Abstract

In this work, alkaline hydrogen peroxide pretreatment (AHP), at low concentrations of chemical reagents and mild temperature, on sugarcane bagasse was evaluated for production of bioethanol via enzymatic hydrolysis using Cellic® CTec3 from Novozymes® and fermentation using Saccharomyces cerevisiae wild-type strain AR5. Sodium hydroxide NaOH and calcium hydroxide Ca(OH)2 as alkaline reagents were used and combined with hydrogen peroxide (H2O2) as oxidant reagent. AHP pretreatment with NaOH increased cellulose content up to 78% and holocellulose content up to 90%, resulting in 35% more of cellulose and holocellulose contents compared with AHP pretreatment with Ca(OH)2. Results of enzymatic hydrolysis of substrate coming from pretreatment with NaOH achieved high holocellulose-to-reducing sugar yield up to 81% in 7 h of reaction time, 30% higher production than using Ca(OH)2. Besides, for the fermentation process, the necessity and effectiveness of removing remaining solids after enzymatic hydrolysis are not reported in the open literature. Finally, the maximum theoretical yield (95%) was obtained using bothalkaline reagents for the fermentation experiments, producing a maximum ethanol concentration of 39 g/L when AHP pretreatment with NaOH was used, as well the ethanol production balances of 28.9% and 19.1%, were achieved according to the pretreatments with NaOH and Ca(OH)2, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Lignocellulosic biomass is a long-term feedstock with immense potential for biofuel production, being the bioethanol one of the most promising in tackling today’s global energy crisis and environment quality deterioration [1]. The sugarcane bagasse is considered as an agro-residue with high potential to produce fermentable sugars and consequently represents an important source of energy [2].

The main four process steps for bioethanol production from lignocellulosic biomass are as follows: (1) the biomass pretreatment to make susceptible the cellulose and hemicellulose to the enzymes; (2) the enzymatic hydrolysis of pretreated biomass to convert the carbohydrate complex to reducing sugars, like glucose; (3) the fermentation of reducing sugars to ethanol by microbes, e.g., Saccharomyces cerevisiae; and (4) the bioethanol purification from fermentation broth up to a fuel grade purity [3]. The pretreatment is a crucial step from the technical and economic perspective, because of its strong influences in the other three downstream main process steps involved in a bioethanol-aimed refinery [4, 5]. Regardless of the type of lignocellulosic biomass, the pretreatment must provide high availability of holocellulose (cellulose plus hemicellulose) to enable in a first instance the production of a high amount of reducing sugars.

A large number of pretreatment methods for biomass have been studied, which can be broadly classified into physical [6], chemical [3], physio-chemical [7], and biological [8]. Although there is not a universal pretreatment, the ultimate goal in pretreatment research is to enhance the enzymatic hydrolysis of holocellulose; in this way, by improving the overall bioconversion efficiency for production of fermentable sugars, bioethanol production in fermentation process is increased as well [9]. Chemical pretreatment has been considered one of the most effective and promising for industrial application; e.g., either acid or alkali applications are effective in removal of lignin and hemicellulose [10]. The alkali reagent can be even combined with H2O2, resulting in an AHP pretreatment considered as one of the better strategies in enhancing the enzymatic hydrolysis significantly [11] that not only improves the lignin depolymerization and the digestibility of lignocellulosic materials at a low operating cost but also maximize the utilization of the holocellulose [12].

The AHP is an environment-friendly pretreatment that can be carried out at mild temperature and pressure, which leads to minor inhibitor formation [13]. The oxidative action of the H2O2-derived radicals is thought to contribute to the depolymerization of lignin by attacking lignin side chains and fragmenting the lignin macrostructure into a number of low-molecular-weight compounds [14]. However, to carry out an AHP pretreatment, a high concentration of H2O2, around 10%, on biomass is generally required, which implies a high processing cost, and consequently, this does not favor the economy in the bioethanol production from lignocellulosic feedstocks [15]. Thus, oxidant reagent, and alkaline reagent as well, must be used at low concentrations, e.g., 0.5–2%, that enable a high conversion rate of holocellulose-to-reducing sugars. Additionally, the use of mild temperature values to avoid the extreme conditions are preferred in order to reduce energy inputs, e.g., between room temperature and 60 °C [16, 17].

NaOH is a high-performance alkali reagent used in alkaline or AHP pretreatments; its disadvantage lies in that it is more expensive than other bases. Therefore, researchers have considered to either replace NaOH or reduce its dosage [18]. Ca(OH)2 is an alkali reagent considered as alternative because it is safer to handle, less expensive, and can avoid significant loss of carbohydrates, but which of the two alkali reagents is a better choice in terms of performance that provide to an enzymatic hydrolysis process is currently in the twilight. Yan et al. [19] and Jin et al. [20] made a comparison between the conversion efficiency in enzymatic hydrolysis process between NaOH and Ca(OH)2, using sorghum bagasse and catalpa sawdust as lignocellulosic substrates, respectively. The results showed that Ca(OH)2 yielded higher than NaOH for both cases. Conversely, Chang et al. [21] and Jiang et al. [22] compared both alkali reagents, being NaOH more suitable than Ca(OH)2 for treating sugarcane bagasse and giant reed, respectively, due to its advantage of higher enzymatic hydrolysis efficiency and easier lignin recovery.

A first step to evaluate the efficiency of a pretreatment approach is through the obtainment of reducing sugars in enzymatic hydrolysis experimentation [23] and considering compounds released in the pretreatment process, and also it is convenient to evaluate the pretreatment effect on fermentation process [24].

Besides, for the fermentation process, the necessity and effectiveness of removing remaining solids after enzymatic hydrolysis are not reported in the open literature. This aspect is important in the bioethanol production because one of the challenges is to carry out fewer steps as possible.

On the other hand, to make the bioethanol production economically feasible, the fermentation broths must achieve at least 40 g/L of ethanol [25], meaning that the initial concentration of six-carbon sugars must be at least of 80 g/L when Saccharomyces cerevisiae is used [26]. Fermentation can be considered the core of the global process, and any improvement in this step can benefit the plant productivity and economics, being the biomass solid loading one of the major challenges and topic of research in lignocellulosic ethanol production. Bioethanol recovery and downstream processing, which account for about 40–45% of total thermal energy use in the whole process, are directly dependent on its final concentrations [27]. To reach the concentration of 80 g/L of six-carbon sugars, one of the strategies consists of carrying the enzymatic hydrolysis process with a load of pretreated biomass greater than 15% w/v [28, 29]. However, this leads to a difficult mixing, which in turn brings out problems of process condition adjustments, as in pH and temperature [30]. For this reason, another strategy is to carry out the process of enzymatic hydrolysis at low solids (e.g., 5% w/v) and next bring the hydrolysates under a pre-concentration process (e.g., evaporation) to increase the concentration of six-carbon sugars, thus obtaining a higher concentration of ethanol.

From the abovementioned, in this work, the process of bioethanol production from sugarcane bagasse was studied considering AHP as the pretreatment method, comparing the use between NaOH and Ca(OH)2 at low reagent concentrations and the effects of both reagents in the processes of enzymatic hydrolysis and fermentation. Another goal is the evaluation of the pre-concentration approach from hydrolysate broths through an evaporation process and the use of hydrolysate broths with remaining sugarcane bagasse of the previous step in the fermentation process as well.

2 Materials and methods

2.1 Lignocellulosic biomass and pretreatment

The raw sugarcane bagasse (RSB) was provided by the sugar mill El Refugio, located near Xalapa, Veracruz (México). RSB was collected immediately after the extraction of sugarcane juice, with moisture of 22.5% w, and was milled and screened to collect particles of size between 0.425 and 0.850 mm (mesh screen size #20–40).

Two alkaline-oxidative mediums were considered to pretreat RSB; in both, H2O2 is the oxidative reagent, and for each medium, the different alkaline reagents were NaOH and Ca(OH)2. The pretreatments were carried out at a solid load of 6% w/v (dry weight) and reaction volume of 1 L and concentrations of 2% v/v of alkaline reagent and 2% v/v of oxidative reagent, with a reaction time of 5 h, at 60 °C, and pH was manually controlled in 11.5 throughout the processing time.

Both sugarcane bagasse pretreated with NaOH (KSB) and sugarcane bagasse pretreated with Ca(OH)2 (CSB) were washed by distilled water to remove impurities: 1 L of distillate water to 60 g of pretreated biomass. Finally, they were stored in refrigeration.

The chemical composition for RSB, KSB, and CSB was determined, in duplicate, following the methodology established by Goering et al. [31] and Van Soest et al. [32]. This technique consists in three steps: (i) analysis of neutral detergent fiber (NDF) to measure the extractives content; (ii) analysis of acid detergent fiber to measure hemicellulose content; and (iii) analysis for Klason lignin method to determine the cellulose, soluble lignin, and insoluble lignin [31, 32].

2.2 Enzyme complex

The enzyme complex used in all the enzymatic hydrolysis experiments was the Cellic® CTec3 (CT3) from Novozymes®. According to the open technical information, this enzyme complex contains cellulase and hemicellulase that ensure the conversion of holocellulose-to-reducing sugars. Besides, the effective performance occurs at a temperature between 50 and 55 °C and a pH of 4.75–5.25. In addition, it is suggested to test the enzyme complex with different dosing levels and generate a dose-response curve to make a comparison between enzyme dosing versus percentage cellulose conversion.

2.3 Determination of effective process conditions for the enzymatic hydrolysis

On the basis that two substrates and one enzyme complex were considered, two enzyme-substrate systems were generated as well: (i) KSB-CT3 and (ii) CSB-CT3. To determine the effective process conditions for the enzymatic hydrolysis of each system, a microhydrolysis technique was followed [33]. This consists on carrying out enzymatic hydrolysis experiments in 1.5 mL tubes placed in a Thermomixer comfort (by Eppendorf®) during 1 h, which enables to perform 24 experiments simultaneously at a constant temperature but with different pH and enzyme complex dose. The pH was not controlled during the reaction because there are some complications in its measurement due to the small reaction system, although the change of pH in 1 h of reaction is not considerable.

Therefore, the conditions evaluated followed a full factorial design where the factors considered were the enzymatic dose (E), temperature (T), and pH; the levels were 4 for E (93.75, 218.75, 343.75, and 468.75 μL/g-KSB or g-CSB), 3 for T (45, 50, and 55 °C), and 3 for pH (4.5, 5.0, and 5.5).

The yields represent the mass (g) of reducing sugars according to the total mass of KSB or CSB. The mass (g) of reducing sugars were calculated from the reducing sugar concentrations (g/L) of the microhydrolysis and the reaction volume of 1.5 mL.

The effective process conditions were determined by applying the response surface methodology using the statistical software Minitab-v 17.1 (Minitab Inc., PA, USA), where a quadratic model of the response surface was recalled [34].

where E refers to the enzyme load and T is temperature. This methodology was applied for both enzyme-substrate systems.

2.4 Enzymatic hydrolysis in a stirred tank reactor

In order to determine the effectiveness of the pretreatment mediums, and for the generation of hydrolysate broths for fermentation, the enzymatic hydrolysis experiments in triplicate were performed.

The reaction system to perform the enzymatic hydrolysis consisted in a stirred tank reactor system is composed of a flask of 0.5 L (Proculture® glass spinner flask by Corning®) warmed by a hot plate with a temperature controller (stirring hot plate Corning® PC-420D) and mechanically stirred (overhead stirrer IKA® RW-20 Digital) with three marine propellers.

The set of the enzymatic hydrolysis experiments were carried out at 5% w/v using the effective process conditions determined in the enzymatic microhydrolysis experiments. The pH was controlled manually throughout the processing time.

The reaction time of the enzymatic hydrolysis using the KSB was 8 h, while the CSB was 20 h, due to the performance of the kinetics. Samples of 1 mL were frequently taken out to construct the kinetics. To determine the concentration of reducing sugars, the calculations were made considering the lost volume by the sampling.

Once the enzymatic hydrolysis process is finished, the hydrolysate was filtered through a commercial cloth mesh to remove the solids as much as possible. Considering the total solids in the hydrolysate as the total biomass load minus the cellulose and hemicellulose converted to reducing sugars, the amount of solids removed was around 70% (dry basis).

2.5 Fermentation process

To evaluate the performance of each substrate in fermentation, their hydrolysate broths were tested. The yeast used was the wild-type strain Saccharomyces cerevisiae AR5, which was maintained on YPD agar plates with 2% glucose, 2% bacto peptone, and 1% yeast extract (w/v) and was grown at 28 °C for 48 h [35].

The reaction system to grow the cells consisted of shaking water with flasks of 0.5 L, and the liquid medium used was part of the hydrolysates.

The fermentation experiments were carried out at a temperature of 33 °C in duplicate; pH values were in a range between 4 and 5 (coming from hydrolysate broths), in the same shaking water bath, using flasks filled with 50 mL from the corresponding hydrolysate broth. The pH was not controlled during experiments. The fermentations lasted 26 h, and seven samples of 1 mL were taken out frequently. To determine the ethanol concentration, the lost volume by the sampling was considered for calculations of ethanol concentration.

Specifically, the hydrolysates of both KSB and CSB were prepared and used in four different ways: (1) the hydrolysate broths were used with all the remaining solids from enzymatic hydrolysis experiments (solids); (2) the hydrolysate broths were evaporated with all the remaining solids from the enzymatic hydrolysis (solids and pre-concentrated); (3) the hydrolysate broths were centrifugated, and the solids were removed (no solids); and (4) the hydrolysate broths were evaporated after solids removal (no solids and pre-concentrated). Therefore, 8 different reaction systems were considered for the fermentation process.

2.6 Measurement of liquid samples

The DNS technique established by Miller [36] was used to measure reducing sugars of the enzymatic microhydrolysis experiments (Sect. 2.3) and the samples taken from the enzymatic hydrolysis experiments at 0.5 L (sect. 2.4) as well. The DNS technique was performed in microtubes of 1.5 mL of volume and was carried out in triplicate. After the corresponding dilution of the experiment samples, 100 μL of dilute sample plus 100 μL of DNS reagent were added to the microtube and boiled by 5 min and then immediately cooled by 5 min. Next, each DNS sample was filled with 1 mL of distilled water, and finally the absorbance measurement was at wavelength of 540 in Spectrophotometer Genesys® 10S.

The glucose concentration, for both samples from enzymatic hydrolysis experiments at 0.5 L and fermentation experiments, was measured by the biochemical analyzer YSI 2700 Select [37].

The PerkinElmer® Clarus® 500 Gas Chromatograph with the Thermo Scientific® TRACE® TR-WaxMS Column (the stationary phase is polyethylene glycol and a carrier gas pressure of 55.1 kPa) was used to measure ethanol concentration.

2.7 General outline of the experimentation carried out

Figure 1 shows the general scheme of experimentation followed in this work, from the reception of the lignocellulose substrate (RSB) until the conversion of reducing sugars to bioethanol production. The chemical characterization for cellulose, hemicellulose, and lignin was determined before and after the pretreatment and after enzymatic hydrolysis as well. It is included a microhydrolysis technique to determine the effective process conditions for enzymatic hydrolysis step was assayed, and finally, in the fermentation, the use of remaining solids from the previous step and a pre-concentration process was evaluated.

3 Results and discussion

3.1 Chemical composition of substrates

The chemical composition of RSB, KSB, and CSB is shown in Table 1. Cellulose content with 54% is the most abundant in RSB, reaching up to twice compared to hemicellulose content of 27%; meanwhile, the amount of lignin of 10% is in the smallest proportion [38]. Cellulose and hemicellulose contents are according to the studies reported in the literature; Arni [39] presented several studies in where the raw sugarcane bagasse is measured for chemical composition obtaining the ranges of cellulose fraction between 35% and 55%, hemicellulose fraction from 16 to 33%, and lignin fraction of 17–27%. Although lignin content of 10% of the raw material (Table 1) differs from studies here cited, it must be recalled that composition of certain biomass of certain region is different to the one of any other regions [40].

In Table 1, it can be observed that pretreatment caused an increase of cellulose composition but a reduction of hemicellulose from 27% to 12% for both cases; indeed, the loss of hemicellulose has been reported in other works using an alkaline pretreatment [41]. NaOH provides an increase of cellulose content in 35% with respect to Ca(OH)2, 78% in comparison with 43%, respectively, and according to hemicellulose content, both NaOH and Ca(OH)2 had a reduction effect of 50%. The reduction in the cellulose content of the biomass pretreated with Ca(OH)2 could concern to the presence of calcium residues belonging to the biomass extractives [42, 43].

Holocellulose fractions by using NaOH and Ca(OH)2 were 90% and 56%, respectively. Arni [39] and Ho et al. [44] presented several studies in which the cellulose after pretreatment is over 70%, even up to 83%. Luo et al. [45] reached 82% and 83% of cellulose and holocellulose of 85% and 86% in poplar and birch, respectively. Also Shimizu et al. [46] reported cellulose fractions over 70% by using different concentrations of alkali reagent in alkaline and peroxide pretreatments on banana pseudostem, reaching more than 80% in holocellulose content. Goldbeck et al. [47] reached a holocellulose content of 95% using acid-H2O2 on sugarcane bagasse.

The delignification process was effective (Table 1): lignin content decayed from 10% in RSB down to 3% and 4% in KSB and CSB, respectively; this means 70% and 60% of lignin removal, respectively. It is worthy to recall that this delignification efficiency was performed at low concentration of H2O2, in order of 2% v/v; meanwhile in the literature, it is pointed out the need of a high H2O2 concentration, such as in Rego et al. [48], where H2O2 was optimized in a concentration of 7.5% v/v for AHP of sugarcane bagasse, yielding 75% of lignin removal. Generally, for enzymatic hydrolysis process, it is considered that a delignification efficiency between 20% and 65% is sufficient to increase the accessibility of cellulose in pretreated lignocellulosic biomass to enzyme complex [49].

In general, NaOH exhibited a higher efficiency in increasing the cellulose content than Ca(OH)2; meanwhile the effects in hemicellulose and lignin fractions were similar.

3.2 Effective process conditions of enzymatic hydrolysis

High-throughput screening techniques have the ability to readily miniaturized the experiments [50] and offer several opportunities for a more successful implementation to macroscale such as costs for experimentation, more efficient workflows, and savings in time [51] as it is evidenced in this study into determining that time reaction of 1 h allows a performance of around 70% according to the total yield that can be achieved in longer time [33, 52].

The effective process conditions of enzymatic hydrolysis for both enzyme-substrate systems KSB-CTec3 and CSB-CTec3 and the yield reached are given in Table 2. Considering that each enzyme-substrate system has its own optimal process conditions in the enzymatic hydrolysis process on lignocellulosic biomass [33], using the quadratic model (1), it can be observed that for both enzyme-substrate systems, the effective process conditions are different to reach the highest performance in 1 h of reaction; it means that both enzyme-substrate systems have their own set of parameters.

The quadratic models obtained for KSB-CTec3 (2) and CSB-CTec3 (3), from the response surface methodology, are the following:

Table 2 shows that optimal E is the same for both enzyme-substrate systems; however, T and pH do not; pH is significantly higher by 0.6 units in KSB-CTec3 than in CSB-CTec3, and likewise T is significantly lower by 10 °C

It is worthy to notice that although the value of E is the same for both enzyme-substrate systems, which was the highest amount used, the yield of KSB is 40% higher than the obtained with CSB. In this sense, it seems that NaOH will enable a better performance of enzyme complex than Ca(OH)2.

3.3 Pretreatment effectiveness in enzymatic hydrolysis

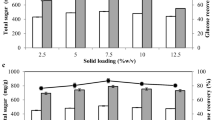

Figure 2 shows the trajectories of yields according to glucose concentration with respect to cellulose concentration (G/C), reducing sugar concentration with respect to KSB concentration (RS/KSB), and reducing sugar concentration with respect to holocellulose concentration (RS/Ho); the yields at the end point were 63.5 ± 5.1, 73.3 ± 2.7, and 80.8 ± 2.9, respectively. According to the chemical composition of KSB, the maximum yield that could be achieved regarding reducing sugars with respect to holocellulose content is 90%. In terms of concentration, the values achieved for reducing sugars and glucose were 36.8 and 27.3 g/L, respectively. For instance, de Godoy et al. [53] worked with enzymatic hydrolysis of sugarcane bagasse pretreated hydrothermally in batch reactor and 5% w/v of solids, reaching a slightly lower glucose concentration of 23 g/L.

In Fig. 2, it can be observed after 5 h that the curves of RS/KSB and RS/Ho increase a little, meaning that conversion of hemicellulose to reducing sugars, as xylose, has not ended; however, this reducing sugar increase is not considerable with respect to glucose. Figure 3 shows the trajectories of the yields of the enzymatic hydrolysis experiments with CSB. The yields in the end points of G/C, RS/CSB, and RS/Ho, at 8 h of reaction time, were 45.7 ± 0.5, 29.7 ± 1.1, and 50.9 ± 2.0, respectively. In terms of concentration, the values achieved for reducing sugars and glucose were 15.83 and 11.36 g/L, respectively.

In comparison with KSB, according to holocellulose content, the yields were lower by 30%. To enhance the glucose concentration using Ca(OH)2, it is necessary to increase the cellulose content after pretreatment; Table 2 shows that cellulose of CSB decreased 11% in comparison with RSB; this result is also noted in Jiang et al. [22] within the use of AHP pretreatment with Ca(OH)2 at concentrations of 1–5% v/v on giant reed biomass, but Ca(OH)2 with concentrations loading of 7–20% can achieve higher cellulose content.

In Fig. 3, it is observed that CSB experiments were longer than those in which the KSB was used. Final samples were taken at 18 and 20 h of reaction time to see if the performance was still increasing because at 8 h of processing time the performance of the reaction seemed low; however, the experiments had already reached their maximum performance with values of reducing sugars and glucose concentrations of 18.63 and 11.57 g/L, respectively.

The outcomes of the enzymatic hydrolysis experiments of KSB and CSB made evident the improvement that comes with the use of NaOH as an alkaline reagent. KSB not only resulted in a higher yield (around 30%); also its experiments were performed at a lower temperature, by 10 °C less (Table 2), which in turn implies a lower processing thermal energy. Although in literature Ca(OH)2 is proposed as a reliable alkali alternative due to its lower cost than NaOH [18, 54], the thermal requirement would not be enough to support the use of Ca(OH)2 instead of NaOH.

With the use of NaOH during pretreatment, higher holocellulose (cellulose plus hemicellulose) amount is obtained, and thus higher sugar concentration may be produced. Besides, the use of Ca(OH)2 leaves a large amount of salts that have not be completely washed. The calcium residues may have negatively influence in the enzymatic complex accessibility in the biomass obtaining a low concentration of sugars during enzymatic hydrolysis [42, 43].

Table 3 gives an overview of the amount of solid biomass inputs and outputs in pretreatment and enzymatic hydrolysis and components. The initial amount of CSB was 60 g (dry basis) for pretreatment, and the initial one for enzymatic hydrolysis of both substrates was 25 g (dry basis). It is worthy to highlight that in enzymatic hydrolysis experiments with KSB, the converted amount of holocellulose was 21.4 g and, meanwhile with CSB, was 10 g; it means that these converted amounts to reducing sugars are according to the reducing sugars obtained in the experiments, 36.8 and 18.6 g/L, respectively. Besides, after the enzymatic hydrolysis experiments, KSB kept a lower cellulose content, 1.1 g in comparison with the 3.6 by using CSB.

Table 3 shows the increasing of solids in the CSB up to 60.6 g due to the calcium salts that are part of the extractive content [42, 43]. For KSB, the cellulose content changed from 32.5 g of RSB to 29.0 g of KSB because AHP can also remove a small fraction of cellulose; the same effect occurs with CSB, but in this case, the cellulose changed from 32.5 g of RSB to 26.3 g of CSB, evidence that Ca(OH)2 was more aggressive with cellulose regions removing a little more cellulose fraction.

After enzymatic hydrolysis, the hydrolysates were filtered through a commercial cloth mesh to remove solids (around 70% in less than 1 minute). Removing solids through a typical method like filtration with filter paper and vacuum is nonpractical because the filter paper is quickly clogged and the power of the vacuum pump quickly breaks the filter paper. Another method to remove the solids is centrifugation, which is recommended when volume is low (e.g., 0.5 L); however, it does not guarantee the removal of small particles. On this matter, it is worthy to mention that in the open literature, they are not addressed the removal and the effect of remaining solids in hydrolysates for fermentation.

Another relevant matter comes from the low concentration of reducing sugars in hydrolysates due to the low substrate load in enzymatic hydrolysis (5% w/v) to avoid mixing problems, resulting in a low ethanol concentration in fermentation broths. In this work, it is explored the evaporation of hydrolysates to increase the reducing sugars concentration for fermentation.

3.4 Fermentation of hydrolysates

3.4.1 Fermentation of KSB hydrolysates

The yeast cells obtained from the pre-inoculum with hydrolysate KSB are used for fermentation process.

Table 4 shows and compares the achieved values of glucose and ethanol, maximum number of cells, and yield of the four hydrolysates proposed for fermentation.

With respect to the cells achieved, every experiment starting with a cell amount around 2 × 107 cells/mL, it can be observed that pre-concentrated hydrolysates enabled a greater cell growth than the non-pre-concentrated ones.

According to initial glucose, the hydrolysate broths that were pre-concentrated began from 78 g/L of glucose, while the hydrolysate broths that were not pre-concentrated did so from 37 and 40 g/L. Thus, Table 4 showed that there is not negative effect in fermentation process regardless if 78 g/L or 37 g/L of glucose concentration is used for the conversion. It means there was no limitation to reach the maximum theoretical yield in all the fermentation experiment reported in Table 4, even when the ethanol production is increasing up to 40 g/L. The glucose consumption coincides with the ethanol production, since it can be noticed in Table 4 that the production of ethanol reached the maximum theoretical yield of 95%.

Although the yields in the four scenarios proposed are similar, the scenarios using the hydrolysate mediums with the remaining lignocellulosic material coming from the enzymatic hydrolysis are slightly higher.

3.4.2 Fermentation of CSB hydrolysates

Table 4 shows the outcomes for the four scenarios proposed in the fermentation of hydrolysates of CSB.

Concerning to number of cells achieved, with a concentration that starts around 2 × 107 cells/mL, the maximum number of cells reached an approximate concentration of 8.7 × 107 cells/mL for the four scenarios. In the line of initial glucose, the hydrolysate broths that were pre-concentrated began from 25 and 29 g/L of glucose, while the hydrolysate broths that were not pre-concentrated did so from 12 and 15 g/L. The yields of ethanol are similar for the four scenarios, but it is worthy to take into account that the experiments with solids reach the maximum theoretical yield of 95%.

The highest ethanol concentration in the fermentation experiments was obtained using the hydrolysate of KSB instead of using the one of CSB, this is basically because the glucose concentration in KSB hydrolysate is greater than in CSB, even in pre-concentrated hydrolysates. These results evidence that the pretreatment step can be considered as a major limiting factor for a high bioethanol production, since it affects the performance in fermentable sugar production and crude fermentation broth [55].With respect to the KSB hydrolysate, the maximum ethanol concentration reached was 39 g/L and for the CSB hydrolysate was 15 g/L; KSB ethanol concentration is similar to the one obtained in Huang et al. [49], an ethanol concentration of 42 g/L by using Moso bamboo residues, and also in comparison with Saha et al. [56], who obtained an ethanol concentration of 43 g/L from sugarcane bagasse by using membrane-integrated bioreactor, and significantly lower ethanol concentration of 18 g/L in batch reactor operation. However, for both, the ethanol yields reached the maximum theoretical of 95% being consistent in the four sceneries proposed. This indicates that wild-type strain Saccharomyces cerevisiae AR5 had enormous potential for acclimation to the different hydrolysates to which the yeast was subjected and does not need an adaptively yeast propagation; i.e., 50% hydrolysate plus 50% YPD medium, during the previous cell growth, as Zhang et al. [57] suggested.

The conversion of glucose to ethanol almost reached the maximum theoretical yield of 95%, meaning that the likely toxic by-products did not affect the fermentation process, as expected since AHP produce minimal inhibitory compounds [9, 58, 59].

It indicates that the fermentation process with lignocellulosic material can be carried out with remaining lignocellulosic material from enzymatic hydrolysis process and the pre-concentration method represents a good strategy to achieve the ethanol concentration pointed out of 40 g/L of ethanol from the enzymatic hydrolysis process at low solids of 5% w/v.

It is worthy to comment that pre-concentration of hydrolysates broths is a reported practice that likely brings an economic gain with itself by enhancing the ethanol concentration in fermentation broths.

3.5 Balance of the ethanol production

Figure 4 shows the balance of the RSB entering the pretreatment process and the concentration of ethanol obtained in the proposed scenarios. The yields of ethanol production of KSB and CSB according the 60 g of RSB are 15.7% and 10.3%, respectively, and accordingly the cellulose content in those 60 g of RSB are 28.9% and 19.1%, respectively. Highest conversion of 28.9% is according to studies in literature such as Kumar et al. [27], who reached 32% of ethanol conversion through conventional fermentation.

On the other hand, the bioethanol mass obtained from fermentations of KSB and CSB hydrolysates are 9.4 and 6.2 g, respectively. The ratio of highest bioethanol mass is similar to the one obtained by Huang et al. [49], who achieved 201 g of ethanol from 1000 g of bamboo residues.

4 Conclusions

In this work, it was compared and evidenced a greater effectiveness of NaOH over the Ca(OH)2 in the AHP pretreatment of sugarcane bagasse. NaOH could yield more cellulose content up to 78%, which resulted in a higher glucose concentration and therefore a higher concentration of ethanol as well.

On the other hand, the effective process conditions for enzymatic hydrolysis of KSB showed that a temperature of 45 °C is necessary to perform the process; meanwhile, the temperature for enzymatic hydrolysis of CSB was 55 °C. In addition, in fermentation process, it is not necessary to remove the residues from the enzymatic hydrolysis process to reach the maximum theoretical ethanol yield. Pre-concentration approach was effective since it was possible to reach an ethanol concentration of 39 g/L coming from an enzymatic hydrolysis process at low solids.

Finally, according to the 60 g of raw sugarcane bagasse that enter to the pretreatment step, the bioethanol yields of KSB and CSB were 15.7% and 10.3%, respectively, given at maximum bioethanol mass of 9.4 g.

References

Aditiya HB, Mahlia TMI, Chong WT, Nur H, Sebayang AH (2016) Second generation bioethanol production: a critical review. Renew Sust Energ Rev 66:631–653. https://doi.org/10.1016/j.rser.2016.07.015

De Bhowmick G, Sarmah AK, Sen R (2018) Lignocellulosic biorefinery as a model for sustainable development of biofuels and value added products. Bioresour Technol 247:1144–1154. https://doi.org/10.1016/j.biortech.2017.09.163

Gupta A, Verma JP (2015) Sustainable bio-ethanol production from agro-residues: a review. Renew Sust Energ Rev 41:550–567. https://doi.org/10.1016/j.rser.2014.08.032

Huang C, Ma J, Liang C, Li X, Yong Q (2018) Influence of sulfur dioxide-ethanol-water pretreatment on the physicochemical properties and enzymatic digestibility of bamboo residues. Bioresour Technol 263:17–24. https://doi.org/10.1016/j.biortech.2018.04.104

Huang C, Lin W, Lai C, Li X, Jin Y, Yong Q (2019) Coupling the post-extraction process to remove residual lignin and alter the recalcitrant structures for improving the enzymatic digestibility of acid-pretreated bamboo residues. Bioresour Technol 285:121355. https://doi.org/10.1016/j.biortech.2019.121355

Chen H, Fu X (2016) Industrial technologies for bioethanol production from lignocellulosic biomass. Renew Sust Energ Rev 57:468–478. https://doi.org/10.1016/j.rser.2015.12.069

Baeyens J, Kang Q, Appels L, Dewil R, Lv Y, Tan T (2015) Challenges and opportunities in improving the production of bio-ethanol. Prog Energy Combust Sci 47:60–88

Hassan SS, Williams GA, Jaiswal AK (2018) Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour Technol 262:310–318. https://doi.org/10.1016/j.biortech.2018.04.099

Kim JS, Lee YY, Kim TH (2016) A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour Technol 199:42–48. https://doi.org/10.1016/j.biortech.2015.08.085

Seidl PR, Goulart AK (2016) Pretreatment processes for lignocellulosic biomass conversion to biofuels and bioproducts. Curr Opin Green Sustain Chem 2:48–53. https://doi.org/10.1016/j.cogsc.2016.09.003

Martínez-patiño JC, Ruiz E, Romero I, Cara C, López-Linares JC, Castro E (2017) Combined acid/alkaline-peroxide pretreatment of olive tree biomass for bioethanol production. Bioresour Technol 239:326–335. https://doi.org/10.1016/j.biortech.2017.04.102

Sun S, Sun S, Cao X, Sun R (2016) The role of pretreatment in improving the enzymatic hydrolysis of lignocellulosic materials. Bioresour Technol 199:49–58. https://doi.org/10.1016/j.biortech.2015.08.061

Rabelo SC, Andrade RR, Filho RM, Costa AC (2014) Alkaline hydrogen peroxide pretreatment, enzymatic hydrolysis and fermentation of sugarcane bagasse to ethanol. Fuel 136:349–357. https://doi.org/10.1016/j.fuel.2014.07.033

Cabrera E, Muñoz MJ, Martín R, Caro I, Curbelo C, Díaz AB (2014) Alkaline and alkaline peroxide pretreatments at mild temperature to enhance enzymatic hydrolysis of rice hulls and straw. Bioresour Technol 167:1–7. https://doi.org/10.1016/j.biortech.2014.05.103

Yuan Z, Wen Y, Kapu NS (2018) Ethanol production from bamboo using mild alkaline pre-extraction followed by alkaline hydrogen peroxide pretreatment. Bioresour Technol 247:242–249. https://doi.org/10.1016/j.biortech.2017.09.080

Yuan Z, Wen Y, Li G (2018) Production of bioethanol and value added compounds from wheat straw through combined alkaline/alkaline-peroxide pretreatment. Bioresour Technol 259:228–236. https://doi.org/10.1016/j.biortech.2018.03.044

Fernández-Delgado M, Plaza PE, Coca M, García-Cubero MT, González-Benito G, Lucas S (2019) Comparison of mild alkaline and oxidative pretreatment methods for biobutanol production from brewer’s spent grains. Ind Crop Prod 130:409–419. https://doi.org/10.1016/j.indcrop.2018.12.087

Gong Y, Fu Z, Liu M, Dai Y, Lin J, Liu Z (2019) Combined alkali pretreatment for enhanced enzymatic saccharification of sugarcane leaf. Bioresour Technol Reports 7:100196. https://doi.org/10.1016/j.biteb.2019.100196

Yan Z, Li J, Chang S, Cui T, Jiang Y, Yu M, Zhang L, Zhao G, Qi P, Li S (2015) Lignin relocation contributed to the alkaline pretreatment efficiency of sweet sorghum bagasse. Fuel 158:152–158. https://doi.org/10.1016/j.fuel.2015.05.029

Jin S, Zhang G, Zhang P, Li F, Fan S, Li J (2016) Thermo-chemical pretreatment and enzymatic hydrolysis for enhancing saccharification of catalpa sawdust. Bioresour Technol 205:34–39. https://doi.org/10.1016/j.biortech.2016.01.019

Chang M, Li D, Wang W, Chen D, Zhang Y, Hu H, Xiufang Y (2017) Comparison of sodium hydroxide and calcium hydroxide pretreatments on the enzymatic hydrolysis and lignin recovery of sugarcane bagasse. Bioresour Technol 244:1055–1058. https://doi.org/10.1016/j.biortech.2017.08.101

Jiang D, Ge X, Zhang Q, Zhou X, Chen Z, Keener H, Li Y (2017) Comparison of sodium hydroxide and calcium hydroxide pretreatments of giant reed for enhanced enzymatic digestibility and methane production. Bioresour Technol 244:1150–1157. https://doi.org/10.1016/j.biortech.2017.08.067

Rastogi M, Shrivastava S (2017) Recent advances in second generation bioethanol production: an insight to pretreatment, saccharification and fermentation processes. Renew Sust Energ Rev 80:330–340. https://doi.org/10.1016/j.rser.2017.05.225

Zabed H, Sahu JN, Suely A, Boyce AN, Faruq G (2017) Bioethanol production from renewable sources: current perspectives and technological progress. Renew Sust Energ Rev 71:475–501. https://doi.org/10.1016/j.rser.2016.12.076

Liu Z, Chen H (2016) Periodic peristalsis enhancing the high solids enzymatic hydrolysis performance of steam exploded corn stover biomass. Biomass Bioenergy 93:13–24

Sassner P, Galbe M, Zacchi G (2008) Techno-economic evaluation of bioethanol production from three different lignocellulosic materials. Biomass Bioenergy 32:422–430. https://doi.org/10.1016/j.biombioe.2007.10.014

Kumar D, Juneja A, Singh V (2018) Fermentation technology to improve productivity in dry grind corn process for bioethanol production. Fuel Process Technol 173:66–74. https://doi.org/10.1016/j.fuproc.2018.01.014

Helena L, Cândida S, Carvalho A (2015) Effects of the pretreatment method on high solids enzymatic hydrolysis and ethanol fermentation of the cellulosic fraction of sugarcane bagasse. Bioresour Technol 191:312–321

Liu Y, Xu J, Zhang Y, Yuan Z, Xie J (2015) Optimization of high solids fed-batch saccharification of sugarcane bagasse based on system viscosity changes. J Biotechnol 211:5–9

Geng W, Jin Y, Jameel H, Park S (2015) Strategies to achieve high-solids enzymatic hydrolysis of dilute-acid pretreated corn stover. Bioresour Technol 187:43–48

Goering HK, Van Soest PJ (1970) Forage fiber analyses (apparatus, reagents, procedures, and some applications)

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597

Hernández-Beltrán JU, Cervantes-Quintero K, Hernández-Escoto H (2018) A quick and effective method for evaluating substrate-enzyme systems in the enzymatic hydrolysis of lignocellulosic biomass. Biomass Convers Biorefinery 8:437–446. https://doi.org/10.1007/s13399-017-0297-z

Montgomery DC (2012) Design and analysis of experiments. New Jersey

Vargas-Maya NI, González-Hernández GA, Padilla-Guerrero IE, Torres-Guzmán JC (2017) Overexpression of smORF YNR034W-A/EGO4 in Saccharomyces cerevisiae increases the fermentative efficiency of Agave tequilana weber must. J Ind Microbiol Biotechnol 44:63–74. https://doi.org/10.1007/s10295-016-1871-2

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Dowe NS, Lussier JN, Gleason RM (2008) Novel method for the rapid simultaneous measurement of xylose and glucose for bioethanol production. http://ysi.com. Accessed 10 September 2019

Bizzo WA, Lenço PC, Carvalho DJ, Paulo J, Veiga S (2014) The generation of residual biomass during the production of bio-ethanol from sugarcane, its characterization and its use in energy production. Renew Sust Energ Rev 29:589–603. https://doi.org/10.1016/j.rser.2013.08.056

Arni SA (2018) Extraction and isolation methods for lignin separation from sugarcane bagasse: a review. Ind Crop Prod 115:330–339. https://doi.org/10.1016/j.indcrop.2018.02.012

Musule R, Alarcón-Gutiérrez E, Houbron EP, Bárcenas-Pazos GM, del Pineda-López MR, Domínguez Z et al (2016) Chemical composition of lignocellulosic biomass in the wood of Abies religiosa across an altitudinal gradient. J Wood Sci 62:537–547. https://doi.org/10.1007/s10086-016-1585-0

Seok J, Lee YY, Hyun T (2016) A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour Technol 199:42–48. https://doi.org/10.1016/j.biortech.2015.08.085

Kaar WE, Holtzapple MT (2000) Using lime pretreatment to facilitate the enzymic hydrolysis of corn stover. Biomass Bioenergy 18:189–199. https://doi.org/10.1016/S0961-9534(99)00091-4

Rabelo SC, Amezquita Fonseca NA, Andrade RR, Maciel Filho R, Costa AC (2011) Ethanol production from enzymatic hydrolysis of sugarcane bagasse pretreated with lime and alkaline hydrogen peroxide. Biomass Bioenergy 35:2600–2607. https://doi.org/10.1016/j.biombioe.2011.02.042

Ho MC, Ong VZ, Wu TY (2019) Potential use of alkaline hydrogen peroxide in biomass pretreatment and valorization – a review. Renew Sust Energ Rev 112:75–86. https://doi.org/10.1016/j.rser.2019.04.082

Luo M, Tian D, Shen F, Hu J, Zhang Y, Yang G, Zeng Y, Deng S, Hu Y (2019) A comparative investigation of H2O2-involved pretreatments on lignocellulosic biomass for enzymatic hydrolysis. Biomass Convers Biorefinery 9:321–331. https://doi.org/10.1007/s13399-018-0364-0

Shimizu FL, Monteiro PQ, Ghiraldi PHC, Melati RB, Pagnocca FC, de Souza W, Sant'Anna C, Brienzo M (2018) Acid, alkali and peroxide pretreatments increase the cellulose accessibility and glucose yield of banana pseudostem. Ind Crop Prod 115:62–68. https://doi.org/10.1016/j.indcrop.2018.02.024

Goldbeck R, Gonçalves TA, Damásio ARL, Brenelli LB, Wolf LD, Paixão DAA, Rocha GJM, Squina FM (2016) Effect of hemicellulolytic enzymes to improve sugarcane bagasse saccharification and xylooligosaccharides production. J Mol Catal B Enzym 131:36–46. https://doi.org/10.1016/j.molcatb.2016.05.013

Rego ASC, Valim IC, Vieira AAS, Vilani C, Santos BF (2018) Optimization of sugarcane bagasse pretreatment using alkaline hydrogen peroxide through ANN and ANFIS modelling. Bioresour Technol 267:634–641. https://doi.org/10.1016/j.biortech.2018.07.087

Huang C, He J, min CH, Jameel H, Yong Q (2017) Coproduction of ethanol and lignosulfonate from moso bamboo residues by fermentation and sulfomethylation. Waste Biomass Valori 8:965–974. https://doi.org/10.1007/s12649-016-9629-7

Longwell CK, Labanieh L, Cochran JR (2017) High-throughput screening technologies for enzyme engineering. Curr Opin Biotechnol 38:196–202. https://doi.org/10.1016/j.copbio.2017.05.012

Žnidaršič-Plazl P (2019) The promises and the challenges of biotransformations in microflow. Biotechnol J 1800580:1800580. https://doi.org/10.1002/biot.201800580

Hernández-Beltrán JU, Hernández-Escoto H (2018) Enzymatic hydrolysis of biomass at high-solids loadings through fed-batch operation. Biomass Bioenergy 119:191–197. https://doi.org/10.1016/j.biombioe.2018.09.020

de Godoy CM, Machado DL, da Costa AC (2019) Batch and fed-batch enzymatic hydrolysis of pretreated sugarcane bagasse – assays and modeling. Fuel 253:392–399. https://doi.org/10.1016/j.fuel.2019.05.038

Chen H, Liu J, Chang X, Chen D, Xue Y, Liu P, Lin H, Han S (2017) A review on the pretreatment of lignocellulose for high-value chemicals. Fuel Process Technol 160:196–206. https://doi.org/10.1016/j.fuproc.2016.12.007

da Silva ARG, Ortega CET, Rong B-G (2016) Techno-economic analysis of different pretreatment processes for lignocellulosic-based bioethanol production. Bioresour Technol 218:561–570. https://doi.org/10.1016/j.biortech.2016.07.007

Saha K, Maharana A, Sikder J, Chakraborty S, Curcio S, Drioli E (2019) Continuous production of bioethanol from sugarcane bagasse and downstream purification using membrane integrated bioreactor. Catal Today 331:68–77. https://doi.org/10.1016/j.cattod.2017.11.031

Zhang K, Wells P, Liang Y, Love J, Parker DA, Botella C (2019) Effect of diluted hydrolysate as yeast propagation medium on ethanol production. Bioresour Technol 271:1–8. https://doi.org/10.1016/j.biortech.2018.09.080

Su Y, Du R, Guo H, Cao M, Wu Q, Su R et al (2015) Fractional pretreatment of lignocellulose by alkaline hydrogen peroxide: characterization of its major components. Food Bioprod Process 94:322–330. https://doi.org/10.1016/j.fbp.2014.04.001

Hernández-Beltrán JU, Hernández-De Lira IO, Cruz-Santos MM, Saucedo-Luevanos A, Hernández-Terán F, Balagurusamy N (2019) Insight into pretreatment methods of lignocellulosic biomass to increase biogas yield: current state, challenges, and opportunities. Appl Sci 9:3721. https://doi.org/10.3390/app9183721

Funding

Experimental infrastructure from National Council of Science and Technology (CONACYT) and Secretary of Energy (SENER) (Project CONACYT-SENER 2009–150001 and Project CONACYT-SENER 2014-05-249564) was used to carry out part of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Meléndez-Hernández, P.A., Hernández-Beltrán, J.U., Hernández-Guzmán, A. et al. Comparative of alkaline hydrogen peroxide pretreatment using NaOH and Ca(OH)2 and their effects on enzymatic hydrolysis and fermentation steps. Biomass Conv. Bioref. 11, 1897–1907 (2021). https://doi.org/10.1007/s13399-019-00574-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00574-3