Abstract

The purpose of this paper is to present a methodology for characterizing the rheological properties of heterogeneous gastric contents, for the first time, to our knowledge. Pigs were used as a model because their gastric system is similar to that of humans. Bread was chosen as a high-calorific, solid test meal. The bread was made with flours offering a wide range of amylose/amylopectin ratios. A specific method of extraction and measurement was developed. For the study, the vane test technique was chosen in order to take into account the heterogeneity and short lifetime of the boluses. The variation in viscosity values for each gastric system was compared with their moisture contents, different residence times in the stomach, and various amylose/amylopectin ratios. The viscosities decrease significantly as the residence time increases. Furthermore, we suggest that the amylose/amylopectin ratio (Am/Ap) determines the moisture content, which then provides the viscosity level, since the gastric contents behave as a concentrated suspension. Pigs add variability to the results because the structure of the bolus depends on mastication.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The rheological properties of gastric contents, such as viscosity, play an important role in gastric emptying, the kinetics of starch digestion and glycemic response [1–4]. Gastric juices containing bread tend to create a semi-fluid medium with large swollen lumps. It is therefore quite a challenge to monitor the relevant rheological properties during digestion and take into account the real in vivo conditions [5–7]. The main objective of the present study is to overcome these difficulties. Most published results relate to the viscosity of the meal and rarely to the viscosity of the in vivo gastric juices, where the physiological function is supposed to take place [8]. Because human gastric contents cannot easily be extracted, pigs are used here, as their gastric system is similar to that of humans. Breads were chosen as the original meal because the modification of their carbohydrate content provides a wide spectrum of bolus consistency. A dedicated device had to be designed to take into account the multiple characteristics of the gastric juices, such as large particles, temperature, and short lifetime of the sample, owing to the rapid changes in physical and chemical properties of the bolus.

The measurements aim for evaluating the impact of carbohydrate on the rheological properties of the gastric contents, by using different carbohydrate compositions within the bread. The influence of fibers, such as carbohydrates, has been noted in several studies [9–12]. In some papers, authors proposed to increase the bolus viscosity with addition of different fibers, to reduce the glycemic response and to increase satiety [13–15]. In such context, carbohydrates, especially amylose and amylopectin, have been used to modify the rheological properties of in vitro solutions [16–22]. In this study, we want to evaluate the impact of the amylose/amylopectin ratio, denoted by Am/Ap, on the rheological properties of the in vivo gastric juices during digestion. This investigation is carried out by monitoring two major parameters, namely the residence time and the moisture content.

The objective of our work is therefore to present the sampling and measurement methodology that concern extraction, sample loading, measurements, and calculations. As soon as the rheological behavior of the gastric juices is described, the data are than correlated with the moisture content, the gastric residence time, and Am/Ap. Finally, we propose to investigate the role of Am/Ap at different stages of digestion, and to analyze the variability induced by pig mastication behavior.

Material and Methods

Material

Animals

In the present study, eight animals (large white female pigs, 35 ± 3 kg) were considered. A large gastric cannula (ID 1.2 cm) was surgically inserted into the proximal stomach to obtain access to the gastric contents. The large diameter was chosen so that large particles in the gastric juice could be sampled without any possible skimming of the gastric content. This protocol has been approved by the French veterinary services (authorization numbers A35-622 and 01894).

The pigs were pre-anaesthetized with ketamine (5 mg kg−1, i.m.). A surgical level of anesthesia was obtained with halothane (3–5 %, v/v) delivered by a mechanical ventilator (SAL 900, Siemens, Saint-Denis, France). The oxygen fraction (FiO2) and tidal volume were adjusted such that the spO2, measured by pulse oximetry (Ohmeda, Limonest, France), and the spCO2, measured by an IR capnometer (Amstrong, Coleraine, N. Ireland), were found to be larger than 98 % and lower than 5 %, respectively. A venous cannula was inserted into the marginal vein of the ear to infuse Ringer’s lactate (500 mL h−1) during surgery to prevent dehydration. A T-shaped silicon cannula (1 cm ID) was introduced in the fundus, 15 cm distal from the lower esophageal sphincter and exteriorized in the left flank.

Breads

Bread samples, referred as bread 1, bread 2, and bread 3, were made with three different flours distinguished by their Am/Ap. The characteristics of the breads and flours are shown in Table 1. They consist of a mix of flours based on standard T55 flour (Girardeau, France), HI-maize 260 amylose powder (National Starch and Chemical Company, Bridgewater, USA), and Alice amylose-free waxy flour (Limagrain, Saint-Beauzire, France).

The breads were obtained by using a Moulinex bread machine (SEB, Ecully, France) incorporating a 2 h 30ʹ cooking program. When starting the process, the following ingredients were inserted into the manufacturing vessel at the beginning of the program: 216 ml of water, 5 g of NaCl, 360 g of flour and 4.7 g of yeast. Each test session was performed with breads made 12 h before the experiment.

Methods

Bread Characterization

Once cooked, the bread loaves were practically of same size, although the texture of each bread was visually different (Fig. 1). To appreciate the different textures, we chose to measure the ratio of trapped air and the average size of air bubbles in the crumbs by the means of tomographic analysis.

In practice, each loaf of bread was placed in the tunnel of a medical X Computerized Axial Tomography Scan (Hi-Speed NTxi, GE Médical System, Meylan, France). A set of 3-mm-thick transversal slices was obtained at a voltage of 120 kV with an X-ray tube current of 40 mA. The CAT was calibrated before each imaging session with air and water density. An assessment of the spatial resolution was also performed by using a suitable phantom surrounded by water.

Each axial section was transferred to the Image J software for quantitative image analysis. A binary threshold, based on the Hounsfield scale, was chosen and the air value was set to −1,000. The mask thus created was then analyzed. The results are compiled in Table 1. Bread 3 was found to be significantly more compact than the two other samples, with smaller air inclusions and a reduced proportion of trapped air.

Rheometry

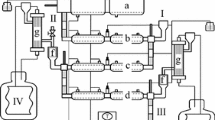

From their visual appearance, the gastric contents are suspensions of soft particles of varying numbers and sizes (Fig. 2). Particles of bread are inflated with a pool of water, saliva, and gastric secretions. Numerous constraints have been required for rheological characterization of the gastric juices. Depending on their residence time, gastric juices may be described as ranging from a highly concentrated non-Newtonian suspension to a Newtonian fluid containing a reduced number of particles, leading to explore a broad range of viscosities for fluids containing soft and deformable particles. The maximum particle size was found to be approximately 2 mm, evaluated from images of the samples, as shown in Fig. 2 for bread 2. To satisfy conditions of a continuous medium, we adopted a large gap in our rheometry experiments. Furthermore, owing to the rapid physical, chemical, and thermal changes taking place in the bolus, a fast and simple method was carried out. Additionally, the volume of the sample may vary with residence time. These constraints finally led us to adopt the vane test technique for the experiments, along with suitable measurement and analysis protocols.

An experimental device has been set up for gastric juice rheology, using a Couette cell combined with a VT-550 viscometer (Thermo, Karlsruhe, Germany), consisting of a fixed cup filled with the sample and a vane half-inserted in the sample. The depth of insertion of the vane depended on the available volume of gastric juice extracted from the pigs (between 100 and 300 ml). To impose an adhesion at the wall, the inner surface of the cup was roughened to produce a grid with a 5-mm-mesh size. The gap between the vane and the cup was 12.5 mm, which is more than six times longer than the maximum diameter of particles. Such procedures were essential to satisfy the continuity assumption of the medium during the test, requiring the use of a large gap geometry for the rheology experiments and involving corrections and specific calculations.

The shear rate γ was calculated by means of Eq. 1 [23], where ω is the rotational velocity, R v the radius of the vane and R c the radius of the cup.

Owing to the pasty nature of the fluids, characterized by a yield stress, the entire gap may be not sheared, especially at low velocities. Accordingly, the value of the radius of the true sheared zone, Rs, was used instead of the cup radius. Rs was extracted from the videos. Thus, Eq. 1 becomes Eq. 2, as follows.

The shear stress was calculated with the hypothesis under the assumption of no secondary flow between the blades. The calculations related to (Eq. 3)

took into account the fact that the vane was not fully inserted into the fluids [24]. The apparent viscosity η was therefore calculated with Eq. 4.

Protocols

Meal Intake

The animals were allowed 1 week to recover from surgery before starting experiments. During the second week, the animals were presented with the bread test meal to accustom them to it. The animals were housed in modified metabolism crates to restrict their mobility. The trials were carried out after a fasting of 12 h. Immediately after the test meal and during the experimental session, the animals were not allowed to drink water.

The bread was cut into cubes of approximately 2 cm3. To obtain extractable gastric juices through the gastric cannula, the test meal consisted of 500 kcal cubes of bread (171 g for bread 1, 182 g for bread 2, and 177 g for bread 3) mixed with 150 ml of water. The quantity of bread was adapted to obtain isocaloric meals. The animals ate the meals in less than 5 min.

Three samplings of the gastric contents were carried out at 30, 60, and 120 min after starting the test meal. To limit any alteration in viscosity due to experimental constraints, each sampling operation was performed once during an experimental session, i.e., there was no reintroduction of gastric chyme after the full sampling of all the gastric contents. After opening the cannula, the gastric contents were completely poured into a container by gravitational flow. The maximum available quantity of juices was then isolated and immediately transferred into the measuring cell.

Test Sequence

The temperature of the samples was measured systematically before and after the rheological tests. Less than 2 min elapsed between the extraction of the gastric juice from the pig and the start of the rheological test. The cup was maintained at 39 °C before filling. The thick plastic wall of the cup prevented major heat loss during the test. The average heat loss measured was 2.2 °C, with a standard deviation of 0.9 °C.

Several rotational velocity steps were applied to the sample, from 0.01 to 30 rad/s. For each velocity, the test was stopped after reaching permanent flow in order to limit the total strain applied to the sample. Flow curve acquisition lasted less than 3 min to minimize changes in physical, chemical and thermal characteristics of the gastric juice. Flow at the free surface was recorded simultaneously.

During the rheological test, a video of the free surface was taken at each step. A tracer powder was dropped on the free surface before beginning the test. The flow at the free surface was considered to be representative of the bulk flow. For each test, the strain fields were extracted from the videos. At low shear rates, typically under 0.5 s−1, the strain imposed by the vane could not propagate from the vane to the cup wall. In the unsheared area, the stress level is below the yield stress. The true shear rate was therefore corrected using a new gap, in which the fluid was sheared from the edges of the vane to the unsheared area. The radius of the virtual wall (defined by R s in Eq. 2) was monitored by videos, which also determine the fluid velocity at the wall, to check the adherence conditions.

After performing the rheological tests, the weight of the gastric juices are measured and desiccated. The moisture content was then determined using the ratio of the dry weight to the initial weight.

Results

Influence of Residence Time on Rheological Properties and Moisture Content

For bread 1, Fig. 3a shows the changes in viscosity according to shear rate, for three residence times in the stomach, Fig. 3b gives the change in the corresponding shear stress. The flow curves demonstrate the pasty behavior of the gastric contents for short residence times (30 and 60 min). In fact, the shear stress for lowest the shear rate tend to a plateau value. This stress value is representative of the yield stress of the gastric contents. When the shear rate increases, the viscosity decreases non-linearly. In this state, the gastric contents are therefore shear-thinning yield stress fluids. When the residence time increases (120 min), the level of shear stress decreases significantly, when compared to those corresponding to 30 and 60 min. The shear stresses then have a linear correlation with the shear rate and the viscosity is nearly constant. The gastric contents are no longer pasty but exhibit a Newtonian behavior. The viscosity level is still at least 100 times the viscosity of water (>100 mPa.s). These viscosity data have been measured previously using gastric contents from liquid meals [12]. Moreover they cannot be explained simply by the presence of saliva, the viscosity of which is at most 10 times the viscosity of water [25]. Carbohydrates may completely cover the non-Newtonian behavior of saliva and other gastric proteins.

For a short residence time of 30 min, large particles of bread created by chewing are observed (Fig. 2a). The gastric juice is a concentrated suspension of deformable lumps swollen with water. Contacts between particles are lubricated to varying degrees depending on the available water quantity. The yield stress may be due to particles jamming together while they are still rigid. When increasing the residence time up to 60 min, a certain amount of liquid is added from the pig’s stomach, which dilutes the gastric juice (Fig. 2b). The lumps also dissolve in the liquid medium, and the particles tend to be softer. In addition, the amylase breaks starch down into sugars and thereby reduces the molecular weight. Those three mechanisms contribute to liquefy the suspension and reduce viscosities, until it practically reaches a liquid state at 120 min, with few immersed particles (Fig. 2c).

For further analysis, we chose a viscosity at a low shear rate, i.e. 0.03 s−1, because flow through the duodenum is quite low and the order of magnitude of the velocity is small. The low viscosities of Newtonian juices at 0.03 s−1 result in low torques, which cannot be measured by our device, on account of the transducer sensitivity. Therefore, as Newtonian fluids exhibit a constant viscosity regardless of shear rate, the viscosity was extrapolated from data obtained at higher shear rates.

Figure 4 shows the change in viscosity (Fig. 4a) and in moisture content (Fig. 4b) according to residence time for the three breads. Moisture content increases with residence time. At 30 min, the moisture content and viscosity are constant regardless of the breads. The moisture is directly related to the water content of the original meal before ingestion, leading us to decide that the pigs should not have access to drinking water during the experiments. After ingestion, the pigs add a certain amount of liquid themselves depending on digestive activity. The moisture content therefore tends to increase at 60 min, and the viscosity decreases as a consequence. The trend is influenced by the different gastric secretions and the breads, owing to the differences in Am/Ap. This increase in moisture content and decrease in viscosity have been noticed previously [5]. Finally, a viscosity reduction of the order of two to three decades is recorded after a residence time of 120 min, with an increase in moisture content.

It should be pointed out that the overall change in viscosity versus the residence time clearly depends on the individual pig. This can be explained by the differences in oral and gastric secretions, and by those concerning chewing behavior. The drop in viscosity confirms the mechanism of dilution, lump dissolution and amylase action on starch.

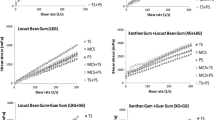

Relation Between Moisture Content and Rheological Properties

The rheological properties are very sensitive to the moisture content of the gastric juice, as shown in Fig. 5. The decrease in rheological properties with increasing moisture content confirms the fact that the gastric juices are suspensions. Indeed, the viscosity is related to the moisture content according to an exponential law, fitted over the entire digestion period. Such correlation highlights the assumption that the rheological behavior of gastric juices with particles is rather governed by the particle concentration, and therefore by their dissolution and dilution. The rheological behavior of the gastric juices may be also considered as depending on the shape and size of the particles, but our rheological approach based on bulk measurement cannot discriminate this effect.

Influence of Am/Ap on Rheological Properties and Moisture Content

The Am/Ap is the main chemical parameter that changes with the composition of the bread. As shown in Fig. 4a, the viscosities at 30 and 60 min are not significantly different with any of the breads. For those residence times, the rheology of the gastric juices may be governed more by the mechanical structure, i.e., the macroscopic particles immersed in a yielded suspension (Fig. 2a, b), than by the chemical properties of the carbohydrates. On the other hand, a significant difference in viscosity can be noted at 120 min, especially in the case of Bread 1. Therefore, we provide in Fig. 6a the viscosities versus the Am/Ap ratio. The increase of viscosity with Am/Ap is quite significant at 60 min, but more significant at 120 min, as the particles have been largely dissolved (Fig. 2c) and the gastric juice is no longer a yield stress fluid (pasty). In parallel, a significant drop in moisture content as a function of Am/Ap can be observed only in the case of a long residence time, 120 min (Fig. 6b). Thus, the two breads with higher amylose content appear to maintain a higher viscosity at 120 min as they absorb less moisture. The origin of the trend will be discussed in the next section of the present article.

Discussion

During the digestion process, gastric juices behave as a concentrated suspension, as visually illustrated by Fig. 2 and by rheological data of Fig. 5, that depicts the exponential relation between viscosity and moisture content. This relation is not significantly affected for breads containing various Am/Ap. During the process, the suspensions switch from a yield stress behavior of jammed particles to a less concentrated suspension, with smaller and softer particles. Previous results (Fig. 6) show that the Am/Ap does not significantly modify the moisture content and the rheology at the beginning step of digestion. After a certain residence time, the suspensions became “soft” enough to perceive the effect of Am/Ap on their rheological properties (Results section).

In this section, we wish to propose an explanation for the difference in viscosities between the breads observed after 120 min. This requires an accurate analysis of the continuous process from ingestion to digestion from mechanical and chemical points of view, in light of the rheological data.

Initially, the breads have an alveolar sponge-like structure, depending on the flour, as shown in Fig. 1. The breads have various crumb densities due to the Am/Ap ratio, and therefore different porous media (Table 1). The bread cubes are swollen with water before ingestion but the porous medium is not saturated. During mastication, the cubes are reduced to pieces of different sizes. Once ingested, the gastric juices are a structure of large swollen lumps of bread lubricated with water (Fig. 2a). The lumps are progressively dissolved by the action of enzymes and water through the porous medium, which differs from bread to bread. The measurements carried out at 30 min show that the moisture content and viscosity are similar regardless of the Am/Ap (Fig. 4a–b), which proves that the porous media induced by Am/Ap does not affect the way the lumps are dissolved. As observed in the previous section, the rheology of the gastric juices is determined more by the lumps jamming up to 30 min.

As dissolution takes place in the stomach, a slight rise in the moisture content is observed at 60 min in the case of the bread with the lowest Am/Ap (Fig. 4b). Several studies have suggested that once solubilized, amylopectin retains a larger quantity of water [16, 18, 26–28]. But the difference in moisture content is not significant at 60 min, maybe because the suspension is not sufficiently degraded to solubilize a large amount of amylopectin. Indeed the juices have nearly the same appearance at 30 min (Fig. 2a) and 60 min (Fig. 2b). The slight decrease in viscosity observed at 60 min in the case of the bread with the highest Am/Ap (Figs. 4 and 6a) may be correlated with the rise in moisture content, not with the Am/Ap itself from a chemical point of view.

After 120 min, the lumps have practically disappeared (Fig. 2c). Measurements show that the moisture content is much higher in the case of high Am/Ap bread, but the corresponding low viscosity cannot be explained only by the moisture content, because the gastric juice is visibly no longer a concentrated suspension (Fig. 2c). The amylopectin is more rapidly degraded by the amylase action, and no longer contributes to the consistency of the juice. In contrast, the amylose is more resistant to degradations in stomach, and rather degraded in the intestines [7, 29–31]. The amylose therefore helps to increase the viscosity of the liquid phase with a long residence time.

The pig’s chewing behavior and gastric secretion affects the results, as shown in Figs. 4 and 6. Those may change the particle size distribution and moisture content of the concentrated suspension. Their influence is stronger in the case of a short residence time, where the particles determine the behavior of the suspension. In the case of a long residence time, lump dissolution reduces the effect of the initial chewing, but the effect of secretion is still apparent, leading to variable moisture contents and viscosities. However, some important observations can be made at 120 min. The initial meal could be homogenized by mechanical mashing. This would reduce the influence of the individual pigs in the case of short residence times, but the experiment would be far from representing real bread consumption by humans.

Conclusions

The main objective of this study was to present a methodology for rheological characterizing gastric contents from a solid meal. This characterization was carried out by a vane test associated with the proper experimental conditions and a suitable analysis. Despite the constraints linked to the suspensions studied and the strong influence of the pigs’ behavior, the results revealed that the rheology of gastric contents is dictated by their suspension nature up to a residence time of 60 min. The consistency of the concentrated lump suspension produced by particle jamming almost surpasses any effects caused by the different Am/Ap ratios. The viscosity decreases with residence time in the stomach, which is correlated with an increase in the moisture content. We suggest that the Am/Ap only influences the moisture content and viscosity in the case of a long residence time, after 120 min. The gastric contents are no longer concentrated lump suspensions, since the lumps of bread are digested through amylase action. The viscosity is then dictated by the molecular weight of the amylopectin and amylose in solution. As the amylopectin is rapidly degraded, the amylose contributes more to the viscosity because it is less susceptible to amylase action and therefore maintains a higher molecular weight and higher viscosity.

Rheology may be a relevant method for understanding the changes in gastric juices during residence in the stomach, and the influence of amylose and amylopectin on the process. It should be noted that the variability in viscosity between the different animals suggests that the way the meal is broken down by chewing has an influence on the rheological behavior of the gastric juice, especially after short digestion periods.

References

Björck I, Granfeldt Y, Liljeberg H, Tovar J, Asp NG (1994) Food properties affecting the digestion and absorption of carbohydrates. Am J Clin Nutr 59:699S–705S

Edelbroek M, Edelbroek M, Wishart J, Akkermans L (1993) Effects of erythromycin on gastric emptying, alcohol absorption and small intestinal transit in normal subjects. J Nucl Med: Off Publ, Soc Nucl Med 34:582–588

Horowitz M, Edelbroek MAL, Wishart JM, Straathof JW (1993) Relationship between oral glucose tolerance and gastric emptying in normal healthy subjects. Diabetologia 36:857–862

Jebb SA (2007) Dietary strategies for the prevention of obesity. Proc Nutr Soc 64:217–227

Johansen HN, Knudsen KB, Sandstrom B, Skjoth F (1996) Effects of varying content of soluble dietary fibre from wheat flour and oat milling fractions on gastric emptying in pigs. Br J Nutr 75:339–352

Kong F, Singh RP (2008) Disintegration of solid foods in human stomach. J Food Sci 73:R67–R80

Lindberg JE, Arvidsson A, Wang J (2003) Influence of naked barley cultivar with normal, amylose-rich or amylopectin-rich starch and enzyme supplementation on digestibility and piglet performance. Anim Feed Sci Technol 104:121–131

Cherbut C, Albina E, Champ M, Doublier JL, Lecannu G (1990) Action of guar gums on the viscosity of digestive contents and on the gastrointestinal motor function in pigs. Digestion 46:205–213

Deshpande SS, Cheryan M (1984) Effects of phytic acid, divalent cations, and their interactions on α-amylase activity. J Food Sci 49:516–519

Brown NJ, Worlding J, Rumsey RDE, Read NW (1988) The effect of guar gum on the distribution of a radiolabelled meal in the gastrointestinal tract of the rat. Br J Nutr 59:223–231

Potkins ZV, Lawrence TLJ, Thomlinson JR (1991) Effects of structural and non-structural polysaccharides in the diet of the growing pig on gastric emptying rate and rate of passage of digesta to the terminal ileum and through the total gastrointestinal tract. Br J Nutr 65:391–413

Guerin S, Ramonet Y, LeCloarec J, Meunier-Salaün MC, Bourguet P, Malbert CH (2001) Changes in intragastric meal distribution are better predictors of gastric emptying rate in conscious pigs than are meal viscosity or dietary fibre concentration. Br J Nutr 85:343–350

Granfeldt Y, Liljeberg H, Drews A, Newman R, Björck I (1994) Glucose and insulin responses to barley products: influence of food structure and amylose-amylopectin ratio. Am J Clin Nutr 59:1075–1082

Akerberg Å, Liljeberg H, Björck I (1998) Effects of amylose/amylopectin ratio and baking conditions on resistant starch formation and glycaemic indices. J Cereal Sci 28:71–80

Marciani L, Gowland PA, Spiller RC, Manoj P, Moore RJ, Young P, Al-Sahab S, Bush D, Wright J, Fillery-Travis AJ (2000) Gastric response to increased meal viscosity assessed by echo-planar magnetic resonance imaging in humans. J Nutr 130:122–127

Morita N, Maeda T, Miyazaki M, Yamamori M, Miura H, Ohtsuka I (2002) Effect of substitution of waxy-wheat flour for common flour on dough and baking properties. Food Sci Technol Res 8:119–124

Dikeman CL, Murphy MR, Fahey GC (2006) Dietary fibers affect viscosity of solutions and simulated human gastric and small intestinal digesta. J Nutr 136:913–919

Van Hung P, Maeda T, Morita N (2006) Waxy and high-amylose wheat starches and flours—characteristics, functionality and application. Trends Food Sci Technol 17:448–456

Sandhu KS, Singh N (2007) Some properties of corn starches II: physicochemical, gelatinization, retrogradation, pasting and gel textural properties. Food Chem 101:1499–1507

Juhász R, Salgó A (2008) Pasting behavior of amylose, amylopectin and their mixtures as determined by RVA curves and first derivatives. Starch - Stärke 60:70–78

Xie F, Yu L, Su B, Liu P, Wang J, Liu H, Chen L (2009) Rheological properties of starches with different amylose/amylopectin ratios. J Cereal Sci 49:371–377

Sulaiman R, Dolan KD (2013) Effect of amylose content on estimated kinetic parameters for a starch viscosity model. J Food Eng 114:75–82

Macosko CW (1994) Rheology: principles, measurements, and applications. Wiley, New York

Yoshimura AS, Prud’homme RK, Princen HM, Kiss AD (1987) A comparison of techniques for measuring yield stresses. J Rheol 31:699–710

Schipper RG, Silletti E, Vingerhoeds MH (2007) Saliva as research material: biochemical, physicochemical and practical aspects. Arch Oral Biol 52:1114–1135

Tester RF, Morrison WR (1990) Swelling and gelatinization of cereal starches. I. Effects of amylopectin, amylose, and lipids. Cereal Chem 67:551–557

Eastwood MA, Morris ER (1992) Physical properties of dietary fiber that influence physiological function: a model for polymers along the gastrointestinal tract. Am J Clin Nutr 55:436–442

Singh J, Dartois A, Kaur L (2010) Starch digestibility in food matrix: a review. Trends Food Sci Technol 21:168–180

French D (1984) Organization of starch granules. Starch: Chem Technol 2:183–247

Black JL (2001) Variation in nutritional value of cereal grains across livestock species. Proceedings of the Australian Poultry Science Symposium 13, 22–29

Kim JC, Mullan BP, Pluske JR (2005) A comparison of waxy versus non-waxy wheats in diets for weaner pigs: effects of particle size, enzyme supplementation, and collection day on total tract apparent digestibility and pig performance. Anim Feed Sci Technol 120:51–65

Acknowledgments

This work was made possible through the financial support of the French National Research Agency (ANR), within the framework of the Nomac project. We wish to thank all of the partners involved in this project. We wish to extend our grateful thanks to the technical staff of the Laboratoire Rhéologie et Procédés. The Laboratoire Rhéologie et Procédés is part of the LabEx Tec 21.

Conflicts of Interest

The authors have nothing to disclose.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Patarin, J., Blésès, D., Magnin, A. et al. Rheological Characterization of Gastric Juices from Bread with Different Amylose/Amylopectin Ratios. Food Dig. Res Curr Opin 6, 2–9 (2015). https://doi.org/10.1007/s13228-014-0037-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13228-014-0037-9