Abstract

The use of nanoemulsions in cosmetic products has been enlarged in the last decades because of several formulative advantages (e.g., the improved self-life stability, better texture properties). In addition, nanoemulsions seemed to improve the penetration of active ingredients through the human skin, comparing to conventional emulsion. In this contest, the risk of a higher systemic exposure of consumer to active ingredients, due to the ability of nanoemulsion to enhance permeation, results a critical attribute that should be evaluated for assuring the consumer safety. The aim of this work was the evaluation of how an oil-in-water (O/W) nanoemulsion can influence the in vitro skin permeation profiles of two model active ingredients with different polarity (i.e., caffeine and ethyl ximenynate). Preliminarily, since both selected molecules influenced the physical stability of nanoemulsion, formulative studies were carried out to identify the most stable formulation to perform in vitro permeation studies. The overall results demonstrated that nanoemulsions could significantly influence the permeation profiles of molecules as a function of their physicochemical properties. In particular, O/W nanoemulsions significantly improved the permeation profiles of apolar active ingredients in comparison to conventional emulsions, whereas no differences were observable for polar molecules. Considering such findings, it is worth observing that there is room for reconsidering the risk assessment of nanoemulsion-based cosmetic products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanoemulsions are emulsions with uniform and extremely small droplets with size in the range of 20–200 nm [1, 2], whereas classical emulsions are characterized by a coarse droplet size which can reach 1 μm. Nanoemulsions appear transparent or translucent with a bluish Tyndall effect, which is light scattering phenomenon commonly observed in all colloidal dispersions. In comparison to conventional emulsions, the nanosize droplets are more kinetic stable, resulting in a lower tendency of nanoemulsions to creaming, sedimentation, flocculation or coalescence [2, 3]. However, since they are non-equilibrium systems, nanoemulsions are usually obtained mechanically using both high-energy input (e.g., high-shear stirring, high-pressure homogenizers or ultrasound generators) or low-energy emulsification methods, such as the phase inversion temperature (PIT) method [2, 4].

Considering the technological advantages and the availability of scalable manufacturing methods, the application of nanoemulsions in food, cosmetic and pharmaceutical fields has been increased in the last decades [5,6,7,8]. For example, nanoemulsions have been used in the manufacturing of several cosmetic products intended to be applied on the skin, because of the higher physical stability during shelf-life and the enhanced texture properties of the final product.

Despite their nanosize dimension, this type of emulsions is not univocally considered as “nanomaterial” by a regulatory point of view [9]. Indeed, if they fulfil the nanomaterial definition given by FDA [10], they are not according to the Regulatory Framework on cosmetic products currently enforced in the European Economic Area (EEA). Regulation (EC) No 1223/2009 defines a nanomaterial as “an insoluble or biopersistant and intentionally manufactured material with one or more external dimensions, or an internal structure, on the scale from 1 to 100 nm”, excluding de facto all other nanoscale soluble systems such as nanoemulsions [11]. Considering also that the regulatory requirements for cosmetics containing nanomaterials are more stringent than for conventional products [12], the different regulatory interpretation between the Atlantic Ocean shores can significantly influence the way in which manufacturers conduct the risk assessment of nanoemulsion-based cosmetic products. Such findings are more critical for cosmetic products intended to be commercialized both in the USA and EEA.

From a toxicological point of view, blank nanoemulsion and conventional emulsion are generally superimposable. Nevertheless, risk concerning the skin permeation pattern of active ingredients should be considered since it has been demonstrated that nanoemulsion could enhance their permeation profiles [5, 13]. In general, cosmetic ingredients can penetrate the upper layer of human skin, but they must not permeate in-depth through human skin. Therefore, the risk that their permeation profile could be enhanced by using a nanoemulsion should be considered as a critical attribute for assuring the consumer safety.

The aim of this work was to evaluate how much the use of an oil-in-water (O/W) nanoemulsion in place of a conventional emulsion can influence the skin permeation of two model active ingredients with different polarity (i.e. caffeine and ethyl ximenynate). Caffeine (CAF) was generally used in anti-cellulite and anti-ageing products [14], whereas ethyl ximenynate (EXM) is a microcirculation improver. Starting from previous published studies [15] and preliminary results, the oil phase composition and percentages of active ingredients in the nanoemulsion were also investigated as well as the need to add a secondary emulsifier to improve the stability of the system. The performances of CAF- or EXM-loaded nanoemulsions and conventional emulsions were compared in terms of the in vitro skin permeation study and retained amounts using modified Franz-type diffusion cell and human epidermis (HE), as a membrane.

Materials and methods

Materials

Each component is used in the study was here reported by using the INCI name in agreement with the conventional nomenclature for cosmetic-grade ingredients. CAF was purchased by A.C.E.F. S.p.A. (I). Ethyl Ximenynate (EXM) was supplied by Indena S.p.A. (I). The dicaprylyl ether (DE) and lauryl-glucoside (LG) were purchased by Cognis Italy (I). Ethylhexyl isononanoate (EI) was supplied by Prodotti Gianni (I). The commercial mixture of PPG-26-Buteth-26 and PEG-40 hydrogenated castor oil was supplied by Res Pharma (I). Polysorbate 20 was supplied by Bregaglio (I). Phenoxyethanol, methylparaben, buthylparaben, ethylparaben, propylparaben and the potassium lauroyl wheat amino acid (and) palm glycerides (and) capryloyl glycine (NANOCREAM®) were kindly gifted by Sinerga S.p.A. (I). All other reagents and solvents were purchased from Sigma-Aldrich S.R.L. (I) and used without further purification.

Preparation of viscous yellowish gel-like structure

The emulsifier [i.e., potassium lauroyl wheat amino acids (and) palm glycerides (and) capryloyl glycine] was added in ratio 1:1 with respect to oil phase (EI 8% w/w; DE 2% w/w). Mixtures were maintained in constant stirring by a blade impeller (150–250 rpm) for 10–12 min to obtain a uniform and completely homogeneous oil phase (phase A). On the other side, water was weighted (phase B). The preservative system (i.e., phenoxyethanol, methylparaben, buthylparaben, ethylparaben, propylparaben) was also added at 1% w/w. After heating both phases at about 70–75 °C, small aliquots of phase B were added step by step to phase A under moderate stirring. A viscous gel-like structure of yellow colour was obtained. The mixture was cooled down to room temperature under stirring. When the active ingredients were added, CAF were loaded in concentrations of 0.4% w/w in phase B, while EXM was 0.8% w/w in phase A. Percentages referred to final formulation. CAF or EXM were added before proceeding in the preparation of viscous yellowish gel.

Preparation of nanoemulsion

Phase A and phase B used for the preparation of nanoemulsion were made as previously described for viscous yellowish gel-like structure. Different ratio of EI and DE were used as oil phase as reported in Table 1. The emulsifier [i.e., potassium lauroyl wheat amino acids (and) palm glycerides (and) capryloyl glycine] was then added in ratio 1:1 with respect to oil phase. Mixtures were maintained in constant stirring by a blade impeller (150–250 rpm) for 10–12 min to obtain a uniform and completely homogeneous oil phase (phase A). On the other side, water was weighted (phase B) and preservative system (i.e., phenoxyethanol, methylparaben, buthylparaben, ethylparaben, propylparaben) was added at 1% w/w. Phase A and an aliquot of phase B (about 30% w/w) were, then, heated at 70–75 °C and mixed to reach the gel-like structure, then, phase B was further added until its concentration reached about 70% w/w. During the addition, the mixture colour turned from yellowish to bluish Tyndall, indicating the formation of the nanoemulsion (F1–F6, Table 1). Blank nanoemulsion F2 were selected as vehicle to load CAF (F7–F10) and EXM (F11–F13). As previously reported for the gel-like structure, EXM was added in phase A, whereas CAF was added in phase B. The nanoemulsions F14 and F15 were made adding 1.5% w/w of LG to F7, F11, respectively. Percentages referred to final formulation.

Preparation of emulsion

To prepare the conventional emulsion, the emulsifier system was made mixing Polysorbate 20 (3% w/w) to a commercial mixture of PPG-26-buteth-26 and PEG-40 hydrogenated castor oil (3% w/w). The ratio of EI and DE was fixed at 8:2. The lipophilic components (i.e., EI, DE, emulsifier system) and the preservative were heated at 70–75 °C and, then, were added to an aqueous solution containing the hydrophilic components heated at the same temperature under vigorously stirring. The preservative system (i.e., phenoxyethanol, methylparaben, buthylparaben, ethylparaben, propylparaben) was added at 1% w/w. The emulsion was cooled down to room temperature under continuous stirring. Final ratio water/oil was 70/30. 0.8% w/w EXM was added in phase A, whereas 0.4% w/w CAF was added in phase B. Percentages referred to final formulation.

Nanodroplet dimension measurements

Measurements of nano-droplet dimension were performed at 23 °C using a NICOMP380/dynamic light scattering (DLS; Particle Sizing System, USA). For each formulation, 1 mL was loaded in a cylindric cuvette and directly analysed by DLS. For the elaboration of raw scattering signal, 0.933 cP of the water viscosity at 23 °C and 1.333 of diffraction index were used as parameter.

Stability study

The stability of the nanoemulsions at room temperature (RT), 40 and 50 °C was checked each month over a period of 3 months by visual inspection, comparing the aspect of nanoemulsion with photograph taken at the preparation time.

In vitro human skin permeation study

The permeation study was performed by modified Franz’s cell system (self-made apparatus) with a diffusion area of 0.785 cm2 and a receptor volume of about 6 mL.

The in vitro permeation and retention studies were performed using HE as a membrane. The HE originated from the abdominal skin of a single donor who underwent cosmetic surgery. Briefly, the full-thickness skin was sealed in evacuated plastic bags and stored within 6 h after removal, and HE samples were prepared following an internal standard procedure [16]. In particular, the skin was thawed at room temperature, and the excess of fat was carefully removed. The skin sections were cut into squares of about 4.0 cm2 and after immersion in water at 60 °C for 1 min; the HE was gently separated from the remaining tissue with forceps. Then, the HE was frozen at −20 °C until use. All the HE samples used in the in vitro permeation studies were stored for not more than 1 month.

Prior to experiments, HE sample was visually checked to avoid damaged samples. Adequate samples were hydrated in 0.9% w/v NaCl solution for 1 h. Then, the sample was mounted on the Franz's diffusion cells, whose receptor compartments were filled with degassed pH 7.4 phosphate buffer saline solution for CAF or with ethanol/water solution (50/50% v/v) for EXM. Special care was given to avoid air bubbles between the buffer and the membrane in the receptor compartment. The upper and lower parts of the Franz's cell were sealed with Parafilm® and fastened together by means of a clamp. The system was kept at 37 °C with a circulating water bath, so that the membrane surface temperature was at 32 ± 1 °C throughout the experiment. At the beginning of experiment, 1 mL of nanoemulsion, gel-like structure and emulsion containing either CAF or EXM were loaded in donor compartments. At predetermined times, 200 μL samples were withdrawn from the receiver compartment and analysed in HPLC. The withdrawn aliquot was replaced with the same volume of fresh receiver medium. Sink conditions were maintained throughout the experiments. The results were expressed as the average of parallel experiments performed in triplicate. The cumulative amount permeated through the HE per unit area (QP) was calculated from the drug concentration in the receiving medium and plotted as a function of time. The steady state flux (J) was determined as the slope of the linear portion of the plot.

Drug retention study

At the end of permeation experiment, HE samples were removed from the Franz's diffusion cells. Any residue on the surface of the skin was removed using a cotton tip applicator and each HE membrane was then carefully rinsed with 5 mL methanol. The skin samples were then cut into small pieces and placed in 10 mL of methanol. The suspension was sonicated for 30 min, soaked for 24 h at 4 °C, and then filtered. The concentrations of CAF or EXM were assayed by the HPLC method reported below. The retained amount into the HE (QR) was expressed as micrograms per unit of area.

Quantitative determination of caffeine and ethyl ximenynate

The concentrations of CAF and EXM in the medium were determined by a HPLC method (HP 1100, ChemStations, Hewlett Packard, USA). The following analytical conditions were adopted.

Caffeine

The CAF separation was performed at 25 °C using a Spherisorb 3 μm ODS2 (Waters S.p.A., USA) and acetonitrile/0.05 M acetic acid (75:35 v/v) as mobile phase. The flow rate was set at 1.0 mL/min and the injection volume at 20 μL. The drug concentration was determined at 275 nm from two standard curves (0.01–10 μg/mL; 10–100 μg/mL).

Ethyl ximenynate

the EXM separation was performed at 25 °C using a Spherisorb 5 μm ODS2 (Waters S.p.A., USA) and acetonitrile/water acidified with 0.3% phosphoric acid 85% (90:10) as mobile phase. The flow rate was set at 1.2 mL/min and the injection volume at 10 μL. The drug concentration was determined at 215 nm from two standard curves (0.01–10 μg/mL; 10–100 μg/mL).

Statistical analysis

Dixon’s tests were performed on the obtained results to identify outliners, using a value of 0.970 as confidence level at 90% [17]. The statistical difference in performances of the formulations samples were at each sampling point by T test (Excel 2016, Microsoft, USA). The level of significance was taken as p < 0.05.

Results

Preparation and stability of nanoemulsions and gel-like structure

O/W nanoemulsions containing ethylhexyl isononanoate (EI) and dicaprylyl ether (DE), as oily phase, and a blend of natural derived surfactants, potassium lauroyl wheat amino acids, palm glycerides and capryloyl glycine (Nanocream®), as nanoemulsifier were prepared [18]. The emulsifier appears like a semi-consistent yellow gel, with a characteristic odour and pH value between 6.5 and 7.5; it is a non-irritant blend and it is compatible with oils having a branched-structure on the carbonic chain and a limited steric volume (e.g., iso-stearate, ethyl isononanoate or iso-hexadecane). The ratio oil phase/nanoemulsifier was set 1:1 w/w, according to previous evidences [15]. Rheological measurements (data not shown) demonstrated that oil phase/nanoemulsifier system could incorporate low amounts of water (<25–30%) without altering its gel-like structure. DLS analyses did not evidence any droplet formation inside this structure. On the contrary, a fluid O/W nanoemulsion was obtained when the water concentration reaches 70% (w/w), regardless of the oil phase composition.

All prepared blank nanoemulsions had a low viscosity as they easily flowed (data not shown). They appeared clear or opalescent after preparation (Table 1), and DLS analyses confirmed that droplet dimensions ranged from 30 to 50 nm. The higher DE concentration, the higher clearness of system.

The stability studies demonstrated that almost all blank formulations (F1–F6) remained stable over 3 months both at RT and at 40 °C, whereas phase separation (e.g., creaming) was observed at 50 °C (Table 1). The visual aspect of some formulations proceeded from the clearness towards the opalescence to reach, in case of instability, the whitening and then creaming, but it could also happen that from an opaque system they went back to a transparent one. According to the stability data reported in Table 1, best results were obtained with the ratio EI/DE fixed at 8/2, 4/6 and 2/8.

The addition of CAF or EXM significantly affected the physical properties and the stability of all the nanoemulsions (Table 1, Table A1). When different concentrations of CAF and EXM were added to the formula, nanoemulsions made with the EI/DE 2/8 and 4/6 resulted unstable at high temperature within 1 month after the preparation (Table A1). On the contrary, when EI/DE was fixed at 8/2, the nanoemulsions containing 0.4% w/w CAF (F7) were clear and stable for a longer period, whereas the higher CAF concentration (i.e., 0.8–2.0% w/w, F8–F10) resulted quickly unstable at elevated temperatures (Table 1). The DLS analyses highlighted significant variation in droplet dimension: if droplet dimension of 0.8% w/w CAF nanoemulsion (i.e., 38 nm) resulted superimposable to blank formulation immediately after preparation, after 3 months at room temperature three different droplet populations were observable (range: 12–601 nm). Such findings were confirmed by visual observation: instability appeared as a separation phase characterized by a white cream at the top of the sample, while at the bottom the system remained transparent. On the contrary, the samples containing 0.8% (F11) and 1.4% (F12) w/w EXM were homogeneous for a longer period of time with respect to those with CAF, even if DLS analyses highlighted the presence of a 338-nm population of droplets. A 2% w/w EXM (F13) formulation resulted unstable also at RT. Differences were observed at 50 °C; separation phase was observed after 1 month in the case of 1.4% w/w. Therefore, to improve the stability of formulations F7 and F11, LG, a non-ionic mild surfactant, was added. A mixture of lauryl glucoside and sodium lauryl glucose carboxylate combined to a polymeric stabilizer is commonly used in emulsion formulations to improve stability [19].

All gel-like structures were stable at each condition of time and temperature, except for CAF 0.8 w/w. In this case, at room temperature the active precipitated as needle-like particles, due to achievement of the solubility limit.

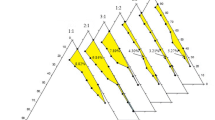

In vitro permeation studies

In vitro permeation studies were carried out comparing performances of nanoemulsions F14 and F15 (Table 1) with those of emulsions and gel-like structures containing CAF (0.4%, w/w) or EXM (0.8%, w/w). As shown in Table 2, both model drugs were able to penetrate significantly the stratum corneum and to permeate through the HE. However, the permeated and retained percentage were lower than 2% of both CAF and EXM in the case of nanoemulsions. The permeation profiles of EXM-loaded emulsion resulted negligible, whereas those obtained by nanoemulsion were significantly higher after 24 h (p value <0.05). On the other side, the results obtained by using the CAF-loaded emulsion was comparable to that of the nanoemulsion F14. QR were not statistically different (p value >0.05).

The gel-like structures permitted to increase QP,24 independently of the considered model drug. Indeed, the QP,24 value for CAF was 12.6 ± 7.2% of drug loading. It was over ten times higher than those of nanoemulsion and coarse emulsion (p value <0.05), whereas the QR values were only slightly increased. For EXM, QP,24 value was 4.1 ± 1.3% of drug loading.

Discussion

The current manuscript showed whether and to what extent the permeation profiles of CAF or EXM were modified when loaded in nanoemulsions. The performance of nanoemulsions in terms of permeation profile of CAF or EXM were tested using as reference a coarse emulsion. Moreover, the impact on permeation profiles of the different organization of the semi-solid structure due to a reduced water phase was also evaluated using the viscous gel-like structures. As shown in Table 1 and Table 2, the loading of CAF or EXM in this nanoemulsion system has significantly modified its stability and permeation parameters of the actives, but the enhancement effect of nanoemulsion in comparison to coarse emulsion varies according to the polarity of the tested molecule.

Based on the results obtained by using CAF, the permeation and retention pattern of polar molecules seemed to not vary between nano- or conventional emulsions (Fig. 1a). The obtained permeation fluxes (J) also resulted in agreement with previously published data obtained with CAF aqueous solutions [20], suggesting that both formulations did not alter the CAF permeation profile. On the contrary, the J value was significantly increased when viscous gel-like structure was used as vehicle (Table 2). Considering the lower water concentration of this formulation with respect to the nanoemulsion (i.e., 30 vs 70%), such enhancement effect may be caused by the higher thermodynamic activity of CAF inside the gel-like structure [21]; higher occlusive properties could also influence this result [22]. The closeness to maximum solubility of CAF is evidenced by preliminary stability studies. Indeed, in CAF-loaded gel-like structures the drug crystal precipitation occurred when its concentration approaches 0.8% w/w, while no CAF precipitation was observed in the case of nanoemulsion till 2% w/w.

In vitro permeation studies of CAF (a) and EXM (b) through human epidermis using different semisolid vehicles (CAF 0.4% w/w; EXM 0.8% w/w). The results showed the impact of vehicle selection on the permeation profiles both active ingredients. The selected semisolid vehicles are emulsion (solid line), gel-like structure (dashed line) and nanoemulsions profile (dotted line) (mean ± St. dev.; n = 3)

When nanoemulsion was loaded with an apolar molecule (e.g., EXM), a significant enhancement effect on the permeation profile is observable (Fig. 1b). While the permeation profile of EXM was negligible for the conventional emulsion, the nanoemulsion and gel-like structure resulted in comparable QP- and J values. Between the two formulations, no significant differences in terms of permeation parameters were observed, despite LG was added only in the nanoemulsion. The addition of LG, a secondary emulsifying agent, was needed for obtaining an acceptable stability of nanoemulsion during times, especially when CAF and EXM were loaded. LG was selected with respect to previous experiences as nanoemulsion stabilizer, being quite common this need. Even if release from an emulsion and human skin permeability of active ingredients could be affected by the type of emulsifier [23], in this case, it is possible to exclude that the addition of a further emulsifier system plays a role in promoting the permeation of CAF or EXM through the skin.

Unlike CAF, these findings suggested that it is possible to improve the permeation profiles of apolar active ingredients, using nanoemulsion as vehicle. Moreover, due to the different O/W ratio, the EXM release was more efficient in the presence of the highest amount of water, even if permeation parameters were not significantly altered.

The overall results agreed with previous published studies that demonstrated that nanoemulsions could improve the permeation profiles of loaded active ingredients [24,25,26]. The different performance of nanoemulsion in comparison to a coarse emulsion can be explained considering that the interface between oil and aqueous phase resulted increased in the case of O/W nanoemulsion with respect to the equivalent emulsion. The higher interface area between the two phases, the higher proximity between the droplets of the disperse phase and the skin surface after a topical application. In this context, the different in vitro permeation profile observed for apolar molecules with respect to polar ones may be explained with a higher partition tendency of the formers between the vehicle and the skin surface due to the increased concentration at the skin-vehicle interface.

Such evidences suggested that the safety profiles of nanoemulsion cannot be considered a priori superimposable to coarse emulsion with similar composition of phases, especially when molecules with physicochemical properties favourable for the skin permeation were loaded.

On the bases of such considerations, a revision of regulatory framework of nanoemulsion to preserve the costumer safety appears necessary in consideration of the widespread diffusion of such nanomaterials in cosmetic products. Nanoemulsions are not classified as nanomaterials by European authorities [11] and their risk assessment is mainly based on the safety profile of all the ingredients contained in the cosmetic product. Indeed, since nanoemulsions are equally based on the well-known and well-characterized raw materials used for conventional emulsions, they are not considered risky for the safety of European consumers. Nevertheless, even if the composition of a nanoemulsion is similar to coarse emulsion and with safety ingredients, the reduced droplet dimensions or modification in the emulsifier systems for preserving the formulation stability have to be considered as function of their impact on the safety profile of the formulation. Therefore, novel approach proposed by FDA to solve the criticisms results of interest. FDA classifies nanoemulsions as nanomaterials [10] and recommends to conduct a deepened characterization of both ingredients and final formulation as a function of the intended route of exposure [27]. For exposure via dermal absorption, since nanoemulsions are expected to disintegrate in their molecular components upon the application to skin, their safety assessment is not considered particularly critical by the American authorities again. However, FDA highlights the importance to conduct proper in vitro studies through intact and impaired skin to verify that permeation rate of ingredients is not enhanced by the nanoemulsion, excluding thus a high risk of systemic exposure after skin application.

Conclusions

The overall results demonstrated that nanoemulsions are able to influence significantly the permeation profiles of molecules as a function of their physicochemical properties. In particular, O/W nanoemulsions can improve significantly the permeation profiles of apolar active ingredients in comparison to conventional emulsions, whereas no differences were observable for polar molecules. Considering such findings, it is worth observing that there is room for reconsidering the regulatory framework on the basis of the risk assessment of nanoemulsion-based cosmetic products. Indeed, according to our results, the lack of the skin permeability evaluation in the current European legislation seems appropriate for assessing the safety of O/W nanoemulsions containing active polar ingredients, since their use for improving the physical properties of final products does not influence the skin permeation pattern of ingredients. On the other hand, the loading of apolar active ingredients in O/W nanoemulsions should be carefully considered to avoid any unexpected increase of exposure to active ingredients and, therefore, potential risks for the consumer safety. Therefore, an upgrade and harmonization of the regulatory framework is desirable to assess better how the use of a nanoscale emulsion instead conventional one can impact on the consumer exposure to ingredients contained in cosmetic products intended to be commercialized in both Europe and the USA.

References

Yukuyama MN, Ghisleni DDM, Pinto TJA, Bou-Chacra NA. Nanoemulsion: process selection and application in cosmetics–a review. Int J Cosmet Sci. 2016;38:13–24.

Solans C, Solé I. Nano-emulsions: formation by low-energy methods. Curr Opin Colloid Interface Sci. 2012;17:246–54.

Sadurní N, Solans C, Azemar N, García-Celma MJ. Studies on the formation of O/W nano-emulsions, by low-energy emulsification methods, suitable for pharmaceutical applications. Eur J Pharm Sci. 2005;26:438–45.

Fernandez P, André V, Rieger J, Kühnle A. Nano-emulsion formation by emulsion phase inversion. Colloids Surf A Physicochem Eng Asp. 2004;251:53–8.

Nohynek GJ, Lademann J, Ribaud C, Roberts MS. Grey goo on the skin? Nanotechnology, cosmetic and sunscreen safety. Crit Rev Toxicol. 2007;37:251–77.

McClements DJ. Edible nanoemulsions: fabrication, properties, and functional performance. Soft Matter. 2011;7:2297–316.

Shah P, Bhalodia D, Shelat P. Nanoemulsion: a pharmaceutical review. Systematic reviews in pharmacy. 2010;1:24–32.

Fratter A, Semenzato A, Casiraghi A, Minghetti P. Nanoemulsion technology for sublingual delivery of melatonin: characterization and preliminary data of absorption; In: Acuña-Castroviejo D, Rusanova I, Escames G. New Development in Melatonin Research, Nova Science Publishers, 2013;267–282.

Musazzi UM, Marini V, Casiraghi A, Minghetti P. Is the European regulatory framework sufficient to assure the safety of citizens using health products containing nanomaterials? Drug Discov Today. 2017; doi:10.1016/j.drudis.2017.01.016.

Food and Drug Administration (FDA). Guidance for industry: considering whether an FDA-regulated product involves the application of nanotechnology. June 2014.

Regulation (EC) No 1223/2009 of the European Parliament and of the Council of 30 November 2009 on cosmetic products. Official Journal of the European Union. L.342/59–209.

Scientific Committee on Consumer Safety (2012) Guidance on the Safety Assessment of Nanomaterials in Cosmetics (SCCS/1484/12).

Klang V, Schwarz JC, Lenobel B, Nadj M, Auböck J, Wolzt M, Valenta C. In vitro vs. in vivo tape stripping: validation of the porcine ear model and penetration assessment of novel sucrose stearate emulsions. Eur J Pharm Biopharm. 2012;80:604–14.

Herman A, Herman AP. Caffeine’s mechanisms of action and its cosmetic use. Skin Pharmacol Physiol. 2013;26:8–14.

Guglielmini G. Evaluating droplet size in nanoemulsions from a novel emulsifier system. Cosmetics and Toiletries 2006;121.

Musazzi UM, Matera C, Dallanoce C, Vacondio F, De Amici M, Vistoli G, Cilurzo F, Minghetti P. On the selection of an opioid for local skin analgesia: structure-skin permeability relationships. Int J Pharm. 2015;489:177–85.

Rorabacher DB. Statistical treatment for rejection of deviant values: critical values of Dixon’s “Q” parameter and related subrange ratios at the 95% confidence level. Anal Chem. 1991;63:139–46.

Comini M, Lenzini M, Guglielmini G. Nanoemulsions Comprising Lipoaminoacids and Monoglycerides, Diglycerides and Polyglycerides of Fatty Acids. Sinerga, Italy, MI2005A000218. 2006.

Korać R, Krajišnik D, Savić S, Pantelić I, Jovančić P, Cekić N, Milić J. A new class of emulsion systems–fast inverted o/w emulsions: formulation approach, physical stability and colloidal structure. Colloids Surf A Physicochem Eng Asp. 2014;461:267–78.

Van de Sandt JJM, van Burgsteden JA, Cage S, Carmichael PL, Dick I, Kenyon S, et al. In vitro predictions of skin absorption of caffeine, testosterone, and benzoic acid: a multi-centre comparison study. Regul Toxicol Pharmacol. 2004;39:271–81.

Casiraghi A, Di Grigoli M, Cilurzo F, Gennari CGM, Rossoni G, Minghetti P. The influence of the polar head and the hydrophobic chain on the skin penetration enhancement effect of poly(ethylene glycol) derivatives. AAPS PharmSciTech. 2012;13:247–53.

Casiraghi A, Musazzi UM, Rocco P, Franzè S, Minghetti P. Topical treatment of infantile haemangiomas: a comparative study on the selection of a semi-solid vehicle. Skin Pharmacol Physiol. 2016;29:210–9.

Casiraghi A, Franzè S, Selmin F, Dazio V, Minghetti P. Investigation of the effect of different emulsifiers on the transdermal delivery of EGCG entrapped in a polymeric micelle system. Planta Med. 2016;83(5):405–11.

Kumar D, Ali J, Baboota S. Omega 3 fatty acid-enriched nanoemulsion of thiocolchicoside for transdermal delivery: formulation, characterization and absorption studies. Drug Delivery. 2016;23:591–600.

Aqil M, Kamran M, Ahad A, Imam SS. Development of clove oil based nanoemulsion of olmesartan for transdermal delivery: Box–Behnken design optimization and pharmacokinetic evaluation. J Mol Liq. 2016;214:238–48.

Ahad A, Al-Saleh AA, Akhtar N, Al-Mohizea AM, Al-Jenoobi FI. Transdermal delivery of antidiabetic drugs: formulation and delivery strategies. Drug Discov Today. 2015;20:1217–27.

Food and Drug Administration (FDA). Guidance for industry–safety of nanomaterials in cosmetic products. June 2014.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest in publishing the results contained in the manuscript.

Electronic supplementary material

ESM 1

(DOCX 16 kb).

Rights and permissions

About this article

Cite this article

Musazzi, U.M., Franzè, S., Minghetti, P. et al. Emulsion versus nanoemulsion: how much is the formulative shift critical for a cosmetic product?. Drug Deliv. and Transl. Res. 8, 414–421 (2018). https://doi.org/10.1007/s13346-017-0390-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13346-017-0390-7