Abstract

Various structural health monitoring techniques have been developed over the years. Due to the lack of a common platform to test the efficiency of these methods, the damage analysis models have been tested on different structures selected according to the choice of researches. Therefore, perfect comparison among the models was not possible. In light of this event, a benchmark structure was developed providing a common ground to analyse the effectiveness of the damage detection strategies. This structural damage analysis consists of different damage patterns, major damages and minor damages. The damage detection algorithms were tested for the detection of these different damage patterns and the effectiveness against noise contamination. Also the amount of data required for the algorithms to effectively detect damage was also recorded, which indicated the efficiency of the method applied. The paper deals with the application of different damage detection techniques on the ASCE benchmark Phase-I and Phase-II structure and studies their efficiency against the other structures. A brief comparison has been made among different damage detection models such as Bayesian model, neural network, autoregressive models, and model update. These methods have been successfully implemented on the benchmark structure and their efficiencies have been measured in terms of noise contamination, the amount of data required to measure the damage and the detection of damage (major and minor). Out of all the techniques discussed, model update technique, wavelet approach, autoregressive technique, convolution neural network and synchrosqueezed wavelet transform have proved to a robust damage analysing tool.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Structural Health Monitoring (SHM) is a very interesting field, attracting researchers to investigate and evaluate the structural health. This process mainly involves two steps: (a) diagnosis; this includes damage identification, localization and quantification, and (b) prognosis; this includes the estimation of structure’s residual capacity and forecasting its residual life [1, 2]. To process the huge information provided by the sensors and to simplify them for measurement of the structural condition, an improved algorithm is required [3]. Under this field, a number of techniques have been developed and implemented successfully for damage analysis: vibration based methods, local diagnostics method, non-probabilistic methods and time series based methods [4]. The 2 different model approaches used for real-time automated damage analysis are: model-based and non-model based approach [5]. The model-based approach is a mathematical model that has to be developed, assuming that the system is time invariant and linear. The damage diagnostic is done by studying the change in stiffness, natural frequency, damage ratio, etc. In non-model approach, instead of acquiring the structural parameters, sensors are used to extract data from the structure for diagnosis. Thus, this approach is suitable for real-time damage detection. The sensor signals, however, have to feed in a time series-based algorithm for the monitoring process. Few of such techniques are the flexibility-based model update method [6], free modelled artificial neural network-based approach [7], combined wavelet Hilbert Transform [8], model updating [9], and Bayesian-based adaptive filter-based technique [10]. But most techniques have been implemented by the researchers on different structures of their own choice. Therefore, a comparative study is hard to perform for the damage detection methods.

In the light of these events, an ASCE benchmark structure has been designed by the IASC–ASCE Structural Health Monitoring Group. The structure is a G + 3 Storeyed 2*2 bay steel frame quarter scaled model building (Fig. 1) [11, 12]. The benchmark structure has been researched in two phases. Phase-I deals with various types of damage introduced in the structure, the sensor data and the introduction of sensor noise in the structure and obtaining the different response using analytical methods [11]. This phase deals with analysis considering shear building model. Therefore, the discrepancies, i.e. user-defined damage, between analytical model and real model were not considered. In Phase-II, the freedom for user to define the type and point of damage has been included [13]. In this phase, the building model can be modified in a number of ways to analyse damage. Also, each phase consists of one analytical model and one experimental model.

IASC–ACSE benchmark structure-quarter scaled model [11]

For efficient damage detection, the algorithm chosen shall effectively analyse damage using the minimum number of sensor data [14]. This criterion will determine the efficiency of the algorithm. This paper deals with a comparative study of different damage detection techniques that have been implemented on the benchmark structure for damage analysis.

2 Damage detection techniques

To obtain a good comparative study of the different damage detection techniques, researchers all around the world implemented various innovative techniques to the benchmark problem. The damage detection techniques discussed in the paper are classified into two groups according to the structures used for analysis (Phase I and II). Further, both Phase-I and Phase-II structures consist of analytical model and experimental model on which these methods have been tested. This benchmark helped the researchers to perform a comparative study among the different algorithms and determine if the algorithms are appropriate for locating and quantifying the damage in the structure. The algorithms applied on the analytical ASCE benchmark include system identification methods, damage index method, flexibility based approach, wavelet approach, adaptive recursive least square filter, autoregressive models, time history approach, parameter identification tool, model update and decomposition models, artificial neutral network, adaptive neuro-fuzzy inference system and hierarchical sparse Bayesian learning (HSBL) algorithm. The ASCE experimental model benchmark was experimented with power spectral density method, Bayesian model, Fuzzy network, damage pattern recognition, autoregressive model, pole transfer method, model update, HSBL algorithm, neural network and convolutional neural network model.

3 Damage algorithms on Phase-I structure

Phase-I deals with the analytical model and the experimental data of the benchmark structure, and extraction of structural parameters related to different damage cases. Damage in the structure has been provided by removal of braces or loosening the bolted connections. The removal of braces from the structure indicates the reduction of stiffness to zero without affecting the mass matrix. A broken connection cannot transfer moments in any direction but only shear and axial forces. A number of damage detection techniques have been implemented on this model for comparison of efficiency.

3.1 Analytical Phase-I benchmark structure

The analytical phase-I structure comprises a 12 DOF model and 120 DOF model of the G + 3 storey building. The damage patterns introduced in the structure are shown in Table 1 and the damage patterns are shown in Fig. 2 [11]. The removal of braces in the storey, which leads to stiffness reduction, is considered as major damage scenario and the weakening of beam column joint by loosening of bolts or reduction of stiffness for braces is considered as minor damage scenario of the structure. This condition holds true for phase-I and phase-II analytical and experimental structure. For phase-I structure, the major damage patterns include Pattern 1, 2, 3 and 4 whereas minor damage is included in damage pattern 5 (loosening of bolts) and 6 (reduction of 1/3rd stiffness). In case of this phase, the modelled damage patterns are pre-defined and the analysis is carried out accordingly.

The damage scenarios for analytical phase-I benchmark structure [11]

3.1.1 System identification methods

3.1.1.1 Natural excitation technique (NExT) and eigensystem realization algorithm (ERA)

Caicedo et al. [14] made use of NExT in combination with ERA to determine the damage in the structure by determining the change in stiffness of the ASCE benchmark structure. The NExT technique is used to extract the modal parameters of the structure. Under the assumptions that the input is stationary and structural parameters can be easily determined, it was seen that the cross-correlation function between the reference output and the actual output of the system is similar and matches the homogeneity equation of motion [15].

This cross correlations can thus be treated as free response data due to the similarity. This approach does not need the previous excitation data and, hence, can be applied for excitations that are not measureable, ambient vibration. It has been assumed that the ratios of the masses are approximately equal. Therefore, the technique uses only the mass of the structure, which is required for stiffness problem formulation. Later, it was experimented and showed that the assumption made did not hamper the modal parameter detection system [16,17,18,19].

Once the modal parameters are obtained, the ERA is used to identify the modal properties so as to identify the damage to the structure. This algorithm is effective in determining damage in lightly damped structures and can be applied for multi-input/multi-output systems [20]. The success of the technique lies in determining the damage accurately with the help of minimum number of data. The sample chosen was for time record generated at 1000 Hz which was down-sampled to 125 Hz. The reasons for such sample were: (1) high-resolution cross-spectral data are useful for ERA and (2) the frequency is twice the natural frequency and, thus, no higher modes will be omitted or miss-interpreted. The ERA method obtained an accurate result of natural frequencies in a short time record; hence, using larger time frame size was not required. Also, the sum of error in stiffness is seen to increase slightly with the increase of time. The error in natural frequency and stiffness is shown in Eqs. 1 and 2, respectively.

where n is the number of natural frequencies, λi identified and ki identified are the natural frequency and stiffness identified with the help of ERA method, and λi exact and ki exact are the exact natural frequency and stiffness of the ith floor.

The damage case 1 and 2 is considered for observation. It can be observed that for 12-DOF and 120-DOF model, the average error in natural frequencies is 0.79 and 0.17%, respectively. The error in stiffness for 12-DOF model was reported to be 0.766% for undamaged case. For 120-DOF model, the least square estimate was used and could not be compared with the exact values but it was less than the equivalent stiffness of identified 12-DOF. However, the results showed good agreement with the original data. Therefore, this technique was effective in determining the damage in structure when the input to the structure is unknown. Also, an iterative process can be implemented when the sensor data are limited.

3.1.1.2 OKID/ERA nonlinear optimization

Lus et al. [21] made use of Observer/Kalman filter Identification algorithm (OKID) to identify the damage in the structure. Using this algorithm, the Markov parameters of the system could be calculated [22, 23]. These parameters can be used in ERA for discrete time first-order system matrices realization [20]. This model was further refined using a nonlinear sequential quadratic programming-based optimization approach to obtain the exact physical parameters (stiffness, damping and mass matrices) [24, 25]. From this model, the parameters of second-order model (finite element model) can be retrieved [24, 26] which can identify the damage.

The OKID algorithm is used to derive the Markov parameters. From these Markov parameters, the set of minimum order discrete time matrices is obtained. This process is carried out with the help of ERA which uses singular value decomposition of Hankel matrix.

The system Markov parameters can be obtained from observer Markov parameters with the help of back substitution [21]. The initial state space model obtained with the help of OKID and ERA is again passed through nonlinear optimization scheme for further optimization or refining. However, for proper optimization, the backbone of the methodology, OKID/ERA approach must be performed accurately to obtain initial state space model. Nonlinear sequential quadratic programming is used to obtain the physical structural parameters [24]. From the calculated structural parameters, the damage can be located. This method is advantageous as it does not take into consideration any assumptions, does not require any data manipulation and it can use information from both actuators and sensors. The relative changes in the stiffness along x-axis and y-axis are used for damage analysis.

The algorithm, when applied on damage case 3, showed a good initial warning along with modelling error or measurement errors of 1–5%. Therefore, this method holds good for damage analysis without the help of any complex numerical calculations. Also, the presence of noise in the structure does not hamper the major damage identification results.

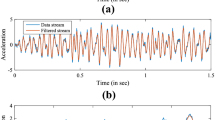

3.1.1.3 Model parameter identification by synchrosqueezed wavelet transform

The method proposed uses the vibration signals from the structure for identification of modal parameters natural frequencies and damping ratios [27]. The methodology is shown in Fig. 3. The modal parameters obtained for Phase-I structure with ambient vibration were compared with the original analysis. The frequency calculated using the above technique showed an error of 0.33%, whereas the damping result showed an error of 15%.

Modal parameter estimation using synchrosqueezed wavelet transform (SWT) [27]

3.1.2 Damage index method

The damage index method was one of the most basic algorithms developed by Stubbs [28] and proved to be a good competitor against the other vibrational based damage analysis techniques, change in stiffness [29], change in flexibility method [30] and change in uniform load surface curvature method [31]. The damage index method was accurate in damage analysis as compared to the other methods [32]. The main advantages offered by this method is that: (1) the unit-mass normalized mode shapes are not required for calculation, (2) few modes (≤ 3) are required for extracting good results, and (3) statistical approach can be incorporated with this method to determine the level of structural reliability [33].

Barrosa and Rodriques [33] performed the experimental verification of damage index method on the ASCE benchmark structure for comparative study. The modal parameters were obtained from the stimulated data using Frequency Domain Decomposition (FDD) method. Previously, the frequency domain decomposition was used to extract the modal parameters in which the data collected at two points in time were analysed [34]. In this study, the researchers proposed a new technique to identify the undamaged structural state with the help of ratio calculation between mass and stiffness values from the eigen value problem [33].

To validate the result, Modal Assurance Criterion was applied for the actual and identified undamaged structure. The MAC value close to unity signifies good agreement between the two observed values.

Damage in the structure is determined from the Eq. 3:

where αj is the damage expression, and k * j and kj are the stiffness of damaged and undamaged structure. The damage in the structure is indicated as αj < 0.

Case 4 of the benchmark was studied which consists of severe damages (pattern 1 and pattern 2) and the less severe patterns. This technique was successful to identify the severe damage patterns (1 and 2), but for the less severe patterns it gave false alarms. Therefore, modification in the technique has to be done for identification of less severe damages.

3.1.3 Flexibility based approach

Bernal and Gunes [35] analysed the benchmark problem for damage detection and quantification with the help of flexibility matrix extracted from the sensor readings. In this study, the realization parameters were calculated from the measured signals using OKID/ERA algorithm [20] when input is known and using Sub-Id technique when input is stochastic [36]. The flexibility matrices are extracted from the realization matrices and compared for damage detection. To enhance this process, damage locating vector technique (DLV) [37] was used to localize the damage taking vector of weighed stress indices as damage indicator. For stochastic input, a “general model update solution” was used for damage analysis. WSI < 1 indicates the damaged storey.

For quantification of damage, the change in interstorey stiffness of a storey is taken into consideration (Eq. 4). It is the shear occurring due to unit drift in a particular storey, the storey to be quantified for damage, when drifts and twist for all the other storeys are zero.

where δj is the displacement vector due to the unit drift at level j and * indicates pseudo-inverse operation. This approach is only valid for the case in which the output sensor data for all the storeys are known. For limited sensor data condition, the model is updated using weighing constants and error vector. The case 5 damage pattern 4 has been studied for damage algorithm validation considering level 1 and 3 in study. The damage technique showed good agreement for damage detection in the respective levels. However, it has been pointed out by the researchers that this approach may encounter some difficulty in the field structures due to the complex computation of physical parameters from large modal space matrix.

3.1.4 Modal algorithm using expectation algorithm

Expectation Maximization (EM) model is a well known algorithm that can compute the maximum likelihood estimate of structure damage with original structure. This algorithm works on evaluating a conditional Expectation (E-step) and maximizing the previous expectation in an iterative loop until a convergence is achieved (M-step) [38]. The algorithm has been shown in Fig. 4. The drawback of this algorithm is that the iterative loop is a slow converging one and the dependence of the algorithm on setting a starting point which may produce sub-optimal maximum likelihood estimates [39]. These drawbacks can be reduced by the use of (1) Stochastic Subspace Identification (SSI) combined with EM algorithm and (2) generation of random starting points to make the algorithm smooth and easy [40].

EM algorithm for modal identification [38]

Both the methods were implemented on the 12 DOF ASCE Phase-I benchmark problem and a comparative study was conducted to mark the efficiency of the methods. It was concluded that the three methods were able to detect the low-frequency and high-frequency damage. The results were compared with the SSI algorithm. Method 1 gave a more accurate result than SSI algorithm used alone except one mode which was hard to excite. When using Method 2, it was observed that the results are more accurate for modal identification.

3.1.5 Wavelet approach

On the event of damage occurrence, the acceleration data recorded at damaged location show discontinuity. This discontinuity can be detected with the help of wavelet analysis which can estimate the time instant and location for damage [41, 42]. The wavelet approach or wavelet analysis may be regarded as an extension of the traditional Fourier transformation, which is an effective tool for health monitoring. As suggested by some researchers, the wavelet analysis is termed as examination of local data with the help of zoom function with adjustable focus. This phenomenon allows this technique to provide great details of damage and approximate the original signal [43]. Method of decomposition [44] and Hilbert transform [45] have been used for analysis which proved to be more precise in decomposing a signal in frequency-time domain.

3.1.5.1 Decomposition method

3.1.5.1.1 Direct wavelet decomposition

In this method, damage can be identified from the presence of impulse in the mapping of the high-resolution wavelet decomposition of acceleration response data [46]. The wavelet transformation is given by Eq. 5 [47,48,49].

where a is the dilation parameter which indicates the wavelet window width, b is the translation parameter which represents the location of moving wavelet window in wavelet transformation, f(t) is the signal, Ψ(t) represents the mother wavelet and \(\bar{\varPsi }(t)\) is the complex conjugate.

Hera and Hou [43] used this wavelet analysis for damage monitoring of the ASCE benchmark structure Case 1 damage pattern 1. The response found was for dynamic loading, stochastic wind load which was achieved by breaking the braces after 5 s. The damage was identified by the spike in wavelet graph. This damage was not identified when the damage case was tested for Fast Fourier Transform algorithm. Wavelet approach also proved to be less model dependant and can detect damage without and prior knowledge of structural model parameters. The drawback of the direct wavelet decomposition method is that when the measured signal is corrupted with noise, the damage identification is difficult [5].

3.1.5.1.2 Empirical decomposition method (EMD)

The EMD method can detect the time instant and location of damage by observing the damage spike caused due to change in stiffness. This method uses the spline fitting to construct the lower and upper envelopes of signal and the mean of both is calculated, from which the signal is subtracted. This process is repeated till a mono-component resulting signal is obtained. This signal is called the intrinsic mode functions (IMF) and follows the well-behaved Hilbert transform. Repeated IMFs are obtained by (Eq. 6) [44]:

where x(t) is the measure signal, cj(t) is the IMF of x(t) and rn(t) is the residue. The first IMF has the highest frequency contents of the signal, thus identifying the stiffness change in a structure, damage indicator.

The method was demonstrated on ASCE benchmark building for damage pattern 2 by Yang et al. [50]. The damage result obtained was similar to the Direct Wavelet Decomposition method, i.e. detection of damage is only possible in case of low or zero noise and severe damage. The contamination due to noise may mask the low level damage, thus making it difficult to extract the parameters. Also, a great number of sensors have to be employed to response measurement.

3.1.5.2 Hilbert–Huang transformation

To reduce the noise phenomenon observed in different techniques, Yang et al. [50] used the Hilbert–Huang transformation to determine the damage characteristic with the use of one sensor. The algorithm followed for analytical signal Y(t) is (Eq. 7) [44]. The analysis uses EMD method, along with band-pass filters [51], to decompose the cross-correlation functions of measured acceleration responses into modal components.

where ωj is the frequency, t is the time, Aj(t, ωj) is the amplitude of jth IMF cj(t). Following this algorithm, the natural frequencies have been obtained for Damage Pattern 2. It was observed that the natural frequencies obtained for healthy and damaged structure are approximately equal to the theoretical value. Also, it can be observed that the effect of noise (R = 10%) on the measurement has negligible effect. Therefore, this algorithm can be utilized for damage analysis.

The Hilbert–Huang spectral analysis was used by Yang et al. [52] to identify the damage in the IASC–ASCE benchmark Phase-I structure for case 1 [11]. It was observed that the parameters measured were approximately equal to the theoretical value, thus effectively determining the damage using single noisy response from the accelerometer. Similar study has also been performed by Lin et al. [53] and the results obtained were similar to the above described case.

To calculate both the natural frequencies and damping ratio, an alternate method based on Random Decrement Technique (RDT) [54, 55] and Hilbert transform has been design by Yang et al. [50] and was tested for damage case 2. The RDT converts the free vibration model response to system response which is processed using Hilbert transform to obtain the phase angle and instantaneous amplitude. The parameters identified were more accurate (about 0.1% for frequency identification) than the Hilbert–Huang spectral analysis discussed before.

3.1.6 Adaptive recursive least squares (RLS) filter

Most of the analytical methods discussed above utilize the entire data recorded at one time for damage analysis. Whereas for the effective damage detection, the use of real-time data is more preferable for algorithm modelling. To achieve these data, Chase et al. [56] employed adaptive filtering, digital filtering with self-adjusting coefficients, methods for real-time sample to sample identification, Adaptive Recursive Least Square (RLS) filter. In this method, sample to sample adjustment of coefficients is done to minimize the mean square error (MSE) between the modelled value and the measured noisy value. The RLS filter algorithm is given by Haykins [57] and Ifeachor and Jervis [58] which require the vector signal (γk) from each element for processing. The only drawback of this method was that for large DOFs, the number of vector signal would be large and, hence, includes complex calculations [56]. Therefore, a One-Step Method, a vectorized approximation, for RLS filter has been developed to reduce the number of operations. 12 DOF model was tested for the comparison of one-step method and RLS filter algorithm. The convergence time for RLS filter algorithm was seen to be less than that of one step method, thus proving its robustness in damage detection for structure with less DOFs.

3.1.7 Autoregressive (AR) models

With the development of SHM techniques, an autoregressive (AR) technique was developed which uses statistical pattern recognition and time series analysis to monitor [59]. This model is a two-stage prediction process which combines autoregressive (AR) and autoregressive with exogenous inputs (ARX) model. The model uses signal from the healthy structure for damage analysis. da Silva et al. [60] proposed a method for damage analysis in which the damage detection was based on AR-ARX model [59] and quantification of damage was based on the fuzzy c-means algorithm [61]. The model was tested on the IASC–ASCE Phase-I benchmark structure [11] and the first four damage scenarios. 16 acceleration readings were recorded for each case (2 along x-axis and 2 along y-axis) and these served as the input for AR-ARX model. The AR-ARX model for damage scenario 12 was considered for comparison of probability density function of residual error from damage with reference signal (signal). To quantify the damage fuzzy clustering was used. This method can be of interest for damage analysis of complex structure. However, further investigation has to be performed for noise other than Gaussian White noise for conformation of the method. The damage measured is in global level.

Unlike the above technique, ARMA model is used for damage analysis at the local level [62, 63]. The autoregressive moving average (ARMA) model is used to design linear stochastic time history response models of the structures even if the structural excitation response in unknown [64, 65].

The autoregressive (AR) function is given as (Eq. 8) [66]:

Equations 8 and 9 show that the ARMA parameters obtained represent the dynamic structural characteristics which are useful for health monitoring. From Eq. 9, it can be observed that the damping ratio (ξ) and natural frequency (ω) can be determined from the AR parameter only [67, 68]. Therefore, the moving average (MA) parameters are considered to be less important for system identification though they are important for the purpose of modelling. MA parameters are mainly associated with mass, damping properties and stiffness of the structural system. AR model can be used without the MA terms, by inverting the MA parameter series to AR parameter series. But this approach may give rise to a series of infinite length which is not desirable, but the estimation can be obtained by linear least-squared manner which is easier to calculate. If the residuals at input side obtained are not white, then the excitation poles, system dynamics, filter characteristics, measurement noise or any combination of these have not been measured by the ARMA model [66]. Suitable model orders, Akaike Information Criterion (AIC), Rissanen’s Minimum Description Length (MDL) criterion and Bayesian Information Criterion (BIC), may be used in order to determine the suitable model orders [69].

Carden and Brownjohn [70] used the ARMA in collaboration with time series approach to detect damage in IASC–ASCE benchmark structure for Phase-I [11]. The damage sensitivity features, the first three AR coefficients, were compared using t test with both experimental and analytical results. The damage was successfully determined and the change in first two AR coefficients can detect the damage location. The AIC was used for estimation of model orders [69]. This classifier-based algorithm has been used to separate damaged state from undamaged in the ARMA model. However, this model failed to detect damage due to high-order and low-order assumptions for which no clear results could be obtained.

Nair et al. [63] designed a new method for damage detection using the ARMA model. AR coefficients-based damage sensitive feature (DSF) was used to detect damage from the signals obtained from undamaged and damaged structure. For locating the damaged region on the structure, two localization indices (LI1 and LI2) have been introduced.

Using the first three AR coefficients, α 21 ,\(\alpha_{2}^{2}\) and α 23 , a robust DSF has been proposed [63]:

As the stiffness decreases due to the presence of damage, the AR parameters will also change due to varying structural response. The DSF can detect the change in measurements between damaged and undamaged state for analysis. The damage localization indices LI1 and LI2 are as follows (Eq. 11) [63]:

where dmean is the distance between the midpoints of undamaged and damaged clouds, dundam cloud and ddam cloud are the distance from the origin to center of undamaged cloud and damaged cloud, respectively (undamaged and damaged clouds in AR coefficient space). Damage localization was applied on the four damage patterns: 1, 2 (major damage) and 3, 4 (minor damage). It was observed that LI1 was a better localization index than LI2.

The damage decision has been decided on the hypothesis test with a significance level of 0 [63]. The damage decisions for the analytical major and analytical minor patterns have been studied and it can be observed that as the p values are very less; hence, H0 (null hypothesis) is rejected in all the cases and H1 (alternate hypothesis) is accepted indicating damage in the structure. Therefore, the probability that the damage has occurred cannot be predicted only by DSF even if the structure is damaged. This ARMA-based time series algorithm has been successful in detection of damage. The advantage is that no finite element modelling is required. This algorithm is suitable for wireless sensor analysis which can process data through embedded algorithms.

3.1.8 Time history approach

Nair and Kiremidjian [71] used time series analysis of vibrational signals along with Gaussian Mixtures Modelling to identify damage extent in terms of Mahalanobis distance. The pre-damage and post-damage vibrational sensor data have been normalized and fitted into ARMA model. These data are used in the Gaussian Mixture Model (GMM) to classify the damage pattern [72]. The damage extent is characterized with the help of Mahalanobis distance between centroid of mixture distribution of the damage occurred and the baseline mixture [73]. The damage extent or Mahalanobis distance is calculated using Eq. 12 [71].

It was observed that the damage extent holds good correlation even in noisy environment. The limitations pointed were that the previous knowledge about the structure has to be known and the damaged data have to be properly measured using full sensor data. Failing to do this may lead to false damage indication.

The strategy was experimented on ASCE benchmark Phase-I structure [11] by Nair and Kiremidjian [71]. The damages considered are all the 6 damage patterns. With the increase in damage progress, the Mahalanobis length increased indicating detection of damage.

3.1.9 Parameter identification tool

The use of vibrational signals measured from sensors for real time damage analysis is challenging but important in the field of research. Most of the techniques developed so far have dealt with the linear structures requiring both reference and damaged data, with the help of sensors, for detection of damage [74]. However, the reference data may not be available in several cases and also it is desired that the number of sensors used be minimized. To minimize these problems, new methods were developed: Extended Kalman Filter (EKF) [75] and Sequential NonLinear Least Square Estimation (SNLSE) [76].

3.1.9.1 Extended Kalman filter

The commonly used parameter identification tool is the Extended Kalman Filter (EKF) [77], which is effective for the identification of structural parameters with limited and unknown measurements [75, 78,79,80]. However, the traditional EKF method is unable to estimate the nonlinear damage with unknown inputs. A number of researches have been performed to estimate the nonlinear damage condition by combining EKF with iterative least squares methods [81] and using unscented Kalman Filter (UKF) [82]. However, these techniques were suitable for unknown offline inputs. For online tracking of the evolved structural damage parameter, the least squares objective function has been minimized to derive EKF with unknown inputs [83]. However, these approaches make use of inputs in observation equations which pose a challenge for sensor installation [81,82,83,84].

Pan et al. [85] proposed the use of General EKF with unknown inputs (GEKF-UI) to identify the unknown inputs and structural parameters simultaneously. In this method, it is not required to measure the responses of all the DOFs. The responses for which some entries of input are missing are calculated for analysis. This parameter identification method was implemented on ASCE Phase-I structure with white noises (5 and 10%) at 2nd and 4th floors along the weak direction. It can be observed that though an error of 1–7.2% has been recorded, the method holds a good agreement with the identified parameters.

3.1.9.2 Sequential nonlinear least square estimation

Yang and Huang [86] used the SNLSE with unknown excitations (input) and responses (output) (SNLSE-UI-UO) for SHM analysis with a goal to reduce the number of sensors used [87]. This process involves extraction of state vectors including velocity and displacement from the recursive solution derived by minimizing sum-square error. The recursive solution is obtained from the constant parametric vector using adaptive tracking technique. And the adaptive factor is determined from the current input data. To verify the result of this technique, it has been implemented on the ASCE benchmark structure Phase-I, with symmetric loads and ambient vibration, as white noise, in the 4th floor (CASE 3) [11]. The white noise and absolute acceleration of the 2nd floor are unknown and can be identified from unknown external excitation, state vector and parametric vector.

3.1.10 Model update and damage analysis

System identification and damage detection techniques have been a favourite area of interest for SHM. The damage detected due to the dynamic load such as earthquake and wind force can provide global evaluation of the structural condition. A number of methods have been developed in this research area for system identification; Fast Fourier Transform (FFT) method [88], natural excitation technique with an eigen system realization algorithm (ERA) [89], ARMA model [90] and stochastic subspace identification [36].

For the purpose of damage detection, a number of damage detection technique has been developed; Statistical Model Updating Method [91], Synthesized Flexibility Matrices method [35], Least Squares Approach [14] and Finite Element (FE) Modelling [92]. The updating techniques require a set of structural models to predict different possibilities of model conditions. Most of these methods utilize the Bayesian model updating technique to characterise modelling uncertainties of structural system. The reason behind this choice is the ability of Bayesian model to consider more than one structural model for analysis [93].

3.1.10.1 Two-stage model update

Yuen et al. [94] designed a two-stage SHM approach for Phase 1 benchmark structure. The process is modelled in such a way that in stage 1, modal identification is carried out using MODE-ID technique [95,96,97] and in stage 2, damage detection is carried out using model updating [98, 99].

The modal parameters are extracted in stage 1 from the time domain measured data. The identified parameters are damping ratio, modal frequency, effective modal participation factors and initial modal velocities and displacements. To obtain the stiffness parameters, modal identification is carried out. Then, updated probability density function (PDF) is calculated using Bayes theorem [96, 100]. The main aim of model updating method is to update the PDF of stiffness parameters of identification model, by MODE-ID technique, based on the data measured from the damaged and undamaged structure [101].

For unknown excitations, the correlation functions should satisfy the free vibration equation where “pseudo-time” is considered for time lag [102]. This algorithm is effective for providing the modal parameters but failed to directly provide the uncertainly of modal parameters. Therefore, the stage two is performed for structural model identification.

In this stage, a Bayesian statistical approach has been employed to update PDF for the stiffness parameters utilizing the identified modal parameters of stage 1 [98, 99]. The method determines the probability of change in the values of stiffness. The PDF estimated is derived based on Bayes’ theorem.

The following algorithm was tested on the ASCE benchmark problem—Phase I for the 6 cases. For all the cases, 12-DOF shear building model was adopted for simple structural study and the cases 2 (including model error, known inputs and unknown inputs), 3 (with roof excitation and unknown inputs) and 5 (with model error and unknown inputs) have been shown in the study.

In the first stage of the procedure, the modes’ shapes have been extracted and normalized. The coefficient of variation (COV) percentages, ratio of sample standard deviation to sample mean value, have been shown in the brackets [11]. The variation in frequencies (< 1%) and damping ratios (~ 50%) has also been observed for all the cases. In spite of large variation in damping ratio, the method has been chosen because the SHM process does not include the damping ratio for the formulation [94].

The second stage involves damage detection in which the stiffness parameters are globally updated. Multidimensional Gaussian distribution is used to approximate the updated PDF [100]. It can be seen that for case 2 the results obtained are not satisfactory due to the presence of model error. The ratios shifted from unity even though there was no damage in storey 2 and 4. Also, the 120-DOF has been simplified to 4-DOF system which may have hampered the readings. Therefore, it has been recommended by the researchers to use the marginal PDFs for stiffness parameters for damage detection. It can be observed that damage patterns 4 and 5 are negligibly different though the damage has been introduced by loosening the bolt. Therefore, minor damage cannot be easily detected. This error may be due to the damage being local. This method uses mainly the global stiffness matrix for damage analysis.

3.1.10.2 Statistical model updating approach

The Statistical Model Updating Approach developed by Lam et al. [91] uses One Step Model Updating Approach to determine damage in the structure. Unlike the two-stage update method, this method uses identification vector which includes stiffness parameters θ along with modal frequencies. The stiffness matrix is parameterized in linear manner as in Eq. 13.

where K0 is the initial global stiffness matrix and Ki is the stiffness of ith substructure.

The PDF is then used for model update. One step approach adopted ensures that the structural model corresponding to the optimal stiffness parameters is same as the optimal structural model. This property is not absolutely true for the two-step method. Case 2 of ASCE benchmark was considered for study which includes 120 DOF model. Modelling error recorded was not a hindrance in locating damage, thus proving the effectiveness of the algorithm even in the presence of noise.

3.1.11 Data-driven approach

Data-driven stochastic subspace identification (SSI-DATA) is an iterative algorithm to determine damage coefficients [103]. This strategy is applied so as to detect the damage characteristics such as position and severity. The method considers two assumptions: (1) in case of damage, the mass matrix remains unchanged whereas the stiffness and damping matrix change and (2) behaviour of the structure is linear before and after the damage occurrence. The method derives the frequency, mode shapes and damping ratio from the output data and from the damaged stiffness matrix using iterative process. Then, the damage coefficient is calculated and iteration is done to reduce the residual function and acquiring a good result of damaged structure. The method has been implemented on ASCE benchmark structure for damage patterns 1, 2 and 3. The damage locations and severity of damage were identified using the algorithm.

3.1.12 Artificial neural network

Artificial Neural Network (ANN) is a damage detection algorithm widely used for analysis in construction, machinery, aerospace, etc. It has got three main characteristics: strong nonlinearity, large-scale parallel distribution management and strong fault tolerance and robustness [104, 105]. ANN consists of group of interconnected neurons, processing units, which individually performs simple computation process. ANN is a self-learning network which can change the weights of network and numerical biases using iterative process according to the previous data [106]. The neurons are organized in layers with one neuron for each input in the first layer, and one neuron for each output in the last layer. The number of neurons in the intermediate layers may be numerous. The ANN architecture is very crucial for efficient performance of the network; a factor that has been overlooked by numerous researchers [107, 108].

Shi and Yu [5] used the non-model approach for analysis with the help of ANN. This process is an adaptive learning and nonlinear mapping system which can adjust the network connections to minimize the mean square error at the output. The SHM process for wavelet analysis includes sensor measurement, signal pre-processing, feature extraction (using wavelet analysis) and damage detection using ANN. The raw data obtained from the sensors are pre-processed/filtered for noise reduction. Then, the wavelet transform is applied to extract structural feature vectors or wavelet coefficients. These serve as the input for ANN which determines if the structure is healthy or not. The algorithm was used for damage detection of IASC–ASCE Phase-I benchmark structure using neural network of level 5. Damage cases 1 and 2 were studied and the differences between training and testing stage obtained were 4.03 and 2.25%, respectively, which show damage detection with good accuracy even in the presence of noise.

3.1.13 Adaptive neuro-fuzzy inference system

SHM mainly monitors the changes in vibrational signals, damping coefficients and stiffness, to calculate the mode shapes and natural frequency for damage analysis. Many artificial intelligence (AI) methods have been developed, such as generic algorithm [109], generic fuzzy system [110] and fuzzy cognitive maps [111], for mapping of parameters in modal domain to damage location and severity [2]. These studies, however, did not take into consideration the rapid damage identification of engineering structures in short period of time [112].

Zhu and Wu [2] conducted their research on a rapid damage detection technique using non-parametric Adaptive Neuro-Fuzzy Inference System (ANFIS) [113], a system identification (SI) method, for structural system identification and interval modelling technique for rapid damage detection [114]. ANFIS can be used for obtaining the input (location and extent of crack)–output (structural eigen frequencies) relation of the structural system [113]. A time-delayed ANFIS can be used for modelling magnetorheologocal (MR) dampers under forces of high impact [115], whereas wavelet-based ANFIS can be utilized for modelling the nonlinear behaviour of smart structures installed with MR dampers [116]. Interval Modelling Technique is mainly used for quantification of the uncertainties in a structural dynamics problem [117]. This method has been used for identifying the dynamic models under numerous test conditions from the time domain input–output data [118].

Several techniques have been designed in order to fit the single output of the wavelet-based ANFIS; average method, weighted average method and interval modelling method. The first two methods work on the principle of output adjustments to obtain a comprehensive result. Therefore, this technique could not be used as damage feature extractor for damage identification [2]. The last method is similar to PCA which can be effective for damage feature extraction [119]. The damage detection algorithm has been shown in Fig. 5. The damage is indicated if \(|M_{iT} | > \rho .\)

Rapid damage detection algorithm using ANFIS [2]

For better performance of ANFIS, complex network has to be designed and trained involving more fuzzy rules and membership functions and longer training time. Noise of 10% is introduced in order to predict the response of practical structure, as such structures always include noise [2]. This condition was applied on damage patterns 2 and 3 and it was observed that for both the cases, damage was identified at a lesser time. However, for low level damage, as that of pattern 3 (as compared to pattern 2), the algorithm was not able to detect any damage.

3.1.14 Cuckoo optimization algorithm

Cuckoo algorithm is an optimization technique which uses the reproductive strategy of cuckoo, brood parasite method, to optimize and detect damage in structure [120]. This method uses flexibility matrix to calculate static displacement to indicate damage in the structure [121]. Static displacement is a good measure for damage analysis as it is directly related to stiffness of the structure. The cuckoo algorithm has shown in Fig. 6. This iterative optimization process can be used to calculate cost function.

Cuckoo algorithm [120]

where E is the error vector between calculated displacement obtained from the modal data and displacement of damaged structure with unknown damage severity.

The method has been tested on ASCE benchmark structure to determine the damage severity for damage pattern 2, 4 and 6 indicating major, medium and minor damage, respectively. The damage severities were detected accurately. To evaluate the performance of the algorithm, the results have also been compared with an evolutionary optimization algorithm based on natural and generic selection principles, Generic Algorithm (GA) [122]. The cuckoo algorithm was observed to be faster in detecting the damage severity due to its high convergence speed.

3.1.15 Comparison and discussion

A comparative study was carried out among the different damage detection techniques for phase 1 study. Different techniques implemented on ASCE benchmark structure have been studied and a uniform platform for damage comparison has been obtained. This comparison has been framed for the ability of the algorithms to detect damage and quantify damage as major damage or minor damage, detect if the results are noise contaminated and to quantify the amount of data used to obtain the damage result (Table 2). The lesser the number of data used to achieve the final result, the more efficient the algorithm. Similar comparison has been made for Phase-II analytical and the experimental model for Phase-I and Phase-II. The different methods have their own pros and cons.

The system identification technique uses NExT/ERA method and OKID method for damage detection. OKID can detect both major and minor damage to the structure with the help of the data available from the sensors, unlike NExT/ERA method in which the presence of noise reduces the ability to sense small change in stiffness. However, like the NExT/ERA method, the results obtained are contaminated with noise making it ineffective to measure damage severity. Modal identification using Synchrosqueeze wavelet transform also showed good agreement with the original benchmark analysis. The Damage Index method offers an improvement in detection process by measuring the damage severity using all the data from the structure but only for major damage to the structure. Due to noise contamination, the minor damages are masked with the noise. The flexibility method detects damage as similar to the OKID technique without any noise interference, but using the full set of data available. EM algorithm which can calculate maximum likelihood estimate of structure with original structure uses a slow iterative loop to converge at the damage point. This was improved with the help of SSI to improve the efficiency of the algorithm. Wavelet Analysis consists of Direct Decomposition, EMD, EMD-HHT and RDL-HHT. Out of these methods, Direct Decomposition and EMD methods have a similar way of detecting damage, i.e. they can measure damage in the structure if its nature is severe using the full set of data. The result obtained is a noise contaminated up to certain extent making the lower level damages not measureable. The improved EMD technique, EMD-HHT, has proved to be more robust than normal EMD technique in detection of both severe and less severe damages without any noise contamination. The method made use of full set of data from the structure and can eliminate the noise using Hilbert–Huang Transformation with the data from one sensor. A modified wavelet analysis, RDL-HHT, was implemented which can perform as efficiently as the EMD-HHT, but with the limited set of sensor data. The plotted least square fit graph helps to determine the missing sensor data. Thus, for structures where it is not possible to place a sensor in particular place, this method can be used to calculate damage. Adaptive RLS filter works similar to the advanced wavelet analysis techniques, but utilize the full set of data from the structure. The full data are used to obtain the convergence time which indicates the damage in the structure. The faster the convergence, the more accurate the damage detected. Autoregressive methods, such as ARX model and ARMA by DSP, proved to be good damage detecting models which can detect and quantify damage without any noise contamination in the presence of full set of sensor data from the structure. However, ARMA by AIC was unable to detect damage as it is a classifier-based algorithm which makes the assumption of higher order and lower order derivative for damage evaluation. Hence, no clear result is obtained for the damage. Time History analysis using Mahalanobis distance have been able to identify the damage severity. The noise contamination has been reduced so that the damage can be detected. However, previous knowledge of the structure needs to be obtained; failing to do so may lead to false damage indication. The GEKF and SNLSE methods analyse the missing input data from the given response and has proved to be effective in presence of noise. Thus, these methods are good for damage analysis. The model update techniques used for study are two-stage model update and Statistical Model Updating Approach. The two-stage approach using Bayesian approach uses the full set of data available to measure and quantify the severe damage. As the method utilizes global stiffness matrix, the local damages are not measured. The Statistical Model Update Approach uses a one step update approach to detect damages in the absence of any modelling error or noise. The SSI DATA are a good iterative method to determine the structural parameters and determine damage coefficients; however, it is not able to detect minor damages. Both the Artificial Neural Network and Adaptive Neuro-Fuzzy Inference System are good techniques without any noise contamination and good at measuring severe damages to the structure. Both these methods require a full set of data for damage analysis. Cuckoo algorithm has proved to be robust optimization algorithm for damage detection.

3.2 Experimental Phase-I model

The experimental phase-I model has been proposed to implement and study the damage techniques under excitation [123]. The excitation is provided with the help of Ling Dynamic Electrodynamic shaker and placing mass on the top floor. The damage conditions implemented are as shown in Table 3. The ambient vibration was also considered as a scenario for damage detection. The damage introduced is mainly by removal of braces and bolts. This phase has been experimented to obtain the results so that a phase-II model can be developed for benchmark analysis. Cases C, D, F, I and J include major damage which considers the removal of braces. Cases E, G and H include minor damage to the structure which means loosening of beam column connection.

3.2.1 Power spectral density method

A damage identification technique, Power Spectral Density (PSD), has been introduced by Mikami et al. [124] for localization, detection and monitoring of damage rate with the use of unknown input. The technique utilizes the acceleration time history data to determine PSD data instead of the measurement of excitation forces. These data can then be statistically analysed to determine damage location. The damage is indicated by the difference in PSD readings after and before the damage (Eq. 15).

where f is the frequency value for the channel number i, G * i (f) and Gi(f) are the PSD readings for damaged and undamaged cases, respectively.

The damage cases for the IASC–ASCE benchmark for cases B,C,D and E were studied and were found that due to small variation in damage data, the frequency range cannot be used to determine the damage for Case C [123].

Thus, the total change is obtained by summation of all the PSD change values for different frequencies, which is employed for damage analysis. Though the method was found to be weak for indicating damage localization, it can be used for the detection of damage occurrence and monitoring the damage growth. Damage location was indicated assuming that the environmental noises are negligible and severe damages produce more difference in PSD data. Therefore, the damage has been detected for all the cases. This method has been seen to provide damage results for single damage case and successfully indicating damage and monitoring its growth, but is unable to detect damage severity [124].

3.2.2 Bayesian damage detection model

Most of the techniques developed face problem due to incomplete nature of sensed data, complicated nonlinear structural behaviour and uncertainties in the model predicted and sensed data. To reduce the modelling errors and data uncertainty, the Bayesian Probabilistic Method was developed for SHM [11, 91, 98,99,100, 125, 126]. The two-step Bayesian process has been employed for SHM and it has been a success for damage detection [98, 100, 127].

Jiang and Mahadevan [128] employed a nonparametric damage detection technique based on Bayesian Probabilistic Method. A Bayesian hypothesis is designed to evaluate the damage. The process includes the application of dynamic fuzzy wavelet neural network (WNN) model [129] for identifying the nonparametric system. The system training is conducted with the help of Bayesian null point hypothesis-based method and relative root mean square (RRMS) error method [128].

The quantitative measure for overall reliability assessment of system identification is given as (Eq. 16):

The above method was employed for damage analysis for the ASCE benchmark problem considering damage with electrodynamic shaker and the damage results for the 5 cases, C, D, E, G and H [123]. The technique proved to be a good detecting tool for global damage detection giving damage in x direction for cases C and D and damage in y direction for cases D and E. However, the local damage is mostly considered for damage detection which was not effectively calculated by this algorithm (cases G and H). To localize the damage, classical neural networks can be combined with Bayesian method.

3.2.3 Fuzzy stochastic neural network

To extent the work of other researchers in the field of ANN [130], Jiang et al. [131] designed a dynamic fuzzy stochastic neural network (SNN) model for non-parametric damage identification. A number of researches have been performed using the ARMA model for non-parametric analysis. However, the problems faced were uncertainties in predicted and sensed data and the complicated structural behaviour. The dynamic fuzzy SNN can handle fuzzy information (by fuzzy logic) and uncertainties form the sensed data for damage analysis (by Bayesian hypothesis). The fuzzy SNN model is created using fuzzy c-cluster and the Kullback–Leibler distance criterion is developed to train the model. The model analysis was carried out in time domain and frequency domain using RMSS error-based metric and Bayesian hypothesis based metric. The technique was used on ASCE benchmark building with ambient vibrations (Cases B and F) and was found to be effective under stationary random excitations [123]. The difference between the two sets of data for case B is insignificant indicating that the fuzzy SNN model can detect the structural system correctly. Thus, the model is effective for stationary random excitations.

3.2.4 Comparison and discussion

Similar to the analytical phase-I study, a comparative study is made among the different damage techniques used by different researchers on experimental study (Table 4). The methods are PSD, Bayesian damage detection model and Dynamic fuzzy SNN model. All the methods were good for analysis in their own respect.

The PSD method is a good damage detecting method which can provide results for single damage case successfully indicating damage and monitor its growth. The environmental noise is also suppressed in this method subtracting the standard deviation of total maximum changes in PSD from the maximum change in PSD, thus reducing the noise. However, the method was unable to detect the damage severity. The Bayesian method for damage detection uses neural network to detect and localize the damage in the structure. The full set of data measured is required for measuring the damage but the minor damages are ignored in the algorithm as the method is used for global damage detection. Dynamic Fuzzy SNN model makes use of fuzzy logic to process the data and Bayesian hypothesis to analyse he damage. The method uses the full set of data available and is unable to quantify the damage.

4 Damage algorithms on Phase-II structure

The second phase of study was initiated keeping in mind that the mathematical model selected is much simpler than the real complex structure. Similar to phase-I, analytical and experimental model was prepared for this phase.

4.1 Analytical Phase-II benchmark structure

Phase-II analytical structure consists of user-defined condition of damage insertion. The parameters that were treated to be deviating are mass value, position of centre of mass, stiffness of bracing element and rotational stiffness of the beam–column connection. The phase-II gives the user freedom to choose the type of damage according to the problem statement. This privilege was not available in case of phase-I structure. The few damage details commonly used for damage analysis have been shown in Table 5 [13]. These damage cases have been considered for the study of bracing system damage and beams to column connection damage. The beam to column damage is studied considering unbraced condition. The major damage includes cases RB.fs, DP1B.fs, DP2B.fs and DP3B.fs. The minor damage (loosening of bolts) includes cases RU.fs, DP1U.fs and DP2U.fs. Due to the user friendly nature of phase 2 analytical structure, most of the researchers prefer to use self-defined damage.

4.1.1 Hierarchical sparse Bayesian learning algorithm (HSBL)

Huang et al. [132] made use of Hierarchical Sparse Bayesian learning for high-resolution damage localization. This method uses the sparse Bayesian learning (SBL) [133] and Bayesian compressive sensing for damage analysis [134]. The SBL method eliminates the unreliable approximation from the original theoretical function. Along with compressive sensing, the method reduces error due to stiffness inversion and computes the mass, stiffness and mode shapes effectively. The SBL phase includes calibration of the structural model to estimate the uncertain parameters (stiffness) due to occurrence of damage. The commonly used SBL technique requires adjustments to obtain real-time data [135]. To overcome this problem, the new SBL method (HSBL) uses no approximation and uses probabilistic method to infer the stiffness reduction. The second part of the algorithm is the monitoring part which uses the data from SBL to indicate damage in the structure. The algorithm proposed possess a scale invariance property which gives it independence to choose the units of mass and stiffness matrices according to availability. Also the stiffness inversion can be achieved by suppressing the mean stiffness. This optimizes the algorithm and the Maximum A Posteriori (MAP) estimates for parameters are obtained. The proposed algorithm has been applied on the IASC–ASCE Phase-II benchmark structure (simulated and experimental) for damage detection [13, 136]. Generally, each member of the structure is treated as a substructure so that the dynamic data can be obtained in case of any damage. In view of reducing the network of sensors and the modal parameters, assembly of structural members has been considered as a single substructure. During monitoring, the MAP values from the calibration stage is used to detect damage in the second stage. The application of the method in ASCE benchmark problem has found importance for damage detection for severe damage case.

4.1.2 ANN

For the study of ANN on Phase-II ASCE benchmark, the Back Propagation (BP) algorithm has been adopted by Yang and Mi [137]. A two-stage damage identification process has been followed in the study. In the first stage, the damage substructure with similar material characteristic and the consistent parts of dynamic characteristics is recognized. The second stage deals with damage location in the structure. This procedure seems to reduce the modified parameters, reduce calculations and increase the efficiency of damage analysis [138]. The BP training model for ANN also consists of two layers: a) positive process, which processes the input information, obtained from input layer to hidden layer and calculates the layer by layer output value of each element, and b) reverse process, which adjusts the weighed value, by calculating the error between the expected and actual output, when the expected output in the output layer is not obtained [138]. Yang and Mi [137] used the BP algorithm and L–M rule for damage analysis of braces, columns and beams. It can be observed that the damage in braces and columns was detected perfectly (output of ANN = 1). But the beam damage could not be justified as the damage in beam has slight change in the overall structural natural frequency. The method also proved to be effective for detection of multiple damages in most of the cases.

4.1.3 Model update using Gibbs sampler

The model updating methods discussed in previous part of the paper were used to define a linear model by identifying the structural stiffness. But using these techniques did not ensure the errors due to modelling as there may be more than one optimal model [139]. This problem was resolved when the amount of data used for identification was in large amount [100]. To encounter the problem of small amount of data, Markov chain Monte Carlo algorithm was used by Beck and Au; however, the method has proved to be efficient for low dimension problems [140].

For the purpose of developing model update algorithm valid for all the types of structure, Ching et al. [93] used Gibbs Sampler (GS) to update linear structural models with incomplete model data. The GS decomposes the uncertain model parameters into three groups (λ, ϕ, σ2). The individual dimension of the three groups is large, but the effective dimension used for calculation is three. This ensures that exact sample can be obtained from one parameter group conditional on other groups and hence the modal data can be calculated. Linear structural model is identified with the help of Bayesian Approach. PDF is defined using Gibbs sampler algorithm for model update and structural health monitoring. Monitoring is done by providing index to measure damage severity and locate damage. The damage is compared with the undamaged state and possible damaged state by determining the damage probability exceeding threshold.

Using GS process, the Markov chain samples of stiffness, mode shapes and stiffness are obtained. The advantage of GS approach is that the efficiency does not degrade with increase in the number of uncertain structural parameters. This feature is a plus point when compared to Markov chain which has been observed to burn out after 1000 samples, i.e. after 1000 samples the result for all the cases are almost similar [93]. However, it was observed that though GS method gave no false alarms for the 120 DOF ASCE structure and is suitable for high dimensional uncertain values, the method is not suitable for local damage where the PDF value is high [93].

4.1.4 Wavelet packet decomposition approach

Sun and Chang [141] used a covariance-driven wavelet packet signature extraction method to monitor structural degradation due to random ambient excitation. This method measures response from one location of the structure to establish a wavelet package which can serve as a damage indicator. This method uses response covariance which reflects the structural condition indicating the probable changes in the properties. The response covariance functions are normalized to form wavelet packet decomposition signal in time domain. These wavelet packet signatures (WPS) are used as input of neural network (NN) model to be used as damage indicator for damage occurrence and damage quantification (Eq. 17).

where E i j is the WPS of the measured data and \(\hat{E}_{j}^{i}\) is the baseline WPS.

The main advantage of this method is that it does not require any previous mathematical knowledge of the structure. The technique was modified to reduce the noise by eliminating the mean square values from output covariances which may be the reason for noise contamination. For the Phase-2 structure damage conditions, the algorithm was able to detect damage with a confidence level of 95–99%.

4.1.5 Symmetry measure for damage detection

Continuous symmetry measure (CSM) is an algorithm to determine the symmetry of shape for a structure [142]. This method is applicable for determining any kind of symmetry such as translational, rotational or mirror symmetry using mode shapes of structure. Hence, only the mass and stiffness properties are required for analysis. Increase in the CSM value indicates asymmetric structure which in turn means that damage in structure is high. The CSM is calculated as:

where n is the number of modes, \(v^{\prime}_{i}\) is the final vertex mode shape and vi is the initial vertex mode shape. CSM value of 0 represents perfect symmetry.

The phase-II structure was considered for damage analysis considering damage scenarios of Phase-I and self-made damage scenarios and considering 120° of freedom model [143]. Frequency domain decomposition was implemented to obtain the operational deflection shapes from simulated time series. The first 8 bending modes are considered for CSM calculation, 4 bending modes in X direction and 4 in Y direction were analysed separately. The deviation of CSM value is the greatest for the case of removal of braces in structure, indicating major damage; and the smallest value of CSM was obtained for stiffness reduction of brace by 2/3 in first floor, indicating minor damage. Therefore the minor damage detection has to be studied as low level damages in the structure, such as creep, corrosion and loosening of joints, is common. The algorithm has been found out to work for asymmetric damage case rather than symmetric damage as the CSM values for symmetric case showed negative damage.

4.1.6 Comparison and discussion

The analytical phase-II structure has been an interesting subject for study. The real-time damage analysis was possible as the users were given the freedom to choose the type of damage they want to input. In this structure, different damage detection algorithms such as HSBL, BP algorithm, Model Update using GS and Wavelet Decomposition have been implemented (Table 6). The behaviour of algorithms under the damage cases has been studied.

The HSBL algorithm uses the damage probability to observe damage in the structure. To reduce the amount of data to be used, the assembly of structural members is done in such a way that it is considered as a single substructure. Then, this substructure is checked for any loss in stiffness. Therefore, the severe as well as minor damages can be recognized and the damages can be quantified without any noise interference. The ANN technique is used on the benchmark problem using BP algorithm and L–M rule for damage analysis of braces, beams and columns. The method indicated good damage for severe damages. However, due to noise contamination, the method was unable to detect the minor damages and damage severity. The GS method has been a good damage indicator for damage and gave no false alarms; however, the PDF value must be in nominal range to detect minor damages to the structure. Wavelet packet decomposition approach does not require any previous structural data for damage analysis and hence can detect severe and minor damages in the structure and also quantify the damage. The noise contamination is also reduced. Therefore, the damage in the structure can easily be identified. CSM method was implemented for 120 DOF ASCE benchmark structure. The method works on shifting of mode shapes from the original symmetry. This method was robust and can easily detect damage in structure even for small change in mode shapes, i.e. corrosion, creep or loose joints.

4.2 Experimental Phase-II benchmark structure

This structure is similar to the Phase-I experimental structure. The excitation cases for this structure are due to the electrodynamic shaker, the impact hammer and the ambient vibration. The experimental case for Phase-II consists of damage patterns considered for detection as shown in Table 7 [136]. The major damages considered for this phase are 2, 3, 4, 5, 6 and 7, and the minor damages as loose beam column joints are included in cases 8 and 9.

4.2.1 Structural damage pattern recognition

An innovative damage detection technique based on Fuzzy Cluster (FC) algorithm and Artificial Immune Pattern Recognition (AIPR) has been introduced by Chen and Zang [144]. The FC algorithm is used to generate an initial memory which can store the damage pattern. Then, the AIPR is being employed to modify the quality of memory cells that represent the different damage patterns. This system is similar to the human adaptive immune system which can learn from the diseases occurring. The SHM method uses data measured from the multiple sensors and feeds them to the autoregressive algorithm to obtain damage pattern. This pattern is stored in the memory cell generated by fuzzy clustering. The AIPR system then evolves the memory cell by continuous damage pattern update. These evolved cells are used for damage pattern detection. The method has been used on ASCE Phase-II benchmark structure [136] for validation. The technique was successful in detecting damage with a success rate of approx. 83%.

4.2.2 ARMA model

Carden and Brownjohn [66] studied the Phase-II of the ASCE benchmark for ARMA model application taking into consideration the experimental phase II damage pattern [136]. The study deals with only the case in which the responses were obtained from electrodynamic shaker.

The shaker input force showed peaks in the spectrum at resonant frequencies due to structure–shaker interaction [101]. This state made it difficult to extract the modal parameters. This problem was minimized or eradicated by applying ARMA model to the time response of the shaker [66]. The DSF method used by Nair et al. [63] has been implemented on experimental benchmark structure where the damage patterns C and D have been considered. The results received were not accurate as one of the sensor data recorded for damaged node was false.

4.2.3 Pole transfer method

The previous damage detection systems included the use of modal parameters, mode shapes and frequencies, for damage analysis. These parameters provide good estimation of dynamic systems as they are dependent on the structural mass and stiffness. However, the complex calculative models and error due to noise may hinder the results [4]. In order to counter this problem, the input and output response data of the structure are considered to extract the complex domain transfer function which can estimate the undamaged structure. On occurrence of damage, the transfer function characteristics equation roots are compared with the undamaged structure for analysis [145]. Lynch [145] used the time series-based autoregressive (ARX) model to estimate the modal damping ratio and modal frequency of the dynamic system. The pole transfer function can be written as (Eq. 19):

where H(z) is the pole transfer function, a and b are the weights on past observations of system output and input, respectively, na and nb are the observations of the system output and input, respectively, and z is the Z-transform discrete time analogue of continuous-time Laplace transform.

The ARX system identification model pole locations for all the 5 configurations have been shown. It can be seen that the damaged clusters have migrated from the original undamaged condition indicating the damage in the structure and the migration distance indicated damage extent. Therefore, it can be seen that configuration 2 and 3 has got higher damage severity than that of 4 and 5, thus proving the accuracy of the method. This method can be easily used to determine the damage extent for each scenario, but further study has to be conducted for detection of damage in structure and measuring the influence of environmental noise in the measured readings.

4.2.4 Model update

4.2.4.1 FE-based algorithm

The FE-based model adopted by Friswelli and Mottershead [92] used to estimate the experimental damage was successful. But FE model updating using ambient vibrational data measurement is very rarely being researched upon. A two-stage finite element (FE)-based model updating system has been used by Wu and Li for the ASCE benchmark structure Phase-II taking into consideration the ambient vibrations [146]. In the first stage, the stiffness of the beam-column joints has been identified via FE model updating. In the second stage, the cross-section areas of the braces are obtained by FE model updating, through comparing the differences between undamaged and damaged structure. Following this process, the damaged braces can be located and quantified.

4.2.4.2 Bayesian-based algorithm

4.2.4.2.1 Expectation–maximization algorithm

Ching and Beck [101] utilized the Bayesian-based method, a two-step probabilistic SHM approach, for damage analysis. This algorithm has previously been used by Yuen et al. [94]. In this method, the updating algorithm has been modified to expectation–maximization (EM) algorithm which is more reliable as compared to the previous model [101]. The damage detection is based on the probability that each substructure stiffness parameter has a factional decrement of damage severity from undamaged to probable damaged stage. The first step is the extraction of experimental modal parameters from the time domain measure acceleration data with the help of modal identification procedure, MODE-ID [95, 96, 102]. This procedure uses Euclidean norm to estimate the modal parameters in case of excited forces. For ambient vibration, the structural responses and excitations are modelled as weakly stationary stochastic processes [102]. These extracted modal parameters are used for damage analysis in the next step using Bayesian statistical approach to calculate updated PDF for stiffness and mass parameters [99, 100, 147].