Abstract

A four-air cathode single-chamber microbial fuel cell (4ACMFC) with MnO2 as cathode catalyst and a packed bed of graphite granules as anode was studied, aiming at continuous treatment of municipal wastewater in parallel to electric power production. When fed with synthetic wastewater, the system achieved a maximum power density of 13.6 W m−3, a COD removal of 85 %, and a Coulombic efficiency (CE) of 21 %. When municipal wastewater was treated, the achieved COD removal was 45 %, and the CE 7.8 %. By increasing the municipal wastewater conductivity through salt addition, the CE increased to 22.3 %. During the long-term operation of the cell, non-exoelectrogenic bacteria and catalyst degradation were observed to be present. The 4ACMFC performance was assessed at different hydraulic retention times. The electrochemical impedance characterization of the 4ACMFC was also carried out.

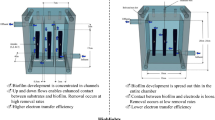

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Microbial fuel cells (MFCs) have emerged as promising and exciting candidates to be applied in bioenergy technology. In MFCs, electric power is generated as a result of bioelectrochemical oxidation of electron donors, such as organic compounds present in wastewater [1]. MFC technology is considered suitable for sustainable bioenergy production due to the ability of MFCs to generate electricity from wastewaters while simultaneously treating them [2].

The most widely used method for wastewater treatment is the activated sludge process. This technology has several disadvantages, the most serious one being the large energy demand, in the form of power used for aeration [3]. On the contrary, the main advantage of MFC technology in wastewater treatment is that it is accompanied by energy production rather than consumption [4]. Furthermore, since the activated sludge is an aerobic process, bacterial biomass production (sludge) is high, compared to that in the anaerobic MFC technology. Sludge management is one of the most costly and challenging aspects of the activated sludge process [3–5].

Anaerobic digestion (AD) is an anaerobic process that has been widely applied as an alternative method of wastewater treatment. However, unlike the MFC process, the AD technology is not in general the most appropriate when treating low-strength wastewater, such as municipal wastewater. In addition, as an energy production process, AD is a two-step process (methane generation followed by burning in an internal combustion engine) in contrast to MFC system, which allows direct harvesting of electricity [6, 7].

In order to exploit the advantages offered by MFC technology, it needs to be developed as a wastewater-treatment technology, and the proposed configurations must be technically and economically sustainable. In this direction, many research groups have examined MFCs either as stand-alone technology [8–10] or as integrated in existing wastewater treatment processes [4, 11–13]. In particular, the concepts of air-cathode MFCs as well as the single-chamber architecture have been examined by many research groups [14–19]. The lack of a need for aeration coupled with the elimination of the second (cathode) chamber offer the advantages of increased power production and reduced capital cost of MFCs. Although several bioreactor designs have been investigated under different operating conditions and both expensive and cheap materials have been tested with municipal wastewater as substrate, the MFC technology is still in its infancy. The main obstacles that this technology has to overcome in order to be implemented in real-scale systems are the low power output obtained, due to high internal resistance and possible oxygen diffusion from cathode to anode chamber, as well as the high costs of materials [12].

In view of these facts, the aim of this work is the examination of a significant number of performance indices during the long-term performance of a novel four-air cathode MFC (4ACMFC) design under continuous wastewater treatment conditions. This design is based on the use of multiple (four)-air cathodes and a packed bed of carbon granules as anode (with multiple current collectors), and in the absence of a polymer electrolyte membrane (PEM) and an expensive noble metal catalyst. Specifically, MnO2 was used as catalyst, while GORE-TEX ® cloth was used as separator and cathode catalyst support. Moreover, no aeration was provided to the system, thus keeping the cost low.

Synthetic and municipal wastewaters were treated in this system in batch- and continuous-flow modes. The performance of the 4ACMFC was assessed in terms of organic matter (COD) removal and electricity production, while the effect of hydraulic retention time (HRT) was studied for the continuous mode experiments. Electrochemical characterization of the system using impedance spectroscopy was also performed. The presence of non-exoelectrogenic bacteria and catalyst degradation as well as the effect of the ionic strength of the municipal wastewater were investigated. The long-term stability of the 4ACMFC was also studied.

The key novelty of the present work lies in the fact that for the first time, a four-air cathode single-chamber microbial fuel cell, which was constructed using the specific selection and combination of materials, was examined for its long-term stability under various conditions, and its long-term performance was assessed on the basis of a systematic combination of a significant number of performance indices.

2 Materials and methods

2.1 The 4ACMFC configuration

A schematic of the four-air-cathode microbial fuel cell (4ACMFC) is shown in Fig. 1. The 4ACMFC is composed of a single-cylindrical plexiglas chamber with a conical base and four perforated plexiglas tubes which run through the chamber, providing a structural support to the separator (Fig. 1). Further construction details can be found elsewhere [20]. The total volume of the cell is 938 cm3 and approximately 70 % of this volume is filled with non pretreated graphite granules (type 00514, Le Carbone, Belgium, 1.5–5 mm diameter). Five graphite rods (13 cm long, 7 mm diameter) are inserted into the packed bed of granules. The anode chamber had an interstitial volume of 348 cm3 available for filling with liquid [20]. This value was reduced during the first 3–4 cycles of acclimation, leveling off to approximately 180 cm3, due to biofilm development on the granules. GORE-TEX ® cloth (W. L. Gore & Associates, Inc., Newark, U.S.A.), tightly bound on the outside wall of each perforated tube, is used as separator and cathode catalyst support. The cloth was made electrically conductive and catalytically active, using MnO2 as the catalyst, as described by Zhuang et al. [21, 22]. To prepare the conductive catalytic coating, 32 g of conductive paint based on graphite (HSF54 paint, YSHIELD GmbH & Co. KG, Ruhstorf, Germany) and 8 g electrolytic MnO2 (TOSOH HELLAS A.I.C., Thessaloniki, Greece) were ultrasonically dispersed in the solvent (16 mL, 50 % ethanol, 50 %: 1,2-xylene) for 25 min using a Vibra-Cell™ ultrasonic processor (Sonics & Materials Inc., Newtown, USA). Then the paste was coated on the GORE-TEX® cloth and left to be dried in air at room temperature. The effective area covered with catalyst coating (air-facing side) was 56.25 cm2 (7.5 cm × 7.5 cm), resulting in a MnO2 loading of 142.2 mg cm2 [20]. During 4ACMFC operation, the anode graphite rods and the cathodes were connected via copper wires with a 100-Ω external resistor (unless stated otherwise), forming a closed electrical circuit. The cathode tubes were open to the atmosphere, and no special aeration was employed.

2.2 MFC enrichment and operation

The enrichment and adaptation of the electrochemically active bacteria in the 4ACMFC was performed in batch mode (four cycles), as described in detail elsewhere [20]. During inoculation, glucose-based synthetic wastewater (0.8 gCOD L−1) was used as feed. Anaerobic sludge (AD) collected from the Wastewater Treatment Plant in Patras, Greece, was used as the bacterial inoculum. After a stable voltage was obtained, the cell was fed with synthetic wastewater (SW), for five batch cycles, without adding a fresh culture of microorganisms.

Following the enrichment of the 4ACMFC, the reactor operation was shifted to continuous mode, using glucose-based synthetic wastewater (0.8 gCOD L−1) as feed in the anode chamber, and the cell operated for ~135.4 days. Τhe cell operated at a flow rate equal to 0.2 mL min−1 (HRT 15 h) (unless stated otherwise). The cell voltage and the COD of the effluent were followed over time. In order to investigate the factors that affect these parameters and thus the performance of the 4ACMFC, a series of tests were conducted during continuous mode operation. They corresponded to N2/CO2 sparging, aeration, cathode replacement, and HRT variation, as described in detail below.

After continuous operation using glucose-based synthetic wastewater, the feed was replaced with municipal wastewater (0.34 gΤCOD L−1) without any additives, and the 4ACMFC was operated for 34.5 days. Subsequently, in order to study the impacts of wastewater conductivity, phosphate buffer, potassium chloride, and bicarbonate were added to the municipal wastewater feed, and the cell was operated for another 25.9 days. The municipal wastewater was continuously fed at a flow rate 0.2 mL min−1 (HRT 15 h) in both cases. As in the case of synthetic wastewater, the cell voltage and the COD of the effluent were monitored over time to assess the MFC performance under the particular conditions.

The temperature in all experiments was maintained at 30 °C, by performing the experiments in a thermostated chamber. During batch and continuous operations of the 4ACMFC, liquid samples were taken, at selected time intervals in order to measure COD and pH.

2.3 Feed characteristics

Synthetic wastewater (SW) was made up of the following constituents: phosphate buffer solution (pH 7) consisting of 4.22 g L−1 NaH2PO4 and 2.75 g L−1 Na2HPO4; 5 g L−1 of NaHCO3; 0.16 g L−1 of KCl; and 10 mL L−1 of a trace metals’ solution [23]. The COD concentration of the synthetic wastewater was controlled via addition of an appropriate amount of glucose (0.8 gCOD L−1). The conductivity of the synthetic wastewater was equal to 12.21 mS cm−1.

The municipal wastewater (MW) was collected from the grate effluent of the Patras Wastewater Treatment Plant during a summer period. The characteristics of the MW used in this study are listed in Table 1. It was collected in a single batch and stored at 4 °C until usage. Its COD did not change during storage.

After 828 h of continuous operation of the cell with MW, the MW feed was modified by adding the following constituents: 4.22 g L−1 NaH2PO4 and 2.75 g L−1 Na2HPO4—phosphate buffer (pH 7)—5 g L−1 of NaHCO3 and 0.16 g L−1 of KCl. The conductivities of the MW before and after the addition of these constituents were 1.6 and 10.3 mS cm−1, respectively.

2.4 Performance indices: chemical analysis of the anolyte

The performance of the 4ACMFC system was assessed in terms of COD removal efficiency, Coulombic efficiency (CE), and power density, based on the anodic liquid volume (180 cm3), which were calculated as described in Logan et al. [3]. The measurements of dissolved and total COD, TSS, and VSS were carried out according to the standard methods [24]. The pH and conductivity were measured using a digital pH-meter and a conductivity meter (Model HQ440d multiparameter meter, HACH GmbH, Düsseldorf, Germany), respectively. The total nitrogen, the phosphates, and the nitrates, were measured with kit tests from HACH GmbH (Düsseldorf, Germany).

2.5 Electrochemical characterization of the 4ACMFC

The fuel cell voltage, U cell, was monitored and recorded at 10-min intervals, using an ADAM-4019+ data acquisition system (Advantech Co. Ltd., Taipei, Taiwan R.O.C.) connected to a personal computer, while the current, Ι, passing through the cell was measured using a digital precision multimeter (Model MY 64, Mastech, Taipei, Taiwan R.O.C.).

Polarization experiments, for batch operation, were conducted after addition of the fresh substrate and establishment of a constant power output. The power outputs of the MFCs were calculated using the recorded steady-state voltage and current values, for different external resistances, ranging from 0.04 to 80 kΩ. The internal resistance R in of the 4ACMFC was determined using the power-density peak method [5].

In order to elucidate the relative contributions of the various components of Rin under different operating conditions, electrochemical impedance spectroscopy (EIS) experiments were performed during the 4ACMFC operation. After 195.8 days of continuous operation of the cell, the 4ACMFC operation was shifted to batch mode. Two batch cycles were conducted using glucose (0.8 gCOD L−1) and municipal wastewater as substrates. In both cases, EIS measurements were carried out after the cell voltage had reached its quasi-steady-state (highest) value. A two-electrode set-up was used, i.e., the EIS characteristics of the entire cell were studied. The measurements were performed under open- and closed-circuit conditions and, selectively, with varying number of anode graphite rods and cathode electrodes.

The EIS measurements were conducted using an Autolab PGSTAT302N potentionstat–galvanostat (Metrohm-Autolab B.V., Utrecht, The Netherlands) equipped with a frequency response analyzer (FRA) and controlled by the Autolab FRA & GPES software packages. The EIS data were collected over the frequencies ranging from 1 MHz to 1 mHz, using a stimulus of 10 mV amplitude.

3 Results and discussion

3.1 Acclimation stage

Figure 2 shows the changes in the monitored cell voltage U cell (100 Ω external load) and in COD during the start-up stage (nine-batch cycles). It can be clearly observed that after the third batch cycle the peak voltage was stabilized to a value around 614 mV, which corresponded to a current of 6.14 mA. The 4ACMFC was able to decrease COD by more than 75 % in all cycles. Moreover, a reproducible cell performance for the last seven cycles occurred. Coulombic efficiency (CE) ranged between 12 and 14 % for the last seven batch cycles, while the duration of these cycles remained constant, equal to approximately 1.25 days.

4ACMFC voltage, U cell, and COD versus time during the enrichment of the 4ACMFC with electrochemically active bacteria. The first four batch cycles were performed after addition of anaerobic sludge (10 % vol.) and synthetic wastewater (glucose 0.8 gCOD L−1). The following five batch cycles were performed using only synthetic wastewater (glucose 0.8 gCOD L−1). External load R ext = 100 Ω

3.2 Continuous operation of the 4ACMFC using glucose as substrate

Following inoculation, the system performance was examined in continuous mode using synthetic wastewater (SW) as substrate (glucose, 0.8 gCOD L−1) for 135.4 days. The variations of the cell voltage and of the organic content of the output (in terms of COD) during continuous flow with SW are presented in Fig. 3. The 4ACMFC exhibited good stability over an operational period of 22.2 days. During this period, the steady-state cell voltage was equal to 0.551 ± 0.019 V and the Coulombic efficiency was 21 %.

4ACMFC voltage, U cell, and COD of the cell effluent versus time during continuous operation of the cell with synthetic wastewater (glucose 0.8 gCOD L−1, at the inlet); External load R ext = 100 Ω. Arrows indicate the interventions made during operation. Time, t, is measured from the onset of cell operation in batch mode (continuous operation started at t = 14.8 days). See text for discussion

After 135.4 days of continuous operation (~150.2 days of total operation, Fig. 3), the voltage and the Coulombic efficiency (CE) gradually decreased to 0.244 ± 0.011 V and 8.34 %, respectively. On the other hand, COD removal remained relatively high, increasing from 66–74 to 80–85 % after 83.3 days of cell operation. The fact that glucose degradation during continuous operation remained high (70–85 %), while the 4ACMFC performance, in terms of voltage generation and Coulombic efficiency, was reduced, indicates that during the long-term operation of the 4ACMFC microbes other than exoelectrogens were grown. In order to elucidate the factors that caused this decrease and to enhance the performance of the 4ACMFC, a series of relevant targeted experiments were conducted, as described below.

3.2.1 Effect of N2/CO2 (80/20 v/v) sparging

Due to the open-pore structure of the GORE-TEX® cloth, oxygen diffusion to the anode chamber is in principle possible, causing competitive electron scavenging and leading to a decrease of the Coulombic efficiency [21]. Since GORE-TEX® cloth was used as a separator in the present study, the possibility of oxygen crossover into the anolyte was examined. In order to test the presence of aerobic bacteria in the anode chamber, after approximately 76.5 days (t ≈ 91.5 days in Fig. 3) of continuous operation (U cell = 0.334 ± 0.040 V, CE 12 %) the anolyte solution was sparged with N2/CO2 (80/20, v/v) gas for 30 min. This action did not affect the 4ACMFC performance, indicating that during long-term operation of the cell, aerobic activity is insignificant.

3.2.2 Effect of air exposure

Since the 4ACMFC was inoculated with anaerobic sludge (AD), which contains mixed bacterial cultures such as methanogens, the presence of methanogens (non-exoelectrogenic bacteria) in the anode chamber was examined. Methanogens compete actively with exoelectrogens for their substrate, causing a decrease in the performance of MFCs [25]. Furthermore, methanogens are quite sensitive, and their inhibition can be achieved by air exposure. In order to suppress the possible presence of methanogens, two air stresses were imposed. After aeration, the anolyte was sparged with N2/CO2 (80/20 v/v) to run the MFC. As shown in Fig. 3, following the first aeration of the anolyte (for 30 min) at t = 97.9 days, where time t is measured from the onset of the operation of the cell in batch mode, an increase by 22 % of the cell voltage (U cell = 0.33 V) and an increase by 23.6 % of the Coulombic efficiency (CE 11.02 %) were observed after 20 h of continuous cell operation. However, the cell voltage and the Coulombic efficiency decreased then gradually (within 2 h) to their previous values. When the second aeration (of 1 h duration) was imposed at t = 101.1 days, after the same delay of 20 h, similar increases of the cell voltage and Coulombic efficiency were observed, i.e., by 22 and 24 %, respectively. U cell and CE dropped again to their previous values, but only after 5.1 days of continuous operation. Thus, the time for resuming the previous state, possibly related with the methanogens recovery time, was greatly affected by the duration of aeration.

3.2.3 Effect of the catalyst layer coating

Since the voltage was not completely recovered to its initial value after air stresses (Fig. 3), the possibility that the catalyst layer coating is degraded over time was examined. In order to determine the effect of the catalyst degradation, the cathode electrodes were replaced by new identical ones, after 117.7 days of total operation in batch and continuous modes. When the cathode electrodes were replaced, an increase by 60.3 % (0.391 ± 0.144 V) of the cell voltage and an increase by 58.6 % (CE = 13.23 %) of the Coulombic efficiency were observed. The enhanced performance of the MFC remained stable for 7 days, while U cell and CE gradually later decreased, reaching their values before the replacement of the cathode electrodes after 22.1 days of continuous operation. Although the MnO2 catalyst layer coating used in the present study was suitable for oxygen reduction, the results indicated that it is not stable over time. Other cathode assemblies should be investigated in order to enhance the performance and the longevity of the 4ACMFC. Zuo et al. [26] used an ultrafiltration hydrophilic tubular membrane as cathode, coated with graphite paint and co-tetra-methylphenylporphyrin (CoTMPP) as cathode catalyst. Similarly to the present study, they observed that during continuous flow, the catalyst layer coating gradually cracked, whereas a visible salt accumulation on the cathode tube occurred. The system operated for only 4.16 days before the catalyst layer showed large cracks.

During the long-term continuous operation of the 4ACMFC (135.4 days), the cell voltage was overall decreased by 55.7 %. On the basis of the observed cell voltage increases after aeration and that after replacement of the cathode electrodes, it can be estimated that the competing action of methanogenic bacteria contributed to the voltage drop by 25.1 %, while catalyst layer degraded by 47.9 %. This still leaves an undefined voltage reduction percentage of 27 %, which could be mainly attributed to graphite granule clogging and could possibly be minimized by further improving the electrical contact among the granules [5].

Polarization experiment, which was conducted approximately after 50.3 days of total cell operation, showed that the internal resistance, R in, of the cell was 40 Ω at a maximum power density P max of 13.6 W m−3 (U cell = 0.34 V, I = 7.2 mA). The open-circuit potential (OCP) of the 4ACMFC was 0.57 V. It should be noted that the P max produced by the 4ACMFC is within the range of the power densities reported in previous studies using air-cathode systems. You et al. [27] reported a maximum power density of 50.2 W m−3, using a graphite-granule membrane-less tubular air cathode MFC. Zhuang et al. [22] studied the performance of a tubular air–chamber MFC equipped with graphite-based conductive paint and nonprecious metal catalyst (MnO2) as a cloth cathode assembly and reported a maximum power density of 2.83 W m−3.

3.2.4 Effect of HRT on the 4ACMFC performance using glucose as substrate

In order to study the effect of the HRT on the 4ACMFC performance, after 36 days of continuous operation (t = 50.8 days) at HRT = 15 h the cell was exposed to several HRTs (15, 7.5, 5, 3.75, 3, 2, and 1.76 h) for a total period of 16 days (Fig. 3). In order to examine the flexibility of the cell and the reproducibility of the results, HRT gradually decreased from 15 to 1.76 h (15, 7.5, 5, 3.75, 3, 2, and 1.76 h) and then gradually increased from 3 to 15 h. For each HRT, the cell was operated for a time equal to at least three HRTs, to obtain stable performance.

The variations of cell voltage and organic load of the effluent (in terms of COD) over the period of 4ACMFC operation at different HRTs (continuous mode) are presented in Fig. 4. The number above each double-sided arrow indicates the HRT used in the time period corresponding to this particular arrow. As shown in the figure, the change in cell voltage with HRT for the first 10 days of operation (after t = 50.8 days) is insignificant, remaining approximately constant at 0.446 ± 0.019 V. Then, a small decrease by 10.8 % (U cell = 0.398 ± 0.010 V) in the voltage is observed. No further variations in the voltage were noted when the HRT was then consecutively switched to 1.76, 3, 3.75, 7.5, and 15 h. This absence of dependence of the cell voltage on the HRT implies that the limiting step of the process is not the biodegradation of the substrate.

Detailed views of the dependences of the 4ACMFC voltage, U cell, and COD of the cell effluent versus time during the stage of continuous operation of the cell at various hydraulic retention times (HRTs); Time, t, is measured from the onset of cell operation in batch mode (continuous operation started at t = 14.8 days)

The COD removal efficiency and the Coulombic efficiency at different HRTs are shown in Fig. 5. As shown in the figure, the COD removal efficiency increased with the increasing HRT values. In particular, the COD removal efficiency at relatively short HRTs (1.76–3.75 h) was in the range of 39.5–45 %, while for longer HRTs (5–15 h), it gradually increased to values ranging from 53 to 73.4 %. The lower COD of the effluent for 4ACMFC operation at longer HRTs is probably due to the fact that in the latter case, there was more time available for consumption of the substrate. Low COD removal at short HRTs indicates that there was insufficient contact time between the substrate in the solution and the biofilm on the graphite granules in order for the substrate to be fully oxidized (kinetic limitation). The effects of HRT on the COD of the effluent are consistent with previous findings [28–30].

Effects of HRT (Fig. 4) on the performance of the 4ACMFC in terms of COD removal efficiency and Coulombic efficiency, CE

As shown in Fig. 5, the Coulombic efficiency increased with increasing HRTs. In particular, the Coulombic efficiency at the relatively short HRTs (1.76–5 h) was in the range of 3–8.4 %, while at longer HRTs (7.5 and 15 h) it ranged from 10 to 18.6 %. Aelterman et al. [31] and Kim et al. [29] also observed an increase in CE at lower organic loading rates (OLR) (higher HRTs). It should be mentioned that the opposite behavior of increasing Coulombic efficiency with decreasing organic load has been reported in other studies [17, 32]. Consequently, the effect of HRT on CE is still rather dubious. It might be attributed to mass transfer limitation within the biofilm on the anode, or to the competing consumption of substrate by non-exoelectrogenic species that may well vary significantly between different studies of mixed culture microbial fuel cells.

3.3 Continuous operation of the 4ACMFC using domestic wastewater as substrate

When SW was replaced by municipal wastewater a sharp decrease by 90.2 % of the cell voltage occurred, to a value equal to 0.035 ± 0.030 V. Moreover, the COD removal decreased by 46 %, to the value of 45 %, and the CE decreased by 33 %, to the value of 7.8 %. The variations of the voltage and the effluent COD during continuous operation of the 4ACMFC using municipal wastewater (MW) as substrate are presented in Fig. 6.

4ACMFC voltage, U cell, and COD versus time during continuous operation of the 4ACMFC with municipal wastewater (MW). Time, t, is measured from the onset of cell operation in batch mode. At t = 184.6 days, the municipal wastewater was modified by adding phosphate buffer and potassium chloride. External load R ext = 100 Ω

The decline of cell performance when synthetic wastewater was replaced by municipal wastewater has been also reported in previous studies [17, 18]. There are several factors which may lead to a lower cell performance when real wastewater is treated. Some of these factors often are the low ionic strength (resulting in low conductivity), the availabilities of other electron acceptors (such as nitrate and sulfate), the presence of complex, hardly degradable or recalcitrant substrates, and the presence of non-electrochemical active bacteria which compete with the exoelectrogens for organic matter consumption [17] and space at the surface of the anode electrode. In the present study, the municipal wastewater had a conductivity of 1.596 mS cm−1 which was 7.65 times lower compared to the conductivity of the SW used (12.21 mS cm−1).

In order to determine the effect of conductivity, the wastewater was modified by adding phosphate buffer, potassium chloride, and bicarbonate to the feed. The additives increased the wastewater conductivity to 10.25 mS cm−1, and an increase in the cell performance was observed. The cell voltage increased by 139 %, to an average value of 0.082 ± 0.039 V, and the CE increased by 185 %, to a value of 22.3 %. The COD removal remained approximately constant (38 %).

The improvement of the MFC performance with the increasing conductivity of real wastewaters has been also reported in previous studies. The increase in conductivity lowers the ohmic resistance, while it improves proton flux between the electrodes [33]. A low conductivity can limit current densities, and thus it may allow other non-exoelectrogenic bacteria to colonize the electrodes and inhibit growth of exoelectrogenic bacteria [34].

Another important observation is the remarkable increase of the CE efficiency value (by 62.6 %) when the 4ACMFC treated the real wastewater with the additives, compared to the cell operation when synthetic wastewater was used as feed. This behavior can be attributed to the lower organic loading rate in the case of municipal wastewater (0.544 kgTCOD m−3 days−1, HRT 15 h), compared to that when glucose was treated (1.28 kgTCOD m−3 days−1, HRT 15 h).

3.4 Electrochemical impedance spectroscopy characterization

Electrochemical impedance spectroscopy (EIS) was used for identification of the limiting factors for power output in the 4ACMFC. EIS data were obtained both for glucose and municipal wastewater as substrate, in batch operation mode. The experiments were conducted when the MFC voltage had reached a practically constant value after the addition of the substrate and connection to the MFC of an external resistance of 100 Ω.

In Fig. 7a, b, c, for different numbers of anode electrodes (graphite rods), the impedance characteristics of the 4ACMFC with glucose (Fig. 7a, c) and municipal wastewater (Fig. 7b) as substrate, under open- (Fig. 7a, b) and closed-circuit conditions (Fig. 7c) are compared. The impedance data are presented in the form of Nyquist plots with the corresponding Z re versus log f plot as inset (f frequency). Despite the significant overlapping, at least two individual spectral features can be observed in the Nyquist plots, more clearly under closed-circuit conditions (Fig. 7c), reflecting the contribution of the MFC’s anode and cathode. Figure 7a, b shows that under open circuit, the contribution of the polarization resistance R p of the cell is dominant compared to that of the ohmic resistance R ohm, whereas it is by approximately a factor of 2 higher for municipal wastewater compared to that for synthetic wastewater (glucose). The latter observation is in agreement with the observed inferior performance of the 4ACMFC with municipal wastewater, as it concerns volumetric power density. The higher open-circuit polarization resistance for municipal wastewater (0.34 gCOD L−1) reflects the fact that it consists of complex hardly degradable or recalcitrant substrates, whereas glucose (0.8 gCOD L−1) is an easily and completely biodegradable substrate. On the basis of this difference in R p , higher activation overpotential can be expected under operating conditions (closed circuit) when municipal wastewater is used, compared with synthetic wastewater (glucose), and thus a lower value of maximum power density. Under closed-circuit conditions (Fig. 7c), specifically for applied cell voltage equal to 0 V corresponding to short-circuit of the cell, the relative contribution of R ohm in determining the power output of the cell with glucose as substrate becomes significant, as under these conditions the polarization resistance R p is only around 3.5 times higher than R ohm. As shown in Fig. 7a, b, c, the number of graphite rods does not seem to affect significantly the impedance characteristics of the 4ACMFC, in particular R ohm and R p , irrespective of substrate and polarization. This implies a sufficiently good electrical contact between the graphite granules, despite the existence of the biofilm, which renders essentially unimportant the effects of position and number of current collectors (graphite rods).

Impedance characteristics (Nyquist plots with the corresponding Z re vs. log f plot as inset) of the 4ACMFC (four-air cathodes) for different substrates and number of anode rods under open or closed-circuit conditions: a glucose as substrate (0.8 gCOD L−1) open-circuit conditions (U cell,ο ≈ 0.5 V), b municipal wastewater as substrate (0.34 gTCOD L−1), open-circuit conditions (U cell,ο ≈ 0.55 V), and c glucose as substrate (0.8 gCOD L−1), closed-circuit conditions (short-circuiting, U cell = 0 V)

In Fig. 8a, b, c are compared the open-circuit characteristics of the cell with municipal wastewater as substrate, for different number of cathode electrodes. The impedance data are presented in the form of Nyquist (Fig. 8a), Z re versus log f (Fig. 8b) and −Z im versus log f (Fig. 8c) plots. The figure shows that the open-circuit characteristics of the ACMFC are not practically affected when decreasing by one the number of air cathodes, i.e., from four to three, whereas they completely change by further decreasing this number. The corresponding Nyquist plots do not appear as depressed semicircles but as inclined lines, presumably parts of incomplete large depressed semicircles, whereas the apparent polarization resistance (not possible to be determined) increases dramatically. This behavior implies that the available surface area of the cathode electrodes has become the limiting factor for the ACMFC performance and indicates that an operation of the 4ACMFC with less than three cathodes is not practically possible.

4 Conclusions

A four-air cathode MFC was operated in batch and continuous-flow modes, for ca. 208.3 days. For synthetic wastewater (glucose) feed, a maximum power density of 13.6 W m−3, a COD removal of 85 %, and a Coulombic efficiency (CE) of 21 % were obtained. For municipal wastewater feed, COD removal was 45 % and CE was 7.8 %, the latter increasing to 22.3 % after salt addition. CE increased with the hydraulic retention time (HRT), whereas cell voltage is not affected significantly. During long-term continuous operation, catalyst degradation occurred, whereas competing action of non-electrogenic microorganisms for substrate consumption was evident.

References

Rabaey K, Rodriguez J, Blackall LL, Keller J, Gross P, Batstone D, Verstraete W, Nealson KH (2007) Microbial ecology meets electrochemistry: electricity driven and driving communities. ISME J 4:9–18

Logan BE, Regan JM (2006) Electricity-producing bacterial communities in microbial fuel cells. Trends Microbiol 14:512–518

Logan BE, Hamelers B, Rozendal R, Schroeder U, Keller J, Freguia S, Aelterman P, Verstraete W, Rabaey K (2006) Microbial fuel cells: methodology and technology. Environ Sci Technol 40:5181–5192

Huggins T, Fallgren PH, Jin S, Ren ZJ (2013) Energy and performance comparison of microbial fuel cell and conventional aeration treating of wastewater. J Microbial Biochem Technol. doi:10.4172/1948-5948.S6-002

Logan BE (2008) Microbial fuel cells. Wiley, New Jersey

Lefebvre O, Uzabiaga A, Chang IS, Kim BH, Ng HY (2011) Microbial fuel cells for energy self-sufficient domestic wastewater treatment: a review and discussion from energetic consideration. Appl Microbiol Biotechnol 89:259–270

Oh ST, Kim JR, Premier GC, Lee TH, Kim C, Sloan WT (2010) Sustainable wastewater treatment: how might microbial fuel cells contribute. Biotechnol Adv 28:871–881

Sevda S, Dominguez-Benetton X, Vanbroekhoven K, Wever HD, Sreekrishnan TR, Pant D (2013) High strength wastewater treatment accompanied by power generation using air cathode microbial fuel cell. Appl Energy 105:194–206

Gonzalez del Campo A, Lobato J, Caρizares P, Rodrigo MA, Fernandez Morales FJ (2013) Short-term effects of temperature and COD in a microbial fuel cell. Appl Energy 101:213–217

Dong Y, Qu Y, He W, Du Y, Liu J, Han X, Feng Y (2015) A 90-liter stackable baffled microbial fuel cell for brewery wastewater treatment based on energy self-sufficient mode. Bioresour Technol. doi:10.1016/j.biortech.2015.06.026

Wang YP, Liu XW, Li WW, Li F, Wang YK, Sheng GP, Raymond J, Zeng RJ, Yu HQ (2012) A microbial fuel cell membrane bioreactor integrated system for cost-effective wastewater treatment. Appl Energy 98:230–235

Min B, Angelidaki I (2008) Innovative microbial fuel cell for electricity production from anaerobic reactors. J Power Sources 180:641–647

Chen Y, Luo J, Yan Y, Feng L (2013) Enhanced production of short-chain fatty acid by co-fermentation of waste activated sludge and kitchen waste under alkaline conditions, and its application to microbial fuel cells. Appl Energy 102:1197–1204

Liu H, Logan BE (2004) Electricity generation using an air-cathode single chamber microbial fuel cell in the presence and absence of a proton exchange membrane. Environ Sci Technol 38:4040–4046

Liu H, Ramnarayanan R, Logan BE (2004) Production of electricity during wastewater treatment using a single chamber microbial fuel cell. Environ Sci Technol 38:2281–2285

Nimje VR, Chen CY, Chen HR, Chen CC, Huang YM, Tseng MJ, Cheng KC, Chang YF (2012) Comparative bioelectricity production from various wastewaters in microbial fuel cells using mixed cultures and a pure strain of Shewanella oneidensis. Bioresour Technol 104:315–323

Yu J, Seon J, Park Y, Cho S, Lee T (2012) Electricity generation and microbial community in a submerged-exchangeable microbial fuel cell system for low-strength domestic wastewater treatment. Bioresour Technol 117:172–179

Ahn Y, Logan BE (2010) Effectiveness of domestic wastewater treatment using microbial fuel cells at ambient and mesophilic temperatures. Bioresour Technol 101:469–475

Koroglu EO, Baysoy DY, Cetinkaya AY, Ozkaya B, Cakmakci M (2014) Novel design of a multitube microbial fuel cell (UM2FC) for energy recovery and treatment of membrane concentrates. Biomass Bioenerg 69:58–65

Tremouli A, Intzes A, Intzes P, Bebelis S, Lyberatos G (2015) Effect of periodic complete anolyte replacement on the long term performance of a four air cathodes single chamber microbial fuel cell. J Appl Electrochem 45:755–763

Zhuang L, Chunhua F, Zhou S, Li Y, Wang Y (2010) Comparison of membrane and cloth-cathode assembly for scalable microbial fuel cells: construction, performance and cost. Process Biochem 45:929–934

Zhuang L, Zhou S, Wang Y, Liu C, Geng S (2009) Membrane-less cloth cathode assembly (CCA) for scalable microbial fuel cells. Biosens Bioelectron 24:3652–3656

Skiadas IV, Lyberatos G (1998) The periodic anaerobic baffled reactor. Water Sci Technol 8:401–408

APHA, Awwa, WPFC (1998) Standard methods for the examination of water and wastewater, 20th edn. American Public Health Association, Washington, DC

Chae KJ, Choi MJ, Kim KY, Ajayi FF, Park W, Kim CW, In S, Kim IS (2010) Methanogenesis control by employing various environmental stress conditions in two-chambered microbial fuel cells. Bioresour Technol 101:5350–5357

Zuo Y, Cheng S, Call D, Logan BE (2007) Tubular membrane cathodes for scalable power generation in microbial fuel cells. Environ Sci Technol 41:3347–3353

You S, Zhao Q, Zhang J, Jiang J, Wan C, Du M, Zhao S (2007) A graphite-granule membrane-less tubular air-cathode microbial fuel cell for power generation under continuously operational conditions. J Power Sources 173:172–177

Wei L, Yuan Z, Cui M, Han H, Shen J (2012) Study on electricity-generation characteristic of two-chambered microbial fuel cell in continuous flow mode. Int J Hydrog Energy 37:1067–1073

Kim KY, Yang W, Logan BE (2015) Impact of electrode configurations on retention time and domestic wastewater treatment efficiency using microbial fuel cells. Water Res 80:41–46

Li X, Zhu N, Wang Y, Ping Li P, Wu P, Wu J (2013) Animal carcass wastewater treatment and bioelectricity generation in up-flowtubular microbial fuel cells: effects of HRT and non-precious metallic catalyst. Bioresour Technol 128:454–460

Aelterman P, Versichele M, Marzorati M, Boon N, Verstraete W (2008) Loading rate and external resistance control the electricity generation of microbial fuel cells with different three-dimensional anodes. Bioresour Technol 99:8895–8902

Sharma Y, Li B (2010) The variation of power generation with organic substrates in single-chamber microbial fuel cells (SCMFCs). Bioresour Technol 101:1844–1850

Feng Y, Wang X, Logan BE, Lee H (2008) Brewery wastewater treatment using air-cathode microbial fuel cells. Appl Microbiol Biotechnol 78:873–880

Liu G, Yates MD, Cheng S, Call DF, Sun D, Logan BE (2011) Examination of microbial fuel cell start-up times with domestic wastewater and additional amendments. Bioresour Technol 102:7301–7306

Acknowledgments

This research has been co-financed by the European Union (European Social Fund—ESF) and Greek national funds through the Operational Program “Education and Lifelong Learning” of the National Strategic Reference Framework (NSRF)—Research Funding Program: Heracleitus II. Investing in knowledge society through the European Social Fund.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tremouli, A., Martinos, M., Bebelis, S. et al. Performance assessment of a four-air cathode single-chamber microbial fuel cell under conditions of synthetic and municipal wastewater treatments. J Appl Electrochem 46, 515–525 (2016). https://doi.org/10.1007/s10800-016-0935-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-016-0935-3