Abstract

This work investigates the physical–thermal properties of nanofluids made from graphene powder, propylene glycol, and water. Propylene glycol and water were mixed in the following ratios to make nanofluids: 100:0, 75:25, and 50:50. Graphene was added at 0.25 and 0.5% of the mixture's volume to the three base fluids. Nanofluids' viscosity, density, thermal conductivity, and specific heat are studied. After mixing with graphene nanopowder, critical fluids increased in density and thermal conductivity. Essential fluids showed these advantages. When the temperature was elevated, viscosity and specific heat decreased. Despite constant temperatures, this was the case. Increasing graphene concentration increases thermal conductivity by 10–16%. The viscosity of nanofluids with graphene nanopowder is less affected by temperature. As temperature rises, nanofluid density falls. Temperature and density are inversely related; thus, this makes sense. Adding graphene to propylene glycol at different concentrations increased its specific heat by 8–14%, depending on the concentration.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nanotechnology may be used to change several material properties. Nanoparticles improve cooling systems. In addition, nanotechnology has produced nanofluids. Particles are distinct in movement and properties. Ultrafine particles are 1–100 nm in size. Nanoparticles may have size-linked properties that differ from microscopic particles or entire materials. Nanoparticle research has potential mechanical, biological, and electrical uses [1, 2]. Several disciplines have used nanofluids for decades. They may improve industrial heat transfer. Since nanofluids were invented, scientists have concentrated more on making them heat-conducting than thinner. A nanofluid is a combination of nanoparticles and a base fluid. According to studies [1,2,3,4], specific heat and thermal conductivity increase with temperature on graphene nanopowder in nanofluids. The temperature lowered the viscosity and density. Nanofluids offer better thermal conductivity and viscosity than microfluidics for heat transfer applications.

Scientists have studied how nanomaterials may improve heat transfer since the 1990s. They studied heat transfer in ultra-efficient cooling systems. Nanofluids have significant potential for usage in electrical and chemical engineering, automotive, construction, microelectronics, knowledge, and other industries [17]. Numerous combinations of metallic oxide nanoparticles have been used to create and test nanofluids: CuO, Al2O3, TiO2, and Fe3O4 nanoparticles. A medium-sized solar thermal system's thermic fluid must stay liquid under high heat fluxes. Boiling and vaporization heighten the danger of overheating and system failure. Solar thermal heat transfer fluids need a high boiling point [18]. Assessment of the nanofluids' thermophysical properties is also important for determining their solar thermal suitability.

Leena et al. [3], in their work, explained the thermophysical properties of TiO2/propylene glycol water nanofluids for heat transfer applications. Naik et al. [4] investigated the rheological property of copper oxide nanoparticles suspended in propylene glycol water-based fluids. Satti et al. [5] in their work explained the investigation of the thermal conductivity of propylene glycol nanofluids. It was very challenging during the study with nanofluids because of their low heat conductivity (700 °C) and high 700 °C viscosity [6]. Thermophysical research on base fluids has been conducted for 20 years. Adding nanoparticles to a base liquid may increase its heat conductivity and viscosity. Nanofluids' thermal conductivity, viscosity, density, and specific gravity are studied. Kakac et al. [7] reviewed numerous nanofluid properties. These studies discuss preparation and characterization methods for evaluating thermal conductivity, thermophysical properties, and convective heat transfer coefficients (HTC). Nanofluids have a high thermal conductivity and heat transfer coefficient despite a slight increase in viscosity. Das et al. [8] explored nanofluid heat transfer. Existing theories could not explain these nanofluids' enhanced thermal conductivity. Liquid suspensions show no sign of a micrometer-scale change. Pak and Cho [9] studied fluid flow and heat transmission using submicron metal oxide particles. Furthermore, nanofluids and 3% water had lower convective heat transfer coefficients at a given average velocity. To achieve this, more significant, more thermally conductive particles were suggested. Reddy and Rao [10] studied ethylene glycol and water at three nanoparticle concentrations. Nanofluids are created from water, 40% ethylene glycol, and 60% water, or ethylene glycol and water (50:50). When nanoparticle volume and temperature both increased, TC rose from 30 °C to 70 °C. GaweZya and Jacek Fal [11] tested the viscosity, electrical conductivity, and thermal conductivity of ethylene glycol-coated nano-SiO2. The conductivity of nanofluids is measured. Nanoparticle concentration increases nanofluids' electrical and thermal conductivity and heat transfer efficiency. Sharma and Raja Sekhar [12] studied water's heat capacity and viscosity using 48-nm alumina nanoparticles. Nanofluids are nanoparticles in distilled water. In addition, nanofluid viscosity was tested between 250 and 450 °C. Particle aggregation affects viscosity nonlinearly. Furthermore, improved thermal diffusivity reduces nanofluid-specific heat. In addition, regression equations derive viscosity and specific heat capacity using particle concentration, diameter, and temperature. Titania-Silica hybrid nanofluid distributed in 60:40 water/ethylene glycol would boost thermal conductivity and dynamic viscosity, according to RizalmanMamat et al. [13] Between 5 and 3% volume concentrations produced a stable TiO2/SiO2 dispersion. The thermal conductivity of nanofluids increased with concentration and temperature. The concentration and temperature of a nanofluid determine its viscosity. Nanofluid dynamics remained Newtonian up to 3% volume. Shyam Sundar et al. [14] examined alumina nanoparticles in nanofluids. Solvents were 20–60% ethylene glycol and water. 0.2% to 1.6% of volume were examined for thermal conductivity and viscosity.

In addition, the nanofluid thermal conductivity increases with concentration and temperature. Furthermore, nanofluid viscosity decreases with temperature and volume concentration. 20:80 EG-water nanofluid thermal conductivity was 33% greater at 1.5% volume concentration and 60 °C. A 60:40 EG-water nanofluid has 2.58 times the base fluid's viscosity at 0 °C. Sharma et al. [15] tested nanofluids containing titanium dioxide in a circular tube with turbulent flow. Viscosity and thermal conductivity were sampled from 30 to 800 degrees Celsius. At 600 °F and 1.5 vol%, thermal conductivity increased by 16%. From 30 to 700 degrees, the relative viscosity changed by 4.6–33.3%. Nusselt increased by 23% at 500 °C and 29% at 700C. More nanofluid increased friction. Temperature and concentration impact nanofluids' thermal conductivity, viscosity, and heat transfer coefficient. Zhang et al. [16] used a transient short hot wire to measure the thermal conductivity and thermal diffusivity of nanogold, nanoalumina, nanotitania, and nanocopper oxide nanofluids. The smallest spherical particle measured 34 nm, largest 41 nm. Propylene glycol is the basis fluid in this study, combined with graphene nanopowder, which is new. Various quantities of water are added, and the thermal conductivity, viscosity, density, and specific heat are noted. Table 1 summarizes studies on the viscosity of nanofluids by other researchers with the correlations proposed:

This study uses graphene powder mixed with propylene glycol and water to create nanofluids to investigate their physical–thermal properties. Various nanofluids were produced by mixing propylene glycol and water in the following proportions: 100:0, 75:25, and 50:50. Increasing graphene concentration increases thermal conductivity, whereas the viscosity of nanofluids with graphene nanopowder is less affected by temperature. As temperature rises, nanofluid density falls. Adding graphene to propylene glycol at different concentrations increased its specific heat. The main objective of the present work is to check how the nanofluid will enhance the thermophysical properties by changing the nanopowder concentration up to what extent there is improvement or decrement in the properties.

2 Materials and Methodology

The main liquid ingredient in these compositions, propylene glycol, was purchased from Naveen Chem. The International Union of Pure and Applied Chemistry (IUPAC) describes propylene glycol as a thick, colorless liquid with a flavor that may be somewhat agreeable. Propane-1,2-diol is another name for propylene glycol. The chemical formula for this compound is CH3CH(OH)CH2OH. It is categorized as a diol since it contains two distinct alcoholic functional groups. Numerous solvents, including water, acetone, and chloroform, may dissolve it. Glycols have very little volatility and don't irritate in their natural condition. There are several uses for propylene glycol, including making polymers and using them in the food and beverage sectors.

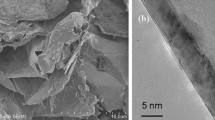

Atomic sheets are arranged in two dimensions in a honeycomb crystal lattice to form carbon nanostructures like graphene. To indicate the many double bonds found in graphite, the prefix "-ene" (derived from "graphite") was added. Each atom in a graphene sheet contributes one electron to its overall valence band, forming a solid connection with the three bits next to it. This bonding may be found in glassy carbon, PAHs, fullerenes, and carbon nanotubes. Because the conduction and valence bands are in contact with one another, graphene is a semimetal with exceptional electrical properties that may be described using theories for massless relativistic particles. These hypotheses help explain the characteristics of graphene. The linear rather than quadratic energy dependence on the momentum of the charge carriers makes graphene field-effect transistors capable of bipolar conduction. The material shows ballistic charge transport over large distances, massive nonlinear diamagnetism, and gigantic quantum oscillations. Heat and electricity can be conducted exceptionally well via the graphene plane. Because of its high ability to absorb visible light, graphite seems entirely black. Graphene is a material, yet a single sheet of it is so thin that it is almost transparent. This combination is about 100 times more potent than the stiffest steel. Due to its extraordinary tensile strength, electrical conductivity, opacity, and status as the world's most durable material, graphene is well known as a valuable and practical nanomaterial.

The strongest and thinnest two-dimensional material in existence is called graphene. The majority of graphene demand in 2012 came from the research and development segments of the semiconductor, electronics, electric battery, and composites industries, which helped to drive the $9 million worldwide graphene market. Graphene nanopowder was procured from Ultrananotech Pvt. Ltd. Graphene is > 99% pure and has a 5–10 nm thickness. This study will examine the physical–thermal characteristics of nanofluids made of water, propylene glycol, and graphene powder. Using propylene glycol and water in ratios of 100:0, 75:25, and 50:50, several nanofluids were created. Each of the two distinct types of base fluids received an addition equal to 0.25 and 0.5% of the total volume of the combination.

2.1 Thermal Conductivity Enhancement

A material's thermal conductivity is a measurement that can determine how well it moves heat by letting heat pass through them. One of the many methods that may be used to determine this knowledge is to investigate the degree to which the material conveys thermal energy. The temperature rise causes an increase in the kinetic energy of the molecules. This, in turn, leads the molecules to collide with one another more often and at higher rates of speed. Due to this, the material can transmit heat more efficiently. This makes it a more effective conductor of heat. The procedure for establishing the rate at which heat may be transferred from liquids to solids is likely one that must be carried out over an extended period to be successful. This is because convection is responsible for the transfer of heat throughout the fluid while the test is being carried out, and as a consequence, this result may be linked to the phenomenon that convection is. This is because convection transfers heat throughout the fluid, while the test is carried out. However, thermal conductivity has been measured by using KD2 thermal pro analyzer.

2.2 Viscosity Measurement

In order to evaluate of propylene glycol–water nanofluid, Redwood Viscometer was presented. However, a fluid's viscosity indicates how much it resists changing shape at a given pace. Shear stress decreases with temperature, leading to less viscosity. Increasing temperatures cause molecules in a liquid to become restless and migrate. Because of the additional energy imparted by this motion, the forces that keep the molecules together are being overcome, and the liquid becomes less viscous and more fluid. Using phenomenological hydrodynamic equations, Einstein [17] first determined the effective viscosity of colloidal spherical solids. The effective viscosity of nanofluids was only measured for a small number of nanofluids in experiments. The parameter ranges themselves are narrow (volume concentration of the particles, temperature, etc.). However, contrary to current theoretical predictions, actual data suggest a pattern in which the efficient viscosities of nanofluids are greater. Einstein's equation is employed when there are inadequate numbers of tiny particles. Here, equation 1 represents the Einstein's famous formula (1).

2.3 Measurement of Density

Density, also known as volumetric or specific mass, is the ratio of a substance's mass to its volume. The Latin letter D may also represent density, although the Greek letter (lowercase rho) is more often employed. According to Eq. 2, density is the ratio of mass to volume.

where ρ is the density, m is the mass, and V is the volume. It is common practice to mistake density for the weight per unit volume; this value is more accurately referred to as the specific weight. In the case of a pure substance, the mass concentration and density are directly proportional to one another. The density of an item may be an essential factor in defining its buoyancy, purity, and packing, among other characteristics of the object. Osmium and iridium are the elements with the highest density known to exist under typical temperature and pressure conditions. To make it easier to compare the many different systems of units, density is sometimes replaced by the dimensionless number "relative density" or "specific gravity." These terms refer to the ratio of the density of the substance being measured to that of a reference material, which is most commonly water. If a substance has a lower relative density than water, it will float on the water's surface. When the temperature and pressure of a substance are altered, the resultant change in density may be seen. This distinction is often not apparent when referring to solids and liquids, but it is when discussing gases. Anything subjected to a greater force will undergo compression and grow denser. When a material is heated, its volume often expands, which causes the density of the substance to decrease. Because the heated fluid has a lower density than the denser unheated material, it rises due to convection, which is the movement of heat from lower to higher levels in a fluid. This occurs because the heated fluid has a greater temperature than the unheated material. Thus, in this article, density measurement has been measured by using Anton Paar Density meter.

2.4 Specific heat

A material's specific heat capacity may be calculated using the principles of thermodynamics by dividing the total heat capacity of a sample by the sample's mass. This yields the cp value of the material, denoted by the symbol. To increase the temperature of a certain mass of a substance by one degree Fahrenheit, a particular amount of heat must be applied to it. Consideration is given to the substance's bulk. The symbol for joules per kilogram Kelvin used to express specific heat capacity is Jkg1K. This measures how well heat is transferred from one place to another. The energy required to raise the temperature of one kilogram by one degree Celsius is one joule. Consequently, water has a specific heat capacity of 4184 J kg1K1 at a temperature of 1 degree Celsius.

The specific heat capacity of a substance changes depending not just on temperature but also on the state of matter the material is in. At room temperature, liquid water has a specific heat capacity of roughly 4184 kg1K1. Since the heat is being utilized to alter the state of the substance rather than raise its temperature, the material’s specific heat capacity is theoretically infinite during a phase transition. Suppose a material, especially a gas, is permitted to expand while it is heated (specific heat capacity at constant pressure. In that case, the material's specific heat capacity may be much higher than if it were heated in a closed vessel (specific heat capacity at constant volume). The phrases "specific heat" and "specific gravity" are sometimes used synonymously. An object's specific heat is defined as its specific heat capacity at a particular temperature divided by the specific heat capacity of a reference substance (often water) at the same temperature. Specific gravity is the ratio of a substance's specific heat capacity to a reference substance at a given temperature. Specific heat capacity is connected to several distinct measurements of strong heat capacity, each of which has a different numerator. The molar heat capacity of a material may be calculated by dividing the substance's specific heat by its molecular weight. The joule per kelvin per mole is the SI unit used to measure this quantity. Suppose the volume is meant to be representative of the sample volume. In that case, as is often done in engineering, the volumetric heat capacity is stated in SI units as joules per kelvin per cubic meter. This is because joules are a metric system of measurement. However, specific heat has been measured by using KD2 thermal pro analyzer.

2.5 Preparation of base fluids And nanofluids

Propylene glycol–water samples of three kinds (50:50), (75:25), and (100:0) are prepared in this experimentation. The graphene nanoparticles are dispersed in the designed solutions with the help of an ultrasonic probe sonicator at 0.25 and 0.5 wt%. Figure 1 shows the prepared nanofluid samples.

The properties of propylene glycol are shown in Table 2. The description of graphene is shown in Table 3.

Compared to traditional carbon nanotubes, graphene possesses superior heat flow properties, which contribute to the material's increased ability to improve the thermal conductivity of nanofluids. Graphene is ideal for other existing nanoparticles in terms of its thermal conductivity, stability, and resistance to erosion and corrosion. The dispersion of surfactant CTAB observes the stability of nanofluids into the prepared nanofluids. These nanofluids are checked for strength for the 1st day, 5th day, 10th day, and 15th day and it is observed that propylene glycol (100%) mixed with graphene nanopowder is found to be stable when compared to the other two fluids. Figure 2 shows the stability of nanofluids [41].

3 Results and Discussion

3.1 Measurement of Thermal Conductivity

A material's thermal conductivity refers to its ability to facilitate the movement of heat without trapping heat inside the material. As the temperature rises, there is a rise in the total number of molecular collisions and the overall force of these collisions [42]. This occurs because of the increased number of molecules colliding with one another. This is due to the accelerated rate at which molecules crash into one another. Because of this transformation, the material’s thermal conductivity directly improves. Testing the inherent heat conductivity of solids is a far less arduous and time-consuming procedure when compared to the process of evaluating the intrinsic heat conductivity of liquids, which may be very time-demanding [43]. The natural convective heat transfer process, which occurs in the fluid when the measurement is being carried out and adds to the situation’s complexity, is the source of this difficulty. The measure is carried out within the fluid.

3.2 Variation of Thermal Conductivity

Figure 3a displays the dependence of thermal conductivity on temperature for a propylene glycol sample doped with varying amounts of graphene nanopowder. As the temperature of nanofluids increases, there is a noticeable increase in their thermal conductivity [18]. Evidence suggests that adding 10–12% more graphene to propylene glycol might improve its thermal conductivity. Because the thermal conductivity of a sample of propylene glycol and water with a composition of 75:25 is displayed as a function of temperature in Fig. 3b, it is evident that the thermal conductivity increases with increasing temperature. Consequently, thermal conductivity should be considered because it is so apparent that thermal conductivity rises with increasing temperature. The thermal conductivity of a 75:25 combination of propylene glycol and water was found to increase by 11% and proportionally by 14% when the graphene content was increased by several percentage points [1s9]. Figure 3c depicts the temperature behavior of the thermal conductivity of the propylene glycol/water (50:50) sample. As the temperature rises, the thermal conductivity also increases. Only at sufficiently high temperatures can the thermal conductivity function as intended. Researchers found that combining propylene glycol and water (in a 50:50 ratio) may improve its thermal conductivity by adding 13 to 16 percent more graphene. Graphene nanopowder enhanced the material’s thermal conductivity when the temperature was raised [44]. As temperature increases, the number of free electrons and lattice vibrations increase. Thus, the thermal conductivity of the metal is expected to increase.

a Thermal conductivity and temperature-dependent changes for a propylene glycol sample doped with varying concentrations of graphene nanopowder, b Thermal conductivity and temperature-dependent changes for a propylene glycol–water (75:25) sample doped with varying concentrations of graphene nanopowder. c Thermal conductivity and temperature-dependent changes for a Propylene Glycol–water (50:50) sample doped with varying concentrations of graphene nanopowder

3.3 Determination of Viscosity

The degree to which a fluid resists being moved is referred to as its viscosity, and it is used to describe how dense the fluid is. This phrase refers to the resistance to motion that may be found inside a fluid and describes the phenomenon in this way. A fluid with a higher viscosity contains molecules organized in a way that makes it possible for them to experience higher levels of internal friction. This, in turn, causes the fluid to move at a more glacial pace [45]. On the other hand, it is easy to control fluids with a low viscosity since the molecular structure of the fluid results in less friction. This makes the fluid easier to handle. This makes it simpler to control the fluid's movement [20]. Research has shown that the nanofluid’s viscosity determines how much pumping power is needed. Considering the situation in this way is a more realistic and valuable approach. The shear tension between the fluid layers is reduced due to an increase in temperature, which decreases the fluid’s viscosity. As a fluid's temperature increases, molecules that are already present in it become agitated and migrate. Because of this, the molecules in the fluid are forced to give up energy, which, in turn, reduces the fluid's viscosity. Molecules already present in a fluid will become agitated and begin to migrate as the temperature of the fluid increases[46].

3.4 Variation of Viscosity

The temperature-dependent viscosity variations shown in Fig. 4a are for a propylene glycol sample containing different graphene nanopowder concentrations. As was to be predicted, the viscosity of nanofluids reduces as the temperature increases [21]. As shown in Fig. 4b, a rise in temperature results in a reduction in viscosity in the sample consisting of 75 percent propylene glycol and 25 percent water. Figure 4c depicts the temperature dependency of the sample's viscosity, which is a mixture of propylene glycol and water at a ratio of 50:50, and it indicates a tendency to decrease viscosity as the temperature rises. The boiling point causes this disparity in the most significant temperature that may be lowered when water is included in the mix. When heated to greater temperatures, all fluids experience a decrease in their dynamic viscosity [22]. Compared to their base fluid equivalents, nanofluids perform better in dynamic viscosity when the temperature is low. The viscosity of nanofluids, including distributed graphene nanopowder, has decreased as temperature increases [47]. Increasing temperature decreases viscosity because a more significant temperature means particles have tremendous thermal energy and can more easily overcome the attractive forces binding them together.

aTemperature-dependent changes in viscosity of a graphene nanopowder-doped Propylene Glycol sample, b Temperature-dependent changes in viscosity of a Graphene nanopowder-doped Propylene Glycol–water (75:25)sample, c Temperature-dependent changes in viscosity of a Graphene nanopowder-doped Propylene Glycol–water (50:50) sample

3.5 Variation of Density

When the temperature of a sample of propylene glycol that includes varying amounts of graphene nanopowder is elevated (as shown in Fig. 5a), a drop in density may be noticed. This finding was made possible by the observation that density decreases with increasing temperature (23). The graph demonstrates the existence of this phenomenon. As can be seen in Fig. 5b, the density of the propylene glycol–water (75:25) sample noticeably decreases as the temperature increases. It is crucial to make this observation since it demonstrates that the sample grows less dense as time moves on. Figure 5c depicts the fluctuation in density that occurs with temperature for the propylene glycol–water (50:50) sample, indicating a tendency to decrease as the temperature increases [24]. The graph shows this tendency. When a liquid or gas is heated, the molecules move faster, bump into each other, and spread apart. Because the molecules are spread apart, they take up more space. They are less dense.

a Variations in density with temperature for a sample of propylene glycol with varying amounts of graphene nanopowder, b Variations in density with temperature for a sample of propylene glycol–water (75:25) with varying amounts of graphene nanopowder, c Variations in density with temperature for a sample of propylene glycol–water (50:50) with varying amounts of graphene nanopowder

4 Variation of Specific Heat

Figure 6a shows how the specific heat of propylene glycol containing various weight percentages of graphene nanopowder varies with temperature. It is clear from this figure that as the temperature rises, so does the specific heat of nanofluids [25]. It was discovered that varying concentrations of graphene added to propylene glycol increased the particular heat of the mixture by 8% and 11%, respectively. The change in specific heat with temperature for the propylene glycol/water (75:25) sample is shown in Fig. 6b. It is easy to see that particular heat improves with rising temperatures, which should be considered. The enhancement of specific heat for propylene glycol–water with a ratio of 75:25 was determined to be between 10 and 13%, depending on the amount of graphene in the mixture. Figure 6c, which depicts the fluctuation of specific heat with temperature for the propylene glycol/water (50:50) sample, reveals that the particular heat increases as the temperature rises. This trend can be observed in the graph. The temperature must be raised before the specific heat can be accurately measured. It was discovered that increasing the proportion of graphene in propylene glycol and water (50:50) mixtures by varying amounts led to a 12% and 14% increase in the specific heat, respectively. There is a real sign of an improvement in specific heat with the dispersion of graphene nanopowder, which is seen in conjunction with a temperature rise as the substance heats up and the average kinetic energy of the molecules increments. The collisions confer enough energy to permit rotation to happen. Rotation at that point adds to the internal energy and raises the specific heat.

a Specific heat and its temperature-dependent changes for a sample of propylene glycol containing varying amounts (in weight%) of graphene nanopowder, b Specific heat and its temperature-dependent changes for a sample of propylene glycol–water (75:25) containing varying amounts (in weight%) of graphene nanopowder, c Specific heat and its temperature-dependent changes for a sample of propylene glycol–water (50:50) containing varying amounts (in weight%) of graphene nanopowder

4.1 Effects of Different Parameters on \({\mu }_{nf}\)

To achieve the ideal viscosity, it is necessary to analyze how input parameters interact. Figures 7 and 8 automatically selected spectra using the program Design Expert. According to apparent light, violet colors also have the best viscosity. Red has the most negligible thickness as it has a minor recurrence of obvious light. A three-dimensional diagram of \({\upmu }_{nf}\) versus \(\mathrm{\varphi }\) and temperature at \(\dot{\upgamma }=\) 3999 s−1 and \({\upmu }_{nf}\) versus temperature and \(\dot{\upgamma }\) at \(\mathrm{\varphi }\) = 0.5% is illustrated in Fig. 7. Figure 8 shows the viscosity at high temperatures and high shear rates is lowest. This indicates that the nanoparticles are better dispersed in the base oil under these conditions.

Contour curve of \({\upmu }_{nf}\) versus \(\mathrm{\varphi }\) and temperature at \(\dot{\upgamma }=\) 3999 s−1 and \({\upmu }_{nf}\) versus temperature and \(\dot{\upgamma }\) at \(\mathrm{\varphi }\) =0.5% is demonstrated in Fig. 8. The insoluble particles in the oil increase viscosity with increasing nanoparticles. Results show a drastic reduction in the influence of \(\mathrm{\varphi }\) and \(\dot{\upgamma }\) on \({\upmu }_{nf}\) In temperatures higher than 45 °C, their effect is considerable in lower temperatures [48].

4.2 Uncertainty Analysis of Variables

Table 4 shows the uncertainty analysis of different variables; in addition, the experimental results of this study were compared to those of some other researchers, as shown in Table 5.

5 Future Scope

Using the prepared nanofluids, we will use them in heat transfer analysis in the helical coil heat exchanger and calculate the heat transfer coefficient. Different nanopowders can also be used along with propylene glycol–water solution to evaluate the thermophysical properties and heat transfer characteristics.

6 Conclusions

The essential fluids were propylene glycol and water, which were mixed in the following proportions: 100:0, 75:25, and 50:50 to form nanofluids. Both base fluids had 0.25 or 0.5 graphenes added. Because of the system's design, nanofluid thermal conductivity grows with temperature. Propylene glycol's thermal conductivity might increase between 10 and 12 percent with varying quantities of graphene. Thermal conductivity increased by 13% and 16% when graphene was added to propylene glycol and water in a 50:50 ratio. Graphene enhanced heat conductivity by 11% and 14% in propylene glycol–water mixtures. The propylene glycol–water ratio in these combinations is 75:25. Surprisingly, temperature decreases nanofluid viscosity. Adding water reduces the liquid's boiling point, lowering the maximum temperature. A fluid's dynamic viscosity decreases with temperature. Nanofluids have substantially higher dynamic viscosity at low temperatures than base fluids with equivalent characteristics. The nanofluid's viscosity is less affected by temperature when graphene nanopowder is present. Nanofluid density decreases with temperature.

Given that density inversely correlates with temperature, this result makes logical. This phenomenon shows that, as expected, nanofluids' specific heat increases with temperature. The particular heat of propylene glycol rose by 8% and 11% when graphene was added at varied concentrations. The specific heat rose by 12% and 14% when graphene was added to 50:50 propylene glycol and water solutions. As temperature increases, graphene nanopowder dispersion improves specific heat. This connection may be shown. When graphene was added, the particular heat of propylene glycol–water (75:25) mixtures increased by 10% and 13%, respectively.

Data Availability

Not applicable.

Code Availability

Not applicable.

References

Baby, T.T.; Ramaprabhu, S.: Enhanced convective heat transfer using graphene dispersed nanofluids. Nanoscale Res. Lett. 6, 289 (2011). https://doi.org/10.1186/1556-276X-6-289

Murshed, S.M.S.; Leong, K.C.; Yang, C.: Thermophysical and electrokinetic properties of nanofluids–a critical review. Appl. Therm. Eng. 28(17–18), 2109–2125 (2008)

Leena, M.; Srinivasan, S.: Experimental investigation of the thermophysical properties of TiO2/propylene glycol-water nanofluids for heat-transfer applications. J. EngPhysTherm. 91, 498–506 (2018). https://doi.org/10.1007/s10891-018-1770-7

Naik, M.T., et al.: Experimental investigation into rheological property of copper oxide nanoparticles suspended in propylene glycol–water based fluids. ARPN J. Eng. Appl. Sci 5(6), 29–34 (2010)

Satti, J.R.; Das, D.K.; Ray, D.: Investigation of the thermal conductivity of propylene glycol nanofluids and comparison with correlations. Int. J. Heat Mass Transf. 107, 871–881 (2017)

Patil, M.S., et al.: Review on synthesis, thermo-physical property, and heat transfer mechanism of nanofluids. Energies 9(10), 840 (2016)

Özerinç, S.; Kakaç, S.; YazIcIoğlu, A.G.: Enhanced thermal conductivity of nanofluids: a state-of-the-art review. Microfluidics Nanofluidics 8(2), 145–170 (2010)

Das, S.K.; Choi, S.U.S.; Patel, H.E.: Heat transfer in nanofluids–a review. Heat Transf. Eng. 27(10), 3–19 (2006). https://doi.org/10.1080/01457630600904593

Pak, B.C.; Cho, Y.I.: Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp. Heat Transf. 11(2), 151–170 (2007). https://doi.org/10.1080/08916159808946559

Reddy, M.C.S.; Rao, V.V.: Experimental studies on thermal conductivity of blends of ethylene glycol-water-based TiO2 nanofluids. Int. Commun. Heat Mass Transfer 46, 31–36 (2013). https://doi.org/10.1016/j.icheatmasstransfer.2013.05.009

Gawel, Z.; Jacek, F.: Viscosity, thermal and electrical conductivity of silicon dioxide-ethylene glycol transparent nanofluids: an experimental studies. ThermochimicaActa 650, 106–113 (2017). https://doi.org/10.1016/j.tca.2017.02.001

Raja Sekhar, Y.; Sharma, K.V.: Study of viscosity and specific heat capacity characteristics of water-based Al2O3 nanofluids at low particle concentrations. J. Exp. Nanosci. 10(2), 86–102 (2015). https://doi.org/10.1080/17458080.2013.796595

RizalmanMamat, M.F.; Nabil, W.H.; Azmi, K.A.: Hamid, An experimental study on the thermal conductivity and dynamic viscosity of TiO2-SiO2 nanofluids in water: ethylene glycol mixture. Int. Commun. Heat Mass Transfer 86, 181–189 (2017). https://doi.org/10.1016/j.icheatmasstransfer.2017.05.024

SyamSundar, L.; VenkataRamana, E.; Singh, M.K.; Sousa, A.C.M.: Thermal conductivity and viscosity of stabilized ethylene glycol and water mixture Al2O3 nanofluids for heat transfer applications: an experimental study. Int. Commun. Heat Mass Transf. 56, 86–95 (2014). https://doi.org/10.1016/j.icheatmasstransfer.2014.06.009

Sharma, P.; Baek, I.; Cho, T.; Park, S.; Lee, K.B.: Enhancement of thermal conductivity of ethylene glycol based silver nanofluids. Powder Technol. 208, 7–19 (2011)

Zhang, X.; Gu, H.; Fujii, M.: Experimental study on the effective thermal conductivity and thermal diffusivity of nanofluids. Int. J. Thermophys. 27(2), 569–580 (2006). https://doi.org/10.1007/s10765-006-0054-1

Einstein, A.: Investigation on Theory of Brownian Motion. Dover, New York (1956)

Surakasi, R.; Sekhar, K.C.; Yanmaz, E.; Yuvaraj, G.; Venugopal, J.; Srujana, S.; Begum, N.: Evaluation of physicothermal properties of silicone oil dispersed with multiwalled carbon nanotubes and data prediction using ANN. J. Nanomater. (2021). https://doi.org/10.1155/2021/3444512

Palabiyik, I., et al.: Dispersion stability and thermal conductivity of propylene glycol-based nanofluids. J. Nanoparticle Res. 13, 5049–5055 (2011)

Surakasi, R.; Sekhar, K.C.; Kavitha, E., et al.: Evaluation of physico-thermal properties of TiO2–water mixture dispersed with MWCNTs. Nanotechnol. Environ. Eng. 7, 325–331 (2022). https://doi.org/10.1007/s41204-022-00242-4

Haribabu, A.; Surakasi, R.; Thimothy, P., et al.: Study comparing the tribological behavior of propylene glycol and water dispersed with graphene nanopowder. Sci. Rep. 13, 2382 (2023). https://doi.org/10.1038/s41598-023-29349-7

Sekrani, G.; Poncet, S.: Ethylene- and propylene-glycol based nanofluids: a litterature review on their thermophysical properties and thermal performances. Appl. Sci. 8, 2311 (2018). https://doi.org/10.3390/app8112311

Sekhar, K.C.; Surakasi, R.; Garip, I.; Srujana, S.; Kumar, V.V.P.; Begum, N.: Evaluation of physicothermal properties of solar thermic fluids dispersed with multiwalled carbon nanotubes and prediction of data using artificial neural networks. J. Nanomater. 2021, 13 (2021). https://doi.org/10.1155/2021/7306189

Vajjha, R.S.; Das, D.K.; Chukwu, G.A.: An experimental determination of the viscosity of propylene glycol/water based nanofluids and development of new correlations. J. Fluids Eng. Trans. ASME 137(8), 1–15 (2015). https://doi.org/10.1115/1.4029928

Raviteja, S.; Srujana, S.; Sarada, P.N.; Sibtain, A.; Bharat, S.; Manoj, T.; Rahel, A.H.: Synthesis and characterization of TiO2-water nanofluids. Adsorp. Sci. Technol. 3286624, 9 (2022). https://doi.org/10.1155/2022/3286624

Esfe, M.H., et al.: Heat transfer characteristics and pressure drop of COOH-functionalized DWCNTs/water nanofluid in turbulent flow at low concentrations. Int. J. Heat. Mass Transf. 73, 186–194 (2014)

Aberoumand, S., et al.: Experimental study on the rheological behavior of silver-heat transfer oil nanofluid and suggesting two empirical based correlations for thermal conductivity and viscosity of oil based nanofluids. Appl. Thermal Eng. 101, 362–372 (2016)

Abdolbaqi, M.K., et al.: Experimental investigation and development of new correlation for thermal conductivity and viscosity of BioGlycol/water based SiO2. Int. Commun. Heat Mass Transf. 5, 996 (2016)

Abdolbaqi, MKh., et al.: An experimental determination of thermal conductivity and viscosity of BioGlycol/water based TiO2 nanofluids. Int. Commun. Heat Mass Transf. 77, 22–32 (2016)

Baratpour, M., et al.: Effects of temperature and concentration on the viscosity of nanofluids made of single-wall carbon nanotubes in ethylene glycol. Int. Commun. Heat Mass Transf. 74, 108–113 (2016)

Nabil, M.F., et al.: An experimental study on the thermal conductivity and dynamic viscosity of TiO2-SiO2 nanofluids in water: ethylene glycol mixture. Int. Commun. Heat Mass Transf. 86, 181–189 (2017)

Esfe, M.H., et al.: "Examination of rheological behavior of MWCNTs/ZnO-SAE40 hybrid nano-lubricants under various temperatures and solid volume fractions. Exp. Thermal Fluid Sci. 80, 384–390 (2017)

Aberoumand, S.; Jafarimoghaddam, A.: Experimental study on synthesis, stability, thermal conductivity and viscosity of Cu–engine oil nanofluid. J. Taiwan Inst. Chem. Eng. 71, 315–322 (2017)

Chiam, H.W., et al.: Thermal conductivity and viscosity of Al2O3 nanofluids for different based ratio of water and ethylene glycol mixture. Exp. Thermal Fluid Sci. 81, 420–429 (2017)

Elias, M.; Mahbubul, I.M.; Saidur, R.; Sohel, M.; Shahrul, I.; Khaleduzzaman, S.; Sadeghipour, S.: Experimental investigation on the thermo-physical properties of Al2O3 nanoparticles suspended in car radiator coolant. Int. Commun. Heat Mass Transf. 54, 48–53 (2014)

Vo, D.D.; Hedayat, M.; Ambreen, T.; Shehzad, S.A.; Sheikholeslami, M.; Shafee, A.; Nguyen, T.K.: Effectiveness of various shapes of Al2O3 nanoparticles on the MHD convective heat transportation in porous medium. J. Therm. Anal. Calorim. 139(2), 1345–1353 (2020)

Gundarneeya, T.P.; Vakharia, D.: Performance analysis of journal bearing operating on nanolubricants with TiO2, CuO and Al2O3 nanoparticles as lubricant additives. Mater. Today Proc. 45, 5624–5630 (2021)

Ghaffarkhah, A.; Afrand, M.; Talebkeikhah, M.; Sehat, A.A.; Moraveji, M.K.; Talebkeikhah, F.; Arjmand, M.: On evaluation of thermophysical properties of transformer oil-based nanofluids: a comprehensive modeling and experimental study. J. Mol. Liq. 300, 112249 (2020)

Sawicka, D.; Cieśliński, J.T.; Smolen, S.: A comparison of empirical correlations of viscosity and thermal conductivity of water-ethylene glycol-Al2O3 Nanofluids. Nanomaterials 10(8), 1487 (2020)

Giwa, S.; Sharifpur, M.; Meyer, J.P.; Wongwises, S.; Mahian, O.: Experimental measurement of viscosity and electrical conductivity of water-based γ-Al2O3/MWCNT hybrid nanofluids with various particle mass ratios. J. Therm. Anal. Calorim. 143(2), 1037–1050 (2021)

Warade, H.; Ansari, K.; Bhaskar, K.; Naaz, Z.; Khan, M.A.; Khan, N.A.; Zahmatkesh, S.; Hajiaghaei-Keshteli, M.: Optimizing the grass bio methanation in lab scale reactor utilizing response surface methodology. Biofuels 5, 1–12 (2023)

Ahmad, M.; Althobaiti, A.T.; Ali, W.; Masood, K.; Ramadan, M.F.; Chaudhary, B.; Zafar, M.; Akhtar, M.S.; Sultana, S.; Zahmatkesh, S.: Membrane-processed honey samples for pollen characterization with health benefits. Chemosphere 6, 137994 (2023)

Abutaleb, A.; Imran, M.; Zouli, N.; Khan, A.H.; Hussain, S.; Ali, M.A.; Bakather, O.; Gondal, M.A.; Khan, N.A.; Panchal, H.; Zahmatkesh, S.: Fe3O4-multiwalled carbon nanotubes-bentonite as adsorbent for removal of methylene blue from aqueous solutions. Chemosphere 9, 137824 (2023)

Jiang, H.; Zahmatkesh, S.; Yang, J.; Wang, H.; Wang, C.: Ultrasound-enhanced catalytic degradation of simulated dye wastewater using waste printed circuit boards: catalytic performance and artificial neuron network-based simulation. Environ. Monitor Assess. 195(1), 144 (2023)

Zahmatkesh, S.; Amiri, M.K.; Zaferani, S.P.G.; Emami, M.R.S.; Hajiaghaei-Keshteli, M.; Albaqami, M.D.; Tighezza, A.M.; Shafahi, M.; Han, N.: Machine learning modeling of polycarbonate ultrafiltration membranes at different temperatures, Al2O3 nanoparticle volumes, and water ratios. Chemosphere 313, 137424 (2023)

Zahmatkesh, S.; Ni, B.-J.; Klemeš, J.J.; Bokhari, A.; Hajiaghaei-Keshteli, M.: Carbon quantum dots-Ag nanoparticle membrane for preventing emerging contaminants in oil produced water. J. Water Process Eng. 50, 103309 (2022)

Zahmatkesh, S.; Hajiaghaei-Keshteli, M.; Bokhari, A.; Sundaramurthy, S.; Panneerselvam, B.; Rezakhani, Y.: Wastewater treatment with nanomaterials for the future: a state-of-the-art review. Environ. Res. 216(3), 114652 (2022)

Zahmatkesh, S.; Rezakhani, Y.; Arabi, A.; Hasan, M.; Ahmad, Z.; Wang, C.; Sillanpää, M.; Al-Bahrani, M.; Ghodrati, I.: An approach to removing COD and BOD based on polycarbonate mixed matrix membranes that contain hydrous manganese oxide and silver nanoparticles: a novel application of artificial neural network based simulation in MATLAB. Chemosphere 308, 136304 (2022)

Acknowledgements

This work did not receive any financial support.

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The author declares no competing interest.

Ethical Approval

The author has read, understood, and complied as applicable with the statement on "Ethical responsibilities of Authors" as found in the Instructions for Authors and is aware that with minor exceptions, no changes can be made to authorship once the paper is submitted.

Consent to Participate

Not applicable.

Consent to Publication

This version has been approved by all other co-authors.

General Information

I have not submitted my manuscript to a preprint server before submitting it to Arabian Journal for Science and Engineering

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sekhar, G.C., Thimothy, P., Surakasi, R. et al. Graphene Nanopowder and Propylene Glycol Solutions: Thermal and Physical Properties. Arab J Sci Eng 48, 16039–16050 (2023). https://doi.org/10.1007/s13369-023-07952-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-07952-0