Abstract

We report structural, dielectric, ferroelectric, magnetic, and low frequency magnetoelectric (ME) properties of (1−x) Bi0.5Na0.5TiO3 (BNT)–xNi0.5Zn0.5Fe2O4 (NZFO) (x = 0.05–0.30) microwave sintered particulate composites. Distinct phases of BNT and NZFO were confirmed by X-ray diffraction and scanning electron microscopy. Raman spectroscopy measurement showed the absence of micro-strains within the composite. The temperature dependent dielectric studies revealed the ferroelectric to anti-ferroelectric transition at 220 °C and anti-ferroelectric to paraelectric transition at 320 °C. The ac conductivity showed both frequency dependent and independent behavior. Temperature dependent dc conductivity showed that upto 200 °C charge conduction is due to hopping of electrons, whereas at higher temperature diffusion of oxygen vacancies are responsible for the conduction. Ferroelectric and leakage current density measurements showed enhanced conduction losses with NZFO content. The maximum ME coefficient at 10 Hz frequency is obtained for 0.80BNT–0.20NZFO (4.33 mV/cm.Oe at 800 Oe).

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The magnetoelectric (ME) composites has gained great deal of attention over to single phase multiferroics due to its strain mediated ME coupling between piezoelectric and magnetostrictive phase [1, 2, 3]. Such ME composites with high coupling have paved the way for practical device application in meRAMs, sensors, and low frequency energy harvesters etc. [4, 5, 6, 7, 8]. The resultant ME coupling depends upon the type of magnetic and piezoelectric phase, their relative fraction, and type of geometry [9, 10]. Among the choices, Pb-based piezoelectric materials showed highest ME coupling due to its high piezoelectric coefficient (d33), high remanent polarization (Pr) and low coercivity (Ec) [11, 12]. Several reports on Pb-based ME composites as energy harvesters evidences its enormous ME response [13, 14, 15]. However, the hazardous effect of Pb, inclined researchers to explore the environment friendly alternate piezoelectric phase with slightly compromised properties [16, 17, 18, 19]. One of the most investigated piezoelectric phase is Bi0.5Na0.5TiO3 (BNT) which possess good Pr ~ 38 μC cm−2, moderate d33 ~ 58–95 pC/N and high temperature sustainability upto 320 °C [20, 21, 22]. On the other hand, spinel NiFe2O4 (NFO) is suitable magnetic phase as it exhibit strong piezomagnetic coefficient (dλ/dH ~ 251 ppm/T), good saturation magnetization (Ms ~ 55 emu/g) and low coercivity (Hc ~ 180 Oe) [23, 24, 25]. Further, the partial substitution of Ni2+ by Zn2+ enhances the MS as well dλ/dH [26, 27, 28].

Several studies on BNT based composites with different spinel ferrites were carried out and demonstrated the presence of ME coupling (4.0–7.5 mV/cm.Oe) [29, 30, 31, 32]. However, the applied frequency and dc magnetic field was 1 kHz and 3–5 kOe respectively, which is relatively high for device realization. In this work, composites of BNT and Ni0.5Zn0.5Fe2O4 (NZFO) were prepared by microwave sintering and their structural, dielectric and ME properties were investigated. The ME coupling of 4.3 mV/cm.Oe at very low magnetic field (800 Oe) and frequency (10 Hz) is observed, which indicate this ME composite could be a potential material, where low frequency is prerequisite requirement.

2 Experimental

High purity Bi(NO3)3 5H2O, CH3COONa, TiC12H28O4, Fe(NO3)3 9H2O, Ni(NO3)2 5H2O, and Zn(NO3)2 6H2O, were used to synthesized BNT and NZFO powders. The respective phase precursors were weighed in stoichiometry ratio and dissolved in acetic acid, and 2-methoxy ethanol for preparing solution of BNT and in deionized water, and citric acid for synthesizing solution of NZFO. The pH for solution of NZFO was maintained at 7 by adding ammonia into it. These solutions were continuously stirred and set at 120 °C till the gel formation. The obtained gels were dried at 180 °C and a white powder was obtained for BNT whereas the combustion has taken place for NZFO. The as-synthesized powders of BNT and NZFO were calcined at 600 °C and 900 °C respectively for 3 h. To prepare (1−x)BNT–xNZFO composites (x = 0.05–0.30; Δx = 0.05), the appropriate weight ratio of calcined powders were wet mixed using planetary ball mill for 3 h. The rpm and charge to ball ratio were fixed to 250 and 1:5 respectively. After mixing, powders were dried and uniaxially pressed into cylindrical pellets at a pressure of 50 MPa. The sintering of as-pressed pellets were carried out in microwave furnace at 1050 °C for 1 h. The phase identification of sintered pellets were carried out by X-ray diffraction (XRD) (X'PERT Pro, PANalytical) pattern, using Cu–Kα radiation. Raman spectroscopy was carried out by Micro-Raman Spectrometer (Labram HR Confocal, Horiba, France) (instrumental resolution ± 1 cm−1) equipped with a 532 nm diode pumped solid state laser at 25 mW power. A field emission gun-scanning electron microscopy (FEG–SEM) (Sigma 500, Carl-Zeiss, Germany) was used to study the microstructure of the samples. Prior to electrical and ME measurements, silver paint was used on both surfaces of the pellets. The frequency dependent dielectric measurements (100 Hz–1 MHz) were carried out using impedance analyzer (Solarton I-1260, UK) at 40–400 °C. The composite specimens were poled for ferroelectric measurements at 10 kV with 2 cm tungsten needle to specimen distance using Corona poling unit (Millman thin films PVT. LTD. Pune, India). Keithley (6517B, USA) electrometer was used to measure the leakage current density (J) with varying dc electric field (E). The d33 measurements were carried out using d33 meter (Sinocera, YE2730A, China). Ferromagnetic studies were done by vibrating sample magnetometer (VSM) (Lakeshore-7404, USA). Further, the Precision multiferroic-II system (Radiant Technology, USA) was used for ferroelectric and ME voltage coefficient (αME) measurements. The ME measurements were carried out in an applied ac magnetic field of 3 Oe at 10 Hz using Helmholtz coil (Lakeshore MH-6, USA). The dc magnetic field was varied using electromagnets (GMW 5480, USA). In this charge (q) and capacitance (C) was measured with Hdc at fixed Hac. The calculated voltage (Vout = q/C) was used to determine αME in terms of thickness (t) and Hdc as

3 Results and Discussions

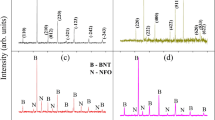

Figure 1 shows the representative XRD pattern of sintered 0.80BNT–0.20NZFO composite refined with rhombohedral (R3c) and cubic (Fd3m) phases. Both BNT and NZFO phases coexists without any impurity, which suggests no intermediate reaction has taken place among the phases within the used sintering conditions. The refined parameters, Rexp, Rwp were closed to 20 and χ2 is nearly 1 that suggests good agreement between obtained and fitted patterns. No changes in the lattice parameters and characteristic peak positions were observed for both the phases with obvious reasons. The obtained phase fraction from the refinement is comparable with the relative weight fraction of individual phases that used to prepare composites.

Figure 2 depicts the Raman spectra of BNT, NZFO and 0.80BNT–0.20NZFO specimens ranging from 100 to 750 cm−1. As suggested by group theory all 3 Raman active modes (A, B and C) are observed for BNT and in close agreement with previous studies [15, 17]. The bands A, B and C demonstrate the vibrations of Bi/Na–O, Ti–O, and Ti–O6 octahedra respectively. Further, these bands were deconvoluted with eight peaks that expressed the stretching and bending of the metal–oxygen bonds. The spectra of NZFO showed three Raman bands denoted by M, N and O. The M and N are related to symmetric stretching and anti-symmetric bending of metal–oxygen bonds at octahedral site respectively, whereas O corresponds to stretching at tetrahedral site [33]. The deconvoluted Raman peak positions of pure BNT and NZFO is tabulated in Table 1. In composites, the peaks of both the phases have been observed. However, low intensity of NZFO peaks ascribed to its low volume fraction. It is to be noted that similar to XRD, no change in peak position is observed, which denied the presence of micro-strain towards bond compression/stretching along interphase boundaries.

Figure 3 shows the representative backscattered electron images along with elemental mapping of 0.80BNT–0.20NZFO sintered composite. A dense microstructure with well distinguished sharp interphase boundaries of BNT (bright) and NZFO (dark) is clearly visible in the composite samples. Both phases have equiaxed grains with similar size distribution of 1–3 μm. However, the BNT shows larger fraction of coarse grains due to its higher phase fraction, whereas grain growth of NZFO may be hindered by the major BNT phase. The NZFO phase is found to be agglomerated as a consequence of mechanical mixing. The elemental mapping (Fig. 3b) along with individual elements present confirms BNT and NZFO grains as bright and dark contrast respectively in the samples. Mapping of Na element is beyond the detection limit of the equipment.

Figure 4 depicts the temperature (T) dependent dielectric constant (εr) and loss tangent (tanδ) at 1 MHz for (1−x)BNT–xNZFO specimens. For pure BNT and 0.90BNT–0.10NZFO specimens, εr found to increase gradually with temperature upto 220 °C and then a sharp increase has been observed. Previously, temperature dependent XRD and neutron diffraction studies suggested ferroelectric to anti-ferroelectric phase transition (referred as depolarization temperature, Td), with a corresponding change in the crystal structure i.e., rhombohedral to tetragonal respectively [34, 35]. The enlarged view of tanδ for BNT (inset Fig. 4b) also confirmed the transition at 220 °C. The anomalous increase in εr upto 320 °C suggests that transition is not sharp and persists till 400 °C [36]. This increase in εr despite the occurrence of antiferroelectric phase, may be ascribed to the existence of interphase boundaries which contributes to the polarization. The decrease in εr above 320 °C (Tm) is due to antiferroelectric to paraelectric phase transition as supported by sharp increase in tanδ after 320 °C [36] The composite with higher NZFO (x > 0.10) content showed diffuse phase transition behavior, which is usually observed in ME composites [37, 38].

Figure 5 showed the frequency dependent conductivity (σac) plots for BNT-NZFO specimens at different temperatures. The σac is calculated by the formula [39, 40],

here ε0 is absolute permittivity in free space, ε″ is imaginary permittivity of specimen and ω = 2пf is angular frequency. The plot appears to be the combination of plateau and inclined conductivity regions. According to the Jonscher’s power law, the plateau indicates the dc conductivity (σdc) and inclined region represent frequency dependent conductivity (Aωn). Therefore, σac can be written as [41]

The increase in conductivity with frequency suggests that the conduction is governed by hopping of charge carriers between the localized state in accordance to Jump relaxation model (JRM) [42, 43]. On increasing temperature, thermally activated charge carriers contribute towards conduction. At sufficiently high temperatures, the contribution of frequency dependent conductivity is relatively small within the studied frequency range. Further Arrhenius plot of dc conductivity (σdc) for (1−x)BNT–xNZFO specimens are shown in Fig. 6. The activation energy (Eg) is calculated by

where K is the Boltzmann constant.

The conductivity increases with temperature for each specimen that represents their semiconducting behavior. Two slopes in low and high temperature regime are observed and suggests the different types of carriers are responsible for the conduction. At low temperatures, the conduction is governed by the hopping of electrons, while at high temperature the diffusion of oxygen vacancy contributes [44]. The increase in interphase boundaries fraction with NZFO content, restricts the movement of oxygen vacancies and consequently requires higher Eg as observed.

The ferroelectric behavior of (1−x)BNT–xNZFO specimens is confirmed by their RT P–E loops at 10 Hz as shown in Fig. 7a.

A well saturated hysteresis has been observed for x = 0.00 and x = 0.05. Further increase of low resistive NZFO phase enhances the conduction losses, result in low field sustainability and unsaturated loops of composites. The obvious decrease in Pr is found with non-ferroelectric NZFO phase induction as shown in Table 2. Figure 7b depicts the E dependent bipolar strain plot of BNT–NZFO specimens. A normalized strain of 105.2 pm/V has been observed in pure BNT, which is decreased in composites with NZFO content. Further, an obvious declined trend in d33 is observed with NZFO content as tabulated in Table 2. The enhancement of conduction losses with NZFO content in composite specimens is confirmed by J–E plots as shown in Fig. 7c. The sharp increase in J till 0.5 kV/cm attributes to the space charge conduction. Above 0.5 kV/cm, gradual increase of J indicates the contribution of grain boundaries, and Poole-Frankel emission [45, 46]. The M–H loops for (1−x)BNT–xNZFO specimens are shown in Fig. 7d. The saturation magnetization (Ms) increases in composites due to high magnetic phase (NZFO) content.

The ME coupling is a product tensor of both ferroelectric and ferromagnetic characteristics. As composite has exhibited both ferroelectric and ferromagnetic properties, a large ME response in such specimens is expected. The ME coefficient (αME) for all composites as a function of dc magnetic field (Hdc) with an ac field (Hac) of 3 Oe at 10 Hz has shown in Fig. 8a. The αME increases with Hdc till 800 Oe and decreases afterward that suggest the maximum strain mediated coupling occurred at 800 Oe. As NZFO content increases αME also increases upto x = 0.20 content and thereafter decreases (Fig. 8b). The maximum obtained value of αME is 4.33 mV/cm.Oe for 0.80BNT–0.20NZFO composite. The low αME for composite below x = 0.20 is due to the small fraction of magnetostrictive phase. For x > 0.20, the lower value of αME is due to the excess amount of NZFO content that have high J and limits the poling effect in composite [47]. Further, the effect of f on αME has been investigated as shown in Fig. 8c. No noticeable changes have been observed with f that suggest the linear behavior of αME at off-resonance f condition [48, 49], which is further supported by identical behavior of αME for 0.8 BNT–0.2 NZFO with Hdc at different f as shown in Fig. 8d. The high value of αME at low frequency is not reported so far, which indicates the potential of material. A comparative of BNT based ME composites is shown in Table 3.

4 Conclusion

Lead-free ME particulate composite of BNT–NZFO were successfully synthesized. The coexistence of both phases was confirmed by XRD and FEG-SEM. The Raman spectroscopy suggested absence of interfacial micro-strains between BNT and NZFO phase. The temperature dependent dielectric study displayed the Td (~ 220 °C) and Tm (~ 320 °C) for pristine BNT and 0.90BNT-0.10NZFO specimens. However, such transition temperatures were obscured in 0.80BNT–0.20NZFO and 0.70BNT–0.30NZFO. The frequency dependent σac plot at different temperature followed the Jump relaxation model. The value of Eg was found to be increased with NZFO content that suggest the interphase boundaries restrict the movement of charge carriers. The NZFO content enhanced the ferroelectric losses and leakage current density in composites. An obvious increase in Ms with NZFO content were observed in composites. All samples showed good ME coupling and highest value of 4.33 mV/cm.Oe at 800 Oe was obtained for 0.80BNT–0.20NZFO at 10 Hz.

References

Chu, Z., Pourhosseiniasl, M., Dong, S.: Review of multi-layered magnetoelectric composite materials and devices applications. J. Phys. D Appl. Phys. 51, 1–21 (2018). https://doi.org/10.1088/1361-6463/aac29b

Yu, S., Huang, H., Zhou, L., et al.: Structure and properties of PMN–PT/NZFO laminates and composites. Ceram. Int. 34, 701–704 (2008). https://doi.org/10.1016/j.ceramint.2007.09.011

Rani, A., Kolte, J., Vadla, S.S., Gopalan, P.: Structural, electrical, magnetic and magnetoelectric properties of Fe doped BaTiO3 ceramics. Ceram. Int. 42, 8010–8016 (2016). https://doi.org/10.1016/j.ceramint.2016.01.205

Pradhan, D.K., Kumari, S., Rack, P.D.: Magnetoelectric composites: applications, coupling mechanisms, and future directions. Nanomaterials 10, 1–22 (2020). https://doi.org/10.3390/nano10102072

Li, P., Wen, Y., Huang, X., et al.: Wide-bandwidth high-sensitivity magnetoelectric effect of magnetostrictive/piezoelectric composites under adjustable bias voltage. Sensors Actuators A Phys. 201, 164–171 (2013). https://doi.org/10.1016/j.sna.2013.07.005

Zhou, Y., Apo, D.J., Priya, S.: Dual-phase self-biased magnetoelectric energy harvester. Appl. Phys. Lett. 103, 1–5 (2013). https://doi.org/10.1063/1.4829151

Song, H., Hwang, G.-T., Ryu, J., Choi, H.: Stable output performance generated from a magneto-mechano-electric generator having self-resonance tunability with a movable proof mass. Nano Energy 101, 107607 (2022). https://doi.org/10.1016/j.nanoen.2022.107607

Annapureddy, V., Palneedi, H., Hwang, G.T., et al.: Magnetic energy harvesting with magnetoelectrics: an emerging technology for self-powered autonomous systems. Sustain. Energy Fuels 1, 2039–2052 (2017). https://doi.org/10.1039/c7se00403f

Pattanayak, R., Raut, S., Kuila, S., et al.: Multiferroism of [Na0.5Bi0.5TiO3–BaFe12O19] lead-free novel composite systems. Mater. Lett. 209, 280–283 (2017). https://doi.org/10.1016/j.matlet.2017.08.023

Fernandez Perdomo, C.P., Kiminami, A.R.H.G., Garcia, D.: Microwave assisted sintering of nanocristalline PMN–PT/CoFe2O4 prepared by rapid one pot pechini synthesis: dielectric and magnetoelectric characteristics. Ceram. Int. 45, 7906–7915 (2019). https://doi.org/10.1016/j.ceramint.2019.01.101

Guo, R., Cross, L.E., Park, S.E., et al.: Origin of the high piezoelectric response in PbZr1-xTixO3. Phys. Rev. Lett. 84, 5423–5426 (2000). https://doi.org/10.1103/PhysRevLett.84.5423

Tyagi, M., Kumari, M., Chatterjee, R., Sharma, P.: Large magnetoelectric response in modified BNT based ternary piezoelectric [72.5(Bi1/2Na1/2TiO3)–22.5(Bi1/2K1/2TiO3)–5(BiMg1/2Ti1/2O3)]-magnetostrictive (NiFe2O4) particulate (0–3) composites. Appl. Phys. Lett. 106, 1–4 (2015). https://doi.org/10.1063/1.4921521

Ryu, J., Kang, J.E., Zhou, Y., et al.: Ubiquitous magneto-mechano-electric generator. Energy Environ. Sci. 8, 2402–2408 (2015). https://doi.org/10.1039/c5ee00414d

Annapureddy, V., Na, S.M., Hwang, G.T., et al.: Exceeding milli-watt powering magneto-mechano-electric generator for standalone-powered electronics. Energy Environ. Sci. 11, 818–829 (2018). https://doi.org/10.1039/c7ee03429f

Song, H., Patil, D.R., Yoon, W.H., et al.: Significant power enhancement of magneto-mechano-electric generators by magnetic flux concentration. Energy Environ. Sci. 13, 4238–4248 (2020). https://doi.org/10.1039/d0ee01574a

Venkata Ramana, E., Zavašnik, J., Graça, M.P.F., Valente, M.A.: Magnetoelectric studies on CoFe2O4/0.5(BaTi0.8Zr0.2O3)-0.5(Ba0.7Ca0.3TiO3) lead-free bilayer thin films derived by the chemical solution deposition. J. Appl. Phys. 120, 1–10 (2016). https://doi.org/10.1063/1.4961394

Shrout, T.R., Zhang, S.J.: Lead-free piezoelectric ceramics: Alternatives for PZT? J. Electroceram. 19, 111–124 (2007). https://doi.org/10.1007/s10832-007-9047-0

Saito, Y., Takao, H., Tani, T., et al.: Lead-free piezoceramics. Nature 432, 84–87 (2004). https://doi.org/10.1038/nature03028

Singh, P., Laishram, R., Sharma, P., Kolte, J.: Giant magnetocapacitance in magnetoelectric BNT/NFO particulate composites. J. Mater. Sci. Mater. Electron. 32, 21288–21296 (2021). https://doi.org/10.1007/s10854-021-06631-w

Niranjan, M.K., Karthik, T., Asthana, S., et al.: Theoretical and experimental investigation of Raman modes, ferroelectric and dielectric properties of relaxor Na0.5Bi0.5TiO3. J. Appl. Phys. 113, 1–7 (2013). https://doi.org/10.1063/1.4804940

Karthik, T., Asthana, S.: Polarization extension mechanism revealed through dynamic ferroelectric hysteresis and electric field driven structural distortions in lead free Na0.5Bi0.5TiO3 ceramic. J. Phys. D Appl. Phys. 50, 1–6 (2017). https://doi.org/10.1088/1361-6463/aa7fa7

Sahu, M., Karthik, T., Srinivas, A., Asthana, S.: Structural and microstructural correlation with ferroelectric and dielectric properties of nanostructured Na0.5Bi0.5TiO3 ceramics. J. Mater. Sci. Mater. Electron. 26, 9741–9746 (2015). https://doi.org/10.1007/s10854-015-3643-6

Narendra Babu, S., Hsu, J.H., Chen, Y.S., Lin, J.G.: Magnetoelectric response in lead-free multiferroic NiFe2O4–Na0.5Bi0.5TiO3 composites. J. Appl. Phys. 109, 1–3 (2011). https://doi.org/10.1063/1.3540623

Bichurin, M., Petrov, V., Zakharov, A., et al.: Magnetoelectric interactions in lead-based and lead-free composites. Materials (Basel) 4, 651–702 (2010). https://doi.org/10.3390/ma4040651

Jaffe, H.: Piezoelectric ceramics. J. Am. Ceram. Soc. 41, 494–498 (1958). https://doi.org/10.1111/j.1151-2916.1958.tb12903.x

Costa, A.C.F.M., Silva, V.J., Cornejo, D.R., et al.: Magnetic and structural properties of NiFe2O4 ferrite nanopowder doped with Zn2+. J. Magn. Magn. Mater. 320, 370–372 (2008). https://doi.org/10.1016/j.jmmm.2008.02.159

Zhang, Y.Z., Kang, Z.T., Chen, D.: Process of synthesizing high saturation magnetization Ni0.5Zn0.5Fe2O4 by microwave assisted ball milling. Mater. Lett. 133, 259–261 (2014). https://doi.org/10.1016/j.matlet.2014.07.031

Atif, M., Nadeem, M., Grössinger, R., Turtelli, R.S.: Studies on the magnetic, magnetostrictive and electrical properties of sol–gel synthesized Zn doped nickel ferrite. J. Alloys Compd. 509, 5720–5724 (2011). https://doi.org/10.1016/j.jallcom.2011.02.163

Kumar, Y., Yadav, K.L., Manjusha, J., et al.: Structural, dielectric, magnetic and magnetoelectric properties of (x)Bi0.5Na0.5TiO3–(1–x)Ni0.2Co0.8Fe2O4 composites. Mater. Res. Exp. 3, 1–9 (2016). https://doi.org/10.1088/2053-1591/3/6/065701

Manjusha, Yadav KL., Adhlakha, N., et al.: Strain mediated magnetoelectric coupling induced in (x)Bi0.5Na0.5TiO3–(1–x)MgFe2O4 composites. Phys. B Condens. Matter. 514, 41–50 (2017). https://doi.org/10.1016/j.physb.2017.03.027

Kumar, Y., Yadav, K.L., Shah, J., Kotnala, R.K.: Investigation of magnetoelectric effect in Bi0.5Na0.5TiO3–CoMn0.2Fe1.8O4 composites. IEEE Trans. Dielectr. Electr. Insul. 26, 561–567 (2019). https://doi.org/10.1109/TDEI.2019.007577

Bhasin, T., Agarwal, A., Sanghi, S., et al.: Crystal structure, dielectric, magnetic and improved magnetoelectric properties of xNiFe2O4–(1–x)Na0.5Bi0.5TiO3 composites. Mater. Res. Exp. 5, 1–15 (2018). https://doi.org/10.1088/2053-1591/aad9e3

Jadhav, J., Biswas, S., Yadav, A.K., et al.: Structural and magnetic properties of nanocrystalline Ni–Zn ferrites: in the context of cationic distribution. J. Alloys Compd. 696, 28–41 (2017). https://doi.org/10.1016/j.jallcom.2016.11.163

Xu, C., Lin, D., Kwok, K.W.: Structure, electrical properties and depolarization temperature of (Bi0.5Na0.5)TiO3–BaTiO3 lead-free piezoelectric ceramics. Solid State Sci. 10, 934–940 (2008). https://doi.org/10.1016/j.solidstatesciences.2007.11.003

Tan, X., Ma, C., Frederick, J., et al.: The antiferroelectric ↔ ferroelectric phase transition in lead-containing and lead-free perovskite ceramics. J. Am. Ceram. Soc. 94, 4091–4107 (2011). https://doi.org/10.1111/j.1551-2916.2011.04917.x

Jones, G., Thomas, P.A.: Investigation of the structure and phase transitions in the novel A-site substituted distorted perovskite compound Na0.5Bi0.5TiO3. Acta Crystallogr. Sect. B 58, 168–178 (2002)

Ciomaga, C.E., Neagu, A.M., Pop, M.V., et al.: Ferroelectric and dielectric properties of ferrite-ferroelectric ceramic composites. J Appl Phys 113, 1–8 (2013). https://doi.org/10.1063/1.4792494

Rathore, S.S., Vitta, S.: Large low field room temperature magneto-dielectric response from (Sr0.5Ba0.5)Nb2O6/Co(Cr0.4Fe1.6)O4 bulk 3–0 composites. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 204, 1–7 (2016). https://doi.org/10.1016/j.mseb.2015.11.002

Elliott, S.R.: A.c. conduction in amorphous chalcogenide and pnictide semiconductors. Adv. Phys. 36, 135–217 (1987). https://doi.org/10.1080/00018738700101971

Long, A.R.: Frequency-dependent loss in amorphous semiconductors. Adv. Phys. 31, 553–637 (1982)

Jonscher, A.K.: Review a new understanding of the dielectric relaxation of solids. J. Mater. Sci. 16, 2037–2060 (1981)

Solid, P.S., Chem, S.: Jump relaxation in solid electrolytes. Prog. Solid State Chem. 22, 111–195 (1993)

Sharma, R., Pahuja, P., Tandon, R.P.: Structural, dielectric, ferromagnetic, ferroelectric and ac conductivity studies of the BaTiO3-CoFe1.8Zn0.2O4 multiferroic particulate composites. Ceram. Int. 40, 9027–9036 (2014). https://doi.org/10.1016/j.ceramint.2014.01.115

Tirupathi, P., Mandal, S.K., Chandra, A.: Effect of oxygen annealing on the multiferroic properties of Ca2+ doped BiFeO3 nanoceramics. J. Appl. Phys. 116, 1–14 (2014). https://doi.org/10.1063/1.4904861

Dietz, G.W., Antpöhler, W., Klee, M., Waser, R.: Electrode influence on the charge transport through SrTiO3 thin films. J. Appl. Phys. 78, 6113–6121 (1995). https://doi.org/10.1063/1.360553

Li, G., Wu, X., Ren, W., Shi, P.: Effect of excessive K and Na on the dielectric properties of (K, Na)NbO3 thin films. Thin Solid Films 548, 556–559 (2013). https://doi.org/10.1016/j.tsf.2013.09.027

Ryu, J., Priya, S., Uchino, K., Kim, H.: Magnetoelectric effect in composites of magnetostrictive and piezoelectric materials. J Electroceram. 8, 107–119 (2002). https://doi.org/10.1023/A:1020599728432

Kang, M.G., Sriramdas, R., Lee, H., et al.: High power magnetic field energy harvesting through amplified magneto-mechanical vibration. Adv. Energy Mater. 8, 1–11 (2018). https://doi.org/10.1002/aenm.201703313

Annapureddy, V., Kim, M., Palneedi, H., et al.: Low-loss piezoelectric single-crystal fibers for enhanced magnetic energy harvesting with magnetoelectric composite. Adv. Energy Mater. 6, 1–10 (2016). https://doi.org/10.1002/aenm.201601244

Krishnaiah, R.V., Srinivas, A., Kamat, S.V., et al.: Effect of CoFe2O4 mole percentage on multiferroic and magnetoelectric properties of Na0.5Bi0.5TiO3/CoFe2O4 particulate composites. Ceram. Int. 40, 7799–7804 (2014). https://doi.org/10.1016/j.ceramint.2013.12.123

Acknowledgements

The authors acknowledge DRDO, New Delhi for providing the grant through project (No. ERIP/ER/201709007/M/01/1731) to carry out this research. We are very thankful to DST (FIST-I & II) for providing VSM, FEG-SEM, Raman, and multiferroic measurement facility.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, P., Laishram, R., Kolte, J. et al. Low Frequency Magnetoelectric Effect in Bi0.5Na0.5TiO3–Ni0.5Zn0.5Fe2O4 Particulate Composites. Electron. Mater. Lett. 19, 442–451 (2023). https://doi.org/10.1007/s13391-023-00423-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-023-00423-6