Abstract

One of the engineering challenges in aviation is the design of transitioning vertical take-off and landing (VTOL) aircraft. Thrust-borne flight implies a higher mass fraction of the propulsion system, as well as much increased energy consumption in the take-off and landing phases. This mass increase is typically higher for aircraft with a separate lift propulsion system than for aircraft that use the cruise propulsion system to support a dedicated lift system. However, for a cost–benefit trade study, it is necessary to quantify the impact the VTOL requirement and propulsion configuration has on aircraft mass and size. For this reason, sizing studies are conducted. This paper explores the impact of considering a supplemental electric propulsion system for achieving hovering flight. Key variables in this study, apart from the lift system configuration, are the rotor disk loading and hover flight time, as well as the electrical systems technology level for both batteries and motors. Payload and endurance are typically used as the measures of merit for unmanned aircraft that carry electro-optical sensors, and therefore the analysis focuses on these particular parameters.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Transitioning vertical take-off and landing (VTOL) aircraft try to combine the best of two worlds: a vehicle that combines a helicopter’s ability to take off and land almost anywhere, with the speed, range, endurance and load carrying capability of a fixed wing aircraft. Some sources call these vehicles ‘convertiplanes’ or ‘hybrid aircraft’ and many different configurations are used [1, 2]. While rotorcraft are sometimes referred to as “VTOL aircraft”, in this paper the abbreviation will be used exclusively for fixed wing aircraft that can transition between hovering and wing-borne flight.

There are many missions where a VTOL aircraft is superior to a conventional take-off and landing (CTOL) solution. Ground infrastructure is minimal, especially when small, unmanned VTOL aircraft are considered. Without the need for launch and recovery equipment, they can attain a mobility that is difficult to achieve with CTOL vehicles. Take-off and landing zones are very small for VTOL aircraft and even with short take-off and landing technology the same deployment flexibility cannot be attained for CTOL planes [3, 4].

Recently, a new ‘hybrid’ configuration has gained interest amongst designers of transitioning VTOL aircraft: the fusion between a multicopter and conventional aircraft [5]. Recent improvements in electrical motor technology and battery systems allow adding an electric hover-propulsion system to an otherwise conventional UAV, giving it VTOL capability.

This paper explores the impact of a supplemental electric propulsion system for a fixed-wing UAV to achieve hovering flight. Electric lift systems offer low complexity and are easy to integrate. Lift systems that use combustion engines or turbojets were described in [6] and are not considered in this work. To quantify the mass increase due to an electric lift system, sizing studies were conducted with the aircraft’s gross mass as the key performance metric. Three different design missions were considered, as well as two different approaches for the lift system configuration: a lift system completely separated from the cruise propulsion system (lift + cruise configuration) and the integrated lift + lift/cruise configuration. To assess the impact of technology, each mission was sized for three different technology levels with each level corresponding to an advance over the current state of the art.

Finally, this paper highlights the impact of top-level requirements (VTOL or CTOL) on aircraft mass and size. Since there is a link between aircraft mass and aircraft cost, this comparison gives an overview of the system performance from a cost–benefit perspective.

2 Transitioning VTOL configurations

The configuration design of VTOL aircraft is discussed extensively in literature (e.g. [1] or [7]). Therefore, the basic definitions, as well as pros and cons of certain configurations relevant to this paper, will be presented here in an abbreviated form. Three historical manned VTOL projects will be used to illustrate the discussion.

The simplest method to enable VTOL capability for any aircraft is to add lift engines to the airframe.

This approach was successfully employed by Dassault in the 1960s. Their VTOL fighter Mirage III–V (V for vertical), shown in Fig. 1, used a single turbofan for horizontal flight and eight additional Rolls-Royce lift-jets in the fuselage for vertical flight. In level flight, the Mirage III–V reached Mach 2 and is still today the only VTOL capable aircraft to achieve this feat [8]. However, it was unable to take off vertically and attain supersonic flight during the same mission. This points to the problems of this configuration: A dedicated lift system takes up internal volume, which reduces fuel and payload space, requires effort to avoid excess drag in cruise, and causes a considerable mass increase. However, the big advantage lies in the possibility to size the main propulsion system for efficient cruise or loiter—thus reducing the fuel fraction for that part of the flight. Consequently, also the lift engines can be designed for a single high power operating point.

Since dedicated lift engines are added to a cruise engine, this is called the lift + cruise approach.

Another extreme method to enable VTOL capability for aircraft is to use the same propulsion system for both cruise and hover. This eliminates the need for an additional propulsion system, which would only represent dead mass during the cruise or loiter part of the flight.

To this specification, the Ryan X-13 Vertijet (Fig. 2) was designed. This tailsitter aircraft took off (and landed) on a hook on a wall, instead of sitting on its tail on the ground, to not choke the jet engine [9]. Unfortunately, powerful engines that are sized to the hover thrust constraint cause low efficiency and high fuel consumption during forward flight. Additionally, considering this paper’s focus on UAVs that are rarely used on missions requiring very high speeds or very high climb rates, the excess power cannot be coined into an advantage.

This approach to VTOL is called lift = cruise.

The third option is called lift + lift/cruise. The cruise engine is used for both forward flight and hover, but supplemented by some sort of dedicated powered lift system. This is usually considered the best way to achieve VTOL for any aircraft lift + cruise — multicopter + conventional airframe unmanned or manned [10]. Dornier applied the lift + lift/cruise configuration on the Do 31, which is shown in Fig. 3. This German VTOL transport flew as a prototype between 1967 and 1970. It had eight Rolls-Royce RB162 dedicated lift jet engines and two additional Rolls-Royce Pegasus thrust-vectoring turbofans for both cruise and hover. The lift jets had a very high thrust-to-weight ratio of more than 18:1 [11] and were housed in pods at the wing tips. For best performance, the ratio of lift between the lift engines and the cruise engines had to be carefully investigated and optimized.

If such a complex system is not properly laid out, the overall performance can easily be degraded to the point where it performs worse than a well thoughtout lift + cruise configurations.

The lift + cruise and lift + lift/cruise configurations will be discussed further in the following subchapters. For each concept, several unmanned aircraft representative of the respective technology will be listed in a table.

2.1 Lift + cruise — multicopter + conventional airframe

VTOL aircraft require a thrust-to-weight ratio greater than unity for the vertical part of their mission; however, once transition to forward flight is commenced, typically not more than a thrust-to-weight ratio of 0.1 is needed to sustain steady flight (naturally, this number depends on the actually achieved L/D—an L/D of 10 is assumed in this simple exemplary calculation). Due to this huge gap in required power, a single propulsion system for both hover flight and cruise flight suffers from reduced efficiency, as its primary operation points are very far from each other.

To improve efficiency, many manufacturers of UAVs employ separate propulsion systems for hover and cruise flight (Figs. 4, 5). Each system is decoupled and used in its most effective state. Using the multicopter system, the aircraft ascends to obstacle height and then uses the regular propulsion system to accelerate and sustain wing-borne flight. Of course, the landing procedure is carried out in reversed order.

Usually, the chosen multicopter layout is symmetric about the aircraft’s longitudinal axis (e.g. a quad-, hexa- or octo-configuration—see [1]). The rotors can then be mounted inline for minimal drag impact.

Hybrid propulsion options (meaning electric lift motors and combustion engines for endurance flight) are used frequently and minimize the mass impact. Because electric motors have a vastly higher power-to-mass ratio than internal combustion engines (currently about 5 kW/kg vs. 1 kW/kg), they are very much suited for this application. Another benefit of using electric motors for short durations is their ability to operate in overload conditions for a short time. While this heats up the motors significantly, this can be of benefit in case of an engine failure. This is not possible for a traditional combustion engine.

Multicopter systems can be used as an ‘add-on’, allowing the airframe to be converted between the VTOL and CTOL configuration with respect to mission requirements. This is shown exemplarily in Fig. 4. Another possibility is to design the multicopter system to be an integral part of the airframe (Fig. 5), to minimize the impact on structural mass.

Exemplarily, a selection of UAVs that use the L + C configurations is listed in Table 1.

The add-on configuration with four equally sized, electrically powered lifting rotors and a combustion engine for cruise flight is chosen as the baseline for the sizing studies, which are presented in Sect. 4 of this paper.

2.2 Lift + lift/cruise — multicopter + conventional airframe

Mechanical simplicity can be traded against mission performance if the VTOL aircraft is configured in such a way that the cruise engine supports some of the aircraft’s mass during hover.

One possibility is to use additional actuators to rotate the cruise engine/propeller combination (or just the cruise flight propeller). If the tricopter configuration (see [1]) is chosen, one has the distinct advantage of having the least amount of motor/rotor pairs and is therefore a configuration, which is easy to integrate (Fig. 6).

Since the rotor torque does not need to be evenly distributed, an uneven disk loading can be applied. This enables the tilting rotors to be optimized for forward flight and the dedicated hover rotors to be adapted to their separate flight regime.

Exemplarily, a selection of UAVs that use the L + L/C configurations is listed in Table 2.

The tricopter configuration with two electrically powered lifting rotors and a combustion engine for cruise and hover flight is selected to assess the improvements this topology allows over the L + C baseline. Naturally, the lever arm of the tilting pusher–propulsor needs to be adjusted to properly balance the aircraft in hovering flight. Also, constraints for rotor spacing might dictate a layout with two lifting rotors on each boom (four lifting rotors, one tilting propeller). However, a detailed configuration layout is not part of the work presented in this paper.

3 Modelling flight performance

For this work, the sizing tool, which was presented in [12], was modified and now supports electric propulsion systems for hovering flight. For completeness, the most important assumptions are explained in this chapter.

3.1 Endurance modelling and VTOL performance

The core of the sizing tool is a model that allows deriving the endurance performance of an aircraft. The basic approach to determining the aircraft’s endurance is outlined in Fig. 7.

The basic aircraft parameters include the aircraft’s MTOM, the specification of the propulsion system and the engine type, a payload requirement, and all required inputs for the aerodynamic model. The atmospheric conditions are calculated from the ISA atmospheric model. For a given gross mass, the empty mass is estimated using the mass fraction model. The empty mass includes the cruise propulsion system and all additional systems, e.g. avionics. When adding a given payload mass, the mass remaining for fuel can be determined. The propulsion system model incorporates thrust requirements from the aerodynamic model.

The actual endurance calculation is an incremental process based on the fuel consumption in all flight stages. During loitering flight, at any given mass, the drag of the aircraft is determined by the aerodynamic model. Then, the propulsion system model calculates the fuel flow for that certain moment in flight. The fuel flow multiplied with the time step is subtracted from fuel mass and the process is repeated until just the reserve fuel and the fuel for descend and landing remain.

Since VTOL aircraft use a significant portion of their fuel during the vertical take-off and landing, this fuel mass cannot be estimated by employing statistics. Because the entire aircraft’s mass is supported by the propulsion system, fuel flow is highly dependent on the specific kind of propulsion system and on the type of VTOL system employed.

For the comparative purpose of this work, it is decided to use the CTOL aircraft of a certain mass (and the corresponding empty mass fraction mempty/m0) and add the mass of the additionally required VTOL propulsion system to it. The maximum mass stays the same. Consequently, the mass remaining for fuel and payload is reduced. The influence of a certain empty mass fraction improvement (e.g. 5% less than average) will be explored in Sect. 4.4, since the relevant equations can be easily adapted.

Basically, the empty mass increase due to the additional VTOL propulsion system only depends on the required power to lift the aircraft at zero airspeed and the flight duration spent hovering.

3.2 Modification for electric hover propulsion

3.2.1 Determination of required motor power

If a dedicated propulsion system for hover is chosen, the entire aircraft’s mass must be supported by the thrust:

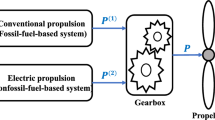

If the cruise engine(s) are contributing to the lift during VTOL, then this thrust must be subtracted.

The static thrust of the cruise propulsion system TCstatic is determined by using a static thrust correction factor, which is described in [6], based on a methodology presented in [13]. It accounts for the thrust and efficiency loss a propeller experiences due to operation at an advance ratio of zero. Naturally, the efficiency is poor (typically about 50%), as this is not the design point for cruise propellers [14].

For propeller and rotor systems, the necessary power for hovering flight can be derived using momentum theory [15]:

Besides a reduction of disk area, power requirements in hover are increased by operation at high altitudes (decreasing air density ρ).

In rotorcraft design, the ratio between ideal power and the actual required power is referred to as the figure of merit “M”. The figure of merit typically lies in the range between 0.70 and 0.80—the same range as the maximum propeller efficiency ηP. Also, M covers the blockage effect of the motor mounting. Additionally, due to the small length scales found for UAV applications, rotors operate at very low Reynolds numbers, and a performance degradation must be assumed. Nevertheless, rotors designed for low Reynolds number applications with minimal blockage can still reach 70% efficiency [16].

For the lifting rotors of this study, M is optimistically assumed to be of this constant value (M = 0.7) because the chosen configurations are assumed to have minimal blockage and the rotors can specifically be optimized for static conditions.

This part of the propulsion system sizing is carried out for all propeller-driven VTOL configurations, whether a combustion engine or electric motor drives the rotor.

For electrical systems, the actually consumed power is calculated by dividing the required power by the efficiency of the electrical system ηES.

The term ηES is used as a catch-all phrase for the efficiency of the battery, the DC–AC power converter and speed controller, the gearbox—if required—and the efficiency of the electric motor.

3.2.2 E-VTOL mass estimation

The mass of the electric motors is sized based on the results of the previous calculations (Eq. 3). Using the nominal required power P as input, the mass of each electric motor (as required by the configuration), the electronic speed controllers and the integration mass of the motors can be determined using the formulas below:

The specific power factors P* are technology factors and need to be defined as required.

To determine the mass of the batteries necessary to supply the electric hover system with energy, the required time in hover during take-off and landing must be known:

Here, τ is the energy reserve fraction. This should not be set below 0.2, as the aging process of lithium-based batteries is directly connected to the depth of discharge [17]. The number of cycles can be increased by allowing for a higher energy reserve fraction. Additionally, this reserve can be used for emergency purposes.

The battery mass can be calculated as follows:

Just like the specific power factors, the specific energy E* of the batteries is a technology factor and needs to be defined as required.

The batteries for the hover system were selected using just the E* as figure of merit. The power rating (C rating) of batteries was not considered in this sizing process. Cycle life is not a priority for this study and it is assumed that the number of cells and capacity of each cell are selected in a later design stage.

Using the equations above, the total additional mass for an electric VTOL system can be calculated using Eq. (10):

If the L + L/C configuration is used, the cruise propulsion system contributes to the thrust in hover flight. As explained previously, this requires a tilting mechanism for the cruise propulsion system. Because the mass of the cruise propulsion system is a part of the aircraft’s empty mass, it is difficult to assess the specific mass impact of such a tilting mechanism. For this reason, a simple penalty of 0.5% of the empty mass fraction is applied to any L + L/C VTOL UAV design (i.e. if the original empty mass fraction is mempty/m0 = 50.0%, then this is increased to mempty/m0 = 50.5%). This value is easily adaptable, once more dependable data becomes available.

With this information, the mass of electric VTOL aircraft can be expressed as such:

4 Hybrid UAV performance analysis

To assess the performance of electric hover systems, three case studies will be carried out. For each case study, a reference mission will be defined. Then, different levels of technological assumptions will be applied and their impact on the design will be evaluated.

4.1 Mission specification

Three missions will be defined to assess the performance of electrical hover propulsion systems. An overview of all missions is shown in Table 3. Missions are confined to medium endurance, because long and ultralong endurance missions are typically satisfied with large aircraft that cannot benefit from the increase in operational flexibility that VTOL offers, since a sophisticated ground infrastructure is needed for large aircraft.

All missions assume a hot day (ISA + 20 °C) and take-off and landing at 1000 m altitude. These are quite demanding specifications for a VTOL aircraft, as the reduction in air density increases the power requirements. However, electric lift systems can cope better with increasing density altitudes, because electric motors do not suffer from reduced altitude performance like combustion engines do.

The loitering portion of each mission is assumed to be performed at 500 m AGL, or the equivalent 1500 m above MSL. For hover at 1000 m altitude, the required power is calculated with a thrust-to-weight ratio (surplus thrust factor) of 1.5. This is about the lowest tolerable factor for quadcopters, but should be sufficient for hot day conditions, as performance will be better for normal day operations.

For all missions, the time spent in hover and while climbing vertically to the obstacle height during take-off is set at 2 min. The same time is allocated for the vertical descent from obstacle height to touchdown during the landing phase. While reference [18] recommends a minimum time of 30 s for VTO and 90 s for VL, the authors believe that these values are optimistic and leave little room for errors. The chosen values of 2 min for each phase thus incorporate a factor of safety.

For each payload, a certain average power consumption over the course of the flight is assumed. The amount is dependent on the payload mass and was derived from a market survey of UAV payloads. It is assumed that the payload power is supplied by an engine-driven generator and the drawn current will therefore increase the fuel consumption.

Because the loitering phase of the flight is assumed to be powered by a combustion engine, all missions allow payload to be traded for fuel and vice versa.

Since only VTOL missions are considered, no part of the fuel fraction was allocated to taxi, climb, and descend.

4.1.1 Mission 1 (10 kg payload, 8 h endurance)

The first mission is typical for a small, tactical unmanned system. A payload of 10 kg is representative of an optical sensor and line-of-sight communication link.

The endurance requirement of 8 h puts this mission in the medium endurance class.

4.1.2 Mission 2 (50 kg payload, 3 h endurance)

The second mission is representative of a short endurance (3 h) UAV that needs to satisfy relatively high payload (50 kg) requirements. A probable use case could be the surveillance of sporting events or agriculture use with powerful multispectral sensors. While cargo missions put more emphasis on range than on endurance performance, this could be a possible scenario to adapt this mission to.

4.1.3 Mission 3 (90 kg payload, 5 h endurance)

The third mission is very similar to the missions of the Bell Eagle Eye [19] and the KARI Smart [20] UAVs. A large payload of 90 kg allows high power optical sensors for day and night operations, radar sensors, as well as powerful communication systems.

The medium endurance of 5 h is sufficient for coast guard operations and civil surveillance.

4.2 Technology assumptions

Because of constant improvements in the field of electrical system technologies, it is uncertain what level of performance the next generation of unmanned VTOL aircraft can offer. Before the performance of any future aerospace system can be analyzed, a reference for the technological assumptions must be set.

For the sizing study, three levels of technology were decided on. They are summarized in Table 4.

Technology level 1 is representative of today’s (2017) technology, and all components, according to [21], are at a technology readiness level (TRL) of more than 6. This level indicates readiness for flight testing.

Level 2 is believed to be achievable in the near term (5 years), while level 3 technologies should be attainable in the next 15 years.

The authors are aware that, compared to other publications, levels 2 and 3 both consider relatively low improvements in electrical system technologies. However, it is believed that the considered technology will actually be available to designers in the specified time frame.

Considering the specific power of electric motors, manufacturers already advertise with values of twice the values specified for level 3. Unfortunately, such motors still require a liquid-cooling system, which decreases the specific power significantly, if the entire system is considered, while increasing complexity.

The mass reduction of DC–AC converters and motor controllers is expected to proceed at a slower pace than motor development. Many miniature components of today’s controllers are already limited by their ability to dissipate heat, and lighter controllers will need larger cooling systems.

As explained in Sect. 3.2.1, the electrical system efficiency ηES covers the losses of the entire electrical system from the battery to the propeller shaft.

The assumptions regarding battery specific energy are always a controversial topic for designers of electric aircraft systems. The authors selected comparatively low values, because the specific energy at the battery pack level is considered.

In a recent publication [22], Airbus’ Vahana eVTOL project’s batteries are said to offer a specific energy of “just under 200 Wh/kg”. In the same article, Uber’s goals are quoted as “300 Wh/kg at the pack level by 2023”. In general, industry leaders believe that a battery specific energy of 400 Wh/kg would be a key threshold for enabling electric aviation, but this value is beyond today’s state of the art [22]. Accordingly, the specific energies used in this study were selected as 180, 250 and 400 Wh/kg. There are cells today, which already surpass the assumptions shown in Table 4.

However, such cells cannot provide the discharge rates required for powered lift applications with additional condition monitoring systems the achievable values at the pack level are much lower.

Because this paper explores the technology of electric lift systems, the technology of the cruise-propulsion system is kept constant to avoid too many parameter variations. Combustion engine performance is derived from a thorough market study, which is presented in [6]. For this study, four-stroke engines were selected, because they offer a fuel burn advantage over two-stroke-, or rotary engines.

Data for the brake specific fuel consumption (BSFC) at maximum power and sea level conditions is extrapolated from manufacturer data to a polynomial function depending on the engine’s power (Eq. 12). The equation is derived in [6] and gives the SFC in kg/kW/h for engines up to 80 kW power:

Environmental influences are implemented by using the Gagg and Ferrar altitude performance model [23].

The cruise engine’s mass is, as explained in Sect. 3.1, part of the aircraft’s empty mass, and is thus not explicitly modeled.

The simplest way to assess aircraft performance (e.g. with Breguet’s range and endurance equations) is to assume a constant lift to drag ratio (L/D). As the aircraft consumes fuel and loses mass over time, it must either climb to a greater altitude, where the decreasing density of the air will allow the operating point to remain constant, or the aircraft must slow down.

As the here presented work is endurance oriented and no range will be calculated, it is assumed that the aircraft will slow down over the course of the flight, to stay at a specified L/D. For a baseline comparison of different propulsion concepts, assuming a constant L/D also helps to stop changing too many variables at once. This is very helpful when conducting parameter studies.

The impact of size on the drag polar is neglected for this study. A constant lift-to-drag ratio of L/D = 12.0 was assumed for loitering flight. This choice allowed this design space exploration to be independent of the UAV’s configuration made it possible to compare lift + cruise and lift + lift/cruise configurations. While modern UAVs can reach values far beyond this in clean conditions, an L/D of 12 is more reasonable if the added drag of gimballed optical payloads and communication antennas, as well as the added drag of the hover propulsion system is taken into account. Additionally, the most efficient loiter speed for a propeller aircraft occurs at 86.6% of the maximum L/D [7].

All aircraft are sized using a disk loading of 60 kg/m2 as the baseline. A similar value is found for manned tilt rotors [7]. Higher disk loadings lower the hover efficiency, and therefore cause a rise of propulsion system mass. This will, of course, reduce total flight time.

The mass fraction model determines the empty mass fraction based on regression analysis for UAVs (mempty/m0 = 0.699 m0−0.051—valid between 20 and 1000 kg MTOM), which is presented in [12]. While this regression is valid for CTOL UAVs with combustion engines, it is valid to use for the empty mass definition used here. As shown in Eq. (11), the electric lift system is not counted toward the empty mass.

Finally, the same technology factors can be used if either a lift + cruise or a lift + lift/cruise configuration is used. To determine the impact of the VTOL configuration, both options will be compared against each other in Sect. 4.3.

4.2.1 Wing and engine sizing

After determining the gross mass, which is required to fulfil the missions defined in Sect. 4.1, under the technology assumptions in Sect. 4.2, the necessary wing size would usually be selected together with the engine size from a point performance sizing plot (compare [13, 24] or [25]). This step is not performed for this work.

Because the goal is to perform parametric studies, an optimization of each UAV’s layout will not be performed. Instead, the wing size is assumed to be set by the stall speed requirements. Because there is no hard stall speed limit for UAVs—unlike, for example, the 31.3 m/s (61 kts) limit for Part-23 aircraft—a statistical correlation between aircraft size and stall speed (data from [6]) was used. This is displayed in Fig. 8.

The engine’s power is usually determined in the sizing process with respect to climb rate, ceiling, take-off distance or top-speed requirements. If this process has been performed for a certain aircraft concept, or if an existing aircraft needs to be evaluated, the actual power figure can be used for all further calculations. For design space exploration, exact requirements typically are not given.

To avoid the step of sizing with arbitrary requirements, the data from the market study in [6] is used to establish a statistical relationship between MTOM and rated engine power.

4.3 Sizing results

The three, previously defined, technology levels were used to determine the impact of technology on the size of UAVs. Accordingly, three UAVs were sized using the requirements from Table 3. The three missions mainly distinguish themselves by payload and endurance.

The sizing studies use the sizing tool described above, which considers only vertical take-off, loiter and vertical landing. An allowance of 7% of the fuel mass is given to reserves and for trapped fuel. Other than that, the results are presented assuming no reserves for the endurance requirements.

Maximum sized masses are restricted to less than 1000 kg, since the statistical trends for airframe and power plant performance were not analyzed for larger UAVs.

Table 5 shows the results of the sizing: As expected, the highest gross masses for all missions were reached for the 2017 technology assumptions (Level 1). Technological improvements result in lower sized gross masses.

Additionally, choosing a lift + lift/cruise configuration over a lift + cruise configuration, will always result in lower sized mass. As explained in Sect. 2.2, the trade-off is increased mechanical complexity and more moving parts.

To compare these results against a conventional baseline, a CTOL UAV was sized to the same requirements and technology factors.

4.3.1 Lift + cruise configuration

For the lift + cruise configuration, the results are visualized in Fig. 11: Using today’s technology (Level 1), an L + C VTOL UAV is significantly larger than its CTOL counterpart.

Mission 1 sees a gross mass increase of 600%, and mission 2 and 3 of roughly 290%. This means, that a requirement for VTOL capabilities for similar missions will require UAVs three to six times the size of a ‘regular’ CTOL UAV. Since cost scales almost linearly with aircraft mass in this mass class [26] (UAV airframe costs are assumed similar to general aviation cost), one can assume a cost increase of at least three to six times due to the VTOL requirement.

Interestingly, the ratio of mass increase is very similar for mission 2 and 3. The authors attribute this unexpected behaviour to the almost identical payload fraction of the designs.

The change from technology level 1 to level 2 is more significant in terms of gross mass, than the step from level 2 to level 3 in all cases. This could be considered counter-intuitive, since the technology improvement regarding battery specific energy is much larger from level 2 to level 3. However, it is just the leverage effect of sizing, which causes aircraft to scale nonlinearly.

The high endurance requirement of mission 1 is a significant contributor to the large size of the UAV. The relatively large fuel fraction is the main reason for the significant growth in size. To match endurance requirements, the airframe grows, which leads to larger engines—a process shown in Fig. 9.

Using the technology assumptions of level 3, the VTOL requirement causes a mass increase between 40 and 85%. This is an acceptable growth factor, as the operational envelope is improved significantly.

A graphical representation of the results for L + C technology is provided in Fig. 10.

4.3.2 Lift + lift/cruise configuration

If the lift + lift/cruise configuration is considered (Figs. 11, 12), the prognosis are much improved. The overall trends are equal to the results of the lift + cruise configuration discussed previously; however, the absolute mass increase is much less.

With level 1 technology, a mass decrease of 55% over the L + C configuration is achieved for mission 1 and about 37% for missions 2 and 3. Again, the largest drop-off in mass is for the shift from level 1 to level 2. Level 3 technologies can bring the gross mass increase to just 25% for missions 2 and 3. Nevertheless, it can be concluded that the best results are achievable if the L + L/C configuration is chosen for low technology levels, and heavy aircraft, since these conditions maximize its potential for mass reduction.

4.4 Sizing sensitivity studies

To study how various parameters influence the gross mass of electrified VTOL UAV concepts, several sensitivity studies are performed. The technology factors defined in Table 4 are used for each study.

The sensitivity study considers the variations of parameters in a partial derivative sense: all other variables are held at constant values while just one parameter is changed.

Because the same sizing logic explained in the previous sections is used, the maximum sized masses are restricted to less than 1000 kg.

The sized concepts from Sect. 4.3 were used as the baseline, about which parameters were varied. This method was selected, to see the potential improvements that an individual technology can offer. It is therefore possible to identify the most important contributors to aircraft performance. At the same time, the least important parameters can be recognized. From this information, the most important research areas can be identified, which offer the highest benefit regarding flight performance.

The parameters on which the sensitivity studies were performed were divided into two groups, mission factors and technology factors. Table 6 gives an overview over the parameter variations:

For every mission, each parameter for every technology level and for both the lift + cruise and lift + lift/cruise configuration was varied about the baseline design point. The results are shown in Figs. 13 and 14.

Each column represents one technology level and the ordinate axis of each plot is the sized aircraft gross mass in 100 kg. In each graph, there are six plots: Three plots for the three missions and the respective L + C configurations, and three plots for the three missions and the respective L + L/C configurations. Results for mission 1 are always colored in blue, mission 2 is marked in red and mission 3’s data are featured in green. Vertical dashed lines mark the baseline point, for each parameter of the different technology levels. If there are multiple baselines, e.g. for payload, the same color coding as for the missions is used for the vertical lines. Because the empty mass fraction is a function of MTOM, six different baselines needed to be shown. Therefore, instead of vertical lines, the baseline points are added to the plots as circles for the L + C designs and diamonds for the L + L/C designs.

The shape of several of the plots looks distinctly like a “knee”. A good example is the variation of energy density for any mission and any technology level. The plots show a strong influence (steep gradient) of the energy density on the gross mass up to a certain value, where the curve flattens out (small gradient) and the influence on the gross mass decreases significantly. The charts therefore indicate the so called ‘technology frontiers’. Until the gradients reduce and the horizontal asymptotes are reached, a small change makes huge difference in gross mass, but after these key points are reached, a huge improvement has to be achieved to make comparatively small improvements in gross mass. This naming convention is carried over from Patterson, German and Moore [21].

The first thing that stands out is that the L + C configuration is always heavier than the L + L/C configuration, but the difference between both diminishes the higher the technology level. As explained in the previous section, this effect is due to the additive sizing effects.

The tendencies displayed by the parameter variation are expectedly quite similar. Due to scaling, the effects appear most pronounced for the heaviest aircraft (mission 3). Nonetheless, all data of this study are included for completeness.

4.4.1 Technology factors

4.4.1.1 Battery energy density

Battery energy density is often claimed to be the largest obstacle on the way to electric aviation. However, at least for electric lift systems, the observation of the corresponding plots across all missions shows that the technology frontier is almost reached. For any energy density below the current state of art (180 Wh/kg—level 1), aircraft become prohibitively large but just going to 250 Wh/kg allows very significant mass savings. At 400 Wh/kg far less improvements are possible.

4.4.1.2 Disk loading

Since disk loading is directly connected to the hover efficiency [1], highly loaded rotors need significantly more power than those with a low loading. Accordingly, the power requirements for hover are proportional to the square of the disk loading. In general, the designer should strive for low disk loadings, to minimize power requirements. However, there are several drawbacks: Rotor mass and size becomes excessive, and low disk loadings increase the gust sensitivity.

While this is strictly a design parameter, which is impossible to improve upon, it can be observed that in conjunction with other technological advancements, higher disk loadings have less impact than at lower technology levels. Therefore, future VTOL concepts can consider a trade-off between smaller rotors with lower efficiency for hover but less drag during cruise flight, a factor not considered in this study.

With level 1 technologies, a disk loading beyond 100 kg/m2 becomes unfeasible for the L + C configurations. However, since only the disk loading of the hover rotors is varied and the disk loading of the cruise propeller is determined by statistics, a diminished impact is observed for the L + L/C plot. Generally, this configuration allows much higher disk loadings for an equal mass, thereby offering a possibility to offset the complexity increase, caused by the tilting mechanism.

4.4.1.3 E-motor specific power

Electric motors are in the same state as batteries. The technology frontier is almost reached. If we move from level 1 to level 2 technologies, there will still be a significant impact on aircraft size, but any further increase beyond level 3 will not be as beneficial.

If, apart from performance, also safety is considered, one needs to remember, that current electric motors can be operated in an ‘overload’ condition in emergencies. The motor is then used as a heat sink. This might not be possible with advanced light motors, which operate at the absolute limits.

4.4.1.4 Efficiency of the electrical system

Only a moderate link between the efficiency of the electrical system (battery to rotor hub) can be observed. While significant for lower technology levels, the influence is small, if analyzed at higher levels. In fact, the electric efficiency is the smallest contributor to aircraft mass and should not be prioritized when it comes to optimization processes.

4.4.1.5 Empty mass fraction

The empty mass fraction is directly linked to the structural mass of the aircraft. Sophisticated structures coupled to intelligent load-path design allows lower empty mass fractions.

Since the empty mass fraction depends on the size of the aircraft, all sized configurations, including the L + C and L + L/C designs, do not have the same baseline. Also, the empty mass of the L + L/C designs is further penalized, to account for the tilting system of the cruise propulsor. The exact value is determined in an iterative process, with large aircraft obtaining small mass fractions, due to their superior scaling.

For this study, an empty mass fraction based on regression analysis of CTOL UAVs is used. However, because VTOL aircraft development is highly concerned with mass considerations, it is sensible that lower mass fractions than usual can be obtained [7].

The empty mass is highly critical, as long as battery and electric motor masses have not yet reached their technology frontier. Of course, the designers should always strive for the lightest structures, but this is even truer for VTOL aircraft. Regardless of the technology level, an empty mass fraction (excluding the eVTOL-system) of less than 55% should be the design goal.

If the L + L/C configuration is evaluated, it can be observed that a certain increase in empty mass fraction is tolerable. For the missions of this study, an empty mass fraction increase of 5% for the L + L/C configuration will still yield a lighter UAV, when compared to the L + C configuration.

4.4.2 Mission factors

4.4.2.1 Design payload

Varying the design payload results in a rather linear reaction of the gross mass. The absolute response is depending on the overall mission requirements, especially on endurance. This explains the difference in slope between the different missions.

The slope of the plots allows to conclude on the payload fraction. Consequently, the longer the required endurance, the lower is the payload fraction. For mission 1 with level 1 technologies, and the L + C configuration, a payload fraction of less than 10% can be obtained. Each technology level gives about a 5% increase in payload fraction for this mission. Payload fractions of 30% are reasonable for conventional aircraft, but this threshold can only be reached for the third technology level and the L + L/C configuration.

4.4.2.2 Design endurance

In contrast to payload, increasing design endurance increases the slope of the plot significantly.

Viewed in conjunction with the plots for design payload, it becomes obvious, why no long endurance eVTOL UAVs for heavy payloads are on the market. Taking-off vertically with a high fuel load increases aircraft size exponentially. However, as the plots for mission 3 show, such vehicles become viable with future technology improvements.

4.4.2.3 Hover time

The time spent in hover is another major factor influencing the gross mass. Its influence looks quite similarly to the endurance plots above—however, the hover time is given in minutes, and the endurance in hours.

For the given baseline values, 1 min spent in hover causes a greater mass increase than increasing the endurance requirements by 1 h.

The hover time variation must be viewed in conjunction with the disk loading plots, since both are highly connected. Large disk loadings and long hover times are infeasible for electric lift systems. The high power-to-weight ratio of the motors and low specific energy of the batteries favors this technology for very short hover times. This clearly changes, as battery performance is improved and, if technology level 3 is reached, extended hovering times are reachable.

However, missions that require extended time in hover are unsuited for transitioning VTOL aircraft and are better served by helicopters.

4.4.2.4 Surplus thrust factor

For heave control, suck down effects and recirculation effects, a thrust-to-weight ratio (or surplus thrust factor) of at least 1.2 is recommended in literature (e.g. [7, 27]). Since multicopter systems rely on differential rotor speeds for control [1], a T/W of 1.5 is the absolute minimum and results in a less responsive aircraft—especially about the yaw axis.

A surplus thrust factor of more than 2 is desirable from a redundancy point of view. This way, any thrust loss of a motor can be compensated for by another one (e.g. for octocopter configurations). This goal causes a huge mass gain for current day technology, but for level 2 and level 3 this is an achievable design goal. While the level of redundancy is of less importance for an unmanned design, avoiding critical failure modes should be a priority for any design for flight.

4.4.2.5 Lift-to-drag ratio

The lift-to-drag plot is mission specific. Since the L/D is only relevant while the aircraft is loitering, the influence is larger for longer loiter times. Therefore, extreme endurance aircraft are highly drag sensitive, while drag is of less importance as long as the mission is short. This is the reason why helicopters (L/D ≈ 4) or multicopters (L/D ≈ 2) are sensible for short-range transport, but inefficient if long flight times are required.

For the specific plots presented here, a frontier can be made out: if the L/D is increased beyond 20, improvements are still possible, but the returns are diminished.

4.5 Implications on design and technology

This sizing sensitivity study shows that the key to successful VTOL UAVs with electric lift system in the near term is a minimal hover time requirement and a low rotor disk loading. If endurance requirements can be reduced, this will have significant impact on the size of the flight vehicle. Looking at technology advancements, the highest payoff is achievable by improving battery and electric motor mass. Improving the efficiency of the electric systems any further than today’s state of the art has little influence on vehicle size. Low empty mass fractions are highly important for successful designs, as well.

5 Conclusion

In this paper, the effects of the VTOL requirement on aircraft size and mass were thoroughly assessed for transitioning UAVs, which use electric lift systems. The influence of key variables on flight performance and mass was calculated and discussed.

VTOL concepts were evaluated against a state-of-the-art ‘conventional’ CTOL baseline and this allowed to perform trade-offs for the definition of mission specifications. This allows answering questions such as: “How much performance does the operator really need, and how much will an extra performance cost in terms of mass?” and: “What will be the mass increase if a certain mission shall be performed by a VTOL instead of a CTOL aircraft?”

The hybrid propulsion option (meaning electric lift motors and combustion engines for endurance flight) was shown to be a practical method to enable VTOL capabilities. The lift + lift/cruise VTOL configuration, while more complex, allowed a significant reduction in sized mass when compared the simpler lift + cruise configuration. However, for both configurations, electric hover propulsion is only a viable option, if the time spent in hover is kept to an absolute minimum. Otherwise, the mass savings of the electric motors will be completely negated by a heavy battery system.

The performance of these systems will rapidly increase in the near term, as new technologies are almost ready for the market. Gains in battery and electric motor performance will result in the largest improvements in terms of a reduction in sized mass. The sizing studies show, that these new technologies will significantly reduce the cost of VTOL in the near future and that more UAVs with significantly improved capabilities can be designed and operated in a moderate timeframe. It is likely that battery and electrical systems will improve beyond the technology assumptions of this study. This will open up the field of purely electric VTOL aircraft.

Abbreviations

- \(\dot {m}\) :

-

Mass flow rate

- A/C:

-

Aircraft

- AC:

-

Alternating current

- Bat:

-

Battery

- C :

-

Cruise

- CTOL:

-

Conventional take-off and landing

- DC:

-

Direct current

- e :

-

Electronic

- E :

-

Energy

- E*:

-

Mass specific energy

- ES:

-

Electrical system

- ESC:

-

Electronic speed controller

- g :

-

Gravitational acceleration

- ISA:

-

International standard atmosphere

- L :

-

Lift

- L/D :

-

Lift-to-drag ratio

- M :

-

Figure of merit

- m :

-

Mass

- m 0 :

-

Design gross mass

- MSL:

-

Mean sea-level

- MTOM:

-

Maximum take-off mass

- n :

-

Number of

- P :

-

Power

- P :

-

Propeller

- P*:

-

Mass specific power

- S :

-

Area

- T :

-

Thrust

- t :

-

Time

- T/W :

-

Thrust-to-weight ratio

- TO:

-

Take-off

- TRL:

-

Technology readiness level

- UAV:

-

Unmanned aerial vehicle

- VTOL:

-

Vertical take-off and landing

- η :

-

Efficiency

- ρ :

-

Density of air

- τ :

-

Energy reserve fraction

References

Finger, D.F., Braun, C., Bil, C.: A review of configuration design for distributed propulsion transitioning VTOL aircraft. In: Asia-Pacific International Symposium on Aerospace Technology APISAT 2017, Seoul (2017)

Bowers, P.M.: Unconventional Aircraft. TAB Books, Blue Ridge Summit (1990)

Kohlman, D.L.: Introduction to V/STOL Airplanes. Iowa State University Press, Iowa (1981)

Campbell, J.P.: Vertical Takeoff and Landing Aircraft. The Macmillan Company, New York (1962)

Warwick, G.: Aviation week and space technology—Uber Unveils 2020 plans for electric VTOL air-taxis demos. 28 April 2017. [Online]. http://aviationweek.com/aviation-week-space-technology/uber-unveils-2020-plans-electric-vtol-air-taxis-demos. Accessed 28 Apr 2017

Finger, D.F.: Comparative performance and benefit assessment of VTOL and CTOL UAVs. Aachen: Master’s Thesis—FH Aachen (2016)

Raymer, D.P.: Aircraft Design: A Conceptual Approach, 5th edn. AIAA, Virginia (2012)

Stevens, J.H.: VTOL aircraft: 1965. Flight Int. 87, 769–792 (1965)

Jenkins, D.R., Landis, T., Miller, J.: American X-Vehicles: An Inventory-X-1 to X-50—SP-2003-4531. NASA History Office, Washington, DC (2003)

Raymer, D.P.: Living in the Future. Design Dimension Press, Los Angles (2009)

Gunston, B.: World Encyclopedia of Aero Engines. Patrick Stephens Limited, Cambridge (1989)

Finger, D.F.: Comparative performance and benefit assessment of VTOL and CTOL UAVs. In: 65. Deutscher Luft- und Raumfahrtkongress DLRK 2016, Braunschweig (2016)

Gudmundsson, S.: General Aviation Aircraft Design: Applied Methods and Procedures. Butterworth-Heinemann, Oxford (2014)

Ahn, J.: Design and performance prediction of a propeller operating in forward and hovering conditions. In: Asia-Pacific International Symposium on Aerospace Technology APISAT 2017, Seoul (2017)

Leishman, J.G.: Principles of Helicopter Aerodynamics, 2 edn. Cambridge University Press, New York (2006)

Russel, C., Jung, J., Willink, G., Glasner, B.: Wind tunnel and hover performance test results for multicopter UAS vehicles. In: AHS 72nd Annual Forum, West Palm Beach (2016)

Jossen A., Weydanz W.: Moderne Akkumulatoren richtig einsetzen. Inge Reichardt Verlag, Untermeitinge (2006)

Kurochkin, F.P.: Principles of Design of Vertical Takeoff and Landing Aircraft, Wright-Patterson Air Force Base. NTIS, Ohio (1971)

Helicopter B.: Eagle Eye Pocket Guide. Bell Helicopter Textron Inc., Fort Worth (2005)

Ahn, O., Kim, J.M., Lim, C.H.: Smart UAV research program status update: achievement of tilt-rotor technology development and vision ahead. In: 27th International Congress of the Aeronautical Sciences ICAS 2010, Nice (2010)

Patterson, M.D., German, B.J., Moore, M.D.: Performance analysis and design of on-demand electric aircraft concepts. In: 12th AIAA Aviation Technology, Integration, and Operations (ATIO) Conference and 14th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Indianapolis (2012)

Warwick, G.: Electric Potential. Are Battery Technologies Advancing Fast Enough to Enable eVTOL, pp. 38–41. Aviation Week & Space Technology, New York (2017)

Gagg, R., Farrar, E.: Altitude performance of aircraft engines equipped with gear-driven superchargers. Troy: SAE Technical Paper 340096 (1934)

Mattingly, J.D., Heiser, W.H., Pratt, D.T.: Aircraft Engine Design, 2nd edn. AIAA, Virginia (2002)

Finger, D.F., Braun, C., Bil, C.: An initial sizing methodology for hybrid-electric light aircraft. In: AIAA Aviation Forum, Atlanta (2018)

Rodas, E.A.E., Lewe, J.-H., Mavris, D.N.: Feasibility focused design of electric on-demand aircraft concepts. In: 14th AIAA Aviation Technology, Integration, and Operations Conference, Atlanta (2014)

Nicolai, L.M., Carichner, G.E.: Fundamentals of Aircraft and Airship Design, Volume 1—Aircraft Design. AIAA, Virginia (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Finger, D.F., Braun, C. & Bil, C. Impact of electric propulsion technology and mission requirements on the performance of VTOL UAVs. CEAS Aeronaut J 10, 827–843 (2019). https://doi.org/10.1007/s13272-018-0352-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13272-018-0352-x