Abstract

WO3 thin films were prepared on indium-tin oxide (ITO) glass substrates at different substrate temperature by radio frequency magnetron sputtering. Then the films were soaked in five organic solvents of acetone, ethanol, cyclohexane, acetonitrile and ethyl acetate for 48 h, respectively. The changes in the microstructure, surface morphology and electrochromic (EC) properties of WO3 thin films before and after the immersion treatment were systematically studied. It was found that after soaking in ethanol, the optical modulation of amorphous WO3 thin films deposited at room temperature increased from 50 to 85%, showing excellent EC performance. Moreover, the immersion treatment in ethanol is also helpful for improving the EC properties of amorphous WO3 thin films prepared at elevated substrate temperature. However, after immersion in the other organic solvents, the optical modulation of WO3 thin films increased less (for acetone: 77%) or even decreased significantly (for cyclohexane, acetonitrile and ethyl acetate: 31%, 30% and 35%, respectively). In addition, the immersion treatment in ethanol cannot improve the optical modulation of crystalline WO3 thin films prepared at 600 °C, which dropped from 58 to 40%. The authors believe that this is mainly related to the different dredging effects of various organic solvents on the transport channels of Li-ions and electrons in WO3 thin films. Therefore, this work provides a new approach for the optimization of EC performance of amorphous WO3 thin films.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Since the introduction of electrophotographic system by Deb et al. in 1969 [1], electrochromic (EC) materials that can occur reversible color changes by applying a voltage have received extensive attention [2,3,4,5]. Compared with other transition metal oxides and organic EC materials, WO3 has high coloration efficiency, fast response time and long service life, and is one of the most detailed EC materials studied so far [6, 7]. In particular, WO3 of amorphous structure have a better coloration efficiency than that of crystalline structure [8], and thus, it has been widely used in many technical applications such as EC displays [9, 10], smart windows [2, 8, 11] and anti-glare rear view mirrors [12, 13]. The discoloration behavior of WO3 is generated basing on the implantation/extraction of Li-ions, during which the WO3 undergoes reversible physicochemical changes, accompanied by photoresponse and ion storage behavior. Specifically, during the coloring process, Li-ions are implanted into WO3 and react with it to generate blue LixWO3; while in the bleaching process, Li-ions are extracted and LixWO3 is decomposed into colourless WO3 again [14, 15]. This discoloration process or model have guiding significance for the design and fabrication of WO3-based materials and devices with excellent EC performance.

Usually, the main indicators for evaluating the EC performance of a material are coloration efficiency, response time, coloring storage time, cycling stability, etc [16]. Among them, coloration efficiency is the most important indicator of EC materials, which can be simply characterized by the difference between the transmittance of the colored state and the bleached state at a certain wavelength in the visible light band (i.e., optical modulation) [17]. The coloration efficiency or optical modulation of a material is not only related to its microstructure, but also closely related to the preparation method and experimental conditions of the material. In the existing literature, the preparation methods of WO3 thin films include magnetron sputtering [18, 19], ion beam sputtering [17, 20], electron beam evaporation [21], hydrothermal method [22] and electrodeposition method [23], etc. The magnetron sputtering is currently the mainstream preparation method of WO3 thin films because of its uniform film layer, good film-base adhesion, easy large-area preparation and high repeatability [19]. Nevertheless, as reported in the existing literature, the optical modulation of WO3 thin films prepared by magnetron sputtering is still not high, usually below 75% [24]. Therefore, it is very necessary to find an effective method to improve the optical modulation of magnetron-sputtered amorphous WO3 thin films.

2 Experimental

2.1 Deposition of WO3 Thin Films

WO3 thin films were deposited on commercial indium-tin oxide (ITO) glass substrates (25 × 40 × 0.7 mm, 3–4 Ω/mm2 resistivity) in a JGP 500 A magnetron sputtering system. A pure tungsten disk (W, 99.999% purity) of 76.2 mm in diameter and 5 mm in thickness was used as the sputtering target. The distance between the target and the ITO substrates was set to be ~ 15 cm. A base pressure of 5 × 10− 3 Pa in chamber was obtained by a combined system of mechanical and turbomolecular pumps before sputtering. High pure argon gas (Ar, 99.999% purity) with a flow speed of 20 sccm was then introduced into the vacuum chamber, and further ionized to generate Ar ions under the action of radio frequency (RF) electric field to sputter W atoms. Before each deposition, the W target was pre-sputtered in pure Ar atmosphere for 15 min in order to remove the possible impurities and oxide layer formed on the surface of target. For all film samples, the sputtering power was 100 W, the working air pressure was 0.3 Pa and the deposition time was 1.5 h. In order to study the influences of microstructure on the optical modulation, the substrate temperature was changed between room temperature and 600 °C to fabricate amorphous films and crystalline films.

2.2 Soaking Treatment

Soak the WO3 film samples in 50 ml of organic solvents each time. The organic solvents include acetone (99.5 wt%), ethanol (99.7 wt%), cyclohexane (99.5 wt%), acetonitrile (99 wt%) and ethyl acetate (99.5 wt%), which were all of analytical purity. After 48 h immersion, the samples were taken out for drying.

2.3 Characterisations

The as-prepared film samples were characterized by an X-ray photoelectron spectroscope (XPS, Kratos Axis Ultra DLD), a filed-emission scanning electron microscope (SEM, ZEISS SUPRA55), a powder X-ray diffractometer (XRD, RIGAKUD/Max 2500 PC) and a home-made EC test system to study their chemical composition, surface morphology, microstructure and EC performance, respectively.

3 Results and Discussion

The SEM image in Fig. 1(a) shows the surface morphology of WO3 thin films deposited at room temperature. It can be observed that the film surface is uniform and dense. Compared to the inset, the sheets-like textured morphology of ITO substrates is almost completely covered by the WO3 films. It was confirmed from cross-sectional SEM images that the film thickness is ~ 110 nm. The XRD patterns in Fig. 1(b) only exhibit the diffraction peaks of ITO substrates, which demonstrates that the as-prepared WO3 films are amorphous. Further, XPS tests were taken on the films, and the results are shown in Fig. 1(c,d). From the core-level peaks of W4f in Fig. 1(c), it can be found that the split double peaks of W6+ at binding energy of 37.8 eV and 35.8 eV correspond to 4f5/2 and 4f7/2, respectively [25, 26]. In addition, as shown in Fig. 1(d), the binding energy of O1s at 530.7 eV corresponds to the typical of O2− bonded to W, and that at 531.5 eV corresponds to the hydroxyl oxygen adsorbed on the film surface [27, 28]. Therefore, it can be concluded that the sputtering products are WO3 thin films. Although no additional oxygen was introduced in this study, the physical sputtering products of W target were still WO3 rather than W and WOx (x < 3). This is because, similar to the sputtering deposition of Cu [29,30,31,32,33,34], in the chamber where the background vacuum is not high enough, the residual oxygen is still sufficient to completely oxidize the W atoms into WO3 molecules.

Figure 2 shows the SEM images of the WO3 film samples soaked in acetone and ethanol solvents for 48 h, respectively. It can be seen from the figure that the samples after soaking in the two solvents clearly exposed the sheets-like textured morphology of ITO substrate (see the inset of Fig. 1(a)). This may be due to a small amount of dissolution of the WO3 films in the solvents. Meanwhile, the surface of the samples soaked in acetone and ethanol solvents become loose (Fig. 2(a,b)). By analyzing the cross-sectional SEM images, however, we found that there was no significant change in the film thickness after immersion treatment. This is consistent with our analysis results below: immersion treatment in solvents will change the porosity or internal channels of the films, but it does not damage the overall framework structure of the films. In addition, the results of XRD and XPS characterizations were similar to those shown in Fig. 1. It demonstrates that the immersion treatment in acetone and ethanol solvents does not significantly change the microstructure and compositions of the films. They are still WO3 thin films of amorphous structure. Further, we have also characterized the samples soaked in other organic solvents, and found that the surface morphology was similar to that in Fig. 1(a) and the WO3 films were still amorphous.

To identify the effects of immersion treatment on the EC characteristics of WO3 thin films, the coloring-bleaching experiments of WO3 thin films before and after soaking in different organic solvents were carried out. 1 mol/L LiClO4-PC (propylene carbonate, PC) solution was used as the electrolyte, and Pt (platinum) was used as the counter electrode, respectively. Coloration and bleaching of the EC cells were performed by applying direct-current voltages of -8.0 V and + 8.0 V, respectively.

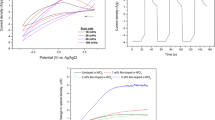

For all samples, the EC phenomena were observed in the coloring-bleaching experiments, and the optical transmittance of WO3 thin films at the colored and bleached states was measured using ultraviolet-visible spectrophotometry, as shown in Fig. 3. It can be seen from Fig. 3(a) that the optical modulation of the as-deposited WO3 thin films without soaking treatment is only 50% at the wavelength of 676.2 nm. Its main problem is that the bleaching effect is not excellent. This can be attributed to the relatively dense film without soaking treatment (Fig. 1(a)). After the WO3 film samples were treated in ethanol and acetone, the surface of the films became loose, which reduced the resistance of ion and electron injection and extraction, and was more conducive to the coloring and bleaching reactions. As a result, the optical modulations of WO3 thin films after immersion in ethanol and acetone increased to 85% and 77% (Fig. 3(b,c)), respectively. Compared with the sample without immersion treatment (Fig. 3(a)), their optical modulation increased by 35% and 27%, respectively. As further shown in Fig. 3(d-f), samples soaked in cyclohexane, acetonitrile and ethyl acetate exhibited good coloring efficiency but worse bleaching efficiency, which resulted in much lower optical modulations, only 31%, 30% and 35%, respectively. Therefore, after soaking in the above five organic solvents, only ethanol and acetone, especially ethanol, can improve the optical modulation of WO3 thin films.

The common feature of WO3 thin films after soaking in the above solvents is that they all have good coloring effects, but the difference lies in their different bleaching effects. This indicates that there is a difference in the ability of Li-ions and electrons to be extracted from the interior of these WO3 thin films. In other words, after immersion in different organic solvents, the porosity or internal channels of WO3 thin films have changed, some becoming smoother and some becoming more congested. This may be related to various factors of the solvents, including the molecular weight, molecular structure, volume size, viscosity, volatilization rate, and so on. They will affect the diffusion ability of solvent molecules within the WO3 thin films, as well as the resulting channel cleaning and dredging effects. In terms of overall performance, ethanol and acetone are the two ideal candidate solvents, which have a good dredging effect on the channels. This inference is well consistent with the SEM observations in Fig. 2. It can also be similarly exemplified in some literature. For example, Xu et al. [35] and Zhang et al. [36] have reported that adding an appropriate amount of ethanol can increase the porosity of the as-grown films.

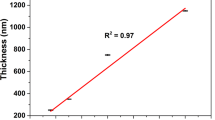

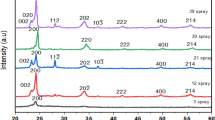

Furthermore, WO3 thin films were prepared at different substrate temperature. Figure 4(a,b) show the surface morphology of WO3 thin films deposited at 550 and 600 °C, respectively. It can be found that many coarse particles were formed on the film surface at 550 °C. This may be due to the fact that high temperature promotes the diffusion or migration of WO3 molecules on the substrate, and small particles aggregate together to form large particles. As a result, the surface of the films becomes rough and the films look much denser. However, when the temperature reached 600 °C, a rods-like porous structure was formed on the film surface. This may be due to the inability of the ITO substrate to withstand such a high temperature, resulting in a significant evolution in the morphology of ITO substrate as well as its supporting WO3 thin film. Figure 4(c) further shows the XRD patterns of the films prepared at substrate temperatures of 550 and 600 °C. The sample at 550 °C only showed the diffraction peaks of ITO substrate, indicating that it was an amorphous structure. However, when the temperature rose to 600 °C, there was a diffraction peak at 2θ = 23.0 °, corresponding to the WO3 (001) orientation (PDF#20-1324). According to Shearer’s formula, we obtained that the grain size of WO3 along (001) orientation was 14.1 nm. In addition, the morphology and XRD pattern of WO3 thin films prepared at 300 °C were similar to those at 550 °C, also showing a relatively dense and rough film surface and an amorphous structure. After immersion in ethanol, the amorphous or crystalline structure of film samples did not change, and the surface morphology did not change visibly either.

Figure 5 shows the coloring-bleaching transmittance spectra of WO3 thin films prepared under different substrate temperature conditions before and after immersion in ethanol for 48 h. As shown in Fig. 5(a,c), the samples prepared at substrate temperatures of 300 and 550 °C showed very small optical modulations before ethanol treatment, 7% and 11%, respectively. This can be attributed to their dense surface topography (Fig. 4(a)) [37], which is difficult for the injection of Li-ions and electrons, resulting in poor coloring efficiency. After soaking in ethanol, as shown in Fig. 5(b,d), the coloring efficiency increased, and the optical modulation also showed a significant increase trend (a→b: 7%→51%; c→d: 11%→26%). However, the higher the temperature, the smaller the increase, which may be related to the higher film density at higher susbstrate temperature. When the substrate temperature was 600 °C, as shown in Fig. 5(e), the optical modulation of the sample before ethanol immersion was 58%, a little higher than that deposited at RT (50%, Fig. 3(a)). The reason for the improvement is that the rods-shaped porous membrane formed at 600 °C (Fig. 4(b)) reduces the resistance of ion and electron injection and extraction. After ethanol treatment, as shown in Fig. 5(f), the coloring efficiency of the film became worse, and the optical modulation dropped to 40%. There are two possible causes or influencing factors. One is the presence of grains in the film may hinder the dredging and cleaning of transport channels by ethanol; the other is that the stability of WO3 thin films with porous structures is relatively poor, and after immersion in ethanol, there is more amount of dissolution, resulting in an increase in the optical transmittance. This indicates that the optical modulation of WO3 thin films enhanced by ethanol is only applicable to samples of amorphous structure, which provides a useful reference or suggestion for optimizing the EC properties of WO3 thin films.

4 Conclusions

In this work, the effects of soaking treatment in various organic solvents on the EC performance of WO3 thin films were systematically investigated. It was found that after soaking in ethanol and acetone, the optical modulation of amorphous WO3 thin films increased from 50 to 85% and 77% respectively, showing good EC performance. However, after immersion in other organic solvents, cyclohexane, acetonitrile and ethyl acetate, the optical modulation of WO3 thin films decreased significantly instead. It can be attributed to the different diffusion ability of solvent molecules within the WO3 thin films, as well as the resulting different channel cleaning and dredging effects. At an elevated substrate temperature between 300 and 550 °C, the WO3 thin films remained amorphous, but the morphology became rough and dense. After soaking in ethanol, the optical modulation can still be effectively improved. However, the immersion treatment in ethanol solvent cannot improve the optical modulation of crystalline WO3 thin films prepared at 600 °C. This may be due to the presence of crystal grains in the films, which hinders the dredging and cleaning of transport channels by ethanol. Therefore, the method of enhancing optical modulation of WO3 thin films by ethanol immersion is only applicable to samples of amorphous structure. In short, this work provides an efficient method for optimizing the EC performance of amorphous WO3 thin films.

References

Deb, S.K.: A novel electrophotographic system[J]. Appl. Opt. 8(101), 192–195 (1969)

Niklasson, G.A., Granqvist, C.G.: Electrochromics for smart windows: Thin films of tungsten oxide and nickel oxide, and devices based on these[J]. J. Mater. Chem. 17(2), 127–156 (2007)

Deb, S.K.: Opportunities and challenges in science and technology of WO3 for electrochromic and related applications[J]. Sol. Energy Mater. Sol. Cells. 92(2), 245–258 (2008)

Granqvist, C.G.: Electrochromics for smart windows: Oxide-based thin films and devices[J]. Thin solid films. 564, 1–38 (2014)

Huang, Z.F., Song, J., Pan, L., et al.: Tungsten oxides for photocatalysis, electrochemistry, and phototherapy[J]. Adv. Mater. 27(36), 5309–5327 (2015)

Bange, K.: Colouration of tungsten oxide films: A model for optically active coatings[J]. Sol. Energy Mater. Sol. Cells. 58(1), 1 (1999)

Lee, S.H., Cheong, H.M., Tracy, C.E., et al.: Electrochromic coloration efficiency of a-WO3 – y thin films as a function of oxygen deficiency[J]. Appl. Phys. Lett. 75(11), 1541–1543 (1999)

Zhang, Y., Liang, X., Jiang, T., et al.: Amorphous/crystalline WO3 dual phase laminated films: Fabrication, characterization and evaluation of their electrochromic performance for smart window applications[J]. Sol. Energy Mater. Sol. Cells. 244, 111820 (2022)

Granqvist, C.G.: Oxide electrochromics: An introduction to devices and materials[J]. Sol. Energy Mater. Sol. Cells. 99, 1–13 (2012)

Bechinger, C., Ferrere, S., Zaban, A., et al.: Photoelectrochromic windows and displays[J]. Nature. 383(6601), 608–610 (1996)

Runnerstrom, E.L., Llordés, A., Lounis, S.D., et al.: Nanostructured electrochromic smart windows: Traditional materials and NIR-selective plasmonic nanocrystals[J]. Chem. Commun. 50(73), 10555–10572 (2014)

Avendaño, E., Berggren, L., Niklasson, G.A., et al.: Electrochromic materials and devices: Brief survey and new data on optical absorption in tungsten oxide and nickel oxide films[J]. Thin solid films. 496(1), 30–36 (2006)

Lynam, N.R.: Electrochromic automotive day/night mirrors[J]. SAE Trans., : 891–899. (1987)

Lee, S.H., Cheong, H.M., Zhang, J.G., et al.: Electrochromic mechanism in a-WO3 – y thin films[J]. Appl. Phys. Lett. 74(2), 242–244 (1999)

Garcia-Belmonte, G., Bueno, P.R., Fabregat-Santiago, F., et al.: Relaxation processes in the coloration of amorphous WO3 thin films studied by combined impedance and electro-optical measurements[J]. J. Appl. Phys. 96(1), 853–859 (2004)

Shi, Y., Sun, M., Zhang, Y., et al.: Rational design of oxygen deficiency-controlled tungsten oxide electrochromic films with an exceptional memory effect[J]. ACS Appl. Mater. Interfaces. 12(29), 32658–32665 (2020)

Wang, Z., Su, J., Qi, H., et al.: Porous nanocrystalline WO3 thin films: Fabrication, electrical and optical properties[J]. Surf. Innovations. 9(4), 214–221 (2020)

Yang, T., Lin, Z., Wong, M.: Structures and electrochromic properties of tungsten oxide films prepared by magnetron sputtering[J]. Appl. Surf. Sci. 252(5), 2029–2037 (2005)

Akl, A.A., Kamal, H., Abdel-Hady, K.: Characterization of tungsten oxide films of different crystallinity prepared by RF sputtering[J]. Phys. B: Condens. Matter. 325, 65–75 (2003)

Xue, J., Zhu, Y., Jiang, M., et al.: Electrochromic WO3 thin films prepared by combining ion-beam sputtering deposition with post-annealing[J]. Mater. Lett. 149, 127–129 (2015)

Madhuri, K.V., Babu, M.B.: Studies on electron beam evaporated WO3 thin films[J]. Materials Today: Proceedings, 3(1): 84–89. (2016)

Su, X., Li, Y., Jian, J., et al.: Situ etching WO3 nanoplates: Hydrothermal synthesis, photoluminescence and gas sensor properties[J]. Mater. Res. Bull. 45(12), 1960–1963 (2010)

Yu, Z., Jia, X., Du, J., et al.: Electrochromic WO3 films prepared by a new electrodeposition method[J]. Sol. Energy Mater. Sol. Cells. 64(1), 55–63 (2000)

Zhao, Y., Zhang, X., Chen, X., et al.: Preparation of WO3 films with controllable crystallinity for improved near-infrared electrochromic performances[J]. ACS Sustain. Chem. Eng. 8(31), 11658–11666 (2020)

Lee, S., Lee, Y., Kwak, D., et al.: Improved pseudocapacitive performance of well-defined WO3 – x nanoplates[J]. Ceram. Int. 41(3), 4989–4995 (2015)

Wang, X.G., Jang, Y.S., Yang, N.H., et al.: XPS and XRD study of the electrochromic mechanism of WOx films[J]. Surf. Coat. Technol. 99(1–2), 82–86 (1998)

Barreca, D., Carta, G., Gasparotto, A., et al.: A study of nanophase tungsten oxides thin films by XPS[J]. Surf. Sci. Spectra. 8(4), 258–267 (2001)

Bathe, S.R., Patil, P.S.: Titanium doping effects in electrochromic pulsed spray pyrolysed WO3 thin films[J]. Solid State Ionics. 179(9–10), 314–323 (2008)

Su, J., Zhang, J., Liu, Y., et al.: Parameter-dependent oxidation of physically sputtered Cu and the related fabrication of Cu-based semiconductor films with metallic resistivity[J]. Sci. China Mater. 59(2), 144–150 (2016)

Ma, J., Wang, Z., Qi, H., et al.: Fabrication of novel pyramid-textured and nanostructured Cu2O/Si heterojunctions[J]. Surf. Innovations. 9(4), 199–206 (2021)

Zeng, X., Ma, J., Su, J., et al.: Fabrication of hand-like CuO nanostructured films by free oxidation of Cu2O nanoporous films in alkaline solution[J]. Mater. Res. Express. 4, 045009 (2017)

Su, J., Wang, Z., Ma, J., et al.: Selective bias deposition of CuO thin film on unpolished Si wafer[J]. Mater. Res. Express. 7, 026402 (2020)

Zhu, Y., Ma, J., Zhou, L., et al.: Cu2O porous nanostructured films fabricated by positive bias sputtering deposition[J]. Nanotechnology. 30, 095702 (2019)

Zhu, Y., Ma, J., Su, J., et al.: Nanoinstabilities of Cu2O porous nanostructured films as driven by nanocurvature effect and thermal activation effect[J]. Nanotechnology. 30, 335711 (2019)

Xu, S., Zhou, C.H., Yang, Y., et al.: Effects of ethanol on optimizing porous films of dye-sensitized solar cells[J]. Energy Fuels. 25(3), 1168–1172 (2011)

Zhang, B., Xu, G., Liu, S., et al.: Electrochromic TiO2 films by a facile solvothermal process: Effect of ethanol content on growth and performance[J]. Opt. Mater. 122, 111744 (2021)

Zhu, X., Qi, H., Chen, J., et al.: Effects of deposition parameters on RF-sputtered WO3 thin films[J]. Surf. Innovations. (2022). https://doi.org/10.1680/jsuin.22.01031

Acknowledgements

This work was financially supported by Natural Science Foundation of Jiangsu Province (BK20191453) and Research and Innovation Program for Graduate Students of Jiangsu Province (KYCX21_2819 and KYCX21_2825).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Su, J., Zhu, X., Chen, L. et al. Optimization of Optical Modulation in Amorphous WO3 Thin Films. Electron. Mater. Lett. 20, 131–139 (2024). https://doi.org/10.1007/s13391-023-00447-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-023-00447-y