research regarding pretreatment-acidification has been funded in the frame of research project: «APPLICATION OF MICROBIAL ELECTROCHEMICAL TECHNOLOGIES TOWARDS ADVANCED BIOFUELS PRODUCTION», which is supported by the 1st Call for H.F.R.I. Research Projects for the support of Post-doctoral Researchers.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Antonopoulou, G., Ntaikou, I., Bebelis, S. et al. On the evaluation of filtered and pretreated cheese whey as an electron donor in a single chamber microbial fuel cell. Biomass Conv. Bioref. 11, 633–643 (2021). https://doi.org/10.1007/s13399-020-00653-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00653-w