Abstract

Increasing concern towards climate change and water conservation has attracted wide attention of researchers to explore the biological carbon fixation and wastewater treatment by using microalgae. Algal biomass can be harvested in an integrated system provided with carbon dioxide from power plants and wastewater released from industrial and domestic sector. In this way simultaneous potential of microalgae can be utilized for simultaneous fixation of CO2 and wastewater treatment. This article present a critical review focusing on challenges in algal biomass production technologies and how to achieve algal biofuel production in an integrated system of CO2 fixation and wastewater treatment by suitable microalgal species. In view of these objectives, this article provides a comprehensive narration about the following: (a) perspectives of carbon uptake by algal biomass; (b) industrial emissions as a CO2 supplement for algal cultivation; (c) water foot print for algal cultivation; and (d) genomics for improvement of algal biofuel production. This review found that technical feasibility, economic viability, and resource sustainability are the key steps for algal biofuel production that can be achieved through flue gas and wastewater nexus in algal cultivation. It also provides salient features of algae-nutrient-wastewater-flue gas dynamics to measure the influences of flue gas and wastewater on algal biomass productivity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Rapid population growth and increasing living standards of people have caused rapid consumption of natural resources like forest, petroleum, water, etc. Municipal, agricultural, industrial, transportation, and infrastructure sectors cause high level of water and air pollution. Similarly, cultivation of crops to produce food and energy also use a substantial amount of fresh water, which reduces the economic viability of conventional biomasses for various end products. Thus, reclamation of wastewater (municipal and industrial) and nutrient recycling are issues of paramount importance to gain sustainability. A conventional wastewater treatment system does not recycle its valuable nutrients (N and P), which is treated either by denitrification or by disposing it in the river. Apart from that, production of 1 kg of N and P fertilizer requires about 10–11 kWh of energy [17]. The other major global concern is emissions of gaseous exhaust from industrial and transportation sector causing global warming, which may result in flooding, melting of glacier, and rise in sea level that cause domino effect. Industrial revolution with technological progress caused the exploitation of fossil fuel reserves, which led the energy insecurity and climate change [115]. Due to increase in industrial emission, greenhouse gases are projected to increase globally by 1.3% per year from 2005 to 2011. Carbon dioxide (CO2) is the major GHG that grew by 25% in the atmosphere since the beginning of industrial revolution [137]. Energy scenario of most of the fastest developing countries is characterized by large share of fossil fuel in electricity generation. In 2015, the share of fossil fuel in electricity generation was about 68% in Indian energy scenario, which has been reduced to 63.05% due to implementation of clean energy technologies [117]. Despite of development in renewable energy technologies, energy scenario of most of the countries is still dominated by fossil fuel-based energy generation. In view of these concerns, a cost-effective and efficient carbon sequestration technology is in demand for maintenance of environmental sustainability [162].

The potential of microalgae to eliminate nitrogen (N) and phosphorus (P) from wastewater and its ability to fix atmospheric carbon make algal biomass as a potential feedstock for valuable products. The water footprint (WFP) of algal cultivation is relatively lower than the conventional bioenergy feedstock [21]. Therefore, potential application of algae to restore the environmental health and renewable energy generation acquires wide attention at global level because: (i) algal biomass has high oil productivity per acre of land area than oil yield obtained from conventional feedstock, and (ii) algal biomass can be grown in marginal water sources (municipal, industrial wastewater, and agricultural runoff). Therefore, a cost-effective technology is required to scale up the algal biomass cultivation. In this context, conventional farming system such as raceway pond and tubular/flat plate photobioreactor system were globally explored. These cultivation systems require the excess of 6000 gallons of water to cultivate 1 gallon of algal oil, which involve about 385.71 MJ kg−1 of energy in pumping and circulation of algal suspension in the cultivation medium. Optimum culture medium/nutrient medium (N and P), CO2 concentration, light, and pH are also added in the cost of algal cultivation [106]. Therefore, an integrated solution is of prime importance to resolve the challenges related to algal cultivation. A few researchers have reported cost-effective life cycle of algal cultivation process using wastewater and flue gas for the supplement of nutrient and carbon, respectively [1]. The initial focus should be given to low-cost and best available resources for photosynthetic biomass growth, i.e., waste effluents (water and flue gasses) from the point and non-point sources at local/national and global level [158]. Several researchers have optimized the efficiency of algal biomass for wastewater treatment and carbon sequestration but combined influence of wastewater and CO2 for algal cultivation has not been the part of study with significant emphasis. Various algal species are found with variation in biochemical composition (carbohydrate, protein, and lipid), growth rate, and efficiency of photosynthetic pigments. Chlorella vulgaris, Chlorella sorokiniana, Haematococcus pluvialis, Anabena sp., Scenedesmus obliquus, Chlorella pyrenoidosa, etc. species produce 2–10× more biomass yield per land area in comparison to terrestrial systems [135]. Estimation of algal productivity based on maximum photosynthetic efficiency and annual algal biomass production yield was also calculated on numerous assumptions without addressing lowest possible returns by various researchers.

The use of metabolic engineering, transgenic technologies, and even system biology engineering to refine algal traits may greatly accelerate the commercial potential of algae as a source of energy and other products. Although there are number of segregated reviews available on wastewater treatment specific to bioprocess routes, wastewater reuse, causes of greenhouse gas emissions and their mitigation strategies, algal biomass for bioenergy applications along with experimental studies in well-reputed journals, but this type of interdisciplinary or integrated vision for all these at one place is not found even after extensive review [87]. Chen [36] very well discussed the concept of 3Es (energy, environment, and ecology) and its interrelatedness. Focus on anyone, directly or indirectly impose an unbalance in natural ecosystem. Proposal with nexus approach for broad issues of climate change, energy and food security, societal growths, and resource management has gained momentum for sustainable economy and to avoid the detrimental consequences also discussed and reported [37, 85, 110]. In this context, algal species being the pioneer community of ecosystem is responsible for eutrophication in freshwater bodies; if this process gets inter-related with nexus of nutrients from wastewater and carbon dioxide emitted flue gases from different point/non-point sources, an effective technology would be developed for the carbon capture and wastewater treatment [10, 145]. It can be a solution for 3Es, i.e., energy crisis due to exploitation of fossil fuels, environmental crisis due to rise in pollutants (air/water), and ecosystem crisis due to misbalancing in reserves and resource with increase in pollution. Due to limited availability of experimental research work on hybrid system of wastewater- and flue gas-based algal cultivation in global water network, this work is highlighting the research gap for this concept. In this regard, this manuscript is providing a critical review on integrated approach for cultivation of alga on wastewater and biofixation of CO2 with emphasis on key factors affecting the biomass cultivation with WFP, to reduce its dependency from freshwater resource with the help of green water networking (GWN). Green water networking is an advanced concept for conserving uses of water and wastewater with sustainable applications [11]. Furthermore, other salient features of this manuscript are in favor of algal-nutrient-wastewater-flue gas dynamics for measuring the algal productivity under the varying parameters. Algal-nutrient-wastewater-flue gas dynamics provides a new insight into algal biomass enhancement.

2 Carbon capture and storage

Carbon dioxide is formed during the process of combustion and the combustion process directly affects the selective CO2 removal process. CO2-capturing technologies are accessible in the market but are costly and not environment-friendly for CO2 capture from sources and transporting it to a storage site for its long-term separation. The chief gases of effluents are CO2, methane (CH4), and nitrous oxide (N2O) along with halocarbons (chlorofluorocarbon). Although CH4 has nearly 21 times more GHGs potential than CO2, tremendous increase in concentration of CO2 and GHGs potential poses great challenges to global environment. For effective CO2 capture and storage or utilization thereof from point sources, various technologies have been explored over the century. Every technology has its own merits and demerits and sometimes it is required one to be used more than the other method for CO2 capture from the flue gas (Table 1).

2.1 Perspectives of carbon uptake by algal biomass

Carbon is a most important nutrient for algal growth followed by N and P [141]. For algal biomass cultivation, up to 60% cost for carbon nutrient is needed in total nutrient cost. The most common resources of carbon for algae cultivation are as follows: (i) atmospheric CO2, (ii) CO2 from industrial exhaust gases (e.g., flue gas and flaring gas), and (iii) chemically fixed CO2 in the form of soluble carbonates [68, 126] as described in Table 2. Thus, they have potential to convert major carbon sources (atmospheric carbon) into the glucose for their cell growth. CO2 concentration plays a significant role in photosynthesis. As its level increases, it leads to increase in the mass transfer mechanism from the gas mixture to the medium, as a consequence, decrease in pH. Due to the decline in pH, there is a drastic reduction in algal cell growth [25]. One of the more attractive features of algal biomass production is the potential to trap gaseous CO2 generated from point sources in ponds as bicarbonate.

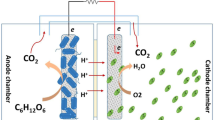

Photosynthesis process is recognized as a foresighted option for sequestration of CO2 from the atmosphere. The use of biomass is not only typically regarded as carbon sequestration [45, 91, 114] but also it will be preferably believed to be means of reducing CO2 emission from the atmosphere in respiration. Biological CO2 sequestration can be enhanced through the natural sink: (i) terrestrial forestation, (ii) ocean fertilization, and (iii) algal sequestration have acted upon the usefulness of photosynthetic organisms for CO2 sequestration. Algae also show the carbon capture and storage (CCS) mechanism for sequestration of CO2 by their unique structure as given in Fig. 1. In the last few years, several researches focused on to identify the potential of algae cultivation system to reduce CO2 emissions [136]. It has been projected that algae produces approximately half of the atmospheric oxygen and simultaneously use CO2 for photosynthesis. In comparison to natural forestry, agricultural, and aquatic plant, microalgae have > 10× higher growth rate and CO2 fixation due to their energy-conserving structure. Among all the microbes, algae have been most commonly grown in photobioreactors [128]. Open pond and continuous cultivation not only help in biofixation of CO2 but also yield value-added products such as protein, fatty acid, vitamins, minerals, pigments, dietary supplements for human and animal and another compound [76]. Microalgae-mediated CO2 fixation can be rendered more sustainable by coupling microalgal biomass production with existing power generation and wastewater treatment infrastructure.

2.1.1 Potential of industrial emissions as CO2 supplement in algal biomass production

Various carbon-emitting units/plants have been established to fulfill the economic growth and development at the global portal (Table 3). The big challenge of industrial processes is to minimize the flue gas emission. The flue gas mainly composed of N2 (82%), CO2 (12%), O2 (5.5%), NOx (400 ppm), SO2 (120 ppm), and soot dust (50 mg m−3) [142]. Thus, the big challenge is to separate the carbon dioxide from flue gas. The concentration of carbon dioxide varies with industrial processes ranging from 10 to 15% along with other gaseous mixture [176]. Therefore, flue gases can be a best alternative among other major sources of CO2 for algae cultivation, where carbon sinking implies as a potential growth factor for algal biomass production.

Waste stream emissions from different industries were investigated by scholars to suggest a valuable solution for anthropogenic emissions of carbon in coupling with algal culture. The relationship between algal-CO2 sequestration and estimated biomass and oil production with industrial sectors are given in Table 4 on comparative basis. The CO2 fixation and biomass production vary distinctly depending on the characteristics of algae species. The consequence of various process parameters in terms of carbon uptake, biofixation, and culture conditions viz, light intensity, dark–light cycle temperature, the pH of medium, etc. must be considered as an important part for cultivating strategies of algal biomass cultivation [48]. Different approaches are considered and adopted by various countries to reduce their CO2 emissions, including improving energy efficiency and promote energy conservation, increase usage of low carbon fuels, deploy renewable energy, apply geo-engineering approaches, and CO2 capture and storage. Among these, captured and stored CO2 can be utilized for algal biomass cultivation at pilot scale which will provide a potential option of biomitigation.

There is a long list of industries available at the global level as contributors of CO2 emission. Among these, only a few or large-scale product capacity industries come under point source emitters. Among the different point source emitters, cement industry alone contributes 5% of global anthropogenic CO2 emission from total cement production at global level (222 kg of C t−1 of cement) [160]. Algal-based biofixation process, i.e., to capture flue gas (CO2), appears to be the most feasible in the near-term application of algal biomass cultivation by Yadav et al. [166]. Mass cultivation of algae at large scale in the next 10 years seems more feasible while considered with diverse range of higher value co-products.

Algal carbon fixation capacity varies with strains due to differences in inorganic carbon assimilation pathways. To achieve high carbon fixation, CO2 must be fed continuously during daylight. The control of CO2 feeding can be evaluated by pH measurements to minimize the loss of CO2. Cyanobacteria (blue-green algae) and eukaryotic algae use bicarbonate as a carbon source with pH between ~ 6.4 and 10.3. CO2 rapidly gets captured into algal cells via bicarbonate transporters present in both the plasma membrane and in the chloroplast envelope of eukaryotic algae. Inside the chloroplast, bicarbonate is converted into CO+ that can be fixed by RuBisCO (ribulose-1,5-bisphosphate carboxylase/oxygenase, carboxylase-oxygenase) to produce two molecules of 3-phosphoglycerate [98]. To reduce the competitive inhibition of oxygen on carbon fixation by RuBisCO, algae actively pump sufficient bicarbonate into cells to elevate internal CO2 concentration by equilibrium with air, and competitively inhibit photorespiration. CO2 emission from power plants, industrial emissions, etc. can be used as a source for CO2, which aids in the maintenance of environmental sustainability [128].

3 Factors and associated challenges in algal cultivation

Algal cultivation is done in various facilities (lab scale/pilot scale), but production of sufficient amount of algal biomass which replace the fossil fuel is widely ignored. Thus, major constraints (Table 5) for commercialization of algal biomass need to be addressed. Despite the availability of potential algal strains, algal-based bioproducts are still expensive in comparison to the cost of conventional products, but major obstacles in cost-effective algal cultivation include minimization of freshwater input, low nutrient supply, low-cost carbon supplement, and regulation of optimum temperature and light conditions.

3.1 Water

Aquatic system provides habitat for algal species to complete their life cycle. It also delivers nutrients (N and P), removes waste products, and maintains thermal regulation [81, 84]. The WFP of algal biomass is relatively lower than the WFP of conventional energy feedstock, which is shown in Table 6. Approximately 5–10 L of water is consumed to produce per kilogram of dry algae biomass [80, 94, 140, 149], which is consumed in upstream and downstream steps and depends on desired final by-products. Water is consumed in the washing of biomass to remove salt and other impurities before the oil extraction. On the other hand, evaporative loss of water is another challenge to be resolved. Thus, an evaluation of the water footprint in the cultivation of algal biomass is essential. Marine algae have a lower water footprint than the freshwater alga and terrestrial crops [69, 158]. WFP for algae grown in fresh water open ponds observed WFP of ~ 3700 kg kg−1 of biodiesel in the absence of water recycles. Recycling reduces the WFP ~ 600 kg kg−1 of biodiesel [62, 124].

Algal cultivation in closed photobioreactor reduces the evaporative loss of water, but the cost of closed photobioreactor reduces the economic viability of such system [6]. Thus, water consumption in biomass processing is a significant challenge for scientists and commercial corporate in the future. So, clear incentive to reduce the net consumption of water in these processes will be needed with stringent environmental regulations on water use and wastewater discharge [72]. Hence, water scarcity noticed through data observed and predicted increasingly becoming scarce as seen in Fig. 2. In fact, it is projected that in 2025, two thirds of the world population will experience water stress [59, 63]. This is clearly anticipated that water consumption in biomass processing is a significant challenge for scientists and commercial corporate in future. So, clear incentive to reduce the net consumption of water in these processes will be needed with rigid environmental regulations on water use and wastewater discharge.

Projected water scarcity in 2025 https://www.fewresources.org/water-scarcity-issues-were-running-out-of-water.html

3.1.1 Water footprint for cultivation of algae

WFP refers to an input of total freshwater volume for production of a product and services for the society and personal use, at a place where it has the origin. Three components of WFPs have been defined, i.e., green water footprint (GWFP), blue water footprint (BWFP), and gray water footprint (GyWFP), in which BWFP is relevant for algal biomass cultivation in the artificial systems. The algal cultivation by water foot print set lifecycle boundary includes upstream which is defined as the water (BWFP, GWFP, and GYWFP) consumed to produce materials and energy inputs to the microalgae-to-biofuel process, such as electricity, fertilizers, and photobioreactor material [77]. GWFP and GyWFP are mainly concerned with the amount of rainwater consumed to grow the crop and amount of freshwater for dilution or assimilation of pollutants, respectively. Freshwater, seawater, or wastewater on the part of water footprints for biofuel production using conventional feedstocks has been reported. In the case of microalgae cultivation, GyWFP is almost zero due to complete recycling of nutrients, but microalgae have significant BWFP [161]. Therefore, algal cultivation is still under the continuous scrutiny to ensure its environmental sustainability and economic viability to produce various by-products. Therefore, large-scale algal cultivation system has been criticized for overconsumption of a significant amount of freshwater [11, 69, 74]. But in contrast, algae-based biodiesel production may utilize much less potable water than conventional feedstock-based biodiesel production if microalgae are grown in seawater or wastewater [93, 125]. Algal culture process requires a regular supply of freshwater to reimburse water loss and avoid salt accumulation due to evaporation in open system. After harvesting of algal biomass, the culture water can be partially recycled by pumping it back into the culture pond. Also, 1 mol of water dissociates into O2 and H2/mol of CO2 consumed in photosynthesis process. In photosynthesis process, estimated water loss of almost ~ 5–10 kg−1 dry algal biomass has been found [55]. Direct water demand for algal growth and development can be calculated as the difference between the volume of water required to support growth and annual precipitation as given in Eq. 1 [169].

The volume of direct water demand required to support the growth of algae at optimum conditions can be calculated by two key factors: (i) amount of water required to sustain the growth and development, and (ii) quantity of water that needs to be restored in growth and development due to water loss or to compensate for GWFP. Particularly, total required water input for cultivation of algae would be the sum of newly acquired water and water recoup along with water loss as shown in Eq. (2). The total volume of freshwater can be computed by the following expression [55]:

Where Vfill = total volume of water required to compensate the evaporative water, Vevap = amount of water consumed in evaporation, Vleakage = amount of water loss due to leakage, Vblowdown = amount of water loss in blow-down, Vphoto = amount of water loss in photosynthesis, Vharvest = amount of water loss in harvesting, Vdrying = water loss during biomass drying, Vgray = water required to assimilate the pollution (ignored in case of algal cultivation).

The water demand for algae production system ranges ~ 4.59 m3 m−2 year−1 in a tropical region and ~ 6.39 m3 m−2 year−1 in an arid environment. Leakage rate of water usually for an ORP was ~ 0.0011–0.0036 m3 m−2 year−1 [64]. The significant water loss from algae cultivation due to evaporation is directly associated to the availability of solar radiation and wind velocity. WFP for algal cultivation varies geographically due to physical factors (solar radiation, temperature, and wind speed). Geographically, higher accessibility of photosynthetically active radiation (PAR) adds elevated algal biomass productivity whereas higher water loss is due to enhanced evaporation rate [155]. The WFP highlights the wide geographical differences which are reflected in particular by the GWFP; generating a unit of biofuel by using same feedstock present in different geographical regions with variable climatic circumstances could result in momentous differences to make up the WFP. An evaporation loss from the surface of ORPs is generally dependent on the local average temperature in addition to relative humidity. Water requirement can vary from 3.5 to 3365 L of water per liter of algal biodiesel. Few studies have been found with the concept of WFP among different algal species given in Table 7 [61]. Lower end of estimate assumes efficient water capture and recycle [22, 108, 138]. Without recycling or reuse of harvested water, the WFP is ~ 3726 kg-water kg−1 biodiesel and ~ 84.1% of the water is discharged after harvesting of algal biomass, while the rest is lost by either pond evaporation or drying. If the harvested water would recycle, the WFP of biodiesel can reduce too as low as 591 kg-water kg−1 of biodiesel. To produce 1 kg of algae through ponds, 1564 L of water is required. When PBRs are used, only 372 L water is required; however, the energy requirements for PBRs are about 30 times higher than for ponds. The variation in microalgae species and geographic distribution is analyzed to reflect microalgae biofuel development in all over the world.

3.1.2 Reducing WFP via green water network with wastewater

Most of the industries refused the concept of reuse and recycling of wastewater. However, it should be recycled to lower the freshwater input. Therefore, an appropriate treatment network in the industrial process is required to reduce the input of freshwater. Various models of water network (WN) system were proposed with the concept of industrial ecology to minimize the flow and cost of the entire process network. Researchers have mainly focused on particular wastewater treatment unit design for fixed outlet concentration and a fixed contaminant removal ratio. The resulting formula from their study represents a simplified model of the network. Both, insight-based method and mathematical optimization-based techniques have been investigated for green water network synthesis (GWNS). Although GWN analysis is applicable for industrial units, it may be a ground-breaking solution which might be incorporated into algal biorefineries for a compatible solution. By GWN synthesis technologies, WFP can be reduced up to 1/5 to 1/3 for algal biofuel per liter. There are two main water consumption stages in the production of biofuels: (i) the water that is used in the production of the biomass, mainly due to irrigation, and (ii) water that is used along the process to transforms the biomass into fuels [25]. Use of wastewater or saline water has been reported by various researchers to reduce the consumption of freshwater in the production of algal biofuel [111]. Commercial production of algal fuels continues to be strong, suggesting that the possibility of an economically viable production at some scale and within a reasonable timeframe should not be entirely discounted. Integrated water network synthesis for recycling and reuse of water for different processes of algal growth and biofuel applications for the case of five process unit and three contaminants was introduced. The integrated process water network is basically a mathematical model, which consist of mass balance equation for water and contaminants present in every unit of network [70]. Thus, it was possible to design an optimal network that efficiently treats and reuses the water by using the superstructure with multiple effects.

Industrial wastewater, i.e., municipal, tannery, dairy, agricultural, wastewater, may be the source for algal culture, with different algal strains, with various wastewaters and their biomass productivity. Therefore, conventional water treatment processes such as aerated lagoons, trickling filter, activated sludge process, oxidation pond, septic tank, Imhoff tank, anaerobic stabilizing pond, etc. and their freshwater use for different industrial processes pose a problem. Conventional water utilization in the industrial process does not use, reuse, or recycle into different water streams. Coupling of bioenergy production options with municipal wastewater treatment makes sense because it represents nutrients reuse and provides a sustainable energy saving for wastewater treatment units. Though, there is a generous spatial and temporal disparity between the water requirements of algae growth and the accessibility of municipal wastewater treatment plant effluent in the southern 17 states, which is an important factor affecting the degree of freshwater replacement for algae biomass cultivation [46]. By the accessibility of spatial and temporal municipal wastewater as a sole source of water, 8.6 billion liters of bio-oil can be produced annually with a freshwater BWFP, but due to lack of technology sharing, it is almost negligible [164].

Algal-based wastewater treatment can opt for secondary or tertiary treatment process for different types of wastewater. It has potential to assimilate the broad range of pollutants, given in Table 8. Selection of alga for wastewater treatment reduces the need for energy-intensive cleaning process and chemicals used in standard treatment procedures.

The mechanism for nutrient removal depends on algal species, which is based on shared fundamental steps, such as a consortium of alga and bacteria successfully degrade the organic matter through photosynthetic aeration. Commonly algal-based treatment is carried out in maturation ponds and facultative or aerobic ponds [34, 67]. Algae enhance the removal of nutrients, heavy metals, pollutants, and pathogens, and provide O2 to aerobic heterotrophic bacteria to oxidize organic pollutants, and the CO2 released from bacterial respiration [12]. Algal potential to uptake nutrients added more value to wastewater remediation. A recent study showed achievement of complete NO3− removal and 33% PO4−3 removal, by Chlamydomonas sp. and similarly demonstrated Chlorella sp. for removal of a high level of ammonia, total nitrogen and phosphorus, and chemical oxygen demand (COD) in 14 days [102]. Heterotrophic and mixotrophic cultivation system also attributed to removal of BOD and COD; for instance, mixotrophic condition facilitates higher algal growth rates (Table 9) and lipid yields. Industrial and municipal wastewater contains a wide variety of pollutants such as heavy metals, phenols, endocrine disruptors, viruses, antibodies, oils, and grease, which can be treated by alga in different ways. Microalgae perform bioaccumulation, inactivation, and biodegradation in response to these pollutants. Uptakes of compounds are species-specific and limited up to a toxic concentration.

3.2 Effect of combined influence of wastewater and flue gas on algal biomass

Flue gas provides a higher concentration of CO2 (~ 20%) in comparison to the atmospheric carbon source, i.e., air (> 360 ppm). Carbon capture by alga involves the photoautotrophic growth of cells; however, algae photosynthesis efficiency declines with increasing temperature, since CO2 solubility is significantly reduced [82]. The constituents of flue gas such as sulfur dioxides (SOx) and nitrogen oxides (NOx) are toxic in nature. SOx from flue gas can be eliminated by chemical desulfurization system. However, NOx removal is more difficult due to its lower solubility in the liquid phase. Thus, potential algal strains such as Botryococcus braunii, Chlorella vulgaris, Chlorella kessleri, Chlorocuccum littorale, Chlamydomonas reinhardtii, Scenedesmus obliquus, Scenedesmus sp., M. minutum, Tetraselmis sp., and Spirulina sp. [92] can be cultivated in these stress conditions. Some algal species are tolerant to high temperatures, high CO2 concentrations, and toxic compounds such as NOx and SOx, as described in Table 10. It shows that a few species of Chlorella and Cyanobacteria could grow well and accomplish a high CO2 fixation rate (500–1800 mg L−1 day−1) with a relatively high tolerance for temperature. Compared with other algal species, i.e., Cyanophytes and Chrysophyte, Chlorella was observed by Zhao and Su [173] to have a better performance in capturing CO2. Its biomass production and carbon fixation rates range between 1060 and 1992 mg L−1 day−1, respectively [143].

Treated industrial effluent/urban wastewater consists of low CNP ratio, which is a major drawback for algal cultivation in wastewater. Integration of flue gas with wastewater for algal cultivation maintains the C/N/P 100:16:1 ratio in wastewater which is required to achieve optimal algal growth [105]. Flue gas addition in wastewater also helps in the pH control of wastewater. Arbib et al. [16] have studied pH control of cultivation medium through flue gas supplement and achieved biomass with less nitrogen reserve and higher lipid content. Thus, the addition of CO2 in culture medium not only improves the carbon availability but also control pH of wastewater. Such integration of flue gas and wastewater is useful to mitigate the pH inhibitions related to the higher free ammonia concentration at higher pH. In another observation by Gentili [57] in algal cultivation in dairy and pulp industry wastewater with added flue gas, higher biomass yield was reported with 96% removal of ammonia. Combined influence of wastewater and exhaust from coal-fired plants was also observed by Ahmad [5]. They observed the highest biomass productivity of 0.44 g L−1 with high lipid productivity. The delivery system of flue gas in culture medium is also found to influence the uptake of CO2 by algal biomass. Sparging of CO2 with large bubbles was found to reduce the CO2 utilization efficiency of alga while small bubbles flow showed better CO2 uptake efficiency [127]. Supply of CO2 up to a concentration range of 5 to 10% is identified as an optimum concentration range for microalgal growth [151]. Chiu et al. [42] investigated the growth of Nannochloropsis oculate in a semi continuous culture and found higher biomass growth in the culture medium with 2% CO2 concentration, while higher CO2 concentration resulted the inhibition of cell growth due to decrease in pH of medium and sedimentation of phosphorus compounds. Bhowmick et al. [26] evaluated the influence of carbon dioxide and wastewater cocktail for sustainable production of lipid and lutein using Chlorella sp. The result shows that in this integrated cultivation system alga efficiently removes nitrogenous and carbon-phosphorus substance by 100 and 85–91%, respectively. The author also achieved twofold increases in the lipid content with 80.74 ± 0.07 mg L−1 day−1 of CO2 uptake. Yadav et al. [166] investigated the biorefinery valorization of industrial wastewater and flue gas by Chlorella vulgaris. Results showed that nutrient removal by 75% was achieved on the fifth day of batch process. They also observed improvement in lipid (17–34%) and carbohydrate (21.5–23%) under mixotrophic cultivation with CO2 biofixation of 5% CO2 concentration.

Hence, algal CO2 fixation, generated from flue gases, part of industrial and transport exhausts, may be an environmentally sustainable when combined with clean environmental processes like wastewater treatment [159] and heavy metal removal [49]. Future research attention on the concept of algal base CO2 removal from flue gases is needed on the practical or commercial part of the investigation. Similarly, non-point sources of flue gases (Brick kilns, small industrial exhausts) should also be targeted for capturing CO2 by algal biomass at local and regional level. Similarly, ethanol plants are also considered to be an ideal carbon source for growth of algal biomass, since it can be used without expensive purification process [23, 122].

Despite having potential for carbon fixation, algal carbon sequestration has various challenges on the technical ground. Various researchers have analyzed the life cycle of algal-based carbon fixation process and revealed that enormous cost and energy is required for algal cultivation, which reduces the positive effect of algae culturing with CO2 sources. For effective cultivation of algae, it needed high surface area per volume ratio and better hydrodynamics to attain maximum surface area for the penetration of light and gas (CO2) transfer. The efficient fixation system must have proper mixing, high gas-liquid transfer rate, and even distribution of light. In the case of algal cultivation in raceway pond, poor light penetration, contamination, and low biomass productivity affect the algal potential for carbon fixation, though it is a low-cost technology for cultivation. However, closed photobioreactor (airlift, flat plate, tubular) for algal cultivation provides several advantages over the raceway pond such as controlled process parameters (pH, nutrient concentration), better mass transfer rate, and higher biomass productivity.

3.3 Algae-nutrient-wastewater-flue gas dynamics

To enhance the algal productivity under certain transitory conditions such as inorganic carbon, nitrate (NO3−), phosphate (PO4−3), light and temperature, etc., it is critical for assessing the profitability in sustainability of algal cultivation at any substantial scale with algal-nutrient-wastewater-flue gas dynamics (ANWFD). The purpose of ANWFD is to design and experiment a combined flue gas sequestration and nutrient-rich wastewater treatment via photosynthetic microalgae. Algae have the potential to grow in nutrient-rich wastewater to capture primarily CO2, and flue gas constituents such as NOx and SOx too from combustion process with aim to improve water quality. This concept provides a technical feasibility, economic viability, and environmental sustainability regarding its indoor and outdoor cultivation. ANWFD focuses on bioprocess geometry (pond depth, light incidence angle), operation (hydraulic retention time, homogenous distribution of nutrients), and environmental stresses [8]. Although, the environmental factors regarding outdoor cultivation is a challenging task for algal activities, influenced by the various environmental parameters. But under ideal environmental conditions, it is possible to enhance the algal biomass productivity per unit of land area. CO2 injections help to maintain the pH at its optimal value while nutrient concentration can be retained by at saturation level to flourish the algal productivity and proper mixing condition for homogenous distribution of nutrients. To overcome these limitations, several models have been proposed to achieve higher algal biomass which in turn reduces environmental limiting factors. ANWFD-based wastewater treatment and flue gas assimilation is the most economical and environmental approach to enhance algal biomass and biofuel conversion. In this regard, advanced technologies have been developed to enhance the microalgal-based CO2 fixation efficiency. Table 11 summarizes different nutrients modeling equations for various algal species used by different researchers. In addition to low carbon supply and reduced water consumption, cost-effective way of the nutrient supplement is equally essential to achieving sustainability in algal biofuel production [144]. On the other hand, atmospheric N-fixation through Haber-Bosch process involves a considerable amount of energy. In this context, wastewater can be again used as a low-cost source of N and P for the cultivation of algae. Various industrial wastewaters such as dairy wastewater and municipal wastewater can provide sufficient nutrients (N and P) for algae growth [84]. As per the estimation provided by Chisti [41], algal oil from wastewater contributes at most 1% of US demand for petroleum and wastewater generated from 10 cities have potential to produce 425,000 Mton of algal oil annually, which is based on the assumption that the wastewater has high nitrogen (85 mg L−1) and phosphorus content (10 mg L−1). Having such a model will be particularly useful for the design and operation of algal mass production systems, as it provides a relationship that can be determined from relatively easily measurable parameters.

4 Genomics strategies to improve algal biofuel production

Recently for the production of biofuels, microalgae have emerged as potential sources of production of carbon-neutral fuels such as biohydrogen and bio-oil. Advances in genomics tools and in silico prediction models have paved the way for the bioprospecting of algae and for developing better traits suited to biofuel production under varied climate conditions. Several strategies have been employed in algal biotechnology for this purpose, from changing carbon flux to obtain increased lipid accumulation, improving light utilization efficiency to enhance biohydrogen production, and modifying lipid production or lipid engineering to modify chain length, and the degree of saturation [19, 86, 110]. For algal biofuel production, systems biology is essential for understandings the molecular mechanisms behind specific phenotypes and that will help in the prediction of cellular response using high-throughput methods coupled with bioinformatics tools. Banerjee et al. [19] reviewed several aspects of systems biology, including enzyme discovery, pathway reconstruction, pathway prediction, and strain optimization for producing better algal strains. System biology played important role in diverting the metabolism of algae to over synthesize the desired products, i.e., lipids, polyunsaturated fatty acids, hydrogen, pharmaceuticals, etc. These metabolic changes in the algal metabolic machinery are guided by transcriptomics, proteomics, and metabolomics approaches. In order to improve the algal strains for biofuel production, some targets such as salinity tolerance, heavy metal tolerance, pest tolerance, disease resistance, and other abiotic (pH, temperature, and light) tolerance traits must be genetically engineered to enhance the fuel productivity.

To improve the economy of biodiesel production from microalgae, the first step is to obtain improved microalgal cultures having high biomass and lipid feedstocks from diverse environment for biodiesel production. Second step is genetically improving microalgae; for this, a variety of bioengineering technologies have been introduced, such as RNA gene silencing, homologous recombination, alteration of gene sequences, tissue culture and transformation optimization, enhancing abiotic stress tolerance, and multi-gene engineering. These technologies can be applied as a useful tool for genetically altering microalgal-based biodiesel. Creation of various algal strains through domestication, hybridization, mutation breeding, gene editing, genetic engineering and simultaneously selection of algal strain, evaluation, multiplication, and release of new variety is an innovative approach for algal-based biofuel production. In the same line, one of the most efficient and cost-effective ways of biodiesel production is the direct synthesis of fatty acid ethyl ester (FAEE) biodiesel in microalgae cells bioengineered with the co-expression of the three enzymes: pyruvate decarboxylase, alcohol dehydrogenase, and wax ester synthase, because these enzymes play a key role in the synthesis of FAEEs [43]. In general, the quality of biodiesel is determined by its chemical composition and structural properties; thus, high oleic acid and high oxidation stability of biodiesel may be the key molecular properties for high-quality biodiesel [7, 11]. The main target for high biodiesel production from algae are as follows: (i) enhancement of PS efficiency of microalgae by over expression of CA; (ii) extracellular production of FFA and TAG by genetic manipulation of fatty acylthioesterase and acyl-CoA synthetase (ACS); (iii) extracellular production of fatty acid ethyl ester (biodiesel) by genetic manipulation of pyruvate decarboxylase, alcohol dehydrogenase, and wax ester synthases; and (iv) quality biodiesel production by genetic manipulation of stearoyl-ACP Δ9 desaturase, thioesterase, ACS, and denaturizes. The availability of sequence and assembled genomes of most of the algae is no longer a limiting factor for algal domestication, though the functioning of whole of their genes is limiting our understanding. Today, our understanding of algal genomes, coupled with high-throughput screening and sequencing methods, including high-throughput sequencing, allows us to rapidly associate genotypes with phenotypes [120]. This increased understanding of gene function will help in increasing the rate at which we improve algal productivity. Du and Benning [53] and Guihéneuf et al. [65] sequenced the genome and developed transformation methods for manipulating the lipid synthesis pathways of Nannochloropsis gaditana, enabling considerable strain improvements using genetic engineering (GE) technologies (Fig. 3).

5 Bioeconomic assessment with suggestive measures

The economic feasibility of mass cultivation of algal biomass depends on a variety of facts, i.e., the feedstock entailed for algae should be with low input such as consumption of CO2 from waste flue gases, nutrient constraint from wastewater generated from diverse industries, development of wasteland (arable and non-arable) with low agricultural value, etc. Use of an alternative feedstock focuses to curtail the cost of algal biomass production [13]. To make algal biodiesel and other value-added products cost competitive with another source of fuel, inexpensive substitute/raw materials are extremely required, or it (algae) can be directly grown on eutrophicated source of water, i.e., sewage water. The authentic cost of biomass generation and biocrudes production entirely depends on the value of procurements of seeds, the scale of manufacturing, government policies related to taxation, appropriate marketing of biofuel and by-products, and utilization of algae given in proposed in Eq. (3).

Typical algal biomass productivity in open pond system is 30 to 50 ton ha−1 year−1 and only harvesting cost contributes to about 20 to 30% of total cost of mass cultivation of algal biomass. Hence, to minimize the harvesting cost, the input raw material must be cheaper, i.e., of zero cost [88]. Earlier it was not feasible on the technical ground, but now it is possible to make established plant near the flue gas emission sources. Carbon sources from flue gasses can be utilized by the algal biomass. Although it requires some technological expenses, it is on time venture and longtime attainment in Eq. (4).

For the establishment of an overall cost production value, evaluation of capital cost and operating costs minus the revenues generated from the entire main and co-products generated from algal biomass must be known [152].

Table 12 is portraying the cost analysis for different parameters associated before and after suggestive measures on comparative basis, where utilization of wastewater, flue gases, and wasteland took with a zero cost; a remarkable reduction of ~ 31% has been predicted in cost at commercial scale on replacement of eco-friendly option with conventional ones where cost was estimated in USD ($) [146]. Therefore, these suggestive measures are economically viable for mass cultivation of algae.

Capital cost is usually related to the one-time expense, i.e., cost of land area (non-arable/barren land), buildings (i.e., indoors or outdoors cultivation system, offices, laboratories, etc.), types of equipment (i.e., reactors, dryer and filter, etc.), other infrastructures (piping and pumps). While, operating cost regarding mass cultivation of algal biomass is combined with the day to day expenses such as power supply (i.e., power required to operate photobioreactors/ padded wheels in open pond system, etc.), raw material required for algae (i.e., water, carbon sources, nitrate, phosphate etc.), expertise cost, labor cost, and other maintenance cost. There are various co-products after lipid extraction is produced such as carbohydrate, protein, pigments, and carotenes, which can be used further in different fields, i.e., medicine, pharmaceutics, biofertilizer industries, and nutritional food, which is adequate to enhance the market potential of algal-derived products as described in Table 13.

Therefore, it would minimize the overall cost given to the whole system as given in Table 13. Similarly, commercialization of any technology would not be complete if cost involvement not used from raw material to final product including revenue generation after the system establishment till next 20 year. Hence, revenue generation or profit analysis from the system totally depends upon what type of reactor (close or open) is chosen for the gain of large quantity of algal biomass. In a study conducted by Zemke et al. [171], cost–profit analysis has been done with the use of photobioreactor for revenue generation, i.e., if photobioreactor was built with a capital cost, C, to be recovered in t years, with an annual rates of returns i, the required annual payment, Q, would be expressed in Eq. (5-7).

Q must be less than or equal to the revenue from the photobioreactor minus the expenses:

The current techno-economic assessment of algal biomass cultivation should be interdisciplinary, by the use of flexible modeling and analysis scaffold that must address the multiple pathways, in coupling with various integration systems for mass cultivation of algal biomass production as well as biofuel and other value-added productions. Although the lipid production and its value-added products are superior to terrestrial oil bringing plants, nevertheless, the cultivation and downstream processing required lots of energy but by the use of biorefinery concepts, i.e., a ground-breaking solution over cost reduction has been proved a milestone. For amplifying the economic feasibility of the whole scenario, this concept must be applied to move towards the biorefinery concept. Biorefinery concept has significant credibility to minimize the capital cost by many folds, which is an attractive approach concerning sustainable algal biomass cultivation as given in Fig. 4. As a consequence, the positive opportunity for using algal biomass with bioenergy options including another value-added product is best suited for biorefinery concept. Algal biorefinery could generate about tenfold more profit than the single use of bioenergy option.

6 Applications of deoiled algal biomass

To explore algal-based green economy with significant benefits, focus should not be restricted primarily on fresh or known algal-based biofuel production processes, deoiled algal biomass (remaining algal biomass after oil extraction) also have the potential to use it for other value-added bioproducts without exploiting environmental and economic benefits; different processing routes to explore these products are shown in Fig. 5. Biomass conversion into biofuel is potentially significant as the remaining biomass can be further applied to produce other chemicals and biomaterials in order to maximize the value of waste algal biomass as well as minimizing waste over the environment, considered here as spent algal biomass. The sustainable cultivation and processing of algal biomass make a broad spectrum of products generated by pure and raw algal biomass. The broad spectrum of algal-based main products and by-products is economically feasible to support the green economy based on algal biomass. Therefore, it is easy to produce high value (biodiesel, bioethanol, biohydrogen, and biogas) and low-value products (cosmetics, pharmaceuticals or neutraceuticals, feed, and fodder, fertilizer, etc.) simultaneously by the application of pure and raw algal biomass [7, 87]. A wide range of industries are being targeted for the use of algal biomass: (i) food industry (bioemulsifier, edible coating, etc.); (ii) cosmetic industry (antioxidants, antibacterial cream, other skin enhancement lotion, etc.); (iii) pharmaceuticals (formulation of vaccines, healing agent, immune modulator agents, inflammatory agents, etc.), given in Table 14.

The spectrum of applications of algal biomass with biodiesel and glycerol ethers from algal bio-oil is a new field of research and need more attention from scientific community [9]. Lipid is the main focus of algal biomass for biodiesel production but bioplastics is another example of commodity bioproducts with huge market opportunities which can be produced by lipid, protein, and carbohydrate. Therefore, in conversion of biofuel and fractionation process of algal biomass, the aqueous hydrolyzate residues along with cell debris is enriched in protein, carbohydrate, peptides, and amino acids. These value-added products, i.e., protein as food and feed, bioplastics, foams, adhesive, biocomposites, are being produced from the deoiled algal biomass after biofuel production.

It has been estimated that 4.5 million tons of residual biomass (algae) are being generated from every billion gallons of produced biodiesel. Although, the algal-based economy is challenging; hence, it is important to harness maximum valuable products from residual biomass. Adessi et al. [2] reported stoichiometric H2 yield, i.e., 33–397.8 mL H2 g−1 from residual algal biomass. Yu et al. [167] reported 15 ± 2% lipid content in dry biomass of C. reinhardtii strain D1 after hydrogen production. The total obtained lipid content was characterized by the presence of 3.3% w/w oil of phytols, 21% w/w oil of triglycerides, 39% w/w oil of polar lipids, and 41% saturated fatty esters, 53% mono unsaturated fatty esters, and 7.2% poly unsaturated fatty esters. The residual biomass (oil cake) after biodiesel production is rich in glycerol and stores 35–73% carbohydrate and proteins which is by-product of the transesterification process and can be used in livestock feed [168]. Quinn et al. [119] have reported 140 mL CH4 g−1 from deoiled algal biomass of Nannochloropsis salina. Similarly, Mishra et al. [101] have also reported an average production of biogas, i.e., 426.26 and 446.02 mL/day from deoiled algal biomass (Microspora sp. and Chlorella vulgaris). Subhash and Mohan [150] have reported a significant hydrogen yield, i.e., 4.9, 3.3, 3.0, and 2.4 mol/kg from different forms of deoiled microalgae, i.e., extract, slurry, solid, and untreated algae, respectively. Zhang et al. [172] have utilized Chlorella sp. (deoiled algae) and molasses for lipid production. The author has reported 335 mg L−1 day−1 of lipid production with maximum concentration of biomass mixture, i.e., 5.58 g/L from deoiled microalgal biomass hydrolysate and molasses. Anaerobic co-digestion of deoiled microalgae, i.e., Botryococcus braunii, with activated sludge (413 mL CH4 g−1) and glycerol (448 CH4 g−1) for biogas production has been reported by Neumann et al. [104] and Beltrán et al. [24].

Similar to this context, a wide range of research has been conducted and is being processed for algal-based biofuel production with variation in wastewater composition [83, 89, 109]. Use of dairy industry wastewater, textile industry wastewater, and wastewater from common effluent treatment plant is very well explored with the use of Chlorella pyrenoidosa and Chlamydomonas polypyrenoideum for algal bio-oil and lipid content by the authors and his research team, although various other researchers also explain the algal-based bio-oil content in integration with wastewater treatment [86].

7 Conclusion and discussions

It is clear from the present review that algal cultivation coupled with wastewater treatment and CO2 capture from flue gas released from industrial exhaust fulfills the criteria of technical feasibility, economic viability, and resource sustainability. Wastewater generated from different sectors such as municipal, industrial, and agricultural sector offers a cost-effective source of nutrients for algal cultivation. Such process not only reduces the cost of algal nutrients but also save the energy expenditure in wastewater reclamation. On the other hand, algal cultivation in wastewater coupled with flue gases supply from various point and non-point sources is found more efficient in terms of economic and technical viability. In this process, enhancement in algal productivity, lipid content, and carbohydrate content was observed by various researchers. Further investigations are required to improve the system designs/reactors based on earlier investigations to achieve maximum efficiency and biomass productivity. For commercial-scale algal production, open race way pond is still found as suitable and cost-effective cultivation system; however, it require further investigations focused on location of selected site, climatic conditions (light intensity and temperature), with different aquatic medium (saline/brackish/industrial wastewater) as a nutrient source in addition to input of CO2 concentration and cell concentration. With large-scale algal production processes, the wastewater-nutrient-flue gas dynamics is the subject of significant consideration with multifaceted approaches. Modification in the existing technologies and their integration with biorefinery concept with water footprinting and water networking can cut down production cost and product cost as well (Fig. 5). Environmental waste streams of water and air from industries with point and non-point sources with emphasis on WFP and GWN with wastewater and combined influence of both waste streams on algal biomass are discussed here with all related pros and cons. Similarly, ANWFD to increase biomass is a salient feature of this article.

Algal biomass cultivated under such integrated system can be used for synthesis of value-added compounds such as lipids, carbohydrate, polyunsaturated fatty acids (PUFAs), etc. Since wastewater grown biomass may contain harmful organic and inorganic substances, hence it is not suitable for use as food or feed. Thus, conversion of lipid into biodiesel is considered as mist suitable end product of these integrated processes. Energy recovery from algal biomass can be enhanced by applying various energy conversion pathways with different components of algal biomass. It is important to identify suitable energy conversion pathway for maximizing the energy recovery from algal biomass. Spent algal biomass is also used as a feedstock for bioenergy production; most of the researchers have investigated biomethane potential of spent algal biomass in integration with biodiesel production. In order to attain environmental sustainability, concepts of green chemistry should be employed in different energy conversion pathways; for example, enzyme-mediated single step transesterification of algal oil involves less chemical consumption with greater efficiency than the conventional transesterification process. It is suggested to identify the resource availability by implication of remote sensing and geographic information system-based technologies, which are important to locate the available aquatic bodies for algal cultivation and industrial establishments. Algal farms equipped with wastewater–flue gas supply, genomics tool, and with in silico prediction models are required for development of better algal traits for high yield biofuel production under varying climatic conditions. These discussed factors could create standard long-term economically viable solutions to overcome the present limitations of the oil sector with prospective bioeconomy.

7.1 Prospective approach

-

1.

ANWFD approach assured to disinfect the environment (air and water) in our surroundings from harmful emissions and discharged pollutant loads (N and P) as algal biomass is the only solution that sequesters both and generates oxygen for sustainable ecosystem.

-

2.

ANWFD approach although involves high capital cost of the system but long-term benefits cut down the cost with multifaceted applications generated by this proposed concept.

-

3.

Water footprinting process in integration with specific strains of algal biomass provides a positive aptitude for alternative clean and low-cost fuels.

-

4.

Symbiosis between the several aspects of systems biology, including enzyme discovery, pathway reconstruction, pathway prediction, and strain optimization for producing better algal strains in search of sustainable bioeconomy with interdisciplinary field of engineering, opens a new door with ANWFD approach.

-

5.

Algal-based bioresource for production of biofuel (from fresh algal biomass and spent algal biomass) has an edge over others as it leaves the least load of waste over the environment due to the wide application of remaining biomass in producing different versatile range of products.

Abbreviations

- GHGs:

-

Greenhouse gases

- WFP:

-

Water footprint

- GWN:

-

Green water networking

- CCS:

-

Carbon capture and storage

- EEE:

-

Enhance energy efficiency

- CCT:

-

Clean coal technologies

- CCM:

-

Carbon capture mechanism

- GWFP:

-

Green water footprint

- BWFP:

-

Blue water footprint

- GyWFP:

-

Gray water footprint

- DWD:

-

Direct water demand

- WSG:

-

Water to support growth

- AP:

-

Annual precipitation

- PAR:

-

Photosynthetically active radiation

- WN:

-

Water network

- GWN:

-

Green water network

- GWNS:

-

Green water network synthesis

- COD:

-

Chemical oxygen demand

- AND:

-

Algal nutrient dynamics

- ANWFD:

-

Algae-nutrient-wastewater-flue gas dynamics

- FAEE:

-

Fatty acid ethyl ester

- DMB:

-

Dry microalgal biomass

- PUFAs:

-

Polyunsaturated fatty acids

References

Adamczyk M, Lasek J, Skawińska A (2016) CO2 biofixation and growth kinetics of Chlorella vulgaris and Nannochloropsis gaditana. Appl Biochem Biotechnol 179(7):1248–1261

Adessi A, Venturi M, Candeliere F, Galli V, Granchi L, De Philippis R (2018a) Bread wastes to energy: sequential lactic and photo-fermentation for hydrogen production. Int J Hydrogen Energ 43(20):9569–9576

AFS Biofarm. http://www.algaefloatingsystems.com. Accessed 15 January 2019

AFS BioOIL. http://www.afsbiooil.com. Accessed 15 January 2019

Ahmad S, Fulekar MH, Bhawana P (2012) Impact of coal based thermal power plant on environment and its mitigation measure. Int Res J Environ Sci 1(4):60–64

Ahmad S, Pandey A, Kothari R, Pathak VV, Tyagi VV, (2017). Closed photobioreactors: construction material and influencing parameters at the commercial scale. Photobioreactors advancement application and research. NOVA Publication, pp. 149–162

Ahmad S, Pathak VV, Kothari R, Singh RP (2018a) Prospects for pretreatment methods of lignocellulosic waste biomass for biogas enhancement: opportunities and challenges. Biofuels 9(5):575–594

Ahmad S, Pathak VV, Kothari R, Kumar A, Krishna SBN (2018b) Optimization of nutrient stress using C. pyrenoidosa for lipid and biodiesel production in integration with remediation in dairy industry wastewater using response surface methodology. 3 Biotech 8(8):326

Ahmad S, Kothari R, Pathak VV, Pandey MK (2019a) Fuel quality index: a novel experimental evaluation tool for biodiesel prepared from waste cooking oil. Waste Biomass Valorization 10(8):2237–2247

Ahmad S, Kothari R, Pathania D, & Tyagi VV 2019b. Optimization of nutrients from wastewater using RSMfor augmentation of Chlorella pyrenoidosa with enhanced lipid productivity, FAME content, and its quality assessment using fuel quality index. Biomass Conversion Biorefinery, 1–18

Ahmad S, Majhi PK, Kothari R, Singh RP (2020a) Industrial wastewater footprinting: a need for water security in Indian context. In: In Environmental concerns and sustainable development. Springer, Singapore, pp 197–212

Ahmad S, Pandey A, Pathak VV, Tyagi VV, Kothari R (2020b) Phycoremediation: algae as eco-friendly tools for the removal of heavy metals from wastewaters. In: In bioremediation of industrial waste for environmental safety. Springer, Singapore, pp 53–76

Algae Product Developing and Manufacturing. http://www.algenol.com. Accessed 15 January 2019

Alhattab M, Kermanshahi-Pour A, Brooks MSL (2019) Microalgae disruption techniques for product recovery: influence of cell wall composition. J Appl Phycol 31(1):61–88

Alzate ME, Muñoz R, Rogalla F, Fdz-Polanco F, Pérez-Elvira SI (2014) Biochemical methane potential of microalgae biomass after lipid extraction. Chem Eng J 243:405–410

Arbib Z, Ruiz J, Álvarez-Díaz P, Garrido-Pérez C, Barragan J, Perales JA (2013) Effect of pH control by means of flue gas addition on three different photo-bioreactors treating urban wastewater in long-term operation. Ecol Eng 57:226–235

Arredondo MR, Kuntke P, Jeremiasse AW, Sleutels THJA, Buisman CJN, &TerHeijne, A. (2015) Bioelectrochemical systems for nitrogen removal and recovery from wastewater. Environ Sci-Wat Res Tech 1(1):22–33

Aslam A, Mughal TA (2016) A review on microalgae to achieve maximal carbon dioxide (CO2) mitigation from industrial flue gases. Int J Res Advent Technol 4(9):1–18

Banerjee A, Banerjee C, Negi S, Chang JS, Shukla P (2018) Improvements in algal lipid production: a systems biology and gene editing approach. Crit Rev Biotechnol 38(3):369–385

Basu S, Roy AS, Mohanty K, Ghoshal AK (2014) CO2 biofixation and carbonic anhydrase activity in Scenedesmus obliquus SA1 cultivated in large scale open system. Bioresour Technol 164:323–330

Batan L, Quinn JC, Bradley TH (2013) Analysis of water footprint of a photobioreactor microalgae biofuel production system from blue, green and lifecycle perspectives. Algal Res 2(3):196–203

Béchet Q, Sialve B, Steyer JP, Shilton A, Guieysse B (2018) Comparative assessment of evaporation models in algal ponds. Algal Res 35:283–291

Behera S, Singh R, Arora R, Sharma NK, Shukla M, Kumar S (2015) Scope of algae as third generation biofuels. Front Bioeng Biotech 2:90

Beltrán C, Jeison D, Fermoso FG, Borja R (2016) Batch anaerobic co-digestion of waste activated sludge and microalgae (Chlorella sorokiniana) at mesophilic temperature. J Environ Sci Health A 51(10):847–850

Bhatt NC, Panwar A, Bisht TS, Tamta S (2014) Coupling of algal biofuel production with wastewater. Scie World J 2014:22–24

Bhowmick GD, Sarmah AK, Sen R (2019) Performance evaluation of an outdoor algal biorefinery for sustainable production of biomass, lipid and lutein valorizing flue-gas carbon dioxide and wastewater cocktail. Bioresour Technol 283:198–206

Binnal P, Nirguna Babu P (2017) Cultivation of Nannochloropsis oculata in centrate and conversion of its lipids to biodiesel in a low-cost microwave reactor. Biofuels 10:439–452 1–14

Bionity. Com. http://www.bionity.com. Accessed 15 January 2019

Blersch DM, Kangas PC, Mulbry WW (2013) Turbulence and nutrient interactions that control benthic algal production in an engineered cultivation raceway. Algal Res 2(2):107–112

Bloomberg. http://www.bloomberg.com. Accessed 15 January 2019

Bohutskyi P, Betenbaugh MJ, Bouwer EJ (2014) The effects of alternative pretreatment strategies on anaerobic digestion and methane production from different algal strains. Bioresour Technol 155:366–372

Boonprasop S, Chalermsinsuwan B, Piumsomboon P (2017) Effect of the operating parameters on the CO2 capture capacity of potassium carbonate supported on gamma alumina (K2CO3/γ-Al2O3) using conventional heat regeneration. J Taiwan Inst Chem E 78:282–289

Bui HH, Tran KQ, Chen WH (2016) Pyrolysis of microalgae residues—a kinetic study. Bioresour Technol 199:362–366

Bushehri HS, Tabatabaie T, Amiri F (2017) Performance of municipal waste stabilization ponds in Bushehr wastewater treatment plant. Advances in Biores 8(1):106–110

Cheah WY, Show PL, Chang JS, Ling TC, Juan JC (2015) Biosequestration of atmospheric CO2 and flue gas-containing CO2 by microalgae. Bioresour Technol 184:190–201

Chen B (2016) Energy, ecology, and environment: a nexus perspective. Energ Ecol Env 1:1–2

Chen B, Chen S (2016) Urban metabolism and nexus. Ecol Informatics 26:1–2

Cheng HH, Whang LM, Wu SH (2016) Enhanced bioenergy recovery from oil-extracted microalgae residues via two-step H2/CH4 or H2/butanol anaerobic fermentation. Biotechnol J 11(3):375–383

Cheng P, Wang Y, Osei-Wusu D, Liu T, Liu D (2018) Effects of seed age, inoculum density, and culture conditions on growth and hydrocarbon accumulation of Botryococcus braunii SAG807-1 with attached culture. Bioresour Bioprocess 5(1):15

Chilebiotech.cl. http://www.chilebiotech.cl. Accessed 15 January 2019

Chisti Y (2016) Large-scale production of algal biomass: raceway ponds. In: Algae biotechnology. Springer, Cham, pp 21–40

Chiu S-Y, Kao C-Y, Tsai M-T, Ong S-C, Chen C-H, Lin C-S (2009) Lipid accumulation and CO2 utilization of Nannochloropsis oculata in response to CO2 aeration. Bioresour Technol 100:833–838

Chung YS, Lee JW, Chung CH (2017) Molecular challenges in microalgae towards cost-effective production of quality biodiesel. Renew Sust Energ Rev 74:139–144

Cole AJ, de Nys R, Paul NA (2014) Removing constraints on the biomass production of freshwater macroalgae by manipulating water exchange to manage nutrient flux. PLoS One 9(7):101284

Colman B, Huertas IE, Bhatti S, Dason JS (2002) The diversity of inorganic carbon acquisition mechanisms in eukaryotic microalgae. Fun Plant Biology 29(3):261–270

Craggs RJ, Lundquist TJ, Benemann JR (2013) Wastewater treatment and algal biofuel production. In: In: Algae for biofuels and energy. Springer, Dordrecht, pp 153–163

Cuellar-Bermudez SP, Garcia-Perez JS, Rittmann BE, Parra-Saldivar R (2015) Photosynthetic bioenergy utilizing CO2: an approach on flue gases utilization for third generation biofuels. J Clean Prod 98:53–65

Daliry S, Hallajsani A, Mohammadi Roshandeh J, Nouri H, Golzary A (2017) Investigation of optimal condition for Chlorella vulgaris microalgae growth. Global J Environ Sci Manag 3(2):217–230

Das S and Dash HR, (2017). Handbook of metal-microbe interactions and bioremediation. CRC Press

Decostere B, Van Hulle SW, Duyck M, Maere T, Vervaeren H, Nopens I (2016) The use of a combined respirometric–titrimetric setup to assess the effect of environmental conditions on micro-algal growth rate. J Chem Technol Biotechnol 91(1):248–256

Del Rosario Rodero M, Posadas E, Toledo-Cervantes A, Lebrero R, Muñoz R (2018) Influence of alkalinity and temperature on photosynthetic biogas upgrading efficiency in high rate algal ponds. Algal Res 33:284–290

Dineshbabu G, Uma VS, Mathimani T, Deviram G, Ananth DA, Prabaharan D, Uma L (2017) On-site concurrent carbon dioxide sequestration from flue gas and calcite formation in ossein effluent by a marine cyanobacterium Phormidiumvalderianum BDU 20041. Energy Convers Manag 141:315–324

Du ZY, Benning C (2016) Triacylglycerol accumulation in photosynthetic cells in plants and algae. In: In: Lipids in plant and algae development. Springer, Cham, pp 179–205

Eloka-Eboka AC, Inambao FL (2017) Effects of CO2 sequestration on lipid and biomass productivity in microalgal biomass production. Appl Energy 195:1100–1111

Endo A, Tsurita I, Burnett K, Orencio PM (2017) A review of the current state of research on the water, energy, and food nexus. J HydrolReg Stud 11:20–30

Gaikwad RW, Gudadhe M, Bhagat S (2016) Carbon dioxide capture, tolerance and sequestration using microalgae—a review. Int J Pharm Chem Biol Sci 6(3):345–349

Gentili FG (2014) Microalgal biomass and lipid production in mixed municipal, dairy, pulp and paper wastewater together with added flue gases. Bioresour Technol 169:27–32

Gerbens-Leenes PW, de Vries GJ, Xu L (2013). The water footprint of biofuels from microalgae. Bioenergy Water 191

Gerbens-Leenes PW, Xu L, Vries GJ, Hoekstra AY (2014) The blue water footprint and land use of biofuels from algae. Water Resour Res 50(11):8549–8563

Gharagozloo PE, Drewry JL, Collins AM, Dempster TA, Choi CY, James SC (2014) Analysis and modeling of Nannochloropsis growth in lab, greenhouse, and raceway experiments. J Appl Phycol 26(6):2303–2314

Grossmann IE, Martín M, Yang L (2014) Review of optimization models for integrated process water networks and their application to biofuel processes. Curr Opin Chem Eng 5:101–109

Grubert E, Sanders KT (2018) Water use in the United States energy system: a national assessment and unit process inventory of water consumption and withdrawals. Environ Sci Technol 52(11):6695–6703

Guerra OJ, Reklaitis GV (2018) Advances and challenges in water management within energy systems. Renew Sust Energ Rev 82:4009–4019

Guieysse B, Béchet Q, Shilton A (2013) Variability and uncertainty in water demand and water footprint assessments of fresh algae cultivation based on case studies from five climatic regions. Bioresour Technol 128:317–323

Guihéneuf F, Khan A, Tran LSP (2016) Genetic engineering: a promising tool to engender physiological, biochemical, and molecular stress resilience in green microalgae. Front Plant Sci 7:400

Hagi H, Neveux T, Le Moullec Y (2015) Efficiency evaluation procedure of coal-fired power plants with CO2 capture, cogeneration and hybridization. Energy 91:306–323

Hammouda O, Abdel-Raouf N, Shaaban M, Kamal M, Plant BSWT (2015) Treatment of mixed domestic-industrial wastewater using microalgae Chlorella sp. J Am Sci 11(12):303–315

Herzog H, Golomb D (2004) Carbon capture and storage from fossil fuel use. Encyclopedia Energy 1(6562):277–287

Holmatov B, Hoekstra AY, Krol MS (2019) Land, water and carbon footprints of circular bioenergy production systems. Renew Sust Energ Rev 111:224–235

Hong X, Liao Z, Sun J, Jiang B, Wang J, Yang Y (2018) Energy and water management for industrial large-scale water networks: a systematic simultaneous optimization approach. ACS Sustain Chem Eng 6(2):2269–2282

Hribernik M, Anwar A, Turkstra A, &Zannini MC, (2013). Potential of clean coal technology in India: an SME perspective. Available at SSRN 2343051

http://www.bp.com/en/global/corporate/energy-economics/statistical-review-ofworld-energy. html

http://www.solixgredients.com. Accessed 15 January 2019

Hwang JH, Church J, Lee SJ, Park J, Lee WH (2016) Use of microalgae for advanced wastewater treatment and sustainable bioenergy generation. J Environ Eng 33(11):882–897

IGV-GmbH Germany. http://www.igv-gmbh.de/en/home . Accessed 15 January 2019

Jebali A, Acién FG, Sayadi S, Molina-Grima E (2018) Utilization of centrate from urban wastewater plants for the production of Scenedesmus sp. in a raceway-simulating reactor. J Environ Manag 211:112–124

Junior EN, Kumar M, Pankratz S, Oyedun AO, Kumar A (2018) Development of life cycle water footprints for the production of fuels and chemicals from algae biomass. Water Res 140:311–322

Kadir WNA, Lam MK, Uemura Y, Lim JW, Lee KT (2018) Harvesting and pre-treatment of microalgae cultivated in wastewater for biodiesel production: a review. Energy Convers Manag 171:1416–1429

Kassim MA, Meng TK (2017) Carbon dioxide (CO2) biofixation by microalgae and its potential for biorefinery and biofuel production. Sci Total Environ 584:1121–1129

Khan MI, Shin JH, Kim JD (2018) The promising future of microalgae: current status, challenges, and optimization of a sustainable and renewable industry for biofuels, feed, and other products. Microb Cell Factories 17(1):36

Kim SK, & Lee CG, (2015). Marine bioenergy: trends and developments. CRC Press

Kotasthane T (2017) Potential of microalgae for sustainable biofuel production. J Mar Sci Res Dev 7(01):223

Kothari R, Pathak VV, Kumar V, Singh DP (2012) Experimental study for growth potential of unicellular alga Chlorella pyrenoidosa on dairy waste water: an integrated approach for treatment and biofuel production. Bioresour Technol 116:466–470

Kothari R, Prasad R, Kumar V, Singh DP (2013) Production of biodiesel from microalgae Chlamydomonas polypyrenoideum grown on dairy industry wastewater. Bioresour Technol 144:499–503

Kothari R, Pathak VV, Chopra AK, Ahmad S, Allen T, Yadav BC (2015) Developments in bioenergy and sustainable agriculture sectors for climate change mitigation in Indian context: a state of art. Clim Chan Env Sust 3(2):93–103

Kothari R, Kumar V, Pathak VV, Ahmad S, Aoyi O, Tyagi VV (2017a) A critical review on factors influencing fermentative hydrogen production. Front Biosci 22:1195–1220

Kothari R, Pandey A, Ahmad S, Kumar A, Pathak VV, Tyagi VV (2017b) Microalgal cultivation for value-added products: a critical enviro-economical assessment. 3 Biotech 7(4):243

Kothari R, Pathak VV, Pandey A, Ahmad S, Srivastava C, Tyagi VV (2017c) A novel method to harvest Chlorella sp. via low cost bioflocculant: influence of temperature with kinetic and thermodynamic functions. Bioresour Technol 225:84–89

Kothari R, Ahmad S, Pathak VV, Pandey A, Singh S, Kumar K, Tyagi VV (2018) Experiment-based thermodynamic feasibility with co-digestion of nutrient-rich biowaste materials for biogas production. 3 Biotech 8(1):34

Kube M, Jefferson B, Fan L, Roddick F (2018) The impact of wastewater characteristics, algal species selection and immobilisation on simultaneous nitrogen and phosphorus removal. Algal Res 31:478–488

Kumar A, Ergas S, Yuan X, Sahu A, Zhang Q, Dewulf J, Van Langenhove H (2010) Enhanced CO2 fixation and biofuel production via microalgae: recent developments and future directions. Trends Biotechnol 28(7):371–380

Kumar S, Bhatnagar RK, Kranthi KR and Datta SK, (2014). The legal battle over field trials of GM crops. Nature India

Lage S, Gojkovic Z, Funk C, Gentili F (2018) Algal biomass from wastewater and flue gases as a source of bioenergy. Energies 11(3):664

Lara-Gil JA, Álvarez MM, Pacheco A (2014) Toxicity of flue gas components from cement plants in microalgae CO2 mitigation systems. J Appl Phycol 26(1):357–368

Lee OK, Kim AL, Seong DH, Lee CG, Jung YT, Lee JW, Lee EY (2013) Chemo-enzymatic saccharification and bioethanol fermentation of lipid-extracted residual biomass of the microalga, Dunaliella tertiolecta. Bioresour Technol 132:197–201

Lenton TM (2010) The potential for land-based biological CO2 removal to lower future atmospheric CO2 concentration. Carbon Manage 1(1):145–160

Leung DY, Caramanna G, Maroto-Valer MM (2014) An overview of current status of carbon dioxide capture and storage technologies. Renew Sust Energ Rev 39:426–443

Lin MT, Occhialini A, Andralojc PJ, Parry MA, Hanson MR (2014) A faster Rubisco with potential to increase photosynthesis in crops. Nature 513(7519):547

Maity JP, Bundschuh J, Chen CY, Bhattacharya P (2014) Microalgae for third generation biofuel production, mitigation of greenhouse gas emissions and wastewater treatment: present and future perspectives—a mini review. Energy 78:104–113

Maurya R, Paliwal C, Ghosh T, Pancha I, Chokshi K, Mitra M, Ghosh A, Mishra S (2016) Applications of de-oiled microalgal biomass towards development of sustainable biorefinery. Bioresour Technol 214:787–796