Abstract

Due to the rheological and structural basis of texture perceived in semisolid foods, the aim of this work was to study the effects of two thickening agents, on rheology and microstructure of soy protein desserts. As rheological parameter values may not be enough to explain the possible perceived texture differences, the effect of composition on two instrumental indexes of oral consistency (apparent viscosity at 50 s−1 and complex dynamic viscosity at 8 Hz) was also studied. Samples were prepared at two soy protein isolate (SPI) concentrations (6 and 8 % w/w), each with four modified starch concentrations (2, 2.5, 3 and 3.5 % w/w) or four Carboxymethyl cellulose (CMC) concentrations (0.3, 0.5, 0.7 and 0.9 % w/w). Two more samples without added thickener were prepared as control samples. The flow curves of all systems showed a typical shear-thinning behaviour and observable hysteresis loops. Control sample flow fitted well with the Ostwald-de Waele model and the flow of samples with thickener to the Herschel-Bulkley model. Viscoelastic properties of samples ranged from fluid-like to weak gel, depending on thickener and SPI concentrations. Starch-based samples exhibited a globular structure with SPI aggregates distributed among starch granules. In CMC-based samples, a coarse stranded structure with SPI aggregates partially embedded was observed. Variation of the two thickness index values with composition showed a similar trend with good correlation between them (R2 = 0.92). Soy desserts with different composition but with similar rheological behaviour or instrumental thickness index values can be obtained.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The inclusion of soy products as part of the regular diet provides many health benefits. Apart from the reduction in the risk of coronary heart disease and breast and prostate cancers (Barnes et al. 2006; Xiao 2008), there is a growing general interest in products with protein from vegetable sources in order to obtain a more balanced ratio of vegetable/animal protein intake (Russell et al. 2006). The main problems facing the acceptance of these products are related to certain flavour and texture defects. The flavours are commonly being referred to as “beany” and with certain astringency and bitter taste notes (Chambers et al. 2006; Da Silva et al. 2012). Several authors have tried to solve these flavour drawbacks using different approaches such as developing soy varieties with lower lipoxygenase or A-saponins content (Yuang and Chang 2007; Takada et al. 2013), modifying process conditions (Endo et al. 2004; Suppavorasatit et al. 2013) or trying to mask the undesirable flavour by adding flavouring or other ingredients such as fruit juices, chocolate syrup, cocoa powder or coffee (Potter et al. 2007; Yuang and Chang 2007; Deshpande et al. 2008; Felberg et al. 2010; Granato et al. 2010). In addition some authors have described the texture of soy-based products as chalky, dry or oily (N’Kouka et al. 2004; Potter et al. 2007) and some of them have proposed the use of different stabilizers, such a gelatine, pectin or gum acacia, to mask the texture defects cited (Mepha et al. 2006; Potter et al. 2007). In any case, the elimination of flavour and texture drawbacks may be not enough to improve the acceptance of the soy products; so that the optimization of their sensory quality is also needed to ensure their market success.

Due to importance of flavour in food acceptance, most of research related to formulation of new soy products have been focussed in optimizing their flavour without considering the possible role of other sensory attributes (Deshpande et al. 2008; Felberg et al. 2010; Granato et al. 2010, Chattopadhyay et al. 2013). In a previous work about acceptance optimization of citrus flavoured soy-based dessert, Arancibia et al. (2013a), showed that despite the importance of citrus flavour intensity and taste attributes (acidity, sweetness and bitterness), the particular consistency preferences of each consumer influenced the product acceptance. The results exhibited that sample acceptability was more closely related to the particular preferences of each consumer subgroup than with consistency level of samples. A consumer subgroup considered that the sample’s consistency as “strong” and “too strong”, and the other consumer subgroup considered that all samples had a “just about right” consistency. These results indicated the convenience of design soy-based dessert with different consistency levels to flavour product acceptance by groups of consumers with different consistency preferences.

Basically, soy desserts are formulated with soy milk or protein isolates, hydrocolloids, sucrose, aroma and colorants. The characteristics of each ingredient, their concentrations and the effects of the interactions among them influence the product structure to different extents and also modify its rheological, mechanical and textural attributes. With regard to protein content, most currently available commercial soy products are formulated with soy protein contents (less than 3 g/100 g) lower than the amount recommended by various public institutions. For example, the FDA requires at least 6.25 g/serving of soy protein to state a health claim on its label (Walker et al. 2010). Therefore, designing soy-protein desserts with adequate protein content and a good sensory quality will be important to increase consumer acceptance by soy products. An important function of hydrocolloids in protein matrices is that they can act as structuring, thickening and stabilizing agents. Starch is one of the most widely used thickeners in the food industry, although carboxymethyl cellulose (CMC) is also being used as an alternative to starch in food products because of its technological and nutritional advantages (Engelen et al. 2005; Bayarri et al. 2010). Sodium carboxymethyl cellulose (CMC) is a linear, long-chain, water-soluble, anionic polysaccharide widely used in the food industry because it is tasteless, odourless, and forms clear solutions without cloudiness or opacity. In mixed protein-polysaccharide systems, associative electrostatic interactions can lead to coacervation or soluble complex formation, depending on the solution conditions (pH and ionic strength) (Dickinson 2003). Considering the structural differences observed in CMC and starch solutions (Ferry et al. 2006) and break-up mechanisms under shear (Desse et al. 2011), the two thickeners would be expected to affect the physical and sensory characteristics of food matrices differently.

In order to gain a better knowledge about the possibility to design high protein soy desserts with novel and different textures, the aim of this work was to study the effect of starch and CMC concentrations on the flow behaviour, viscoelasticity and microstructure of soy protein desserts formulated at two soy protein isolate concentrations.

Material and methods

Composition and preparation of samples

Soy-based desserts were prepared with powdered soy protein isolate (SPI) (90 % protein; PROSOL 90-GF NT, Cargill, Barcelona, Spain) and a medium crosslinked modified tapioca starch (C* Creamtex 75720, Cargill Ibérica SL, Barcelona, Spain) or carboxymethyl cellulose (CMC) (Akucell AF3265 Akzo Nobel, Amersfoort, The Netherlands) as thickeners. Deionized water, commercial sucrose, citrus flavour (Naranja 1594A, Lucta, Barcelona, Spain) and yellow-orange colorant (NC2 SX WS mct, CHR Hansen S.A., Barcelona, Spain) were also used.

An experimental design with two factors, soy protein isolate concentration (two levels: 6 and 8 % w/w) and hydrocolloid concentration (four levels, starch: 2, 2.5, 3 and 3.5 w/w or CMC: 3, 0.5, 0.7 and 0.9 % w/w) was used. Two more samples without added thickener were prepared as control samples. Protein concentration corresponded to 6.75 and 7.9 g protein/125 g product. The amounts of sugar (4 % w/w), citrus flavour (0.01 % w/w) and colourant (0.026 % w/w) used remained constant.

Soy-based desserts were prepared in batches of 800 g. Soy protein isolate powder was dispersed in deionized water and mixed for 15 min, with the help of a propeller stirrer (Heidolph RZR 1, Heidolph, Schwabach, Germany). The dispersion was placed in a water bath at 90 ± 1 °C and was stirred for 20 min. Then it was cooled in a water bath at 10 °C for 10 min and stored at 4 ± 1 °C overnight to ensure complete hydration of soy proteins. The amount of water evaporated in the heating process was replaced gravimetrically. The following day, starch or CMC was added to the SPI dispersion. Starch samples were prepared as follows: starch, sugar, colorant and soy protein dispersion were mixed with the help of a propeller stirrer in a flask for 10 min at room temperature. Afterwards, the flask was placed in a water bath at 90 ± 1 °C and stirred constantly for 25 min. Samples were cooled in a water bath at 10 °C for 10 min. Any water evaporated was replaced gravimetrically. Citrus flavour was added and samples were stirred for 5 min. For CMC sample preparation, a blend of CMC and sugar was added to the SPI dispersion with colorant and stirred for 35 min at room temperature. Five minutes before the end, citrus flavour was added. All samples were transferred to a closed flask and stored (4 ± 1 °C; 24 h) prior to rheological measurements. At least two batches of each composition were prepared.

Rheological measurements

Rheological measurements were carried out in a controlled stress rheometer RS1 (Thermo Haake, Karlsruhe, Germany), using parallel-plate geometry (60 mm diameter; 1 mm gap) and monitored with RheoWin Job software package (version 3.61, Thermo Haake, Karlsruhe, Germany). Measurements were made at 10 ± 1 °C, selected as representative of the usual consumption temperature of this type of desserts. Temperature was maintained during measurements by means of a Phoenix P1 Circulator device (Thermo Haake, Karlsruhe, Germany). Two batch of each composition were prepared and each batch was measured at least twice, using a fresh sample for each measurement. After loading the sample, it was allowed to stand for 10 min to stabilize and reach the desired temperature. After carefully placing the sample between the plates, excess material was wiped off with a spatula.

Flow properties

Sample flow was measured by recording shear stress values when the samples were sheared at linearly increasing shear rates from 1 to 200 s−1 for 60 s and down in reverse sequence for the same time. Experimental data from descending flow curves of control samples were fitted to the Ostwald-de Waele model (Eq. 1) and data of samples with thickener added were fitted to the Herschel-Bulkley model (Eq. 2). These calculations were performed using RheoWin Pro Data software (version 3.61, Thermo Haake, Karlsruhe, Germany).

where σ (Pa) is the shear stress, \( \overset{\cdot }{\gamma } \) (s−1) is the shear rate, σ 0 (Pa) is the yield stress, K (Pa sn) is the consistency index and n is the flow index. These parameters were used to characterize the flow behaviour of the samples. Since parameter K units depend on n values, apparent viscosity values at 1 s−1 (η1) were used to compare sample consistency statistically.

Areas under the upstream data point curve (A up ) and under the downstream data point curve (A down ) as well as the hysteresis area (A up - A down ) were obtained using RheoWin Pro software (Thermo Haake). In view of the influence of the loop contour and of the shear resistance of the sample on the hysteresis area, the percentage of relative hysteresis area (A R ) (Eq. 3) was calculated because it allows a better comparison of flow time dependence behaviour of different samples.

In time-dependent and non-Newtonian shear-thinning products, perceived thickness is difficult to predict with rheological parameter values because flow in the mouth is probably a combination of shear and elongational flow (van Vliet 2002). However, some authors have found that oral thickness correlates with different rheological indices. It has been confirmed that one of them, apparent viscosity at a shear rate of 50 s−1, suggested by Wood in 1968, has practical utility as a possible instrumental index of thickness perceived in semisolid foods (Cook et al. 2003; Arancibia et al. 2013b). Consequently, apparent viscosity values at a shear rate of 50 s−1 (η50) were also calculated.

Viscoelasticity

Prior to mechanical spectrum measurements, it was necessary to determine the linear viscoelastic region (i.e. the range where G’ and G” are independent of the stress/strain of the oscillation). Stress sweeps were run between 0.02 and 300 Pa at a frequency of 1 Hz in all systems. The frequency sweeps were performed from 0.01 to 10 Hz at 0.05 Pa. The oscillatory rheological parameters used to compare the viscoelastic properties of the samples were storage modulus (G’), loss modulus (G”), loss angle (Tan δ) and complex dynamic viscosity (η*) at 1 Hz. This frequency, as stated by Lapasin and Pricl (1995) would appear to be a reasonable compromise between measuring very fast, when intermolecular entanglements could contribute to solid-like responses, and measuring at extremely low frequencies, when loss of precision and reliability in the measurements could be a problem. For semisolid products with viscoelastic behaviour, some authors have obtained a good correlation between oral thickness and small deformation measurements at an oscillatory frequency of 50 rad s−1 (Hill et al. 1995; Tárrega and Costell 2007). Consequently, complex dynamic viscosity values were determined at 8 Hz, equivalent to 50 rad s−1 (η8Hz).

Microstructure

Microstructure of soy desserts was examined with fluorescence microscopy (Nikon Eclipse 90i, Kanagawa, Japan). A drop of sample was placed on a slide with a cover slip and observed using a magnification of 40× and identical exposure time (1 s). The photomicrographs were acquired with a digital camera (Nikon DS-5Mc, Kanagawa, Japan). The excitation wavelength used was 543 nm. Samples were stained with Rhodamine B (Sigma-Aldrich Química S.A., Madrid, Spain) to allow for the visualization of soy proteins. Fluorescent dye was prepared by dissolving 0.01 g/L Rhodamine B in distilled water, and then added to the samples at a concentration of 0.8 mL/g. Samples were stained 10 min before analysis.

Data analysis

The effects of the two factors and the interaction between them on the flow and on the viscoelastic parameter values, as well as, oral thickness index values, were analysed by a two-way ANOVA. Significant differences between individual samples were determined by the Tukey’s test (α = 0.05). All these calculations were carried out with XLSTAT Pro software, version 2007 (Addinsoft, Paris, France).

Results and discussion

Flow properties

All starch-based samples showed hysteresis loops when they were sheared during a complete cycle, indicating that their flow was time-dependent (Fig. 1a, b). The flow curves of the samples showed a non-Newtonian shear-thinning flow with n values from 0.78 to 0.9. The curves of control samples was fitted well to the Ostwald-de Waele model (0.98 < R2 < 0.99). Samples with added starch showed shear thinning with an initial resistance to flow consistent with the Herschel-Bulkley model (R2 > 0.99). ANOVA results showed a significant effect (p < 0.05) of interaction between SPI and starch concentration on σ0, η1 and AR values (Table 1). This interaction indicated that the starch concentration effect differed, depending on the SPI content. As expected, σ0 and η1 values increased significantly with starch concentration, this variation being higher in samples prepared with 8 % SPI (Table 2). As starch concentration increased thixotropic area also increased. A greater difference in both form and magnitude of the hysteresis loops was observed among samples containing 8 % SPI (Fig. 1b). This behaviour was in accordance with what was observed by other authors when studying the effect of starch concentration on time-dependent behaviour of water-starch pastes (Tattiyakul and Rao 2000) and on starch-milk model systems (Abu-Jdayil et al. 2004; Tárrega et al. 2005). This could be explained by taking into account the fact that the structure of the system is affected by an increase in the volumetric fraction of the dispersed phase partially constituted by swollen starch granules. Samples with 8 % SPI and starch content over 2 % showed an evident overshoot in the stress-rate curves, indicating that the system structure broke down partially as a result of increasing shearing time (Fig. 1b). The maximum in the stress may represent the yielding transition from a continuous network to a discontinuous state at this point (Mujumdar et al. 2002). Starch addition effect could be related to a mutual exclusion between starch and SPI that affects the water partition between the two phases, increasing the effective concentration of both biopolymers (Colombo et al. 2011). At the lowest SPI or starch concentrations, the soy dessert samples were relatively deformable by shearing and the flow curves did not show any overshoot. This behaviour could indicate that the two biopolymers behave as individual molecules that are distributed throughout the one-phase system (McClements et al. 2009).

Flow curves (a and b) and mechanical spectra (c and d) (G’, storage modulus: filled symbol and G”, loss modulus: empty symbol) of soy-based desserts containing 6 % (a and c) or 8 % (b and d) of soy protein isolate (SPI) and different starch concentrations (△:0 %, ○:2 %, □: 2.5 %, ▽: 3 % and  : 3.5 %)

: 3.5 %)

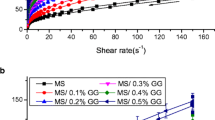

The flow curves of the CMC-based systems also exhibited a time-dependent and shear thinning with yield stress behaviour (Fig. 2a, b). As previously mentioned, control samples for both SPI concentrations did not show yield stress. Measurements of increasing and decreasing shear rate showed hysteresis loops in most samples, indicating thixotropic behaviour. Samples with the higher SPI concentration needed higher energy to break its structure as compared with their counterparts formulated with the lower SPI content (Fig. 2a, b, respectively). This seems to indicate that the flow behaviour of these systems was affected by both SPI and CMC concentrations without the influence of any qualitative structure change or phase separation. In mixed biopolymer systems that contain a protein and an anionic polysaccharide, their possible association is strongly dependent on pH. In this case, the pH of the soy-based samples, which ranged between 6.25 and 6.37, was clearly above the isoelectric point of soy protein (pH ~ 4.5). In this situation, the protein and the polysaccharide have a negative charge and an electrostatic repulsion between them prevents their molecular assembly (González-Tomás and Costell 2006). Flow data of different CMC-based samples were fitted well with the Herschel-Bulkley model, with R2 values >0.99. Two-way ANOVA results showed that both CMC and SPI concentrations, as well as their interaction, had a significant effect on all flow parameters (Table 3). As expected, σ0, η1 and AR values increased with CMC and SPI concentration indicating an increase in the shear-thinning behaviour of the samples (Table 4). With respect to σ0, it was observed that CMC concentration effect was different depending on SPI content. In samples with 6 % SPI, σ0 values varied slightly with CMC concentration, while in samples with 8 % SPI an increase in CMC concentration significantly increased σ0 values. Samples with the lowest CMC concentrations (under 0.5 %) did not significantly differ for η1 values among most of the samples, regardless of SPI content, but when CMC concentration was increased (over 0.5 %) η1 values increased significantly, showing clear differences between different soy dessert samples with different SPI content. This may be due to the increase in the protein volumetric fraction of the dispersed phase and to the distribution and interaction of CMC chains. At lower CMC concentrations, the CMC chains are in their most extended conformation and at higher polymer concentrations extended CMC chains start to overlap and could become entangled, increasing the plasticity and the consistency of sample flow.

Flow curves (a and b) and mechanical spectra (c and d) (G’, storage modulus: filled symbol and G”, loss modulus: empty symbol) of soy-based desserts containing 6 % (a and c) or 8 % (b and d) of soy protein isolate (SPI) and different carboxymethyl cellulose (CMC) concentrations (△:0 %, ○:0.3 %, □: 0.5 %, ▽: 0.7 % and  : 0.9 %)

: 0.9 %)

In general, it can be observed that some soy desserts differing in composition had similar flow behaviour such as samples with 6 % SPI and 0.5 % CMC, with 8 % SPI and 2 % starch or with 8 % SPI and 0.3 % CMC (Tables 2 and 4).

Viscoelasticity

The viscoelastic characteristics of the control samples could not be measured because of their fluidity. As expected, the viscoelastic properties of the remaining samples depended on SPI and thickener concentration. Mechanical spectra obtained for samples with starch are shown in Fig. 1c and d. In general, the viscoelastic behaviour ranged from fluid-like to weak-gel-like, depending on sample composition. For both SPI concentrations, samples with the lowest starch concentration (2 %) showed a strong frequency dependence on dynamic moduli with loss modulus (G”) over storage modulus (G’), indicating a fluid-like behaviour. When the starch concentration was increased, the mechanical spectra changed markedly, depending on the SPI concentration. Samples with 6 % SPI at the intermediate starch concentrations (2.5 and 3 %) showed concentrated polymeric solution behaviour and a lesser frequency dependence. The sample with 6 % SPI and the highest starch concentration (3.5 %) and most of the 8 % SPI samples exhibited viscoelastic properties usually observed for weak-gel systems: elastic response (G’) predominated over viscous response (G”) and both dynamic moduli showed a slight variation with oscillation frequency. These results suggest that the viscoelastic behaviour of the starch-based soy protein desserts depended not only on the volumetric fraction occupied by the swollen starch granules but also on the SPI concentration. Results obtained from ANOVA showed that both factors, as well as their interaction, had a significant effect (p < 0.05) on all parameters obtained at 1 Hz (Table 1). This interaction indicated that the starch concentration effect on viscoelastic parameters was different, depending on SPI content. In general, G’, G” and η* values increased with starch concentration, and this increase was more evident in samples with the higher SPI concentration (Table 2). At the lower starch concentrations (<3.5 %), samples with 6 % SPI did not show significant differences in viscoelastic parameter values among them, while in samples with 8 % SPI, an increase in the starch concentration significantly increased the viscoelastic parameter values, except for tan δ that decreased. At the lowest starch concentration (2 %), viscoelastic parameter values of samples with different SPI concentrations did not differ significantly, except complex dynamic viscosity values. However, at starch concentrations over 2.5 %, samples with 8 % SPI had G’, G” and η* values that were significantly higher than their counterparts made with 6 % SPI. The differences observed in viscoelastic behaviour due to starch and protein contents are in agreement with what was observed in the sample flow behaviour and could be due to the same structural changes as commented previously.

The mechanical spectra obtained for CMC-based samples are shown in Fig. 2c and d. As in the case of the starch-based samples, samples with CMC showed a viscoelastic behaviour that varied from fluid-like to weak-gel-like. Most of the samples containing 8 % SPI, except the sample with the lowest CMC concentration, showed a response typical of weak gels, with a storage modulus (G’) higher than loss modulus (G”), and slight frequency dependence. The sample with the lowest CMC concentration (0.3 %) exhibited a behaviour typical of an entangled polymer solution, with similar values of G’ and G” values. Samples with 6 % SPI showed different behaviours, depending on starch concentration. At the lowest CMC concentration, they behaved as a fluid-like system. When the CMC concentration increased, the mechanical spectra changed significantly, indicating the transition from an entanglement polymer solution (samples with 0.5 % CMC) to a structured system (samples with 0.7 and 0.9 % CMC), and the dynamic moduli became less frequency-dependent and the elastic contribution gradually prevailed over the viscous one. ANOVA results showed a significant interaction effect (P < 0.05) between the two factors considered (CMC and SPI concentration) on all viscoelastic parameter at 1 Hz (Table 3). For the same CMC concentration, samples made with 6 % SPI exhibited significantly lower values of G’, G” and η* and higher values of Tan δ than their counterparts made with 8 % SPI, except for the lowest CMC concentration (0.3 %) (Table 4). In general, raising the CMC concentration increased the G’, G” and η* values and decreased Tan δ, although this effect was more evident in samples with the higher SPI content.

Also in this case, samples with different composition showed similar viscoelasticity. For example, soy dessert with 6%SPI and 0.5 %CMC or 2.5 % starch, and samples with 8%SPI and 0.3%CMC or 2 % starch (Tables 2 and 4).

Microstructure

Starch-based samples showed a globular structure with isolated and swollen starch granules dispersed in the aqueous phase with SPI aggregates distributed among them. As an example, at the highest SPI concentration (Fig. 3a) some regions with starch granules and SPI aggregates closely clumped together can be observed. In mixed biopolymer systems, soybean protein could interact with amorphous regions of starch granules, favouring a mutual exclusion effect or modifying water availability for starch (Colombo et al. 2011). When CMC was added to the protein dispersion, a clearly different structure was observed. As it can been seen in Fig. 3b, which corresponds to CMC-based sample at the highest SPI concentration, a coarse stranded structure with SPI aggregates partially embedded among CMC agglomerates was observed, which is characteristic of this type of systems.

Influence of composition of the soy desserts on instrumental indices of oral thickness

According to the rheological results, these two hydrocolloids– starch and CMC– could be used in the formulation of high-protein soy desserts to obtain products with different composition and nutritional value, and similar rheological behaviour. However, this does not guarantee that it will match the texture perceived. This is logical if one bears in mind that, as commented previously, flow in the mouth is probably a combination of shear and elongational flow during ingestion and swallowing (van Vliet 2002) and that perceived thickness depends not only on the shear forces in the mouth, but also on saliva effect and mouth temperature. Therefore, rheological information alone may not be enough to explain the textural differences perceived, particularly when products with different composition and structure are being compared (González-Tomás and Costell 2006). To obtain preliminary information about the possible influence of composition on oral thickness of soy desserts, their effect on two instrumental index values was analysed. One of them was related with their flow properties (η50, apparent viscosity at 50 s−1) and the other one with their viscoelastic behaviour (η8Hz, complex dynamic viscosity at 8 Hz). A two-way ANOVA was used to study the combined effects of SPI content and thickener concentration on these index values. In starch-based samples, the interaction between these factors was significant for both parameters (η50: F = 211.14, p < 0.01 and η8Hz: F = 679.60, p < 0.01), indicating that the effect of SPI content was different, depending on starch concentration. When the variation in the two thickness index values was compared, a similar trend was observed. In general, η50 and η8Hz increased with starch concentration for both SPI concentrations, but this increase was more evident in samples with the higher SPI concentration (Fig. 4a, b). In these samples (with 8 % SPI), a higher effect of starch on η8Hz values was observed at concentrations over 2.5 %. With respect to the CMC-based samples, similar results were obtained. The interaction between the two effects was also significant in the values of the two thickness indices (η50: F = 1310.6, p < 0.01 and η8Hz: F = 296.5, p < 0.01). In the case of the η8Hz parameter, at the lowest CMC concentration no significant differences were found between samples with the same CMC concentration and different SPI contents, but when the CMC concentration was increased over 0.3 % significant differences were observed (Fig. 4c, d). The good correlation obtained between the two index values (R2 = 0.92) seems to confirm the practical utility of both of these instrumental measurements to predict perceived consistency or thickness in this type of semisolid product (Cook et al. 2003; Arancibia et al. 2013b).

Conclusions

The addition of hydrocolloids with different physicochemical properties and structural characteristics modifies the rheological behaviour and the thickness perceived in soy systems in different ways. Thus, it is possible to obtain high-protein soy desserts of similar rheological behaviour or thickness index values by adding different hydrocolloids at different concentrations. This fact can favour the possibility of designing high protein soy desserts with novel and different textures. In any case, more information about the different hydrocolloids effects on product stability and their perceived flavour and texture is needed to obtain soy desserts with high quality and that are more accepted by consumers.

References

Abu-Jdayil B, Mohameed H, Eassa A (2004) Rheology of wheat starch-milk-sugar systems: effect of starch concentration, sugar type and concentration, and milk fat content. J Food Eng 64:207–212

Arancibia C, Bayarri S, Costell E (2013a) Combining cluster analysis, surface response methodology and Jar scales to increase consumer input in optimizing acceptability of a high-protein soy dessert. J Sens Stud 28:483–494

Arancibia C, Bayarri S, Costell E (2013b) Impact of structural differences on perceived sweetness in semisolid dairy matrices. J Texture Stud 44:346–356

Barnes S, Prasain J, D’alessandro T, Wang C, Zhang H, Kim H (2006) Soy isoflavones. In: Heber D (ed) Nutritional oncology, 2nd edn. Academic, San Diego, pp. 559–571

Bayarri S, Chulia I, Costell E (2010) Comparing λ-carrageenan and an inulin blend as fat replacers in carboxymethyl cellulose dairy desserts. Rheological and sensory aspects. Food Hydrocoll 24:578–587

Chambers E, Jenkins A, Mcguire BH (2006) Flavour properties of plain soymilk. J Sens Stud 21:165–179

Chattopadhyay S, Raychaudhuri U, Chakraborty R (2013) Optimization of soy dessert on sensory, colour, and rheological parameters using response surface methodology. Food Sci Biotechnol 22:47–54

Colombo A, León AE, Ribotta PD (2011) Rheological and calorimetric properties of corn- wheat, and cassava starches and soybean protein cancentrate composites. Starch-Starke 63:83–95

Cook DJ, Hollowood TA, Linforth RST, Taylor AJ (2003) Oral shear stress predicts flavour perception in viscous solutions. Chem Senses 28:11–23

Da Silva J, Prudencio S, Carrão-Panizzi M, Gregorut C, Fonseca F, Mattoso L (2012) Study of the flavour of soybean cultivars by sensory analysis and electronic tongue. Int J Food Sci Technol 47:1630–1638

Deshpande RP, Chinnan MS, McWatters KH (2008) Optimization of a chocolate-flavored, peanut–soy beverage using response surface methodology (RSM) as applied to consumer acceptability data. LWT Food Sci Technol 41:1485–1492

Desse M, Mitchell J, Wolf B, Budtova T (2011) Droplet deformation and break-up under shear: hydrocolloid solution vs. suspension of starch granules. Food Hydrocoll 25:495–502

Dickinson E (2003) Hydrocolloids at interfaces and the influence on the properties of dispersed systems. Food Hydrocoll 17:25–39

Endo H, Ohno M, Tanji K, Shimada S, Kaneko K (2004) Effect on heat treatment on the lipid peroxide content and Aokusami (beany flavour) of soymilk. Food Sci Technol Res 10:328–333

Engelen L, de Wijk RA, van der Bilt A, Prinz JF, Janssen AM, Bosman F (2005) Relating particles and texture perception. Physiol Behav 86:111–117

Felberg I, Deliza R, Farah A, Calado E, Donangelo CM (2010) Formulation of a soy-coffee beverage by response surface methodology and internal preference mapping. J Sens Stud 25:226–242

Ferry AJ, Hort J, Mitchell JR, Cook DJ, Lagarrigue S, Valles Pamies B (2006) Viscosity and flavour perception: why is starch different from hydrocolloids? Food Hydrocoll 20:855–862

González-Tomás L, Costell E (2006) Relation between consumer’s perception of color and texture of dairy desserts and instrumental measurements using GPA. J Dairy Sci 89:4511–4519

Granato D, Ribeiro JCR, Castro IA, Masson ML (2010) Sensory evaluation and physicochemical optimisation of soy-based desserts using response surface methodology. Food Chem 121:899–906

Hill MA, Mitchell JR, Sherman PA (1995) The relationship between the rheological and sensory properties of a lemon pie filling. J Texture Stud 26:457–470

Lapasin R, Pricl S (1995) Rheology of industrial polysaccharides: theory and applications. Blackie Academic and Professional, Glasgow

McClements DJ, Decker EA, Park Y, Weiss J (2009) Structural design principles for delivery of bioactive components in nutraceuticals and functional foods. Crit Rev Food Sci Nutr 49:577–606

Mepha HD, Achinewhul SC, Pillay M (2006) Stabilized cocosoy beverage: physicochemical and sensory properties. J Sci Food Agric 86:1839–1846

Mujumdar A, Beris AN, Metzner AB (2002) Transient phenomena in thixotropic systems. J Non-Newton Fluid 102:157–178

N’Kouka KD, Klein BP, Lee SY (2004) Developing a lexicon for descriptive analysis of soymilks. J Food Sci 69:S259–S263

Potter RM, Dougherty MP, Halteman WA, Camire ME (2007) Characteristics of wild blueberry–soy beverages. LWT Food Sci Technol 40:807–814

Russell TA, Drake MA, Gerard PD (2006) Sensory properties of whey and soyproteins. J Food Sci 71:S447–S455

Suppavorasatit I, Lee SY, Cadwallader KR (2013) Effect of enzymatic protein deamidation on protein solubility and flavour binding properties of soymilk. J Food Sci 78:C1–C7

Takada Y, Sasama H, Sayama T, Kikuchi A, Kato S, Ishimoto M, Tsukamoto C (2013) Genetic and chemical analysis of a key biosynthetic step for soyasapogenol A, an aglycone of group A saponins that influence soymilk flavour. Theor Appl Genet 126:721–731

Tárrega A, Costell E (2007) Colour and consistency of semisolid dairy desserts. Instrumental and sensory measurements. J Food Eng 78:655–661

Tárrega A, Durán L, Costell E (2005) Rheological characterization of semisolid dairy desserts. Effect of temperature. Food Hydrocoll 19:133–139

Tattiyakul J, Rao MA (2000) Rheological behavior of cross-linked waxy mayze starch dispersions during and after heating. Carbohydr Polym 43:215–222

van Vliet T (2002) On the relation between texture perception and fundamental mechanical parameters for liquids and time dependent solids. Food Qual Prefer 13:227–236

Walker J, Boeneke CA, Sriwattana S, Herrera-Corredor JA, Prinyawiwatkul W (2010) Consumer acceptance and purchase intent of a novel low-fat sugar-free sherbet containing soy protein. J Food Qual 33:27–41

Xiao CW (2008) Health effects of soy protein and isoflavones in humans. J Nutr 138:1244S–1249S

Yuang SH, Chang SKC (2007) Selected odour compounds in soymilk as a affected by chemical composition and lipoxigenases in five soybean materials. J Agric Food Chem 55:426–443

Acknowledgments

The authors are grateful to Sistema Bicentenario Becas Chile for the fellowship N° 72090038, to Fondo Social Europeo for financing the contract of second author (I3P program, CSIC) and to Akzo Nobel (Amersfoort, The Netherlands), Cargill (Barcelona, Spain), Lucta (Barcelona, Spain) and CHR Hansen S.A. (Barcelona, Spain), for providing free samples of the ingredients.

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

Hydrocolloid modifies the rheological behavior and structure of soy desserts

Instrumental oral thickness index can be used to predict perceived consistency

Soy desserts with different composition and similar texture can be obtained

Rights and permissions

About this article

Cite this article

Arancibia, C., Bayarri, S. & Costell, E. Effect of hydrocolloid on rheology and microstructure of high-protein soy desserts. J Food Sci Technol 52, 6435–6444 (2015). https://doi.org/10.1007/s13197-015-1756-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1756-9